Grip Rite GRTSN150a, GRTSN100 Operator's Manual

1

OPERATOR’SMANUAL

AND PARTS LIST

MODEL GRTSN150a STAPLER

MODEL GRTSN100 STAPLER

32IMPORTANT SAFETY INFORMATION

Youmust readthisentiremanualandfamiliarizeyourselfwithall

safety,operating, andserviceinstructionsbefore loading,handling,

orusingyour tool. Whenusedcorrectly, pneumatic fastening

toolsprovide a lightweight,powerful,and safemeansof fastening.

Usedimproperly,these tools can cause serious injury to youand

thosearoundyou.

TABLE OF CONTENTS

TABLE OF CONTENTS

-------------------------------

3

GRTSN100 SPECIFICATIONS

----------------------

4

GRTSN100 Fastener Selection Chart

--------

4

GRTSN150a SPECIFICATIONS

---------------------

5

GRTSN150a Fastener Selection Chart

------5SAFETY

----------------------------------------------------

6

TOOL PARTS

------------------------------------------

10

PART DESCRIPTIONS

------------------------------

11

GRTSN150a OPERATION

--------------------------

12

Loading Staples

----------------------------------

12

Adjusting Staple Drive

--------------------------

13

Clearing Staple Jams

---------------------------

13

GRTSN100 OPERATION

----------------------------

14

Loading Staples

----------------------------------

14

Adjusting Staple Drive

--------------------------

15

Clearing Staple Jams

---------------------------

15

TOOL OPERATION

-----------------------------------

16

MAINTENANCE

---------------------------------------

17

Lubrication

-----------------------------------------

17

Cleaning

--------------------------------------------

17

Trigger Check

-------------------------------------

17

GRTSN150a PARTS SCHEMATIC

---------------

18

GRTSN150a PARTS LIST

--------------------------

19

GRTSN100 PARTS SCHEMATIC

-----------------

20

GRTSN100 PARTS LIST

----------------------------

21

TROUBLESHOOTING

-------------------------------

22

TOOL CHECKS

----------------------------------------

23

WARRANTY

--------------------------------------------

24

NOTES

---------------------------------------------------

26

5

4

GRTSN150a SPECIFICATIONS

GRTSN150a SPECIFICATIONS

MODEL

GRTSN150a

FASTENERRANGE

3/4” - 1 1/2 ” (19 mm - 38 mm)

FASTENERTYPE

18 Ga. Staples

CROWNSIZE

1/4” (6.4 mm) Narrow Crown

MAGAZINE CAPACITY

140STAPLES

MAX AIR PRESSURE

110 psi (7.6 bar)

MINAIR PRESSURE

70 psi (4.8 bar)

TOOL WEIGHT

2.8 lbs. (1.3 kg)

TOOL LENGTH

11.25” (28 cm)

TOOLHEIGHT

10.15” (26 cm)

TOOL WIDTH

2.25” (5.7 cm)

STANDARDTRIGGER

Sequential

ACCESSORYTRIGGER

Dual Action (Bump/Trigger Fire)

AIR INLET

1/4NPT

AIRCONNECTION

Male Quick Connect Coupler

LUBRICATION

10W Air Tool Oil (Provided)

NOISE CHARACTERISTIC VALUES IN ACCORDANCE WITH ISO 3774,ISO 11201:

A-weighted single-event sound

pressure level at operator’s position

----------------------------------

LpA, 1s = 89 dBA

A-weighted single-event sound power level

-----------------------

LwA, 1s = 100 dBA

A-weighted single-event surface sound

pressure level

----------------------------------------------------------------

LpA, 1s = 87 dBA

VIBRATION CHARACTERISTIC VALUES IN ACCORDANCE WITH ISO 8862-1

Weighted root mean square acceleration

----------------------------

= 1.9 m/s

2

For best results, use Grip-Rite™ collated fasteners.

LEG

BOX

CROWN

WIRE

GALVANIZED

LENGTH

QTY.

SIZE

GA.

STEELSKU

3/4” (19 mm)

5M

1/418GRL11

7/8” (22 mm)

5M

1/418GRL12

1” (25 mm)

5M

1/418GRL13

1-1/8” (29 mm)

5M

1/418GRL14

1-1/4” (32 mm)

5M

1/418GRL15

1-1/2” (38 mm)

5M

1/418GRL17

FASTENER SELECTION CHART

GRTSN100 SPECIFICATIONS

GRTSN100 SPECIFICATIONS

MODEL

GRTSN100

FASTENERRANGE

1/2” - 1 ” (13 mm - 25 mm)

FASTENERTYPE

18 Ga. Staples

CROWNSIZE

1/4” (6.4 mm) Narrow Crown

MAGAZINE CAPACITY

110 STAPLES

MAX AIR PRESSURE

110 psi (7.6 bar)

MINAIR PRESSURE

70 psi (4.8 bar)

TOOL WEIGHT

2.7 lbs. (1.2 kg)

TOOL LENGTH

9.75” (24.8 cm)

TOOLHEIGHT

8.6” (21.8 cm)

TOOL WIDTH

2.25” (5.7 cm)

STANDARDTRIGGER

Sequential

ACCESSORYTRIGGER

Dual Action (Bump/Trigger Fire)

AIR INLET

1/4NPT

AIRCONNECTION

Male Quick Connect Coupler

LUBRICATION

10W Air Tool Oil (Provided)

NOISE CHARACTERISTIC VALUES IN ACCORDANCE WITH ISO 3774,ISO 11201:

A-weighted single-event sound

pressure level at operator’s position

----------------------------------

LpA, 1s = 89 dBA

A-weighted single-event sound power level

-----------------------

LwA, 1s = 100 dBA

A-weighted single-event surface sound

pressure level

----------------------------------------------------------------

LpA, 1s = 87 dBA

VIBRATION CHARACTERISTIC VALUES IN ACCORDANCE WITH ISO 8862-1

Weighted root mean square acceleration

----------------------------

= 1.9 m/s

2

For best results, use Grip-Rite™ collated fasteners.

LEG

BOX

CROWN

WIRE

GALVANIZED

LENGTH

QTY.

SIZE

GA.

STEELSKU

1/2” (13 mm)

5M

1/418GRL08

5/8” (16 mm)

5M

1/418GRL10

3/4” (19 mm)

5M

1/418GRL11

7/8” (22 mm)

5M

1/418GRL12

1” (25 mm)

5M

1/418GRL13

FASTENER SELECTION CHART

7

6

SAFETY

SAFETY

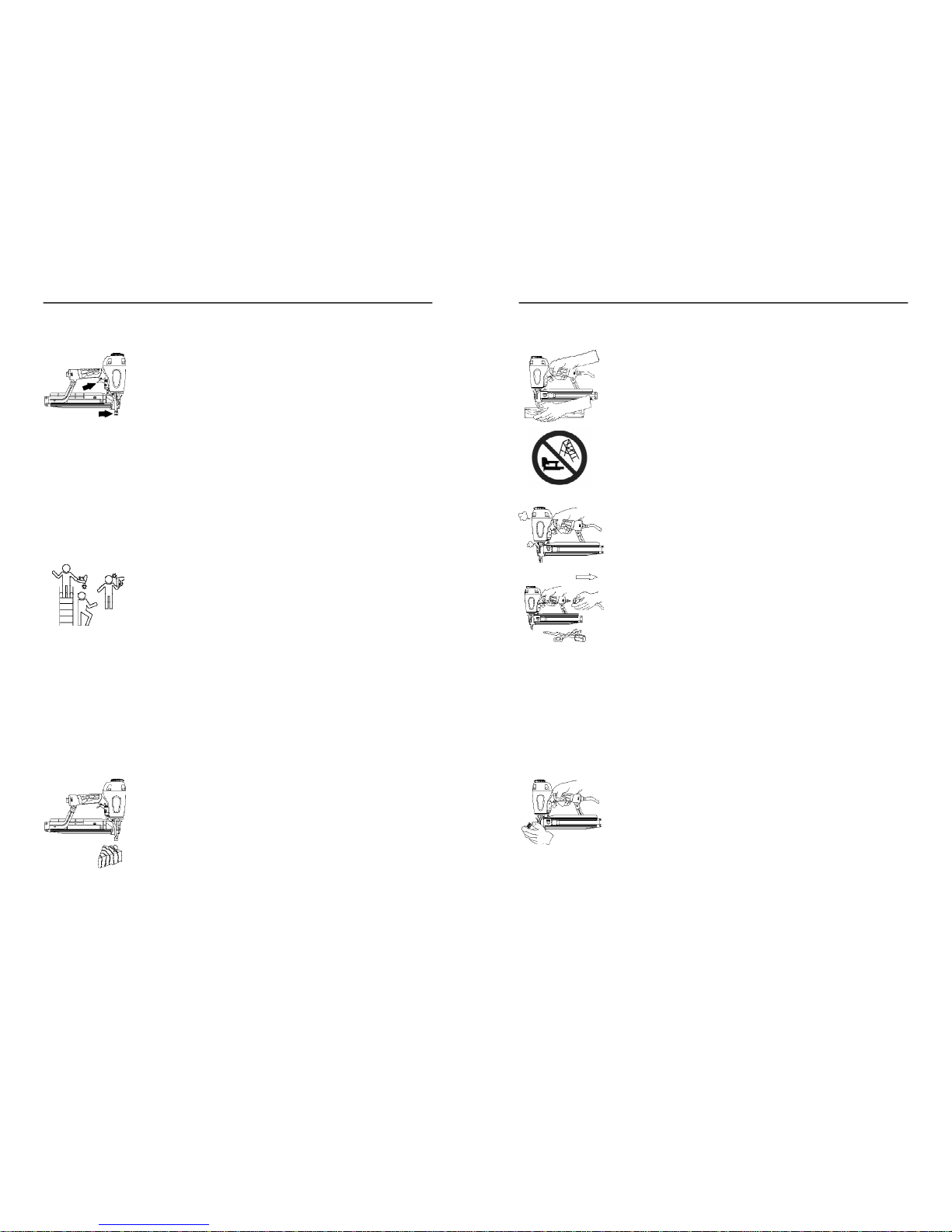

SAFETY LABELS

This pneumatic fastening tool includes a warning label to help remind you of

important safety information when operating the tool. The safety label must be

legible at all times, and must be replaced if it becomes worn or damaged.

SYMBOL

DESCRIPTION

READTHE MANUAL

-Themanualcontains

importantsafetyand operatinginstructions

that must befollowed. All tool users must

readthe manualbefore usingthetool.

WEARSAFETYGLASSES

-Tooloperator

and bystandersmust wear safety glasses

withsideshield thatmeetANSI Z87.1

requirements.

RISKOF PERSONALINJURY

-Failureto

followall safety and operatinginstructions,

or misuse of the tool, can result inserious

injuryto tool operator and bystanders.

WEARSAFETYGLASSES

Always wear safety glasses with side shields that meet ANSI

Z87.1 requirements when operating the tool. Make sure all

others in work area wear safety glasses.

WEARHEARINGPROTECTION

Wear hearing protection to protect your hearing from noise.

Prolonged exposure to loud noise can result in hearing loss.

NEVEROPERATETHETOOLWITHOXYGENOR OTHER

BOTTLEDGASES

Oxygen and other reactive or high-pressure bottled gases

can cause the tool to explode. Use clean, dry regulated

compressed air from a properly operating air compressor.

DONOTEXCEEDMAXIMUMRECOMMENDEDOPERATINGAIR

PRESSURE OF110 PSI/7.6 Bar.

Exceeding the maximum recommended air pressure can

cause the tool housing to burst, or cause premature failure of

components.

NEVERCONNECTTHE TOOLTO AN AIRSUPPLYTHATHAS

THEPOTENTIALTO EXCEED180 PSI/12.4Bar.

Using a regulated air supply with a line or tank pressure

greater than 180 psi can cause the tool to burst if the air line

regulator fails suddenly.

USEAN AIRHOSE RATED FOR 180 PSI/12.4Bar OR

GREATER

Always use air hose rated to handle 180 psi or the maximum

potential pressure of the air supply.

ONLYUSEARELIEVING-TYPEAIRCOUPLINGINTHE TOOL

AIRINLETOPENING.

Use of a non-relieving air coupling on the tool can trap air

inside the tool housing, and allow the tool to drive a fastener

even after the air hose has been disconnected.

SAFETY INSTRUCTIONS

110psi

4.8bar

70psi

7.6bar

SAFETY SYMBOLS

These safety symbols provide a visual reminder of basic safety

rules, and the personal injury hazard that may arise if all safety and

operating instructions are not followed. Make sure you understand

the meaning of each of these symbols, and protect yourself and

others by obeying all safety and operating instructions.

9

8

SAFETY

SAFETY

DONOTATTEMPTTO OPERATETHETOOLIFTHE TOOL’S

OPERATINGCONTROLSHAVEBEENMODIFIEDORARENOT

WORKINGPROPERLY.

Attempting to use a tool with modified or malfunctioning

trigger or workpiece contact can result in a fastener being

driven unintentionally.

USECORRECTFASTENERS

Only use the correct fastener for the tool. Using fasteners

with incorrect specifications can jam the tool or cause

serious injuries.

USETHECORRECTFASTENERSFORTHEAPPLICATION.

Using the wrong fasteners can cause the workpiece to split

and allow the fastener to fly free.

KEEPTOOL POINTEDINA SAFEDIRECTIONWHENLOADING

FASTENERS.

Never point the tool at yourself or anyone else when loading

fasteners.

DONOTLOAD TOOLWITHTRIGGERORWORKPIECE

CONTACTDEPRESSED.

Depressing the trigger or workpiece contact during loading

can result in an unintentional fastener drive if both devices

are accidentally actuated at the same time.

KEEPFINGEROFFTRIGGERUNTILTOOLIS INPOSITIONTO

DRIVEAFASTENER.

An unexpected bump or sudden contact with your body or that

of a bystander can result in serious injuries.

AVOIDDRIVINGFASTENERSINTOKNOTS,ONTOPOF

OTHERFASTENERS,ATWORKPIECEEDGES,ORINTO

BRITTLEMATERIALS.

Driving fasteners into extremely hard materials, or driving into

workpiece edges, can cause fasteners to deflect away from

the workpiece. Flying fasteners can cause serious injuries.

SAFETY INSTRUCTIONS

KEEPHANDSANDBODYPARTSAWAYFROMAREABEING

FASTENED.

Fasteners can deflect and turn as they are being driven into

the workpiece, and penetrate fingers, hands, and other body

parts that may be in the fastening area.

DONOTOVERREACHORWORKWHILEON UNSTABLE

FOOTING

If you lose your balance while fastening, you could drive a

fastener into yourself or a bystander.

DONOTUSETOOLIFTOOL MALFUNCTIONSORBEGINS

LEAKINGAIR.

Operating a malfunctioning tool can result in an unexpected

fastener discharge and injury to yourself or others.

DISCONNECTTHETOOLFROMTHEAIRSUPPLYTORE-

LOAD,CLEARJAMS,ORPERFORMMAINTENANCE.

Never attempt to reload a tool, clear a jam, or perform

maintenance without first disconnecting the air supply.

NEVERLEAVEALOADED,PRESSURIZEDTOOL

UNATTENDED

A loaded, pressurized tool could be picked up or handled by

someone who is unfamiliar with the tool or that has not read

the tool manual.

KEEPTOOLSOUTOFTHEREACHOFCHILDREN

Place the tool back in the tool box after use, and store the tool

out of reach.

DONOTMODIFYTOOL

Modifications can cause a tool to be unsafe and can cause

the tool to operate improperly.

SAFETY INSTRUCTIONS

Loading...

Loading...