Page 1

MODEL T10010

WET GRINDER

COPYRIGHT © NOVEMBER, 2007 BY GRIZZLY INDUSTRIAL, INC. REV. JANUARY, 2012 (ST)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MANUFACTURED SINCE 3/10) #JB9991 PRINTED IN CHINA

Page 2

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Page 3

Table of Contents

INTRODUCTION ...............................................................................................................2

Manual Accuracy ........................................................................................................2

SECTION 1: SAFETY .......................................................................................................3

SECTION 2: POWER SUPPLY ........................................................................................7

SECTION 3: SETUP .........................................................................................................9

Unpacking ...................................................................................................................9

Inventory .....................................................................................................................9

Site Considerations ...................................................................................................10

Wheel Inspection ......................................................................................................10

Test Run ...................................................................................................................12

SECTION 4: OPERATIONS ...........................................................................................13

Grinding Tips ............................................................................................................13

Positioning the Universal Support ............................................................................14

Grinding Jig...............................................................................................................15

Water Reservoir ........................................................................................................16

Angle Guide ..............................................................................................................17

Sharpening ...............................................................................................................18

SECTION 5: ACCESSORIES .........................................................................................19

SECTION 6: MAINTENANCE ........................................................................................21

Wheel Dressing ........................................................................................................21

Grinding Wheels .......................................................................................................21

Wheel Replacement .................................................................................................21

Water Reservoir ........................................................................................................21

SECTION 7: SERVICE ...................................................................................................22

Troubleshooting ........................................................................................................22

SECTION 8: WIRING......................................................................................................24

Wiring Safety Instructions .........................................................................................24

Wiring Diagram .........................................................................................................25

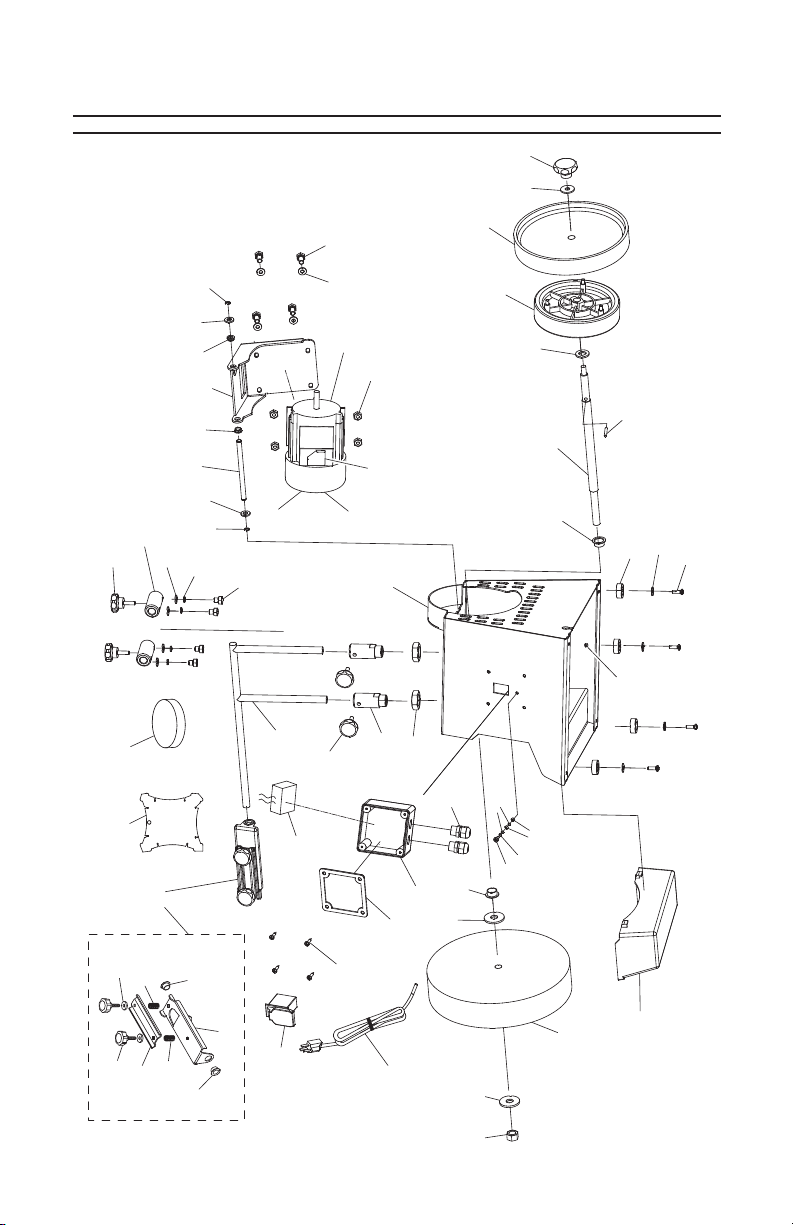

Main Breakdown .......................................................................................................26

Main Parts List ..........................................................................................................27

Machine Labels Breakdown & Parts List ..................................................................28

WARRANTY ...................................................................................................................31

Model T10010 (Mfg. Since 3/10)

-1-

Page 4

INTRODUCTION

We are proud to offer this manual with your new

machine! We've made every effort to be exact

with the instructions, specifications, drawings,

and photographs of the machine we used when

writing this manual. However, sometimes we still

make an occasional mistake.

Also, owing to our policy of continuous improve-

ment, your machine may not exactly match the

manual. If you find this to be the case, and the dif-

ference between the manual and machine leaves

you in doubt, check our website for the latest

manual update or call technical support for help.

Before calling, find the manufacture date of your

machine by looking at the date stamped into the

machine ID label (see below). This will help us

determine if the manual version you received

matches the manufacture date of your machine.

Manufacture Date

of Your Machine

Manual Accuracy Contact Info

We are proud to offer this document with

your new machine! We've made every

effort to be exact with the instructions,

specifications, drawings, and photographs

of the machine we used when writing

this manual. However, sometimes we still

make an occasional mistake.

Also, owing to our policy of continuous

improvement, your machine may not

exactly match the manual. If you find this

to be the case, and the difference between

the manual and machine leaves you in

doubt, immediately call our technical support for updates or clarification.

Before calling, find the manufacture date

of your machine by looking at the date

stamped into the machine ID label (see

below). This will help us determine if the

manual version you received matches the

manufacture date of your machine.

For your convenience, we post all available documentation on our website at

www.grizzly.com. Any updates to this document will be reflected on our website as

soon as complete.

We stand behind our tools. If you have any

questions or need help, use the information below to contact us. Before contacting, please get the serial number and

manufacture date of your machine. This

will help us help you faster.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

E-Mail: techsupport@grizzly.com

We want your feedback on this manual.

What did you like about it? Where could it

be improved? Please take a few minutes to

give us feedback.

Grizzly Documentation Manager

P.O. Box 2069

Bellingham, WA 98227-2069

Email: manuals@grizzly.com

-2-

Model T10010 (Mfg. Since 3/10)

Page 5

Safety

SECTION 1: SAFETY

For Your Own Safety Read Instruction Manual

Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This manual uses a series of symbols and signal words which

are intended to convey the level of importance of the safety messages. The

progression of symbols is described below. Remember that safety messages by

themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates an imminently hazardous situation which, if

not avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

It may also be used to alert against unsafe practices.

NOTICE

This symbol is used to alert the user to useful information about proper operation of the equipment.

Safety Instructions for Machinery

1. READ THROUGH THE ENTIRE

MANUAL BEFORE STARTING

MACHINERY. Machinery presents

serious injury hazards to untrained

users.

2. ALWAYS USE ANSI APPROVED

SAFETY GLASSES WHEN

OPERATING MACHINERY.

Everyday eyeglasses only have

impact resistant lenses, they are

NOT safety glasses.

3. ALWAYS WEAR A NIOSH

APPROVED RESPIRATOR WHEN

OPERATING MACHINERY THAT

PRODUCES DUST. Wood dust is

a carcinogen and can cause cancer

and severe respiratory illnesses.

Model T10010 (Mfg. Since 3/10)

4. ALWAYS USE HEARING

PROTECTION WHEN OPERATING

MACHINERY. Machinery noise can

cause permanent hearing damage.

5. WEAR PROPER APPAREL. DO

NOT wear loose clothing, gloves,

neckties, rings, or jewelry which

may get caught in moving parts.

Wear protective hair covering to

contain long hair and wear non-slip

footwear.

6. NEVER OPERATE MACHINERY

WHEN TIRED, OR UNDER THE

INFLUENCE OF DRUGS OR

ALCOHOL. Be mentally alert at all

times when running machinery.

-3-

Page 6

7. ONLY ALLOW TRAINED AND

PROPERLY SUPERVISED PERSONNEL TO OPERATE MACHINERY. Make sure operation instruc-

tions are safe and clearly understood.

8. KEEP CHILDREN AND VISITORS

AWAY. Keep all children and visi-

tors a safe distance from the work

area.

9. MAKE WORKSHOP CHILD

PROOF. Use padlocks, master

switches, and remove switch keys.

10. NEVER LEAVE WHEN MACHINE

IS RUNNING. Turn power OFF

and allow all moving parts to come

to a complete stop before leaving

machine unattended.

17. REMOVE ADJUSTING KEYS

AND WRENCHES. Make a habit

of checking for keys and adjusting

wrenches before turning machinery

ON.

18. CHECK FOR DAMAGED PARTS

BEFORE USING MACHINERY.

Check for binding and alignment

of parts, broken parts, part mounting, loose bolts, and any other

conditions that may affect machine

operation. Repair or replace damaged parts.

19. US E RE C O M M END E D

ACCESSORIES. Refer to the

instruction manual for recommended accessories. The use of

improper accessories may cause

risk of injury.

11. DO NOT USE IN DANGEROUS

ENVIRONMENTS. DO NOT use

machinery in damp, wet locations,

or where any flammable or noxious

fumes may exist.

12. KEEP WORK AREA CLEAN AND

WELL LIT. Clutter and dark shad-

ows may cause accidents.

13. USE A GROUNDED EXTENSION

CORD RATED FOR THE MACHINE

AMPERAGE. Undersized cords

overheat and lose power. Replace

extension cords if they become

damaged. DO NOT use extension

cords for 220V machinery.

14.

ALWAYS DISCONNECT FROM

POWER SOURCE BEFORE

SERVICING MACHINERY. Make

sure switch is in

reconnecting.

15. MAINTAIN MACHINERY WITH

CARE. Keep blades sharp and

clean for best and safest performance. Follow instructions for lubricating and changing accessories.

16. MAKE SURE GUARDS ARE IN

PLACE AND WORK CORRECTLY

BEFORE USING MACHINERY.

OFF

position before

20. DO NOT FORCE MACHINERY.

Work at the speed for which

the machine or accessory was

designed.

21. SECURE WORKPIECE. Use

clamps or a vise to hold the

workpiece when practical. A secured

workpiece protects your hands and

frees both hands to operate the

machine.

22. DO NOT OVERREACH. Keep

proper footing and balance at all

times.

23. MANY MACHINES WILL EJECT

THE WORKPIECE TOWARD THE

OPERATOR. Know and avoid con-

ditions that cause the workpiece to

"kickback."

24. ALWAYS LOCK MOBILE BASES

(IF USED) BEFORE OPERATING

MACHINERY.

25. BE AWARE THAT CERTAIN

WOODS MAY CAUSE AN ALLERGIC REACTION in people and ani-

mals, especially when exposed to

fine dust. Make sure you know

what type of wood dust you will be

exposed to and always wear an

approved respirator.

-4-

Model T10010 (Mfg. Since 3/10)

Page 7

Additional Safety Instructions for Grinders

1. EYE PROTECTION. Grinding causes

small particles to become airborne at

a high rate of speed that could impact

your eyes, causing severe injury.

ALWAYS wear safety glasses when

using this machine.

6. LUNG PROTECTION. Grinding pro-

duces hazardous dust, which may

cause long-term respiratory problems

if breathed. Always wear a NIOSH

approved dust mask or respirator

when grinding.

2. WHEEL SPEED RATING. Wheels

operated at a faster speed than rated

for may break or fly apart and strike

you with great force. Before mounting a

new wheel, be sure the wheel RPM rating is equal to or higher than the speed

of the grinder.

3. WHEEL FLANGES. Only use the

flanges included with the grinder when

mounting wheels. Other flanges may

not properly secure the wheel or could

cause it to break apart, resulting in serious impact injuries.

4. RING TEST. Perform a “ring test” on

grinding wheels before installation to

ensure that they are safe to use. A

wheel that does not pass the ring test

may break or fly apart during operation,

resulting in serious impact injuries.

5. TRANSPORT. Carry the grinder by

holding underneath the base. DO NOT

use the universal support as a handle.

It can slide out, allowing the grinder to

fall and cause crushing injuries and

property damage.

7. SIDE GRINDING. Grinding on the

side of wheels can cause them to

break and fly apart, resulting in serious impact injuries.—unless the wheel

is rated for side grinding.

8. HAND/WHEEL CONTACT. Grinding

wheels have the capability of removing a lot of skin fast. Keep a firm grip

on the workpiece and position your

hands at a safe distance away when

grinding. Avoid wearing gloves, as

they may get caught in the grinding

wheel and cause even more serious

entanglement injuries.

9. TOOL REST POSITION. If the universal support tool rest or jig is too far

away from the wheel, the workpiece

may be pulled down, causing loss of

control and pulling your hand into the

grinding wheel. Keep the the universal

support or jig within 1⁄8" from the wheel

when operating.

Model T10010 (Mfg. Since 3/10)

-5-

Page 8

MODEL T10010

WET GRINDER

Customer Service #: (570) 546-9663 • To Order Call: (800) 523-4777 • Fax #: (800) 438-5901

MACHINE DATA

SHEET

Overall Dimensions:

Height ................................................................................................................................................................................... 13"

Width .................................................................................................................................................................................... 17"

Depth ..................................................................................................................................................................................... 13"

Net Weight .......................................................................................................................................................................41 lbs.

Footprint .................................................................................................................................................................... 13" x 10¾"

Main Specifications:

Arbor Diameter ................................................................................................................................................................. 12mm

Grinding Wheel Grit ............................................................................................................................................................ 220

Grinding Wheel Size ..........................................................................................................................250mm x 50mm x 12mm

Grinding Wheel Material ................................................................................................................................. Aluminum Oxide

Stropping Wheel Size ......................................................................................................................................200mm x 30mm

Stropping Wheel Material ..................................................................................................................................... ABS/Leather

Wheel Speed ............................................................................................................................................................. 110 RPM

Motor:

Type ....................................................................................................................................... TEFC Capacitor Start Induction

Horsepower ...................................................................................................................................................................... ¼ HP

Phase/Voltage ........................................................................................................................................................ Single/120V

Amps .................................................................................................................................................................................... 3A

Cycle/RPM ......................................................................................................................................................60Hz/1725 RPM

Other:

Country of Origin ............................................................................................................................................................... China

Warranty ........................................................................................................................................................................... 1 Year

Serial Number Location ................................................................................................................... Machine ID Label on Front

Assembly Time ......................................................................................................................................................... 10 Minutes

Features:

Universal Tool Support 12mm

Paddle Switch w/ Disabling Key

Water Reservoir

Included 220 Grit Aluminum Oxide Grinding Wheel

Included Leather Stropping Wheel

Included Stropping Paste

Included Angle Guide

Includes T20880 Straight Edge Jig

Specifications

-6-

Model T10010 (Mfg. Since 3/10)

Page 9

Electrocution, fire, or

equipment damage may

occur if machine is not

correctly grounded and

connected to the power

supply.

For your own safety and protection of

property, consult a qualified electrician if

you are unsure about wiring practices or

electrical codes in your area.

SECTION 2: POWER SUPPLY

Availability

Before installing the machine, consider the

availability and proximity of the required

power supply circuit. If an existing circuit

does not meet the requirements for this

machine, a new circuit must be installed.

To minimize the risk of electrocution, fire,

or equipment damage, installation work

and electrical wiring must be done by a

qualified electrician in accordance with all

applicable codes and standards.

Full Load Current Rating

The full-load current rating is the amperage a machine draws at 100% of the rated

output power. On machines with multiple

motors, this is the amperage drawn by the

largest motor or the sum of all motors and

electrical devices that might operate at

one time during normal operations.

Full-Load Current Rating ............ 3 Amps

The full-load current is not the maximum

amount of amps that the machine will

draw. If the machine is overloaded, it will

draw additional amps beyond the full-load

rating.

Circuit Requirements

This machine is prewired to operate on

a 110V power supply circuit that has a

verified ground and meets the following

requirements:

Nominal Voltage ...............................110V

Cycle .................................................. 60Hz

Phase ...................................Single-Phase

Minimum Circuit Size .........................15A

A power supply circuit includes all electrical equipment between the breaker box

or fuse panel in the building and the

machine. The power supply circuit used

for this machine must be sized to safely

handle the full-load current drawn from the

machine for an extended period of time.

(If this machine is connected to a circuit

protected by fuses, use a time delay fuse

marked D.)

Note: The circuit requirements listed in

this manual apply to a dedicated circuit—

where only one machine will be running at

a time. If this machine will be connected to

a shared circuit where multiple machines

will be running at the same time, consult a

qualified electrician to ensure that the circuit is properly sized for safe operation.

If the machine is overloaded for a sufficient

length of time, damage, overheating, or

fire may result—especially if connected to

an undersized circuit. To reduce the risk

of these hazards, avoid overloading the

machine during operation and make sure

it is connected to a power supply circuit

that meets the requirements in the following section.

Model T10010 (Mfg. Since 3/10)

-7-

Page 10

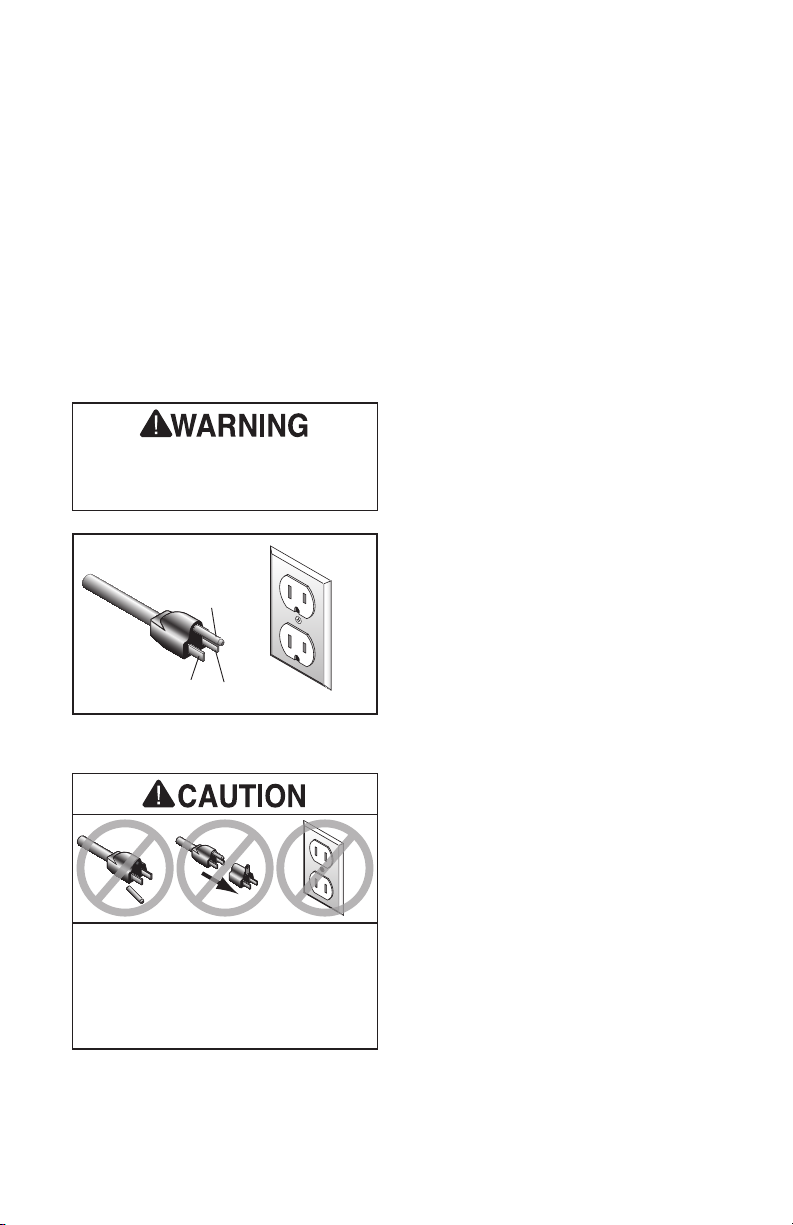

Grounding & Plug Requirements

Grounding Prong

Neutral Hot

5-15 PLUG

GROUNDED

5-15 RECEPTACLE

Serious injury could occur if you connect

the machine to power before completing the

setup process. DO NOT connect to power

until instructed later in this manual.

SHOCK HAZARD!

Two-prong outlets do not meet the grounding

requirements for this machine. Do not modify

or use an adapter on the plug provided—if

it will not fit the outlet, have a qualified

electrician install the proper outlet with a

verified ground.

This machine MUST be grounded. In the

event of certain malfunctions or breakdowns, grounding reduces the risk of

electric shock by providing a path of least

resistance for electric current.

This machine is equipped with a power

cord that has an equipment-grounding wire

and a grounded plug (similar to the figure

below). The plug must only be inserted into

a matching receptacle (outlet) that is properly installed and grounded in accordance

with all local codes and ordinances.

Figure 1. Typical 5-15 plug and

receptacle.

Improper connection of the equipmentgrounding wire can result in a risk of

electric shock. The wire with green insulation (with or without yellow stripes) is

the equipment-grounding wire. If repair or

replacement of the power cord or plug is

necessary, do not connect the equipmentgrounding wire to a live (current carrying)

terminal.

Check with a qualified electrician or service personnel if you do not understand

these grounding requirements, or if you

are in doubt about whether the tool is

properly grounded. If you ever notice that

a cord or plug is damaged or worn, disconnect if from power, and immediately

replace it with a new one.

Extension Cords

We do not recommend using an extension

cord with this machine. If you must use an

extension cord, only use it if absolutely

necessary and only on a temporary basis.

Extension cords cause voltage drop, which

may damage electrical components and

shorten motor life. Voltage drop increases

as the extension cord size gets longer and

the gauge size gets smaller (higher gauge

numbers indicate smaller sizes).

-8-

Any extension cord used with this machine

must contain a ground wire, match the

required plug and receptacle, and meet

the following requirements:

Minimum Gauge Size ................. 16 AWG

Maximum Length .............................. 50 ft.

Model T10010 (Mfg. Since 3/10)

Page 11

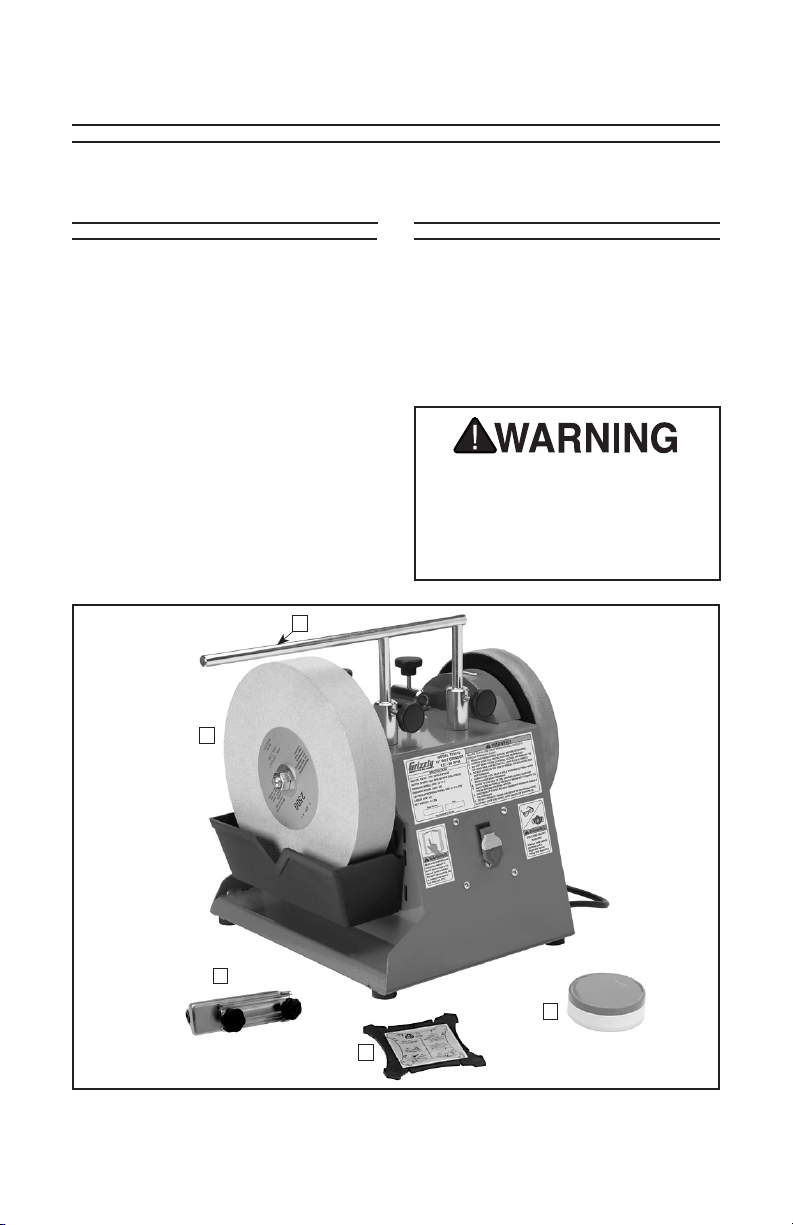

SECTION 3: SETUP

Unpacking Inventory

The Model T10010 was carefully packed

when it left our warehouse. If you discover

any par ts are damaged after you have

signed for delivery, please immediately

call Customer Service at (570) 546-9663

for advice. Save the containers and all

packing materials for possible inspection

by the carrier or its agent. Otherwise, filing

a freight claim can be difficult. When you

are completely satisfied with the condition

of the shipment, you should inventory the

contents.

E

A

Model T10010 Inventory (Figure 2)

A. T10010 Wet Grinder .......................... 1

B. Grinding Jig ........................................ 1

C. Angle Guide ....................................... 1

D. Polishing/Honing Paste ...................... 1

E. Universal Support .............................. 1

The Model T10010 Wet Grinder weighs

41 pounds. DO NOT over-exert yourself while unpacking or moving the

grinder. Use proper lifting techniques

to prevent injury.

B

Figure 2. Model T10010 inventory.

Model T10010 (Mfg. Since 3/10)

D

C

-9-

Page 12

Site Considerations

13"

17"

STOP

Rated 3500 RPM

Make sure your grinder is not

faster than the rated RPM of this wheel

WARNING

Grinding can be dangerous

Visually inspect this wheel

for cracks, nicks,chips

Type-1

Aluminum

Oxide

60 Grit

Grade L

Vitrified Bond

Wheel Inspection

Bench Load

Refer to the Machine Data Sheet on

Page 6 for the weight and size specifica-

tions of the machine. Some workbenches

may require additional reinforcement to

support both the machine and the forces

applied during use.

Placement Location

See Figure 3 for the minimum working

clearances. Remember that the Model

T10010 Wet Grinder has no specific front

or back side and must be repositioned

depending on the desired grinding/sharpening/honing action.

Figure 3. Minimum working clearances.

Children and visitors

may be seriously injured

if unsupervised. Lock all

entrances to the shop

when you are away. DO

NOT allow unsupervised

children or visitors in

your shop at any time!

Do not assume that a wheel is in sound

condition just because it is new—damage

can often occur in shipping, with age,

or with prolonged exposure to moisture.

Inspect every wheel for damage.

First, do a Visual Inspection. Look for any

cracks, chips, nicks or dents in the surface

of the wheel. If you see any of these,

DO NOT use the wheel.

Second, do a Ring Test. This test will give

you an indication of any internal damage

that may not be obvious during a visual

inspection.

To perform a Ring Test:

1. Make sure the wheel that you test is

clean and dry; otherwise, you may get

false results.

2. If size permits, balance the wheel with

your finger in the hole. If this is not possible, hang the wheel in the air with a

piece of cord or string looped through

the hole in the center.

3. At the spots shown in Figure 4, gently

tap the wheel with a light non-metallic

device such as the handle of a screwdriver or a wooden mallet.

-10-

Figure 4. Tapping locations when

performing a ring test.

Model T10010 (Mfg. Since 3/10)

Page 13

— An undamaged wheel will emit a

clear metallic ring or “ping” sound

in each of these spots. A damaged

wheel will respond with a dull thud

that has no clear tone.

— If you determine from the ring test

that the wheel is damaged, DO NOT

use it!

Finally, check that the grinding surface

is square. Lower the universal support to

1

⁄16"– 1⁄8" above the grinding wheel. Using

the universal support as a visual guide,

check that the entire top surface of the

grinding wheel is consistent and parallel to the universal support, as shown in

Figure 5. If th is is not the case, se e Wheel

Dressing on Page 21.

Universal

Support

TO AVOID DAMAGING THE

MOTOR, REMOVE STYROFOAM

BLOCK AND WIRE TIE

BEFORE OPERATING

THE GRINDER

.

To prevent the motor from moving and

causing damage during shipping, a styrofoam block and plastic tie wrap have been

inserted in the grinder. You must remove

these items before connecting the grinder

to power. Failure to do this will result in

incorrect operation, may put undue strain

on the motor, may damage machine components, and will void your warranty!

Check

Parallel

Figure 5. Parallel check.

Model T10010 (Mfg. Since 3/10)

Grinding

Surface

To remove the motor shipping support:

1. Make sure the machine is not con-

nected to power.

2. Carefully place the machine on its

back.

3. Locate the plastic tie wrap that secures

the motor to the machine base. It is

looped from the motor shaft to one of

the vent holes in the machine base.

4. Hold the motor to prevent it from swinging, cut and remove the tie wrap,

remove the styrofoam block, then slowly release the motor.

5. Carefully return the motor to the upright

position.

-11 -

Page 14

Test Run

Once the Model T10010 is positioned,

test run the machine to make sure it runs

properly.

6. Listen and watch for abnormal noises or actions. Under normal conditions, the grinder will make a humming

noise, with only minor vibration. A

slight wobble from one or both wheels

is normal and will not affect grinding

performance.

If, during the test run, you cannot easily

locate the source of an unusual noise or

vibration, stop using the machine immediately, then review the Troubleshooting

on Page 21.

If you still cannot remedy a problem, contact our Tech Support at (570) 546-9663

for assistance.

To test run the machine:

1. Make sure you have read the safety

instructions at the beginning of the

manual and that the grinder is set up

properly.

2. Make sure all tools and objects used

during setup are cleared away from the

grinder.

3. Make sure the switch is pushed in to

the OFF position.

4. Connect the grinder to the power

source.

— Investigate and correct strange or

unusual noises or vibrations before

operating the machine further.

Always disconnect the machine from

power when investigating or correcting potential problems.

7. Turn the grinder OFF.

8. Remove the switch disabling key, as

shown in Figure 6, then attempt to turn

the machine ON.

— If the grinder does not start, the

switch disabling feature is working.

— If the grinder starts, stop it. The

switch disabling feature is not working. This safety feature must work

properly before proceeding. Call

Tech Support for help.

5. Pull the bottom of the switch out to turn

the grinder ON. Make sure your hand

stays poised over the switch in case

you need to quickly turn it OFF.

-12-

Figure 6. Removing the switch disabling

key.

9. Re-insert the switch disabling key.

Model T10010 (Mfg. Since 3/10)

Page 15

SECTION 4: OPERATIONS

Damage to your eyes and lungs could

result from using this machine without proper protective gear. Always

wear safety glasses/face shield and

a dust mask/ respirator when operating this machine.

Loose hair and clothing could get caught

in machinery and

cause serious personal injury. Keep

loose clothing and

long hair away from

moving machinery.

Although the Model T10010 Wet

Grinder wheels are designed specifically for slow rotation, there is still the

possibility that blades and tools being

sharpened on either wheel could be

dislodged from your grasp. Be sure

that satisfactory space is allocated

between the grinder and areas where

others are working. Always wear safety glasses and keep the universal

support in the proper position when

grinding or sharpening.

If you have never used this type of

NOTICE

machine or equipment before, WE

STRONGLY RECOMMEND that you

read books, trade magazines, or get

formal training before beginning any

projects. Regardless of the content

in this section, Grizzly Industrial

will not be held liable for accidents

caused by lack of training.

Grinding Tips

The grinder is a safe tool when used properly. In addition to the safety instructions

beginning on Page 2 in this manual, the

most important safety consideration is to

use common sense at all times. What may

be acceptable in one situation, may not be

safe in another.

Here are some tips to keep in mind

while grinding:

• Always be sure the grinding wheel is

wet before grinding by having the reservoir filled and in the proper location.

• Wear the proper protective clothing.

Safety glasses/face shield and a dust

mask should be worn at all times.

• Grasp the workpiece firmly and properly support it on the universal support or grinding jig during operation.

Maintain even pressure and control of

the workpiece when grinding.

Model T10010 (Mfg. Since 3/10)

• Concentrate on the task at hand. STOP

grinding if other people are distracting

you or your mind is on something else.

-13-

Page 16

Positioning the

Universal Support

The Model T10010 Wet Grinder is equipped

with a universal support that serves as

a tool rest and as an attachment point

for task-specific accessories. It can be

attached in two positions, allowing for

grinding with or against the rotation direction of the grinding wheel. The tightening

knobs on each attachment point allow

the universal support to be adjusted and

locked in position, depending on the specific task required.

Working against the rotation removes large

amounts of materials quickly but does not

yield precise results. Use this method for

coarse tools such as axes.

Working with the rotation yields much

more precise results and removes less

material. Use this method for finer tools,

such as knives or car ving tools.

Do not make adjustments while the

machine is running. Disconnect the

grinder from power before attempting

to make adjustments to the universal

support, water reservoir, changing

wheels or the angle guide.

3. Attach the universal support in the ver-

tical mounts, as shown in Figure 7. Be

sure it is securely positioned and will

not move during grinding. Re-connect

the grinder to power.

4. Rest your workpiece on the universal support with the sharpened edge

pointing away from you. Grind your

workpiece in the indicated grinding

area.

Grinding

Area

Universal

Support

Grinding Against Wheel

Rotation

1. DISCONNECT GRINDER FROM

POWER!

2. Position the machine with the ON/OFF

switch facing you.

-14-

Vertical

Mounts

Figure 7. Vertical mount.

NOTICE

The universal support should never

be placed in the vertical mounts

when using the leather stropping

wheel. Working against the direction

of rotation in this case will cause

severe damage to the leather wheel.

Model T10010 (Mfg. Since 3/10)

Page 17

Grinding With Wheel Rotation

1. DISCONNECT GRINDER FROM

POWER!

2. Position the machine with the ON/OFF

switch facing away from you.

3. Attach the universal support in the horizontal mounts as shown in Figure 8.

Be sure it is securely positioned and will

not move during grinding. Reconnect

the machine to power.

Grinding Jig

The grinding jig provided with the wet

grinder is used for securing a variety of

tools, and can be positioned to grind with

and against the wheel rotation.

To mount the grinding jig:

1. DISCONNECT GRINDER FROM

POWER!

4. Rest your workpiece on the universal support with the sharpened edge

pointing away from you. Grind your

workpiece in the indicated grinding

area.

Grinding

Area

Horizontal

Mounts

Figure 8. Horizontal mount.

Universal

Support

2. Slide the grinding jig onto the universal

support, as illustrated in Figure 9.

Tool

(Varies)

Lock

Knobs

Universal

Figure 9. Grinding jig installed.

3. Insert the tool into the jig clamp, then

use the angle guide, as described on

Page 16, to set the grinding angle.

4. Once the grinding angle is set, tighten

both lock knobs to secure the tool in

place.

5. Re-connect the grinder to power and

perform the operation.

Grinding

Jig

Support

Model T10010 (Mfg. Since 3/10)

-15-

Page 18

Water Reservoir

The Model T10010 Wet Grinder is designed

for wet grinding and should never be used

without water.

3. Attach the reservoir to the grinder.

— If the grinder is going to be used

immediately, position the reservoir

in the upper grinding position by

attaching it in the upper slot (see

Figure 11).

Before filling the water reservoir, identify

the high and low reservoir mounting slots,

as shown in Figure 10. These slots allow

the reservoir to be raised during grinding

and lowered when not in use.

The mounting tabs on the reservoir serve

as hooks to attach to the reservoir mounting slots.

Mounting

Tab

Figure 10. Reservoir mounting positions.

Upper Slot

(Grinding)

Lower Slot

(Storage)

NOTICE

DO NOT attempt to use the grinding

wheel without filling the reservoir

with water. Overheating caused by

lack of lubrication could damage the

grinding wheel, as well as the tool

or blade you are grinding. Ensure

that the reservoir is filled with clean

water. Sediment-filled water can

clog the wheel and reduce the effec tiveness of the grinder.

— If the grinder is not going to be used

immediately, position the reservoir in

the lower storage position by attaching it in the lower slot (see Figure

12).

Important: The grinder must never

be stored with the wheel submersed

in water. Leaving part of the wheel

in water will create potential hazards

from being off-balance and damage

from prolonged exposure to water.

Placing the reservoir in the storage

position reduces the likelihood of

these hazards.

Figure 11. Grinding position.

To fill and position the reservoir:

1. DISCONNECT GRINDER FROM

POWER!

2. Remove the reservoir, clean it out (if

necessary), and fill it with water to just

below the V-shaped notch.

-16-

Figure 12. Storage position.

Model T10010 (Mfg. Since 3/10)

Page 19

To use the angle guide:

DO NOT allow the grinding wheel

to stay immersed in water for long

periods of time without running.

The water can cause the wheel to

become waterlogged and unbalanced and may cause sections of

the wheel to break off when the

grinder is started. Always empty or

lower the reservoir to the storage

position after operations.

Here are some tips for using the wet

grinder water reservoir:

• Check the water level before every use

and be sure the wheel is wet before

you begin grinding. DO NOT use the

grinder without water.

• Leaving the grinding wheel stored in

water will cause damage to the wheel

and create potential hazards because

the wheel will become unbalanced.

Once any grinding process is complete,

return the reservoir to the storage position to prevent prolonged water exposure to the wheel.

• Empty, rinse, and refill the reservoir

regularly. This prevents metal and

stone from accumulating in the reservoir.

1. Locate the eight measuring notches on

the angle finder (see Figure 13).

Angle Edge

Workpiece

Desired

Angle Notch

Measuring

Notches

Figure 13. Measuring notches.

2. Find the angle notch that best fits the

tool you wish to grind by placing the

sharpened edge of the workpiece into

each notch.

3. Place the angle guide on the wheel

with the desired angle notch (found in

Step 2) against the wheel and adjacent to the universal support (see

Figure 14).

Correct

Grinding Angle

• Place a magnet in the reservoir to catch

and collect metal filings. This will help

prevent excessive metal accumulation

on the grinding wheel.

Angle Guide

The Model T10010 Wet Grinder comes

with an angle guide to help identify and

maintain the cutting angle on a variety of

tools.

Model T10010 (Mfg. Since 3/10)

Desired

Angle Notch

Figure 14. Angle guide usage.

4. Adjust the positioning of the tool and

the universal support height as necessary so that the sharpened edge of the

tool is flat against both the grinding

wheel and the angle edge on the angle

guide, as shown in Figure 14.

Note: For precision grinding, use the

provided grinding jig (see Page 14).

Angle Edge

Workpiece

-17-

Page 20

Sharpening

The leather stropping wheel on the Model

T10010 and the included abrasive stropping paste can be used to obtain a razor

sharp edge on many tools. Before use,

the stropping wheel must be properly

prepared.

Note: A slight wobble of the stropping

wheel when it is rotating is normal and

does not affect the performance.

The preparations below will be sufficient

for sharpening five to ten tools. If you

notice a drop in sharpening performance

or have sharpened more than ten tools,

repeat as necessary.

To prepare the stropping wheel:

1. DISCONNECT GRINDER FROM

POWER.

2. Secure the universal support in the

horizontal mounts so that sharpening

will be performed with the direction of

rotation.

Never sharpen against the direction

of rotation. The edge of the tool may

dig into the leather wheel, damaging

the wheel and causing the tool to

eject from the machine. This could

result in personal injury or property

damage.

3. Evenly apply a light machine oil to

the leather wheel. Use enough oil to

provide a thorough coating, but not so

much as to saturate the leather and

result in dripping.

4. Apply a thin coat of abrasive honing

paste to the leather wheel using a

wooden spreader or similar device.

Distribute the paste evenly by handturning the wheel while spreading.

5. Connect the machine to power, then

turn it ON and continue to distribute the

paste, still using the wooden spreader.

Move the spreader lightly in a circular

motion across the wheel.

6. Once the paste is evenly distributed,

begin sharpening.

-18-

Model T10010 (Mfg. Since 3/10)

Page 21

SECTION 5: ACCESSORIES

T10023—Accessory Kit #1 includes fix-

tures for sharpening small knives, large

knives, scissors and axes.

Figure 15. Model T10023

T10024— Accessory Kit #2 includes a

stone dresser and fixtures for sharpening

scrapers, screwdrivers and hollow chisels.

Figure 16. Model T10024.

T10025 —Sharpening Jig

Jig for sharpening 16" planer blades sharpens all planer and jointer blades up to 16"

long.

Figure 17. Model T10025.

G712 0 — Heavy Duty Grinder Stand

This is one of the most stable bench

grinder stands on the market. Once you

have one, you’ll wonder how you ever got

along without it. 32

installation of a tabletop (not included) for

use with the Model T10010 Wet Grinder.

49 lbs.

1

⁄2 " high. Will require the

Model T10010 (Mfg. Since 3/10)

Figure 18. Model G7120.

-19-

Page 22

H5891, H5892 Diamond Dressers

Industrial diamond for dressing grinding

wheels. 8¼" long round body with knurled

grip for maximum control. Includes protective rubber end cap.

Model H5891 ¼ Carat

Model H5892 ¾ Carat

Figure 19. Models H5891 & 5892.

H5944, H5945, H5946 Wheel Dressers

Exposes new grains for aggressive cutting on all types of grinding wheels. Star

wheels and discs are hardened steel. Cast

iron handle provides stabilizing mass for

better control.

H5944 #0 Wheel Dresser

H5945 #1 Wheel Dresser

H5946 #2 Wheel Dresser

Figure 20. Models H5944, H5945, H5946.

-20-

Model T10010 (Mfg. Since 3/10)

Page 23

SECTION 6: MAINTENANCE

!

Grinding Wheels

The grinding wheel should be inspected before every use. Use the ring test

method noted in Wheel Inspection on

Page 10 to verify the structural integrity.

Take care when storing grinding wheels

to avoid potential moisture damage, being

Always DISCONNECT POWER before

servicing, adjusting, or doing maintenance to reduce the risk of accidental injury or electrocution.

For optimal performance, routinely check

the condition of the following items and

repair or replace as necessary:

• Cracked or loose grinding wheel.

• Loose hardware.

• Bent universal support.

• Worn switch.

• Worn or damaged cords and plugs.

• Any other condition that could hamper

the safe operation of this machine.

dropped, or having other items drop on

them.

Wheel Replacement

To replace the grinding or stropping

wheel:

1. DISCONNECT THE GRINDER FROM

POWER!

2. Hold the wheel from turning, and

remove the arbor nut or knob that holds

the wheel on.

Wheel Dressing

Depending on the type of grinding you do,

the grinding wheel may require periodic

dressing.

A variety of dressing tools are available

(see Accessories on Page 20) and can be

used to restore the abrasive quality of the

wheel surface and bring the wheel edge

back to a square form.

Refer to the instructions that accompany

your dressing accessory for complete

details on how to properly dress a wheel.

Model T10010 (Mfg. Since 3/10)

3. Remove the outer washer and wheel.

4. Install the new wheel, then replace the

washer and nut or knob.

Water Reservoir

Be sure to periodically empty, rinse and

refill the water reservoir with clean water.

Failing to do so can lead to a buildup of

sediment on the wheel itself, reducing

grinding performance.

-21-

Page 24

SECTION 7: SERVICE

Troubleshooting

Motor and Electrical

Symptom Possible Cause Solution

Motor will not start;

fuses or circuit

breakers blow

Motor slows, stops,

or will not start;

fuses or circuit

breakers blow.

1. Disabling key is at fault.

2. Open circuit in motor or loose

connections.

3. Start capacitor is at fault.

4. Short circuit in motor or loose

connections.

5. Incorrect fuses or circuit breakers in power supply.

1. Motor overloaded.

2. Short circuit in motor or loose

connections.

1. Install/replace disabling key;

replace switch.

2. Inspect/repair all lead connections on motor for loose

or open connections.

3. Replace start capacitor.

4. Inspect all connections on

motor for loose or shorted

terminals or worn insulation.

5. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Inspect connections on

motor for loose or shorted

terminals or worn insulation.

-22-

Model T10010 (Mfg. Since 3/10)

Page 25

Grinder Operations

Symptom Possible Cause Solution

Lines on surface of

workpiece.

Wheel dulls quickly,

grit falls off.

Wavy condition

on surface of

workpiece.

Grinding wheel

clogs.

Excessive

vibrations from

machine.

Stropping wheel

loses performance.

1. Impurity on wheel surface.

2. Workpiece not being held tightly.

1. Depth of cut too great.

2. Bad wheel dress.

3. Defective wheel bonding.

1. Machine vibrating.

2. Workpiece is not held in place

firmly.

3. Wheel face uneven.

1. Bad wheel dress.

2. Wrong material is being

ground.

3. Dirty water in reservoir.

1. Bad wheel dress.

2. Wheel is water-logged.

3. Machine is positioned on

uneven surface.

1. Insufficient wheel preparations.

2. Wheel is damaged.

1. Dress the grinding wheel.

2. Use a holding device to

firmly retain the workpiece.

1. Decrease the pressure of

the workpiece into wheel.

2. Dress the wheel.

3. Consult manufacturer of

grinding wheel.

1. Make sure machine is

securely positioned on a

level surface.

2. Use a holding device to

firmly retain the workpiece.

3. Dress the grinding wheel.

1. Dress the wheel.

2. Grind ferrous metals only.

3. Drain and refill reservoir.

1. Dress the wheel.

2. Allow wheel to dry, then

inspect wheel, replace if

needed.

3. Reposition machine.

1. Prepare wheel.

2. Replace wheel.

Model T10010 (Mfg. Since 3/10)

-23-

Page 26

The photos and diagrams

included in this section are

best viewed in color. You

can view these pages in

color at www.grizzly.com.

SECTION 8: WIRING

These page are current at the time of printing. However, in the spirit of improvement, we

may make changes to the electrical systems of future machines. Compare the manufacture

date of your machine to the one stated in this manual, and study this section carefully.

If there are differences between your machine and what is shown in this section, call

Technical Support at (570) 546-9663 for assistance BEFORE making any changes to the

wiring on your machine. An updated wiring diagram may be available. Note: Please gather

the serial number and manufacture date of your machine before calling. This information

can be found on the main machine label.

Wiring Safety Instructions

SHOCK HAZARD. Working on wiring that

is connected to a power source is extremely dangerous. Touching electrified parts

will result in personal injury including but

not limited to severe burns, electrocution,

or death. Disconnect the power from the

machine before servicing electrical components!

MODIFICATIONS. Modifying the wiring

beyond what is shown in the diagram

may lead to unpredictable results, including serious injury or fire. This includes

the installation of unapproved aftermarket

parts.

WIRE CONNECTIONS. All connections

must be tight to prevent wires from loosening during machine operation. Doublecheck all wires disconnected or connected

during any wiring task to ensure tight connections.

CIRCUIT REQUIREMENTS. You MUST

follow the requirements at the beginning of

this manual when connecting your machine

to a power source.

WIRE /COMPONENT DAMAGE. Damaged

wires or components increase the risk of

serious personal injury, fire, or machine

damage. If you notice that any wires or

components are damaged while per forming a wiring task, replace those wires or

components.

MOTOR WIRING. The motor wiring shown

in these diagrams is current at the time of

printing but may not match your machine. If

you find this to be the case, use the wiring

diagram inside the motor junction box.

CAPACITORS/INVERTERS. Some capacitors and power inverters store an electrical

charge for up to 10 minutes after being

disconnected from the power source. To

reduce the risk of being shocked, wait at

least this long before working on capacitors.

EXPERIENCING DIFFICULTIES. If you

are experiencing difficulties understanding

the information included in this section,

contact our Technical Support at (570)

546-9663.

-24-

Model T10010 (Mfg. Since 3/10)

Page 27

MOTOR

Ground

Bk

Start

Capacitor

24MFD

250VAC

PADDLE SWITCH

(viewed from behind)

Gr

White

Neutral

Black

Hot

Green

Ground

110VAC

5-15 Plug

Wt

Bl

Bl

Bk

Bl

Bl

Wt

Wiring Diagram

Figure 21. Switch connections. Figure 22. Motor connections.

Model T10010 (Mfg. Since 3/10)

READ ELECTRICAL SAFETY ON

PAGE 24 !

-25-

Page 28

Main Breakdown

14

13

10

2

1

39-4

8

39

39-2

18

24

25

40

40

26

25

19

39-1

27

24

29

37-1

3

36

10

38

18

37

32

28

37-2

37-3

21

9

47

31-1

31

45

5

7

12V2

11

43

33

15

44

30

17

16

7

42

22

41

46

-26-

39-5

39-3

39-2

39-1

39-6

34

35

6

5

4

Model T10010 (Mfg. Since 3/10)

23

Page 29

REF PART # DESCRIPTION

1 PT10010001 ANGLE GUIDE

2 PT10010002 HONING PASTE

3 PT10010003 UNIVERSAL SUPPORT

4 PT10010004 HEX NUT M12-1.75

5 PT10010005 FLAT WASHER 12MM

6 PT10010006 GRINDING WHEEL

7 PT10010007 COLLAR BUSHING 15MM ID/17MM OD

8 PT10010008 HORIZONTAL SUPPORT HOLDER

9 PT10010009 VERTICAL SUPPORT HOLDER

10 PT10010010 KNOB BOLT M6-1 X 16

11 PT10010011 DRIVE WHEEL

12V2 PT10010012V2 STROPPING WHEEL V2.03.10

13 PT10010013 FLAT WASHER 8MM

14 PT10010014 KNOB NUT M8-1.25

15 PT10010015 FLAT WASHER 12MM

16 PT10010016 ROLL PIN 4 X 44

17 PT10010017 ARBOR SHAFT

18 PT10010018 FLAT WASHER 6MM

19 PT10010019 EXT TOOTH WASHER 6MM

21 PT10010021 GRINDER CASE

22 PT10010022 FOOT

23 PT10010023 WATER RESERVOIR

24 PT10010024 E-CLIP 8MM

25 PT10010025 FLAT WASHER 10MM

26 PT10010026 MOTOR BRACKET SHAFT

27 PT10010027 MOTOR BRACKET

28 PT10010028 HEX NUT M6-1

29 PT10010029 SPECIAL NUT

30 PT10010030 HEX NUT M4-.7

31 PT10010031 SWITCH HOUSING

31-1 PT10010031-1 SWITCH HOUSING GASKET

32 PT10010032 TAP SCREW M4 X 20

33 PT10010033 PHLP HD SCR M4-.7 X 10

34 PT10010034 SWITCH W/DISABLING KEY

35 PT10010035 POWER CORD

36 PT10010036 S CAPACITOR 10M 250V 1-3/16 X 1-5/8

37 PT10010037 MOTOR 1/4HP 110V 1650RPM

37-1 PT10010037-1 MOTOR FAN COVER

37-2 PT10010037-2 MOTOR FAN

37-3 PT10010037-3 MOTOR 1/4HP 120V 1-PH

38 PT10010038 TAP SCREW M4 X 10

39 PT10010039 GRINDING JIG

39-1 PT10010039-1 BUSHING

39-2 PT10010039-2 COMPRESSION SPRING

39-3 PT10010039-3 CLAMP PLATE

39-4 PT10010039-4 FLAT WASHER 6MM

39-5 PT10010039-5 KNOB M6-1 x 16

39-6 PT10010039-6 BASE PLATE

40 PT10010040 SHAFT BUSHING

41 PT10010041 PHLP HD SCR M6-1 X 12

42 PT10010042 FLAT WASHER 6MM

43 PT10010043 LOCK WASHER 4MM

44 PT10010044 EXT TOOTH WASHER 4MM

45 PT10010045 STRAIN RELIEF

46 PT10010046 FLANGE NUT M6-1

47 PT10010047 THIN HEX NUT M20-2.5

Model T10010 (Mfg. Since 3/10)

Main Parts List

-27-

Page 30

Machine Labels Breakdown & Parts List

101

105

102

103

104

-28-

REF PART # DESCRIPTION

101 PT10010101 ROTATION DIRECTION ARROW

102 PT10010102 MACHINE ID LABEL

103 PT10010103 RESPIRATOR LABEL VERT

104 PT10010104 READ MANUAL-VERTICAL NS 7/05

105 PT10010105 GRIZZLY GREEN TOUCH-UP PAINT

Model T10010 (Mfg. Since 3/10)

Page 31

WARRANTY CARD

Name _________________________________________________________________

Street _________________________________________________________________

City _______________________ State _________________________ Zip _________

Phone # ____________________ Email ________________________ Invoice # _____

Model # ____________________ Order # _______________________ Serial # ______

The following information is given on a voluntary basis. It will be used for marketing purposes to

help us develop better products and services. All information is strictly confidential.

1. How did you learn about us?

____Advertisement ____Friend ____Catalog

____Card Deck ____Website Other:________________________

2. Which of the following magazines do you subscribe to?

____ Cabinet Maker

____ Family Handyman

____ Hand Loader

____ Handy

____ Home Shop Machinist

____ Journal of Light Cont.

____ Live Steam

____ Model Airplane News

____ Modeltec

____ Old House Journal

3. What is your annual household income?

____$20,000-$29,000 ____$30,000-$39,000 ____$40,000-$49,000

____$50,000-$59,000 ____$60,000-$69,000 ____$70,000+

____ Popular Mechanics

____ Popular Science

____ Popular Woodworking

____ Practical Homeowner

____ Precision Shooter

____ Projects in Metal

____ RC Modeler

____ Rie

____ Shop Notes

____ Shotgun News

____ Today’s Homeowner

____ Wood

____ Wooden Boat

____ Woodshop News

____ Woodsmith

____ Woodwork

____ Woodworker West

____ Woodworker’s Journal

____ Other:

4. What is your age group?

____20-29 ____30-39 ____40-49

____50-59 ____60-69 ____70+

5. How long have you been a woodworker/metalworker?

____0-2 Years ____2-8 Years ____8-20 Years ____20+ Years

6. How many of your machines or tools are Grizzly?

____0-2 ____3-5 ____6-9 ____10+

7. Do you think your machine represents a good value? ____Yes ____No

8. Would you recommend Grizzly Industrial to a friend? ____Yes ____No

9. Would you allow us to use your name as a reference for our customers in your area?

Note: We never use names more than 3 times. ____Yes ____No

10. Comments: _________________________________________________________

______________________________________________________________________

______________________________________________________________________

______________________________________________________________________

Page 32

Send a Grizzly Catalog to a friend:

Name________________________________

Street________________________________

City______________State______Zip_______

FOLD ALONG DOTTED LINE

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Place

Stamp

Here

Page 33

WARRANTY

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original

purchaser from the date of purchase. This warranty does not apply to defects due directly or

indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty and any and all warranties that may be implied

by law, including any merchantability or fitness, for any particular purpose, are hereby limited

to the duration of this written warranty. We do not warrant or represent that the merchandise

complies with the provisions of any law or acts unless the manufacturer so warrants. In no

event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and any legal actions brought against Grizzly shall be tried in the State of Washington,

County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental,

contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details.

We will then issue you a “Return Authorization Number,” which must be clearly posted on

the outside as well as the inside of the carton. We will not accept any item back without this

number. Proof of purchase must accompany the merchandise.

The manufacturers reserve the right to change specifications at any time because they

constantly strive to achieve better quality equipment. We make every effort to ensure that

our products meet high quality and durability standards and we hope you never need to use

this warranty.

Please feel free to write or call us if you have any questions about the machine or the

manual.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail:

techsupport@grizzly.com

Web Site: http://www.grizzly.com

Thank you again for your business and continued support. We hope to serve you again

soon!

Page 34

Buy Direct and Save with Grizzly®– Trusted, Proven and a Great Value!

~Since 1983~

ORDER

24 HOURS A DAY!

1-800-523-4777

Visit Our Website Today For

Current Specials!

Loading...

Loading...