Grizzly G5960, G7958, G8143 User Manual

COPYRIGHT © MAY, 2003 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

PRINTED IN CHINA

ONLINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE CONFIGURATION OF THE MACHINE AS IT IS CURRENTLY BEING SHIPPED. THE

MACHINE CONFIGURATION CAN CHANGE AS PRODUCT IMPROVEMENTS ARE INCORPORATED. IF YOU OWN AN EARLIER VERSION OF THE

MACHINE, THIS MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE . CONTACT CUSTOMER SERVICE IF YOU HAVE ANY QUESTIONS

ABOUT DIFFERENCES. PREVIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

COLLET CLOSER

MODEL G8143

INSTRUCTION MANUAL

FOR USE WITH METAL CUTTING LATHE MODEL G5960 AND G7958

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and

other masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

G8143 Collet Closer -1-

Safety Instructions For Metalworking Machines

METALWORKING EQUIPMENT

SAFETY INSTRUCTIONS

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors should be

kept at a safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DO NOT FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. DO NOT force tool or

attachment to do a job for which it was not

designed.

1. READ AND UNDERSTAND MACHINE

OWNERS MANUAL FOR YOUR LATHE.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form a habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on.

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DO NOT USE IN DANGEROUS ENVIRONMENT. DO NOT use power tools in

damp or wet locations, or where any flammable or noxious fumes may exist. Keep

work area well lighted.

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

This symbol is used to alert the user to useful information about

proper operation of the equipment or property damage hazards.

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

manual uses a series of symbols and signal words which are intended to convey the level of

importance of the safety messages. The progression of symbols is described below. Remember

that safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures.

NOTICE

G8143 Collet Closer-2-

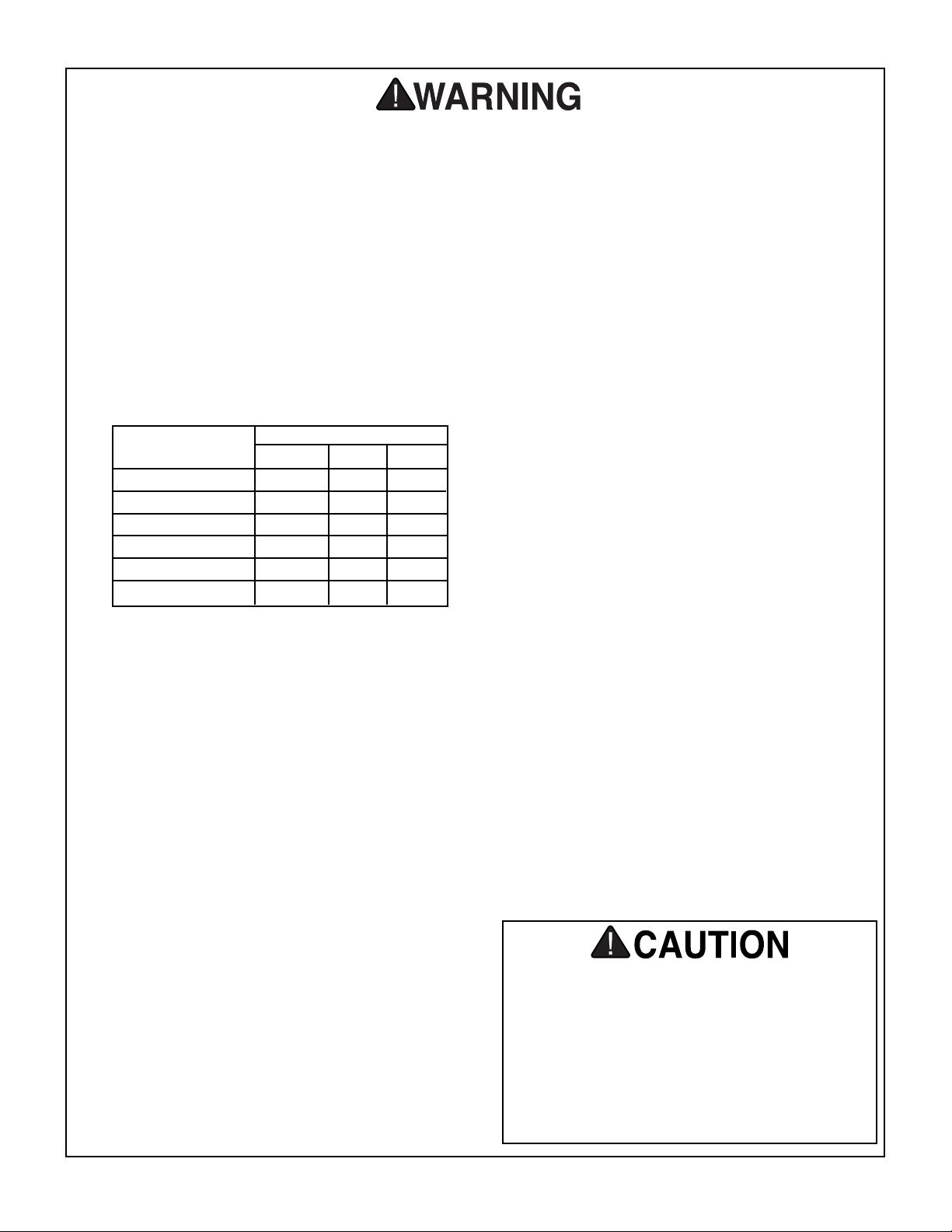

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition. Conductor size should be in accordance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause

a drop in line voltage resulting in loss of

power and overheating. Your extension

cord must also contain a ground wire and

plug pin. Always repair or replace extension cords if they become damaged.

Minimum Gauge for Extension Cords

10. WEAR PROPER APPAREL. DO NOT

wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which

may get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

12. SECURE WORK. Use properly secured

clamps or vises to hold work while performing the machining operation

13. DO NOT OVER-REACH. Keep proper

footing and balance at all times.

14. MAINTAIN TOOLS AND MACHINERY

WITH CARE. Keep tools sharp and clean

for best and safest performance. Follow

instructions for lubricating and changing

accessories.

15. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury.

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 16 16 16

7-10 16 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

Safety Instructions For Metalworking Tools

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. On machines with magnetic

contact starting switches there is a risk of

starting if the machine is bumped or jarred.

Always disconnect from power source

before adjusting or servicing. Make sure

switch is in OFF position before reconnecting.

17. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its

operation. A guard or other part that is damaged should be properly repaired or

replaced.

18. NEVER LEAVE MACHINE RUNNING

UNATTENDED. TURN POWER OFF. DO

NOT leave machine until it comes to a complete stop.

19. SOME COOLANTS USED FOR MACHINING MAY CONTAIN HAZARDOUS CHEMICALS. Read and understand all user infor-

mation on the coolant container and protect

yourself accordingly.

20. NEVER OPERATE A MACHINE WHEN

TIRED, OR UNDER THE INFLUENCE OF

DRUGS OR ALCOHOL. Full mental alert-

ness is required at all times when running a

machine.

No list of safety guidelines can be complete. Every shop environment is different.

Always consider safety first, as it applies to

your individual working conditions. Use

this and other machinery with caution and

respect. Failure to do so could result in

serious personal injury, damage to equipment or poor work results.

G8143 Collet Closer -3-

To begin assembly, follow these initial safety

instructions.

1. Disconnect the lathe from the power

source!

2. Remove the chuck or any other device that is

mounted to the spindle. (Refer to your

owner’s manual.)

3. Make sure the 5-C Collet/Morse Taper

Adapter (included in the kit) and the spindle

opening are clean and free of oil. Use a soft

cloth or rag to wipe up any contaminant.

Disconnect power to your lathe before

beginning installation of the Model

G8143 Collet Closer.

The Model G8143 Collet Closer allows you to

quickly interchange 5-C collets on your Model

G5860 or Model G7958 Metal-Cutting Lathe. The

positive-locking handle clamps standard 5-C collets safely and securely for precision turning.

Grizzly also offers an extensive line of precisionground 5-C collets, ideal for use with the Model

G8143 Collet Closer. See the latest Grizzly

Catalog or visit our web site at www.grizzly.com

for price and ordering information.

Most importantly, we stand behind our tools. If

you have any service questions or parts requests,

please call or write us at the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

e-Mail: support@grizzly.com Site:

http://www.grizzly.com

Mounting the Model G8143 requires the use of a

few simple tools.

Tools Required:

— Adjustable wrench

— 3MM hex key

— 4MM hex key

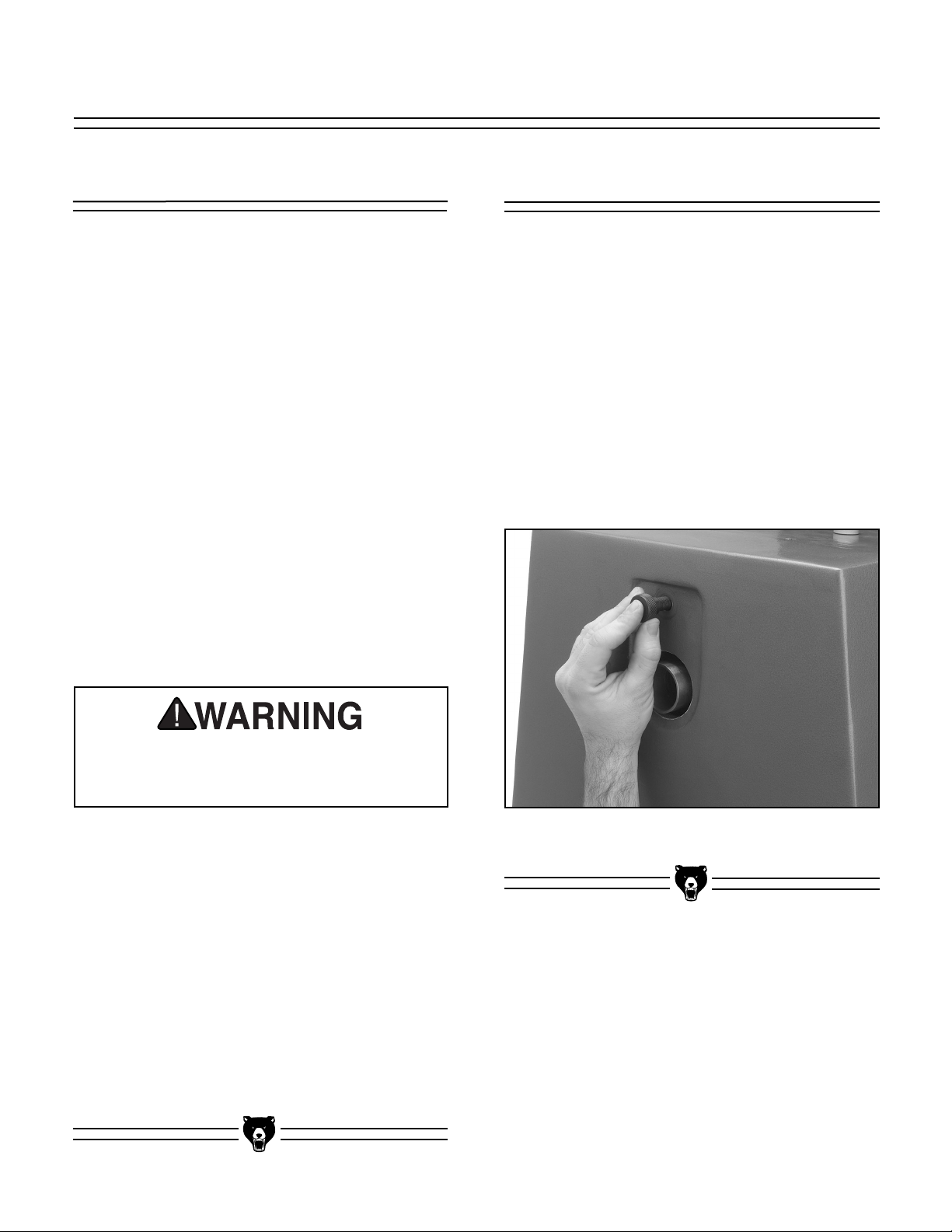

To remove the lathe cover and the mounting

studs:

Remove the end cover from the lathe by

unscrewing the cover knobs on the left end of the

lathe as shown in Figure 1.

Cover Removal

Commentary

INTRODUCTION

Figure 1. Lathe cover removal.

Loading...

Loading...