Grip rite GR2540LR, GR2540 User Manual

OPERATING MANUAL AND PARTS LIST

GR2540 & GR2540LR

COMPRESSOR’S

TABLE OF CONTENTS

Table of Contents..........................................................................1

Safety Symbols .............................................................................2

Safety Instructions........................................................................3

GR2540 Specifications..................................................................5

GR2540LR Specifications............................................................. 6

Compressor Description ..............................................................7

Compressor Parts Description.....................................................8

Set Up........................................................................................... 10

Operation..................................................................................... 12

Maintenance ................................................................................ 13

GR2540 Schematic...................................................................... 14

GR2540 Parts List - Pump .....................................................15-16

GR2540LR Schematic.................................................................17

GR2540LR Parts List - Pump.................................................18-19

Troubleshooting.......................................................................... 20

Storage......................................................................................... 22

Warranty.......................................................................................23

WARNING

This manual contains important safety and operating instructions that must be followed.

You must read and understand this manual before operating this compressor. Failure

to follow all instructions can result in serious injury to operator and bystanders, or

damage to compressor and attachments.

1

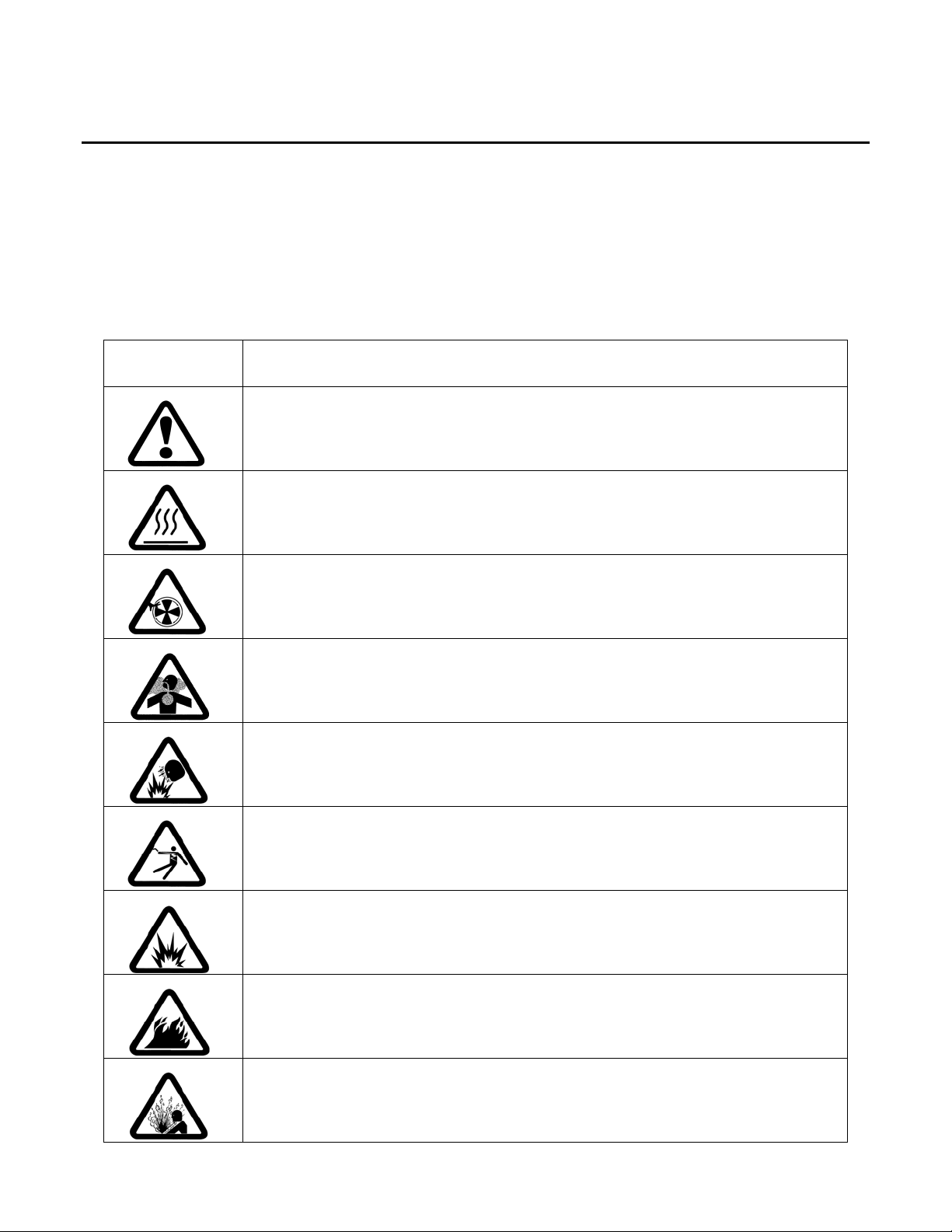

SAFETY SYMBOLS

The safety symbols used on the compressor’s safety labels and in this manual provide an

important visual reminder of basic safety rules, and the hazards that may arise if all safety and

operating instructions are not followed. Make sure you understand the meaning of each of

these symbols, and protect yourself and others by obeying all safety and operating instructions

on warning labels and in this manual.

SYMBOL DESCRIPTION

SAFETY ALERT SYMBOL

Calls attention to important safety information and provides an alert to

potential safety hazards.

HOT SURFACE HAZARD

Hot surfaces can cause serious burn injury if touched. Let unit cool before

handling.

MOVING PARTS/ENTANGLEMENT HAZARD

Contact with moving parts can cause serious injury. Keep guards and

protective covers in place.

INHALATION HAZARD

Compressed air can contain carbon monoxide or other harmful gases. Do

not use compressor to provide air for breathing.

BURST HAZARD

Over-pressurization caused by tampering with controls can cause serious

injury or death from explosion.

SHOCK HAZARD

Contact with live electrical components can cause shock, serious injury, or

death from electrocution. Use a properly grounded power source.

EXPLOSION HAZARD

Electrical sparks from unit can ignite flammable liquids and vapors. Use

compressor in a well ventilated area free from explosive vapors.

FIRE HAZARD

Keep compressor 20’ feet away from spray area when spraying flammable

materials. Operate unit away from obstructions that could block ventilation.

HIGH PRESSURE AIR HAZARD

Release of pressurized air can cause serious injury if directed against body.

Never use air pressure higher than recommended for tool or accessory.

2

SAFETY INSTRUCTIONS

WEAR ANSI Z87.1 APPROVED EYE PROTECTION - Always wear approved eye protection equipment that

provides both front and side eye protection when operating or servicing the compressor.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING PRESSURE OF AIR-POWERED TOOLS OR

OTHER EQUIPMENT BEING USED - Spray guns and other low to medium pressure equipment can burst,

causing serious injury to user and bystanders. Read and follow all manufacturers' pressure recommendations

before connecting tools, sprayers, or other equipment to compressor. Use extreme care when using the

compressor with tires, inner tubes, and other inflatables, as excessive pressure or rapid inflation can cause these

items to burst.

CONNECT COMPRESSOR POWER CORD ONLY TO A PROPERLY GROUNDED POWER OUTLET USING

AN APPROVED 3-PRONG GROUNDED EXTENSION CORD - Using an improperly grounded outlet or extension

cord can result in shock or electrocution. Electrical wiring, outlets, extension cords, and current protection

devices such as fuses and circuit breakers must meet local electrical and safety codes, as well the requirements

of the National Electrical Code. A ground-fault circuit interrupter (GFCI) device may be required for compressor

use outdoors, in garages, and in damp locations.

USE AN EXTENSION CORD THAT IS PROPERLY SIZED - Using an undersize cord can result in overheating of

cord and short-circuiting, resulting in fire and damage to property. Use a UL-listed extension cord rated to safely

handle the power requirements of the compressor .

DO NOT OPERATE IF FLAMMABLE VAPORS ARE PRESENT - The electric motor and pressure switch may

produce sparks, which can ignite flammable vapors and cause fire or explosion. Flammable vapors from

gasoline, solvents, adhesives, and other chemicals may drift some distance from the source, or build up in low

areas. Operate the compressor only in well-ventilated areas that are free of flammable vapors.

DO NOT OPERATE IN THE RAIN OR IN WET AREAS - Operating an electric compressor in wet conditions can

result in severe shock or electrocution. Operate only in dry conditions, using a properly grounded power outlet

that conforms to local and national electrical code requirements. An outlet with ground-fault circuit interrupter

(GFCI) protection is recommended for use outdoors or in garages, and may be required by local electrical codes.

DO NOT TOUCH COMPRESSOR HEAD OR TUBING WHEN UNIT IS OPERATING - Normal compressor

operation will cause tubing and other components to become extremely hot. Contact with hot parts can cause

serious burns. Allow unit to cool before handling or performing service.

3

SAFETY INSTRUCTIONS

NEVER DIRECT COMPRESSED AIR AT ANY BODY PARTS - Compressed air can penetrate skin, or force dirt

and debris into eyes, causing serious injury. Never place hands or body parts over the air discharge opening of

a pressurized nozzle or fitting. Use care when connecting and disconnecting air hose to attachments, pneumatic

tools, and other air-powered devices.

KEEP FLAMMABLE SPRAYS AWAY FROM SPARKS AND OTHER SOURCES OF IGNITION - Spraying

flammable liquids such as oil-base paints, sealers, and finishes near sparks, open flame, and other sources of

ignition such as pilot lights, appliances, water heaters, furnaces, etc. can result in explosion and fire. Turn off all

pilot lights, and avoid using electrical appliances, heaters, torches, and other equipment that may produce sparks

or flame. Keep compressor as far away from spraying area as possible by using an air hose of sufficient length

to prevent spray mist from being ignited by electrical sparks from compressor operation.

DO NOT TAMPER WITH COMPRESSOR PRESSURE SWITCH SETTINGS - The pressure switch settings set at

the factory provide the maximum safe operating pressure recommended for this compressor. Altering these

settings can result in over-pressurization, risk of tank, hose, and pneumatic equipment failure, and serious injury

to operator and bystanders.

USE AIR HOSE RATED FOR 150 PSI OR GREA TER - Air hose must be rated to safely handle maximum

compressor pressure. Air hose that does not meet minimum pressure requirements can rupture, releasing high

pressure air. Replace a cracked or leaking air hose immediately to prevent serious injury from contact with high

pressure air streams.

DISCONNECT POWER CORD AND RELIEVE TANK PRESSURE BEFORE SERVICING UNIT – Never perform

service or maintenance on any part of the compressor while the unit is pressurized or connected to power. The

compressor can start automatically, causing serious injury. Open tank drains slowly to allow air to escape, and

keep clear of air stream.

DO NOT MODIFY COMPRESSOR – Altering the compressor in any way may create a serious safety hazard, and

result in serious injury to operator and bystanders. If compressor does not work properly, stop using unit

immediately. Return unit to an authorized service center for repairs if problem cannot be remedied by following

troubleshooting instructions in this manual.

4

SPECIFICATIONS GR2540

DESCRIPTION SPECIFICATION

Horsepower 2.5 (Peak)

Voltage 115V

Amperage 14

Hz 60

Phase Single

RPM 3450

Capacity

Tanks 1

Air Storage Capacity 4 Gallons

Maximum Air Pressure 150 PSI

CFM 5.7 cfm @ 40 PSI

4.5 cfm @ 90 PSI

Pressure Switch Settings

Pressure Switch - ON 110 PSI

Pressure Switch - OFF 150 PSI

Compressor Pump

Motor

Cylinders 1

Compression Stage 1

Lubrication Splash

Oil Type Compressor Oil SAE 30W (ISO 100)*

Crankcase Aluminum

Bearings Ball

Cylinder Cast Iron

Valves Stainless Steel Reed

Head Aluminum

Filter Canister

Dimensions

Weight 88 Lbs.

Shipping Weight 92 Lbs.

Size ( L X W X H) 23.6" X 22" X 20"

*PROVIDED WITH UNIT

5

SPECIFICATIONS GR2540LR

DESCRIPTION SPECIFICATION

Horsepower 2.5 (Peak)

Voltage 115V

Amperage 12

Hz 60

Phase Single

RPM 1725

Capacity

Tanks 1

Air Storage Capacity 4 Gallons

Maximum Air Pressure 150 PSI

CFM 5.3 cfm @ 40 PSI

4.2 cfm @ 90 PSI

Pressure Switch Settings

Pressure Switch - ON 110 PSI

Pressure Switch - OFF 150 PSI

Compressor Pump

Motor

Cylinders 1

Compression Stage 1

Lubrication Splash

Oil Type Compressor Oil SAE 30W (ISO 100)*

Crankcase Aluminum

Bearings Ball

Cylinder Cast Iron

Valves Stainless Steel Reed

Head Aluminum

Filter Canister

Dimensions

Weight 88 Lbs.

Shipping Weight 92 Lbs.

Size ( L X W X H) 23.6" X 22" X 20"

*PROVIDED WITH UNIT

6

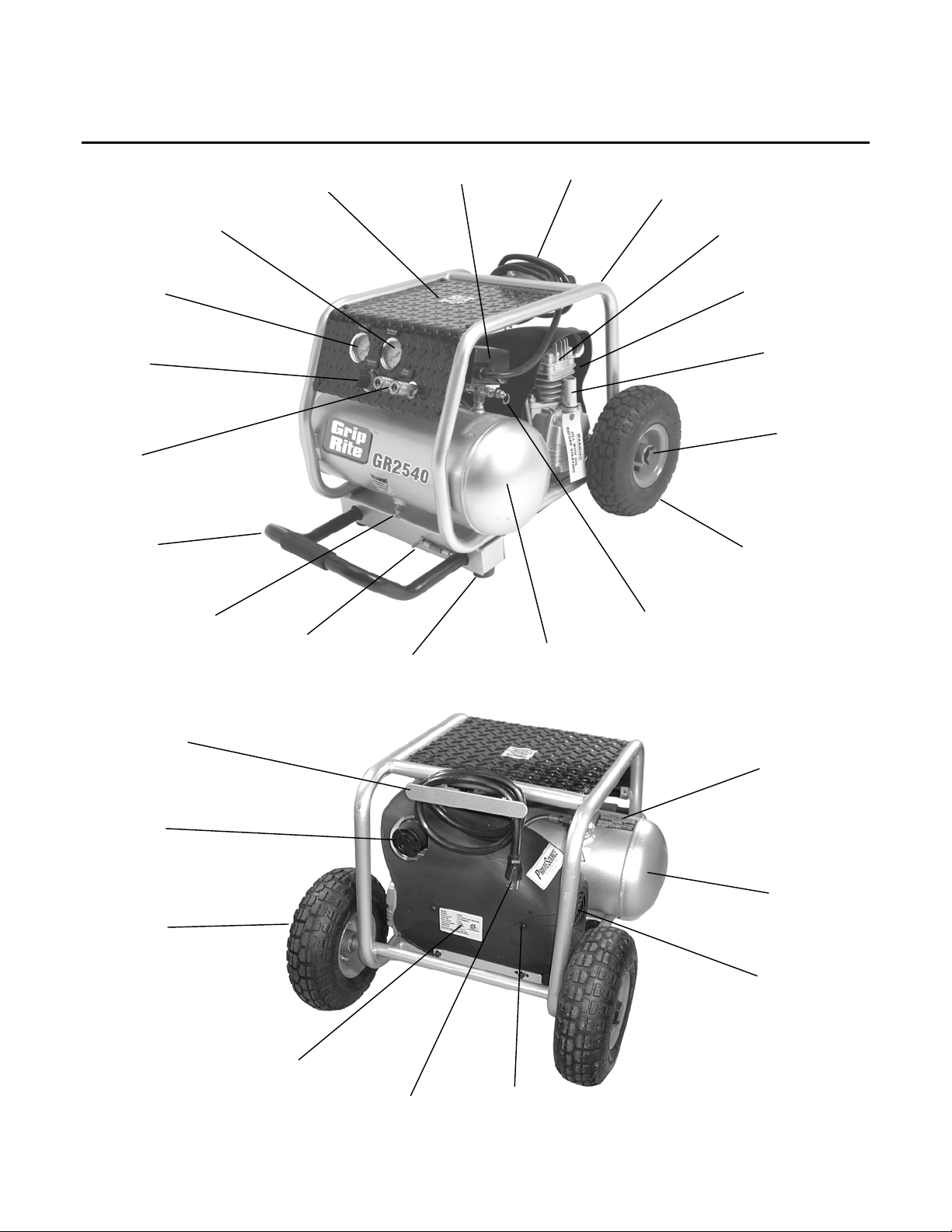

COMPRESSOR DESCRIPTION

18

19

1

2

15

14

16

13

17

12

11

10

3

4

5

6

7

9

8

25

7

26

24

23

7

20

9

21

22

COMPRESSOR PARTS DESCRIPTION

KEY DESCRIPTION FUNCTION

1 Heavy Duty Power Cord Provides power to compressor motor

2 Frame Protects compressor components

3 Compressor Pump Compresses air

4 Reset Switch Protects motor from overloads

5 Dipstick (not on GR254LR) Used to check oil level in pump crankcase

6 Hex Head Wheel Bolt Secures wheels to compressor frame

7 Wheel Assembly Large pneumatic tires allow easy rolling

8 Safety Relief Valve Releases excessive air pressure from tank

9 Air Storage Tank Stores compressed air

10 Rubber Foot Provides stable footing, reduces vibration

11 Handle Latch Secures handle position for easy transport

12 Air Tank Drain Allows moisture to be drained from tank

13 Handle Extends for ease of transport

14 Air Outlet Fittings (2) Allows quick connection of air hoses

15 Regulator Control Knob Adjust discharge air pressure setting

16 Tank Air Pressure Gauge Indicates air pressure in storage tank

17 Air Outlet Pressure Gauge Indicates air pressure at air outlet fittings

18 Compressor Top Plate Protects compressor components

19 On-Off Switch Turns compressor on and off

20 Tank Warning Label Provides important safety information

21 Cooling System Cools compressor components

22 Motor Shroud Protects motor and compressor

23 3-Prong Grounding Plug Safely grounds equipment when properly

connected to a grounded power source.

24 Motor Label Provides important motor information

25 Air Filter Filters intake air to remove dust and debris

26 Power Cord Retainer Secures power cord for storage

8

SET UP

WARNING:

Before being used for the first time, your new compressor requires a simple set-up procedure

that will help your unit deliver years of trouble-free service. Failure to follow all initial set-up

instructions may result in serious damage to your compressor, property damage, or serious

injury to operator and bystanders. Do not start compressor until all set-up steps have been

performed.

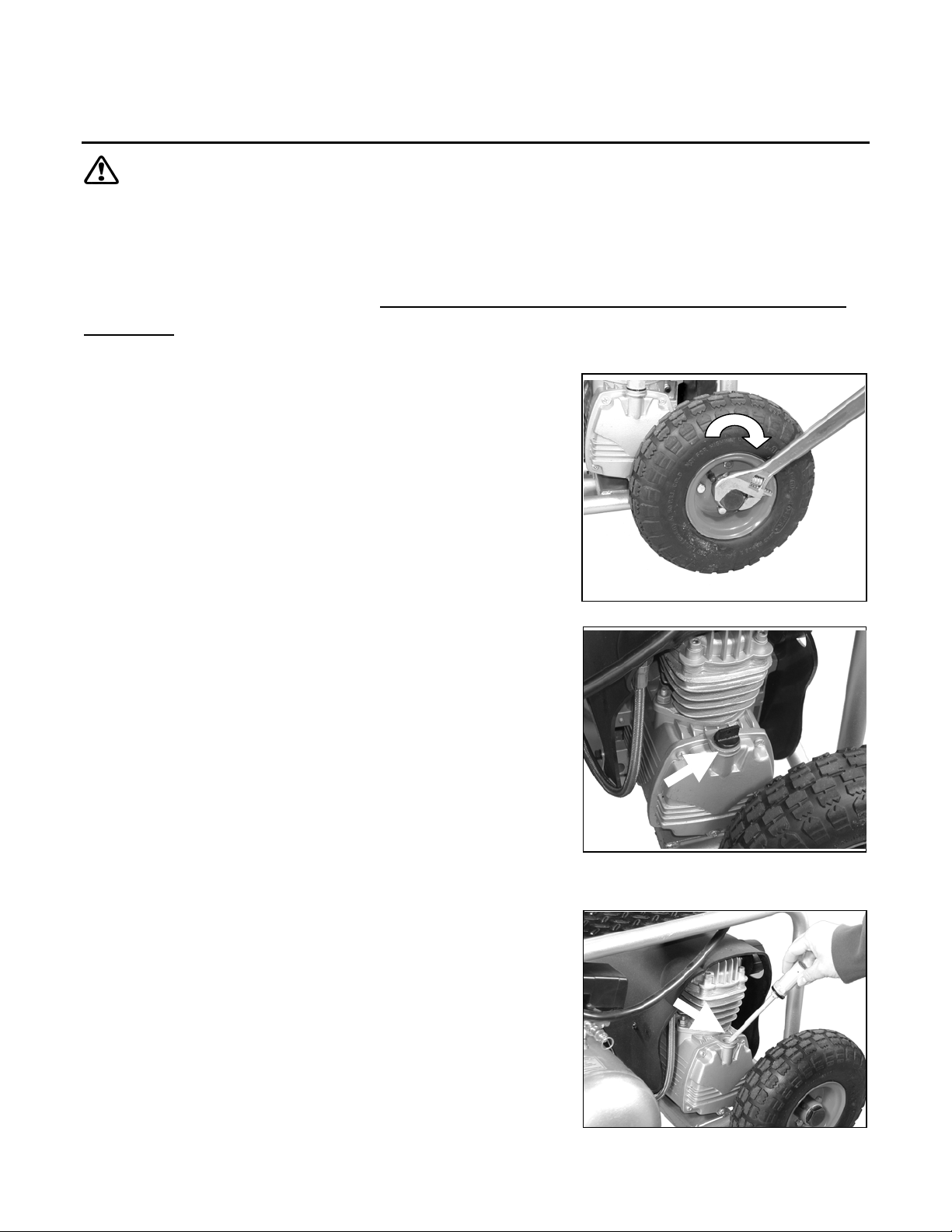

1. Remove compressor and wheel assemblies

from carton.

2. Install wheels on wheel mounts at bottom of

frame using hex head wheel bolts. Tighten

bolts securely with 1-1/4” wrench.

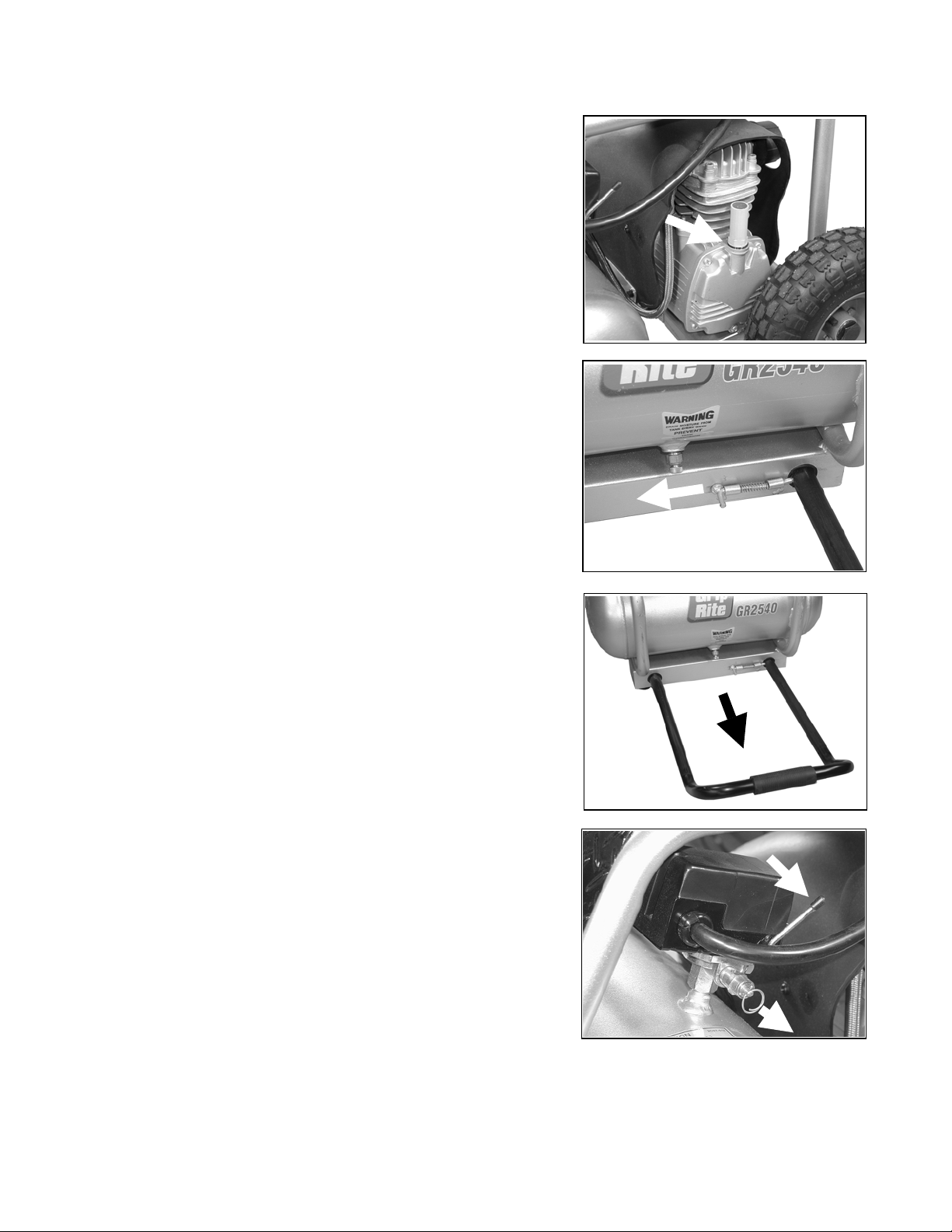

3. Unscrew shipping plug from crankcase. Add

non-detergent oil to compressor and check oil

level in sight glass or with dipstick. Oil level

must be between “L” (Low) and “H” (High)

marks on flat area of dipstick. Crankcase

capacity is ll.8 oz. (350 ml). Use chart below

for correct viscosity:

Air Temperature Viscosity

14 – 40 F SAE 20 (ISO 68)

40 – 80 F SAE 30 (ISO 100)

9

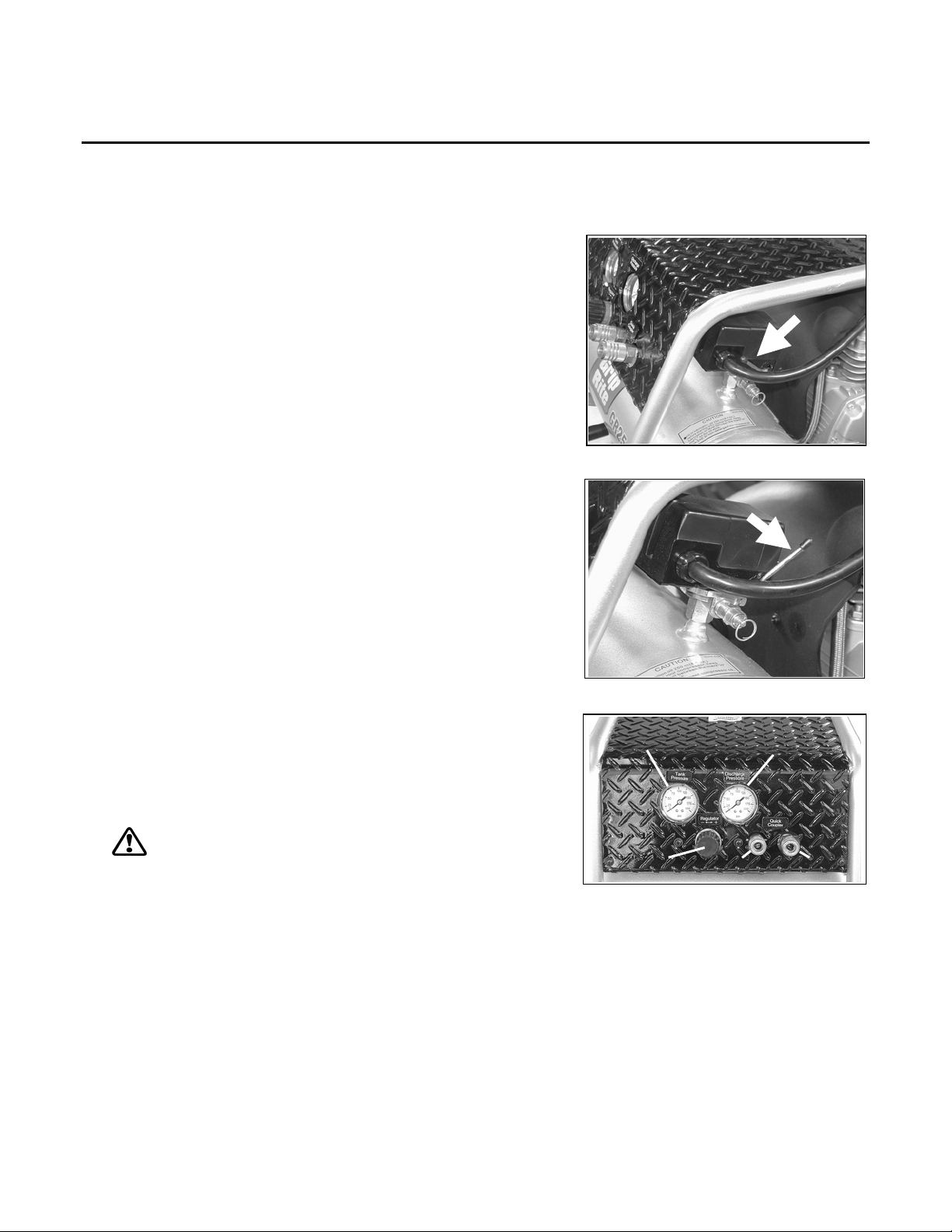

4. Install dipstick in crankcase, and tighten

securely before starting compressor. Make

sure black seal is in place between dipstick and

crankcase to prevent loss of oil during

compressor operation or movement.

5. Check power outlet circuit for correct capacity.

Compressor requires 120V, Single Phase, 14

Amps, 60 Hz. Fuses or circuit breakers must

be rated accordingly.

6. Use an extension cord with 3-prong grounding

plug. Extension cord must be sized to prevent

power loss and overheating of the motor:

Cord Length Wire Gauge Size

Up to 25 ft. 12 ga.

Up to 100 ft. 10 ga.

Up to 150 ft. 8 ga.

Up to 250 ft. 6 ga.

7. Pull handle out until locking hole in handle is

aligned with locking pin on base of compressor.

Lock handle in extended position with locking

pin, and use handle to wheel compressor to

desired area of operation.

8. Position compressor on a secure, stable

surface, no more than 10 degrees off level.

9. Plug power cord in, and unscrew Air Tank Drain

at the bottom of the air tank. Start compressor

by moving On/Off lever up to the “ON” position.

Allow compressor to run for 10 minutes without

stopping. Watch for excessive vibration or

unusual noise while compressor motor is

running. If unit vibrates excessively or makes

unusual noise, shut compressor off by moving

On/Off lever to “OFF” position. Refer to

trouble-shooting chart for corrective action. If

no excessive vibration is noted, tighten the Air

Tank Drain, allow unit to fill the air tanks, and

proceed to step 10.

10. Check operation of Pressure Relief Valve by

pulling release ring out to exhaust air pressure

from tank. Release ring and allow pressure

relief valve to reseat. Contact your dealer if

Pressure Relief Valve does not operate

properly.

11. Compressor is now ready for regular operation.

10

OPERATION

Operating Compressor

1. Move On/Off lever to the "OFF" position.

2. Plug the power cord into the power

receptacle.

3. Move On/Off lever to the "ON" position.

4. Leave compressor in “ON” position while in

use.

5. To stop compressor, move On/Off lever to the

"OFF" position. DO NOT stop compressor

by unplugging power cord.

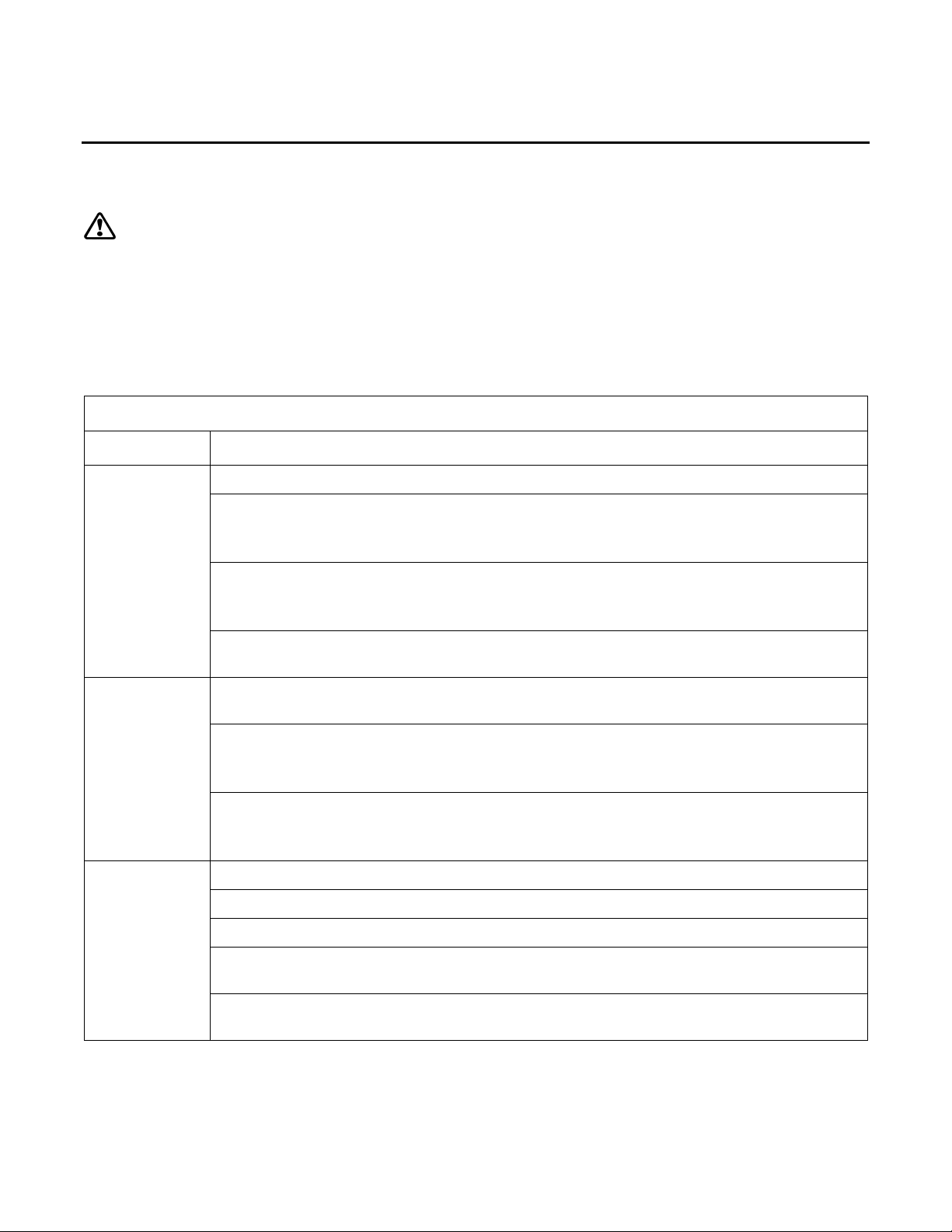

6. Adjust outlet air pressure to desired setting by

turning pressure regulator knob “C.” Turn

knob clockwise (+) to increase air pressure,

counterclockwise (-) to decrease air pressure.

Outlet air pressure is indicated by gauge (B).

Tank pressure is indicated by gauge (A)

7. Connect air hoses to quick-connect fittings (D)

using a male quick-connect fitting. To

connect air hose simply insert male hose

connector. To release air hose, push hose

fitting in, push back outer ring on compressor

fitting, and pull male hose connector out.

WARNING

High pressure air will escape when hose is

disconnected. Keep face away from fittings to

prevent dirt and debris from being blown into eyes.

Always wear safety glasses with side shields to

A

C

D

B

D

protect eyes when using compressor.

11

MAINTENANCE

Maintenance Schedule

DANGER

Never perform maintenance on the compressor when it is in the “ON” position. Always place

On/Off switch in “OFF” position, disconnect power cord from power source, drain air tanks, and

allow unit to cool first. Performing service procedures on a compressor with pressurized

tanks, or in the “ON” position, can result in serious injury.

MAINTENANCE CHART

Interval Maintenance Required

Check lubricant level and fill crankcase as needed

Drain moisture from tanks daily. Open drain slowly and let air pressure

bleed down gradually before opening drain valve completely. Use care

when tipping compressor to drain tanks.

Daily

Weekly

Perform a visual inspection of compressor. Make sure motor cover is in

place, and all components are in good condition. Check compressor power

cord and plug for damage. Don't use compressor if cord or plug is damaged.

Check for unusual noise or vibration, and have problem corrected. Contact

your Grip-Rite dealer for service.

Open air filter cap and clean air filter. Replace filter if damaged or

excessively dirty.

Check Pressure Relief Valve for proper operation. With tank pressurized,

pull on Pressure Relief Valve ring. Air must exhaust when ring is pulled.

Release ring - air must stop exhausting when ring is released.

Check for leaks, cracks, or corrosion on tank, fittings, and tubing.

Discontinue use of equipment if leaks or other major problems are found, and

repair unit before placing back into service.

3 Months/

300 Hours

Change compressor oil and air filter.

Clean/blow off compressor pump fins and motor.

Check for air leaks at connections, and tighten fittings if necessary.

Check tank for cracks, corrosion, leaks, or other damage. Never use a

compressor with a damaged tank.

Check warning labels for legibility, and replace if necessary. Contact your

Grip-Rite dealer for replacement labels.

12

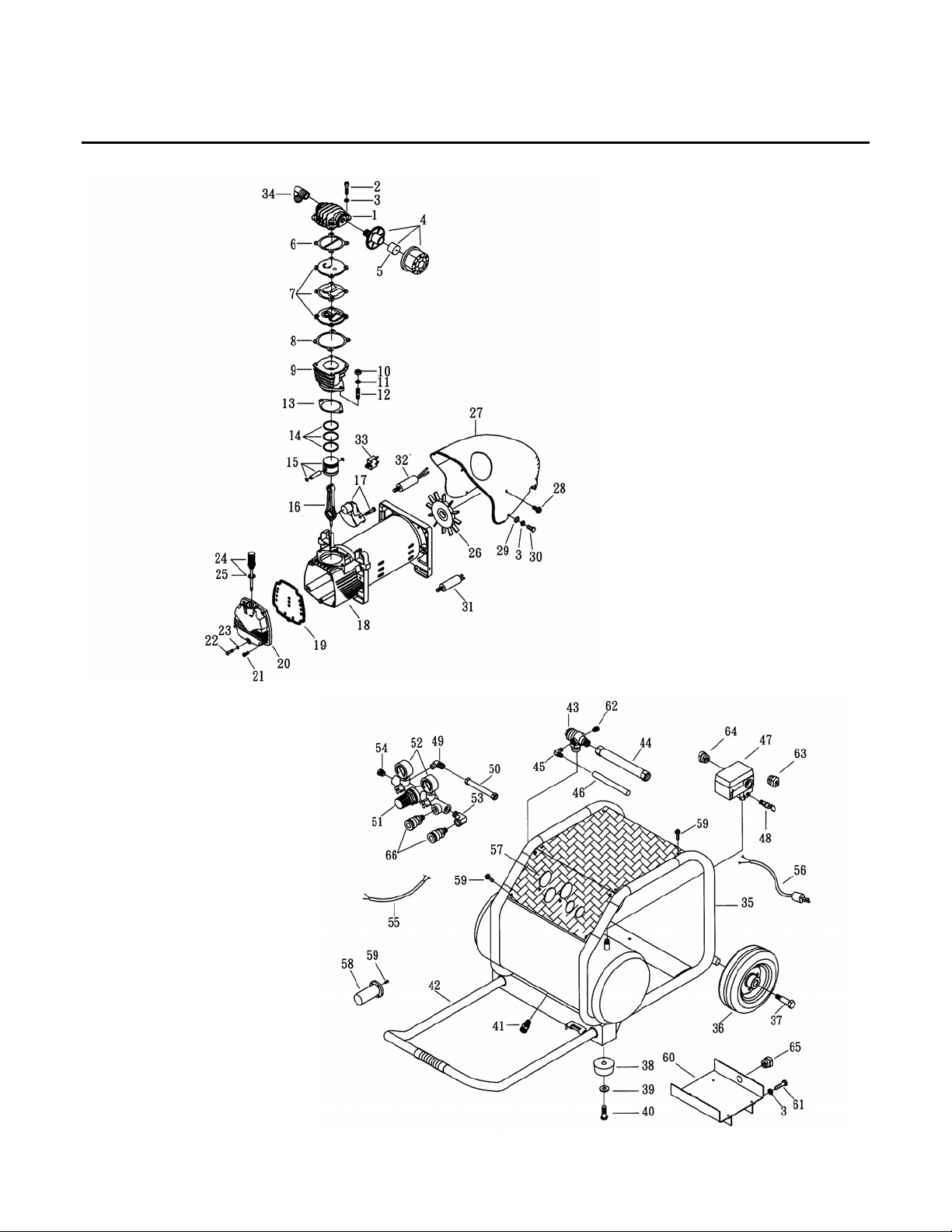

GR2540 COMPRESSOR SCHEMATIC (Silver Tank)

PUMP

TANK/FRAME

13

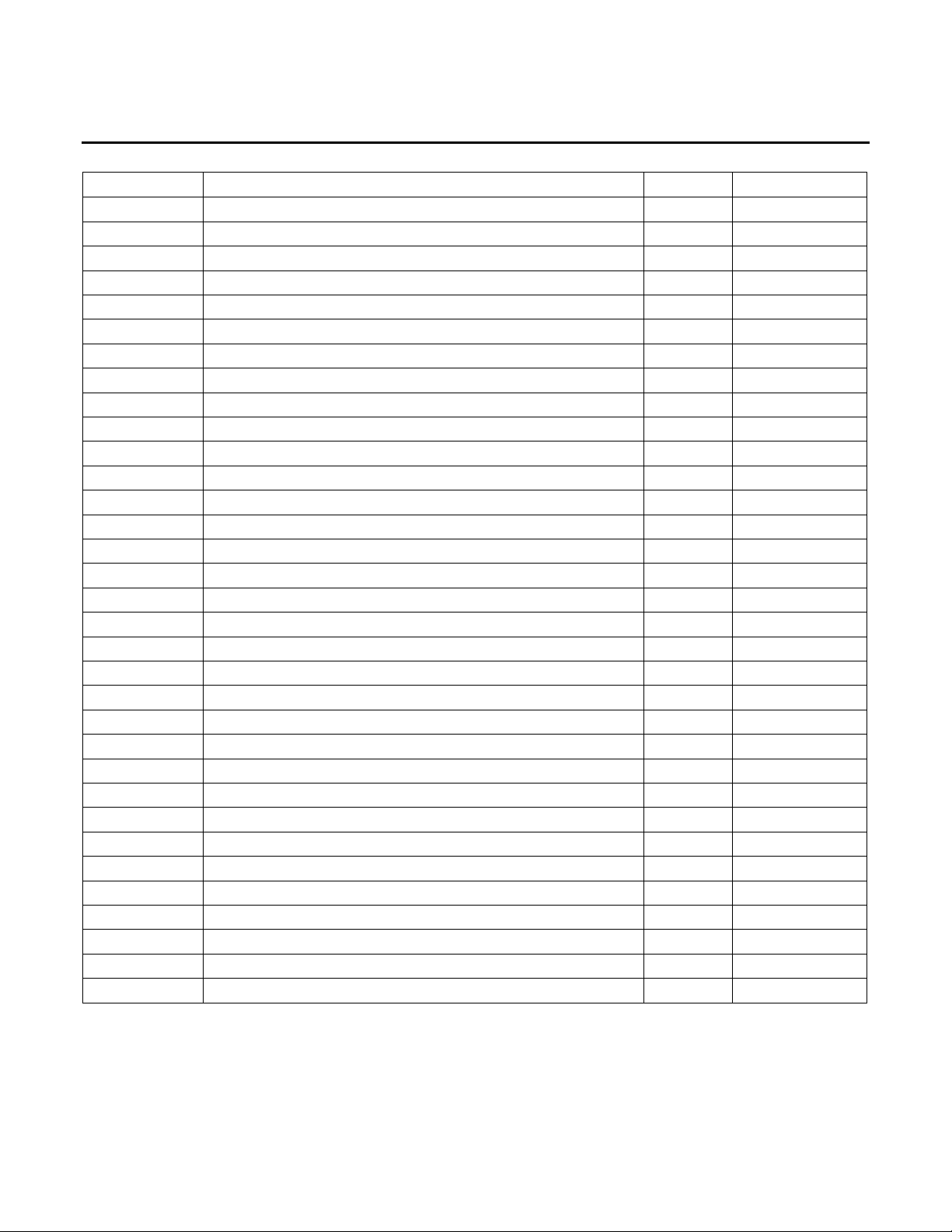

GR2540 COMPRESSOR PARTS LIST - PUMP

REF NO. DESCRIPTION QTY. PART#

1 CYLINDER HEAD 1 PACP408

2 ALLEN BOLT 4 PACP396

3 SPRING WASHER 10 PACP3

4 AIR FILTER 1 PACP409

5 FILTER ELEMENT 1 PACP410

6 CYLINDER HEAD GASKET 1 PACP9

7 IN. & EX. VALVE ASSEMBLY 1 PACP82

8 VALVE SEAT GASKET 1 PACP411

9 CYLINDER 1 PACP412

10 HEXAGON NUT 2 PACP20

11 SPRING WASHER 2 PACP21

12 DOUBLE HEAD SCREW 2 PACP22

13 CYLINDER GASKET 1 PACP14

14 PISTON RING SET 1 PACP413

15 PISTON SET 1 PACP414

16 ROD 1 PACP415

17 CRANKSHAFT & BALANCER 1 PACP416

18 MOTOR SET 1 PACP417

19 FRONT COVER GASKET 1 PACP418

20 FRONT COVER 1 PACP419

21 BOLT 4 PACP27

22 BOLT 1 PACP420

23 O-RING 1 PACP421

24 DIPSTICK SET 1 PACP24

25 DIPSTICK GASKET 1 PACP25

26 COOLING FAN 1 PACP422

27 SHROUD 1 PACP423

28 HEXAGON BOLT SET 4 PACP424

29 PLATE WASHER 4 PACP124

30 HEXAGON BOLT SET 4 PACP425

31 STARTING CAPACITOR 1 PACP426

32 RUNNING CAPACITOR 1 PACP427

33 CIRCUIT BREAKER 1 PACP67

34 EXHAUST ELBOW 1 PACP428

14

GR2540 COMPRESSOR PARTS LIST - TANK/FRAME

REF NO. DESCRIPTION QTY. PART#

35 AIR TANK 1 PACP429

36 TANK WHEEL 2 PACP430

37 TANK WHEEL BOLT 2 PACP431

38 RUBBER PAD 2 PACP432

39 PLATE WASHER 2 PACP45

40 HEXAGON BOLT 2 PACP42

41 DRAIN VALVE 1 PACP35

42 GRIP SET 1 PACP433

43 CHECK VALVE 1 PACP434

44 TUBE 1 PACP435

45 UNLOADING ELBOW 1 PACP48

46 UNLOADING TUBE 1 PACP436

47 PRESSURE SWITCH 1 PACP437

48 PRESSURE RELIEF VALVE 1 PA CP438

49 EXHAUST ELBOW 1 PACP439

50 TUBE 1 PACP440

51 REGULATOR 1 PACP388

52 PRESSURE GAUGE 2 PACP441

53 ELBOW 1 PACP190

54 PLUG 2 PACP56

55 CABLE 1 PACP442

56 POWER CABLE 1 PACP336

57 PANEL 1 PACP443

58 HANDLE BUSHING 2 PACP444

59 BOLT 16 PACP396

60 BODY SEAT 1 PACP445

61 HEXAGON BOLT SET 2 PACP446

62 AUTO RELIEF VALVE 1 PACP447

63 STRAIN RELIEF BUSHING 1 PACP383

64 STRAIN RELIEF BUSHING 1 PACP63

65 STRAIN RELIEF BUSHING 1 PACP337

66 QUICK COUPLER 2 PACP448

15

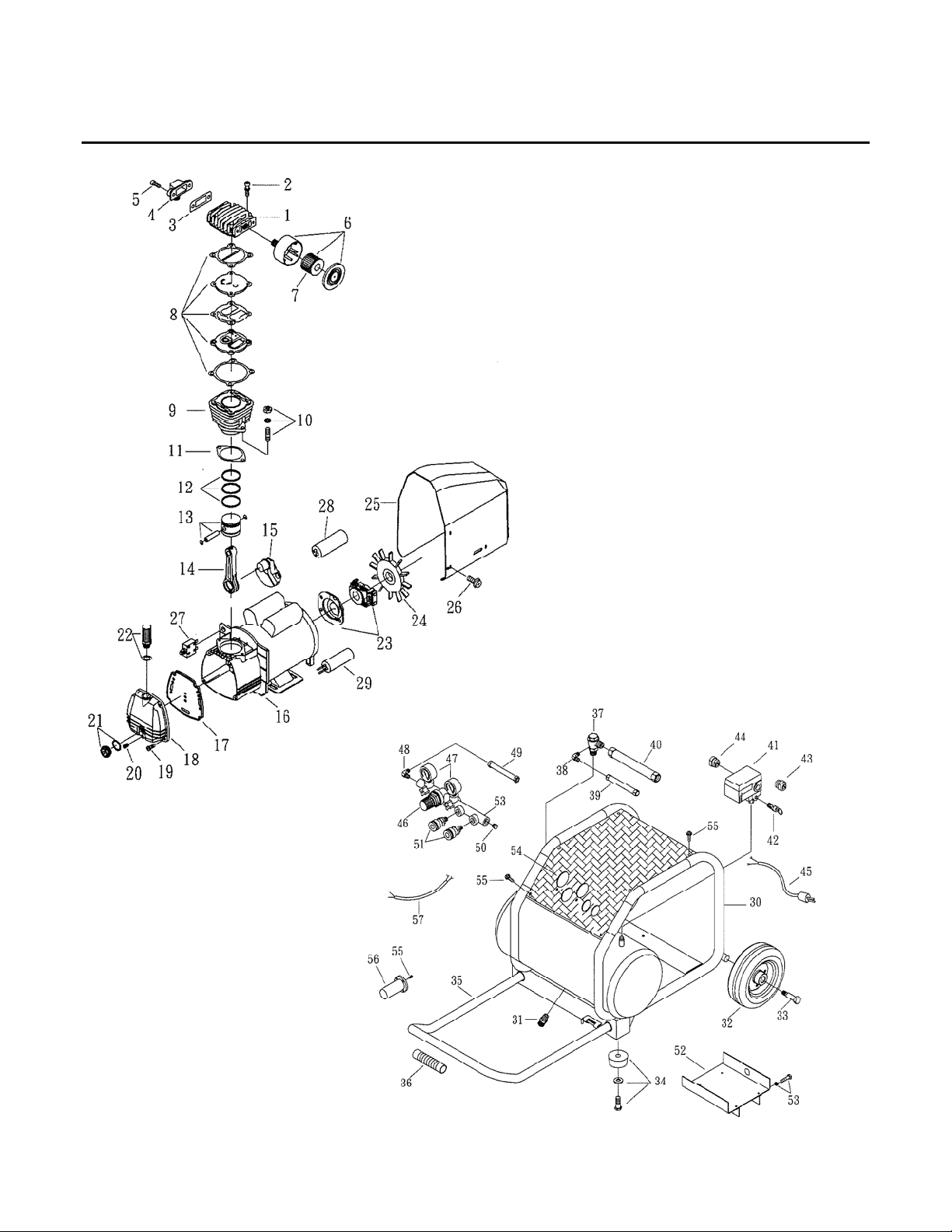

GR2540LR COMPRESSOR SCHEMATIC (Black Tank)

PUMP

TANK/FRAME

16

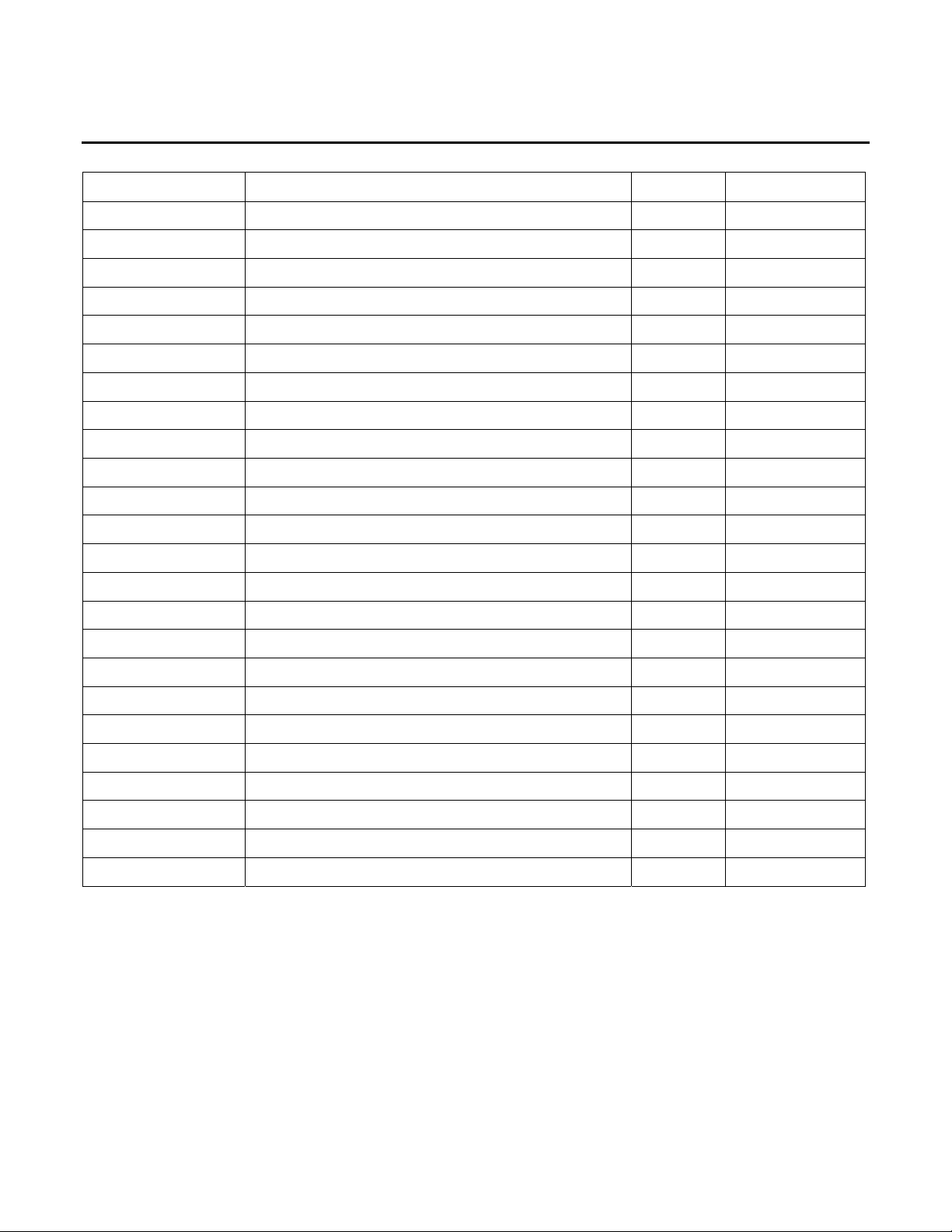

GR2540 COMPRESSOR PARTS LIST - PUMP

REF NO. DESCRIPTION QTY. PART #

1 CYLINDER HEAD 1 PACP1

2 ALLEN BOLT SET 4 PACP496

3 ELBOW GASKET 1 PACP4

4 EXHAUST ELBOW 1 PACP5

5 ALLEN BOLT SET 2 PACP6

6 AIR FILTER SET 1 PACP471

7 FILTER ELEMENT 1 PACP8

8 VALVE ASSEMBLY 1 PACP472

9 CYLINDER 1 PACP473

10 DOUBLE HEAD SCREW SET 2 PACP474

11 CYLINDER GASKET 1 PACP14

12 PISTON RING SET 1 PACP475

13 PISTON SET 1 PACP476

14 ROD 1 PACP17

15 CRANKSHAFT & BALANCER 1 PACP477

16 MOTOR SET 1 PACP478

17 FRONT BEARING SEAT GASKET 1 PACP479

18 FRONT COVER 1 PACP480

19 BOLT 4 PACP27

20 PLUG 1 PACP26

21 OIL SIGHT GAUGE SET 1 PACP481

22 BREATHER SET 1 PACP166

23 CENTRIFUGAL SWITCH SET 1 PACP482

24 COOLING FAN 1 PACP483

25 SHROUD 1 PACP32

26 HEXAGON BOLT 6 PACP424

27 THERMAL PROTECTOR 1 PACP67

28 STARTING CAPACITOR 1 PACP74

29 RUNNING CAPACITOR 1 PACP229

30 AIR TANK 1 PACP484

31 DRAIN VALVE 1 PACP485

32 TANK WHEEL 2 PACP486

33 TANK WHEEL BOLT 2 PACP487

17

GR2540 COMPRESSOR PARTS LIST – TANK AND FRAME

REF NO. DESCRIPTION QTY. PART #

34 RUBBER PAD SET 2 PACP488

35 GRIP 1 PACP489

36 RUBBER GRIP 1 PACP490

37 CHECK VALVE 1 PACP47

38 UNLOADING ELBOW 1 PACP48

39 UNLOADING TUBE 1 PACP491

40 TUBE 1 PACP339

41 PRESSURE SWITCH 1 PACP492

42 PRESSURE RELIEF VALVE 1 PACP438

43 STRAIN RELIEF BUSHING 1 PACP337

44 STRAIN RELIEF BUSHING 1 PACP63

45 POWER CABLE 1 PACP336

46 REGULATOR 1 PACP493

47 PRESSURE GAUGE 2 PACP441

48 EXHAUST ELBOW 1 PACP439

49 TUBE 1 PACP440

50 PLUG 4 PACP56

51 QUICK COUPLER 2 PACP448

52 BODY SEAT 1 PACP494

53 HEXAGON BOLT SET 2 PACP495

54 PANEL 1 PACP443

55 BOLT 16 PACP396

56 HANDLE BUSHING 2 PACP444

57 CABLE 1 PACP442

18

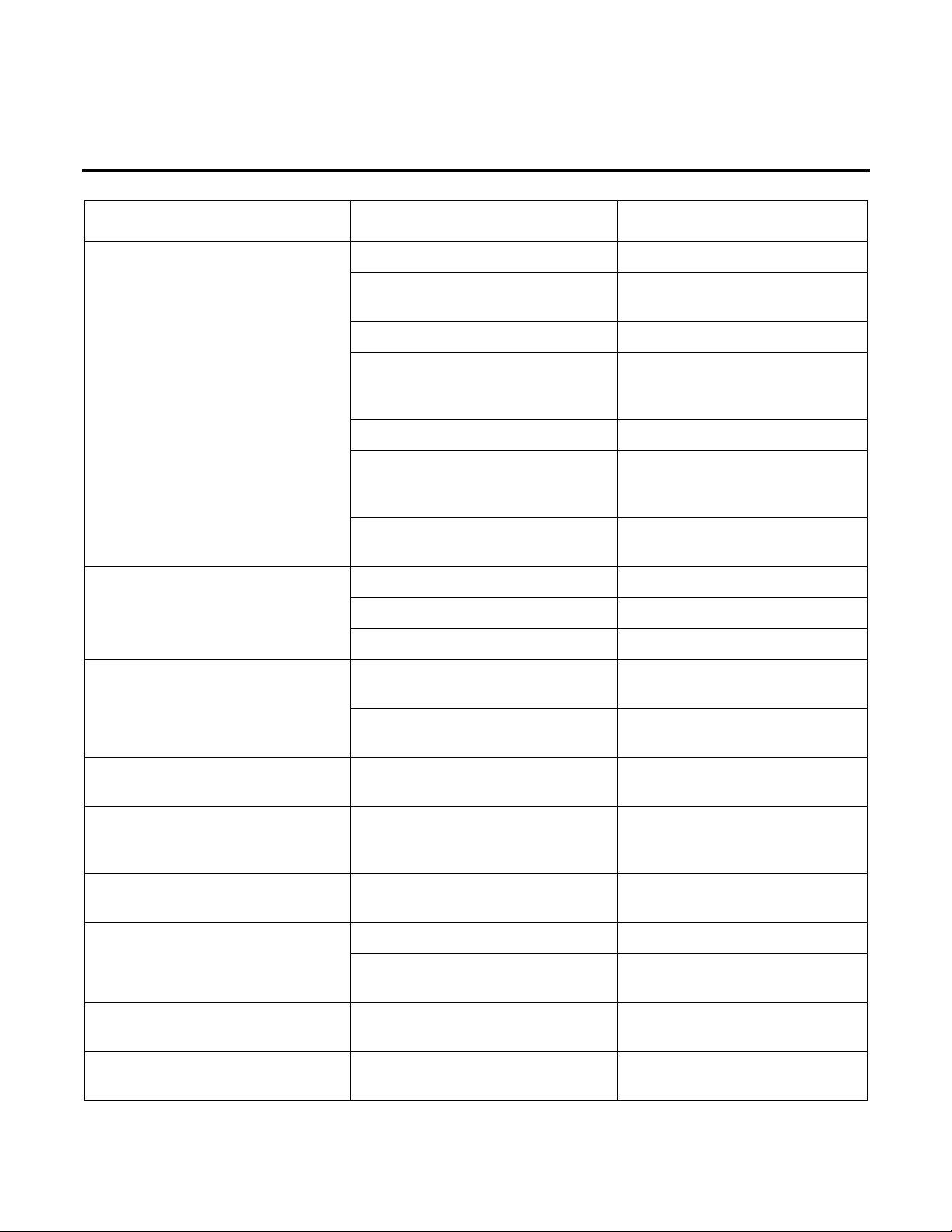

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Compressor won't start

Compressor runs continuously;

doesn't shut off

Safety relief valve pops open

Circuit breaker tripped Reset breaker

Fuse blown in power supply branch

circuit.

Power turned off. Turn power on

Pressure release valve on

motor/pressure switch has not

unloaded pump head pressure.

Defective cord or plug Replace

Motor thermal overload tripped Turn compressor off, allow motor

Motor, capacitor, pressure switch, or

check valve inoperable.

Drain plug open Close drain plug

Safety relief valve stuck open Replace

Air fitting on hose stuck open Repair or replace

Pressure switch misadjusted Have authorized service dealer

Replace fuse. Use Fusetron

type “T” fuse only.

Bleed line by moving switch to

“OFF” position. Pull switch to

“ON” position to restart unit.

to cool, and reset overload

button.

Contact authorized service

dealer.

adjust pressure switch.

Pressure switch inoperable Have switch serviced by

authorized service dealer.

Air leaks from safety relief valve Valve stuck or inoperable Pull on ring and release.

Replace valve if leak continues.

Tool, sprayer, or other accessory

doesn't work properly.

Unit runs continuously Air usage greater than compressor

Air leaks at motor/pressure switch

release valve while motor is running

Air leaks at motor/pressure switch

release valve after motor stops.

Air pressure too low or too high Adjust regulator to provide

pressure recommended by

product manufacturer.

Check CFM requirements of air

output capacity

Oil level low Check for leaks, and add oil Noisy operation

Internal wear or damage Have unit serviced by authorized

Switch inoperable Have authorized service dealer

Switch inoperable Have authorized service dealer

tool or accessory being used.

service dealer.

replace switch

replace switch

19

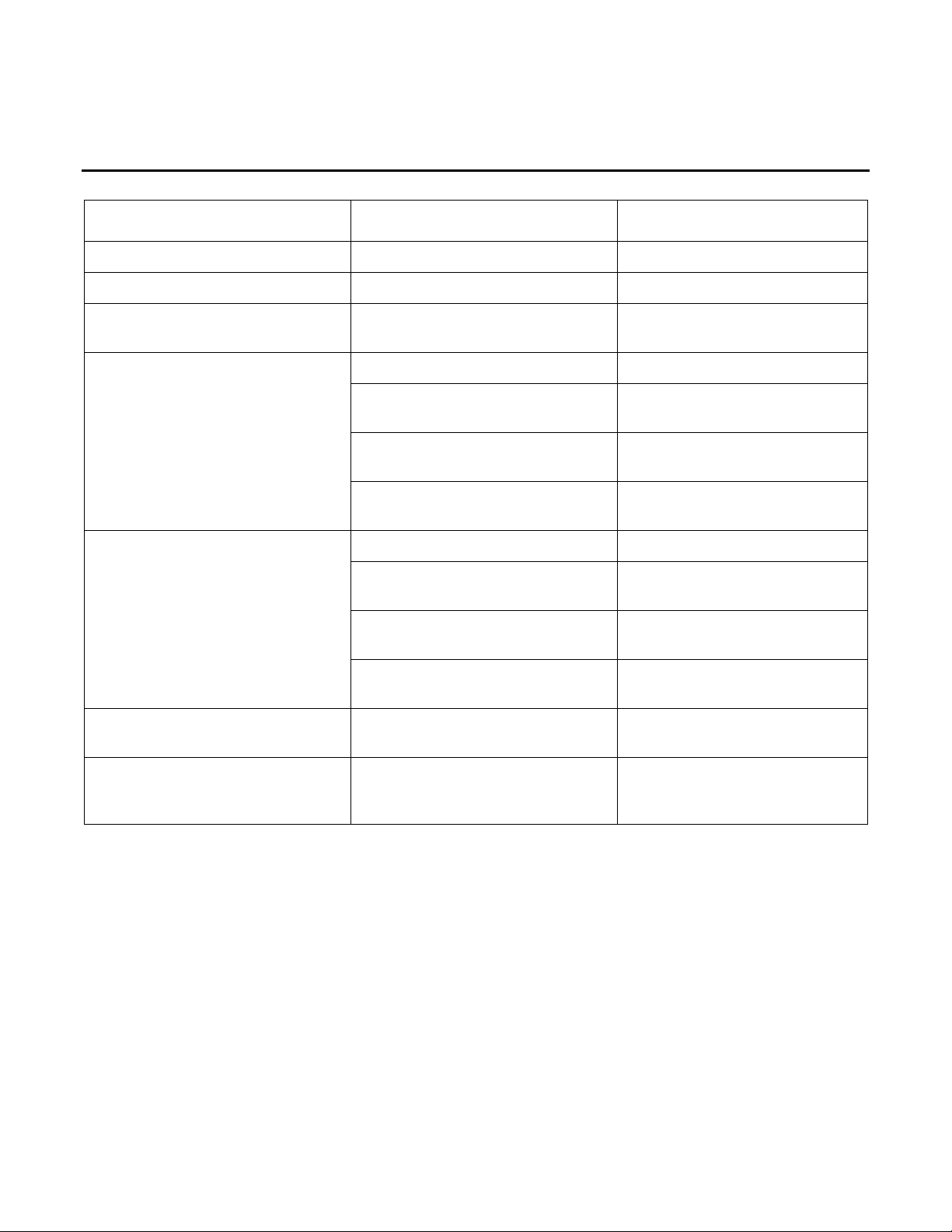

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Air leaks at fittings Fittings loose Tighten fittings

Air leaks at compressor head Head bolts loose Tighten bolts securely

Air blows out of inlet filter Damaged reed valve Have unit serviced by authorized

service dealer

Insufficient pressure at air tool or

accessory

Oil consumption excessive

Crankcase oil appears milky when

dipstick is checked

Moisture in discharge air Excessive condensation in air tank Drain tank more frequently. Tip

Air intake filter dirty Clean or replace filter

Air leaks Check unit for leaks and correct

as needed.

Air hose too small or too long Use large diameter air hose and

larger capacity fittings.

Reed valve worn or damaged Have authorized service dealer

replace.

Air intake filter dirty Clean or replace filter

Compressor positioned on uneven

surface

Oil leakage Have authorized service dealer

Worn cylinder or piston rings. Have authorized service dealer

Water in oil from condensation Change crankcase oil.

Position compressor on level

surface

repair unit.

repair unit.

unit when draining tank to drain

all water.

20

STORAGE

Open tank drain valve and allow all air pressure to escape.

Drain all moisture out of tanks, and close drain valves.

Disconnect air hose and wind hose carefully for storage

Inspect compressor for wear, damage, or missing parts, and have repairs made

promptly.

Store unit in a dry, cool place.

Storage in vehicles or trailers - secure the compressor to keep it from tipping or being

damaged by contact with other equipment. Make sure gauges, fittings, and knobs are

clear of objects that could cause damage.

Do not place heavy objects on top of compressor.

21

Loading...

Loading...