Grip-rite GR90G10X, GR55G10X User Manual

OPERATING MANUAL AND PARTS

LIST

MODEL GR55G10X/GR90G10X

COMPRESSORS

www.grip-rite.com

TABLE OF CONTENTS

Table of Contents..........................................................................1

Safety Symbols .............................................................................2

Safety Instructions........................................................................3

Specifications................................................................................5

Compressor Description ..............................................................6

Compressor Parts Description.....................................................7

Set Up.............................................................................................8

Operation.......................................................................................9

Maintenance ................................................................................ 10

GR55G10X Compressor Schematics and Parts Lists .............. 12

GR90G10X Compressor Schematics and Parts Lists .............. 17

Troubleshooting.......................................................................... 22

Storage......................................................................................... 25

Warranty.......................................................................................26

WARNING

This manual contains important safety and operating instructions that must be followed.

You must read and understand this manual before operating this compressor. Failure

to follow all instructions can result in serious injury to operator and bystanders, or

damage to compressor and attachments.

1

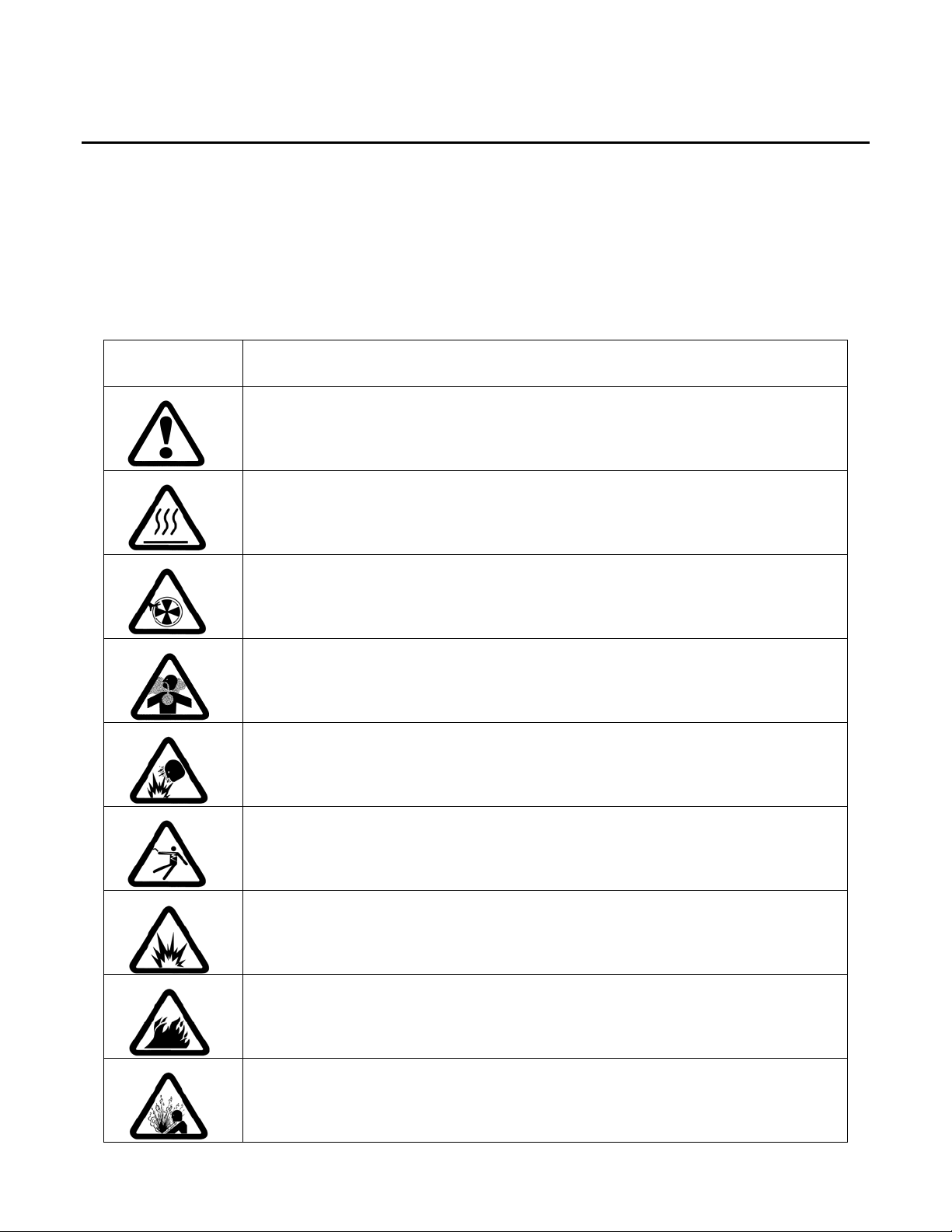

SAFETY SYMBOLS

The safety symbols used on the compressor’s safety labels and in this manual provide an

important visual reminder of basic safety rules, and the hazards that may arise if all safety and

operating instructions are not followed. Make sure you understand the meaning of each of

these symbols, and protect yourself and others by obeying all safety and operating instructions

on warning labels and in this manual.

SYMBOL DESCRIPTION

SAFETY ALERT SYMBOL

Calls attention to important safety information and provides an alert to

potential safety hazards.

HOT SURFACE HAZARD

Hot surfaces can cause serious burn injury if touched. Let unit cool before

handling.

MOVING PARTS/ENTANGLEMENT HAZARD

Contact with moving parts can cause serious injury. Keep guards and

protective covers in place.

INHALATION HAZARD

Compressed air can contain carbon monoxide or other harmful gases. Do

not use compressor to provide air for breathing.

BURST HAZARD

Over-pressurization caused by tampering with controls can cause serious

injury or death from explosion.

SHOCK HAZARD

Contact with live electrical components can cause shock, serious injury, or

death from electrocution. Use a properly grounded power source.

EXPLOSION HAZARD

Electrical sparks from unit can ignite flammable liquids and vapors. Use

compressor in a well ventilated area free from explosive vapors.

FIRE HAZARD

Keep compressor 20’ feet away from spray area when spraying flammable

materials. Operate unit away from obstructions that could block ventilation.

HIGH PRESSURE AIR HAZARD

Release of pressurized air can cause serious injury if directed against body.

Never use air pressure higher than recommended for tool or accessory.

2

SAFETY INSTRUCTIONS

WEAR ANSI Z87.1 (In Canada, CSA Z94.3-99) APPROVED EYE PROTECTION - Always

wear approved eye protection equipment that provides both front and side eye protection when

operating or servicing the compressor.

DO NOT START OR OPERATE COMPRESSOR INDOORS OR IN POORLY VENTILATED

AREAS - Gasoline engine produce carbon monoxide, a poisonous gas that can cause death

or serious injury if inhaled. Use compressor outdoors only.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING PRESSURE OF

AIR-POWERED TOOLS OR OTHER EQUIPMENT BEING USED - Spray guns and other low

to medium pressure equipment can burst, causing serious injury to user and bystanders.

Read and follow all manufacturers' pressure recommendations before connecting tools,

sprayers, or other equipment to compressor. Use extreme care when using the compressor

with tires, inner tubes, and other inflatables, as excessive pressure or rapid inflation can cause

these items to burst.

DO NOT OPERATE IF FLAMMABLE VAPORS ARE PRESENT - The electric motor and

pressure switch may produce sparks, which can ignite flammable vapors and cause fire or

explosion. Flammable vapors from gasoline, solvents, adhesives, and other chemicals may

drift some distance from the source, or build up in low areas. Operate the compressor only in

well-ventilated areas that are free of flammable vapors.

DO NOT TOUCH COMPRESSOR MOTOR, HEAD, OR TUBING WHEN UNIT IS

OPERATING - Normal compressor operation will cause tubing and other components to

become extremely hot. Contact with hot parts can cause serious burns. Allow unit to cool

before handling or performing service.

NEVER DIRECT COMPRESSED AIR AT ANY BODY PARTS - Compressed air can penetrate

skin, or force dirt and debris into eyes, causing serious injury. Never place hands or body

parts over the air discharge opening of a pressurized nozzle or fitting. Use care when

connecting and disconnecting air hose to attachments, pneumatic tools, and other air-powered

devices.

KEEP FLAMMABLE SPRAYS AWAY FROM SPARKS AND OTHER SOURCES OF

IGNITION - Spraying flammable liquids such as oil-base paints, sealers, and finishes near

sparks, open flame, and other sources of ignition such as pilot lights, appliances, water heaters,

furnaces, etc. can result in explosion and fire. Turn off all pilot lights, and avoid using

electrical appliances, heaters, torches, and other equipment that may produce sparks or flame.

Keep compressor as far away from spraying area as possible by using an air hose of sufficient

length to prevent spray mist from being ignited by electrical sparks from compressor operation.

3

SAFETY INSTRUCTIONS

DO NOT TAMPER WITH COMPRESSOR PRESSURE SWITCH SETTINGS - The pressure

switch settings set at the factory provide the maximum safe operating pressure recommended

for this compressor. Altering these settings can result in over-pressurization, risk of tank,

hose, and pneumatic equipment failure, and serious injury to operator and bystanders.

USE AIR HOSE RATED FOR 150 PSI OR GREATER - Air hose must be rated to safely

handle maximum compressor pressure. Air hose that does not meet minimum pressure

requirements can rupture, releasing high pressure air. Replace a cracked or leaking air hose

immediately to prevent serious injury from contact with high pressure air streams.

SHUT OFF COMPRESSOR AND RELIEVE TANK PRESSURE BEFORE SERVICING UNIT –

Never perform service or maintenance on any part of the compressor while the unit is running

or tanks are pressurized. Open tank drains slowly to allow air to escape, and keep clear of air

stream.

DO NOT MODIFY COMPRESSOR – Altering the compressor in any way may create a serious

safety hazard, and result in serious injury to operator and bystanders. If compressor does not

work properly, stop using unit immediately. Return unit to an authorized service center for

repairs if problem cannot be remedied by following troubleshooting instructions in this manual.

DO NOT USE COMPRESSED AIR FROM THE UNIT FOR BREATHING PURPOSES - Air

produced by this compressor may contain poisonous exhaust gases from the engine, and is

not suitable for breathing purposes.

DO NOT REFUEL A HOT OR RUNNING ENGINE - Fuel vapor can be ignited by hot surfaces,

causing fire, explosion, and serious injury to operator and bystanders.

REFILL FUEL TANK OUTDOORS ONLY - Fuel vapor can be ignited by pilot lights, electronic

igniters, electric motors, and other sources of heat, sparks, or open flame. Move compressor

away from refueling area before starting to avoid fire risk from fuel spills or vapor.

DO NOT LEAV E COMPRESSOR RUNNING UNATTENDED - Shut compressor off when done,

and disconnect air hoses to prevent unauthorized use of compressor. Drain air tanks if unit is

to be stored or transported.

NEVER USE A COMPRESSOR WITH A FUEL LEAK - Leaking fuel can be ignited by hot

surfaces on the unit, resulting in fire, explosion, and serious injury to operator and bystanders.

Stop using a unit with a fuel leak immediately, and shut engine off. Allow unit to cool before

handling or moving. All fuel leaks are potentially serious and must be handled with extreme

caution.

4

SPECIFICATIONS

DESCRIPTION SPECIFICATIONS

Horsepower 5.5 9.0

Engine Honda GX160 Honda GX270

Capacity

Tanks 2 2

Air Storage Capacity 10 Gallons 10 Gallons

Maximum Air Pressure 135 PSI 135 PSI

CFM 12.5 cfm @ 100 PSI 18.5 cfm @ 100 PSI

Pressure Switch Settings

Pressure Switch - ON 105 PSI 105 PSI

Pressure Switch - OFF 135 PSI 135 PSI

Compressor Pump

Cylinders 2 3

Compression Stage Single Single

Motor GR55G10X GR90G10X

Lubrication Splash Splash

Oil Type Mineral Oil* Mineral Oil*

*Non-Detergent SAE 10W - 30W SAE 10W - 30W

ISO 32 - 100 ISO 32 - 100

Crankcase Cast Iron Cast Iron

Bearings Ball Ball

Cylinders Cast Iron Cast Iron

Valves Stainless Steel Stainless Steel

Head Aluminum Aluminum

Filter Canister Canister

Dimensions

Weight 170 Lbs. 220 Lbs.

Shipping Weight (198) Lbs. (246) Lbs.

Size ( L X W X H) 46" X 19" X 24" 46" X 19" X 24"

5

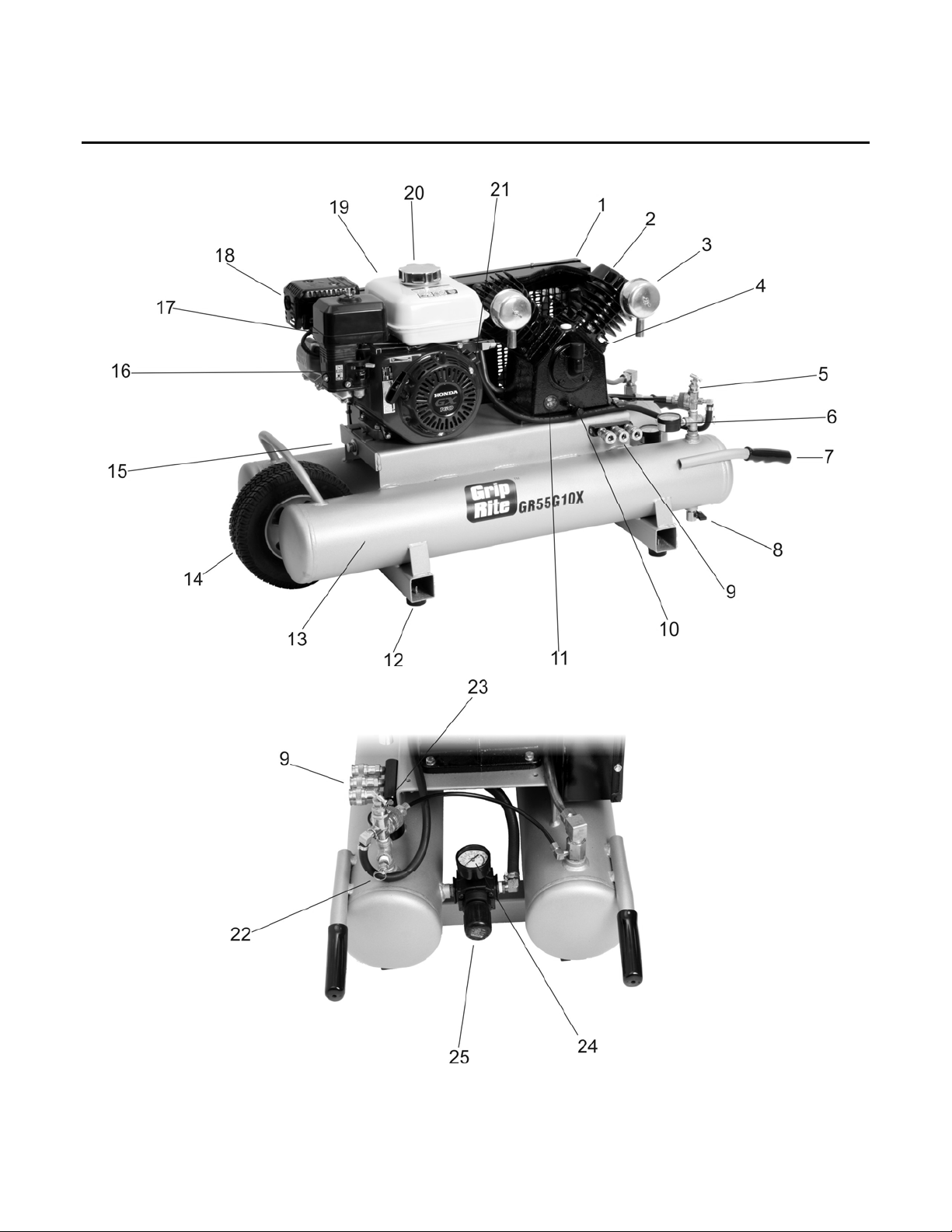

COMPRESSOR DESCRIPTION

6

COMPRESSOR PARTS DESCRIPTION

KEY DESCRIPTION FUNCTION

1 Belt Guard Guards V-belt and pulleys

2 Compressor Pump Compresses air

3 Compressor Air Intake Contains air filter element

4 Crankcase breather/fill plug Used to vent/fill pump crankcase

5 Pilot Valve Controls engine throttle

6 Tank Air Pressure Gauge Indicates air pressure in storage tanks

7 Rubber Hand Grips Provides secure grip for comfortable handling

8 Tank Drain Cock Allows tanks to be drained of moisture

9 Quick Connect Fittings Allows quick connection of air hoses

10 Pump Oil Drain Tube Drains oil for easy oil changes

11 Oil Level Sight Glass Indicates oil level in pump crankcase

12 Cushioned Rubber Foot Provides stable footing, reduces vibration

13 Twin Air Storage Tank s Stores compressed air

14 No Flat Tire Large semi-pneumatic tire allows easy rolling

15 Easy Belt Tightening System Allows for easy belt tension adjustment

16 Engine Fuel/Choke Controls Opens fuel line and sets choke for quick starts

17 Engine Air Filter Keeps dirt and debris out of engine

18 Engine Exhaust Muffler Reduces engine noise

19 Engine Fuel Tank Stores fuel for long run times

20 Fuel Tank Cap Seals fuel tank filler opening

21 Engine On-Off Switch Use to start or stop engine

22 Pressure Relief Valve Releases excessive air pressure from tank

23 Pilot Valve Manual Release Opens valve to release air pressure

24 Air Outlet Pressure Gauge Indicates air pressure at air outlet fittings

25 Regulator Control Knob Adjusts output air pressure setting

7

SET UP PROCEDURE

WARNING:

Before being operated with pressurized tanks for the first time, your new compressor requires

a simple set-up procedure that will help your unit deliver years of trouble-free service. Failure

to follow all initial set-up instructions may result in serious damage to your compressor,

property damage, or serious injury to operator and bystanders. Do not allow compressor to

pressurize tanks until all set-up steps have been performed.

1. Read the entire engine manual.

2. Check compressor and engine oil levels, and

fill as needed. (See #10 below)

3. Fill the fuel tank carefully, observing all safety

rules for handling gasoline. Don’t overfill leave 1/2” at filler opening for expansion.

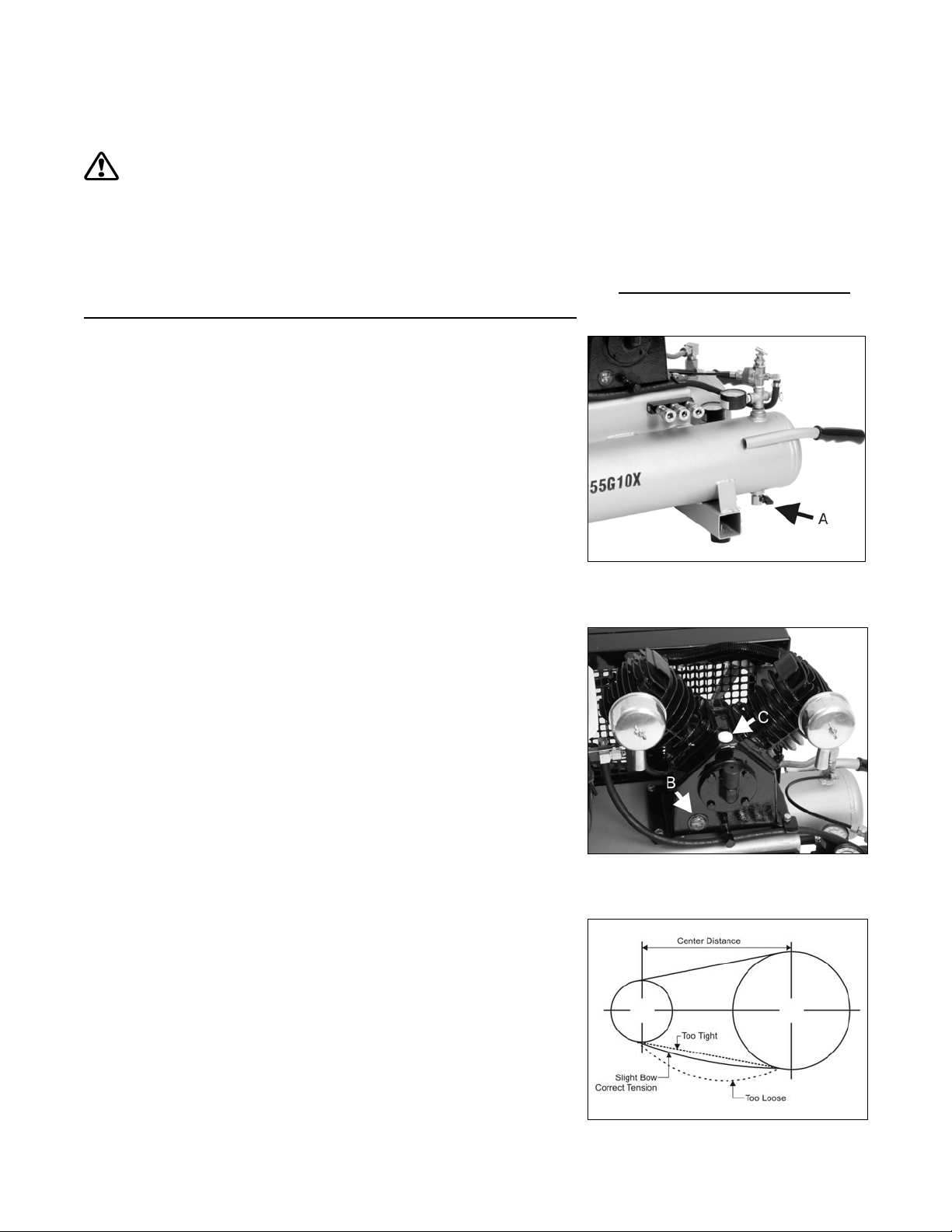

4. Open the tank drain cock (A), or outlet valve.

5. Start the engine (see page 9), and run the

compressor for 20 minutes with drain cock

open to lubricate the bearings and pistons.

6. After 20 minutes, close the drain valve or outlet

valve.

7. Compressor is now ready for normal,

pressurized operation.

8. After first 24 hours of operation, check V-belt

tension. Correct tension setting is 1/2” of

slack when measured at midpoint between

pulleys.

9. Check bolts and nuts periodically and tighten

when necessary.

10. Check oil level at sight glass (B). Oil level must

be maintained between “L” (Low) and “H” (High)

indicator lines. To add oil, remove oil filler

plug (C) and fill until sight glass shows proper

level. Change oil after first 100 hours of

operation. Add non-detergent mineral oil to

compressor.

11. Use chart below for correct viscosity:

Air Temperature Viscosity

34 – 79° F (1 - 26° C) SAE 20W (ISO 68)

80° F & Up (27° C & Up) SAE 30W (ISO 100)

3 – 32° F (16 - 0° C) SAE 10W (ISO 32)

12. Replace oil filler plug before starting

compressor.

8

Loading...

Loading...