Page 1

YOUR INNOVATIVE PARTNER FOR CAMERA SUPPORT

Grip Factory Munich

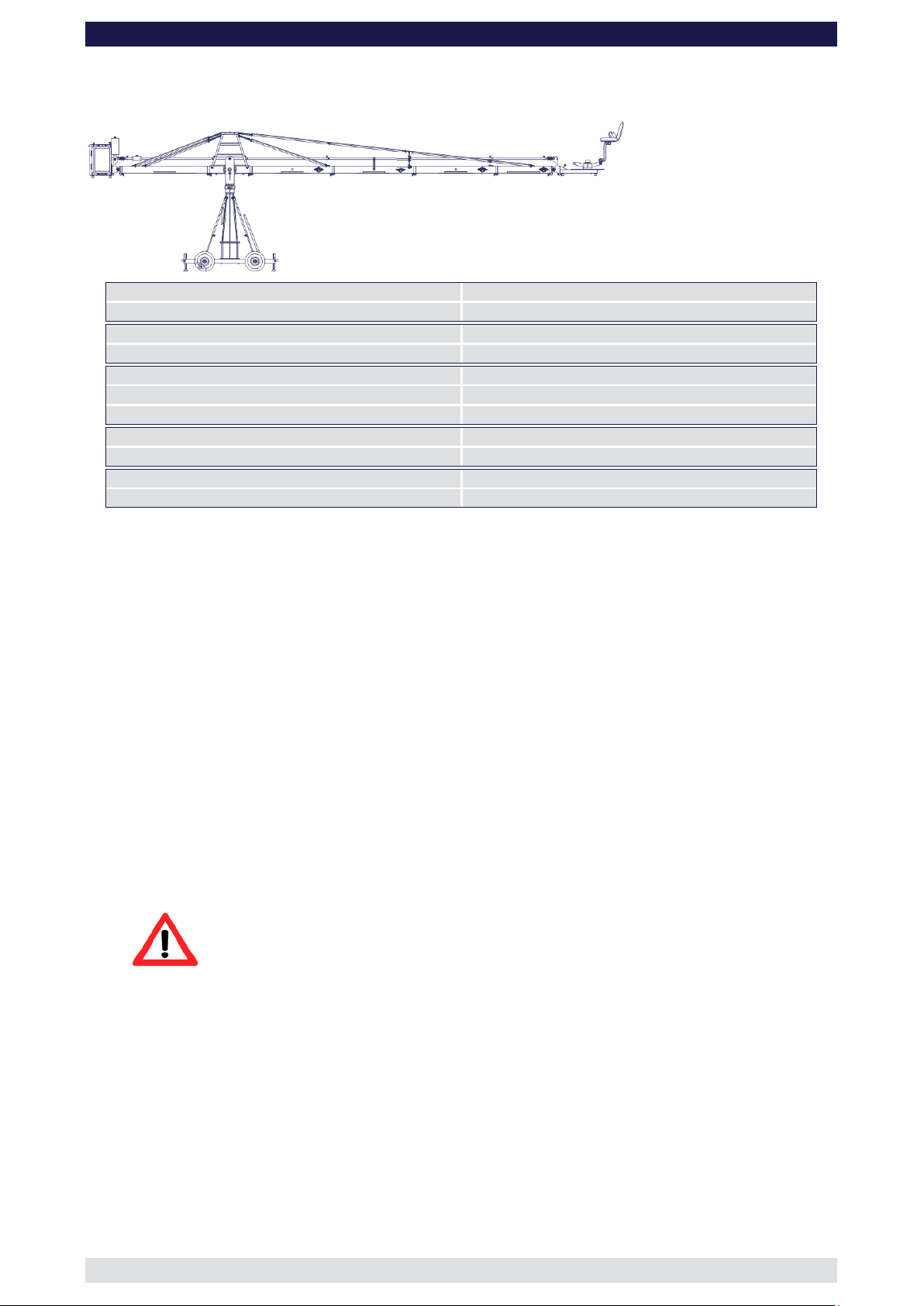

GF-8

Crane System

Instruction Manual

Standard-Versions 1-18

Xten-Versions 1-8

Original english version

Valid: March 2011

Grip Factory Munich GmbH

Fürholzener Straße 1

85386 Eching bei München

Germany

Tel.: +49 (0) 89 319 0 129-0

Fax: +49 (0) 89 319 0 129-9

e-Mail: info@g-f-m.net

http://www.g-f-m.net

Page 2

8 Xten Crane System Instruction Manual

Page: 1

GF-

Contents:

SAFETY GUIDELINES ............................................................................................... 2

General Assembly Procedure – GF-8 ......................................................................... 4

For all GF-8 Standard-Versions: ................................................................................................................... 4

For all GF-8 Xten-Versions: .......................................................................................................................... 8

Assembly & Technical Specification Version 1 to 18 .................................................. 9

Version 1 ....................................................................................................................................................... 9

Version 2 ..................................................................................................................................................... 10

Version 3 ..................................................................................................................................................... 11

Version 4 ..................................................................................................................................................... 12

Version 5 ..................................................................................................................................................... 13

Version 6 ..................................................................................................................................................... 14

Version 7 ..................................................................................................................................................... 15

Version 8 ..................................................................................................................................................... 15

Version 9 ..................................................................................................................................................... 17

Version 10 ................................................................................................................................................... 17

Version 11 ................................................................................................................................................... 18

Version 12 ................................................................................................................................................... 18

Version 13 ................................................................................................................................................... 18

Version 14 ................................................................................................................................................... 19

Version 15 ................................................................................................................................................... 19

Version 16 ................................................................................................................................................... 20

Version 17 ................................................................................................................................................... 21

Version 18 ................................................................................................................................................... 23

Assembly & Technical Specifications for the Xten Versions ..................................... 24

Xten Version 1 ............................................................................................................................................ 24

Xten Version 2 ............................................................................................................................................ 26

Xten Version 3 ............................................................................................................................................ 28

Xten Version 4 ............................................................................................................................................ 30

Xten Version 5 ............................................................................................................................................ 32

Xten Version 6 ............................................................................................................................................ 34

Xten Version 7 ............................................................................................................................................ 36

Xten Version 8 ............................................................................................................................................ 38

Parallelogram Rod Support ....................................................................................... 40

Standard Rigging System ......................................................................................... 41

Double Rigging System ............................................................................................ 43

Lower, front rigging ..................................................................................................................................... 43

Top, front rigging ......................................................................................................................................... 44

Mounting the Extra, Mini Counterweight Bucket for Xten Versions ............................................................. 46

Balancing the crane arm ........................................................................................... 46

Unloading .................................................................................................................. 47

General Safety .......................................................................................................... 48

Taking the crane out of service ................................................................................................................... 48

Accessories for GF- 8 crane ..................................................................................... 49

Mounting the accessories ........................................................................................................................... 49

Use with GFM Track (GF-Track) ............................................................................... 50

Transport trolley for the GF-8 Crane ......................................................................... 51

GF-8 Crane Dollies ................................................................................................... 52

The GF-8 Double Ended Connected Steering Base ................................................................................... 53

Maintenance ............................................................................................................. 55

Regular Inspections .................................................................................................. 56

EC Declaration of Conformity ................................................................................... 57

Page 3

8 Xten Crane System Instruction Manual

Page: 2

GF-

SAFETY GUIDELINES

Adherence of the instruction manual:

The set-up instructions m ust be read and understood before set-up or operation. The crane may only be

assembled in accordance with the manufacturer’s instruction manual. The manufacturers technical

specifications and limits (maximum rated loads of each version) m ust be adhered to at all tim es and in no

way exceeded.

Warranty:

The manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due to

negligence by the crane operator or misuse of the crane or disregarding the instruction manual.

Assembling of the crane:

The GF-8 Crane may only be set-up or operat ed by trained and experienced personne l. To assemble the

crane at least two men are needed. To avoid misuse by untrained personnel, the crane should be dismantled

when not in use or under supervision.

For further information on the qualifications required for test personnel please refer to BGV 1, §33 and §34.

The crane may not be set-up or operated under the influence of alcohol, drugs or any other intoxicating

substances. The respective protective clothing e.g. gloves, should be worn.

Stability of the crane system:

Before assembling the crane ensure that the ground surface is stable and cannot give way. The ground

surface must be stable enough to support at least 1200 kg/m2 = 2640 lbs/ sq yard.

Crane operation is only allowed wit h solid tires. Use with pneum atic wheels is not allowed. Before and while

using the crane the wheels should be inspected.

Intended use of the crane system:

The GF-8 is a mobile crane-system for mounting cameras in a stationary ground position or for movement on

track.

It can be operated manuall y from the ground and can be panned in al l dir ec tions eith er with a remote-bracket

or a 1 to 2 person pl atform. In accordance to the safety guidelines the crane is only allowed to be used on

solid, level and stable ground. While using it stationary the levelling legs have to be used.

The crane operation from the ground is managed by at least one experienced, trained and authorised

personnel from the hand grips on the counterweight bucket.

Operation of the crane is only allowed within the limits and guidelines mentioned in the instructi on manual.

The allowed payloads of each version are clearly shown on the counterweight-bucket (workplace of the

crane operator).

The crane dolly must be level at all times. If necessary, level the crane with the provided levelling legs

ensuring that the le velling legs cannot sink or break through the surface and are supp orted enough where

necessary. W hether operating or m oving the crane on trac k or on a solid ground s urface it is essential that

the track or surface is completely level, stable and free from obstructions.

When operating the c rane on track, ensure th at the track is leve l, properly laid, cons tructed and support ed.

The correct underlay must be used to ensure that the track and underlay are secured against moving,

slipping and collaps e. Ensure that t he underla y meets the specif ied support and s tability requ irements. O nly

GFM Track or com parable track systems with a pa yload capac ity of 1200kg / 2640lbs an d a m aximum track

runner distance of 640mm / 25inches (measured inside edge to inside edge) may be used.

Extreme caution if tracking on curved track (not faster than a slow walking pace)!

Use of the crane on insert vehicles, camera cars or any motorised vehicle is not allowed. The

manufacturer acc epts no liability for damages or injuries for incidents or accidents occurring due to us e of

the crane on insert vehicles, camera cars or any other motorised vehicles.

Changing weather condit ions should be taken into co nsideration. The crane m ust be taken out of operation

before the operational wind speed reaches 40km/h (25mph). For this purpose see page 48.

Operation of the crane:

The complete lift and pan ning range of the GF-8 Crane must be kept clear of obstruc tions at all times. A

safety clearance of 1m / 3' 3" m ust be observed on all sides of the crane d uring operat ion. Only au thorised,

trained and experienced personnel are allowed to operate the crane. For further information on the

qualifications required for test personnel please refer to BGV 1, §33 and §34.

The crane may not be set-up or operated under the influence of alcohol, drugs or any other intoxicating

substances. The respective protective clothing e.g. gloves, should be worn.

Page 4

8 Xten Crane System Instruction Manual

Page: 3

The crane may not be used in the d irect vicinity of high voltage power cables. T o avoid accidents due to

misuse in the vicinity of hi gh voltage power cables, Safety Guide lines especially BGV A1 and A2 (form erly

VBG 1 and 4) as well as VDE regulations (especially 0105 part 100) must be adhered to. If the nominal

voltage cannot be determined, a minimum clearance of 5m / 16ft must be kept at all times.

Failing to do so can cause fatalities!

Personnel on board the crane's platform must use safety belts at all times. They should not make any

sudden, abrupt movements or lean out over the side of the platform. No loose objects m ay be stored or

placed on the crane platform.

Before the counterweights are rem oved from the buc ket, ensur e that the platf orm is res ting on the ground or

alternatively supported by an appropriate stable underlay. Gradually remove the counterweights before

personnel leave the pl atform or before the remote head or camera are dismounted. It’s no t allowed to put

extra weights on top of the counterweight bucket or any other part of the crane!

In the interest of saf e crane operation, when oper ating or moving the crane, abrupt, sudden movem ents of

the crane should be a voided. An element of risk remains by peopl e moving in the operatio nal range of the

crane. The crane operator has to be trained on that and is only allowed to operate the crane in safe range.

Before operating the crane every safety pin as well as every connecting bolt may be checked for a proper fit.

Crane accessories:

For safety reasons only original accessories manufactured by GFM may be used with the crane. Every single

part of the standard GF-8 crane is com patible to the G F-8 Xten and can als o be combined wit h. In case of

any mistiness please contact us.

Procedure in case of accident or damage:

In case of accidents caused by disregarding the manufacturers instruction manual, please act this way:

o Possible damage ma y be immediately told the m anufacturer also the wa y the damage happened as

well as the heaviness of the damage. Dam aged parts of the crane ma y be sent to the manuf acturer

for reparation or replacement.

The use of the crane with dam aged parts is not allowed. The manuf acturer accepts no liability for

damages or injuries for incidents or accidents occurring due to the use of damaged parts of the

crane.

o In case of damage or accidents w ith injured people loc al applicable as w ell as employment pr operty

right regulations may be adhered.

GF-

Page 5

8 Xten Crane System Instruction Manual

Page: 4

GF-

General Assembly Procedure – GF-8

General description:

The GF-8 and GF-8 Xten is a mobile crane-system for mounting cameras in a stationary

ground position or for movem ent on tr ac k.

It can be operated manually from the ground and can be panned in all directions either

with a remote-bracket or a 1 to 2 person platform. In accordance to the safety guidelines

the crane is only allowed to be used on solid, level and stable ground. While using it

stationary the levelling legs have to be used.

The crane operation from the ground is managed by at least one experienced, trained and

authorised personnel from the hand grips on the counterweight bucket.

Operation of the crane is only allowed within the limits and guidelines mentioned in the

instruction manual. The allowed payloads of each version are clearly shown on the

counterweight bucket (workplace of the crane operator).

Attention: Before and during assembly observe the Safety Guidelines.

For all GF-8 Standard-Versions:

1. Secure the base dolly so that it cannot move or roll. Lock all wheel brakes. Move the

steering rod towards the centre of the dolly or remove it so that the set-up personnel

do not trip over it.

2. For the Standard-Versions 1 to 8 bolt the 90cm crane mounting column to the base

dolly (pivot height 154cm). Make sure that the 4 locking bolts are locked securely.

Tip: The carrying handle on the bazooka should point away from the steering end

of the dolly.

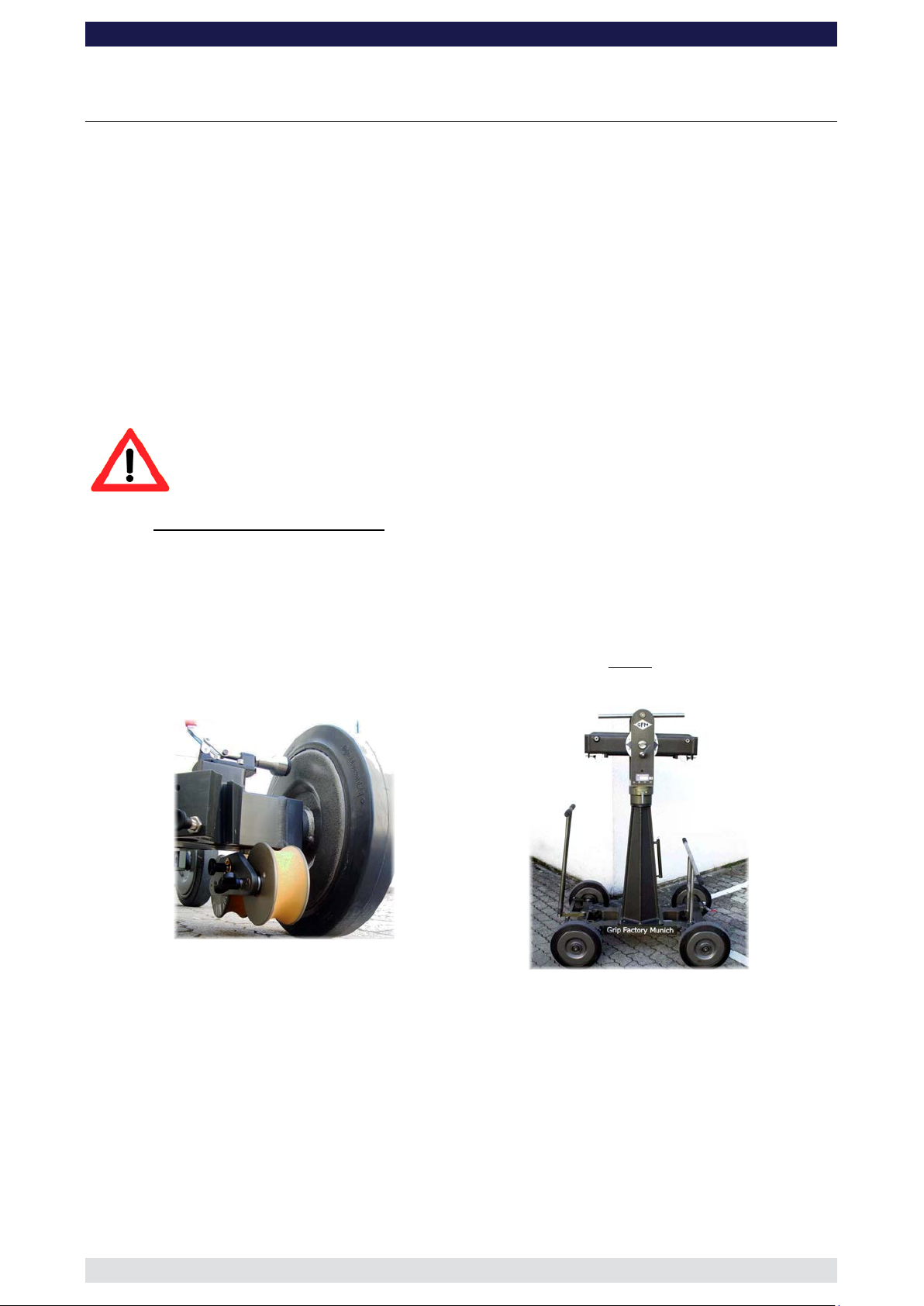

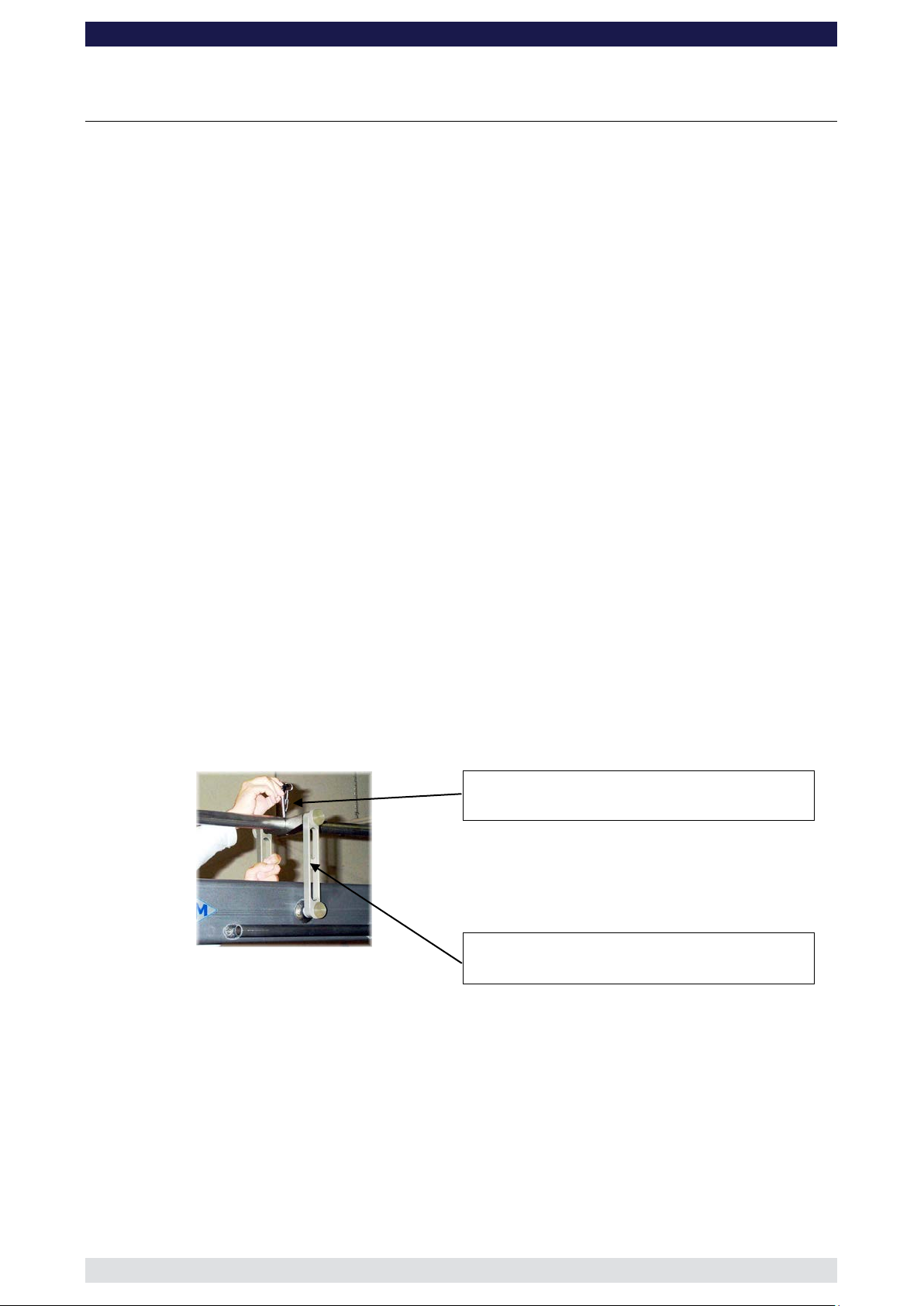

Wheel brake on Base Dolly

Base Dolly with 90cm / 3ft Mounting Column and

Pivot Section (Versions 1-8)

The 30cm / 1ft column extension is used in combination with the 90cm column for

versions 9 to 18 to increase the pivot height from 154cm to 184cm. It is connected to

the standard GF-8 column with 4 locking nuts and bolts. Make sure that the 4 locking

bolts are locked securely.

Page 6

8 Xten Crane System Instruction Manual

Page: 5

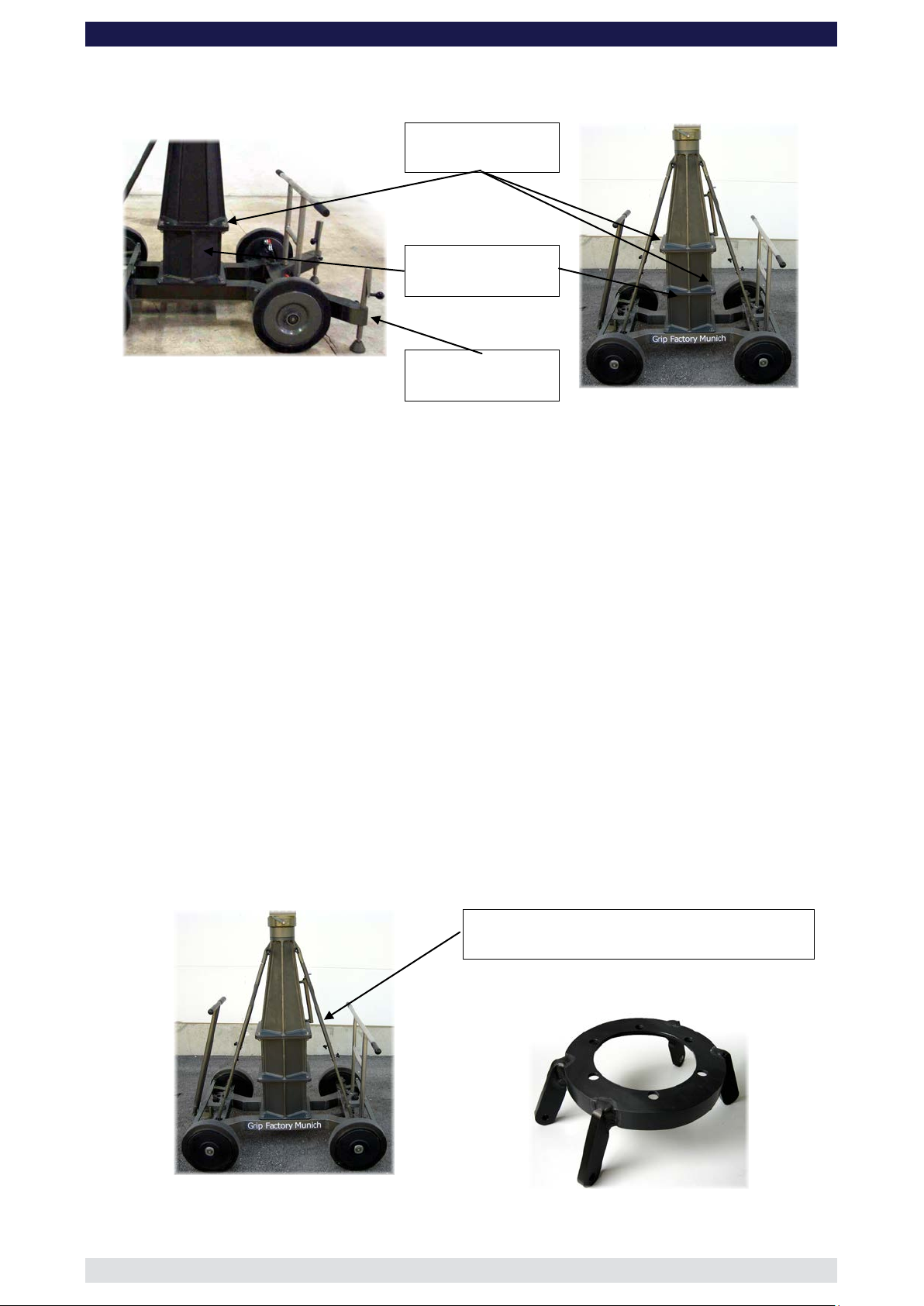

(2 x 30cm + 60cm Column sections) with Supports

Adapter ring for column supports

GF-

As an option a 3 stage column is also available. It consists of 2 x 30cm / 1ft column

extensions and a 60cm / 2ft Mounting Column. Assemble the column extension

between the column and the base dolly locking the 12 locking bolts securely.

Locking bolts

Column Extension

Base Dolly with 30cm / 1ft Column Extension

Extended levelling

legs

3 pivot heights are possible:

o 184cm / 6ft with all 3 parts (2 x 30cm / 1ft and 1 x 60cm) or with two parts (1 x

30cm / 1ft and 1 x 90cm / 3ft)

o 154cm / 5ft with a 30cm / 1ft column extensi on and 60cm / 2ft mounting

column

o 124cm / 4ft with 60cm / 2ft mounting column.

3. For Standard Versions 9 to 18 we recommend using the 4 telescopic column

supports. In smaller versions they are not required but using them does increase the

columns stability. To mount the supports connect the grooved end to the connection

on the column, securing with the locking pin. Remove the locking pin in the middle of

the column support enabling the rod to reach the connection on the base dolly and

secure with the locking pin. The locking pin previously removed from the centre of the

column support can now be reinserted to fix the length. Turn the grooved part in a

clockwise direction to apply tension.

Tip: Should the column not have the 4 connections for the column supports, an

adapter is available. It is connected to the column between the pan bearing

oder besser turnstile??? and the top of the column. To do so the pan bearing

must be removed by unscrewing the 6 screws. The adapter must be mounted

in line to the connections on the base dolly with the adapter ring connectors

pointing towards the base dolly. The original screws must be replaced by

5mm longer screws.

3 Stage Mounting Column

Telescopic Column Supports

Page 7

8 Xten Crane System Instruction Manual

Page: 6

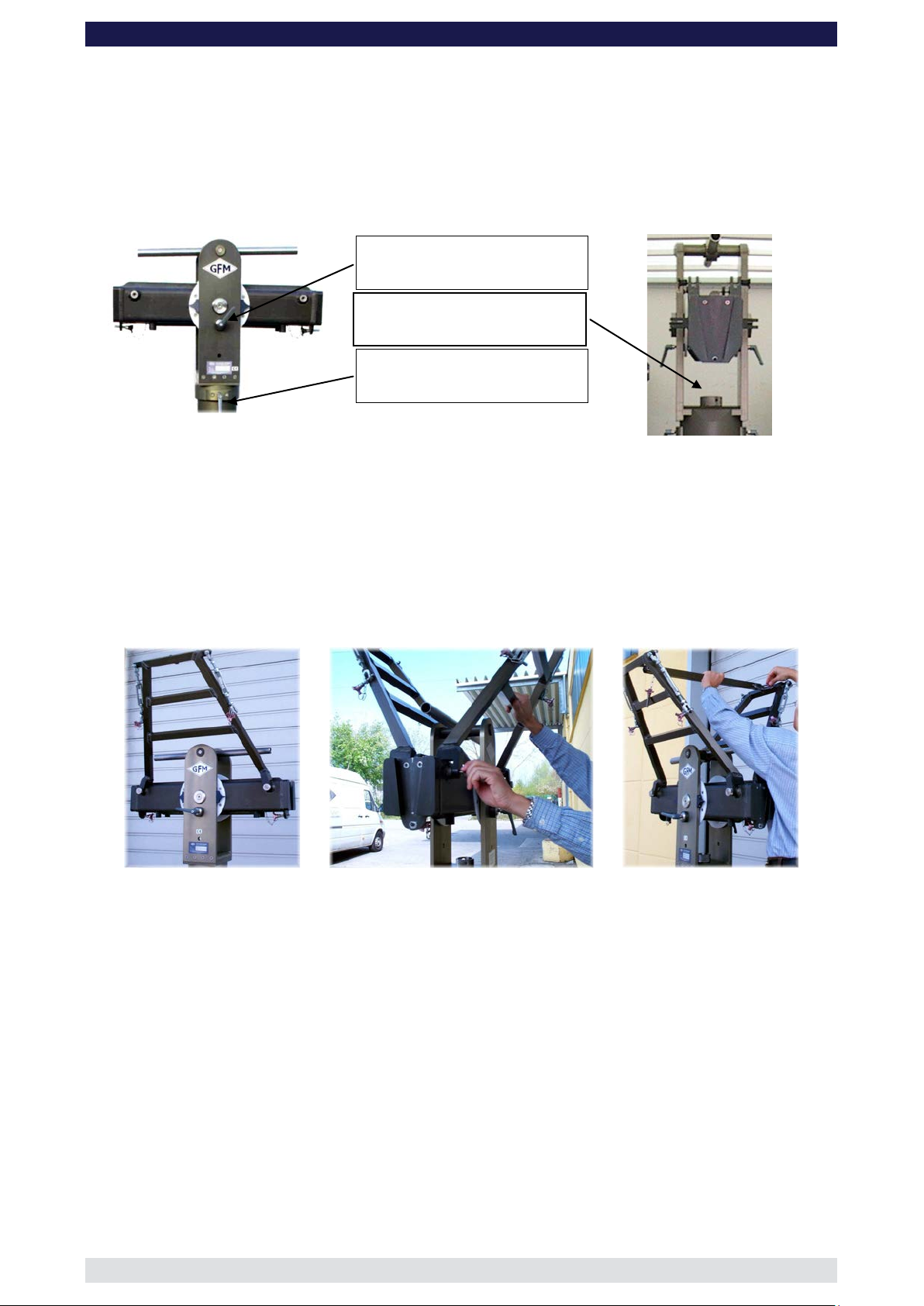

Middle section with pan and tilt lock

GF-

4. Located on the middle section are 2 tilt friction locks which may be used to lock the tilt

during set-up. Set the pivot arm at 90° to the centre post and lock these friction locks

which can be found on the left and right hand side of the middle section. Mount the

middle section on the mounting column. Lock the locking screw tightly.

Tip: A 12mm Allen key can be found in the mounting column’s handle to be used

as a lever.

Attention: Install the middle section to the rotateable bearing of the column with

positive locking. It fits properly only in one position.

Tilt brake

Locking screw

Pan brake

Unless otherwise stated it is required to use the rigging system when more than

1 x 150cm / 5ft section is mounted to the front of the crane i.e. all versions except

1 and 9.

5. Connect the 2 sections of the rigging harness to the middle section of the GF-8.

Ensure that the 4 locking bolts are fastened tightly.

6. Connect the cross bar to stabilize the rigging harness. Ensure that the 2 locking pins

are inserted fully.

7. For Standard Versions 1 to 16 connect the 127cm / 4ft rear arm section to the middle

section. For Standard Versions 17 and 18 connect the 150cm / 5ft section to the

middle section. Slip the connection flanges into each other and secure with the

provided safety pin.

Connect the respective 127cm or 150cm parallelogram rod to the middle section,

mount the sliding weight and secure with the locking screw. Other shorter versions

can be built by using the 100cm / 3’ 3” or 150cm / 5’ extension and its parallelogram

rod.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag.

Page 8

8 Xten Crane System Instruction Manual

Page: 7

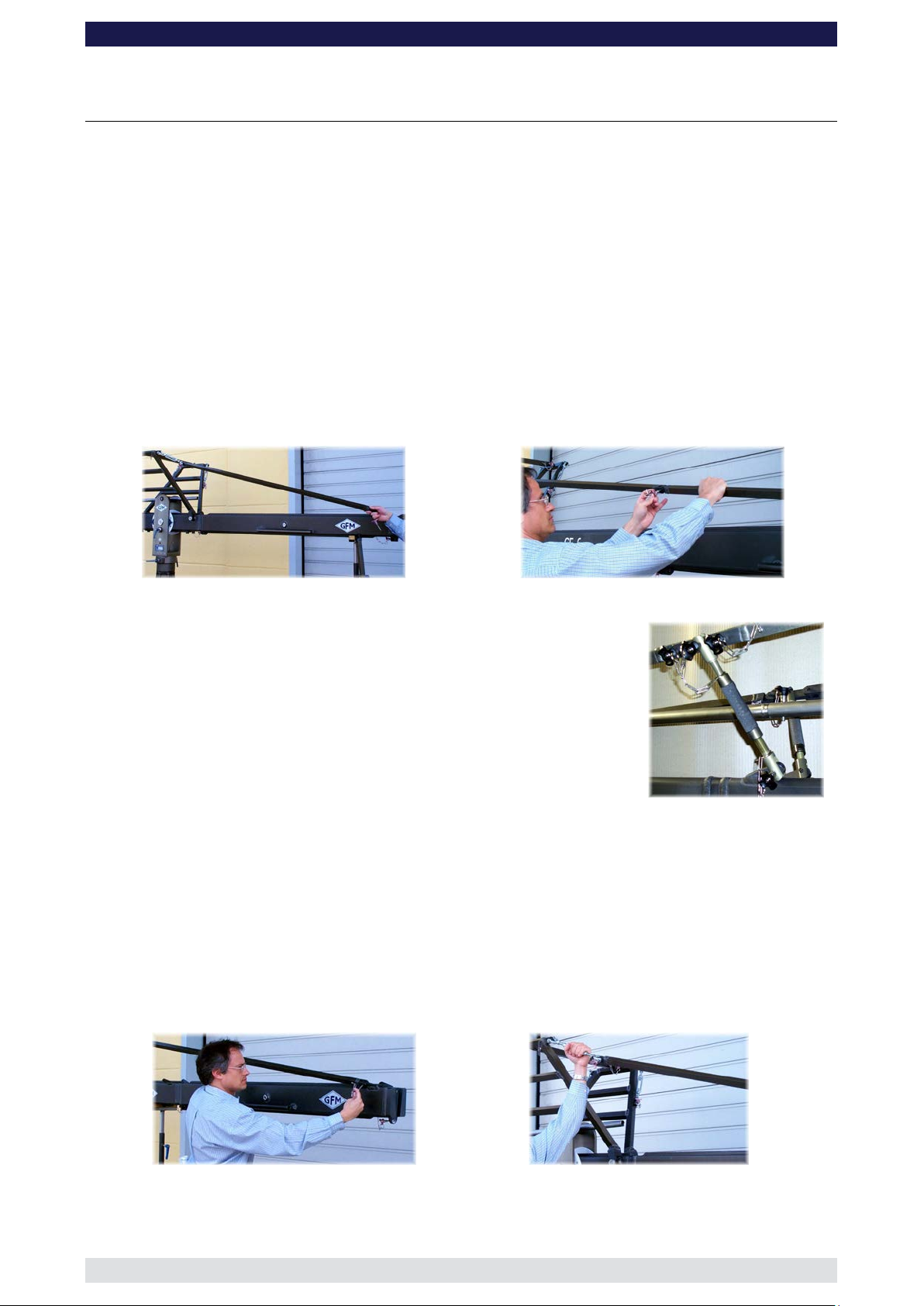

Mounting an extension arm

Securing the arm with a safety pin

Mounting an angle adjuster

Securing with a safety pin

GF-

8. Connect one of the angle adjusters to the end of the 127cm / 4ft or 150cm / 5ft

section and secure it with the provided safety pin.

Attention: Pinch point

Integrated leveller

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances t he crane’ s bal a nc e.

9. Depending on the version being assembled connect 2 of the respective rigging rods

to the turnbuckles on the rigging harness and in turn to the 2 connections on the arm

section leading to the weight bucket.

Arm section 127cm / 4ft = rigging rod 115cm / 3’ 9”

Arm section 150cm / 5ft = rigging rod 142cm / 4’ 7”

Hand tighten the rods by turning the turnbuckles until the rods are taut.

Tip: For easier assembly we recommend to support the arm of the crane with a

stable underlay.

Middle sized rigging rod

Page 9

8 Xten Crane System Instruction Manual

Page: 8

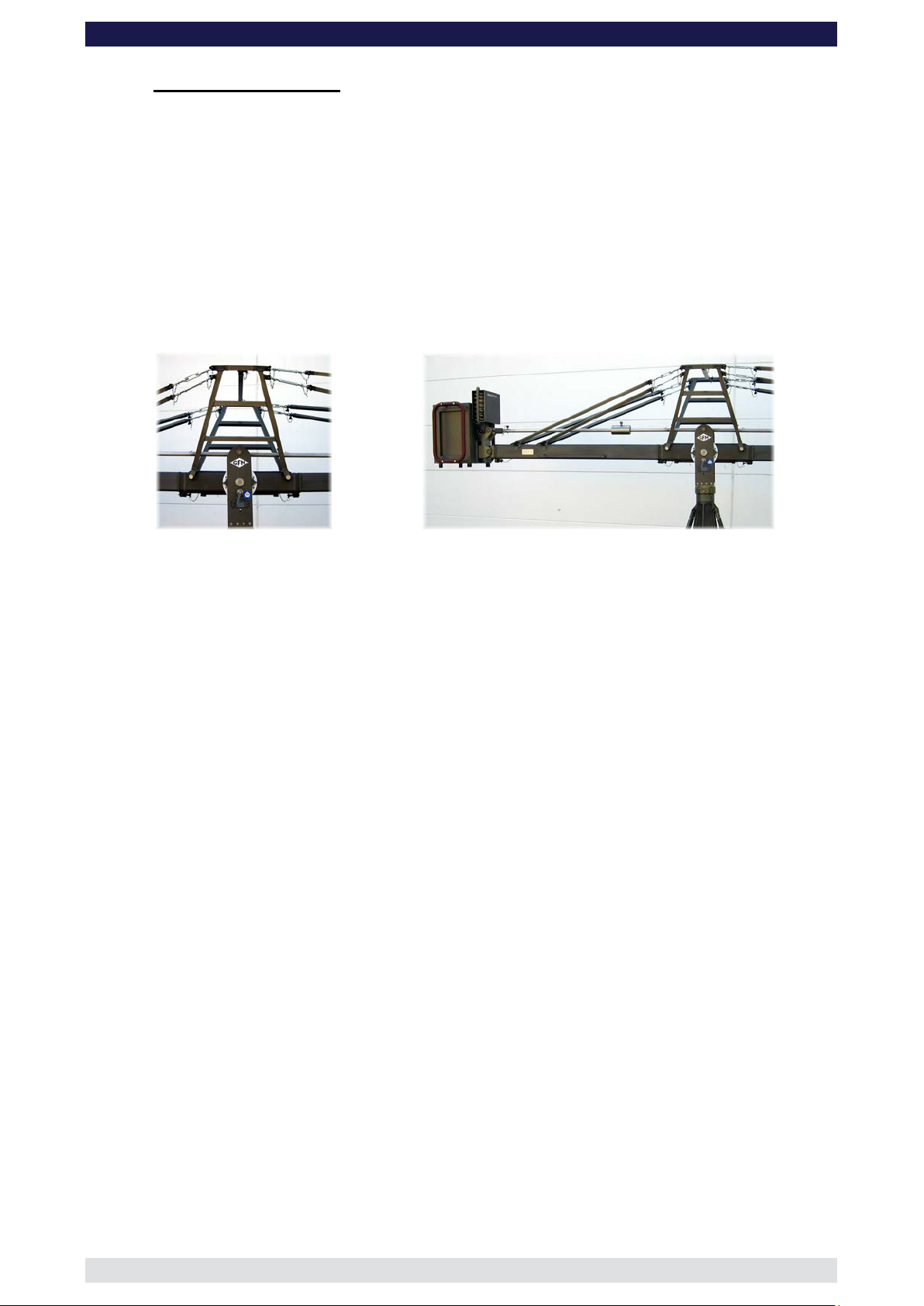

Large Rigging Harness for double Rigging

(Xten Versions 1 to 8)

(Xten-Versions 1 to 8)

GF-

For all GF-8 Xten-Versions:

With the exception of a few steps, the assembly of the Xten Versions are identical with

those of the Standard Versions. However, the following points should be followed:

o All Xten Versions require a pivot height of 184cm / 6ft as follows:

o 30cm / 1ft Column Extension and 90cm / 3ft Mounting Column

o 2 x 30cm / 1ft column extensions and a 60cm / 2ft Mounting Column

More details can be found on page 4.

o The Mounting Column for all Xten Versions (1 to 8) must be supported with the 4

Telescopic Column Supports. More details can be found on page 5.

o All Xten-Versions (1 to 8) require the Large Rigging Harness with the double

turnbuckles. An example of the assembly can be found on page 6.

o All Xten Versions (1 to 8) require the 160cm / 5’ 3“ rear arm extension as well as the

160cm / 5’ 3“ parallelogram rod to be mounted between the pivot and the angle

adjuster. Example of the assembly can be found on page 6 and 7.

o All Xten Versions (1 to 8) require a double rigging system. Connect the 142cm / 4’

7” rigging rods to the top turnbuckles and the outside connections on the rear

extension. Connect the 115cm / 3’ 9” rigging rods to the lower turnbuckles and the

inside connections on t he rear extension.

Double Rigging System with 160cm / 5’3“ Rear Extension

Page 10

8 Xten Crane System Instruction Manual

Page: 9

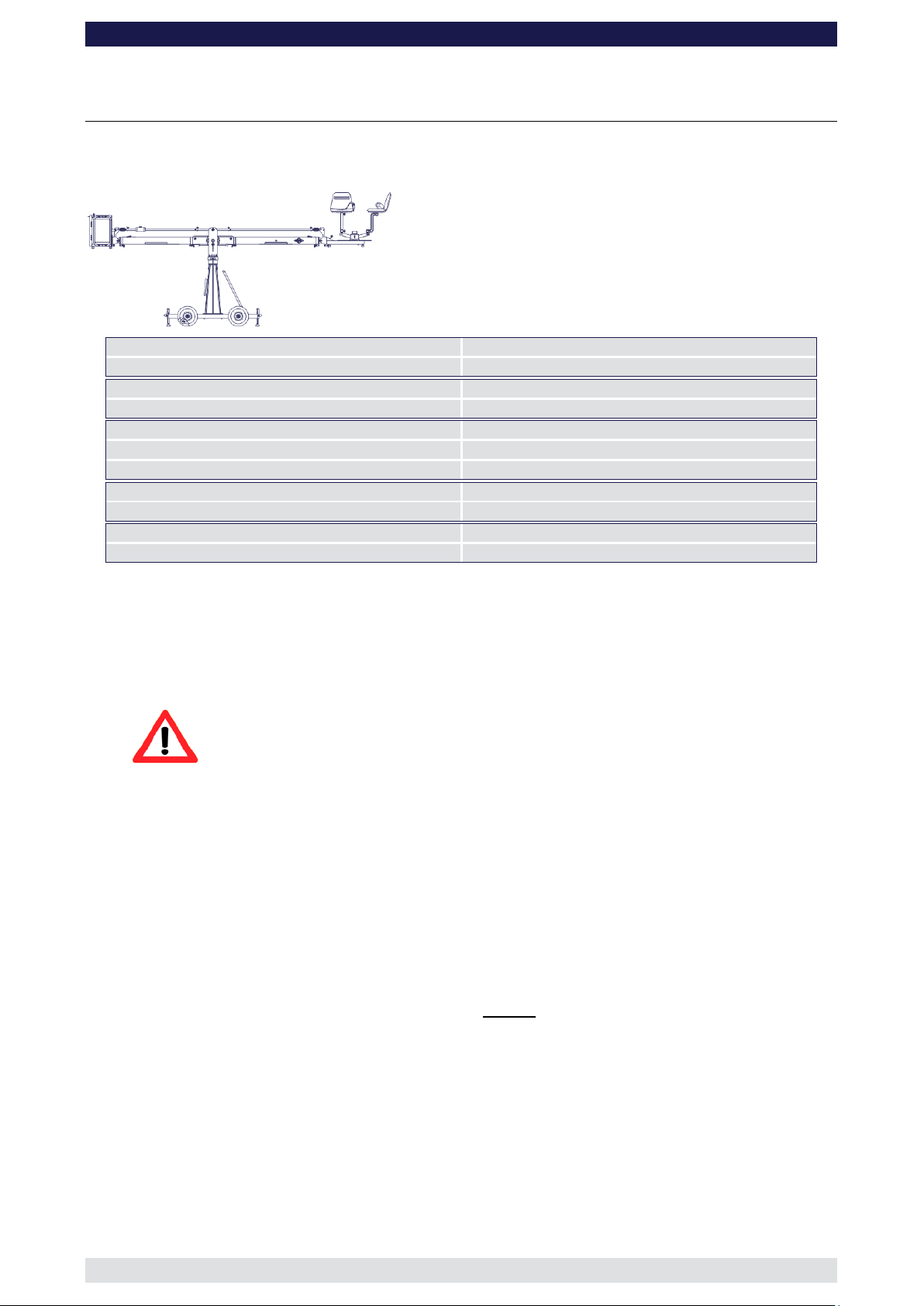

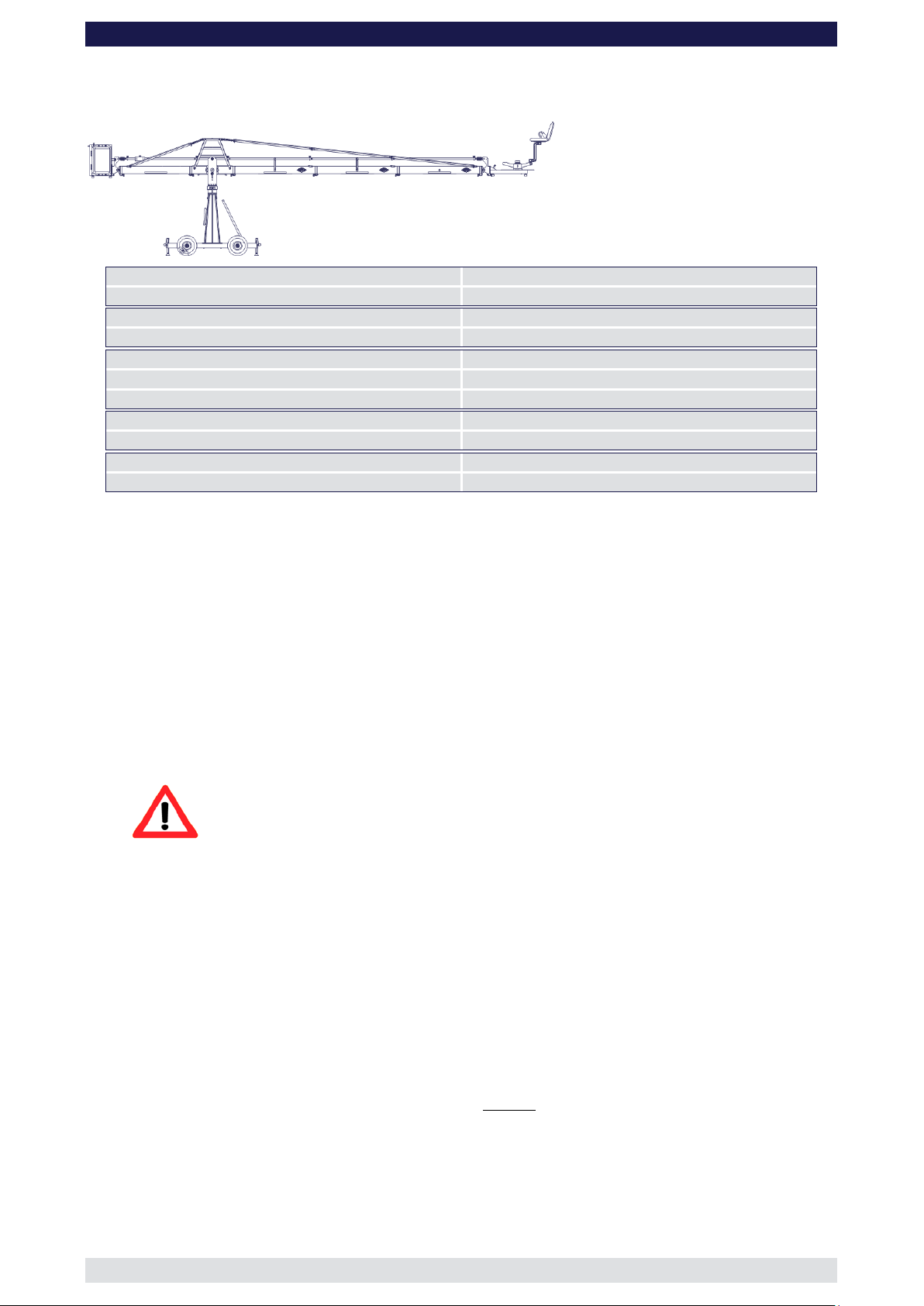

Front extension arms required

1 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

319 cm / 10’ 5”

Maximum Euro-adapter height

331 cm / 10’ 10“

Lift capacity (working load) 2 pers. + accessories

250 kg / 550 lbs

Counterweight required for max. load

276 kg / 607 lbs

Counterweight required to balanc e em pt y arm

0 kg / 0 lbs

Crane weight (excluding dolly and weights)

149 kg / 327 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

253 cm / 8’ 3“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Assembly & Technical Spec if ication Version 1 to 18

Version 1

(Pivot height 154cm / 5ft, Rear Extension 127cm / 4’ 2”)

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect the remaining angle adjuster to the end of the 150cm / 5’ section and secure

it with the provided safety pin.

Attention: Pinch point

12. Connect one of the 150cm / 5’ parallelogram rods to the middle section and the angle

adjuster and secure it with a safety pin at each end.

13. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

14. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 11

8 Xten Crane System Instruction Manual

Page: 10

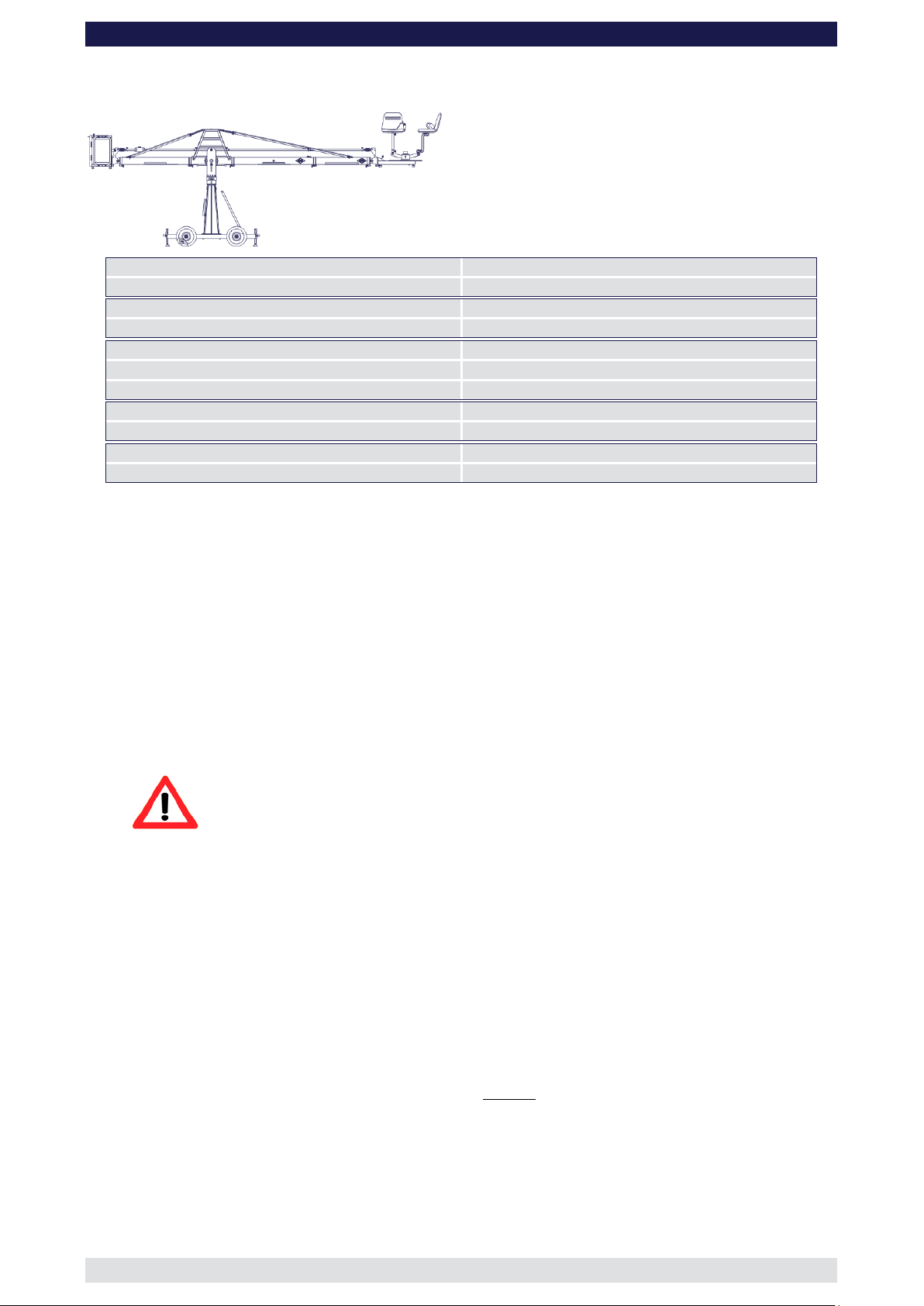

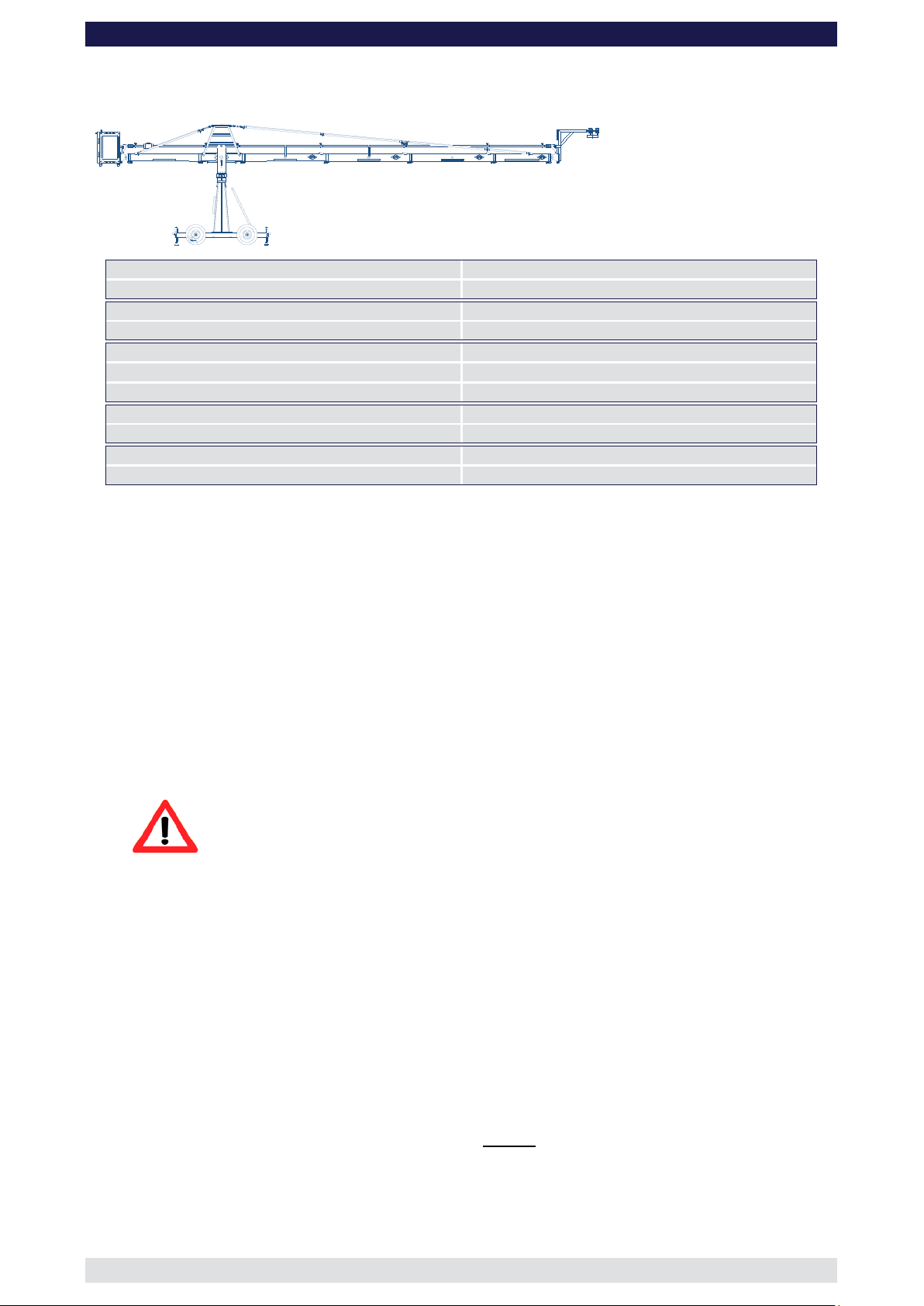

Front extension arms required

1 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

481 cm / 15’ 9”

Maximum Euro-adapter height

412 cm / 13’ 5“

Lift capacity (working load) 2 pers. + accessories

250 kg / 550 lbs

Counterweight required for max. load

456 kg / 1003 lbs

Counterweight required to balance empty arm

28 kg / 61 lbs

Crane weight (excluding dolly and weights)

173 kg / 380 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

351 cm / 11’ 5“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 2

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provi ded sa fety pin.

11. Connect the 100cm / 3’ 3” section to the 150cm / 5’ section. Slip the connection

flanges into each other and secure them with the provided safety pin.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

13. Connect a 150cm / 5’ as well as a 100cm / 3’ 3” parallelogram rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

14. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

15. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

16. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins, locking screws etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 12

8 Xten Crane System Instruction Manual

Page: 11

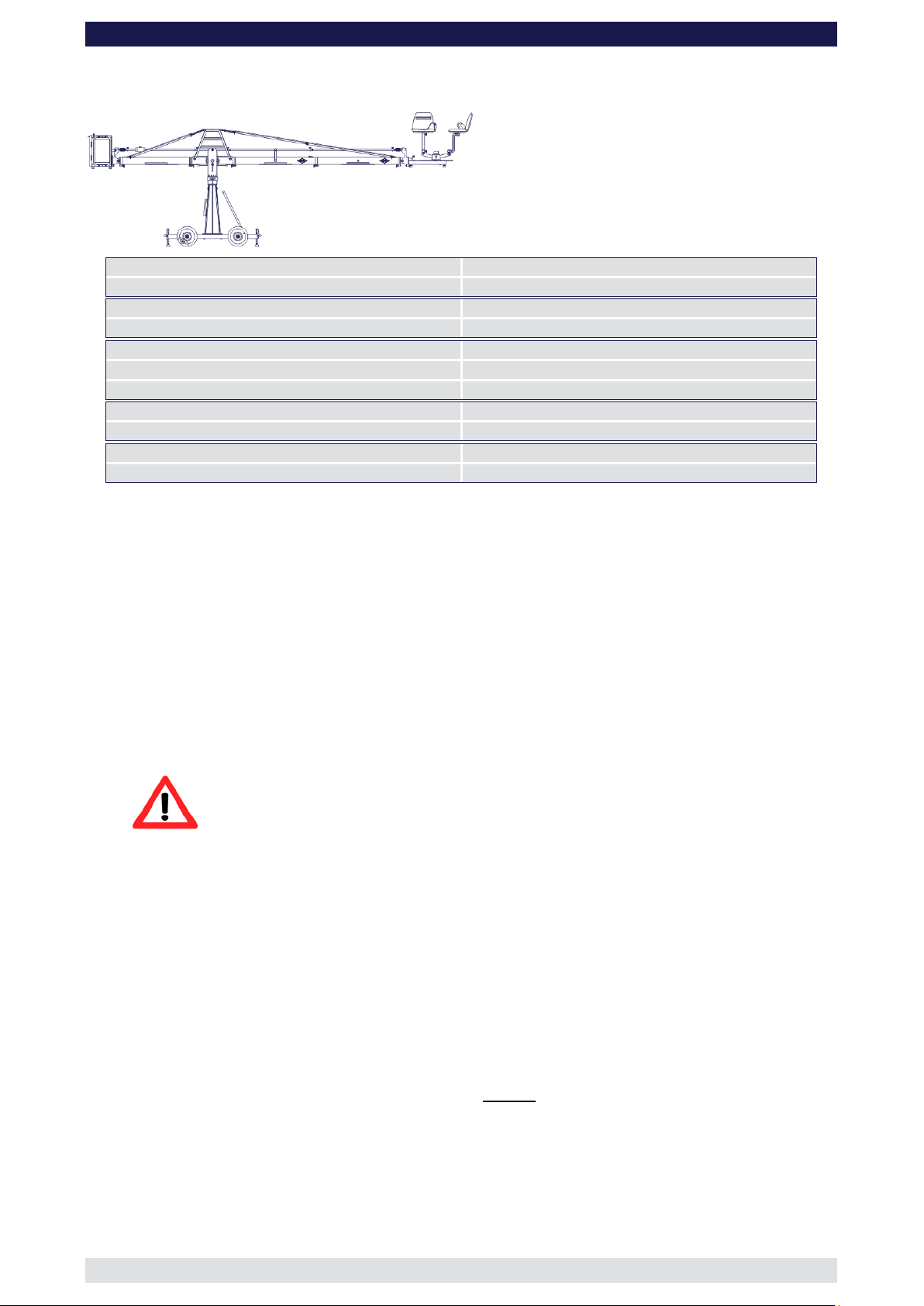

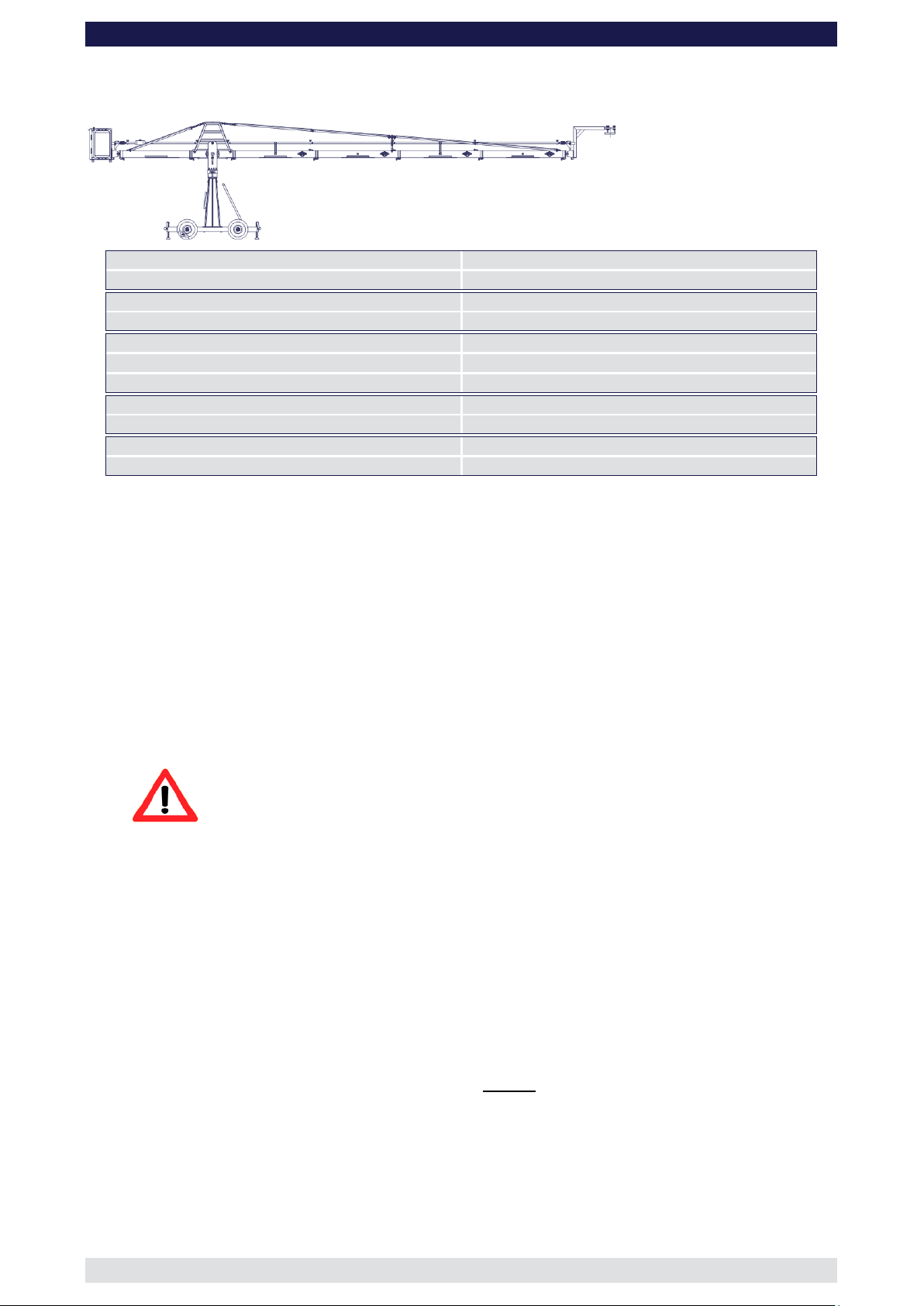

Front extension arms required

2 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

564 cm / 18’ 6”

Maximum Euro-adapter height

453 cm / 14’ 10“

Lift capacity (working load) 2 pers. + accessories

216 kg / 475 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to bal ance em pty arm

46 kg / 101 lbs

Crane weight (excluding dolly and weights)

179 kg / 393 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

401 cm / 13’ 1“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 3

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another 150cm / 5’ section to the first 150cm / 5’ section. Slip the connection

flanges into each other and secure them with the provided safety pin.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the second 150cm / 5’ section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect two 150cm / 5’ parallelogram rods to the middle section and in turn to the

angle adjuster and secure the connections with the provided safety pins.

15. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 13

8 Xten Crane System Instruction Manual

Page: 12

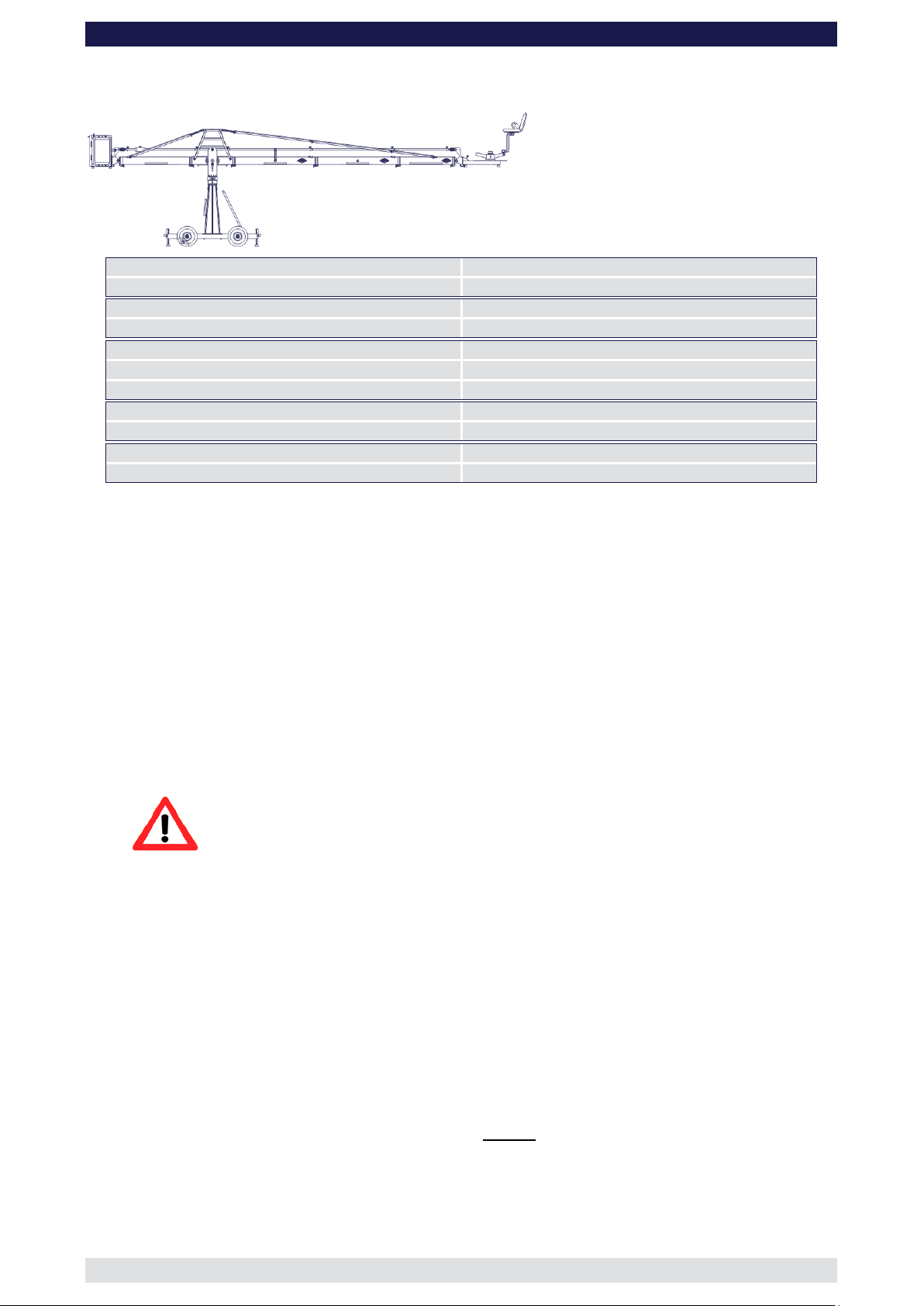

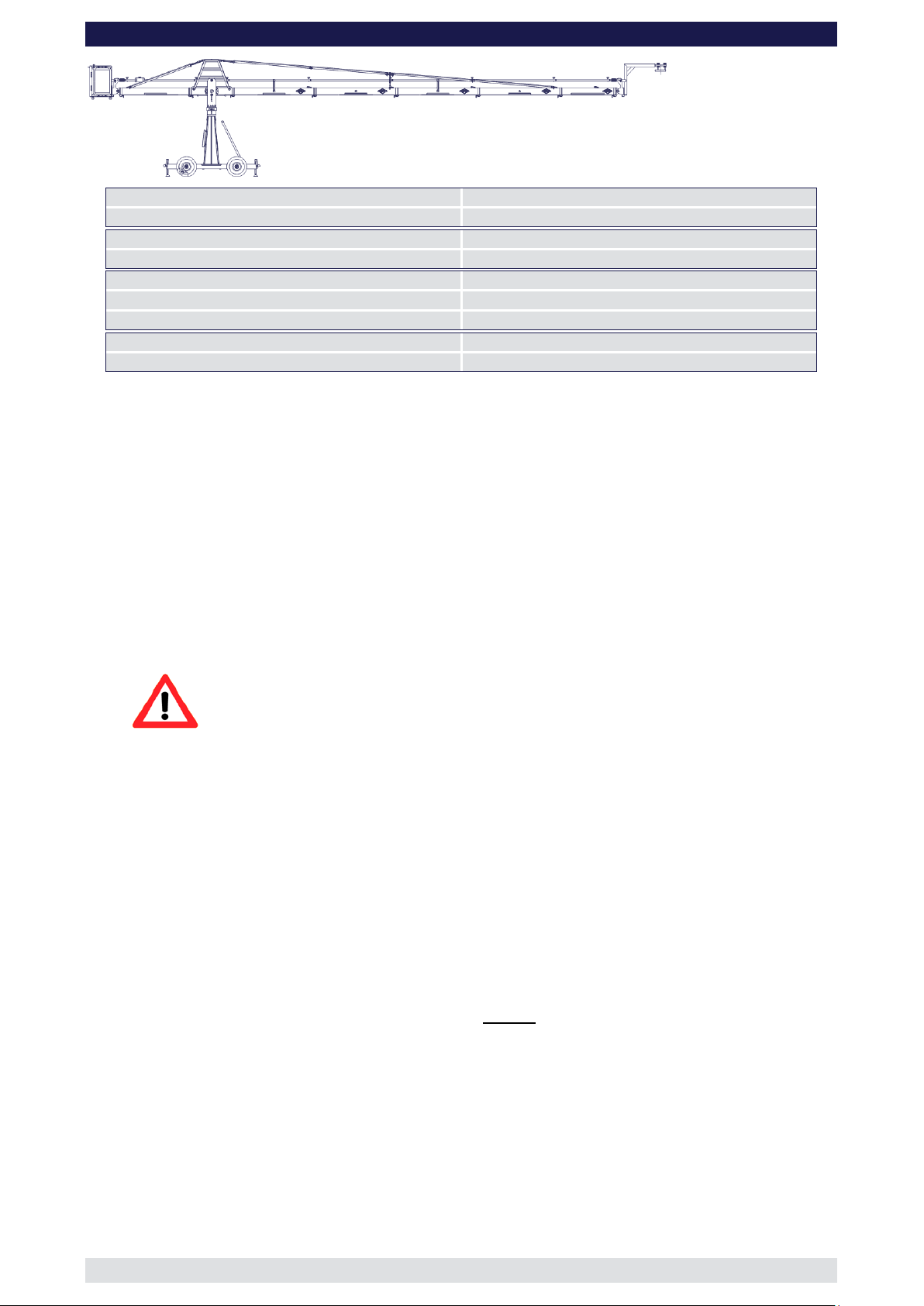

Front extension arms required

2 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

727 cm / 23’ 9”

Maximum Euro-adapter height

534 cm / 17’ 6“

Lift capacity (working load) 1 pers. + accessories

150 kg / 330 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to balanc e em pt y arm

88 kg / 176 lbs

Crane weight (excluding dolly and weights)

191 kg / 420 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

498 cm / 16’ 4“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 4

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another 150cm / 5’ and a 100cm / 3’ 3” section to the first 150cm / 5’ section.

Slip the connection flanges into each other and secure them with the provided safety

pin.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect two 150cm / 5’ parallelogram rods and a 100cm / 3’ 3” rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

15. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 14

8 Xten Crane System Instruction Manual

Page: 13

Front extension arms required

3 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

809 cm / 30’ 7”

Maximum Euro-adapter height

576 cm / 18’ 10“

Lift capacity (working load) 1 pers. + accessories

128 kg / 281 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to bala nce empty arm

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

197 kg / 433 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

549 cm / 18’

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 5

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another two 150cm / 5’ sections to the first 150cm / 5’ section. Slip the

connection flanges into each other and secure them with the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the last 150cm / 5’ section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect three 150cm / 5’ parallelogram rods to the middle section and in turn to the

angle adjuster and secure the connections with the provided safety pins.

15. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 15

8 Xten Crane System Instruction Manual

Page: 14

Front extension arms required

3 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

891 cm / 31’ 10”

Maximum Euro-adapter height

675 cm / 22’ 1“

Lift capacity

80 kg / 176 lbs

Counterweight required for max. load

420 kg / 924 lbs

Counterweight required to balanc e em pt y arm

140 kg / 308 lbs

Crane weight (excluding dolly and weights)

199 kg / 437 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

663 cm / 21’ 8“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 6

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another two 150cm / 5’ sections and a 100cm / 3’ 3” section to the first

150cm / 5’ section. Slip the connection flanges into each other and secure them with

the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect three 150cm / 5’ parallelogram rods and a 100cm / 3’ 3” rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

15. Connect the remote bracket to the angle adjuster by inserting the male flange into the

female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 16

8 Xten Crane System Instruction Manual

Page: 15

Front extension arms required

4 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

1054 cm / 34’ 6”

Maximum Euro-adapter height

716 cm / 23’ 5“

Lift capacity

80 kg / 176 lbs

Counterweight required for max. load

476 kg / 1047 lbs

Counterweight required to balanc e em pt y arm

172 kg / 378 lbs

Crane weight (excluding dolly and weights)

206 kg / 453 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

713 cm / 23’ 4“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 7

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another three 150cm / 5’ sections to the first 150cm / 5’ section. Slip the

connection flanges into each other and secure them with the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the last 150cm / 5’ section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect four 150cm / 5’ parallelogram rods to the middle section and in turn to the

angle adjuster and secure the connections with the provided safety pins.

15. Connect the remote bracket to the angle adjuster by inserting the male flange into the

female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , locking screws etc should be inspe cted to ens ure

that all assembly sections are securely fastened.

Version 8

(Pivot height 154cm / 5ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Page 17

8 Xten Crane System Instruction Manual

Page: 16

Front extension arms required

4 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

1216 cm / 39’ 10”

Maximum Euro-adapter height

798 cm / 16’ 2“

Lift capacity

50 kg / 110 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to balance empty arm

288 kg / 501 lbs

Crane weight (excluding dolly and weights)

217 kg / 477 lbs

Arm reach (pivot to camera head mount)

810 cm / 26’ 6“

GF-

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another three 150cm / 5’ sections and a 100cm / 3’ 3” section to the first

150cm / 5’ section. Slip the connection flanges into each other and secure them with

the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect four 150cm / 5’ parallelogram rods and a 100cm / 3’ 3” rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

15. Connect the remote bracket to the angle adjuster by inserting the male flange into the

female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins, locking s crew s etc shoul d be ins pec ted to ens ure

that all assembly sections are securely fastened.

Page 18

8 Xten Crane System Instruction Manual

Page: 17

Front extension arms required

1 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

319 cm / 10’ 5”

Maximum Euro-adapter height

361 cm / 11’ 10“

Lift capacity

250 kg / 550 lbs

Counterweight required for max. load

276 kg / 607 lbs

Counterweight required to balanc e em pt y arm

0 kg / 0 lbs

Crane weight (excluding dolly and weights)

160 kg / 352 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

253 cm / 8’ 3“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

Front extension arms required

1 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

481 cm / 15’ 9”

Maximum Euro-adapter height

442 cm / 14’ 5“

Lift capacity

250 kg / 550 lbs

Counterweight required for max. load

456 kg / 1003 lbs

Counterweight required to bal ance em pty arm

28 kg / 61 lbs

Crane weight (excluding dolly and weights)

184 kg / 404 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

351 cm / 11’ 5“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Attention: The following versions 9 to 16 require a 127cm / 4’ 2” section to the rear

i.e. Counterweight Bucket End.

The 30cm / 1ft Column Extension is also required to achieve a pivot

height to 184cm / 6ft. See page 4.

Version 9

(Pivot height 184cm / 6ft, Rear Extension 127cm / 4’ 2”)

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 9 is assembled in the same manner as version 1.

Version 10

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 10 is assembled in the same manner as version 2.

Page 19

8 Xten Crane System Instruction Manual

Page: 18

Front extension arms required

2 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

564 cm / 18’ 6”

Maximum Euro-adapter height

483 cm / 15’ 10“

Lift capacity

216 kg / 475 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to balanc e em pt y arm

46 kg / 101 lbs

Crane weight (excluding dolly and weights)

190 kg / 418 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

401 cm / 13’ 1“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

Front extension arms required

2 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

727 cm / 23’ 9”

Maximum Euro-adapter height

564 cm / 18’ 6“

Lift capacity

150 kg / 330 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to balanc e em pt y arm

88 kg / 176 lbs

Crane weight (excluding dolly and weights)

202 kg / 444 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

498 cm / 16’ 4“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Version 11

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 11 is assembled in the same manner as version 3.

Version 12

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 12 is assembled in the same manner as version 4.

Version 13

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Page 20

8 Xten Crane System Instruction Manual

Page: 19

Front extension arms required

3 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

809 cm / 30’ 7”

Maximum Euro-adapter height

606 cm / 19’ 10“

Lift capacity

128 kg / 281 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to balanc e em pt y arm

112 kg / 246 lbs

Crane weight (excluding dolly and weights)

208 kg / 457 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

549 cm / 18’

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

Front extension arms required

3 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

891 cm / 31’ 10”

Maximum Euro-adapter height

705 cm / 23’ 1“

Lift capacity

80 kg / 176 lbs

Counterweight required for max. load

420 kg / 924 lbs

Counterweight required to balanc e em pt y arm

140 kg / 308 lbs

Crane weight (excluding dolly and weights)

210 kg / 462 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

663 cm / 21’ 8“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 13 is assembled in the same manner as version 5.

Version 14

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 14 is assembled in the same manner as version 6.

Version 15

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Page 21

8 Xten Crane System Instruction Manual

Page: 20

Front extension arms required

4 x 150 cm / 5’

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

1054 cm / 34’ 6”

Maximum Euro-adapter height

747 cm / 24’ 5“

Lift capacity

80 kg / 176 lbs

Counterweight required for max. load

476 kg / 1047 lbs

Counterweight required to balanc e em pt y arm

172 kg / 378 lbs

Crane weight (excluding dolly and weights)

217 kg / 477 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

713 cm / 23’ 4“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

Front extension arms required

4 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 127 cm / 4’ 2”

Lift range

1216 cm / 39’ 10”

Maximum Euro-adapter height

828 cm / 27’ 2“

Lift capacity

50 kg / 110 lbs

Counterweight required for max. load

480 kg / 1056 lbs

Counterweight required to bal ance em pty arm

288 kg / 501 lbs

Crane weight (excluding dolly and weights)

288 kg / 501 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

810 cm / 26’ 6“

Length of rear end (pivot to outside of bucket)

220 cm / 7’ 2“

GF-

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 15 is assembled in the same manner as version 7.

Version 16

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 127cm / 4’ 2”)

Assemble the GF-8 Column Extension as per the instructions on page 4.

The GF-8 version 16 is assembled in the same manner as version 8.

Page 22

8 Xten Crane System Instruction Manual

Page: 21

Front extension arms required

4 x 150 cm / 5’ + 127 cm / 4’ 2”

Rear extension arm required

1 x 150 cm / 5’

Lift range

1216 cm / 39’ 10”

Maximum Euro-adapter height

850 cm / 27’ 10“

Lift capacity

50 kg / 110 lbs

Counterweight required for max. load

418 kg / 919 lbs

Counterweight required to balanc e em pt y arm

214 kg / 470 lbs

Crane weight (excluding dolly and weights)

239 kg / 525 lbs

Arm reach (pivot to camera head mount)

837 cm / 27’ 5“

Length of rear end (pivot to outside of bucket)

243 cm / 7’ 11“

GF-

Attention: The following versions 17 and 18 require a 150cm / 5ft. section to the

rear i.e. Counterweight Bucket End.

The 30cm / 1ft Column Extension is also required to achieve a pivot

height to 184cm / 6ft. See page 4

Version 17

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 150cm / 5’)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another three 150cm / 5’ sections and the 127cm / 4’ 2” section to the first

150cm / 5’ section. Slip the connection flanges into each other and secure them with

the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the 127cm / 4’ 2” section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect four 150cm / 5’ parallelogram rods and a 127cm / 4’ 2” rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

15. Connect the remote bracket to the angle adjuster by inserting the male flange into the

female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

Page 23

8 Xten Crane System Instruction Manual

Page: 22

GF-

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 24

8 Xten Crane System Instruction Manual

Page: 23

Front extension arms required

4 x 150 cm / 5’ + 127 cm / 4’ 2” + 100 cm / 3’ 3”

Rear extension arm required

1 x 150 cm / 5’

Lift range

1423 cm / 46’ 8”

Maximum Euro-adapter height

931 cm / 30’ 6“

Lift capacity

50 kg / 110 lbs

Counterweight required for max. load

498 kg / 1095 lbs

Counterweight required to balanc e em pt y arm

228 kg / 501 lbs

Crane weight (excluding dolly and weights)

250 kg / 625 lbs

Arm reach (pivot to camera head mount)

935 cm / 30’ 8“

Length of rear end (pivot to outside of bucket)

243 cm / 7’ 11“

GF-

Version 18

(Pivot height 184cm / 6ft, Standard Rigging Harness, Rear Extension 150cm / 5’)

Rigging is required! Observe guidelines on page 41.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another three 150cm / 5’ sections, the 127cm / 4’ 2” section and the 100cm /

3’ 3” to the first 150cm / 5’ section. Slip the connection flanges into each other and

secure them with the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

13. Mount the parallelogram rod support to the respective section as shown on page 40.

14. Connect four 150cm / 5’ parallelogram rods, the 127cm / 4’ 2” rod and the 100cm / 3’

3” rod to the middle section and in turn to the angle adjuster and secure the

connections with the provided safety pins.

15. Connect the remote bracket to the angle adjuster by inserting the male flange into the

female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the standard rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 17 and 18 on page 41.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 25

8 Xten Crane System Instruction Manual

Page: 24

Front extension arms required

2 x 150 cm / 5’

Rear extension arm required

1 x 160 cm / 5’ 3”

Lift range

564 cm / 18’ 6”

Maximum Euro-adapter height

483 cm / 15’ 10“

Lift capacity

250 kg / 550 lbs

Counterweight required for max. load

456 kg / 1003 lbs

Counterweight required to balance empty arm

28 kg / 61 lbs

Crane weight (excluding dolly and weights)

203 kg / 446 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

401 cm / 13’ 1“

Length of rear end (pivot to outside of bucket)

253 cm / 8’ 3“

GF-

Assembly & Technical Specifications for the Xten Versions

Attention: The following Xten Versions, 1 to 8 require a 160cm / 5’ 3” section to the

rear i.e. Counterweight Bucket End.

In addition to the standard mounting column, the 30cm / 1ft Column

Extension is also required to achieve a pivot height of 184cm / 6ft.

Note: A larger rigging harnes s than the standard and a double rigging rather

than the standard single system is required to the front and r ear of the

crane arm.

Xten Version 1

(Pivot height 184cm / 6ft, Large Rigging Harness, Rear Extension 160cm / 5’ 3")

Double rigging is required! Observe guidelines on page 423 and additiona lly ensure

that the Large Rigging Harness is used with double rigging to the rear and front.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Now the lower front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 43.

12. After the lower front rigging system was assembled and connected to the connectors

of the first 150cm / 5’ section connect another 150cm / 5’ section to the first one. Slip

the connection flanges into each other and secure them with the provided safety pin.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

13. Connect the remaining angle adjuster to the end of the second 150cm / 5’ section and

secure it with the provided safety pin.

Attention: Pinch point

Page 26

8 Xten Crane System Instruction Manual

Page: 25

GF-

14. Connect two 150cm / 5’ parallelogram rods to the middle section and in turn to the

angle adjuster and secure the connections with the provided safety pins.

15. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

16. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

17. Now the top front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 44.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 27

8 Xten Crane System Instruction Manual

Page: 26

Front extension arms required

2 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 160 cm / 5’ 3”

Lift range

727 cm / 23’ 10”

Maximum Euro-adapter height

564 cm / 18’ 6“

Lift capacity

240 kg / 528 lbs

Counterweight required for max. load

586 kg / 1289 lbs

Counterweight required to balanc e em pt y arm

64 kg / 140 lbs

Crane weight (excluding dolly and weights)

220 kg / 484 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

499 cm / 16’ 4“

Length of rear end (pivot to outside of bucket)

253 cm / 8’ 3“

GF-

Xten Version 2

(Pivot height 184cm / 6ft, Large Rigging Harness, Rear Extension 160cm / 5’ 3")

Double rigging is required! Observe guidelines on page 423 and additiona lly ensure

that the Large Rigging Harness is used with double rigging to the rear and front.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Now the lower front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 43.

12. After the lower front rigging system was assembled and connected to the connectors

of the first 150cm / 5’ section connect another 150cm / 5’ section and the 100cm / 3’

3” section to the first one. Slip the connection flanges into each other and secure

them with the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

13. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

14. Mount the parallelogram rod support to the respective section as shown on page 40.

15. Connect two 150cm / 5’ parallelogram rods and the 100cm / 3’ 3” rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

16. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

17. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

Page 28

8 Xten Crane System Instruction Manual

Page: 27

GF-

the platform or the remote brack et before loading any weights.

18. Mount the extra mini counterweight bucket as shown on page 46.

19. Now the top front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 44.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 29

8 Xten Crane System Instruction Manual

Page: 28

Front extension arms required

3 x 150 cm / 5’ + 100 cm / 3’ 3”

Rear extension arm required

1 x 160 cm / 5’ 3”

Lift range

971 cm / 31’ 10”

Maximum Euro-adapter height

687 cm / 22’ 6“

Lift capacity

170 kg / 374 lbs

Counterweight required for max. load

600 kg / 1320 lbs

Counterweight required to balanc e em pt y arm

130 kg / 286 lbs

Crane weight (excluding dolly and weights)

238 kg / 523 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

647 cm / 21’ 2“

Length of rear end (pivot to outside of bucket)

253 cm / 8’ 3“

GF-

Xten Version 3

(Pivot height 184cm / 6ft, Large Rigging Harness, Rear Extension 160cm / 5’ 3")

Double rigging is required! Observe guidelines on page 423 and additiona lly ensure

that the Large Rigging Harness is used with double rigging to the rear and front.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Now th e lower front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 43.

12. After the lower front rigging system was assembled and connected to the connectors

of the first 150cm / 5’ section connect another two 150cm / 5’ sections and the 100cm

/ 3’ 3” section to the first one. Slip the connection flanges into each other and secure

them with the provided safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

13. Connect the remaining angle adjuster to the end of the 100cm / 3’ 3” section and

secure it with the provided safety pin.

Attention: Pinch point

14. Mount the parallelogram rod support to the respective section as shown on page 40.

15. Connect three 150cm / 5’ parallelogram rods and the 100cm / 3’ 3” rod to the middle

section and in turn to the angle adjuster and secure the connections with the provided

safety pins.

16. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

17. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

Page 30

8 Xten Crane System Instruction Manual

Page: 29

GF-

the platform or the remote brack et before loading any weights.

18. Mount the extra mini counterweight bucket as shown on page 46.

19. Now the top front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 44.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 31

8 Xten Crane System Instruction Manual

Page: 30

Front extension arms required

4 x 150 cm / 5’

Rear extension arm required

1 x 160 cm / 5’ 3”

Lift range

1054 cm / 34’ 6”

Maximum Euro-adapter height

728 cm / 23’ 10“

Lift capacity

140 kg / 308 lbs

Counterweight required for max. load

600 kg / 1320 lbs

Counterweight required to balanc e em pt y arm

154 kg / 338 lbs

Crane weight (excluding dolly and weights)

246 kg / 541 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

697 cm / 22’ 10“

Length of rear end (pivot to outside of bucket)

253 cm / 8’ 3“

GF-

Xten Version 4

(Pivot height 184cm / 6ft, Large Rigging Harness, Rear Extension 160cm / 5’ 3")

Double rigging is required! Observe guideli nes on page 43 and additionally ensure

that the Large Rigging Harness is used with double rigging to the rear and front.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another 150cm / 5’ section to the first 150cm / 5’ section. Slip the connection

flanges into each other and secure them with the provided safety pin.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Now the lower front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 43.

13. After the lower fro nt rigging s ystem was assembled and connected to the connectors

of the second 150cm / 5’ section connect another two 150cm / 5’ sections to the first

ones. Slip the connection flanges into each other and secure them with the provided

safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

14. Connect the remaining angle adjuster to the end of the last 150cm / 5’ section and

secure it with the provided safety pin.

Attention: Pinch point

15. Mount the parallelogram rod support to the respective section as shown on page 40.

16. Connect four 150cm / 5’ parallelogram rods to the middle section and in turn to the

angle adjuster and secure the connections with the provided safety pins.

17. Connect the platform to the angle adjuster by inserting the male platform flange into

the female flange on the angle adjuster. Secure it with the safety pin.

18. Attach the weight bucket to the short end of the crane by inserting the male weight

bucket flange into the female flange on the angle adjuster. Secure it with the 2 safety

Page 32

8 Xten Crane System Instruction Manual

Page: 31

GF-

pins on the top of the angle adjuster.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance. Level the weight bucket,

the platform or the remote brack et before loading any weights.

19. Mount the extra mini counterweight bucket as shown on page 46.

20. Now the top front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 44.

Before operation, all locking pins , loc king scr ews etc should be inspe cted to e nsure

that all assembly sections are securely fastened.

Page 33

8 Xten Crane System Instruction Manual

Page: 32

Front extension arms required

5 x 150 cm / 5’

Rear extension arm required

1 x 160 cm / 5’ 3”

Lift range

1299 cm / 42’ 7”

Maximum Euro-adapter height

869 cm / 28’ 6“

Lift capacity

80 kg / 176 lbs

Counterweight required for max. load

526 kg / 1159 lbs

Counterweight required to balanc e em pt y arm

214 kg / 471 lbs

Crane weight (excluding dolly and weights)

255 kg / 561 lbs

Dolly weight

80 kg / 176 lbs

Arm reach (pivot to camera head mount)

861 cm / 28’ 2“

Length of rear end (pivot to outside of bucket)

253 cm / 8’ 3“

GF-

Xten Version 5

(Pivot height 184cm / 6ft, Large Rigging Harness, Rear Extension 160cm / 5’ 3")

Double rigging is required! Observe guideli nes on page 43 and additionally ensure

that the Large Rigging Harness is used with double rigging to the rear and front.

Continue from § 9, page 7

10. Connect one of the 150cm / 5’ sections to the middle section. Slip the connection

flanges into each other and secure them with the provided safety pin.

11. Connect another 150cm / 5’ section to the first 150cm / 5’ section. Slip the connection

flanges into each other and secure them with the provided safety pin.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.

12. Now the lower front rigging system can be assembled. Therefor follow the instructions

as exemplary shown by version 7 and 8 on page 43.

13. After the lower front rigging system was assembled and connected to the connectors

of the second 150cm / 5’ section connect another three 150cm / 5’ sections to the first

ones. Slip the connection flanges into each other and secure them with the provided

safety pins.

Note: After each mounted section the support stand or rostrum can be moved up to

the next fixed section. We recommend to support longer crane versions with

more than one support stand or rostrum.