GOBOSTORM

GR0466

Instruction manual

INDEX

1.0 Introduction ...................................................................................................................................4

1.1 Safety information.........................................................................................................................................................4

1.1.1 Protecting against electric shock ............................................................................................................................4

1.1.2 Installation ..................................................................................................................................................................4

1.1.3 Protection against burns and fire .............................................................................................................................4

1.1.4 Protection against lamp explosion ..........................................................................................................................4

1.1.5 Weather protection....................................................................................................................................................4

1.1.6 Protection against UV radiation................................................................................................................................4

1.3 Compliance ..................................................................................................................................................................4

2.0 Size .................................................................................................................................................5

3.0 Components of the unit................................................................................................................6

4.0 Packaging and transport .............................................................................................................6

4.1 Packaging .....................................................................................................................................................................6

4.2 Transport ........................................................................................................................................................................6

5.0 Quick turn on.................................................................................................................................7

6.0 Installation .....................................................................................................................................9

6.1 Fixing ..............................................................................................................................................................................9

6.2 Adjusting light beam direction ..................................................................................................................................10

6.3 Connection to mains power ......................................................................................................................................10

6.4 Connection to DMX signal .........................................................................................................................................12

7.0 Lamp installation and replacement..........................................................................................13

7.1 Lamp specifications ...................................................................................................................................................13

7.2 Lamp installation.........................................................................................................................................................14

8.0 Replacing gobos and focus ......................................................................................................15

8.1 Replacing gobos.........................................................................................................................................................15

8.2 Focus ............................................................................................................................................................................16

8.3 Mounting the optional 16° Angle lens ......................................................................................................................17

9.0 Use of the unit..............................................................................................................................18

9.1 Setting operating mode .............................................................................................................................................18

9.2 Setting DMX address...................................................................................................................................................18

9.3 DMX functions .............................................................................................................................................................19

10.0 Master-Slave and Automatic function....................................................................................19

10.1 MASTER configuration...............................................................................................................................................20

10.2 SLAVE configuration..................................................................................................................................................20

10.3 AUTOMATIC configuration .......................................................................................................................................21

11.0 Maintenance.............................................................................................................................21

11.1 Cleaning the unit ......................................................................................................................................................21

11.2 Regular checks .........................................................................................................................................................21

12.0 Spare parts ................................................................................................................................22

13.0 Disposal......................................................................................................................................22

14.0 Troubleshooting.........................................................................................................................22

15.0 Technical specifications ..........................................................................................................23

4 English

1.1 Safety information

1.1.1 Protecting against electric shock

• Disconnect the unit from mains supply before servicing it or performing any other action.

• Always ground/earth the unit electrically.

• Before connecting the unit to power supplies, verify that operating voltage and frequency are compatible.

• Do not handle the unit with wet hands or in the presence of water.

• Check regularly that the power supply cable is not damaged or crushed.

• Apply to a qualified technician for any regular maintenance action not described in this manual.

1.1.2 Installation

• Fix the unit with screws, hooks or any other support able to bear the weight of the unit itself.

• If the unit is fixed onto a suspended structure, this structure is supposed to bear at least ten times the weight of

all devices to be fixed.

• The unit installation actions must be performed by a qualified staff.

1.1.3 Protection against burns and fire

• Suitable to be installed onto normally inflammable surfaces.

• If the projector is in a fixed position and the beams is directed towards a flammable surface, the unit should be

kept at a minimum of 1 mt. If the beam is directed to people or thing at a distance lower than 2 mt, please

turn the lamp immediately off.

• The unit is not to be installed in places where the ambient temperature exceeds 35° (95°F).

• The external temperature of the unit surface (front glass) can reach 80°C (176°F).

• The lamp is very hot during operations! Wait at least for 20 minutes before changing.

1.1.4 Protection against lamp explosion

• Please replace any lamp that may present any damage or deformation.

• During the lamp replacement always use adequate body and eye protection (see the lamp manufacturer

instruction)

1.1.5 Weather protection

The unit is classified as device with an IP65 weather protection rate.

1.1.6 Protection against UV radiation

• Never operate the fixture with missing or damaged lenses and / or cover.

• Replace any damaged shields with original GRIVEN spare parts..

• Do not stare directly into the light. Never look at an exposed lamp while it is lit.

1.3 Compliance

• Product in compliance with EN60598-1 EN60598-2-17.

• Product in compliance with 2002/95/CE (RoHS).

1.0 Introduction

Warning!

This unit is suitable for professional use only, not for domestic use.

English 5

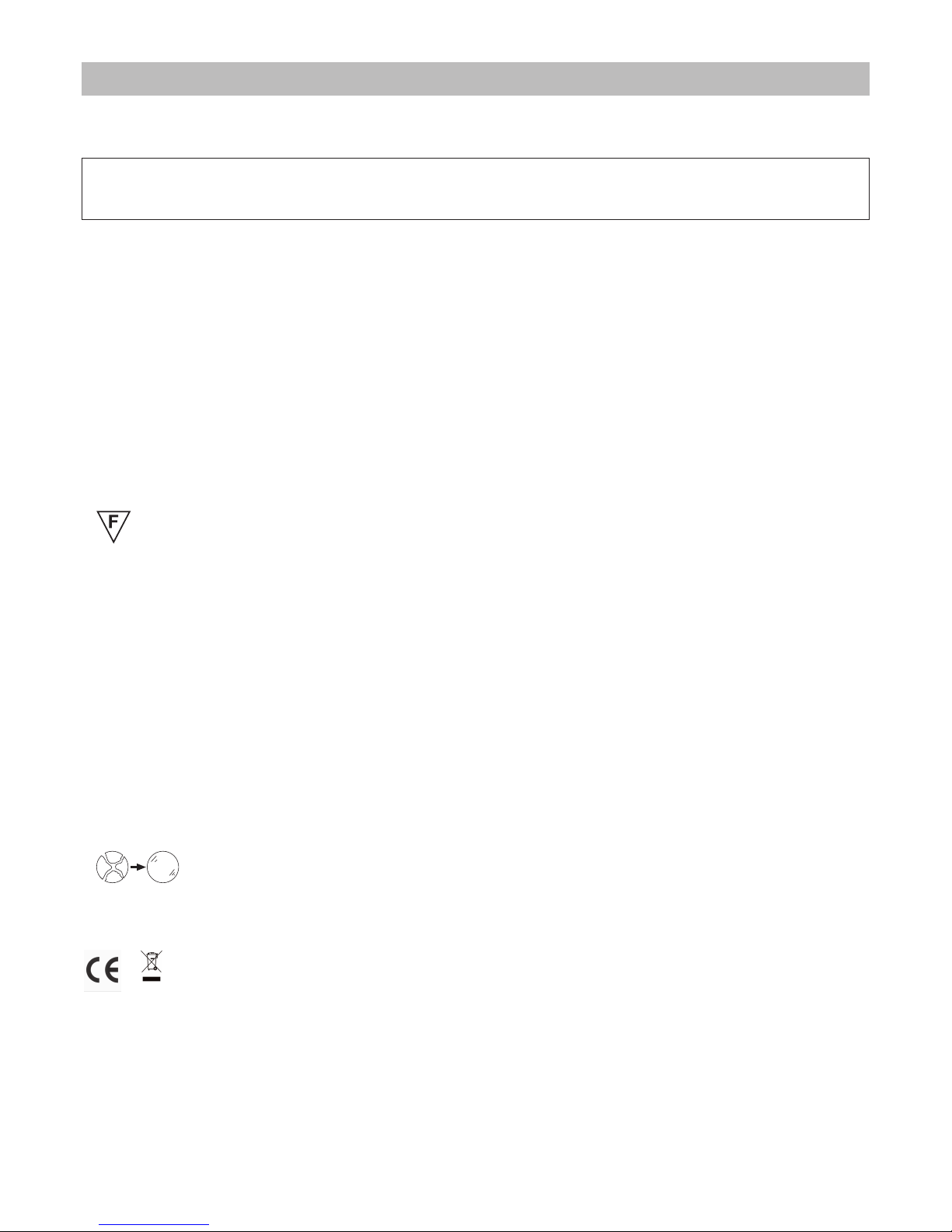

176mm

6,92”

368mm

14,47”

285mm

11,22”

173mm

6,81”

213mm

8,39”

660mm

25,99”

715mm

28,16”

506mm

19,92”

473mm

18,62”

598mm

23,56”

2.0 Size

6 English

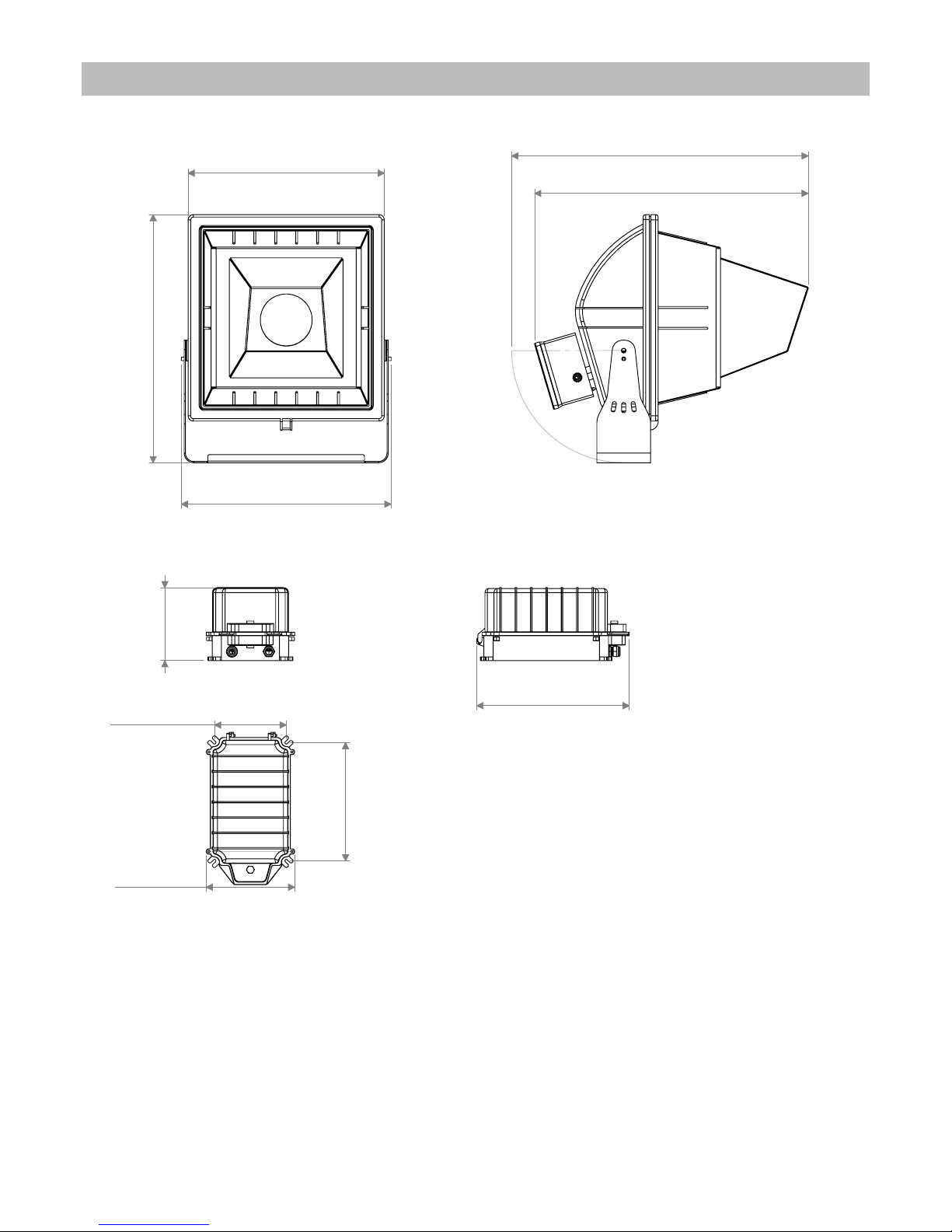

Components description:

A. Front cover

B. Optic group

C. Color and gobos group

D. Electronic box

E. Ballast

4.1 Packaging

Check carefully the content of the box and, in case of damage, contact your forwarder immediately.

The following items are included in the box of this unit:

n° 1 Gobostorm unit

n° 1 owner’s manual

n° 1 Ballast

n° 4 Gobos

n° 1 Fixing springs

4.2 Transport

The carton box has not been designed to be used more than once, therefore, it is recommended to use one of

our flight cases to transport the unit.

Warning!

• Griven S.r.l. liability will cease upon consignment of goods to the forwarder: claims for damage due to transport must be addressed directly to the forwarder.

• Griven S.r.l. will accept claims for broken or missing goods only within seven days of receipt of the goods.

• Returns of equipment will not be accepted without prior authorization granted by Griven S.r.l. and if not duly accompanied by relevant shipping documents.

A

B

C

D

E

4.0 Packaging and transport

3.0 Components of the unit

English 7

In this chapter brief essential instructions for an immediate use of the unit are listed. These instructions are necessary to connect and power up the unit, but they will not describe in complete details the functions of the unit itself. All other chapters in this manual are therefore supposed to be read, in order to learn all pieces of necessary

information relevant to the unit.

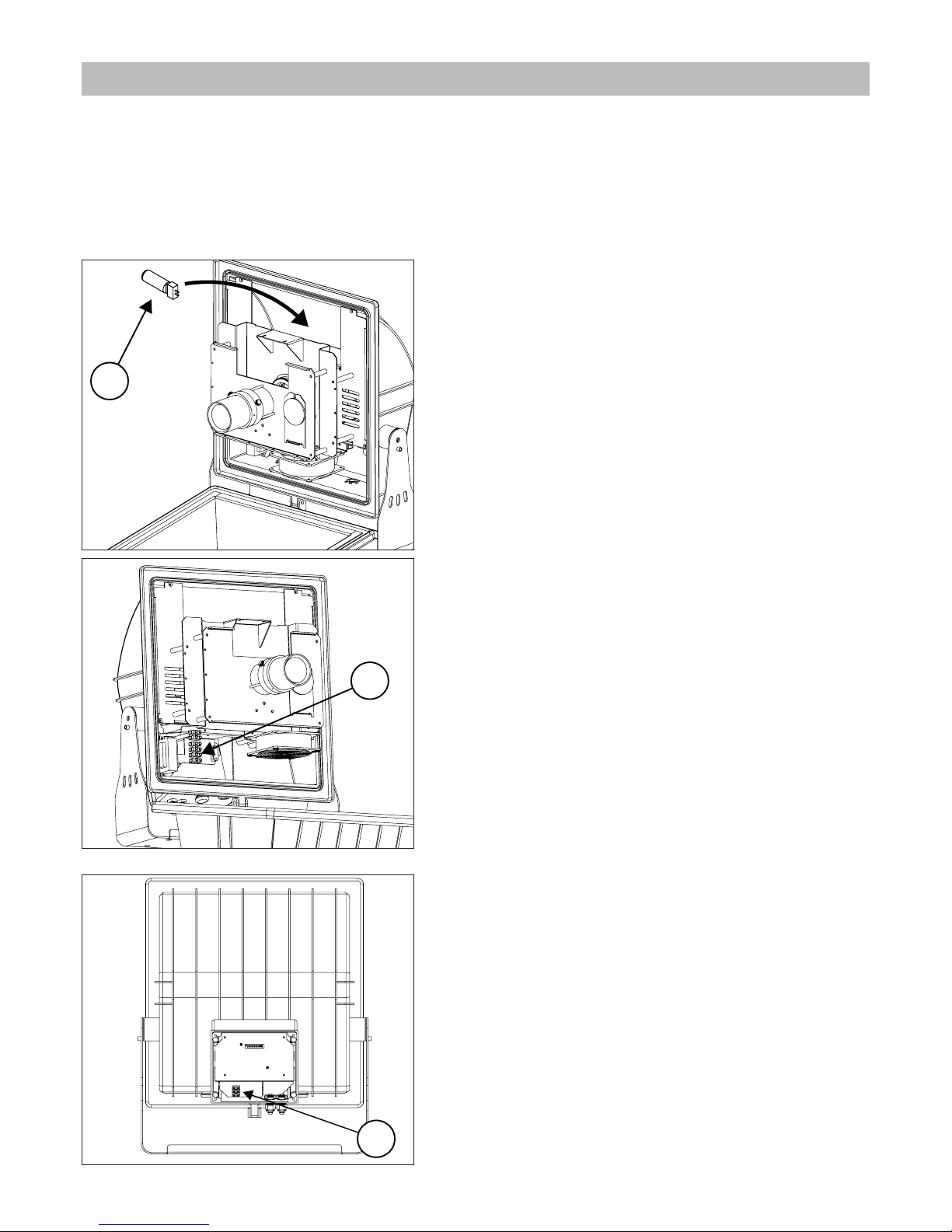

A. Open the box and check the content.

B. Install the unit.

D. Install the lamp “1”.

E. Connect the ballast by using the terminal “2”.

F. Connect the DMX signal by using the terminal “3”.

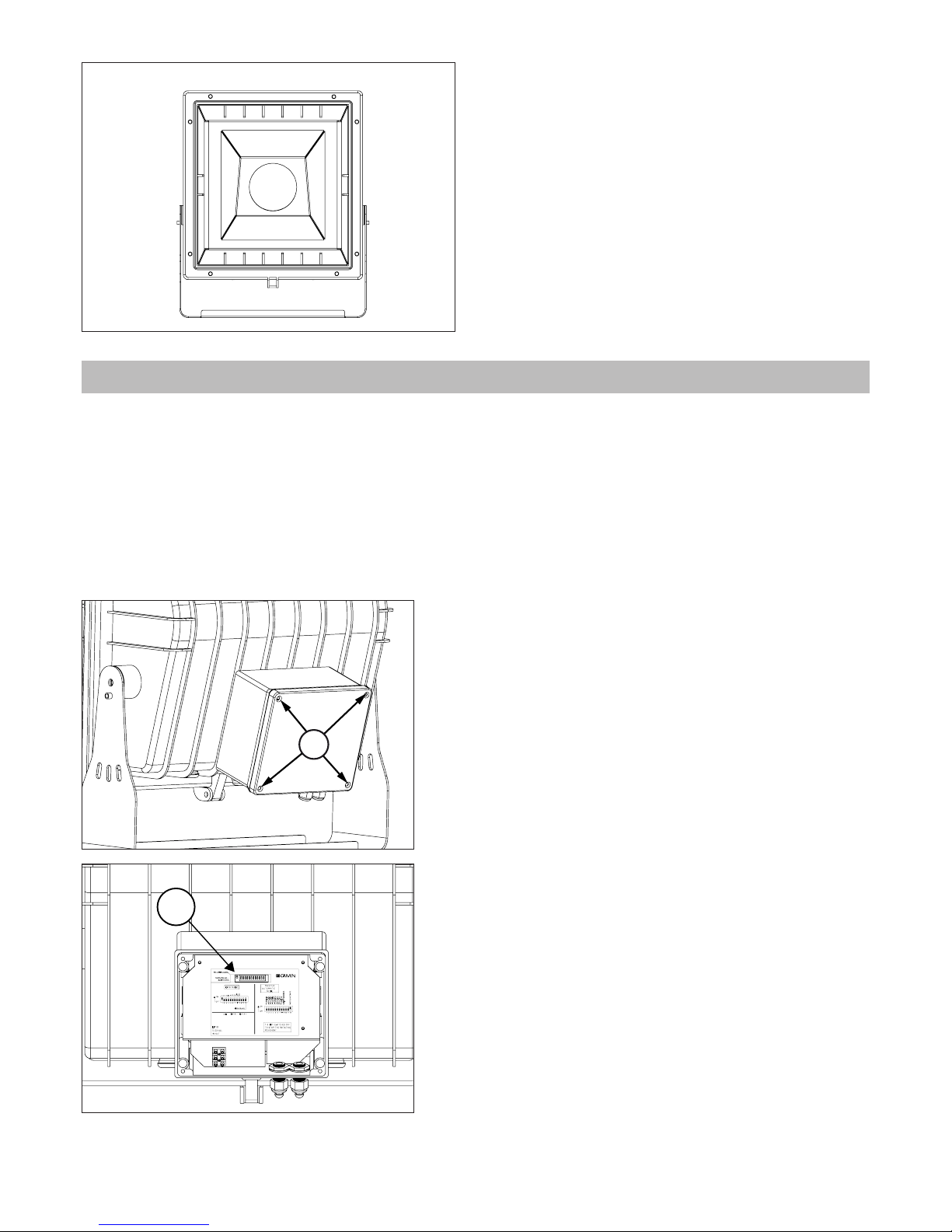

5.0 Quick turn on

1

2

3

8 English

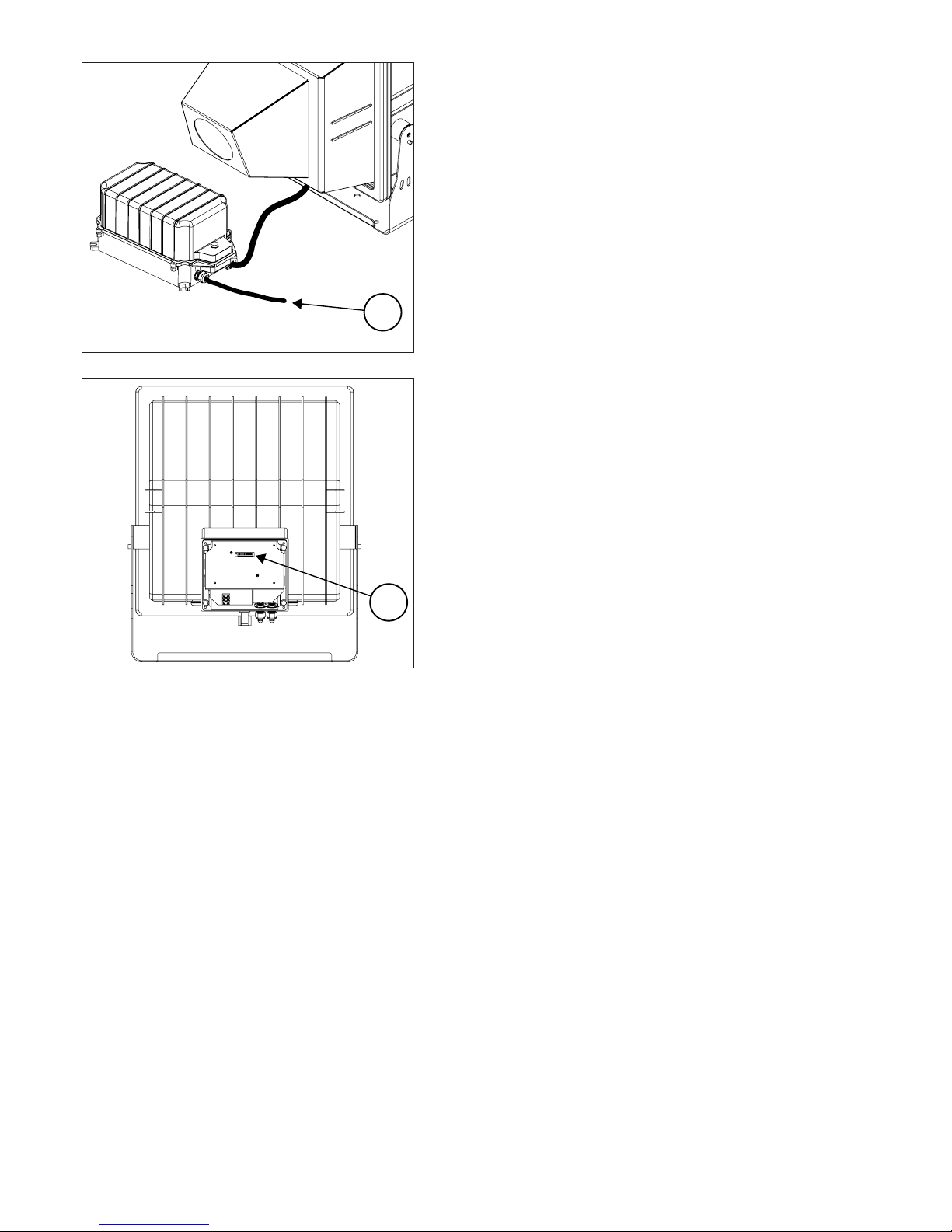

G. Power up the unit by using the cable “4”.

H.Set the DMX address and the working mode using the “5” dip-

switch panel located within the fixture rear box.

4

5

English 9

6.1 Fixing

The unit can be used both rested on floor and fixed onto a structure.

Possible mounting positions are shown in the following picture.

Use the holes Ø12.5 and Ø14 in the bracket to fix the unit.

Min 10 cm

Min 10 cm

70mm

2,76in

70mm

2,76in

90mm

3,54in

180mm

7,09in

180mm

7,09in

14m

m

0,

55in

12mm

0,4

7in

6.0 Installation

10 English

6.2 Adjusting light beam direction

A. Untighten the screws "6" and the grain “7”.

B. Rotate the body of the unit towards desired direction

and tighten the screws “6” and the grain “7”.

6.3 Connection to mains power

The unit can operate with voltage from 200 to 220Vac or 230 to 240Vac and with frequency of 50 and 60Hz.

A. Untighten the screws “8” ed open the projector.

6

7

Warning!

• Before connecting the unit, verify that power supplies features are compatible with the unit features.

• The unit must never be installed if not grounded electrically.

• It is suggested to use a magnetothermic switch along the power supply line, as prescribed by in force rules.

• The unit must not be powered up through a dimmer power device.

• Wiring and connection actions are to be performed by a qualified staff.

8

8

English 11

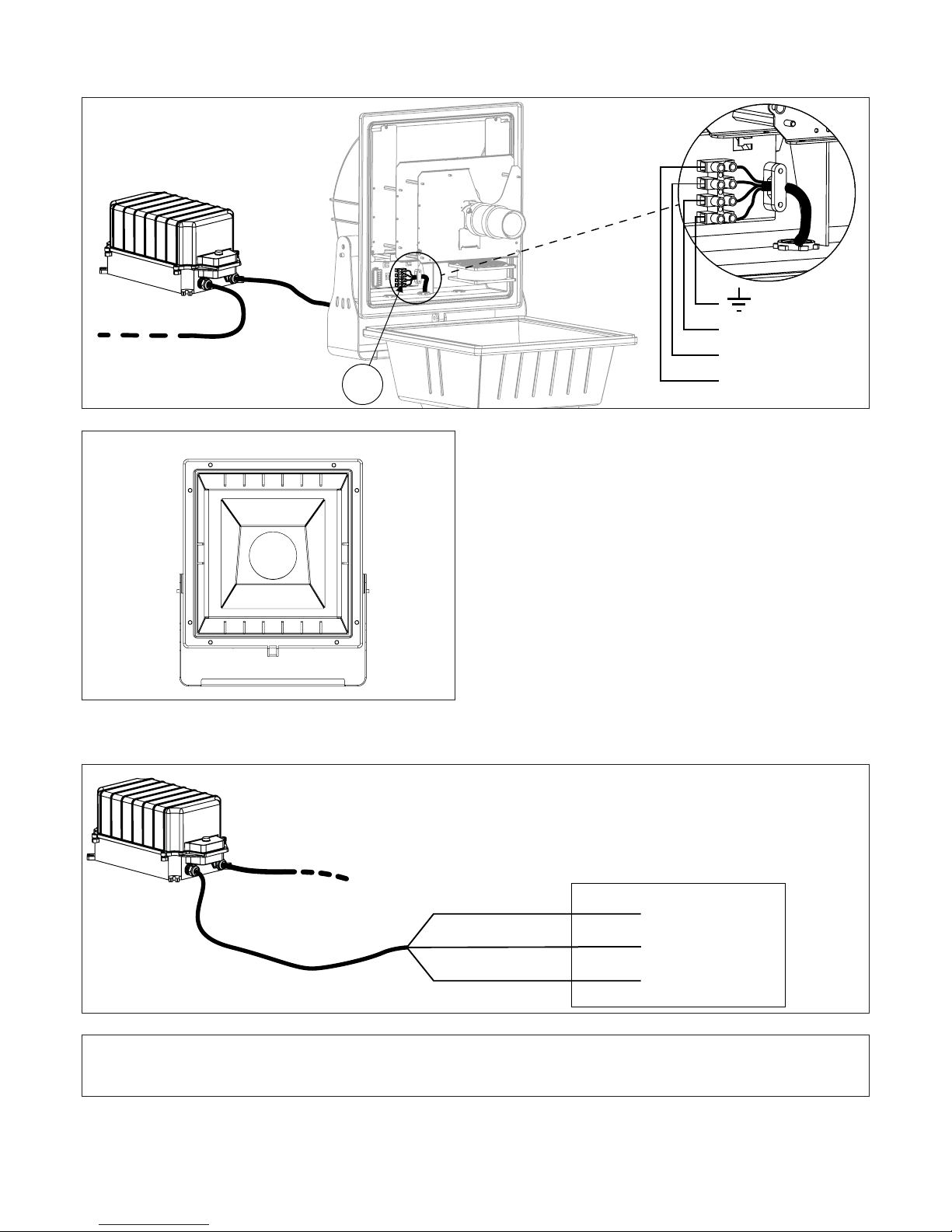

Connect the ballast by using the terminal “9”.

Close the projector following the numerical order shown in

the picture.

Power up the ballast.

9

Cable n° 3

Cable n° 2

Cable n° 1

Vac IN

1

2

3

4

5

67

8

Live

Ground

Neutral

Brown

Yellow Green

Blue

Main supply

Warning!

Follow the instructions provided along with the connection kit to perform the connections.

12 English

6.4 Connection to DMX signal

The DMX signal is to be connected by using a shielded cable designed for devices RS-485.

The unit is fitted with internal pins for the connection of the of the DMX signal cable, as shown in the following

pictures.

A. Untighten the screw “10” and remove the box cover.

B. Let the signal cables pass through the cable glands located

onto the unit body and connect the DMX signal

cables to the pin “11”.

The connection of the cable to the unit must be performed respecting the label next to the terminal box, while from the end

of the DMX controller the connection must respect the following table:

pin 1 = GND

pin 2 = data pin 3 = data +

Size and connection scheme of the DMX cable are shown in

the following picture.

10

11

Pin 1: GND

Pin 2: DATA-

Pin 3: DATA+

ø4 MIN

ø8 MAX

DMX cable size

Warning!

All data wires must be isolated one from another, from the shield and from the metal housing of the connectors.

Pin number 1 of the housing is not to be connected to the electric ground of the unit.

Insert a 120 Ω resistor connected to Data+ and Data- in the last unit.

English 13

C. Close the unit again by tighten the screw “10” previously re-

moved.

7.1 Lamp specifications

Gobostorm is designed to be used exclusively with Philips MSD 575 or MSR 575 lamp.

The lamps are part of the metal halide family of discharge lamps and must be handled with great care. The lamp

operates at high pressure, and the slight risk of explosion of the lamp exists if operated over its recommended life.

We recommend, therefore, that the lamp is replaced within the manufacturer’s specified lamp life.

The specification of the lamp, available via the Griven network of dealers and distributors, are shown in the table

below.

7.0 Lamp installation and replacement

Attention!

Installing any other lamp may create a safety hazard or damage the fixture!

Lamp PHILIPS MSD 575

Griven code LP0997

Rated lamp wattage 575W

Colour temperature 5700K ÷ 6000K

Luminous flux 46000 lm

Average service life 2000 h

CRI 75

Lamp PHILIPS MSR 575

Griven code LP0550

Rated lamp wattage 575W

Colour temperature 6990K ÷ 7200K

Luminous flux 49000 lm

Average service life 1000 h

CRI 70

10

14 English

7.2 Lamp installation

A. Untighten the screws “8” ed open the projector.

B. Place the lamp “11” transversally.

8

8

11

Attention!

Operate the units with the front panel par-

tially open for 30-40 minutes before clos-

ing them for permanent use.

This precaution will avoid the forming of

condensation in the projector.

Attention!

Disconnect the unit from mains supply before servicing it or performing any other action.

The lamp is very hot during operations! Wait at least for 20 minutes before changing.

English 15

Close the projector following the numerical order shown in

the picture.

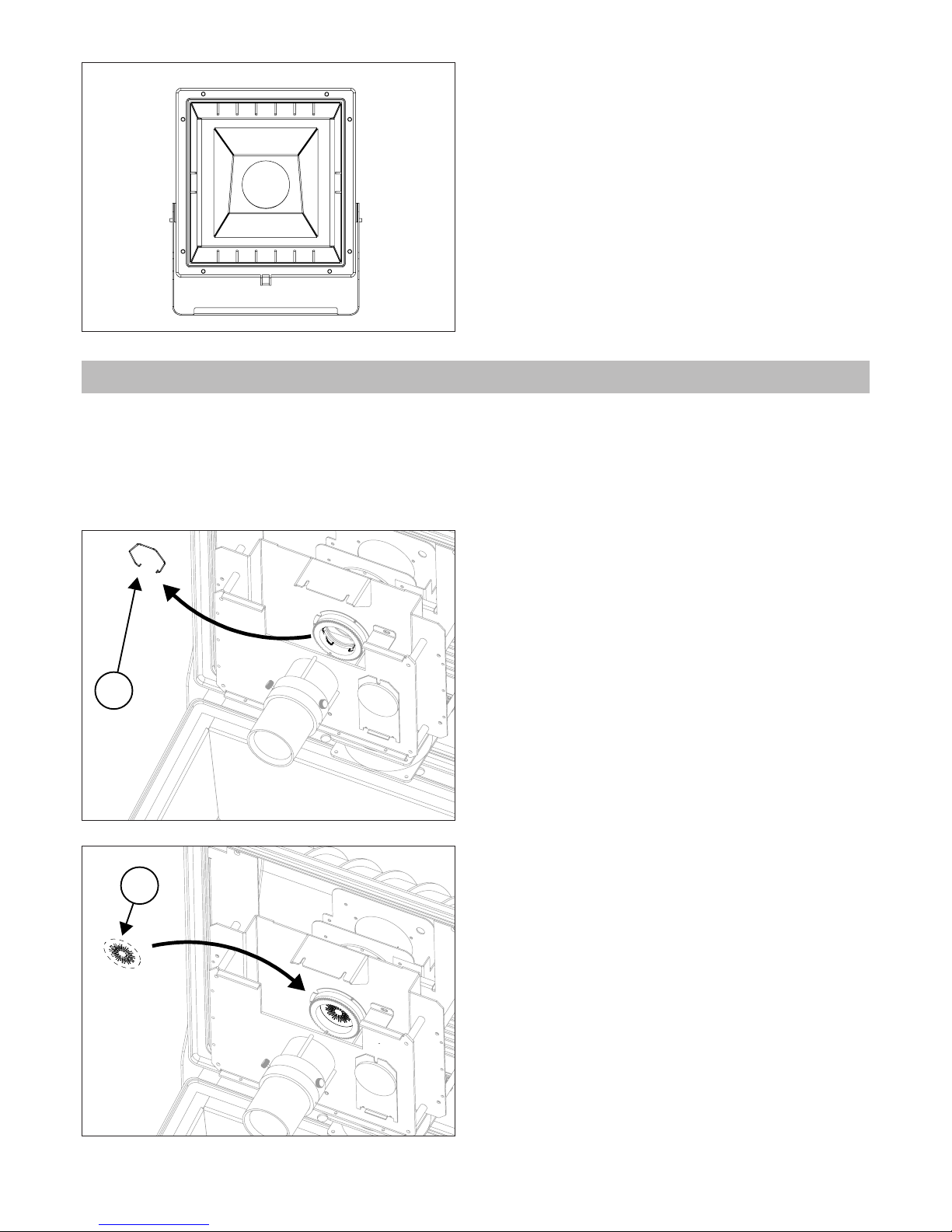

8.1 Replacing gobos

Gobostorm features a gobos wheel hosting up to 5 gobos (D Size: Ext 53,3 – Int 38).

A. Untighten the screws “8” ed open the projector.

B. Slide the metal plate “12” as shown by the arrow.

C. Remove the fixing ring “13” and proceed with the re-

placement of the gobo.

1

2

3

4

5

67

8

8.0 Replacing gobos and focus

12

13

16 English

C. Reinserire l’anello fermagobo “12” facendo in modo

che il gobo aderisca in modo uniforme al supporto.

8.2 Focus

The standard beam angle is 10°. By adjusting the objective it is possible to modify the focusing.

A. Loosen the knobs “14”.

B. Act on the objective “15” to reach the desired focus .

C. Tighten the Knobs “14”.

12

14

15

English 17

8.3 Mounting the optional 16° Angle lens

By installing the optional lens (provided along with the fixture), the projector will achieve a 16° beam angle.

A. Undo the screws “16”.

B. Remove the objective “17”.

C. Place the lens as shown in the picture and secure it

by using the screws previously removed.

D. Loosen the screws “18” and remove the spacer “19”.

E. Install the objective “20” in its seat and perform the focusing.

17

16

18

19

20

18 English

Close the projector following the numerical order shown in

the picture.

9.1 Setting operating mode

By the dip-switch set it is possible to select one of the following operating modes:

• using DMX512 signal control mode

Each fixture is controlled from DMX512 signal control.

• MASTER-SLAVE or AUTOMATIC mode

The projector operates independently, without DMX512 signal control.

9.2 Setting DMX address

To access to the dip-switch panel it is necessary untighten the

screw “21” and remove the box cover.

One led is next to the dip-switch panel to notify the status of the

unit.

In the presence of DMX signal, the red led “22” will be steady on,

while in the absence of the signal the red led will flash.

1

2

3

4

5

67

8

9.0 Use of the unit

21

22

English 19

Each unit will use 1 DMX channel.

The number of the DMX address is to be calculated by summing the values corresponding to the activated dipswitches, which are written in the upper side of the dip-switch set (1, 2, 4, 8, 16, etc.).

9.3 DMX functions

Gobostorm can operate without DMX signal (in AUTOMATIC mode) and can be set so that a single MASTER unit

will command a series of SLAVE units. This function is particularly useful when more units are desired to execute the

same programme in synchrony.

The following picture shows an example of a Master-Slave layout.

Example

Unit with address 005

(dip-switch n°1 and 3= ON)

123456789101112

1248163264

128

256

Master

Canale Funzione Valore Descrizione

1

Gobo

rotation

0-31 Stop

32-55 Clockwise rotation speed 1

56-79 Clockwise rotation speed 2

80-103 Clockwise rotation speed 3

104-127 Clockwise rotation speed 4

128-151 Clockwise rotation speed 1

152-175 Clockwise rotation speed 2

176-199 Clockwise rotation speed 3

200-223 Clockwise rotation speed 4

224-255 Stop

10.0 Master-Slave and Automatic function

MASTER SLAVE 1 SLAVE N

INOUTINOUT

SLAVE 2

INOUT

Terminal resistor

(R=120 ƺ not included!)

20 English

10.1 MASTER configuration

To execute a preset programme set the dip-switch Master to ON and choose the type of programme to be

executed.

The following pictures show some examples of MASTER units configuration.

The following table shows the output effect according to the programme.

10.2 SLAVE configuration

To set up the unit as SLAVE adjust all the dip-switches to OFF.

If the unit is properly set up as SLAVE and the signal is present, the red led next to the dip-switch panel will constantly remain on. The following picture shows an example of configuration of SLAVE units.

Unit set as Master (Master = ON)

program 1° SPEED DX (right) running

(dip-switch 1 = ON)

123456789101112

1° SPEED DX

2° SPEED DX

3° SPEED DX

4° SPEED DX

4° SPEED SX

3° SPEED SX

2° SPEED SX

1° SPEED SX

RANDOM

MASTER

Unit set as Master (Master = ON)

program 4° SPEED SX (left) running

(dip-switch 5 = ON)

123456789101112

1° SPEED DX

2° SPEED DX

3° SPEED DX

4° SPEED DX

4° SPEED SX

3° SPEED SX

2° SPEED SX

1° SPEED SX

RANDOM

MASTER

Attention!

If MASTER-SLAVE mode is being used, no other DMX control device must be present along the line!!

Dip-switch Effect

1 Clockwise rotation speed 1

2 Clockwise rotation speed 2

3 Clockwise rotation speed 3

4 Clockwise rotation speed 4

5 Counterclockwise rotation speed 4

6 Counterclockwise rotation speed 3

7 Counterclockwise rotation speed 2

8 Counterclockwise rotation speed 1

9 Random rotation

Warning!

Set the dip-switches 1-9 to OFF to stop the rotating movement.

Slave unit (Dip 1 = ON )

123456789101112

1248163264

128

256

MASTER

English 21

10.3 AUTOMATIC configuration

To set up the unit as AUTOMATIC the same instructions for the set up as MASTER must be followed (see paragraph

8.1 MASTER configuration). Adjust the dip-switch Master to ON and choose the programme to be executed.

To ensure maximum functionality and light output it is recommended to follow these instructions:

11.1 Cleaning the unit

The unit must be cleaned regularly. Cleaning regularity will depend especially on the environment where the unit

will operate: deposits of dust, smokes or other wastes will reduce the light output performances.

• Clean regularly the glass and the mirror of the unit.

• Be careful when cleaning the components. Operate in a clean, properly illuminated environment.

• Do not use solvents which could damage painted surfaces.

• Remove left particles by a cotton towel dampened with a glass-cleaning liquid or distilled water.

• Dry out by a clean, soft, non-scratching towel or by compressed air.

11.2 Regular checks

• Check electrical connections, especially the ground wiring and the power supply cable.

• Check that the unit is not damaged mechanically. Replace those components which have got deteriorated.

• Replace the lenses, the mirrors and the dichroic filters if they are visibly damaged.

• Replace any lamp that may present any damage or deformation.We recommend, therefore, that the lamp be

replaced within the manufacturer’s specified lamp life.

Replace any damaged shield.

11.0 Maintenance

Attention!

Always remove mains power prior to opening up the fixture.

All components of the unit are available as spare parts at Griven dealers.

Exploded views, wiring diagrams, electronic layouts and advertising brochures are available on request.

To make the job of assistance centres easier, specify serial number and model of the unit which spare parts are

requested for.

The European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE), requires that old

lighting fixtures must not be disposed of the normal unsorted municipal waste stream. Old appliances must be

collected separately in order to optimise the recovery and recycling of the materials they contain and reduce

the impact on human health and the environment.

The crossed out “wheeled bin” symbol on the product reminds you of your obligation, that when you

dispose of the appliance it the must be separately collected.

Consumer should contact their local authority or retailer for information concerning the correct

disposal of their old appliance.

12.0 Spare parts

13.0 Disposal

14.0 Troubleshooting

Inconvenience Possibile Cause Action

The fixture is completely dead

No power to fixture.

Check that power is switched on and cables are

plugged in.

The unit does not

respond properly

to the DMX control.

Incorrect DMX cable

connection.

Check connections and wires. Rectify inefficient

connections. Repair or replace damaged wires.

Unfinished data

connection.

Insert a terminal plug in the output jack of the last unit of

the connection.

Incorrect address

assignment to the units.

Check the addresses of the units and the protocol

settings.

One of the unit is faulty

and it is affecting the

data transmission along

the connection.

Short-circuit units singularly, one by one, since regular

working is restored.

No light output

Lamp blown Disconnect fixture and replace lamp.

Lamp not installed Disconnect fixture and install lamp.

Lamp cuts out

intermittently.

Fixture is too hot.

Let the fixture cool down.

Ensure that the ambient temperature is below 40 °C.

22 English

Projector mechanical features

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .598m (23.56”)

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .506mm (19.92”)

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .660mm (26“)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22Kg (48 Lbs)

Ballast mechanical features

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176mm (6.92”)

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213mm (8.39“)

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .368 (14.47”)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Kg (22 Lbs)

Thermal features

Maximum ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35°C (95°F)

Minimum ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C (-40°F)

Maximum surface temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100°C (176°F)

Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

Electrical features

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200-220Vac or 230-240Vac 50/60Hz

Nominal current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A @ 230V

Maximum power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 738W @ 230V

Light output source

Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .575W discharge lamp

Approved models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PHILIPS MSD/MSR 575 W

Optics

Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lenses

Control

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . USITT DMX-512

Control channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 channel

Construction

Unit body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Iron/Aluminium

Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Scratch resistant black paint

Weather protection rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP65

15.0 Technical specifications

English 23

Via Bulgaria, 16 - 46042 CASTEL GOFFREDO (MN) - Italy

Telefono 0376/779483 - Fax 0376/779682 - 0376/779552

http://www.griven.com/ e-mail griven@griven.com

http://www.griven.it/ e-mail griven@griven.it

User’s manual rel. 2.00EN

Loading...

Loading...