Grizzly G5352 User Manual

SPRAY GUN

MODEL G5352

INSTRUCTION MANUAL

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

COPYRIGHT © MAY, 2006 BY GRIZZLY INDUSTRIAL, INC.

#PC8211 PRINTED IN TAIWAN

SECTION 1: SAFETY

For Your Own Safety Read Instruction Manual

Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This manual uses a series of symbols and signal words which

are intended to convey the level of importance of the safety messages. The

progression of symbols is described below. Remember that safety messages by

themselves do not eliminate danger and are not a substitute for proper accident

prevention measures.

Indicates an imminently hazardous situation which, if

not avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or moderate injury.

It may also be used to alert against unsafe practices.

NOTICE

This symbol is used to alert the user to useful information about proper operation of the equipment.

Safety Instructions For Pneumatic Tools

1. KEEP ALL SAFETY DEVICES IN

PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of check-

ing to see that keys and adjusting

wrenches are removed from tool

before operation.

3. KEEP WORK AREA CLEAN

Cluttered areas and benches invite

accidents.

4. DO NOT USE IN DANGEROUS

ENVIRONMENT. Do not use pneu-

matic tools in damp or wet locations, or where any flammable or

noxious fumes may exist. Keep

work area well lighted.

5. KEEP CHILDREN AND VISITORS

AWAY. All children and visitors

should be kept at a safe distance

from work area.

6. MAKE WORKSHOP CHILD

PROOF by locking your shop and

shutting off air valves.

7. DO NOT FORCE TOOL. It will do

.

the job better and safer at the rate

for which it was designed.

8. USE THE RIGHT TOOL. Do not

force tool or attachment to do a job

for which it was not designed.

9. DO NOT USE UNDER THE

INFLUENCE OF DRUGS OR

ALCOHOL.

Model G5352 Spray Gun-2-

Safety Instructions For Pneumatic Tools

10. USE PROPER AIR HOSE for the

tool. Make sure your air hose is in

good condition and is long enough to

reach your work without stretching.

11. WEAR PROPER APPAREL. Do not

wear loose clothing, gloves, neck

ties, rings, bracelets, or other jewelry which may get caught in moving

parts. Non-slip footwear is recommended. Wear a protective hair covering to contain long hair.

12. ALWAYS USE SAFETY GLASSES.

Also use a face or dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses—they are NOT safety

glasses.

13. WEAR APPROVED HEARING

PROTECTION. Air escaping from

pneumatic tools can exceed safe

exposure limits and may cause

hearing damage with prolonged

exposure.

14. SECURE WORK. Use clamps or a

vise to hold work when practical. It is

safer than using your hand and frees

both hands to operate tool.

15. MAINTAIN TOOLS WITH CARE.

Keep tools lubricated and clean

for best and safest performance.

Follow instructions for lubricating

and changing accessories.

16. REDUCE THE RISK OF

UNINTENTIONAL STARTING. Do

not carry tool with hand on trig

ger and always disconnect from air

when not in use.

17. DISCONNECT TOOLS before servicing and changing accessories.

18. DO NOT OVERREACH. Keep

proper footing/balance at all times.

19. USE THE RECOMMENDED

-

-

ACCESSORIES. Consult owner’s

manual for recommended acces

sories. The use of improper accessories may cause risk of injury.

20. CHECK FOR DAMAGED PARTS

BEFORE USING.

ing and alignment of parts, broken

parts, part mounting, loose bolts,

and any other conditions that may

affect machine operation. Repair or

replace damaged parts.

21. NEVER LEAVE UNATTENDED

TOOL CONNECTED TO AIR.

Disconnect the air hose and do not

leave tool until it is relieved of any

built up pressure.

22. NEVER ALLOW UNTRAINED

USERS TO USE THIS TOOL

WHILE UNSUPERVISED.

23. IF YOU ARE UNSURE OF THE

INTENDED OPERATION, STOP

USING TOOL. Seek formal training

or research books or magazines

that specialize in pneumatic tools.

24. BE AWARE OF HOSE LOCATION

WHEN USING PNEUMATIC

TOOLS. Hoses can easily become

a tripping hazard when laid across

the floor or spread out in a disorganized fashion.

Check for bind-

-

Model G5352 Spray Gun -3-

Additional Safety Instructions for Spray Guns

1. READ THIS MANUAL. This manual

contains proper operating instructions for this spray gun.

2. RE AD MATER IAL LA BE LS

and MATERIAL SAFETY DATA

SHEETS (MSDS). Read and know

all the instructions on the packaging label and the MSDS before

opening the package. This information could save your life.

3. RESPIRATORY PROTECTION.

Always wear a NIOSH approved

respirator when spraying or working around finishing materials.

4. FIRE EXTINGUISHERS. Always

have a fully charged multi-class

or class B fire extinguisher in the

immediate area.

5. FLAMMABLE MATERIAL. NEVER

spray near open flame or where

any spark could occur.

6. FRESH AIR. Always provide adequate exhaust to keep area free of

built-up vapors. NEVER spray in an

enclosed space.

7. DI SC ON NECT COMPRESS ED

AIR. Always disconnect the spray

gun from compressed air before

cleaning, changing attachments or

when performing maintenance of

any kind on this tool.

8. PROTECTIVE CLOTHING. Protect

exposed skin from overspray by

wearing a protective suit or other

approved garment.

9. INAPPROPRIATE USE. DO NOT

point or shoot spray gun directly

at yourself or another person or

animals. Do not attempt to use the

spray gun for any other use than it

was intended.

10. STORAGE. Thoroughly clean and

dry spray gun before storage. Store

in an approved cabinet.

11. SOLVENTS. Always store solvents

and shop towels soaked in solvent

in approved containers.

12. EYE PROTECTION. Wear eye protection whenever spraying or cleaning. Solvents and chemicals can

cause serious eye injury, which

could lead to blindness.

13. OPERATI NG PRESSURE. DO

NOT exceed the recommended

inlet air pressure. Excessive pressure could cause the spray gun to

burst or cause other internal equipment damage.

14. LOCAL LAWS. Consult local

authorities regarding exhaust and

waste disposal requirements.

Model G5352 Spray Gun-4-

SECTION 2: INTRODUCTION

Foreword Contact Information

We are proud to offer the Grizzly Model

G5352 Spray Gun. This model is part

of a growing Grizzly family of fine tools.

When used according to the guidelines set

forth in this manual, you can expect years

of trouble-free, enjoyable operation, and

proof of Grizzly’s commitment to customer

satisfaction.

It is our pleasure to provide this manual

with the Model G5352. It was written

to encourage safety considerations and

guide you through general operating procedures and maintenance.

The specifications, details, and photographs in this manual represent the Model

G5352 as supplied when the manual was

prepared. However, owing to Grizzly’s policy of continuous improvement, changes

may be made at any time with no obligation on the part of Grizzly.

If you have any comments regarding this

manual, please write to us at the following

address:

Grizzly Industrial, Inc.

C/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Most importantly, we stand behind our

tools. If you have any service questions or

parts requests, please call or write us at

the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

Web Site: http://www.grizzly.com

Read the manual before operation.

Become familiar with this tool, its

safety instructions, and its operation

before beginning any work. Serious

personal injury may result if safety or

operational information is not under

stood or followed.

Model G5352 Spray Gun -5-

-

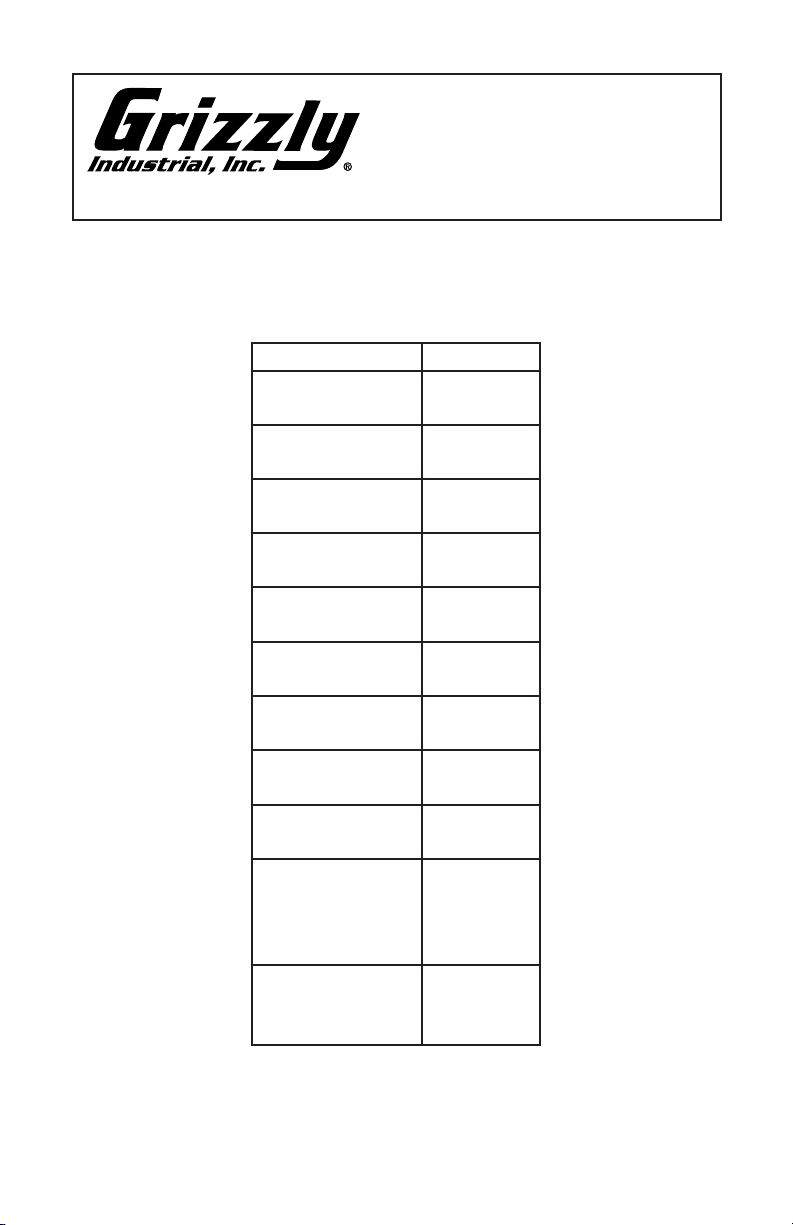

TOOL DATA SHEET

Customer Service #: (570) 546-9663 • To Order Call: (800) 523-4777 • Fax #: (800) 438-5901

GRAVITY FEED SPRAY GUN MODEL

G5352

MODEL G5352

CUP SIZE

TYPE OF FEED

FLUID TIP

AIR CONSUMPTION

INLET AIR

PRESSURE

FLUID PRESSURE

CUP MATERIAL

MAX. PATTERN

WIDTH

BODY MATERIAL

MATERIAL USAGE

WATERBORNE

MATERIAL

COMPATIBLE

600 ml

Gravity

1.4 mm

5 CFM

1.5-3.5 BAR

21-50 PSI

Greater Than

10 PSI

Aluminum

250mm

Painted Metal

Medium

Solids, i.e..

Enamels &

Lacquers

NO

Model G5352 Spray Gun-6-

Loading...

Loading...