Page 1

Mitchell locking nut

Iso Dampener

The Iso Dampener increases the efficiency of gyro stabilized heads by reducing

rotational stress and smoothening out pan starts and stops on telescopic and fixed

arm cranes by isolating high frequency vibrations between the mount and head.

Weight: 9.1kg / 20lbs

Maximum payload: 85kg / 189lbs

Temperature range: -20° to +50° Celsius (-4 to +122° Fahrenheit)

Dimensions: L 42 x W42 x H22cm (16“ x 16“ x 8“ )

Mounting: Mitchell to Mitchell

1. The Iso Dampener is mounted with a Mitchell connection to the crane or Maxi

Shock Absorber fixture and locked off tightly with the Mitchell locking nut. It should be

mounted so that the top arm of the Iso runs as an extension of the mounting fixture

e.g. crane arm.

[1]

Page 2

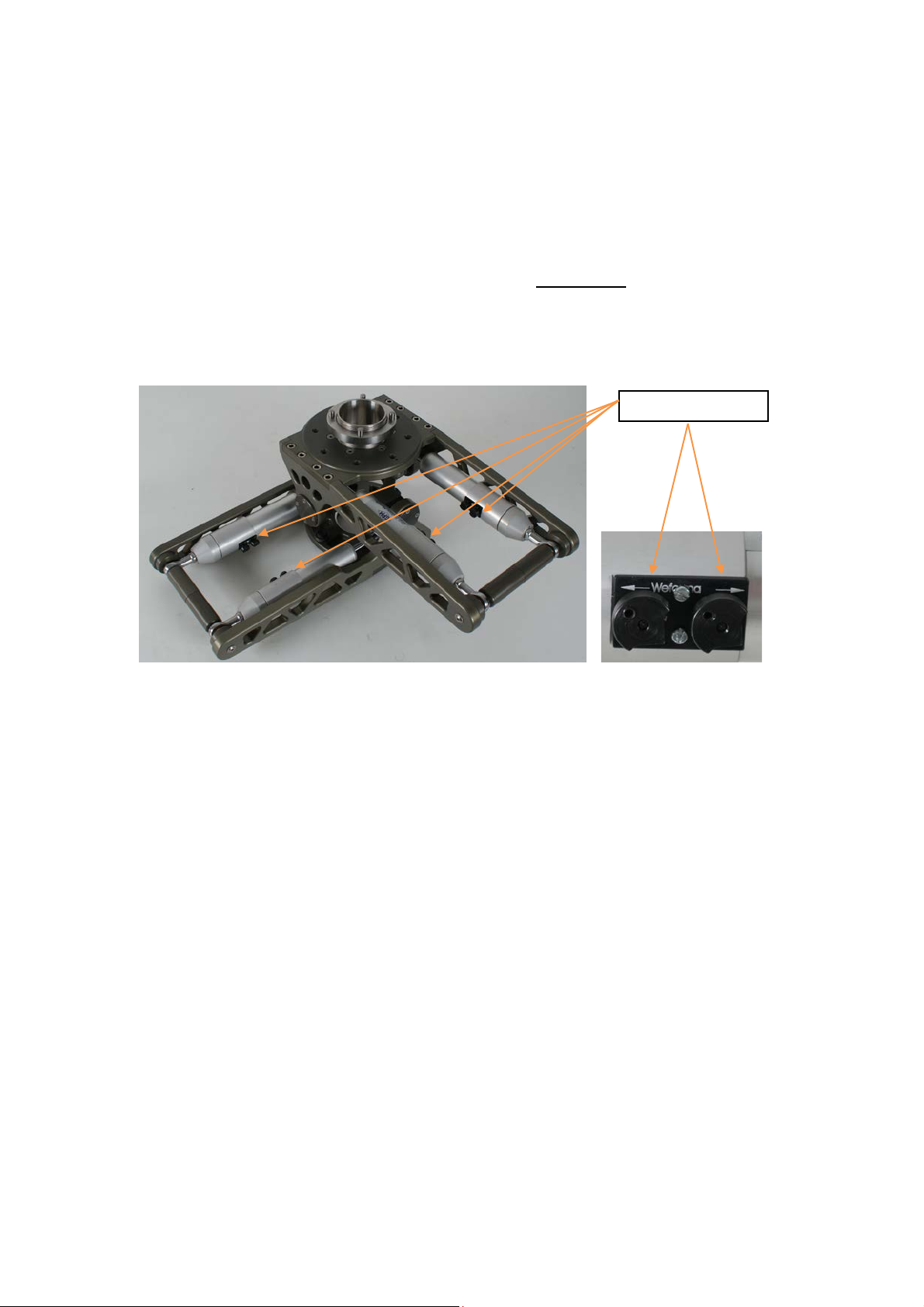

2. Regulating the Iso Dampener is made by adjusting the pair of valves on each of

Adjusting valves

the 4 shocks. In general, the factory setting is between level 6 - 7 for

- temperature range between 0°c and +30°c (-4 to +86° Fahrenheit)

- load 40-60 kg (88-132lbs)

If either temperature or load differ from those figures it is recommended to adjust the

pressure accordingly.

Always adjust each pair of knobs evenly and set all 8 valves to the same

setting!!!!

Note: the valves should never be closed to maximum pressure as it can

damage the dampeners.

Turn valves clockwise to increase and anti-clockwise to decrease pressure!!

3. To check the pressure level of the Iso Dampener, first set the top dampeners so

that the mounted head and camera can swing smoothly to and fro.

When the dampening is correctly set it should be possible to manually push the head

to the maximum tilt angle on one side and when let go the head should swing

smoothly down and over the straight, vertical hanging position, then fall smoothly into

the vertical hanging position within 1 to 2 seconds.

The same adjustment should be made on the lower dampeners so that the pressure

level is equal at each axis.

Grip Factory Munich GmbH

Fürholzener Straße 1

85386 Eching bei München

Germany

Tel.: +49 (0) 89 319 0 129-0

Fax: +49 (0) 89 319 0 129-9

e-Mail: info@g-f-m.net

http://www.g-f-m.net

[2]

Loading...

Loading...