GRIPPLE GS10, GS12, GS19, GS25 Installation Manual

CABLE BRACING INSTALLATION GUIDE

(READ INSTRUCTIONS IN THEIR ENTIRETY BEFORE STARTING INSTALLATION)

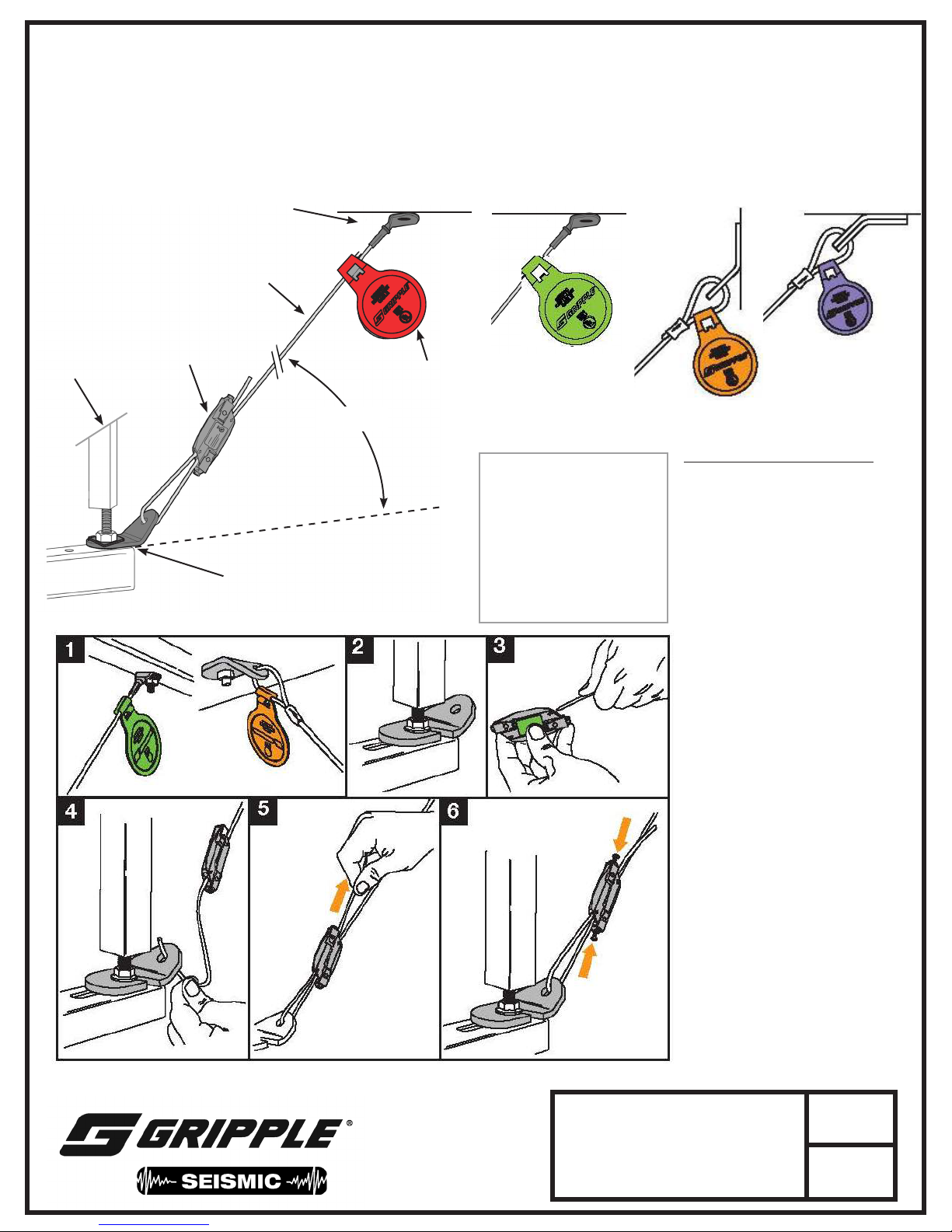

Attachment to structure. Gripple cable end tting

(Eyelet, Standard bracket, or Double Bracket).

Select bracket based on anchor diameter.

Break strength

certied, pre-stretched

Gripple Seismic Cable

GRIPPLE® SEISMIC

Gripple Seismic Cable End Fittings:

GS10

(Eyelet or Bracket)

GS12

(Eyelet or Bracket)

GS19

(Single Bracket)

GS25

(Double Bracket)

Hanger rod

with stiffener

as required,

or equipment

attachment

Gripple Seismic

Fastener

(GS10, GS12,

GS19, GS25)

Attachment to equipment/strut.

Gripple GSS or GSR Bracket.

Select size based on hanger rod

diameter.

Brace angle

30º - 60º

Color coded tag

(see Side 2 for

details)

IMPORTANT INFORMATION:

a.) Each cable brace should be

at an angle between 30-60

degrees to the horizontal, as

shown in drawing at left; 45

degrees is optimal.

b.) Ensure that suitable rod

stiffener is used to prevent

buckling or bending of the

rod in the event of an

earthquake.

INSTALLATION INSTRUCTIONS:

1.) Install Gripple Seismic end tting

(Eyelet or Bracket for GS10 or GS12;

Single Bracket for GS19, or Double

Bracket for GS25, as shown above)

to structure.

2.) Loosen the nut on the rod hanger and

slot the Gripple Seismic Retrot Bracket

onto the rod. Tighten the nut onto the

Gripple Seismic Retrot Bracket.

Ensure that the appropriate washer

per the cable & bracket system being

used is installed and the nut is

tightened down securely onto the

bracket.

3.) Thread free end of cable through rst

channel of the Gripple Seismic fastener.

4.) Thread free end of cable through the

hole in the Gripple Seismic bracket.

5.) Position the Gripple Seismic fastener

up the cable so that it is a min. of 12

inches above the bracket. Thread the

remaining cable through the second

channel in the Gripple Seismic fastener

to form a loop around the bracket.

Pull the tail end of the cable to create

a tight loop, and remove the slack

from the Gripple Seismic cable brace.

Use the Gripple supplied Tightening

Tool for the GS19 and GS25 systems.

6.) Trim the tail end of the cable but leave

a minimum tail length of 2 inches.

Install the locking bolts and ensure

that they are tightened down securely.

Ensure that locking bolts are removed

before trying to remove further slack

from the cable or adjust the position of

the Gripple Seismic fastener along the

cable length.

GRIPPLE INC.

1611 EMILY LANE

AURORA, IL 60502 USA

Phone: 1-630-406-0600

www.grippleseismic.com

DATE:

3/14/2013

PAGE:

1 / 2

GRIPPLE® SEISMIC

CABLE BRACING INSTALLATION GUIDE

(READ INSTRUCTIONS IN THEIR ENTIRETY BEFORE STARTING INSTALLATION)

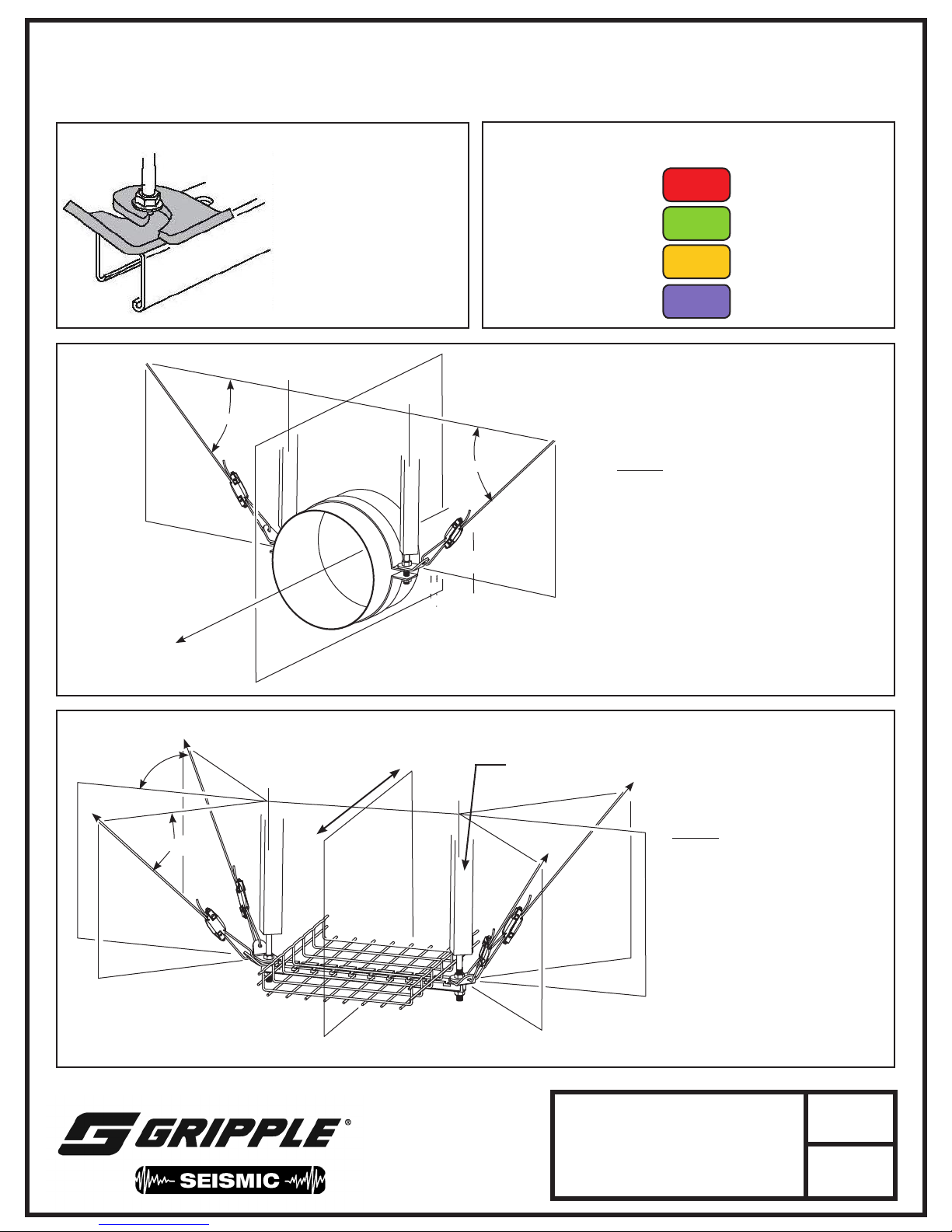

30º- 60º

DOUBLE STACKING:

Gripple Seismic Brackets can be

double stacked as shown.

Ensure that each bracket is in line

with its respective cable brace.

Up to four brackets can be

stacked at one point on rod. It

is advised that no more than two

brackets are stacked at an anchor

point to the structure.

30º- 60º

MAX SYSTEM DESIGN STRENGTHS (LRFD):

BRACE SIZE:

GS10

(5/64” cable)

GS12

(1/8” cable)

GS19

(3/16” cable)

GS25

(1/4” cable)

COLOR CODE:

TRANSVERSE BRACING:

NOTES:

Follow the instructions to install the two

seismic braces.

Tighten cables to remove slack.

Ensure that the cables are in-line with each

other, and in a plane perpendicular to the

service they are bracing.

LRFD:

350 lbs

(158 kgs)

1,050 lbs

(476 kgs)

2,100 lbs

(952 kgs)

3,850 lbs

(1,746 kgs)

Run direction

40º - 50º

30º- 60º

Hanger rod with stiffener

Run direction

‘4-WAY’ BRACING:

NOTES:

Follow the instructions to install the

four seismic braces.

Tighten cables to remove slack.

Two braces are anchored onto each

rod, as shown here. The brackets

must be double stacked as detailed

above.

GRIPPLE INC.

1611 EMILY LANE

AURORA, IL 60502 USA

Phone: 1-630-406-0600

www.grippleseismic.com

DATE:

3/14/2013

PAGE:

2 / 2

Loading...

Loading...