Page 1

Grip Factory Munich

YOUR INNOVATIVE PARTNER FOR CAMERA SUPPORT

GF-9

Crane System

Instruction Manual

Valid: Sep. 2007

Grip Factory Munich GmbH

Fürholzener Straße 1

85386 Eching bei München

Germany

Tel.: +49 (0) 89 319 0 129-0

Fax: +49 (0) 89 319 0 129-9

e-Mail: info@g-f-m.net

http://www.g-f-m.net

Page 2

GF-9 Crane System Instruction Manual

Page: 1

Contents:

SAFETY GUIDELINES ............................................................................................... 2

GF- 9 Assembly procedure on base dolly ................................................................... 3

GF- 9 assembly on tripod ............................................................................................ 6

Assembly of GF- 9 Crane System on Tripod and Track Dolly ..................................... 8

The rigging system ..................................................................................................... 9

Assembly and Technical Specifications .................................................................... 11

Version 1-150 D .......................................................................................................... 11

Version 2-150 D .......................................................................................................... 12

Version 3-150 D .......................................................................................................... 13

Version 4-150 D .......................................................................................................... 14

Version 5-150 D .......................................................................................................... 16

Version 6-150 D .......................................................................................................... 18

Version 7-150 D .......................................................................................................... 20

Version 8-150 D .......................................................................................................... 22

Version 9-150 D .......................................................................................................... 24

Version 10-150 D ........................................................................................................ 26

Balancing the crane arm ........................................................................................... 28

Deloading: .................................................................................................................. 28

General Safety .......................................................................................................... 28

Accessories for GF- 9 crane ..................................................................................... 29

GF-9 Base as Track- or Westerndolly ....................................................................... 30

Page 3

GF-9 Crane System Instruction Manual

Page: 2

SAFETY GUIDELINES

The assembly instructions must be read and understood before set-up or operation. The crane may only be

assembled in accordance with the manufacturer’s instruction manual. The manufacturers technical

specifications and limits must be adhered to at all times and in no way exceeded.

The GF-9 Crane may only be set-up or operated by trained and experienced personnel. To avoid misuse by

untrained personnel, the crane should be dismantled when not in use or under supervision.

For further information on the qualifications required for test personnel please refer to BGV 1, § 33 and §34.

The crane may not be assembled or operated under the influence of alcohol, drugs or any other intoxicating

substances. The respective protective clothing e.g. gloves, should be worn.

The manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due to

negligence by the crane operator or misuse of the crane or disregarding the instruction manual..

Before assembling the crane ensure that the ground surface is stable and cannot give way. The ground

surface must be stable enough to support at least 500 kg/m2 = 1100 lbs/ sq yard.

Crane operation is only allowed with solid tires. Use with pneumatic wheels is not allowed.

The crane dolly must be level at all times. If necessary, level the crane base dolly with the provided levelling

legs or level it on the tripod base. Whether operating or moving the crane on track or on a solid ground

surface it is essential that the track or surface is completely level, stable and free from obstructions.

When operating the crane on track, ensure that the track is level, properly laid and constructed. The correct

underlay must be used to ensure that the track and underlay are secured against moving, slipping and

collapse. Ensure that the underlay meets the specified support and stability requirements.

Extreme caution must be used if tracking on curved track (no faster than a slow walking pace).

Use of the crane on insert vehicles, camera cars or any motorised vehicle is not allowed. The manufacturer

accepts no liability for damages or injuries for incidents or accidents occurring due to use of the crane on

insert vehicles, camera cars or any other motorised vehicles.

Changing weather conditions should be taken into consideration. The crane must be taken out of operation

before the operational wind speed reaches 35kmh. / 22mph. See page 24.

The complete lift and panning range of the crane must be kept clear of obstructions at all times. A safety

clearance of 0.5m / 19" to surrounding objects and 1m /39” to persons must be observed on all sides of the

crane during operation.

The crane may not be used in the direct vicinity of high voltage power cables. To avoid accidents due to

misuse in the vicinity of high voltage power cables, Safety Guidelines (especially VBG 1 and 4) as well as

VDE regulations (especially 0105 part 100) must be adhered to. If the nominal voltage cannot be

determined, a minimum clearance of 5m / 16ft must be kept at all times. Failing to do so can cause fatalities.

No loose objects may be stored or placed on the crane.

Before the counterweights are removed from the bucket, ensure that the remote bracket is resting on the

ground or alternatively supported by an appropriate stable underlay. Gradually remove the counterweights

before the remote head or camera are removed.

In the interest of safe crane operation abrupt, sudden, abrupt movement of the crane should be avoided.

Only original accessories manufactured by GFM may be used with the crane.

Page 4

GF-9 Crane System Instruction Manual

Page: 3

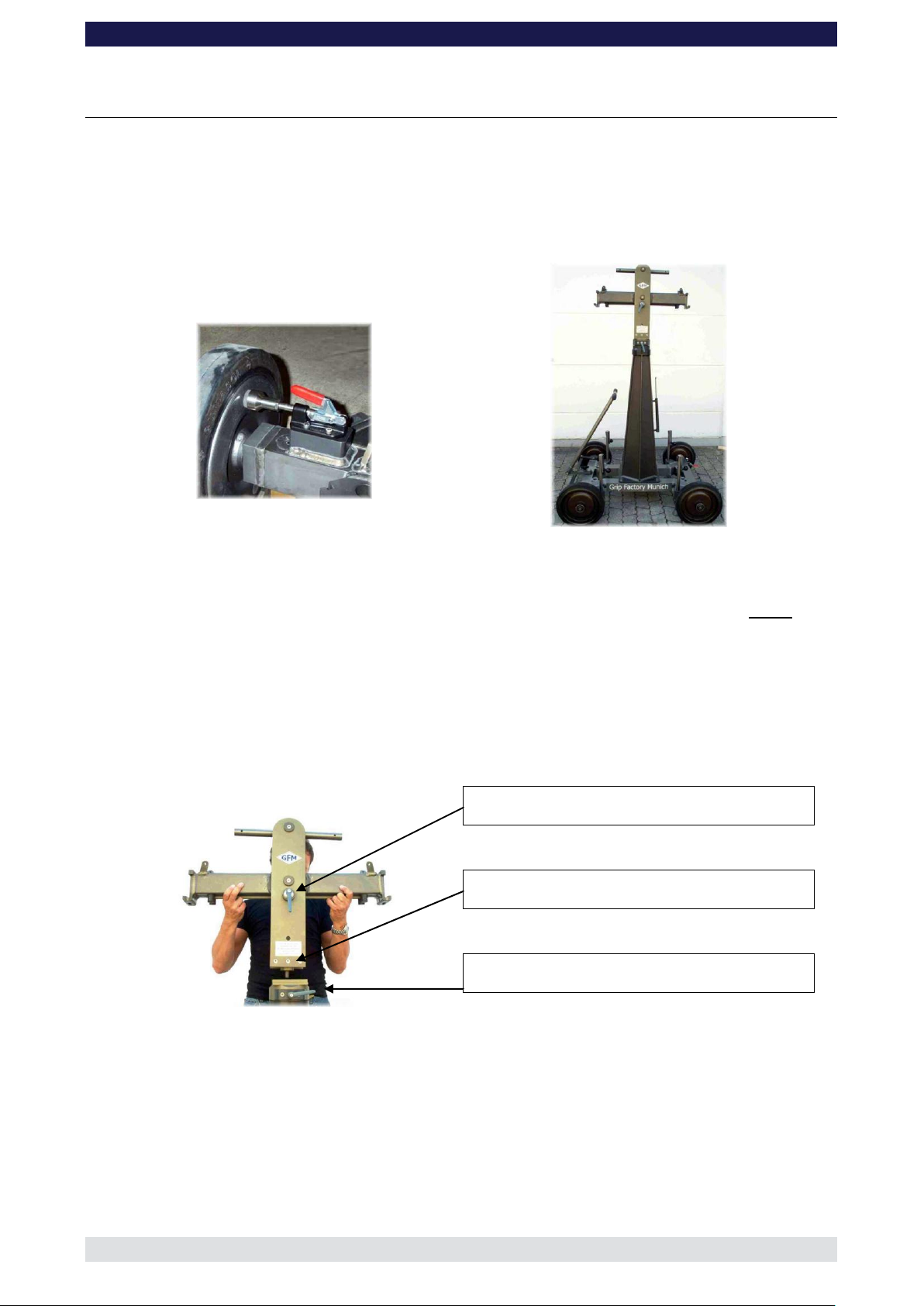

Locked wheel brake on Base Dolly

Base Dolly with mounting column and middle section

Tilt brake

Locking screw

Pan brake

GF- 9 Assembly procedure on base dolly

Before and during assembly observe the Safety Guidelines.

For all versions::

1. Secure the base dolly so that it cannot move or roll. Lock all wheel brakes. Move the

steering rod towards the centre of the dolly or remove it so that the set-up personnel

do not trip over it.

2. Bolt the crane mounting column to the base dolly. Make sure that the 4 locking bolts

are locked securely. (Tip: the carrying handle on the bazooka should point away from

the steering end of dolly).

3. Located on the middle section are 2 tilt friction locks which may be used to lock the tilt

during set-up. Set the pivot arm at 90° to the centre post and lock these friction locks

which can be found on the left and right hand side of the middle section.

4. Mount the middle section on the mounting column. Lock the locking screw tightly.

Tip: A 12mm Allen key can be found in the mounting column’s handle to be used

as a lever

Attention : Pinch point – both tilt brakes should be locked during transport and

assembly!

Page 5

GF-9 Crane System Instruction Manual

Page: 4

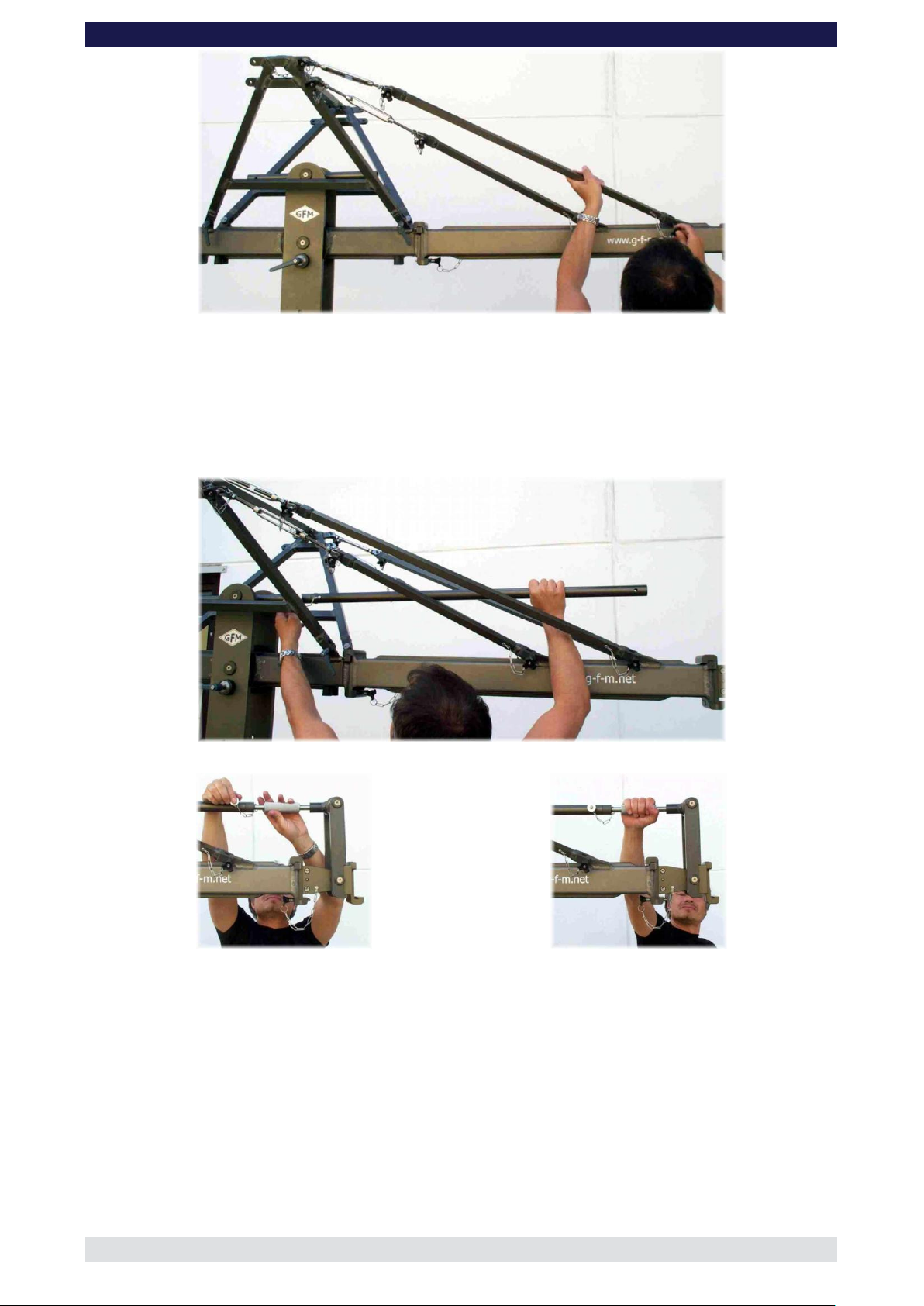

Rigging harness assembly

Mounting an extension arm

Securing the arm with a safety pin

Mounting the angle adjuster

Securing it with a safety pin

5. Connect the 2 sections of the rigging harness to the middle section of the GF-9 and

lock securely with the 4 locking levers..

6. Connect the cross bar to stabilize the rigging harness. Ensure that the 2 locking pins

are inserted fully.

7. Depending on the version being assembled, connect the 100cm section or the 150cm

section (this particular section has 4 connections for rigging rods) to the middle

section. Slip the connection flanges into each other and secure with the provided

safety pin.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest rubbing

the joints with an oiled.

8. Connect the angle adjuster to the end of the 100cm or 150cm section and secure it

from the inner side of the angle adjuster with the provided safety pin.

9. Connect the turnbuckles to the rigging harness. Depending on the rear length being

used, now connect the 4 rigging rods to the turnbuckles and in turn to the rigging rod

connections on the rear extension securing with the safety pins. Hand tighten the rods

by turning the turnbuckles until the rods are taut, then secure the turnbuckles with the

locking nuts.

Page 6

GF-9 Crane System Instruction Manual

Page: 5

Connecting the rigging rod to extension arm

Connecting the parallelogram rod

Securing the parallelogram rod

Levelling the angle adjuster

10. Connect the parallelogram rod (either 100cm or 150cm) to the middle section and the

angle adjuster and secure it with a safety pin at each end.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

The assembly procedure up to this point is the same in all versions.

To assist the set-up procedure and to reduce the risk of accidents it is recommended to

use set-up support stands or rostrums to support the crane arm during set-up and

breakdown.

Page 7

GF-9 Crane System Instruction Manual

Page: 6

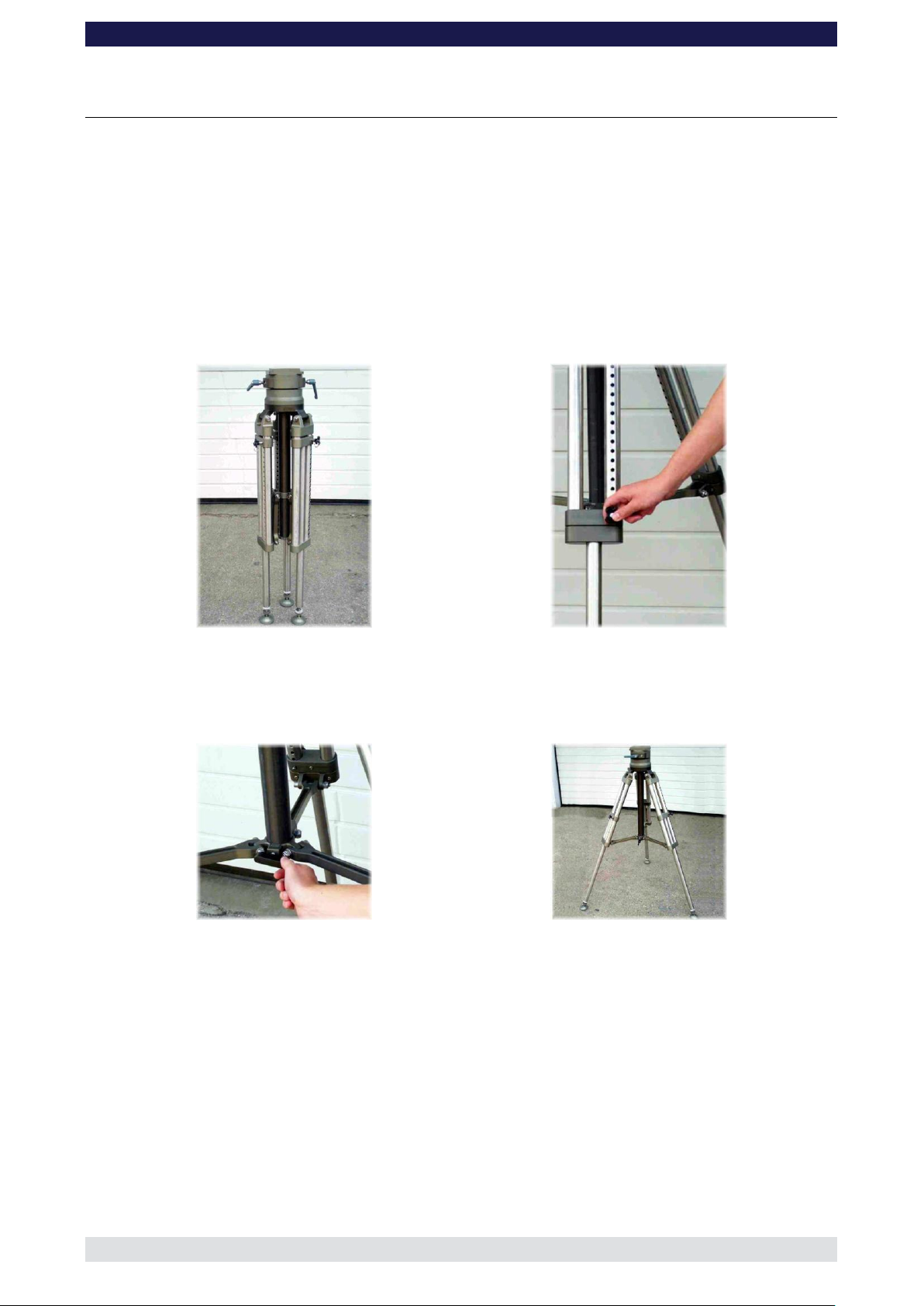

Folded tripod

Securing the tripod legs

Locking the spreader

Extended tripod, maximum width

GF- 9 assembly on tripod

Alternatively the GF-9 may also be mounted on the dedicated GFM Heavy Duty Tripod.

Should the pan bearing not already be on the tripod at this stage it must be mounted and

securely bolted into place by securing the 6 locking bolts with an Allen Key.

Before assembling the crane on the tripod ensure that the ground surface is stable and

cannot give way and that the tripod legs cannot sink into the ground. The surface must be

able to support at least 500 kg/m2 = 1100 lbs/ sq yard. Please follow the following steps:

1. For crane operation the tripod legs must be extended to the maximum length and in

turn each leg must be secured with it’s locking pin.

2. When all 3 legs are extended, spread the tripod spreader so that the legs are at their

maximum width. Secure the spreader by locking it off with the wing nut. Always

ensure that the tripod legs are spread as wide as possible.

Page 8

GF-9 Crane System Instruction Manual

Page: 7

Levelling the tripod

Securing the leveller

Maximum tilt on tripod

Avoid forceful stops into the pan bearing

Max. 30 mm

1 inch

3. Further levelling of the tripod can be achieved by turning the leveller at the bottom of

each leg and observing the water level on the pan section. Attention: the maximum

levelling range is 30mm / 1inch (see below picture). When level, lock off the leveller to

avoid any unwanted movement and twisting.

4. Now the tripod is ready. Continue assembly as from § 3 page 3.

Attention:

When using the crane ensure that the tripod legs/feet cannot shift or move, for example

when panning the arm.

When the crane is at it’s maximum tilt angle, be it in the plus or minus range, it is

important, especially when using the 100cm / 3ft rear section, to stop the arm crashing into

the pan bearing with force. A hard collision can cause the crane to topple over.!

Page 9

GF-9 Crane System Instruction Manual

Page: 8

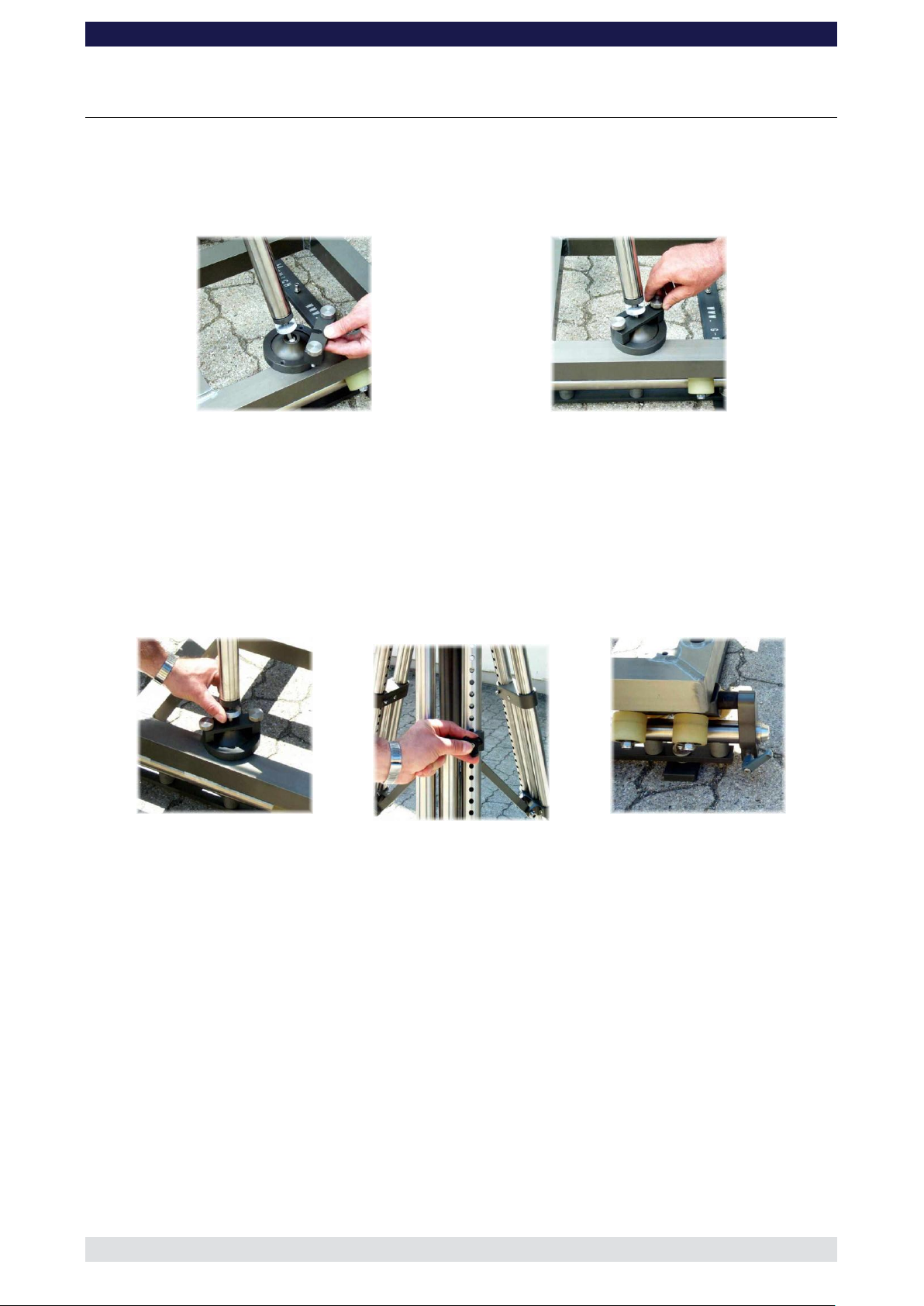

Securing the Tripod on the Track Dolly

Levelling and securing the legs

Adjusting and securing the tripod leg

Braking the Track Dolly

Assembly of GF- 9 Crane System on Tripod and Track Dolly

The assembly of the GF-9 on the Track Dolly is continued in much the same manner as

already described but a few details must be observed:

1. Upon placing the 3 Tripod legs in the fittings on the Track Dolly secure each one with

the 3 locking fasteners securing each with the 2 locking screws until hand tight.

2. Level the Tripod on the Track Dolly by turning the leveller at the bottom of each leg

and observing the water level on the pan section. Attention: the maximum levelling

range is 30mm / 1inch (see page 7). When level, lock off the leveller to avoid any

unwanted movement and twisting. Furthermore it is essential and a prerequisite that

the track is level and supported correctly. Ensure that the track properly laid and

constructed. The correct underlay must be used to ensure that the track and underlay

are secured against moving, slipping and collapse. Ensure that the underlay meets

the specified support and stability requirements.

3. The maximum Pivot Point Height ( tilt point ) allowed when using the GF-9 on the

Tripod mounted on the Track Dolly is 172cm / 5’ 7“ based on the distance from the

actual ground to the Pivot Point. This height may not be exceeded. When using GFM

Track the Tripod can be extended to the 15th hole and then secured with the

respective safety pins.

4. During assembly it is very important to secure the Track Dolly so it cannot move on

the track. For this purpose GFM Dolly Stoppers, sand bags or similar should be used.

Continue the assembly from § 3 page 3.

Page 10

GF-9 Crane System Instruction Manual

Page: 9

Connecting the rigging rods

Rigging rod with double connectors

Connection for rigging rod

The rigging system

To enhance the rigidity and reduce the strain to the GF-9 arm, a rigging system consisting

of various rods and a V shaped harness is required. The rigging system must be used for

all versions.

To simplify assembly, all rigging rods, with the exception of the ones required for the

100cm and 50cm sections, are identical.

The length of the rigging depends on the number of extensions to be used. As a rule, the

rigging runs from the rigging harness mounted on the pivot section to the last section

(Versions 1 to 5) at the front or end of the crane. From Version 6 onwards the rigging runs

from the rigging harness mounted on the pivot section to the last section 150cm / 5ft

section at the front or end of the crane. Detailed drawings can be found in the following

pages. A double rigging system is required as of version 9. In this case the lower rigging

rods connect from the rigging harness to the second section whereby the 2 rods with the

double connectors should be connected to the second extension.

General instructions for assembling the rigging:

1. After connecting the turnbuckles to the rigging harness, connect the required rigging

rod and secure the rods with the provided safety pin.

2. Depending on the version, attach the required number of rods and secure them with

the provided safety pins.

3. Version 9 onwards requires a double rigging system (upper/long and lower/short).

The lower rods connect to the second extension. The 2 rods with the double

connectors as shown below must be connected to the second section with the vertical

connector in an upward direction ( accepts the adjustable rigging rod support).

Versions 1 to 8 have a single rigging system.

4. When the rods are connected together and secured with the respective safety pins,

connect the front rods to the connections for rigging rods on the respective section.

Attention: for certain versions it is necessary to use a rigging rod connector between

the second and third rigging rod (as seen from the pivot section) in the upper (long)

rigging.

5. When all the required rods are in place and connected, the turnbuckles on the rigging

harness can be hand turned until the rods are taut . The turnbuckles should adjust the

run of both sets of rods equally so that the arm is not bent or pulled to one side. Over

adjusting of the rods should be avoided.

Page 11

GF-9 Crane System Instruction Manual

Page: 10

Rigging rod connector

Adjusting the turnbuckle!

Adjustable rigging rod support

Connecting the parallelogram support

Setting the adjustable rigging rod

support

Connecting the safety pin

6. Now connect the adjustable rigging rod support between the vertical connection on

the second lower rigging rod and the rigging rod connector between the second and

third upper rigging rod, securing with the attached safety pins. Now the adjustable

rigging rod support can also be adjusted to ensure that the rods are straight. The

adjustable rigging rod support provides extra support to the rigging and is used in

versions 9 & 10.

Parallelogram supports:

1. From version 3 onwards it is recommended to use the parallelogram supports. To see

the correct positioning, please refer to the drawing of the individual version. The

supports are bolted to both sides of the respective extension and connected to the

parallelogram with the locking pin from above as shown below.

Page 12

GF-9 Crane System Instruction Manual

Page: 11

Front extension arms required

1 x 150 cm / 5’

Rear extension arm required

1 x 150 cm / 5’

Lift range

358 cm / 11’ 8”

Maximum remote bracket height

376 cm / 12’ 7“

Lift capacity

45 kg / 100 lbs

Counterweight required for max. load

28 kg / 61 lbs

Counterweight required to balance empty arm

0 kg / 0 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

92 kg / 202 lbs

Arm reach (pivot to camera head mount)

235 cm / 7’ 8“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Assembly and Technical Specifications

Version 1-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect 2 rigging rods to the turnbuckles and secure with the safety pins. Then

connect the rods to the rigging rod connectors on the 150cm / 5’ section and secure

with the safety pins.

13. Adjust the turnbuckles until the rod are taut.

14. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

15. Connect the remote bracket angle adjuster to the end of the 150cm / 5’ section and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

16. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

17. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 13

GF-9 Crane System Instruction Manual

Page: 12

Front extension arms required

1 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 150 cm / 5’

Lift range

538 cm / 17’ 7”

Maximum remote bracket height

466 cm / 15’ 3“

Lift capacity

45 kg / 99 lbs

Counterweight required for max. load

64 kg / 140 lbs

Counterweight required to balance empty arm

0 kg / 0 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

98 kg / 215 lbs

Arm reach (pivot to camera head mount)

335 cm / 10’ 11“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 2-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect the 100cm / 3’3” sections to the 150cm / 5’. Slip the connection flanges into

each other and secure them with the provided safety pin.

13. Connect 2 rigging rods to the turnbuckles and secure with the safety pins.

14. Connect 2, 100cm / 3’3” rigging rods and in turn connect these rods to the rigging rod

connectors on the 100cm / 3’3” section and secure with the safety pins.

15. Adjust the turnbuckles until the rod are taut.

16. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

17. Connect the 100cm / 3’3” parallelogram rod to the 150cm / 5’ parallelogram rod and

secure it with a safety pin.

18. Connect the remote bracket angle adjuster to the end of the 150cm / 5’ section and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

19. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

20. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 14

GF-9 Crane System Instruction Manual

Page: 13

Front extension arms required

2 x 150 cm / 5’

Rear extension arm required

1 x 150 cm / 5’

Lift range

628 cm / 20’ 7”

Maximum remote bracket height

511 cm / 16’ 9“

Lift capacity

45 kg / 99 lbs

Counterweight required for max. load

84 kg / 184 lbs

Counterweight required to balance empty arm

8 kg / 17 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

101 kg / 222 lbs

Arm reach (pivot to camera head mount)

385 cm / 12’ 7“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 3-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect the 100cm / 3’3” sections to the 150cm / 5’. Slip the connection flanges into

each other and secure them with the provided safety pin.

13. Connect 2 rigging rods to the turnbuckles and secure with the safety pins.

14. Connect another 2 rigging rods to the first 2 and in turn connect these rods to the

rigging rod connectors on the last section and secure with the safety pins.

15. Adjust the turnbuckles until the rod are taut.

16. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

17. Connect the another 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure it with a safety pin.

18. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

19. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

20. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 15

GF-9 Crane System Instruction Manual

Page: 14

Front extension arms required

2 x 150 cm / 5’ + 100cm / 3’ 3”

Rear extension arm required

1 x 150 cm / 5’

Lift range

808 cm / 26’ 6”

Maximum remote bracket height

601 cm / 19’ 8“

Lift capacity

45 kg / 99 lbs

Counterweight required for max. load

126 kg / 277 lbs

Counterweight required to balance empty arm

22 kg / 48 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

108 kg / 237 lbs

Arm reach (pivot to camera head mount)

485 cm / 15’ 10“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 4-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect another of the 150cm / 5’ sections to the first section. Slip the connection

flanges into each other and secure them with the provided safety pin.

13. Connect the 100cm / 3’3” section to the last section. Slip the connection flanges into

each other and secure them with the provided safety pin.

14. Connect 2 rigging rods to the turnbuckles and secure with the safety pins.

15. Connect another 2 rigging rods to the first 2 and secure with the safety pins.

16. Connect 2, 100cm / 3’3” rigging rods to these and in turn connect the rods to the

rigging rod connectors on the 100cm / 3’3” section and secure with the safety pins.

17. Adjust the turnbuckles until the rods are taut.

18. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

19. Connect another 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure it with a safety pin.

20. Connect the 100cm / 3’3” parallelogram rod to the last parallelogram rod and secure it

with a safety pin.

21. Mount the parallelogram rod support to the second section and second rod as

described on page 10.

22. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

23. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

Page 16

GF-9 Crane System Instruction Manual

Page: 15

24. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 17

GF-9 Crane System Instruction Manual

Page: 16

Front extension arms required

3 x 150 cm / 5’

Rear extension arm required

1 x 150 cm / 5’

Lift range

898 cm / 29’ 5”

Maximum remote bracket height

646 cm / 21’ 2“

Lift capacity

30 kg / 66 lbs

Counterweight required for max. load

106 kg / 233 lbs

Counterweight required to balance empty arm

36 kg / 79 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

112 kg / 246 lbs

Arm reach (pivot to camera head mount)

535 cm / 17’ 6“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 5-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect another the 2 of the 150cm / 5’ sections to the first section. Slip the

connection flanges into each other and secure them with the provided safety pin.

13. Connect 2 rigging rods to the turnbuckles and secure with the safety pins.

14. Connect another 2 rigging rods to the first 2 and secure with the safety pins.

15. Connect another 2 rigging rods to the second 2 and secure with the safety pins and in

turn connect the rods to the rigging rod connectors on the last section and secure with

the safety pins.

16. Adjust the turnbuckles until the rods are taut.

17. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

18. Connect another 2, 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure it with a safety pin.

19. Mount the parallelogram rod support to the second section and second rod as

described on page 10.

20. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

21. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

22. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights

Page 18

GF-9 Crane System Instruction Manual

Page: 17

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 19

GF-9 Crane System Instruction Manual

Page: 18

Front extension arms required

3 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 150 cm / 5’

Lift range

1077 cm / 35’ 4”

Maximum remote bracket height

735 cm / 24’ 1“

Lift capacity

30 kg / 110 lbs

Counterweight required for max. load

140 kg / 308 lbs

Counterweight required to balance empty arm

50 kg / 110 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

118 kg / 259 lbs

Arm reach (pivot to camera head mount)

635 cm / 20’ 10“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 6-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect another 2 of the 150cm / 5’ sections to the first section. Slip the connection

flanges into each other and secure them with the provided safety pin.

13. Connect the 100cm / 3’3” section to the last section. Slip the connection flanges into

each other and secure them with the provided safety pin.

14. Connect 2 rigging rods to the turnbuckles and secure with the safety pins.

15. Connect another 2 rigging rods to each the first 2 and secure with the safety pins. In

turn connect the rods to the rigging rod connectors on the last 150cm /5ft section and

secure with the safety pins.

16. Adjust the turnbuckles until the rods are taut.

17. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

18. Connect another 2, 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure them with safety pins.

19. Connect the 100cm / 3’3” parallelogram rod to the last parallelogram rod and secure it

with a safety pin.

20. Mount the parallelogram rod support to the second section and second rod as

described on page 10.

21. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

22. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

Page 20

GF-9 Crane System Instruction Manual

Page: 19

23. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 21

GF-9 Crane System Instruction Manual

Page: 20

Front extension arms required

4 x 150 cm / 5’

Rear extension arm required

1 x 150 cm / 5’

Lift range

1167 cm / 38’ 3”

Maximum remote bracket height

780 cm / 25’ 7“

Lift capacity

30 kg / 66 lbs

Counterweight required for max. load

204 kg / 448 lbs

Counterweight required to balance empty arm

64 kg / 140 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

122 kg / 268 lbs

Arm reach (pivot to camera head mount)

685 cm / 22’ 5“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 7-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect another 3 of the 150cm / 5’ sections to the first section. Slip the connection

flanges into each other and secure them with the provided safety pin.

13. Connect 2 rigging rods to the turnbuckles and secure with the safety pins.

14. Connect another 2 rigging rods to each the first 2 and secure with the safety pins. In

turn connect a rigging rod connector to each of the second rods.

15. Connect 2 adjustable rigging supports to each of the 2 rigging rod connectors and to

the connections on the second 150cm /5’ section and secure with the safety pins.

16. Connect another 2 rigging rods to each of the rigging rod connectors and secure with

the safety pins. In turn connect the rods to the rigging rod connectors on the last

section and secure with the safety pins.

17. Adjust the turnbuckles until the rods are taut.

18. Adjust the 2 adjustable rigging supports until the rods are taut and straight.

19. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

20. Connect another 3, 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure them with safety pins.

21. Mount the parallelogram rod support to the first section and first rod and also the third

section and third rod as described on page 10.

22. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

23. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

Page 22

GF-9 Crane System Instruction Manual

Page: 21

24. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 23

GF-9 Crane System Instruction Manual

Page: 22

Front extension arms required

4 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 150 cm / 5’

Lift range

1347 cm / 44’ 2”

Maximum remote bracket height

870 cm / 28’ 6“

Lift capacity

30 kg / 66 lbs

Counterweight required for max. load

224 kg / 492 lbs

Counterweight required to balance empty arm

84 kg / 184 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

132 kg / 290 lbs

Arm reach (pivot to camera head mount)

785 cm / 25’ 9“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 8-150 D

Continue from § 10, page 5

11. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

12. Connect another 3 of the 150cm / 5’ sections to the first section. Slip the connection

flanges into each other and secure them with the provided safety pin.

13. Connect the 100cm / 3’3” section to the last section. Slip the connection flanges into

each other and secure them with the provided safety pin.

14. Connect another 2 rigging rods to each the first 2 and secure with the safety pins. In

turn connect a rigging rod connector to each of the second rods.

15. Connect 2 adjustable rigging supports to each of the 2 rigging rod connectors and to

the connections on the second 150cm /5’ section and secure with the safety pins.

16. Connect another 2 rigging rods to each of the rigging rod connectors and secure with

the safety pins. In turn connect the rods to the rigging rod connectors on the last

section and secure with the safety pins.

17. Adjust the turnbuckles until the rods are taut.

18. Adjust the 2 adjustable rigging supports until the rods are taut and straight.

19. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

20. Connect another 3, 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure them with safety pins.

21. Connect the 100cm / 3’3” parallelogram rod to the last parallelogram rod and secure it

with a safety pin.

22. Mount the parallelogram rod support to the first section and first rod and also the third

section and third rod as described on page 10.

23. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

Page 24

GF-9 Crane System Instruction Manual

Page: 23

24. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

25. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 25

GF-9 Crane System Instruction Manual

Page: 24

Front extension arms required

5 x 150 cm / 5’

Rear extension arm required

1 x 150 cm / 5’

Lift range

1437 cm / 47’ 1”

Maximum remote bracket height

915 cm / 30’

Lift capacity

30 kg / 60 lbs

Counterweight required for max. load

238 kg / 523 lbs

Counterweight required to balance empty arm

112 kg / 246 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

136 kg / 299 lbs

Arm reach (pivot to camera head mount)

835 cm / 27’ 4“

Length of rear end (pivot to outside of bucket)

247 cm / 8’ 1“

Version 9-150 D

Continue from § 10, page 5

11. Connect 2 of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pins.

12. Connect 2 rigging rods to the lower turnbuckles and secure with the safety pins. In

turn connect the 2 rods with the double connectors to the first rigging rods and then

the rigging rod connectors on the second section and secure with the safety pins.

Mount with the vertical connector in an upward direction ( accepts the adjustable

rigging rod support). Adjust the turnbuckles until the rods are taut.

13. Connect another 3 of the 150cm / 5’ sections to the second section. Slip the

connection flanges into each other and secure them with the provided safety pins.

14. Connect 2 rigging rods to the top turnbuckles and secure with the safety pins.

15. Connect another rigging rod to each the first 2 and secure with the safety pins.

16. Connect the rigging rod connectors to the end of the second rigging rods and secure

with the safety pins.

17. Connect another 3 rigging rods to each of the 2 rigging rod connectors and secure

with the safety pins. In turn connect the rods to the rigging rod connectors on the last

150cm section and secure with the safety pins.

18. Connect 2 adjustable rigging supports to each of the 2 rigging rod connectors and the

vertical connector on the second rigging rods and secure with the safety pins.

19. Adjust the turnbuckles until the rods are taut.

20. Adjust the 2 adjustable rigging supports until the rods are taut and straight.

21. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

22. Connect another 4, 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure them with safety pins.

23. Mount the parallelogram rod support to the first section and first rod and also the third

section and third rod as described on page 10.

Page 26

GF-9 Crane System Instruction Manual

Page: 25

24. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

25. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

26. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 27

GF-9 Crane System Instruction Manual

Page: 26

Front extension arms required

5 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 150 cm / 5’

Lift range

1617 cm / 53’

Maximum remote bracket height

1005 cm / 32’ 11“

Lift capacity

25 kg / 55 lbs

Counterweight required for max. load

252 kg / 554 lbs

Counterweight required to balance empty arm

140 kg / 308 lbs

Dolly weight

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

142 kg / 312 lbs

Arm reach (pivot to camera head mount)

935 cm / 30’ 8“

Length of rear end (pivot to outside of bucket)

247 cm / 28’ 1“

Version 10-150 D

Continue from § 10, page 5

11. Connect 2 of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pins.

12. Connect 2 rigging rods to the lower turnbuckles and secure with the safety pins. In

turn connect the 2 rods with the double connectors to the first rigging rods and then

the rigging rod connectors on the second section and secure with the safety pins.

Mount with the vertical connector in an upward direction ( accepts the adjustable

rigging rod support). Adjust the turnbuckles until the rods are taut.

13. Connect another 3 of the 150cm / 5’ sections to the second section. Slip the

connection flanges into each other and secure them with the provided safety pin.

14. Connect 2 rigging rods to the top turnbuckles and secure with the safety pins.

15. Connect another rigging rod to each of the first 2 and secure with the safety pins.

16. Connect the rigging rod connectors to the end of the second rigging rods and secure

with the safety pins.

17. Connect another 3 rigging rods to each of the 2 rigging rod connectors and secure

with the safety pins. In turn connect the rods to the rigging rod connectors on the last

150cm section and secure with the safety pins.

18. Adjust the turnbuckles until the rods are taut.

19. Connect the 100cm section to the last 150cm section and secure with the safety pin.

20. Connect 2 adjustable rigging supports to each of the 2 rigging rod connectors and the

vertical connector on the second rigging rods and secure with the safety pins.

21. Adjust the turnbuckles until the rods are taut.

22. Adjust the 2 adjustable rigging supports until the rods are taut and straight.

23. Connect one of the 150cm / 5’ parallelogram rods to the middle section and secure it

with a safety pin.

24. Connect another 4, 150cm / 5’ parallelogram rod to the first parallelogram rod and

secure them with safety pins.

25. Connect the 100cm / 3’3” parallelogram rod to the last parallelogram rod and secure it

with a safety pin.

Page 28

GF-9 Crane System Instruction Manual

Page: 27

26. Mount the parallelogram rod support to the first section and first rod and also the third

section and third rod as described on page 10.

27. Connect the remote bracket angle adjuster to the end of the last section and secure it

with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

28. Insert the rod on the remote bracket angle adjuster into the parallelogram rod a

secure with the safety pin.

29. As required, attach the weight bucket or weight rod to the opposite end of the crane

by inserting the male flange into the female flange on the angle adjuster. Secure it

with the safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate on

the angle adjuster can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance. Level the weight bucket before loading any

weights.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Page 29

GF-9 Crane System Instruction Manual

Page: 28

Balancing the crane arm

Attention : When loading the crane the maximum working load capacities / payloads

must never be exceeded.

As a rule, no more than 252kg / 554lbs of counterweight may be used in the

counterweight bucket or 260kg / 572lbs when using the counterweight rod.!

After the assembly procedure has been completed, the remote head and camera etc may

now be assembled. Place the correct amount of counterweight in the weight bucket to

balance the load.

Attention: we recommend that the camera and remote head are additionally secured

to the remote head mount with a safety cord.

Place the required amount of counterweights in the weight bucket so that the crane arm

becomes balanced and remains in the horizontal position. If necessary, the crane can be

fine balanced by adjusting the sliding weight on the rear parallelogram at the weight

bucket. Do not forget to lock the sliding weight in position before tilting the arm.

The counterweight bucket door must be locked when operating the crane.

Deloading:

Attention: The counterweights must always be gradually removed from the

counterweight bucket before removing the camera or remote head. Extreme caution

must be given to the shifting payload at all times. When dismantling the crane it is

essential that the whole arm is supported fully by a stable underlay i.e. rostrum or

ground surface. In any case the remote bracket should not be in the air without

support.

Attention: all necessary precautions should be taken so that unauthorized third

parties cannot use the crane.

General Safety

Operational conditions:

At a wind speed of 35km/h 22mph crane operation must be stopped and the crane

secured, dismounted and the necessary safety precautions taken.

If, for example, it takes 2 mins. to unload the counterweights and take the necessary

precautions to secure the crane, one must commence with the procedure at a wind speed

of 30km/h / 19mph. DIN15019, part 1, section 6.13.

The crane may not be used in a lightening storm as there is the danger of electrocution.

Page 30

GF-9 Crane System Instruction Manual

Page: 29

Levelling leg

Monitor carrier

Push bar

Track wheel with brake

Accessories for GF- 9 crane

Notice:

When operating the crane with the push bar mounted on the dolly, pay attention that the

crane arm at no time collides with the push bar.

The levelling legs must be removed from the base dolly before driving onto a track

mounting ramp. Always use the levelling legs to level the crane when on uneven surfaces.

Page 31

GF-9 Crane System Instruction Manual

Page: 30

GF-9 Base as Track- or Westerndolly

The crane platform may be mounted on the base dolly to provide a track or western dolly

style function. Insert the 3 bolts into the underside of the base, through the platform and

into the turnstile mount. Lock the 3 bolts tightly.

Loading...

Loading...