Page 1

Grip Factory Munich

YOUR INNOVATIVE PARTNER FOR CAMERA SUPPORT

GF-Primo / GF-Secondo

Instruction Manual

Grip Factory Munich GmbH

Fürholzener Straße 1

85386 Eching bei München

Germany

Valid: Jul 2012

Tel.: +49 (0) 89 319 0 129-0

Fax: +49 (0) 89 319 0 129-9

e-Mail: info@g-f-m.net

http://www.g-f-m.net

Page 2

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

1

Contents:

SAFETY GUIDELINES................................................................................................2

Technical Specs for GF-Primo - / GF-Secondo Dolly..................................................4

The Base Dolly............................................................................................................6

Changing the batteries.............................................................................................................6

Connecting the Platforms.........................................................................................................6

Wheel arm adjustment..............................................................................................................8

Connecting the Steering Handle:..............................................................................................9

Adjusting the angle of the Steering Handle:............................................................................10

Adjusting the length of the Steering Handle:...........................................................................10

Connecting the HCU to Steering Handle.................................................................................11

GF-Primo Steering modes:........................................................................................12

GF-Primo‘s 3 steering modes and selector position:...............................................................13

GF-Secondo Steering modes:...................................................................................14

GF-Secondo’s three steering modes and their selector positions:...........................................15

Combi-Wheels – GF-Primo & GF-Secondo:..............................................................16

Disconnecting the wheels from the steering:...........................................................................16

Going on Track:......................................................................................................................17

The Multifunctional Turnstile Mount:.........................................................................18

Removing the Column with the Carry Bars:..............................................................19

Hand Control Unit Components................................................................................20

Starting off..............................................................................................................................21

To connect the cable from the HCU to Electronic:...................................................................23

Hand Control Unit Display......................................................................................................23

Adjusting the Speed or Ramp.................................................................................................24

Generating Movement............................................................................................................24

To select the HCU Mode........................................................................................................24

Setting a new lower and upper limit........................................................................................25

The HCU Modes....................................................................................................................25

Emergency Operation of the Column........................................................................34

Synchronizing the Hand Control Unit and Column....................................................36

Calibrating the column...............................................................................................37

Trouble Shooting.......................................................................................................38

ASSEMBLING THE GF-Primo Jib:............................................................................42

Selecting the “Jib On” mode...................................................................................................47

Page 3

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

2

SAFETY GUIDELINES

Adherence to the instruction manual:

The set-up instructions must be read and understood before set-up or operation. The dolly may only be

assembled in accordance with the manufacturer’s instruction manual. The manufacturer’s technical

specifications and limits (maximum rated loads etc) must be adhered to at all times and in no way exceeded.

Warranty:

The manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due to

negligence by the crane operator or misuse of the crane or disregarding the instruction manual.

Assembling and operation of the dolly:

The Dolly may only be set-up or operated by trained and experienced personnel. To assemble and operate

the dolly at least 1 trained person is required. To avoid misuse by untrained personnel, the dolly should be

dismantled / switched off when not in use or under supervision.

The crane may not be set-up or operated under the influence of alcohol, drugs or any other intoxicating

substances. The respective protective clothing e.g. gloves, should be worn.

Stability of the crane system:

Before assembling or using the dolly ensure that the ground surface is stable and cannot give way. The

ground surface must be stable enough to support at least 1000 kg/m2 = 2200 lbs/ sq yard.

Dolly operation with the GF-Primo Jib is only allowed with solid tires and use with pneumatic wheels is not

allowed. Before and while using the dolly wheels should be inspected.

Intended use of the Dolly system and use of the Dolly system with Jib Arm:

The Dolly is a mobile personnel and camera support system for use on sets and studios with even and level

ground / floors. Also for use on GF-Track.

Standard dolly operation consists of a for lifting 1 to 2 persons and camera or lifting the camera only, without

personnel on board, electromechanical column for lifting 1 to 2 persons and camera or lifting the camera

only, without personnel on board.

In Jib mode a pan and tilt arm is mounted for lifting 1 to 2 persons and camera or lifting the camera only,

without personnel on board

In accordance to the safety guidelines the dolly/jib is only allowed to be used on solid, level and stable

ground with solid wheels, not pneumatic wheels.

The dolly/jib movement on the ground, rotation of the column is managed by at 1 to 2 experienced, trained

and authorised personnel from the hand grips and /or the provided steering handles.

Panning movement of the turnstile mount / column can also be made by the personnel sitting on the

column/dolly when seated on the provided seats.

Vertical lift of the column is controlled via wireless or cable control operated by an experienced, trained and

authorised person.

Operation of the dolly/jib is only allowed within the limits and guidelines mentioned in this instruction manual.

The dolly must be operated on level, stable surfaces at all times or on dolly track. Whether operating or

moving the dolly on track or on a solid ground surface it is essential that the track or surface is completely

level, stable and free from obstructions.

When operating the dolly on track, ensure that the track is level, properly laid, constructed and supported.

The correct underlay must be used to ensure that the track and underlay are secured against moving,

slipping and collapse. Ensure that the underlay meets the specified support and stability requirements. Only

GFM Track or comparable track systems with a payload capacity of 1200kg / 2640lbs and a maximum track

runner distance of 640mm / 25inches (measured inside edge to inside edge) may be used.

Extreme caution if tracking on curved track (not faster than a slow walking pace)!

Use of the dolly on insert vehicles, camera cars or any motorised vehicle is not allowed. The

manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due to use of

the dolly on insert vehicles, camera cars or any other motorised vehicles.

Operation of the Dolly/ Jib:

The complete lift and panning range of the dolly/jib must be kept clear of obstructions at all times. A safety

clearance of 1m / 3' 3" must be observed on all sides of the dolly/jib during operation. Only authorised,

trained and experienced personnel are allowed to operate the dolly/jib. The dolly/jib may not be set-up or

operated under the influence of alcohol, drugs or any other intoxicating substances. The respective

protective clothing e.g. gloves, should be worn.

The dolly may not be used in the direct vicinity of high voltage power cables. To avoid accidents due to

misuse in the vicinity of high voltage power cables, Safety Guidelines especially BGV A1 and A2 (formerly

Page 4

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

3

VBG 1 and 4) as well as VDE regulations (especially 0105 part 100) must be adhered to. If the nominal

voltage cannot be determined, a minimum clearance of 5m / 16ft must be kept at all times.

Failing to do so can cause fatalities!

Personnel on board the jib's platform must use safety belts at all times. They should not make any sudden,

abrupt movements or lean out over the side of the platform. No loose objects may be stored or placed on the

dolly platform.

In the interest of safety, when operating or moving the dolly/jib, abrupt, sudden movements of the dolly

should be avoided. An element of risk remains by people moving in the operational range of the dolly/jib. The

dolly operator has to be trained on that and is only allowed to operate the equipment in a safe range.

Before operating the dolly/jib all connections, mounted accessories, safety pin as well as every connecting

bolt must be checked for a proper fit.

Dolly accessories:

For safety reasons only original accessories manufactured by GFM may be used with the dolly.

Procedure in case of accident or damage:

In case of accidents caused by disregarding the manufacturer’s instruction manual, please proceed as

follows:

o The manufacturer should be immediately informed of any damage to the dolly and the severity of the

damage. Damaged dolly parts should be sent to the manufacturer for evaluation, repair or

replacement.

Use of the dolly with damaged parts is not allowed. The manufacturer accepts no liability for damage

or injuries for incidents or accidents occurring due to the use of damaged parts on the dolly.

o In case of damage or accidents with injured people local applicable as well as employment property

right regulations may be adhered.

Safety Guidelines for dolly operation:

To avoid collisions, ensure that the columns lift range is free from obstructions!

When working with off-set arms ensure that the mounted payload is counter balanced! Never exceed the

manufacturers payloads

In an open space the wireless mode range is approx. 100m / 330yards

In general, the hand control unit should never be left on when not in use or when not under supervision.

To avoid unwanted movement of the column due to misuse or accidental activation of the rocker switch /

hand control unit, ensure that the main electronic switch is OFF when not in use or not under supervision.

The equipment must be handled carefully at all times.

Do not operate or drive the column without payload on the column. At least 1 person and camera

should be on the column when it’s moving.

Attention: Should the HCU software be older than versionr 3.8.5 or the electronic

be older than version 3.7.3 or if you gave a software where it is not

possible to check the version please note that after using the

Emergency switch the column must be calibrated (see page 39)

Page 5

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

4

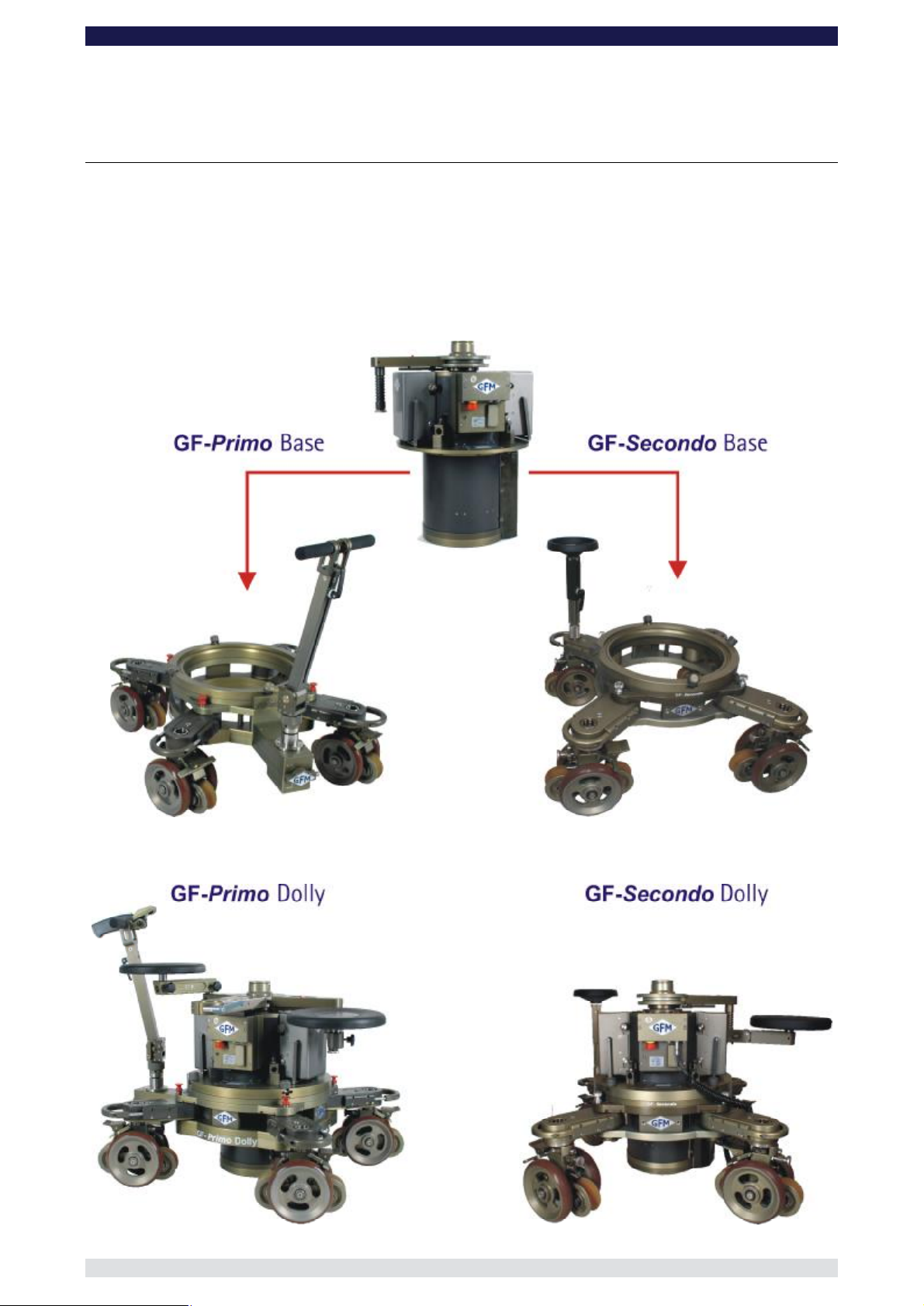

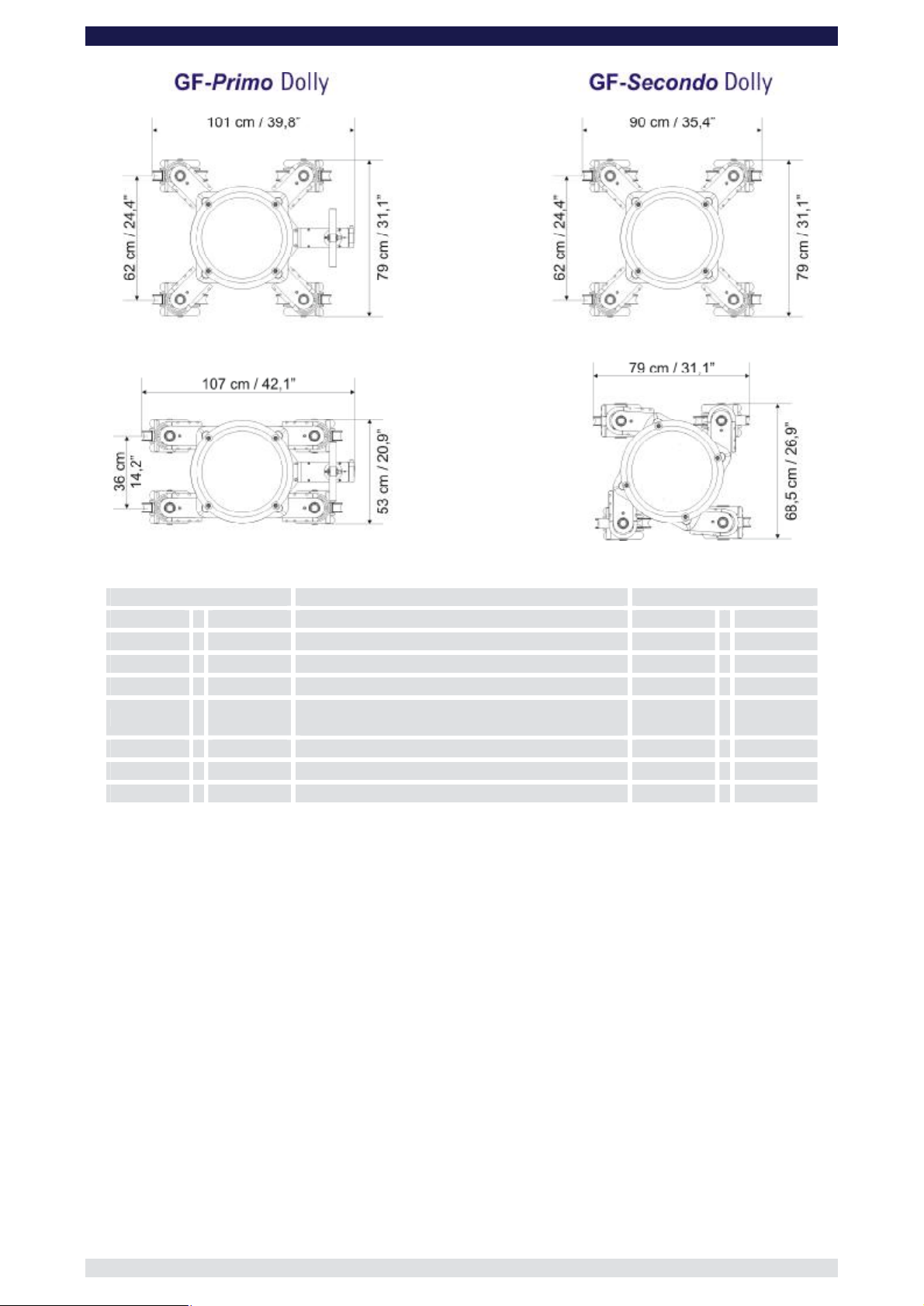

Technical Specs for GF-Primo - / GF-Secondo Dolly

The difference between the GF-Primo - and GF-Secondo Dolly is effectively the different

base dollies. The columns are identical.

The GF-Primo Base has a central "one touch" selector allowing for immediate, one

handed, switch over to crab, front or rear wheel steering. GF-Secondo Base Dolly can

also switch from crab, front or rear wheel steering but to do so, each wheel must be

adjusted individually. The GF-Secondo also has 2cm more ground clearance (column to

ground).

Page 6

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

5

2,5 sec Duration of column lift 2,5 sec

0 – 70cm / 0 – 27“ Lift range 0 – 70cm / 0 – 27“

140cm /

70cm /

250kg / 550lbs Maximum column lift capacity 250kg / 550lbs

900kg / 1980lbs

80kg / 176lbs Transport weight Dolly Base 69kg / 151lbs

68kg / 149lbs Transport weight column without batteries 68kg / 149lbs

54“ Maximin column height 142cm /

27“ Minimum column height 72cm /

Maximum column load capacity when fully

retracted (column movement not allowed)

900kg / 1980lbs

55“

28“

Page 7

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

6

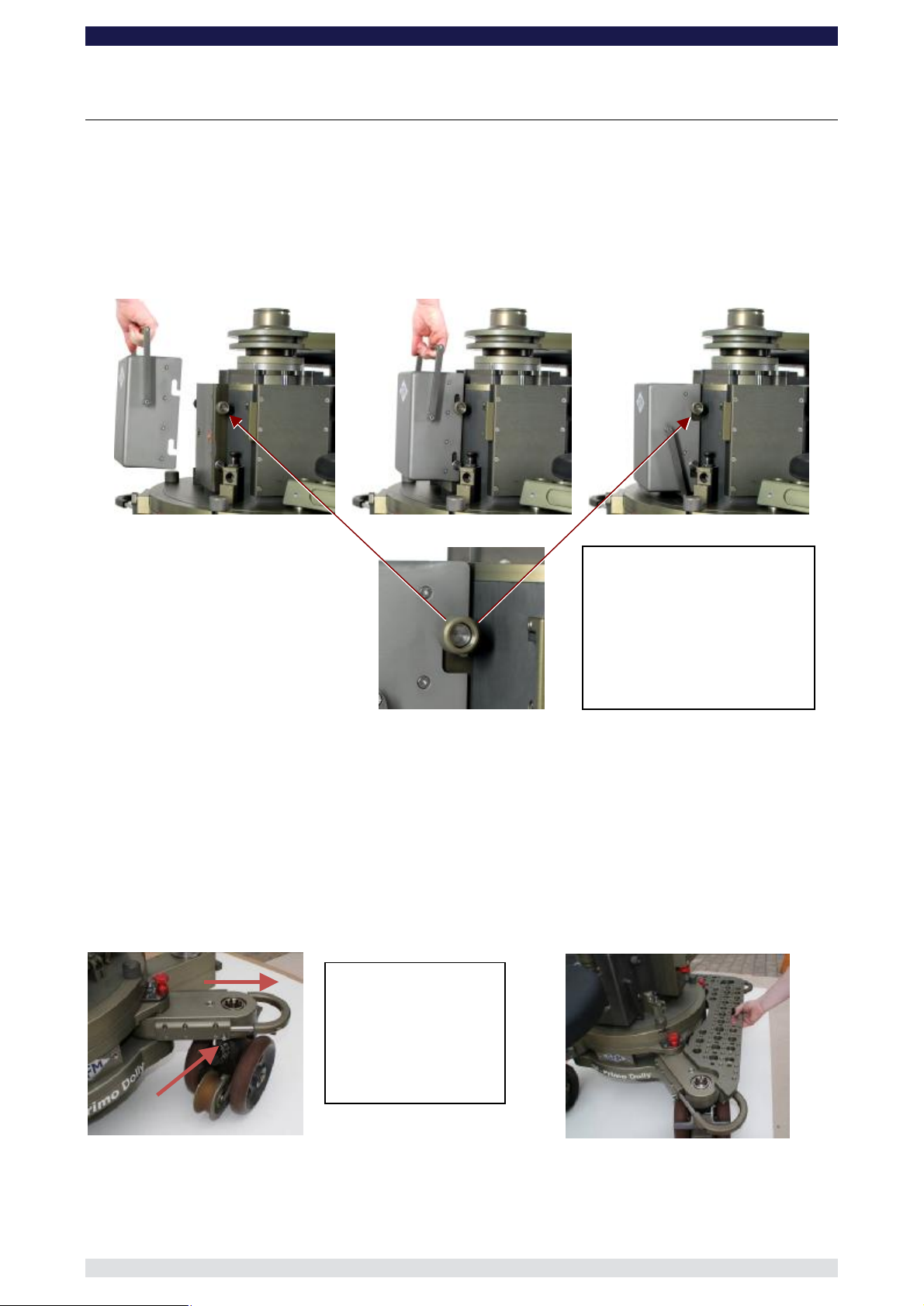

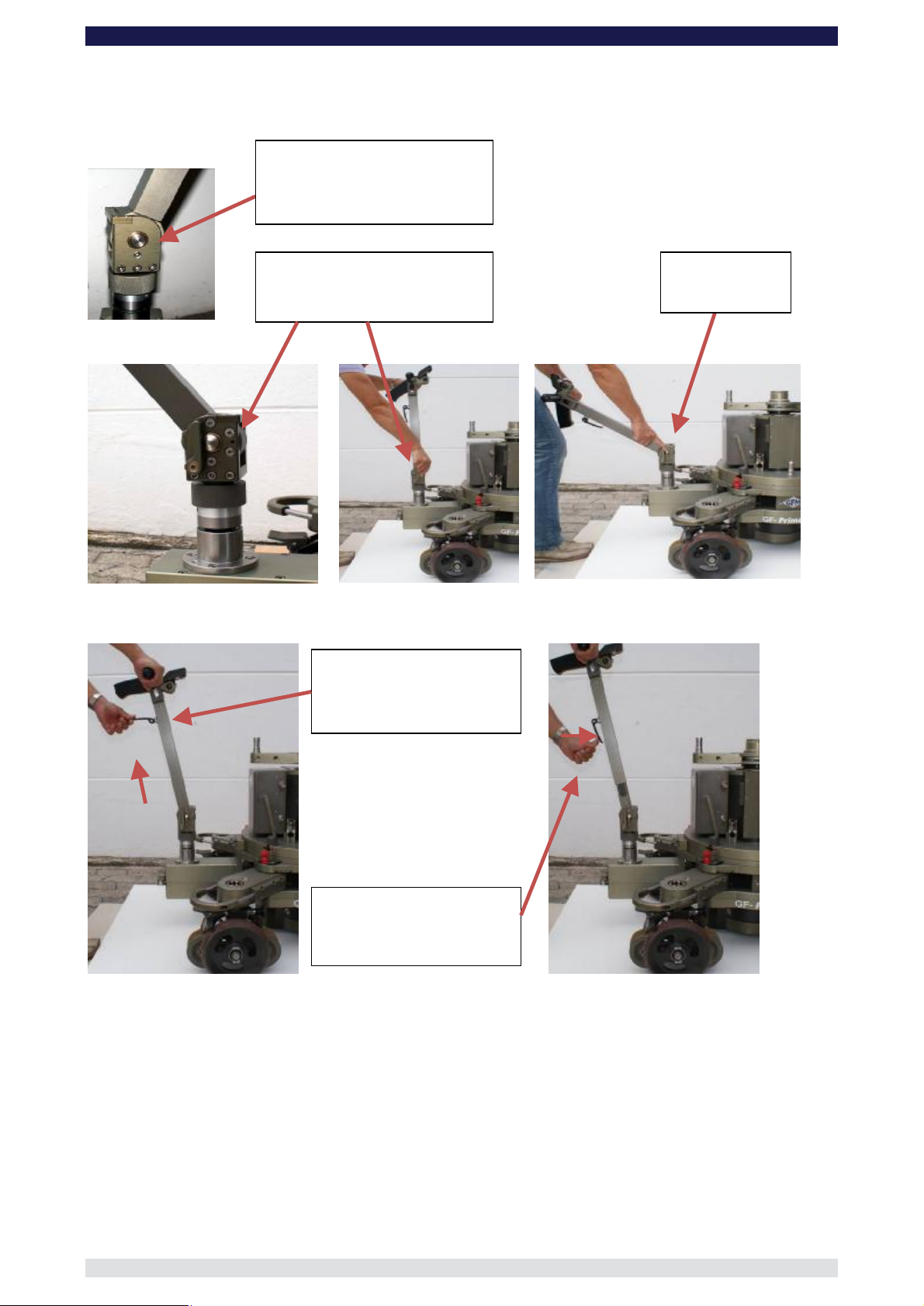

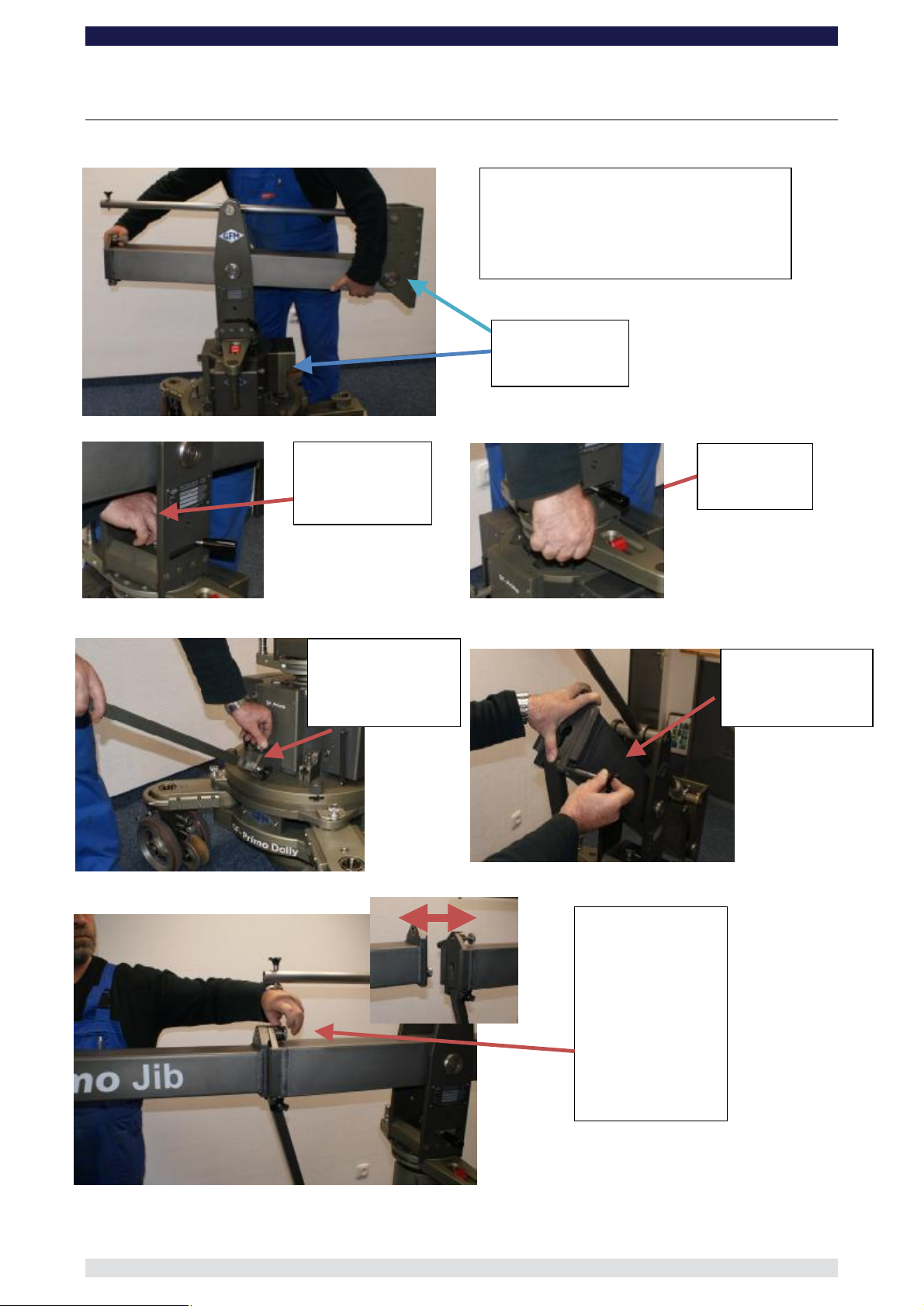

handle double

functions as a lock for

the platforms. Extend the

handle by pressing the

stainless steel button on

the left side of the wheel

arm. At the same time

The Base Dolly

Changing the batteries

The dolly’s’s batteries are connected to the column with a user friendly “drop & go” system.

The column requires 2 x 24Volt Battery units to function.

Centre the battery over the locking mount. Move the battery into position and drop it gently

onto the locking shaft.

Locking shaft & knob

Open the left and right

locking knob to mount the

battery. When in place,

hand tighten the knobs to

secure the battery.

Connecting the Platforms

The Standard Multifunctional Platform Set

The platform set consists of 4 units. Each platform is machined to provide a selection of

threaded (10mm & 3/8”) and non-threaded holes (12, 25 & 28mm).

3 of the units are identical and fit on any of the 3 sides of the dolly. The 4th unit is

machined slightly differently and fits only on the side of the dolly where the steering

gearbox is located.

The carry

pull the handle out.

Page 8

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

7

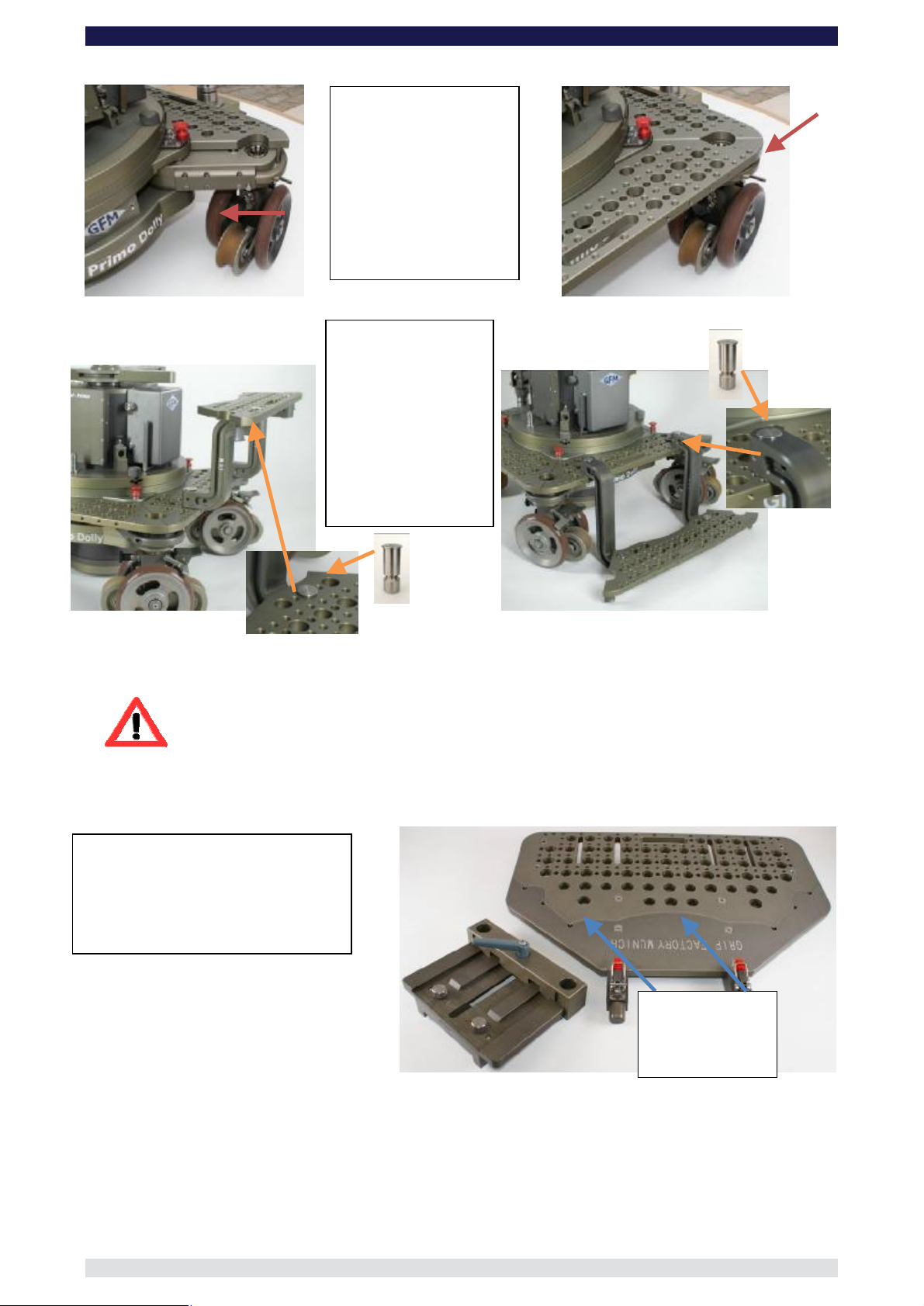

By using seat arm

extensions the

standard platforms can

also be combined to

form steps and low

Special “drop in” pins

are required. The pins

are inserted from top

to bottom and securely

bolted on the bottom

joint.

Attach the required

mber of platforms. To

secure them, press the

stainless steel button and

push the handle towards

the dolly. When the handle

is engaged in the locked

position you will hear an

audible click and the

button will be extended i.e.

unctional Hi/low

Platform can be dismantled by

unscrewing 2 bolts, allowing the

wider platform part to be mounted on

the base dolly as described on the

Remove the 2

locking bolts to

dismantle the

nu

not flush with arm.

platforms.

Attention: When using the platforms ensure that they are mounted and fitted

correctly. The platform must fit snuggly to the dolly frame with no gap

inbetween. Ensure that the steel pin on the locking handle is engaged

correctly as described above i.e. the steel pin must be visible!

Mounting the Low Platform System

The 2 part Multif

previous page

platform

Page 9

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

8

The mounting plate

can be bolted to the

dolly chassis on 3

sides. It self centres

secured with

2 x M10 bolts that

should be tightened

The height of the

platform mount can

be adjusted and

secured with the

grey locking lever.

Hand tighten

Max. payload

Attach

both snap

ull to open

securely.

and is

securely by hand.

locks

Insert platform

100kg / 220lbs

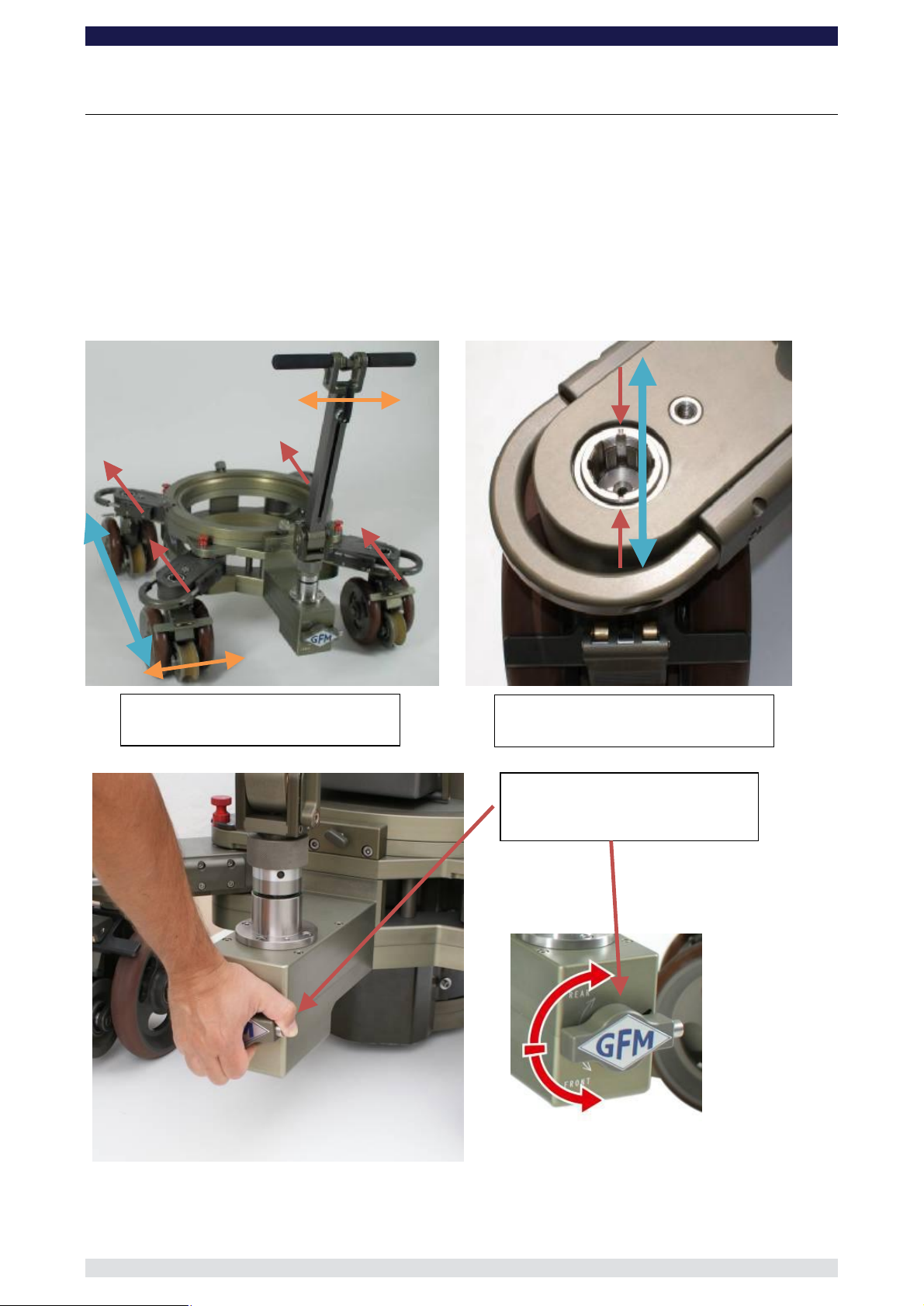

Wheel arm adjustment

Each of the 4 wheel arms has an individual locking mechanism to secure the position of

the wheel arms and ensure a stable, no-play base. To adjust the wheel arms to change

from, for example, standard to narrow gauge note the following.

P

position

Page 10

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

9

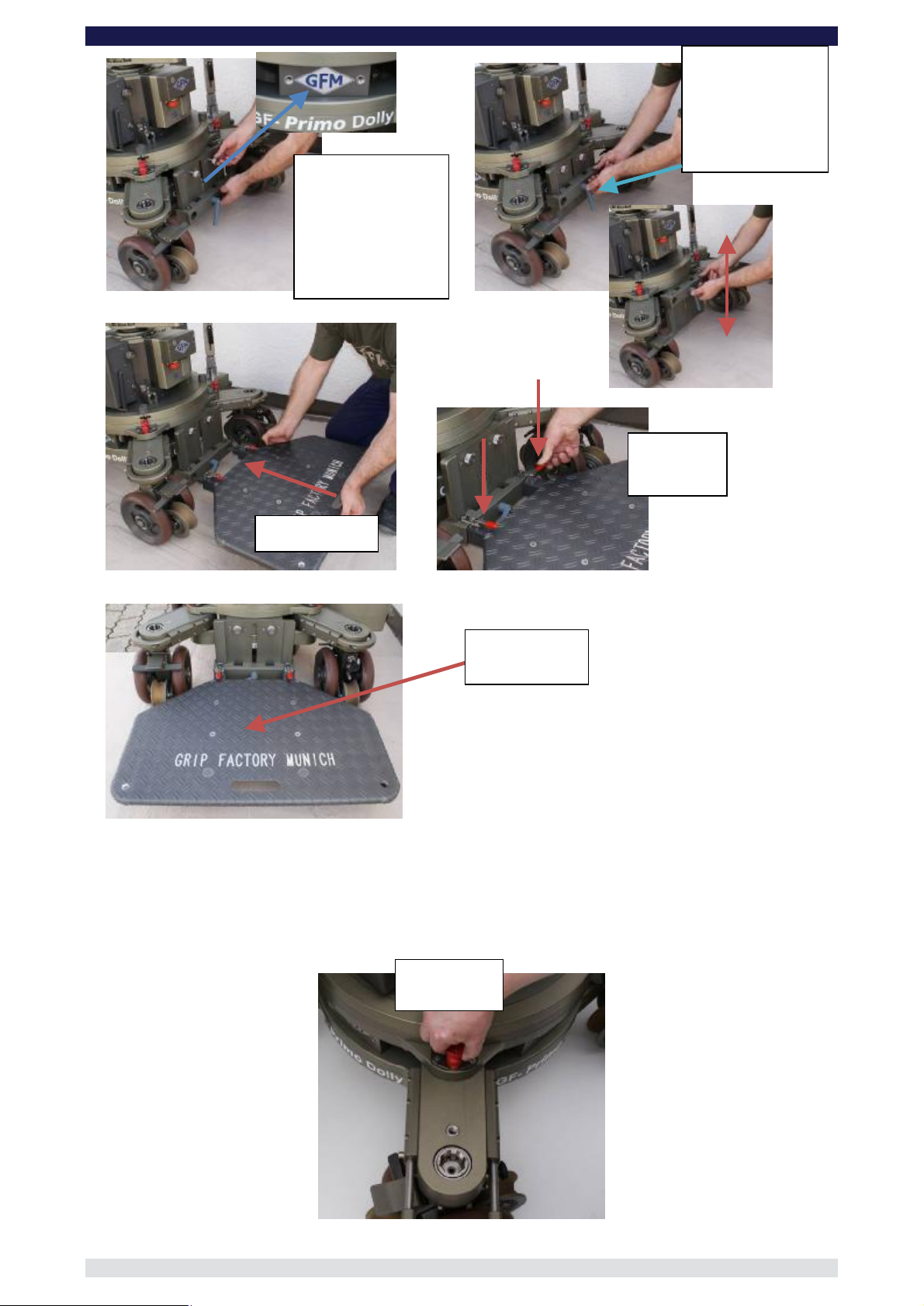

Hold the locking pin in the released

position and at the same time adjust the

wheel arm to required position.

When in position ensure that the locking

Insert the steering

handle into one of the

ns.

To reduce play, hand

tighten by turning the

locking sleeve

is fully inserted.

Connecting the Steering Handle:

The Steering Handle can be attached to each of the 4 wheel arms on the GF-Secondo as

well as the central steering gearbox on the GF-Primo.

5 steering positio

clockwise.

5 steering positions.

Page 11

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

10

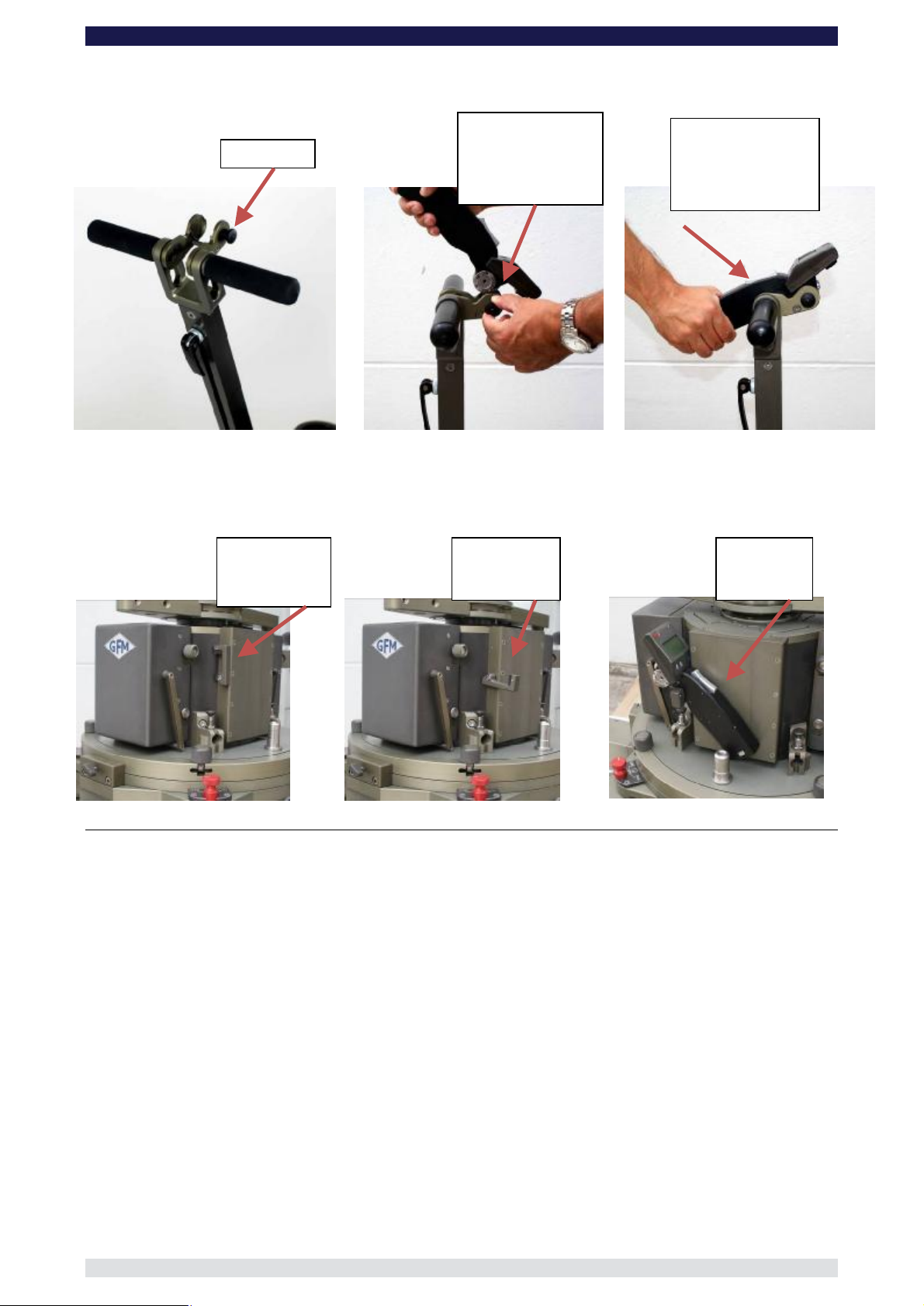

Release lever.

Push forward to

adjust angle and activate stepless

Release lever.

Pull back to set

angle

Drag adjustment:

se in

stepless angle mode i.e. release

To adjust the length of the

steering handle, open the

release handle and adjust to

When the steering handle is

in position, close the release

Adjusting the angle of the Steering Handle:

The GF-Primo’s Steering Handle offers individual height and angle settings. The angle can

be set as follows:

Tighten or loosen for u

lever pushed forward.

angle mode

Adjusting the length of the Steering Handle:

required height.

handle.

Page 12

Page:

11

Connecting the HCU to Steering Handle

e

locking pin and

insert the HCU

rosette into the

matching cradle.

Push the HCU

down so it fits

snugly in the cradle.

Adjust the angle as

When not in

use, fold in

To use, fold

down the

Insert the

HCU into

Hand Control Unit Rest:

Locking pin

the HCU rest.

GF-Primo / GF-Secondo Dolly System Instruction Manual

Pull back th

required.

HCU rest.

the rest.

Page 13

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

12

Press steel release pin and

wheels

rrect positioning of the steering

GF-Primo Steering modes:

To change from one steering mode to another first of all ensure that all 4 Combi-wheels

are pointing in a straight line as seen from the rear of the dolly

In each of the 4 steering rod mounts you will see 2 notches machined into each rim. The

notches should be in line with the actual gearbox. On the steering mount on the GF-Primo

gearbox you will also find the same markings and these should also be in alignment with

the gearbox. It is only possible to change steering mode when the wheels are aligned in

this starting position. If the wheels are out of position they must be reset as described

below.

Positioning of the Combiand steering rod mount

Co

rod mount and Combi-wheel

turn the selector

Wechsel des Lenkmodus

Steering mode selection

Page 14

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

13

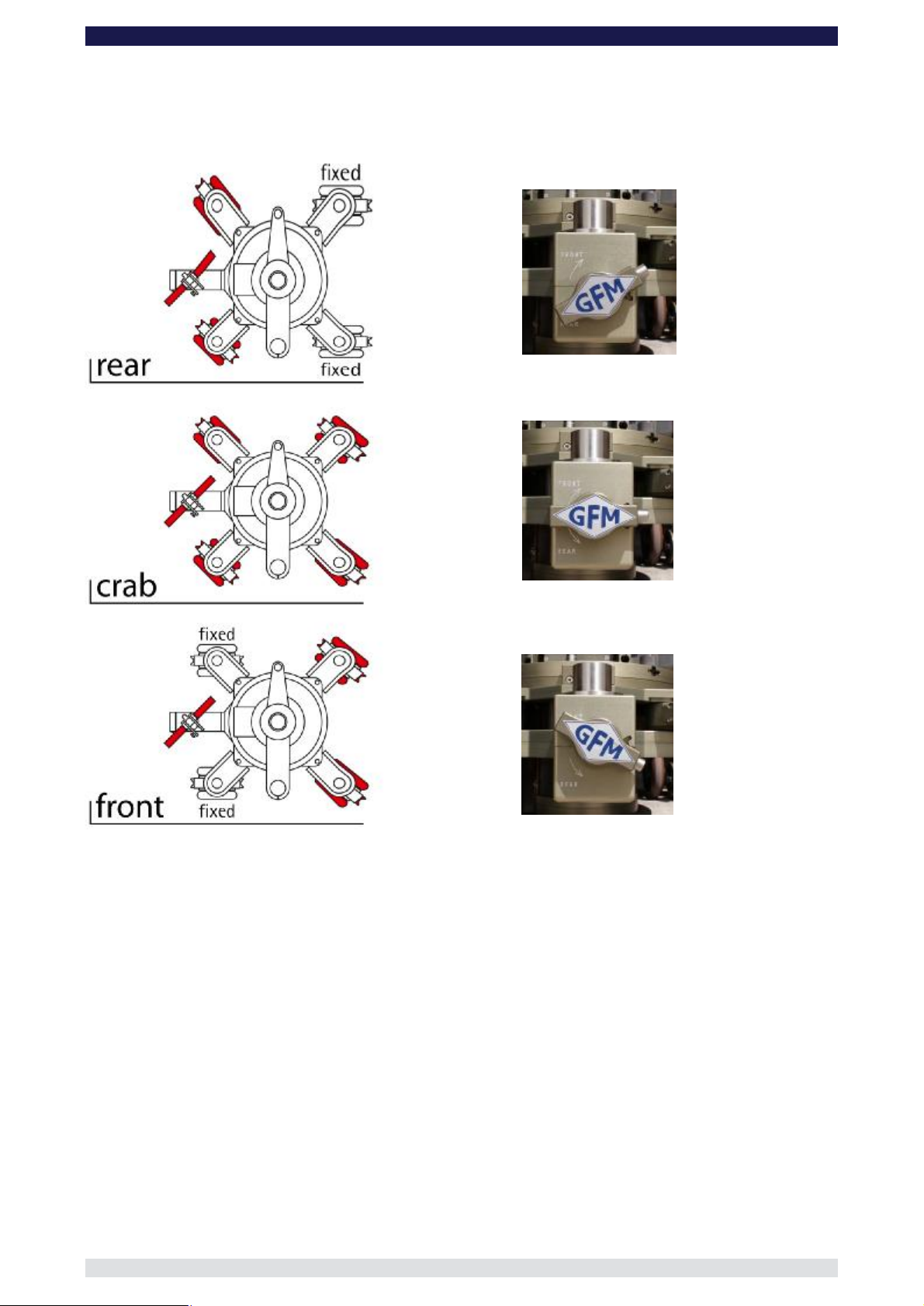

GF-Primo‘s 3 steering modes and selector position:

Page 15

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

14

SP1

-

Selector switch pointing

= wheel not turnable

SP2

-

Selector switch pointing side

SP3

- Selector switch pointing

downwards: Disconnected from

steering = wheel rotates freely i.e. on

GF-Secondo Steering modes:

Each of the 4 combi-wheels has an individual selector switch which enables each wheel to

be fixed, connected or disconnected from the steering mechanism:

Switch position SP 1 ⇒ Combi-wheel in fixed position

Switch position SP 2 ⇒ Combi-wheel steerable

Switch position SP 3 ⇒ Combi-wheel in free rotate

Attention: To change steering mode the top and bottom red

markers must be aligned!

Tip: Regardless of selected mode, the GF-Secondo Dolly can

be steered from any of the 4 steering points at any time.

upwards: wheel in fixed position

wards: Connected to steering

= wheel is steerable

Page 16

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

15

GF-Secondo’s three steering modes and their selector positions:

Page 17

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

16

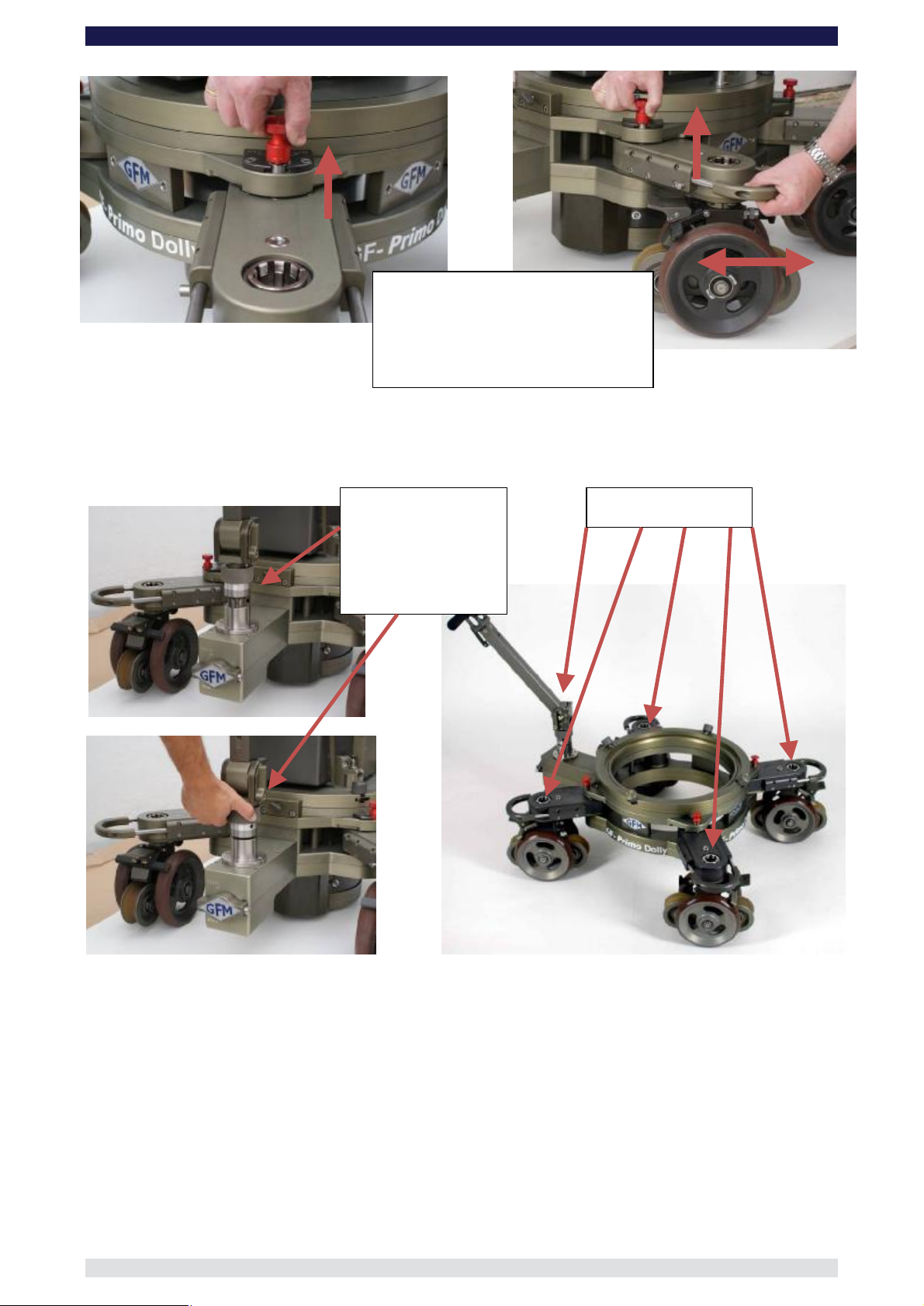

Combined Studio &

Track wheel brake

Kick down to lock the

Studio & Track wheel

To disengage the wheels from

the steering e.g. use on curved

track, simply pull out the locking

Locking pin

to

wheel

wheels

from the base, firstly disengage

the wheel from the steering and

then pull the lower smaller

Note: To remove the wheel the

dolly must either be jacked up or

turned upside down. If jacked

p, hold the wheel securely

when pulling the locking pin as

the wheel will drop.

Combi-Wheels – GF-Primo & GF-Secondo:

Combi-wheel Brake

Each Combi-wheel has a kick down brake for the studio /pneumatic wheels. The 2 Combiwheels at the rear of the dolly also have integrated track wheel brakes attached to the

standard wheel brake.

on rear 2 wheels.

brake.

Disconnecting the wheels from the steering:

for steering

Locking pin

remove Combi-

To remove the Combi-

locking pin out.

u

pin and turn 90°

Page 18

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

17

When driving onto track using a drive

e that the track wheel brakes

wheels are at the rear of

the wheel as it goes onto the track. If not

the brake will engage and stop the dolly

Track wheel

brakes at the rear

Locking pin to

wheel

Selector switch

pointing downwards:

Disconnected from

steering = wheel

Dolly set the selector switch at position SP3. Then pull

the Locking Pin to remove the wheel unit by moving it downwards. Remove carefully and with caution! Hold the

wheel securely so it doesn’t drop off!!

wheels either support the base from underneath allowing sufficient

clearance to remove the wheel. Alternatively, turn the base upside down and lift the wheel off. Remove carefully

Disconnecting the GF-Secondo Combi-wheel from the steering and

removing the Combi-wheel unit

To remove the GF-Secondo Combi-wheels from the Base-

Attention: Before removing the Combiand with caution!

rotates freely i.e. on

Position SP3

remove Combi-

Going on Track:

ramp, ensur

on the Combi-

from moving.

Page 19

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

18

Attach the bracket and

3 x

Turnstile Brake:

Push towards

centre to open, pull

towards seat to

Seat adjustment:

Pull towards seat to

open. Push

towards centre to

lock.

Collision protection:

Seat arm moves

upwards in the event

The Multifunctional Turnstile Mount:

A maximum of 4 brackets can be attached to the turnstile mount. The adjustable seat arm

mount is not removable.

secure tightly with

M8 bolts.

lock.

of a collision.

Page 20

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

19

lifting

position with carry

bars pointing down.

Remove the column

To remove the carry

bars release the

locking pin and pull

out.

Insert the 4 carry

bars ensuring that

the locking pin are

the 4 column

locking nuts and tilt

Removing the Column with the Carry Bars:

engaged fully.

Alternative

E.g. stairs

Open

them back.

carefully by lifting.

2 persons!

Page 21

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

20

e Selector

Hand Control

Hand Control Unit Components

The following describes the individual button functions and components on the Hand Cotrol Unit.

On/Off (emergency Off button)

Status-LED

Channel Selector

Display

RMP-Button

MARK / LIMIT-Button

Radio signal sender

Handle Rosette

SPD-Button

Rocker Switch

Programm and Mod

Button

Connector for

Hand Control

Cable

Battery for

HCU Battery Lock

Unit

Page 22

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

21

Electronic Unit Components

The following describes the electronic components:

Emergency Off Switch!

Press to deactivate

electronic!

Must be extended to

allow operation!!

On- / Off-Switch with Status-LED

Connectors for Hand Control Cable

Cover for Back Up Drive System Channel Selector

Getting started

In general, when the dolly arrives from the factory it will be set up to be switched on in either

Wireless Mode or with Cable connection.

To switch on the dolly requires the following:

In Wireless mode: Dolly batteries must be charged and connected correctly (see page 7)

Electronic and HCU must be on the same channel (see page 23)

HCU battery is charged and inserted into the HCU

The Emergency Switch must be off i.e. switch extended (see page 23)

In Cable mode: Dolly batteries must be charged and connected correctly (see page 7)

Electronic and HCU must be connected via cable (see page 25)

The Emergency Switch must be off i.e. switch extended (see page 23)

Starting off

In wireless mode: Check that Electronic and HCU are on the same channel.

Turn dial to select

channel

Page 23

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

22

Switch on by first pressing the On/Off Switch on main electronic housing. Wait a few seconds until the

LED on the switch starts blinking red/green, then press the On/Off button on the HCU. The display will turn

red, then blue. The column is on.

LED off

Display off

In cable mode: Switch on by pressing the On/Off button on the HCU. The display will turn red, then blue. The

column is on.

Note: Check to make sure the Emergency OFF Switch is not active. It should be extended, not

pushed in.

LED red

Display red

LED green / red

blinking (ready)

Display blue (ready)

Page 24

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

23

Column scale/ position shown in

RMP = Ramp (sets strength of

acceleration and deceleration of

SPD = Speed (sets speed of

columns travel: slow

→

00;

To connect the cable from the HCU to Electronic:

Cable connection

Marking Fischer

Plug

Hand Control Unit Display

Selected User = U1

There is a choice of 4 users.

U1 to U4,

column: hard→00; soft→22)

HCU Mode: N=Normal,

E=Enter, M=Markers

Column height / position

Voltage of columns batteries

mm (also available in ft or %)

Motor temperature in °Celsius

Limit to restrict the columns lift range

(e.g. from 200mm – 500mm)

HCU Battery status

Page 25

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

24

Adjusting the Speed or Ramp

To adjust the speed or ramp press and hold the respective button and press the Rocker

Switch up or down to adjust and select the required speed or ramp

Adjusting the Ramp

Adjusting the speed

Generating Movement

For standard work situations where it is required to just move the column up and down and vary speed and

drive ramps, the HCU should be set on either of the 4 Users and the HCU mode N=Normal should be

selected.

To select the HCU Mode

On the underside of the HCU is the HCU Mode Selector Button. Simply press to

scroll through and select the required mode.

Mode N=Normal

HCU Mode selector

button. Press to

Mode E=Enter Mode M=Marker

Mode Selector

Page 26

Page:

25

Setting a new lower and upper limit

Select N Mode. Position the column at the new lower position e.g. 200. Press the blue LIMIT Button

on the HCU and hold it. Using the Rocker switch drive the column to the new upper position e.g.500.

Release the Limit Button. The column will now remain within the range of 200 to 500.

To cancel the limits press the LIMIT Button

GF-Primo / GF-Secondo Dolly System Instruction Manual

Setting new lower and

upper LIMIT´s

The HCU Modes

Mode NORMAL N ⇒ offers standard movement with selection of speeds and ramps. Lower and

upper limits can be set.

Mode ENTER E ⇒ Entering, editing, deleting and replacing 6 Markers. Setting up the shot.

Mode MARKER M. ⇒ Replaying the shot with variable speeds and ramps. Allows you to manually

drive the column from Marker to Marker.

Mode N

Mode E

Mode M

Page 27

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

26

Button to add or over write

Button to delete set

Currently selected or next

Button to select set or to

Mode ENTER “E”

MARKER

ADDMARKER‘s

Explanation of the individual display symbols:

CLRMARKER’s

Already set MARKER‘s

MARKbe set MARKER‘s

Currently selected MARKER:

Indicates the selected MARKER that can be set, over written or deleted.

Already set MARKER:

MARKERs which have already been set are shown beside the lift range display.

MARK-Button:

With the MARK-Button already set MARKERs can be selected and then with the ADD or

CLR buttons be over written or deleted.

CLR-Taste:

With the CLR-Button already set MARKERs can be deleted.

ADD-Taste:

With the ADD-Button MARKERs can be set or over written.

Setting individually adjustable MARKERs

Page 28

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

27

To set MARKERs, Mode E must be selected.

Setting MARKERs in a numerical sequence:

Press the MARK-Button until the digit 1 shows on the display as the currently

selected MARKER.

By using the Rocker Switch drive the column to the required height and stop in this

position.

Now press the ADD-Button, to allocate MARKER 1 to this position.

The digit 2 will show on the display as the next MARKER that can be set.

Again, by using the Rocker Switch drive the column to the required height and stop

in the required next position.

Now press the ADD-Button again to allocate MARKER 2 to this position.

MARKERs 3 to 6 can be selected in the same manner.

Setting MARKERs

Page 29

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

28

Over writing MARKERs:

Already set MARKERs can be over written as follows:

By pressing the MARK-Button, select the MARKER number you want to over write

e.g. MARK 1 (Height 200 mm)

By using the Rocker Switch drive the column to the new required height e.g. 250mm

Now press the ADD-Button to reset the MARKER 1 from 200mm to 250mm.

Over writting the set

MARKER

Deleting MARKERs:

To delete set MARKERs proceed as follows:

By pressing the MARK-Button select the number of the MARKER you want to

delete, e.g. MARKER 4.

To delete the selected MARKER, press the CLR-Button.

Deleting MARKERs

Note: The deleted MARKER doesn’t necessarily have to be reset. The

software recognizes the digit is missing and will allocate the next

consecutive MARKER, in this case from 3 to 5.

Page 30

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

29

Column scale/ position shown in

MP = Ramp (sets strength of

acceleration and deceleration of

column: hard

→

00; soft

→

22)

SPD = Speed (sets speed of

columns travel: slow

→

00;

There is a choice of 4 users.

Mode NORMAL N

In N-Mode the column can be driven in the selected Ramp RMP and Speed SPD. (To set RMP and SPD see

page 18, Adjusting the Speed or Ramp).

The complete lift range of the column can be used or based on individual requirements the

lift range can be restricted by setting a lower and /or upper limit with the LIMIT-Button.

The following picture shows the display in Normal Mode N upon activation:

Selected User = U1

R

U1 to U4,

HCU Mode: N=Normal,

E=Enter, M=Markers

Column height / position

Voltage of columns batteries

mm (also available in ft or %)

Motor temperature in

°Celsius

Limit to restrict the columns lift range

(e.g. from 200mm – 500mm)

HCU Battery status

Page 31

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

30

Explanation of the individual display symbols as :

Selected User:

The HCU offers a choice of 4 individual Users ⇒ U1, U2, U3, U4. In each of the 4 Users, settings such as

RMP, SPD, set Limits as well as Markers can be entered and recalled.

HCU Mode:

This shows the current operational mode for the column. There are 3 Modes available, Mode N = Normal, E

= Enter and M = Marker. The letter of the selected mode is high-lighted in black when operational.

Attention: Should none of the Mode letters be activated press the HCU Mode selector

button found on the bottom / underside of the HCU.

Column height / position:

The lift range of the column is shown in 2 ways. One method is the vertical bar display (the higher the bar,

the higher the column). The other is the digital numerical display showing in mm, imperial or %. The columns

range is 0 to 705mm.

Column Batteries Voltage:

This shows the voltage of the respective battery. By standing in front of the electronic housing and looking at

the HCU display, the battery on the left hand side of the display represents the battery on the left side of the

column. In turn the battery on the right hand side of the display represents the battery on the right of the

column.

Note: A fully loaded battery will show approximately 26 Volts. During use the voltage will naturally

become lower so that after approximately 200 lifts the voltage will drop below 20 Volts (when

the column is moving).

When a battery drops below 19 Volt the HCU display as well as the respective battery

symbol will flash in red. This signals that the battery needs to be changed and charged.

Should the battery voltage drop below 17 Volt the column will automatically switch off and

the display will show „DOLLY BATTERY LOW“.

Attention To ensure the best performance it is advised to use fully charged batteries. When the

voltage is under 19 Volts a performance drop can be expected.

Motor temperature:

The motor temperature is also shown on the display. It should be noted the temperature shown is that of the

outside of the motor in its isolated housing and not the ambient air temperature

Note: A safety guard is installed to protect the motor from thermal overload:

If, during operation, the motor temperature exceeds 55°C the HCU display will flash red and

Battery identification

Page 32

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

31

the temperature digits will also blink. This signals the movement of the column must be

reduced or stopped. Upon reaching a temperature of 60°C the column will automatically

switch off and the display will show „MOTOR TEMPERATURE HIGH“.

Tip: To protect and ensure a long lifespan for the motor temperatures above 55°C should be

avoided.

Should a temperature of 55°C be exceeded, reduce or stop column movements for 30 to 60

minutes to allow the motor to cool down.

Attention: Over heating of the motor can be caused by over loading the column or driving the column

without load.

Note: During operation the generated heat by the electricity flow is at its highest in the centre of the

motor and spreads to the outside housing. The temperature is measured on the outside of

the motor which can be up to 30°C lower than the inner kern of the motor. Therefore by an

over load of the motor at 60°C it must be shut down as with an inner temperature of 100°C

permanent damage can be caused.

Limit:

LIMIT allows the operator to restrict the columns lift range by resetting the lower and / or upper end stops.

The lift range can be changed from its standard 0 to 705mm to, for example, 200 to 500mm. When reset, the

column can only be moved within the new range until it is or due to a Mode change the column is in a

position outside the new LIMIT range

Hand Control Unit HCU Battery Display:

In wireless mode the HCU is energized with its own battery and not with the columns batteries. The HCU

battery is inserted into the rear of the HCU. The voltage status of the battery is shown on the HCU display as

a battery symbol.

Ramp and Speed:

The columns speed and drive ramp may be adjusted in grades of 23 levels:

Speed Slow → Level 00 Fast → Level 22

Rampe Hard → Level 00 Soft → Level 22

(Longer acceleration and deceleration)

Page 33

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

32

ct required

Currently recorded or set

Mode MARKER M

In M-Mode it is possible to activate the recorded MARKERS. Between each MARKER it is

possible to vary direction, speed, and alter the ramp. Upon reaching each of the 6

MARKERS the column will stop automatically.

Explanation of the individual display symbols:

Set MARKERs:

MARKERs that have already been set or recorded are graphically shown beside the lift

range bar on the display.

Current column position and lift range:

The current column position and driven lift range are shown on the lift range bar display.

The available lift range between 2 positions will also be displayed. When MARKERs are

set, the bar display will indicate the available lift range between the MARKERs.

MARK-Button to select required MARKER:

With the MARK-Button it is possible to select the next required MARKER and if needed,

more than one MARKER can be skipped.

Working in M-Mode

In M-Mode up to 6 individually recorded positions called MARKERS can be utilized to

construct the required shot.

The following explains the operation in MARKER-Modus:

After recording the required MARKERs in E-Mode switch to M Mode by pressing the

Program and Mode Selector Button on the underside of the HCU.

Lift range bar display

MARKERs

Current position and lift range

MARK-Button to sele

MARKER

Page 34

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

33

Settings such as Speed and Ramp are accessible and even different Speeds and

Ramps can be selected between the various positions.

Tip: In between the various MARKERS it is possible to make manual

moves and to control the speed by pressing the Rocker Switch, more

or less to go faster or slower.

By using the Rocker Switch drive to the first MARKER, with the lowest, flashing

digit, e.g. MARKER 1.

Note: After changing to Mode M, the lowest numerical digit will be suggested

as the first MARKER and will blink. As soon as the first position is

reached, the second or next MARKER will be indicated through

flashing and the lift range between these 2 positions will be set.

Attention: By pressing the MARK Button you can select other MARKERs as the

next position.

Selecting MARKERs

Press the MARK Button and use the Rocker Switch to move to the flashing digit /

MARKER.

Tip: The present height is shown on the display with the numerical display

and on the other hand with the shaded vertical bar display. The

direction of the next position is visible.

The column can now be driven in the selected Speed and Ramp and upon reaching

the MARKER it will stop automatically. The next MARKER can recognised as the

respective digit will blink and the vertical height bar will show the new lift range.

Tip: As long as the next MARKER is not reached, movement between the

2 respective MARKERS is not restricted so direction or speed changes

are possible.

Page 35

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

34

Emergency Operation of the Column

The GF-Primo Dolly’s electronic is equipped with a back-up systems to enable movement

of the column in an emergency situation.

Emergency situations are:

o Defective or non-functioning electronic (HCU cannot operate the electronic)

o Defective or lost HCU

Attention: Emergency operation is not for working with! Using the column with a under

load with mounted camera or camera operators is not allowed!

Attention: As soon as the emergency switch is activated the column moves with a

preset speed and NO Ramp. Ensure that no equipment or persons are on the

column. Jib arms etc must be dismantled prior to activation of the emergency

switch. Working in emergency mode is not allowed!

To activate the emergency mode proceed as follows:

Using a 2.5mm Allen Key, remove the cover of the emergency switch by

unscrewing the 4 bolts.

Upon removing the cover, 3 multi-point connectors are visible whereby there is a

plug inserted in the top connector. For normal operation the plug must be inserted

into the top connector!

Emergency Switch Cover Connector for normal operation

Page 36

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

35

In emergency mode, if the column needs to be moved

§ upwards, insert the plug in the middle connector.

§ downwards, insert the plug in the lower connector.

Attention: When inserting the plug do not clamp or jam any cables!

Note: The plug has an anti-twist protection and inserts in one direction only.

Press the hidden emergency button found in the round hole at the bottom of the 3

connectors. The column will move in the respective direction according to where the

plug is positioned.

Plug for upward emergency mode

Plug for downward emergency mode

Attention: When replacing the cover ensure that the emergency plug is inserted into the top

connector as the cover cannot be mounted if the plug is in another position.

Page 37

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

36

Cable connection from HCU

alignment marking

button

Synchronizing the Hand Control Unit and Column

In general, when delivered, the electronic and HCU will already be synchronized and both units will be

selected to the same channel to ensure that wireless mode can be used.

If however, the HCU or electronic unit are replaced, the new unit must be synchronized with the original

opposite unit i.e. if the HCU is replaced it must be synchronized with the original electronic.

Attention: In wireless mode, only 1 HCU unit can be synchronized with the electronic at any one time.

To use a different HCU requires it to be firstly synchronized! To revert back to the first HCU

requires it to be re-synchronized.

Connect the HCU to the electronic with the cable and switch on the column using the On/Off switch (red

button) on HCU.

Tip: When connecting the Fischer Plug align the red dots

Display off.

Press „On“

Cable connection

to Column

Note the

on Fischer Plugs

Red dots

After pressing the

„On“ button the

display turns red

Display blue (ready)

Page 38

Page:

37

Calibrating the column

The column will need to be calibrated :

o After a service or repair

o After a software update

o After the column is crashed / driven against an object / hit the mechanical top or bottom of

column lift range

o After using emergency switch

Calibration procedure

Press and hold the SPD-button, then switch the column / HCU on. As soon as the HCU LED is on

the SPD-button can be released.

The Display shows „CAL DOLLY CONTROL“.

Press the CAL button (RMP) button to begin.

The column will automatically drive to its lowest position and then to the maximum height. Upon

reaching the maximum height press EXIT.

Press SPD and On.

Then press CAL to

begin

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page 39

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

38

Trouble Shooting

The following describes some possible errors and the solutions to correct the errors.

Error:

Dolly and HCU are not functioning in wireless mode

Solution:

Check

o Are the HCU and column equipped with wireless modules?

o Is the emergency OFF Switch inserted into the off position? If so, twist clockwise

to deactivate.

o If the HCU battery is in place. The wireless mode does not work without battery.

o Are the HCU and electronic synchronized? If not, connect via the HCU cable.

o Are both the HCU and electronic sending and receiving on the same channel?

Error:

In wireless mode there is a disturbance in the movement of the column.

Solution:

Select the next or any other channel e.g. 4.

If this doesn’t help, change to cable operation.

Check the battery voltage with a loaded column. Should the voltage fall below 19V replace

or charge the batteries.

Check the motor temperature. In general terms the following can be said about the electromotor:

The hotter the motor becomes, the higher the performance loss. Should the motor reach a temperature of

60°C the column will shut down automatically to avoid permanent damage. However, it is suggested to avoid

use of the column when the temperature exceeds 50°C.

If the above solutions do not result in an improvement of the columns performance please service the

column (see “servicing the column”).

Error:

Disturbance of movement during cable operation.

Solution:

Check the battery voltage with a loaded column whilst moving up and down. Should the

voltage fall below 19V replace or charge the batteries.

Check the motor temperature. In general terms the following can be said about the electromotor:

The hotter the motor becomes, the higher the performance loss. Should the motor reach a temperature of

60°C the column will shut down automatically to avoid permanent damage. However, it is suggested to avoid

use of the column when the temperature exceeds 50°C.

If the above solutions do not result in an improvement of the columns performance please service the

column (see “servicing the column”).

Page 40

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

39

Error:

It’s not possible to switch on the electronic / column.

Solution:

Is the emergency OFF Switch inserted into the off position? If so, twist clockwise to

deactivate.

Check that the batteries are charged and connected correctly to the column.

Remove the batteries from the column and check the battery poles on the column. They

should be sticking out from the connection plate and not flush with it. Reconnect the

batteries and check the connection. The top of the battery housing should be flush with the

column.

If the electronic was removed, double check to make sure it is connected correctly. The

electronic housing must be flush with the connection plate on the column.

Concerning operational mode:

Wireless mode:

Press the on switch on the electronic for approx. 5 seconds.

In wireless mode always activate the electronic, then the HCU.

In wireless mode the HCU and electronic must have been synchronized prior

to use. Synchronization must take place when the HCU is exchanged or

replaced. (see „4.1 Synchronizing the HCU and Column on page 8)

Cable mode:

The column can be switched on directly with the HCU.

Error:

The HCU cannot be switched on or keeps switching itself off (although the electronic is

switched on):

Solution:

Check the operational mode!

In wireless mode:

Check if

o the electronic is switched on. In wireless mode it must be switched on first.

o the emergency OFF Switch is inserted into the off position. If so, twist clockwise

to deactivate.

o the HCU is equipped for wireless operation and not that it’s only equipped for

cable operation.

o the HCU battery is in place. The wireless mode does not work without battery.

o both the HCU and electronic are sending and receiving on the same channel.

Before operating the column and the HCU for the first time it is necessary to synchronize

both units.

Cable mode:

Check if

o the emergency OFF Switch is inserted into the off position. If so, twist

clockwise to deactivate.

o the cable is connected correctly.

o the connectors are damaged (broken or bent pin).

o the same problem occurs with a different cable.

Page 41

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

40

Error:

Column and HCU don’t operate in cable mode.

Solution:

Check if

o the emergency OFF Switch is inserted into the off position. If so, twist

clockwise to deactivate.

o the cable is connected correctly.

o the connectors are damaged (broken or bent pin).

o the same problem occurs with a different cable.

o the battery poles on the column are extended and not flush with column.

o the batteries are charged.

Error:

The column cannot be calibrated.

Solution:

Check if

o the correct button combination is being pressed to activate the calibration mode

(see „4.2 “calibrating the column” on 10).

o the emergency OFF Switch is inserted into the off position. If so, twist clockwise

to deactivate.

o the batteries are charged.

Check the operational mode!

Wireless mode:

Check if

o the electronic is switched on. In wireless mode it must be switched on first.

o the HCU is equipped for wireless operation and not that it’s only equipped for

cable operation.

o the HCU battery is in place. The wireless mode does not work without battery.

o both the HCU and electronic were synchronized (see „4.1 Synchronizing the

HCU and Column on page 8 )and that they are sending and receiving on the

same channel.

If the above solutions do not result in an improvement change to cable mode and repeat the calibration

procedure.

Cable mode:

Check if

o the cable is connected correctly.

o the connectors are damaged (broken or bent pin).

o the same problem occurs with a different cable.

Error:

The calibration mode disrupts by itself during the procedure:

Solution:

Change from cable to wireless mode or vice versa, then try again.

Page 42

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

41

Error:

Upon switching on the column an incorrect height is shown!

Solution:

Calibrate the column.

If this doesn’t solve the problem and the error is still present, repeat the procedure.

Error:

Display is red:

Solution:

If the display is red it can have a few reasons and in general it is not necessarily an error

but also a signal.

If the display turns red it can mean either

o the connection to the electronic is disrupted.

o the motor temperature is too high.

o the battery voltage is too low.

In these cases

o in wireless mode switch both units to the next higher channel and check if there

is contact between both units.

o Check the load on the column and stop operation to enable the motor to cool

down.

o exchange the batteries and recharge the used batteries.

Technical specifications are subject to change without notice!

Page 43

Page:

42

ASSEMBLING THE GF-Primo Jib:

Insert the l

ocking

pin to connect the

middle section to

Fit the connection

rod onto the steel

pin and hand

tighten the locking

Secure by

Secure the

locking bolt by

turning it into

adapter

Place the middle section of the GF

-

Primo

Note: the front of the jib should be

mounted on the same side as the

Jib front and

Connect the rear

section to the

middle section by

joining the key link

pin to the slot and

Hand tighten the

locking bolt and

secure by

tightening the

the Euro-

GF-Primo / GF-Secondo Dolly System Instruction Manual

Jib on to the column’s Euro-adapter.

electronic housing.

electronic

housing

pulling

locking lever

the rod.

dropping down.

locking lever.

Page 44

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

43

The front plate of the

jib has 4 threaded

holes where the

mounting bolt is

inserted depending on

which platform

E.g. for low position.

Screw the mounting

bolt into the lower

Mount the High/Low

Rig onto the mounting

Attach the weight

triangle to the rear

of the arm by

aligning the hole

for the weight rod

over the respective

hole on the rear

arm and inserting

the weight rod.

Ensure that the

weight rod is the

me length on

Connect the

parallelogram rod into

the parallelogram rod

on the middle section

and secure with the

locking pin.

Connect the

parallelogram rod to

the parallelogram rod

on the weight triangle

and secure with the

locking pin.

sa

both sides.

position is required.

bolt

hole.

Page 45

Page:

44

To mount the

High/Low Rig in the

gh position move

the mounting bolt to

Inser

t the locking bolt

and secure with the

Change the position

of the mounting bolt

on the High/Low Rig

Mount the platform

and insert the locking

bolt and secure with

To mount the

High/Low Rig in the

high position move

the mounting bolt to

Mount the High/Low

Rig onto the mounting

bolt and push it

upwards until the

locking bolt is in line

Insert the locking bolt

and secure with the

hi

the high hole.

the high hole.

GF-Primo / GF-Secondo Dolly System Instruction Manual

locking lever.

to the low position

the locking lever.

with the hole.

locking lever.

Page 46

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

45

Mount the platform

and insert the locking

bolt and secure with

the locking lever.

Maximum Payload = 200kg / 440lbs

2582

2595

Maximum Payload = 200kg / 440lbs

1061

795

Page 47

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

46

Maximum Payload = 200kg / 440lbs

2298

1871

2677

2210

337

71

2792

Maximum Payload = 250kg / 550lbs

2298

2133

2575

599

333

2690

Page 48

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

47

Upon switching on the column,

the display will indicate “Jib

Off” or “Jib On” depending on

To change mode, enter the

MENU by pressing the RMP

and SPD buttons

If the Jib mode is off, as in our

example, the menu will

indicate JIB MODE ON and

this can be confirmed by

Note: If the “Jib Mode Off”

hows on the display this

can be confirmed by

Before assembling or operating the GF-Primo Jib ensure that the Jib On operational

mode is selected and that the HCU display is showing “Jib On”.

Selecting the “Jib On” mode

simultaneously.

s

pressing the ENTER button.

DO NOT OPERATE JIB ARMS WHEN THE

”JIB OFF” MODE IS ACTIVE

When operating the GF-Primo Jib observe the following guidelines as well as the

guidelines on page 2 & 3:

1. Know the precise weight that will be placed on the platform i.e. person, camera and

accessories. Do not exceed the maximum payloads i.e. using High / Low Rig maximum

the selected mode.

pressing the ENTER button.

Page 49

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

48

200kg / 440lbs. Not using High / Low Rig 250kg / 550lbs.

2. When the platform is empty, do not have more than 3 counterweights attached to the

weight carrier.

3. With the platform in the lowest position and after mounting the riser, camera, seat arms

and seat on the platform, place 2 more counterweight on to the weight carrier (total 5 units

@ 12kg). Now the first person may take position on the platform.

Attention: use caution when taking position on the platform. Make no sudden or abrupt

movements. Depending on the position of the platform i.e. high, middle or low, a ladder or

rostrum should be used to assist the operator onto the platform.

Do not climb onto the jib!!

4. Depending on the total payload to be lifted on the platform the respective amount of

counterweight can now be added. E.g. 109kg on platform requires 108kg in

counterweights. Please follow the following weight scale:

Without

With High / Low Rig

Counterweight in KG

108

120

132

144

156

168

180

192

Load on

platform in KG

12

24

36

48

60

72

84

96

109,00

122,00

135,00

148,00

161,00

174,00

187,00

200,00

5,00

18,00

31,00

44,00

57,00

70,00

83,00

96,00

High / Low Rig

Counterweight in

KG

Load on

platform in KG

12

24

36

48

60

72

84

96

108

120

132

144

156

168

180

192

10,00

26,00

42,00

58,00

74,00

90,00

106,00

122,00

138,00

154,00

170,00

186,00

202,00

218,00

234,00

250,00

5. Should a second person be required on the platform, firstly add 3 more 12kg weights to

the weight carrier.

6. With the platform in the lowest possible position the second person may take position on

the platform.

Attention: use caution when taking position on the platform. Make no sudden or abrupt

movements. Depending on the position of the platform i.e. high, middle or low, a ladder or

rostrum should be used to assist the operator onto the platform.

Do not climb onto the jib!!

7. To perfectly balance the arm follow the weight chart.

Page 50

GF-Primo / GF-Secondo Dolly System Instruction Manual

Page:

49

Loading...

Loading...