Page 1

COPYRIGHT © AUGUST, 2007 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#TR9786 PRINTED IN CHINA

MODEL H8222

SPRAY GUN

INSTRUCTION MANUAL

Page 2

Model H8222 Spray Gun -1-

Safety Instructions For Spray Guns

1. READ THIS MANUAL. This gun may

cause personal injury if used incorrectly. This manual contains proper

safety and operating instructions that

must be followed to reduce this risk.

2. WEAR EYE PROTECTION. Material

sprayed into eyes may cause serious injury or blindness. Always wear

safety goggles ANSI approved for

spraying (sealing type) to reduce your

risk from this hazard.

3. SPRAY IN VENTILATED AREA.

Airborne particles and fumes are

toxic and can cause brain damage or

death. To reduce your risk, only use

the spray gun in a well ventilated area

with adequate supply of fresh air.

For Your Own Safety Read Instruction Manual

Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This manual uses a series of symbols and signal words which

are intended to convey the level of importance of the safety messages. The

progression of symbols is described below. Remember that safety messages by

themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

Indicates an imminently hazardous situation which,

if not avoided, WILL result in death or serious injury.

This symbol is used to alert the user to useful information about proper operation of the equipment.

SAFETY

NOTICE

4. WEAR A RESPIRATOR. Airborne

material from spraying can be very

hazardous to lungs. Always wear a

respirator NIOSH approved for spraying and fumes of your material type;

or use a supplied air respirator system that delivers fresh air from an

outside location via hoses.

5. MAINTAIN EQUIPMENT. Pressurized

spray guns or hoses may burst unexpectedly if damaged or poorly maintained, causing serious injury. Fix

air leaks immediately and follow all

recommended maintenance. Never

operate this spray gun with loose

or disassembled components. Never

modify the spray gun.

Page 3

Model H8222 Spray Gun-2-

6. USE CORRECT AIR PRESSURE.

Exceeding the maximum PSI rating

of this spray gun may cause unpredictable operation or bursting.

7. DISCONNECT AIR PRESSURE

before servicing, changing accessories, or moving to another location.

Never leave this spray gun unattended when connected to air.

8. AVOID IGNITION SOURCES.

Spraying around ignition sources

may cause fire or an explosion.

Do not spray around any ignition

sources or potential ignition sources.

Be aware of appliances that have

pilot lights or machinery that creates sparks during operation. Do not

smoke in the spraying area or when

spraying.

9. FIRE EXTINGUISHERS. Always

have a fully charged multi-class

or class B fire extinguisher in the

immediate area.

10. A VOID UNIN T E NTIO N A L

OPERATION. Always disconnect air

when not in use, and do not carry

tool with hand on trigger.

11. KEEP CHILDREN AWAY. Prevent

children from injury by keeping

them away from this spray gun.

Disconnect and lock the spray gun

away when not in use.

12. AVOID USE WHEN TIRED OR ON

DRUGS OR ALCOHOL. Avoid using

this spray gun if you are overly tired

or intoxicated. Using this spray gun

during these times may increase the

risk of injury or fire.

13. UNTRAINED & UNSUPERVISED

USE. Untrained operators are not

aware of the safe use of this spray

gun and may injure themselves or

cause fire. All untrained operators

must be directly supervised at all

times if using this spray gun.

14. READ MATERIAL LABELS

and MATERIAL SAFETY DATA

SHEETS (MSDS). Read and know

all the instructions on the packaging

label and the MSDS before opening

the package. This information could

save your life.

15. PROTECTIVE CLOTHING. Protect

exposed skin from overspray by

wearing a protective suit or other

approved garment.

16. INAPPROPRIATE USE. DO NOT

point or shoot spray gun directly

at yourself or another person or

animals. Do not attempt to use the

spray gun for any other use than it

was intended.

17. STORAGE. Thoroughly clean and

dry spray gun before storage. Store

in an approved cabinet.

18. BE AWARE OF HOSE LOCATION.

Hoses can easily become a tripping

hazard when laid across the floor in

a disorganized fashion.

19. SOLVENTS. Always store solvents

and shop towels soaked in solvent in

approved containers.

20. LOCAL LAWS. Consult local

authorities regarding exhaust and

waste disposal requirements.

Page 4

Model H8222 Spray Gun -3-

INTRODUCTION

The specifications, details, and photographs

in this manual represent the Model H8222

as supplied when the manual was prepared.

However, owing to Grizzly’s policy of

continuous improvement, changes may be

made at any time with no obligation on the

part of Grizzly.

If you have any comments regarding this

manual, please write to us at the following

address:

Grizzly Industrial, Inc.

C/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Email: manuals@grizzly.com

Most importantly, we stand behind our

tools. If you have any service questions or

parts requests, please call or write us at

the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

Foreword Specifications

Cup Size ..........................................1000cc

Feed Type .......................................Siphon

Fluid Tip Size ................................... 2.0mm

Air Consumption .................... 4.2–7.1 CFM

Operating Pressure Range ........ 45–60 PSI

Max. Air Pressure .......................... 120 PSI

Cup Material ............................... Aluminum

Pattern Width .......................... 150–200mm

Body Material .................................Chrome

Air Inlet Size ...................................1⁄4" NPT

Read the manual before operation.

Become familiar with this tool, its

safety instructions, and its operation

before beginning any work. Serious

personal injury may result if safety

or operational information is not

understood or followed.

Page 5

Model H8222 Spray Gun-4-

2. Attach the air hose directly to the

air fitting on the spray gun or with a

female 1⁄4" NPT quick connect fitting

(not included).

3. Attach the spray gun to a filtered, regulated air source. See the Specifications

on Page 3 for your spray gun air pressure requirements.

Note: For the best results, use a hose

that will be dedicated for spray use

only. Do not use a hose that has been

used with an in-line oiler or other possible contaminant.

SETUP

Your spray gun left our warehouse in a

carefully packed box. If you discover the

spray gun is damaged after you have

signed for delivery, please immediately

call Customer Service at (570) 546-9663

for advice.

Save all packing materials for possible

inspection by the carrier or its agent.

Otherwise, filing a shipping claim can be

difficult.

After you have unpacked the box you

should find the following:

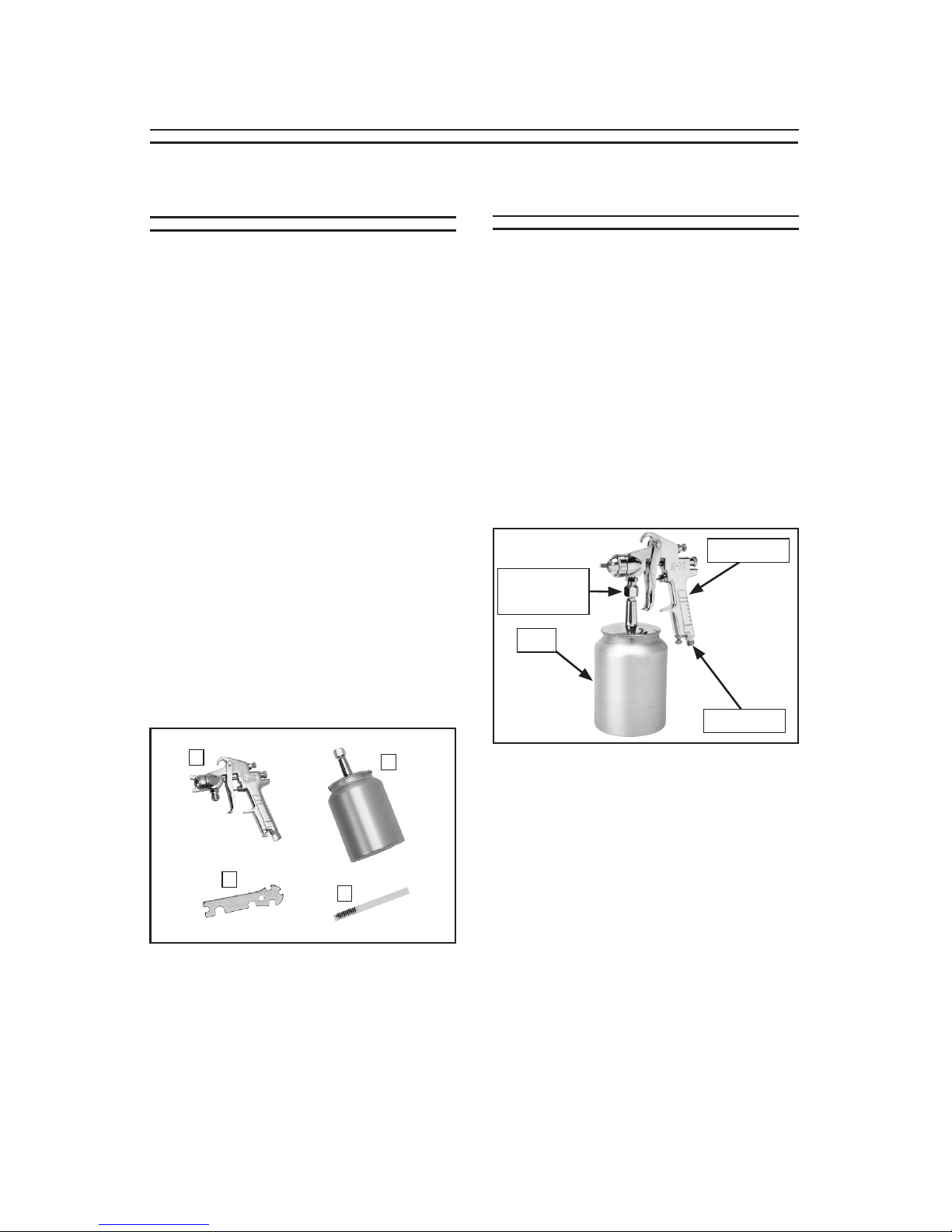

Model H8222 Inventory (Figure 1) Qty

A. Spray Gun .......................................... 1

B. Cup .................................................... 1

C. Multi-Wrench ...................................... 1

D. Cleaning Brush .................................. 1

E. Barbed Hose Fitting (not shown) ....... 1

Inventory

Before assembling and using the spray gun,

thoroughly clean and dry all parts. Please

refer to Cleaning in the MAINTENANCE

section on Page 10 for more detailed

instructions. Make sure all connections are

tight enough to prevent air leaks but not so

tight as to damage the tool.

To setup the spray gun:

1. Attach the gun body to the cup as

shown in Figure 2.

Setup

Figure 2. Model H8222 gun body

installation.

Gun Body

Cup

Connection

Point

Air Fitting

Figure 1. Model H8222 inventory.

B

A

C

D

Page 6

Model H8222 Spray Gun -5-

1. Fluid Control: Controls the volume of

material that travels through the fluid

tip.

2. Pattern Control: Adjusts the spray

pattern from a round pattern to a wide

fan.

3. Atomizing Cap: Controls the spray

pattern from vertical to horizontal.

4. Trigger: Squeeze the trigger half way

to blow air, or squeeze all the way to

spray.

5. Air Flow Control: Controls the fluid

pressure inside the spray gun.

6. Cup: Holds up to 1000cc of material

for spraying.

Controls

Cup Removal & Installation

The cup is removed/installed by loosening/tighting the cup lock cover and engaging/disengaging the cup pins in the cup

cover groove (see Figure 4).

Figure 4. Installing cup.

Cup Lock

Cover

Cup Pin

(1 of 3)

Figure 3. Controls.

Pattern Control

Atomizing Cap

Trigger

Fluid Control

Air Flow Control

Cup

Page 7

Model H8222 Spray Gun-6-

OPERATIONS

The Model H8222 siphon feed spray gun

set is designed to spray a wide variety of

materials such as lacquers, stains, primers, multi-component paints, clear coats,

acrylics, epoxies etc. It is ideal for auto

body and woodworking projects.

To use your spray gun:

1. Read and follow the material manufac-

turer's instructions for spraying, mixing,

safety, disposal, and any other instruction on the label or Material Safety Data

Sheet (MSDS).

2. Ensure the cup is securely tightened

and all other fittings are secure to avoid

air leaks or material spills.

3. Set the inlet air pressure (the air coming

to the spray gun) to the lowest pressure recommended in Specifications

on Page 3 or to the material manufacturer's recommendations.

4. Adjust the atomizing cap to vertical or

horizontal. See Atomizing Cap and

Fan Adjustments on Page 8 for further explanation.

5. Fill the cup with material.

6. Trial-and-error are necessary to

achieve the results you want along with

a fair amount of practice. Test your

material flow and spray pattern on a

piece of cardboard or some scrap of

material similar to your project.

EXPLOSION HAZARD!

DO NOT smoke or have any source

of flame or spark near spraying.

Vapors will explode if ignited.

EYE AND RESPIRATORY HAZARD!

Always wear ANSI approved goggles

and a NIOSH approved respirator

when using spray equipment. Failure

to protect yourself can lead to severe

eye/lung injuries.

TOXIC FUMES!

Only spray in well ventilated areas

or an approved spray booth. NEVER

spray in a confined space where

toxic fumes and flammable vapors

can accumulate to deadly levels.

Spraying

Page 8

Model H8222 Spray Gun -7-

7. Adjust the fluid control knob to start

with a low volume of material and keep

the atomization as low as possible.

You will need to use a combination of

fluid control, inlet air pressure, air flow

control and stroke speed to achieve the

results you want. Spray so the material

wets out nicely without running or sagging.

8. Use the pattern control knob to adjust

the spray fan to your desired pattern.

9. Keep the gun tip perpendicular, parallel

and 6"-12" from the work at all times

when spraying, as shown in Figure

5. Do not allow your wrist to bend.

This will cause the gun to arc across

the surface and distribute the material

unevenly, possibly creating sags and

dry spots.

10. Begin spraying 2-3 inches before the

work and continue to the end of the

work. Continue the motion for a few

inches past the work until you are

ready for the return stroke.

11. Maintain an even speed when spraying.

12. Overlap each stroke by 50%. This will

ensure even coverage as shown in

Figure 6. Overlapping less than 50%,

as shown in the figure to the right,

may lead to missed spots or streaky

results.

NOTICE

Tipping the spray gun may cause

material to spill out of the cup. Always

hold the spray gun perpendicular to

the ground to avoid potential spills

and feed problems.

Figure 5. Spray technique.

13. The spray stroke should have even con-

sistency and parallel edges. If it doesn't,

please refer to Troubleshooting on

Page 12.

Figure 6. Overlap technique.

No

Yes

CONTAMINATION HAZARD!

Dispose of paint waste in a responsible

manner! Follow manufacturer's

recommendations and local laws

regarding disposal.

Page 9

Model H8222 Spray Gun-8-

Figure 9. Fan adjustment.

Rotating the pattern adjustment knob (see

Figure

3) changes the shape of the spray

pattern from a wide spray to a narrow

spray, as shown in Figure 9.

The

atomizing cap can be adjusted for

horizontal or vertical spraying patterns.

Spraying in the wrong direction may lead

to material build up on the atomizing cap

horn. Many performance problems are

caused by clogged atomizing holes on the

atomizing cap horns (see Cleaning on

Page 10).

Atomizing Cap and

Fan Adjustments

Figure 7. Set up for vertical stroke

direction with horizontal fan pattern.

Stroke

Pattern

Figure 8. Set up for horizontal spray stroke

with vertical fan pattern.

Stroke

Pattern

Page 10

Model H8222 Spray Gun -9-

Figure 10. G6261 Campbell Hausfeld™

water filter.

G6261—Campbell Hausfeld™ Water

Filter

Filtering out water and oil before it reaches

the spray gun is critical for high quality

spraying results. This filter is rated at 150

PSI maximum air pressure, and has a 1⁄4"

NPT air inlet.

Figure 12. H7274 Campbell Hausfeld™

pressure regulator.

H7274—Campbell Hausfeld™ Pressure

Regulator

Since PSI drops through lengths of air

hose, attaching a regulator directly to the

spray gun ensures accurate air regulation

for the best results possible. Provides

regulated output pressure of 0 to 125 PSI

for proper tool operation. Locking pressure

knob prevents accidental adjustments. 15

SCFM flow capacity @ 90 PSI. 1⁄4" NPT.

Figure 11. Red rubber air hose.

G8114—3⁄8" x 25 Ft. Air Hose

G8115—3⁄8" x 50 Ft. Air Hose

G8116—3⁄8" x 100 Ft. Air Hose

We recommend dedicating an air hose for

spraying use only, keeping it clean and

free of water and oil by using a filter on the

incoming end. Multi-purpose red rubber

air hose is flexible and abrasion resistant.

Features 200 PSI rating, 800 PSI bursting

strength, and 1⁄4" NPT ends.

ACCESSORIES

Figure 13. H3275 Coil Hose.

H3275—1⁄4" NPT x 25' Recoil Hose

H3276—1⁄4" NPT x 50' Recoil Hose

These recoil hoses are great dedicated air

hoses because they are extremely light

weight and maneuverable, which makes

hours of spraying less tiring on wrists and

arms.

Page 11

Model H8222 Spray Gun-10-

MAINTENANCE

Cleaning

Proper cleaning is the best way to ensure

trouble free performance from your spray

gun. If your gun is not thoroughly cleaned,

damage and poor spraying will result.

Problems caused by improper cleaning will

not be covered by the warranty. Clean the

spray gun immediately after each use.

To clean your spray gun:

1. Empty the cup and spray a small

amount of solvent through the gun.

Note: If you are spraying on a regular

basis, spraying solvents into the air

may be illegal. A cabinet style spray

gun cleaner may be required.

2. DISCONNECT SPRAY GUN FROM

AIR!

3. Remove the cup and cup lid.

4. Disassemble the gun by unscrewing

the fluid control knob then remove the

spring and needle.

5. Unscrew the atomizing cap and the

fluid tip. The fully disassembled gun

should look like Figure 14.

6. Rinse all parts thoroughly in solvent,

then dry with compressed air or let

air dry. Try not to expose O-rings to

solvent or they may get damaged.

Note: If the small holes in the atomiz-

ing cap become blocked, soak in clean

solvent. If the blockage still exists,

clear the blockage with a small needle,

taking great care to not enlarge or

damage the hole. Damage to the hole

will create a disrupted spray pattern.

7. Use the cleaning brush with solvent to

clean the inner orifice and other hard

to reach areas on the outside of the

spray gun body.

8. Wipe the gun body with a lint free shop

towel to dry.

NOTICE

DO NOT soak the spray gun body in

solvent. Prolonged exposure to solvent will rapidly deteriorate the spray

gun washers and seals. Ignoring this

notice will void your warranty.

EXPLOSION HAZARD!

Chlorinated Solvents like 1,1,1Tricloroethane and Methylene

Chloride (methyl chloride) can chemically react with aluminum spray gun

parts and explode. Read solvent

label carefully to avoid using solvent

with these chemicals.

Figure 14. Disassembly for cleaning.

Atomizing Cap

Fluid Tip

Spring

Fluid Control

Knob

Needle

Cup

Lid

Cup

Page 12

Model H8222 Spray Gun -11-

Lubrication

Lubricate the following areas with a nonsilicon spray gun lubricant after cleaning.

A. Atomizing Cap Threads

B. Air Valve Packing

C. Trigger Pin

D. Pattern Control

E. Fluid Control Knob

F. Air Flow Control Knob

Allow the lubricant to coat threads, and run

into gun body to lubricate all moving parts

and seals.

Figure 15. General lubrication points.

A

B

C

D

E

E

Page 13

Model H8222 Spray Gun-12-

Troubleshooting

Symptom Possible Cause Solution

Fluttering or spitting

spray.

1. Dry or worn fluid tip seat permits air to seep into fluid passage.

2. Material level too low.

3. Fluid tip or filter obstructed.

4. Dry needle packing.

1. Tighten fluid tip or replace

seat with new one.

2. Add material.

3. Clean.

4. Lubricate needle.

Uneven top or bot

-

tom pattern.

1. Atomizing cap holes are

obstructed.

2. Build-up on top or bottom of

fluid tip

.

3. Build-up on atomizing cap is

on needle seat.

1. Clear holes.

2. Clean.

3. Clean.

Right or left arc

pattern.

1. Left or right side horn holes

are plugged.

2. Build-up on left or right side of

fluid tip.

3. Build-up of material inside

atomizing cap.

1. Clear holes.

2. Clean.

3. Clean.

Heavy deposit of

material in center.

1. The material flow exceeds the

atomizing cap capacity.

2. Inlet air pressure is too low.

3. Material is too thick.

1. Lower fluid flow.

2. Increase inlet air pressure.

3. Thin material.

Narrow center pat

-

tern.

1. Volume control turned in too

far.

2. Inlet air pressure too high.

3. Fluid pressure is too low.

4. Material is too thin.

1. Increase volume.

2. Reduce inlet air pressure.

3. Increase fluid pressure.

4. Adjust material.

No spray output

. 1. No pressure at gun.

2. Fluid passages dirty.

3. Fluid control closed.

4. Out of paint.

5. Material too thick.

1. Check air supply.

2. Clean gun, remove any

obstructions.

3. Open.

4. Refill.

5. Thin to manufacturer's rec

-

ommendations.

Page 14

Model H8222 Spray Gun -13-

Symptom Possible Cause Solution

Excessive overspray.

1. Fluid pressure too high.

2. Gun is too far from surface.

3. Spraying too fast.

1. Reduce fluid pressure.

2. Keep gun at recommended

distance.

3. Slow down and maintain

consistent, even parallel

stroke.

Unable to control

spray fan.

1. Pattern adjustment screw is

not seating properly

.

2. Atomizing cap is loose.

1. Clean or replace.

2. Tighten atomizing cap.

Runs and sags. 1. Damaged seal. 1. Replace damaged seals.

Material leaks from

cup.

1. Cap not secure.

2. Cup not tight on gun body.

3. Leaking from cap vent hole.

1. Tighten

.

2. Tighten.

3. Hold gun upright; do not tilt.

Material leaks from

gun.

1. Fluid tip loose.

2. Dry or damaged seals.

3. Excessive pressure.

1. Tighten.

2. Replace

seals.

3. Reduce pressure.

Thick dimpled fin

ish: orange peel

appearance.

1. Holding gun too close to surface.

2. Inlet air pressure too low.

3. Material not properly mixed.

4. Surface is dirty or oily.

1. Spray at recommended distance.

2. Check inlet air pressure.

3. Follow manufacturer's

instructions.

4. More surface prep is

required.

Dry Spray.

1. Inlet air pressure too high.

2. Gun too far from surface.

3. Gun stroke too fast.

1. Lower inlet air pressure.

2. Keep gun at recommended

distance.

3. Slow down and maintain

consistent even parallel

stroke.

Gun leaks from

fluid tip.

1. Debris will not let the needle

seat with the fluid tip.

1. Clean or replace both.

Contaminated

paint: fish eye

appearance.

1. Water or oil in the air line. 1. Install an in-line air filter.

2. Replace air line.

Page 15

Model H8222 Spray Gun-14-

Parts Breakdown H8222

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 PH8222001 ADJUSTMENT SCREW 24 PH8222024 NEEDLE GASKET

2 PH8222002 ADJUSTMENT KNOB 25 PH8222025 SEALING WASHER

3 PORS004 O-RING 3.5 X 1.5 S4 26 PH8222026 DIRECTION SCREW

4 PH8222004 FLAT WASHER 3.5MM 27 PH8222027 NOZZLE

5 PH8222005 COMPRESSION SPRING 28 PH8222028 AIR CAP

6 PH8222006 AIR VALVE TUBE 29 PH8222029 SWITCH BOLT

7 PH8222007 AIR INLET JOINT 30 PH8222030 SEALING WASHER

8 PH8222008 GUN BODY 31 PH8222031 SWITCH BOLT

9 PH8222009 SWITCH WASHER 32 PORS009 O-RING 8.5 X 1.5 S9

10 PH8222010 SWITCH BOLT 33 PH8222033 AIR VALVE BODY

11 PORS004 O-RING 3.5 X 1.5 S4 34 PH8222034 COMPRESSION SPRING

12 PH8222012 NEEDLE 35 PH8222035 PAINT INLET CONNECTOR

13 PH8222013 NEEDLE SPRING 36 PH8222036 LID

14 PH8222014 PAINT ADJUST KNOB 37 PH8222037 ALUMINUM CUP 1000CC

15 PH8222015 PATTERN ADJUST NEEDLE 38 PH8222038 THIN HEX NUT M10-1.5

16 PH8222016 PATTERN NEEDLE WASHER 40 PH8222040 PAINT INLET JOINT

17 PH8222017 GUIDING COPPER CIRCLE 41 PH8222041 FLARE NUT 3/8" NPT

18 PH8222018 PATTERN ADJUST SPRING 42 PH8222042 LID GASKET

19 PH8222019 PATTERN ADJUST KNOB 43 PH8222043 SUCTION TUBE

20 PH8222020 PATTERN ADJUST SCREW 44 PH8222044 MULTI-WRENCH

21 PEC02M E-CLIP 4MM 45 PH8222045 O-RING REPAIR KIT

22 PH8222022 TRIGGER 46 PH8222046 BARBED HOSE FITTING

23 PH8222023 TRIGGER PIN 47 PH8222047 BARBED FITTING NUT

Page 16

Loading...

Loading...