Page 1

Grip Factory Munich

YOUR INNOVATIVE PARTNER FOR CAMERA SUPPORT

GF-16

Crane System

Instruction Manual

Grip Factory Munich GmbH

Fürholzener Straße 1

85386 Eching bei München

Germany

Valid: March 2010

Tel.: +49 (0) 89 319 0 129-0

Fax: +49 (0) 89 319 0 129-9

e-Mail: info@g-f-m.net

http://www.g-f-m.net

Page 2

GF-16 Crane System Instruction Manual

Contents:

SAFETY GUIDELINES............................................................................................... 2

Assembly Procedure – GF-16..................................................................................... 3

For all versions: ............................................................................................................3

The GF-16 Adjustable Mounting Column:................................................................... 4

Pivot Section............................................................................................................... 5

General Assembly ...................................................................................................... 5

Version 1 ......................................................................................................................7

Version 2 ......................................................................................................................8

Rigging system........................................................................................................... 9

General:........................................................................................................................9

Rigging Harness Assembly:..........................................................................................9

Parallelogram Supports ............................................................................................ 10

Version 3 ....................................................................................................................11

Version 4 ....................................................................................................................13

Version 5 ....................................................................................................................15

Version 6 ....................................................................................................................17

Version 7 ....................................................................................................................19

Version 8 ....................................................................................................................21

Version 9 ....................................................................................................................23

Version 10 ..................................................................................................................26

Version 11 ..................................................................................................................29

Version 12 ..................................................................................................................32

Version 13 ..................................................................................................................35

Version 14 ..................................................................................................................38

Version 15 ..................................................................................................................41

Remote Head Mount................................................................................................. 43

Balancing the crane arm........................................................................................... 44

Deloading: ..................................................................................................................44

General Safety............................................................................................................44

Positioning the Adjustable Mounting Column............................................................ 45

GF-16 Camera Crane and Dolly Dimensions............................................................ 46

Dolly weight................................................................................................................46

Accessories for GF-16 Crane platform weight list.......................................................47

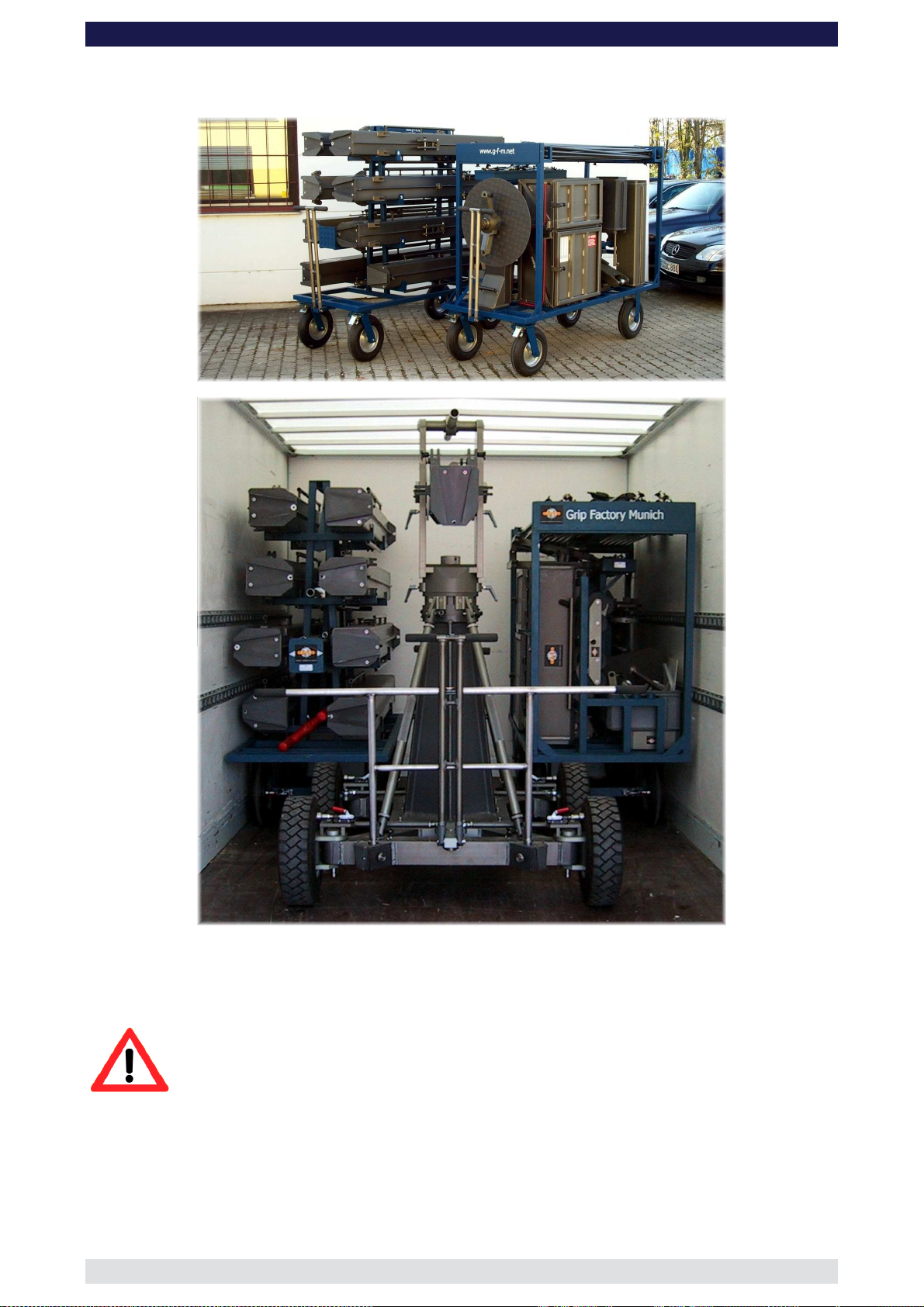

Transport trolley for the GF-16 Crane.........................................................................48

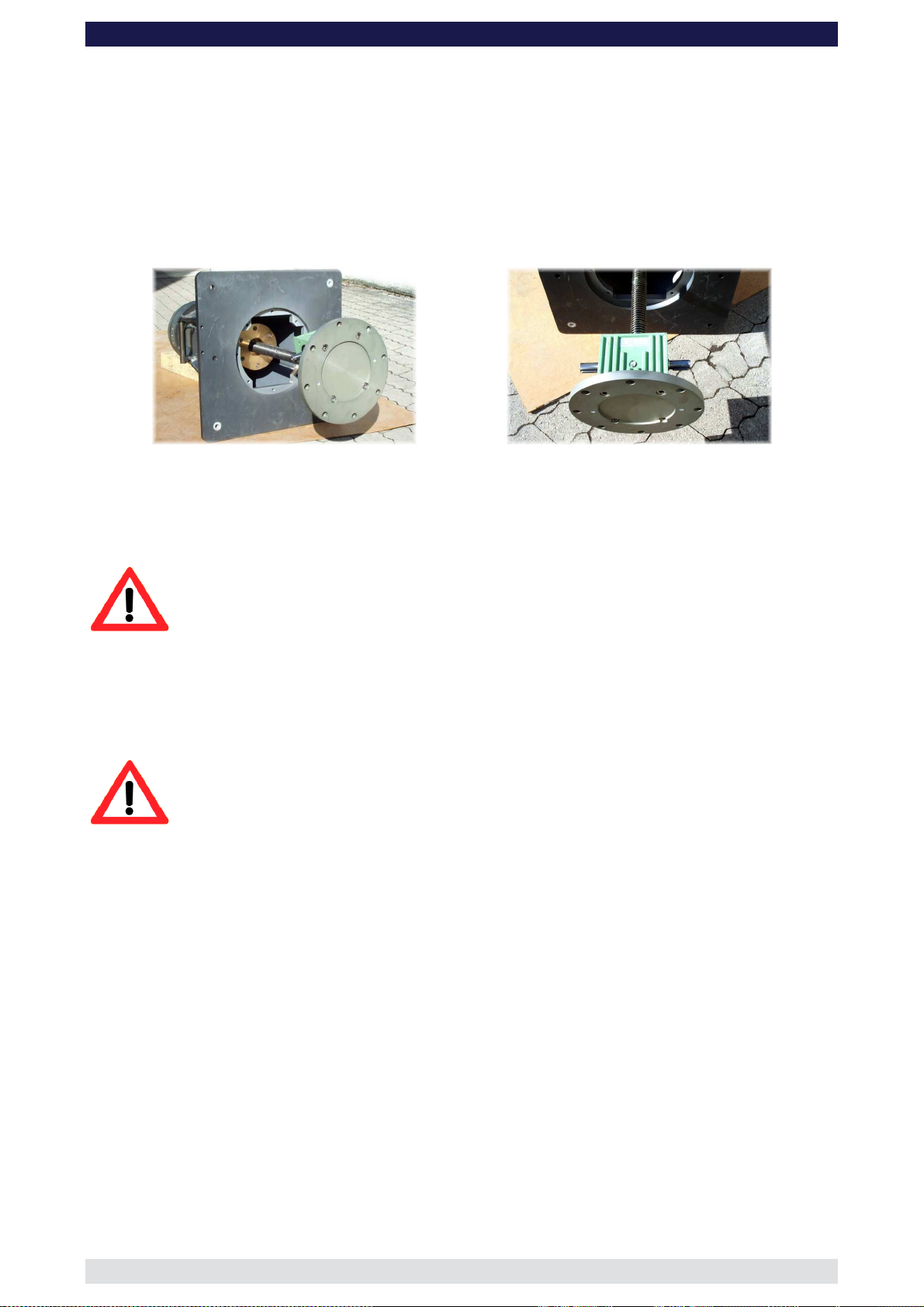

Maintaining the Adjustable Column .......................................................................... 49

Dismantling the column:..............................................................................................49

Maintenance...............................................................................................................50

Regular Inspections....................................................................................................51

EC Declaration of Conformity ................................................................................... 52

Page: 1

Page 3

GF-16 Crane System Instruction Manual

SAFETY GUIDELINES

The set-up instructions must be read and understood before set-up or operation. The crane may only be

assembled in accordance with the manufacturer’s instruction manual. The manufacturers technical

specifications and limits (maximum rated loads of each version) must be adhered to at all times and in no

way exceeded.

The GF-16 Crane may only be set-up or operated by trained and experienced personnel. To assemble the

crane at least two men are needed. To avoid misuse by untrained personnel, the crane should be dismantled

when not in use or under supervision.

For further information on the qualifications required for test personnel please refer to BGV 1, §33 and §34.

The crane may not be set-up or operated under the influence of alcohol, drugs or any other intoxicating

substances. The respective protective clothing e.g. gloves, should be worn.

The manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due to

negligence by the crane operator or misuse of the crane or disregarding the instruction manual.

Before assembling the crane ensure that the ground surface is stable and cannot give way. The ground

surface must be stable enough to support at least 2300 kg/m2 = 5060 lbs/ sq yard.

Crane operation is only allowed with solid tires. Use with pneumatic wheels is not allowed. Before and while

using the crane the wheels should be inspected.

Whether operating or moving the crane on track or on a solid ground surface it is essential that the track or

surface is completely level, stable and free from obstructions. If necessary, level the crane with the provided

levelling legs.

When operating the crane on track, ensure that the track is level, properly laid and constructed. The correct

underlay must be used to ensure that the track and underlay are secured against moving, slipping and

collapse. Ensure that the underlay provides the specified support and stability. Use the manufacturers

mounting ramp when driving on or off track.

Operation on curved track is strictly forbidden.

Use of the crane on insert vehicles, camera cars or any motorised vehicle is not allowed. The

manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due to use of

the crane on insert vehicles, camera cars or any other motorised vehicles.

Changing weather conditions should be taken into consideration. The crane must be taken out of operation

before the operational wind speed reaches 25km/h (15.6mph). For this purpose see page 44.

The complete lift and panning range of the GF-16 Crane must be kept clear of obstructions at all times. A

safety clearance of 1m / 3' 3" must be observed on all sides of the crane during operation. Only authorised,

trained and experienced personnel are allowed to operate the crane. In the interest of safe crane operation,

when operating or moving the crane, abrupt, sudden movements of the crane should be avoided. An

element of risk remains by people moving in the operational range of the crane. The crane operator has to

be trained on that and is only allowed to operate the crane in safe range.

The crane may not be used in the direct vicinity of high voltage power cables. To avoid accidents due to

misuse in the vicinity of high voltage power cables, Safety Guidelines (especially VBG 1 and 4) as well as

VDE regulations (especially 0105 part 100) must be adhered to. If the nominal voltage cannot be

determined, a minimum clearance of 5m / 16ft must be kept at all times. Failing to do so can cause fatalities.

Personnel on board the crane's platform must use safety belts at all times. They should not make any

sudden, abrupt movements or lean out over the side of the platform. No loose objects may be stored or

placed on the crane platform.

Before the counterweights are removed from the bucket, ensure that the platform is resting on the ground or

alternatively supported by an appropriate stable underlay. Gradually remove the counterweights before

personnel leave the platform or before the remote head or camera are dismounted. It’s not allowed to put

extra weights on top of the counterweight bucket or any other part of the crane!

For safety reasons only original accessories manufactured by GFM may be used with the crane.

Page: 2

Page 4

GF-16 Crane System Instruction Manual

Assembly Procedure – GF-16

General description:

The GF-16 is a mobile crane-system for mounting cameras in a stationary ground position

or for movement on track.

It can be operated manually from the ground and can be panned in all directions either

with a remote-bracket or a 1 to 2 person platform. In accordance to the safety guidelines

the crane is only allowed to be used on solid, level and stable ground. While using it

stationary the levelling legs have to be used.

The crane operation from the ground is managed by at least one experienced, trained and

authorised personnel from the hand grips on the counterweight bucket.

Operation of the crane is only allowed within the limits and guidelines mentioned in the

instruction manual. The allowed payloads of each version are clearly shown on the

counterweight-bucket (workplace of the crane operator).

Attention: Before and during assembly observe the Safety Guidelines.

For all versions:

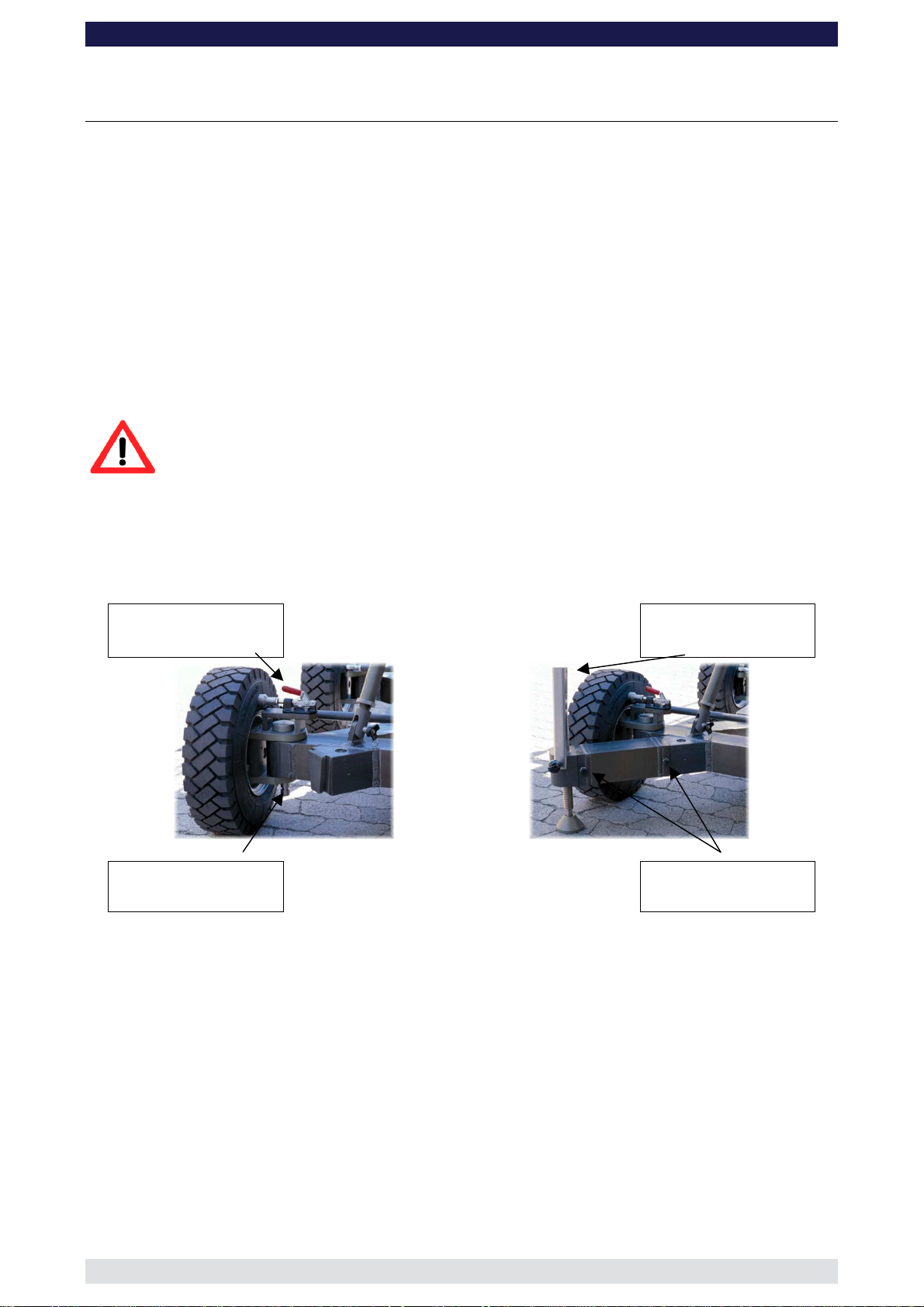

1. Secure the base dolly so that it cannot move or roll. Lock all wheel brakes. Move the

steering rod towards the centre of the dolly or remove it so that the set-up personnel

do not trip over it.

Wheel brake

Track wheel

Connection

The levelling legs should be used to level the base when stationary

Levelling leg

Locking pin

Page: 3

Page 5

GF-16 Crane System Instruction Manual

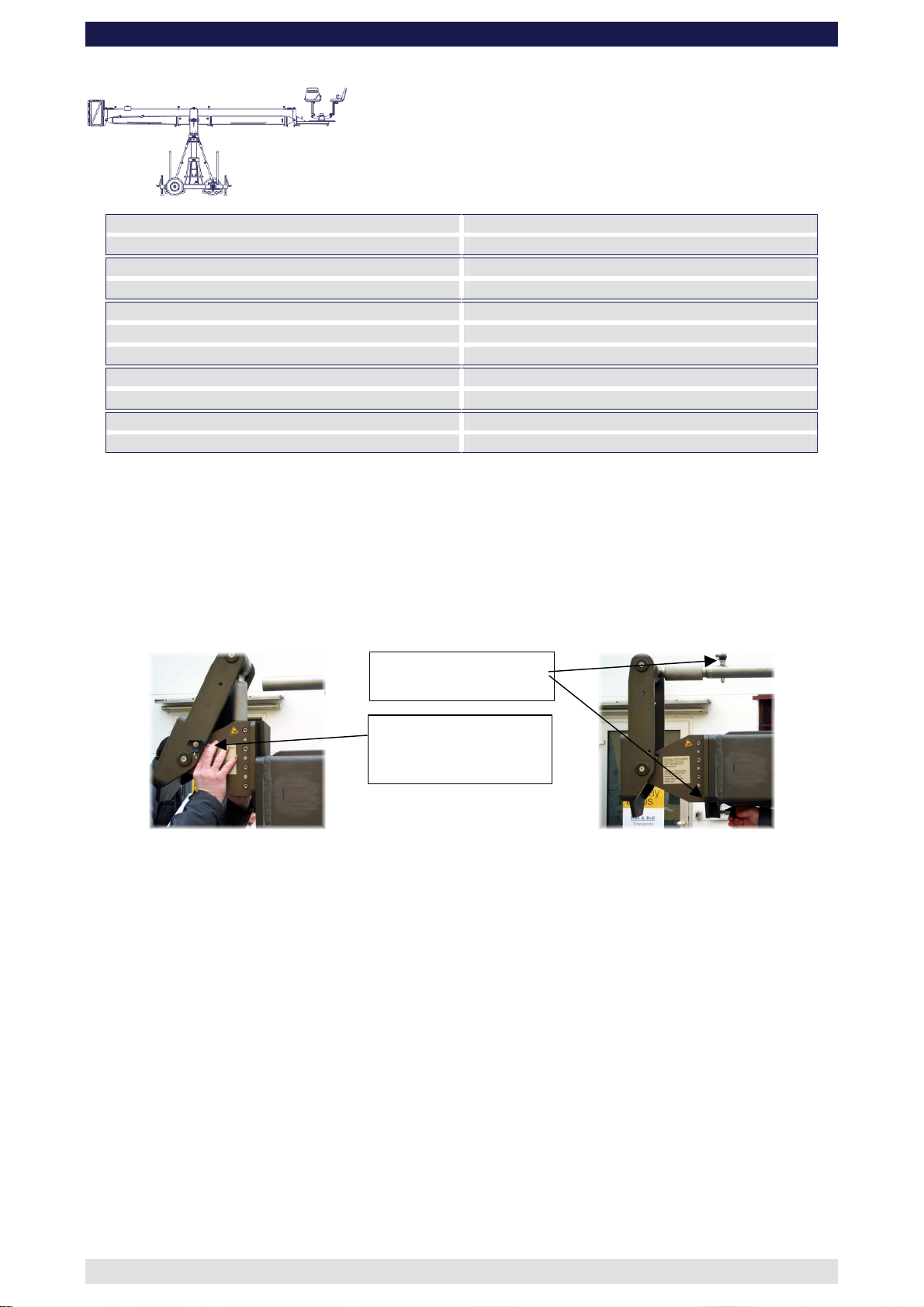

The GF-16 Adjustable Mounting Column:

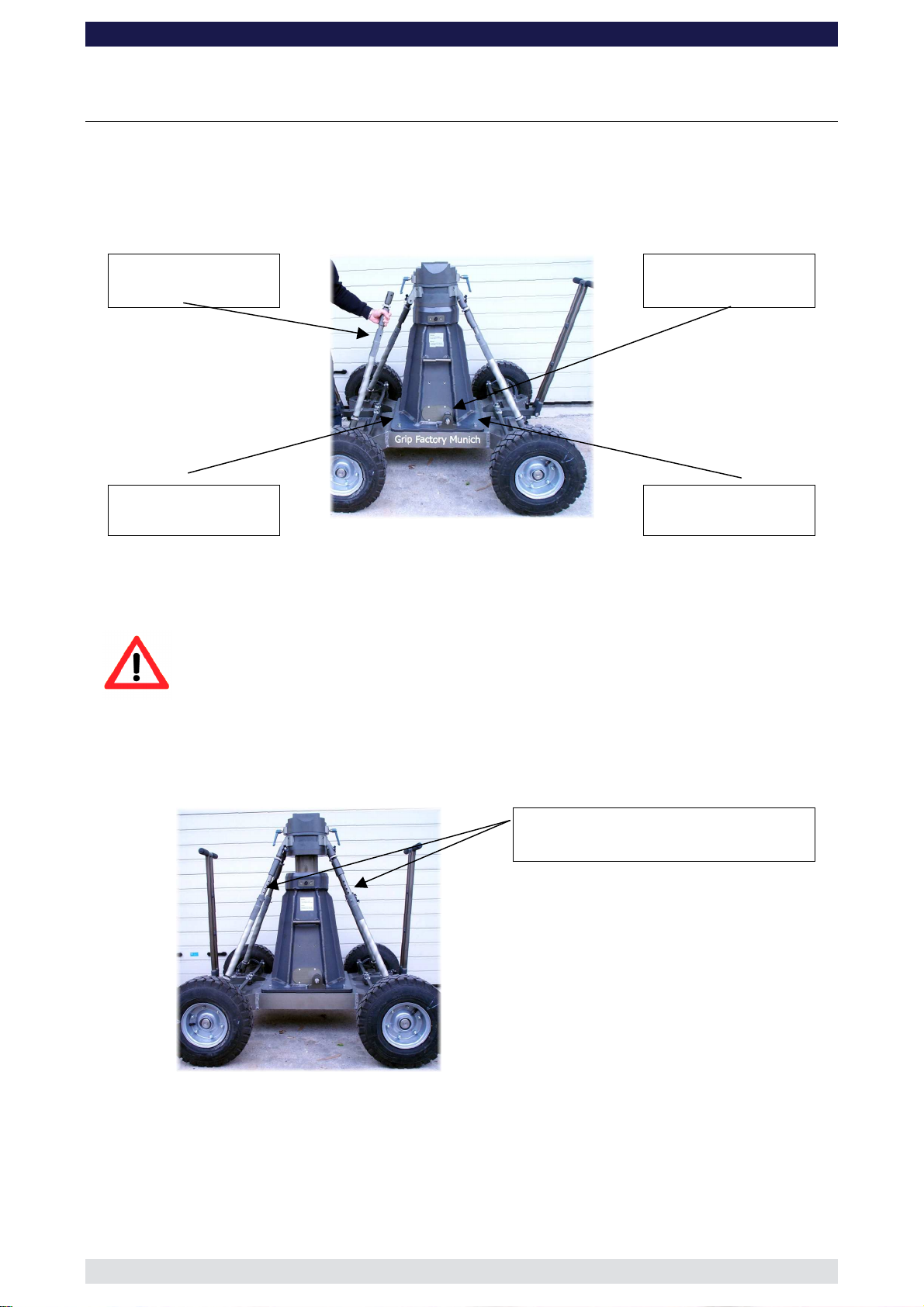

2. Bolt the Adjustable Mounting Column to the base dolly. Make sure that the locking

bolts are locked securely.

Tip: The carrying handles on the bazooka should point to the left and right of the

dolly.

Adjustable stabilizing

rods

Column drive

Connection

Locking bolts

Locking bolts

3. Connect the 4 Adjustable Stabilizing Rods between the base and the column by

securing each one with a locking pin at the top and bottom of each rod.

Important:

When adjusting the height of the column make sure that the 4

Adjustable Stabilizing Rods can move freely and that they are not

restricted in travel. The Rod Locking Pin found in the middle of each

rod must be removed when adjusting the height and reinserted only

when the column is in the required position.

Rod Locking Pins

Page: 4

Page 6

GF-16 Crane System Instruction Manual

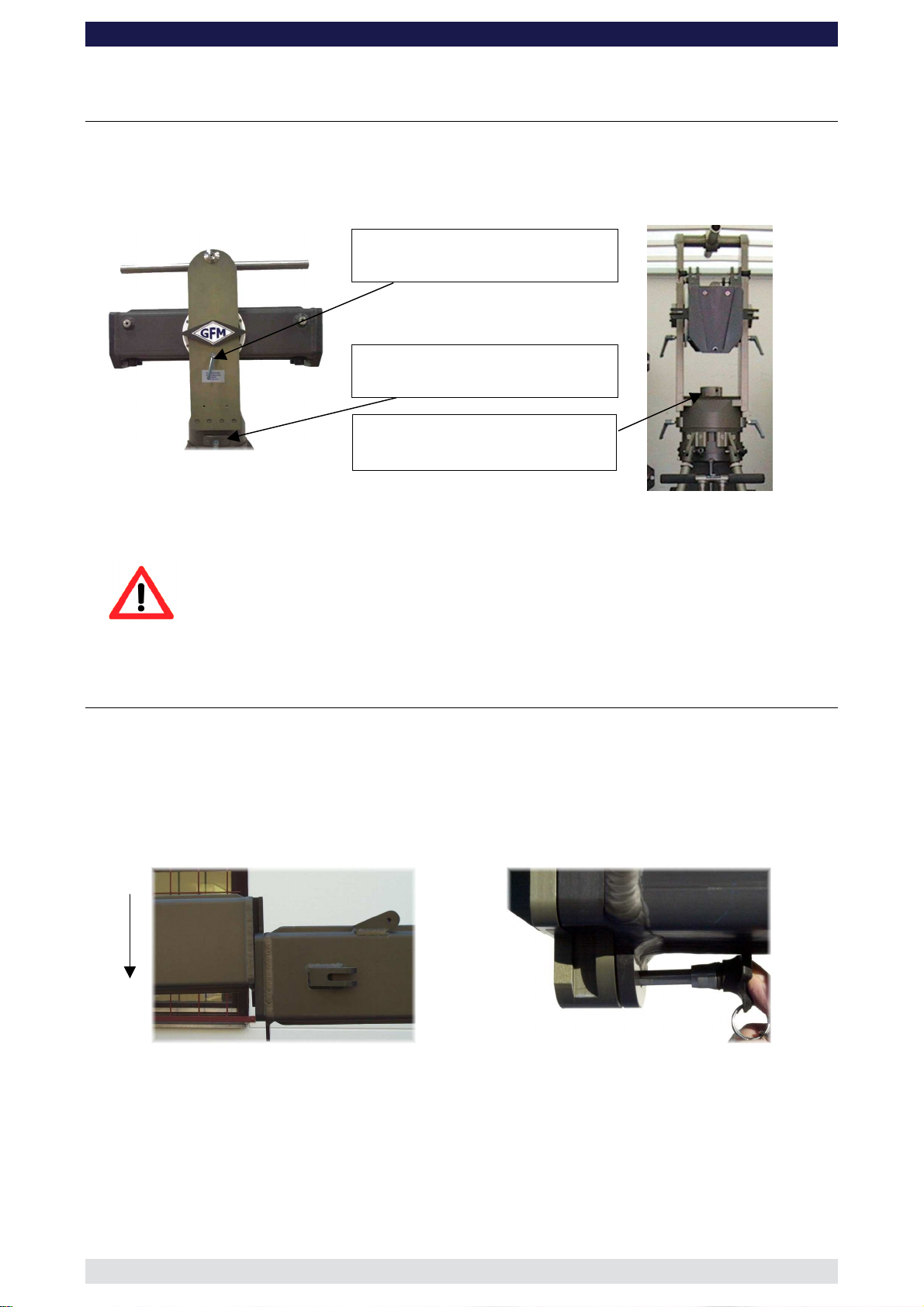

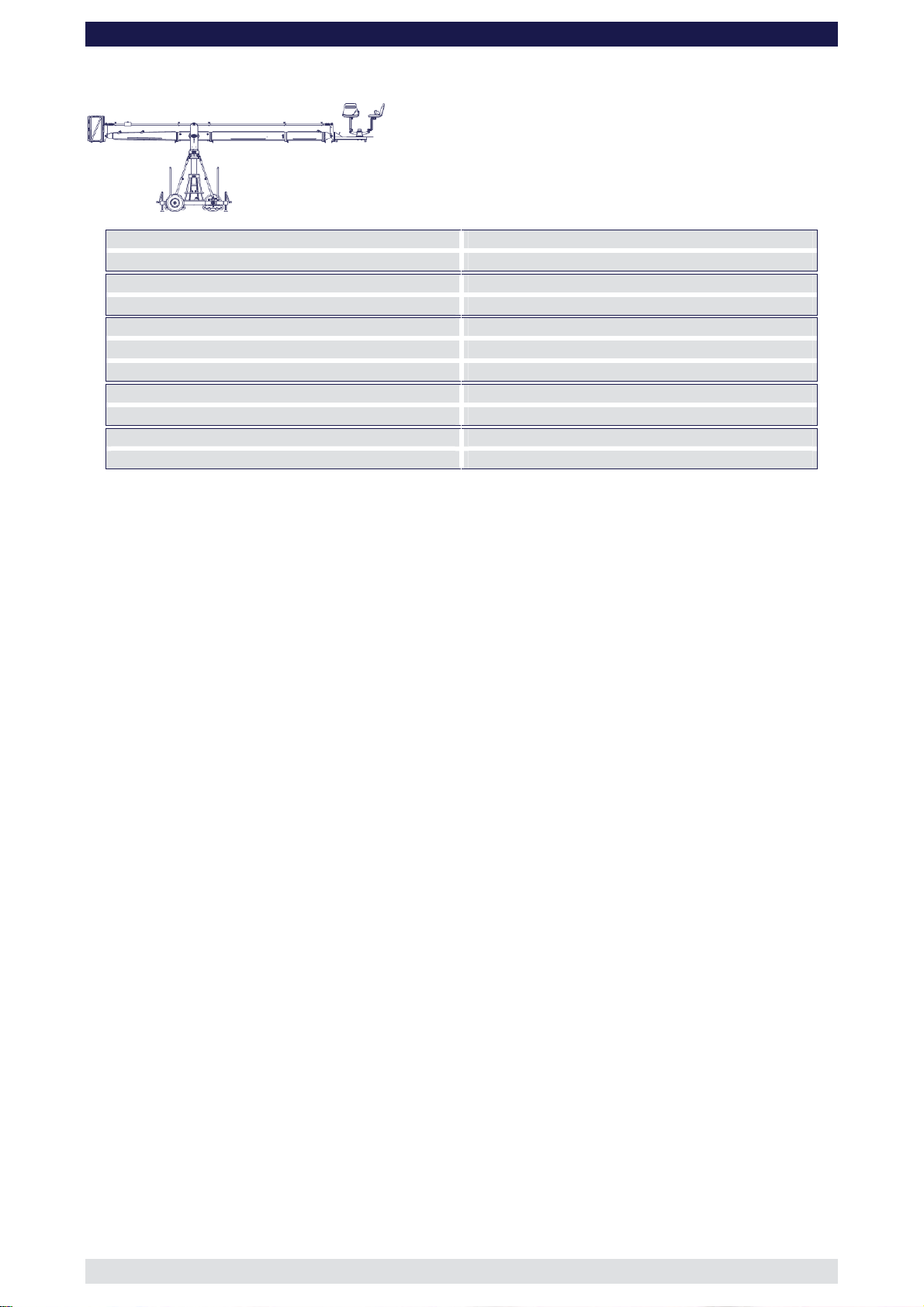

Pivot Section

4. Located on the middle section are 2 tilt friction locks which may be used to lock the tilt

during set-up. Set the pivot arm at 90° to the cent re post and lock the friction locks

which can be found on the left and right hand side of the middle section.

Tilt friction

Pan friction

Middle section

Locking screw

5. Mount the middle section on the mounting column. Lock the locking screw tightly.

Tip: A 12mm Allen key can be found in the mounting column’s handle to be used

as a lever.

Attention: Install the middle section to the rotate able bearing of the

column with positive locking. It fits properly only in one

position.

General Assembly

6. Connect extension number 1 to the middle section. Slip the connection flanges into

each other and secure with the provided safety pin.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

Mounting an extension arm

Securing the arm with a safety pin

7. Connect the 192cm / 6’3” counterweight bucket extension to the middle section. Slip

the connection flanges into each other and secure with the provided safety pin.

8. Connect the 192cm / 6’3” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

9. Release the angle adjuster located at the end of the 192cm / 6’3” section by removing

the safety pin from the side of the angle adjuster.

Page: 5

Page 7

GF-16 Crane System Instruction Manual

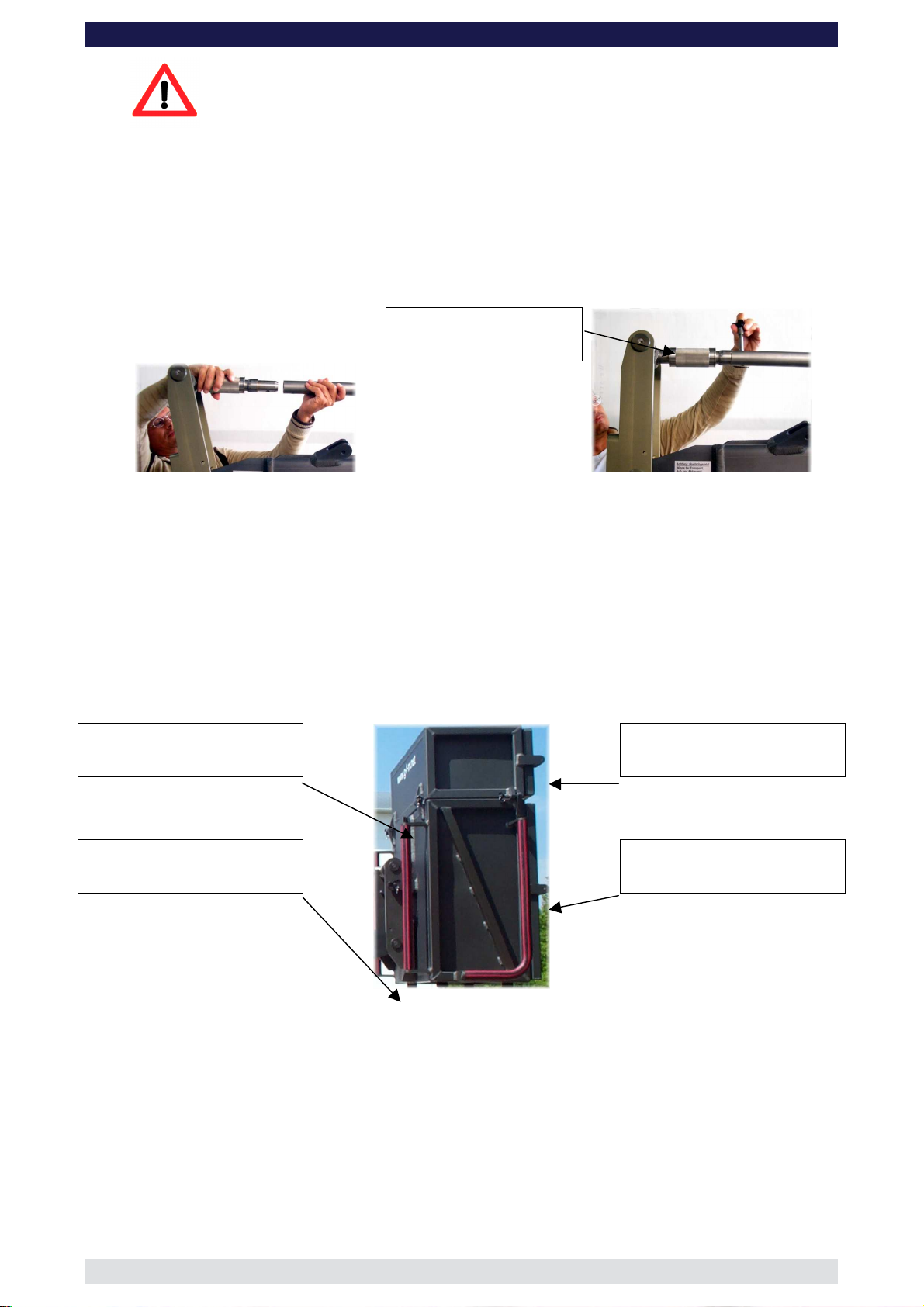

Attention: Pinch point

Tip: With the removed safety pin the connection between counterweight bucket

and angle adjuster has to be secured.

10. Connect the parallelogram rod to the rod on the angle adjuster and secure it with the

provided pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

Leveller

11. Support the mounted counterweight section with a suitable support stand or rostrum.

12. Connect the lower section of the 2 part counterweight bucket to the angle adjuster

located on the rear of the counterweight bucket extension. Slip the connection flanges

into each other and secure with the removed safety pin from the side of the angle

adjuster.

Tip: Do not load weights until the rigging system is mounted (see page 9).

Tip: To mount the top bucket just put it on top of the lower one and screw it either

with the provided safety pins or the captive screws. (See the GF-16

Specifications at which version the Top Bucket is needed)

Bucket connection pins

Safety pin

Top bucket

Lower bucket

The assembly procedure up to this point is the same in all versions.

To assist the set-up procedure and to reduce the risk of accidents it is

recommended to use set-up support stands or rostrums to support the crane arm

during set-up and breakdown.

Page: 6

Page 8

Angle adjuster locked

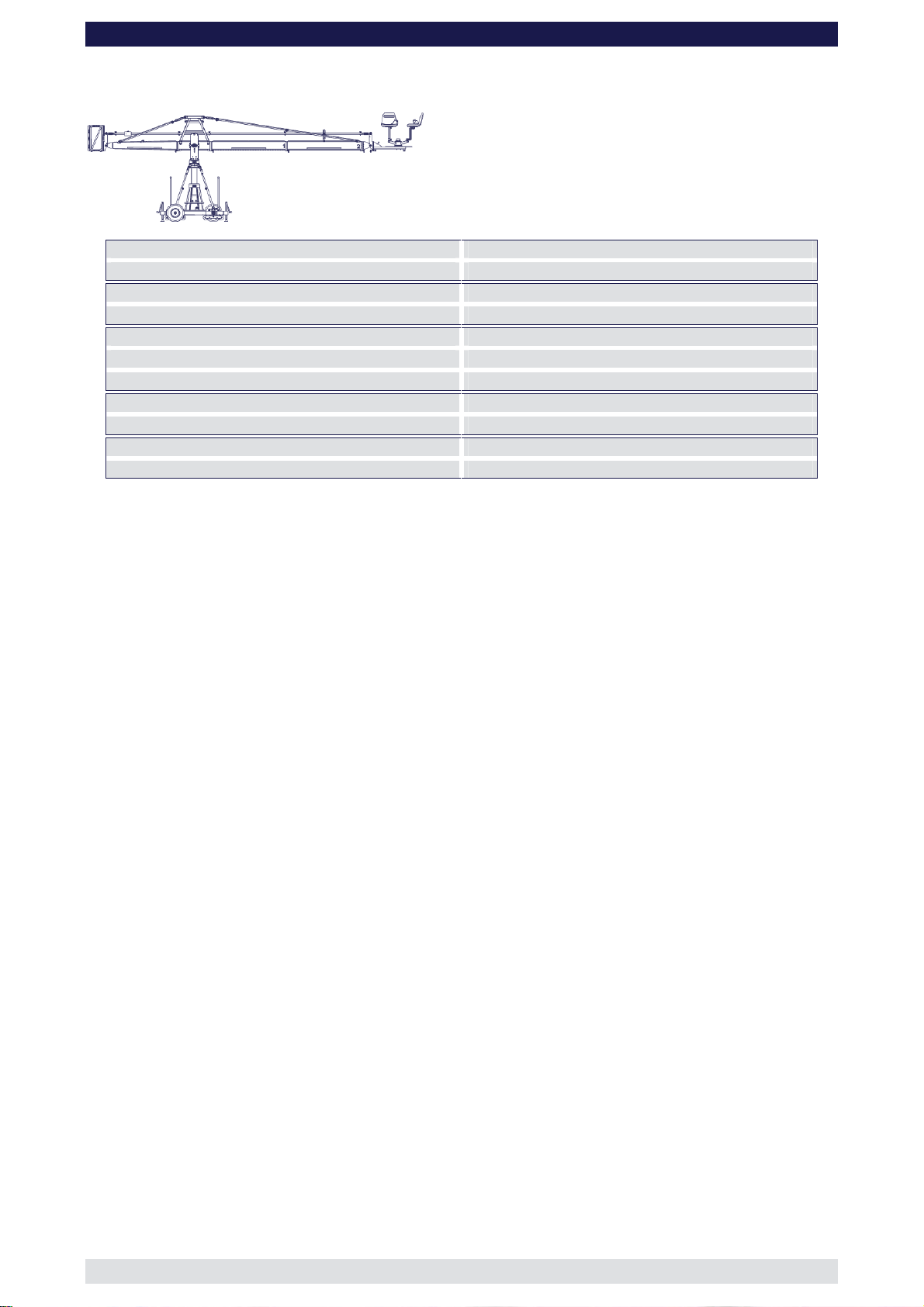

Version 1

GF-16 Crane System Instruction Manual

Front extension arms required 1 x 200 cm / 6' 6”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 420 cm / 13’ 9”

Maximum Euro-adapter height 423 cm / 13’ 10”'

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 274 kg / 602 lbs

Counterweight required to balance empty arm 8 kg / 17 lbs

Crane weight (excluding dolly and weights) 661 kg / 1457 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 336 cm / 11’

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the angle adjuster to the end of the 200cm / 6’ 6” extension number 1.

Release the angle adjuster by removing the safety pins from the side of the angle

adjuster. Secure the angle adjuster to extension number 1 with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

Safety pin

by pin (Transport

position)

Mounting the angle adjuster

Securing the angle adjuster

14. Connect one of the 200cm / 6’ 6” parallelogram rods to the rod connection located on

the middle section and secure it the provided safety pin.

15. Connect the parallelogram rod to the rod connection on the angle adjuster and secure

it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

16. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

17. Remove the support stand or rostrum supporting the counterweight bucket section.

18. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 7

Page 9

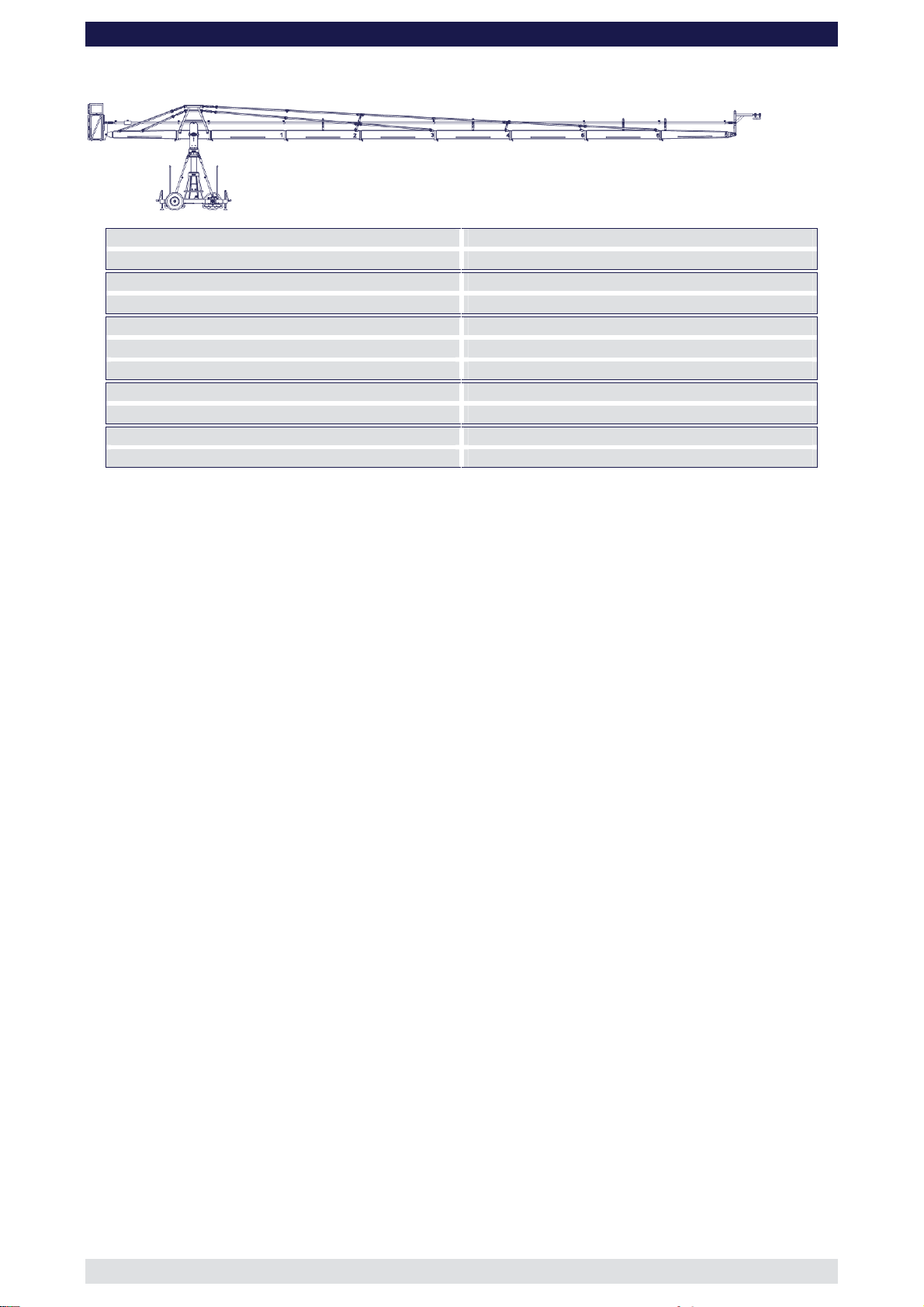

Version 2

GF-16 Crane System Instruction Manual

Front extension arms required 1 x 200 cm / 6' 6” + 1 x 100 cm / 3’ 3”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 575 cm / 18’ 10”

Maximum Euro-adapter height 501 cm / 16' 5 "

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 424 kg / 932 lbs

Counterweight required to balance empty arm 36 kg / 79 lbs

Crane weight (excluding dolly and weights) 678 kg / 1495 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 434 cm / 14’ 2”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 100cm / 3’ 3” extension to extension number 1. Slip the connection

flanges into each other and secure with the provided safety pin.

Note: The 100cm / 3’ 3” section must be supported by a suitable support stand or

rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

15. Connect the 100cm / 3’ 3” parallelogram rod to the first parallelogram connection and

secure it with the provided safety pin.

16. Connect the angle adjuster to the end of the 100cm / 3’ 3” extension. Release the

angle adjuster by removing the safety pins from the side of the angle adjuster. Secure

the angle adjuster to the 100cm / 3’ 3” extension with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

17. Connect the 100cm / 3’ 3” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

18. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

19. Remove the support stand or rostrum supporting the counterweight bucket section.

20. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 8

Page 10

GF-16 Crane System Instruction Manual

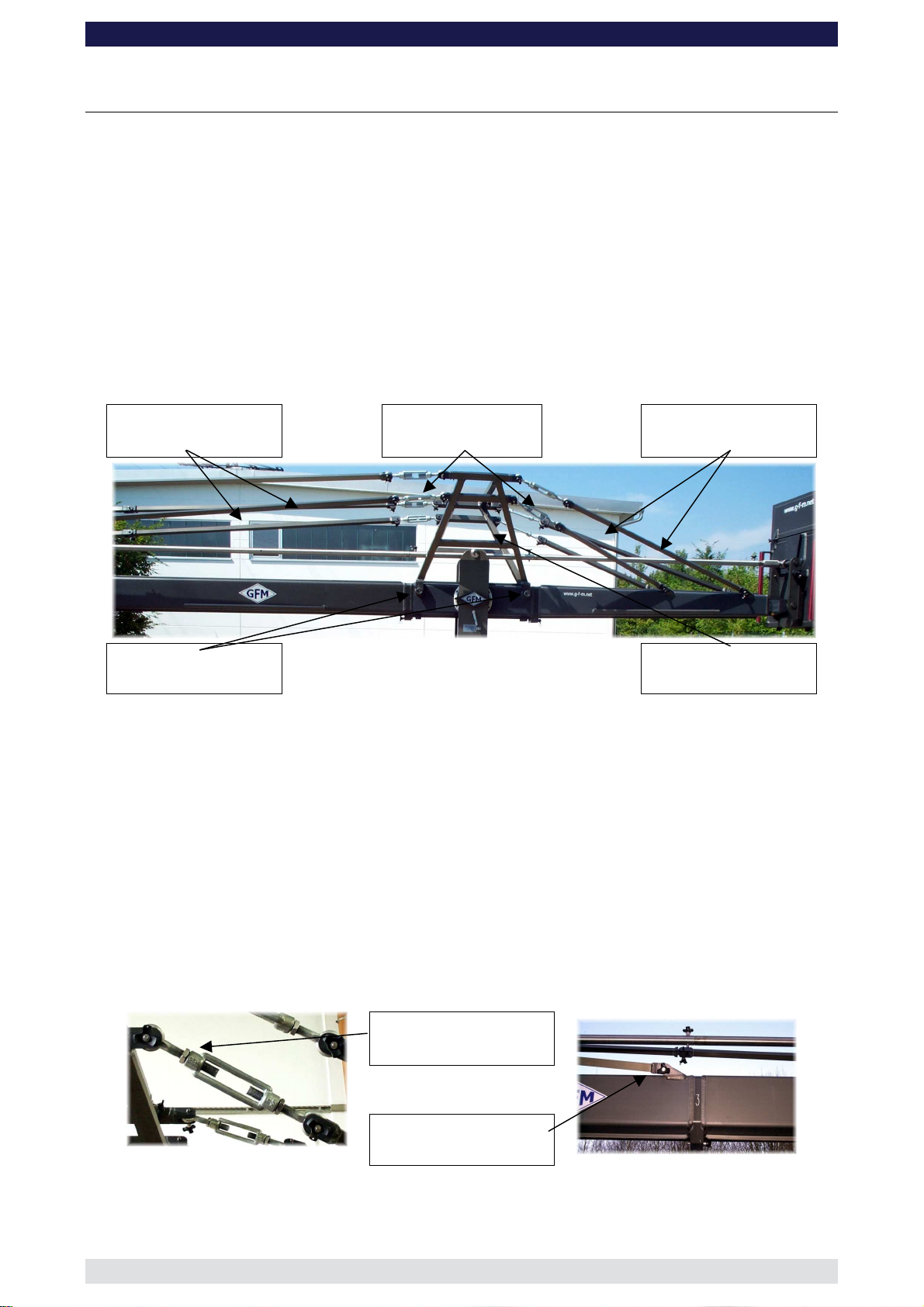

Rigging system

The rigging system must be used from Version 3 upwards.

General:

For versions using more than 3 x 200cm long sections (versions 7 to 15), a double

rigging system must be mounted. During assembly, to support the arm and ensure that it

does not dip, mount the lower rigging system as soon as crane arm sections 2, 3 or 4

(depending on version) are mounted. When the lower rigging is mounted and adjusted,

only then add on section 4, 5 and 6 etc. As soon as the last section is mounted, then

assemble the top rigging system.

Tip: Do not load weights until the rigging system is mounted.

Never use the crane with 2 or more than 2 x 200cm sections mounted without rigging.

Standard Rigging rods

Turnbuckles

Rear Rigging rods

Locking bolts

Rigging harness

Rigging Harness Assembly:

1. Connect the rigging harness to both sides of the middle section and connect with the

2 cross bars. Then ensure that the 4 locking bolts are inserted and tightened fully to

the Pivot Section. Ensure that the 4 locking pins securing the 2 cross bars are

inserted fully.

2. Connect the turnbuckles to the rear rigging harness and in turn connect the 4 rear

rigging rods to the 4 rigging connections on the counterweight bucket arm. Connect

the 2 x 90cm rods to the lower turnbuckles and in turn to the inner connections on the

rear section. Then connect the 2 x 150cm rods to the top turnbuckles and in turn to

the outer connections on the rear section. Ensure that the locking pins are inserted

fully. Hand tighten the rods by turning the turnbuckles until the 4 rods are taut, then

secure the turnbuckles with the locking nut.

Locking nut

Rigging connector

Note: All rigging support brackets are identical, all rigging rod connectors are

identical, all standard rigging rods are identical.

Page: 9

Page 11

GF-16 Crane System Instruction Manual

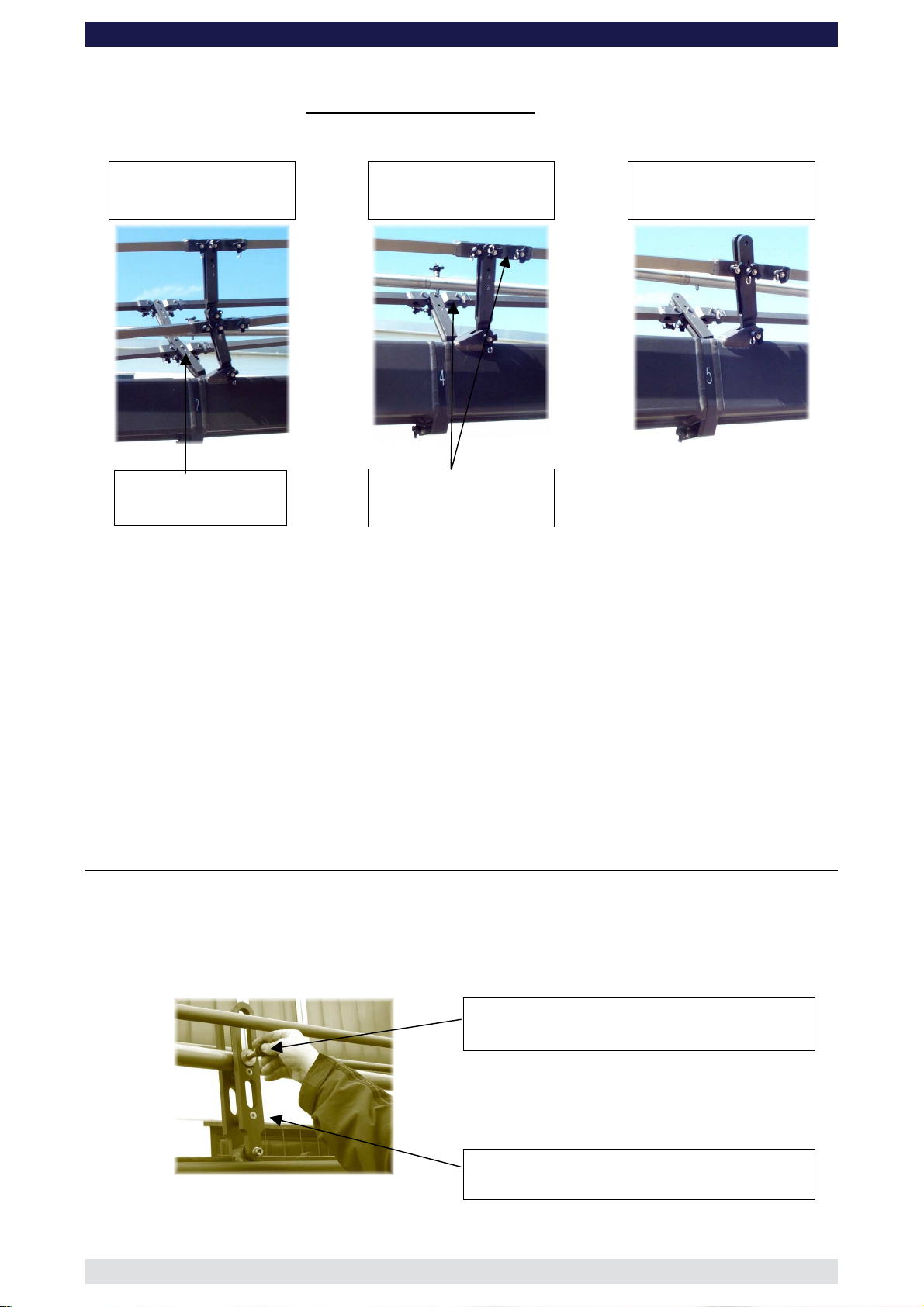

In general, the length of the rigging system depends on the number of extension arms

assembled. For each extension arm, 1 rigging rod length consisting of 2 rods, is required.

From Version 7 upwards, i.e. more than 3 extensions a double rigging system is required

i.e. top and bottom.

Top and lower rigging

support brackets, section

2

Rigging support bracket,

section 4

Rigging support bracket,

section 5

Rigging support

bracket

Rigging rod connector

The top rigging system is assembled in the same manner as the lower but starts off at the

top connection on the harness and finishes at the last extension.

The rigging system should be supported in certain positions with the Rigging Support

Brackets which connect to various sections. The Rigging Support Brackets are connected

to the Rigging Rod Connectors. Please refer to the individual versions as described on

pages 7 to 43.

It is important that the rigging system when taut, should run in a straight line and the crane

extensions should not bend or dip.

The second, fourth and fifth rigging rods are connected to the following rods via a

rigging rod connector.

Parallelogram Supports

By adding extension sections in numerical order plus the respective parallelogram rods, 15

standard versions can be built. When sections number 2, 4 and 6 as well as the Remote

section are used, support the respective parallelogram rods with the integrated

parallelogram supports.

Safety pin

Parallelogram support assembly

Parallelogram support

Page: 10

Page 12

GF-16 Crane System Instruction Manual

Version 3

Front extension arms required 2 x 200 cm / 6' 6”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 734 cm / 24’

Maximum Euro-adapter height 581 cm / 19’

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 554 kg / 1218 lbs

Counterweight required to balance empty arm 56 kg / 123 lbs

Crane weight (excluding dolly and weights) 730 kg / 1609 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 534 cm / 17’ 6”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

15. Connect another 200cm / 6’ 6” parallelogram rod to the first parallelogram connection

and secure it with the provided safety pin.

Note: Support the second parallelogram rod with the parallelogram support on

section 2 and secure with the locking pin as shown on page 10.

16. Connect the angle adjuster to of the 200cm / 6’ 6” extension number 2. Release the

angle adjuster by removing the safety pins from the side of the angle adjuster. Secure

the angle adjuster to extension number 2 with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

17. Connect the last 200cm / 6’ 6” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

18. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

19. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

Page: 11

Page 13

GF-16 Crane System Instruction Manual

20. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

21. Connect the last 2 standard rigging rods to the 2 rigging rod connectors on arm

extension number 2. Ensure that the locking pins are inserted fully.

22. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

23. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

24. Remove the support stand or rostrum supporting the counterweight bucket section.

25. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 12

Page 14

GF-16 Crane System Instruction Manual

Version 4

Front extension arms required 2 x 200 cm / 6' 6” + 1 x 100 cm / 3’ 3”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 890 cm / 29’ 2”

Maximum Euro-adapter height 658 cm / 21' 7”

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 718 kg / 1579 lbs

Counterweight required to balance empty arm 112 kg / 246 lbs

Crane weight (excluding dolly and weights) 750 kg / 1653 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 631 cm / 20’ 8”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect the 100cm / 3’ 3” extension to extension number 2. Slip the connection

flanges into each other and secure with the provided safety pin.

15. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

16. Connect another 200cm / 6’ 6” parallelogram rod to the first parallelogram connection

and secure it with the provided safety pin.

Note: Support the second parallelogram rod with the parallelogram support on

section 2 and secure with the locking pin as shown on page 10.

17. Connect the 100cm / 3’ 3” parallelogram rod to the last parallelogram connection and

secure it with the provided safety pin.

18. Connect the angle adjuster to the end of the 100cm / 3’ 3” extension. Release the

angle adjuster by removing the safety pins from the side of the angle adjuster. Secure

the angle adjuster to the 100cm / 3’ 3” extension with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

19. Connect the 100cm / 3’ 3” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

20. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

Page: 13

Page 15

GF-16 Crane System Instruction Manual

21. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

22. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

23. Connect 2 rigging rods in turn to the connectors on extension number 2. Ensure that

the locking pins are inserted fully.

24. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

25. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

26. Remove the support stand or rostrum supporting the counterweight bucket section.

27. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 14

Page 16

GF-16 Crane System Instruction Manual

Version 5

Front extension arms required 3 x 200 cm / 6' 6”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1049 cm / 34’ 4”

Maximum Euro-adapter height 738 cm / 24' 2”

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 896 kg / 1971 lbs

Counterweight required to balance empty arm 182 kg / 400 lbs

Crane weight (excluding dolly and weights) 769 kg / 1695 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 731 cm / 23’ 11”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6.

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section number 3.

15. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

16. In turn, connect 2 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pins.

17. Connect the angle adjuster to the end of the 200cm / 6’ 6” extension number 3.

Release the angle adjuster by removing the safety pins from the side of the angle

adjuster. Secure the angle adjuster to extension number 3 with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

18. Connect the last 200cm / 6’ 6” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

19. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

20. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

Page: 15

Page 17

GF-16 Crane System Instruction Manual

21. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

22. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully.

23. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 3. Ensure that the locking pins are inserted fully.

24. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

25. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

26. Remove the support stand or rostrum supporting the counterweight bucket section.

27. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 16

Page 18

Version 6

GF-16 Crane System Instruction Manual

Front extension arms required 3 x 200 cm / 6' 6” + 1 x 100 cm / 3’ 3”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1205 cm / 39’ 6”

Maximum Euro-adapter height 816 cm / 26' 9”

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 1078 kg / 2371 lbs

Counterweight required to balance empty arm 266 kg / 585 lbs

Crane weight (excluding dolly and weights) 806 kg / 1777 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 829 cm / 27’ 2”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section 3.

15. Connect the 100cm / 3’ 3” extension to extension number 3. Slip the connection

flanges into each other and secure with the provided safety pin.

16. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

17. In turn, connect 2 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pins.

Note: Support the second parallelogram rod with the parallelogram support and

secure with the locking pin.

18. Connect the 100cm / 3’ 3” parallelogram rod to the last parallelogram connection and

secure it with the provided safety pin.

19. Connect the angle adjuster to the end of the 100cm / 3’ 3” extension. Release the

angle adjuster by removing the safety pins from the side of the angle adjuster. Secure

the angle adjuster to the 100cm / 3’ 3” extension with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

20. Connect the 100cm / 3’ 3” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

Page: 17

Page 19

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

21. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

22. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

23. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

24. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully .

25. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 3. Ensure that the locking pins are inserted fully.

26. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

27. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

28. Remove the support stand or rostrum supporting the counterweight bucket section.

29. Then unlock the tilt friction.

GF-16 Crane System Instruction Manual

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 18

Page 20

Version 7

GF-16 Crane System Instruction Manual

Front extension arms required 4 x 200 cm / 6' 6”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1364 cm / 44’ 9”

Maximum Euro-adapter height 895 cm / 29' 4”

Lift capacity (working load) 2 pers. + accessories 250 kg / 550 lbs

Counterweight required for max. load 1274 kg / 2802 lbs

Counterweight required to balance empty arm 372 kg / 818lbs

Crane weight (excluding dolly and weights) 841 kg / 1854 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 929 cm / 30’ 5”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

14. Connect 2 turnbuckles to the bottom connection on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

15. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

16. Connect another 2 standard rigging rods to the first 2 standard rigging rods and in

turn to the rigging connectors on section 2. Ensure that the locking pins are inserted

fully.

17. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

18. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section number 3.

19. Connect the 200cm / 6’ 6” extension number 4 to extension number 3. Slip the

connection flanges into each other and secure with the provided safety pin.

20. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

21. In turn, connect 3 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pins.

Page: 19

Page 21

GF-16 Crane System Instruction Manual

Note: Support the second and fourth parallelogram rod with the parallelogram

supports located on sections 2 and 4 and secure with the locking pin as

shown on page 10.

22. Connect the angle adjuster to the end of the 200cm / 6’ 6” extension number 4.

Release the angle adjuster by removing the safety pins from the side of the angle

adjuster. Secure the angle adjuster to extension number 4 with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

23. Connect the last 200cm / 6’ 6” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

24. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

25. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

26. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

27. Connect another 2 standard rigging rods to the second 2 standard rigging rods.

Ensure that the locking pins are inserted fully.

28. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 3.

Ensure that the locking pins are inserted fully.

29. Connect a Rigging Rod Connector to each of the third Rigging Rods ensuring that the

locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

30. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 4. Ensure that the locking pins are inserted fully.

31. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

32. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

3 as shown on page 10.

33. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

34. Remove the support stand or rostrum supporting the counterweight bucket section.

35. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 20

Page 22

Version 8

GF-16 Crane System Instruction Manual

Front extension arms required 4 x 200 cm / 6' 6” + 1 x 100 cm / 3’ 3”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1519 cm / 49’ 10”

Maximum Euro-adapter height 973 cm / 31' 11”

Lift capacity (working load) 1 pers. + accessories 140 kg / 308 lbs

Counterweight required for max. load 1022 kg / 2248 lbs

Counterweight required to balance empty arm 448 kg / 985 lbs

Crane weight (excluding dolly and weights) 838 kg / 1847 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 1027 cm / 33’ 8”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

14. Connect 2 turnbuckles to the bottom connection on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

15. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

16. Connect another 2 standard rigging rods to the first 2 standard rigging rods and in

turn to the rigging connectors on section 2. Ensure that the locking pins are inserted

fully.

17. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

18. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section 3.

19. Connect the 200cm / 6’ 6” extension number 4 to extension number 3. Slip the

connection flanges into each other and secure with the provided safety pin.

20. Connect the 100cm / 3’ 3” extension to extension number 4. Slip the connection

flanges into each other and secure with the provided safety pin.

Note: Section 4 must be supported by a suitable support stand or rostrum.

21. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

Page: 21

Page 23

GF-16 Crane System Instruction Manual

22. In turn, connect 3 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pins.

Note: Support the second and fourth parallelogram rod with the parallelogram

supports located on sections 2 and 4 and secure with the locking pin as

shown on page 10.

23. Connect the 100cm / 3’ 3” parallelogram rod to the last parallelogram connection and

secure it with the provided safety pin.

24. Connect the angle adjuster to the end of the 100cm / 3’ 3” extension. Release the

angle adjuster by removing the safety pins from the side of the angle adjuster. Secure

the angle adjuster to the 100cm / 3’ 3” extension with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

25. Connect the 100cm / 3’ 3” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

26. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

27. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

28. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

29. Connect another 2 standard rigging rods to the second 2 standard rigging rods.

Ensure that the locking pins are inserted fully.

30. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 3.

Ensure that the locking pins are inserted fully.

31. Connect a Rigging Rod Connector to each of the third Rigging Rods ensuring that the

locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

32. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 4. Ensure that the locking pins are inserted fully.

33. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

34. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

3 as shown on page 10.

35. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

36. Remove the support stand or rostrum supporting the counterweight bucket section.

37. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 22

Page 24

Version 9

GF-16 Crane System Instruction Manual

Front extension arms required 5 x 200 cm / 6' 6”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1678 cm / 55’

Maximum Euro-adapter height 1053 cm / 34' 6”

Lift capacity (working load) 1 pers. + accessories 140 kg / 308 lbs

Counterweight required for max. load 1166 kg / 2565 lbs

Counterweight required to balance empty arm 554 kg / 1218 lbs

Crane weight (excluding dolly and weights) 876 kg / 1931 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 1127 cm / 36’ 11”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section number 3.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

15. Connect 2 turnbuckles to the bottom connection on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

16. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

17. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

18. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 2.

Ensure that the locking pins are inserted fully.

19. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

20. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 3. Ensure that the locking pins are inserted fully.

21. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

22. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

3 as shown on page 10.

Page: 23

Page 25

GF-16 Crane System Instruction Manual

23. Connect the 200cm / 6’ 6” extension number 4 to extension number 3. Slip the

connection flanges into each other and secure with the provided safety pin.

24. Connect the 200cm / 6’ 6” extension number 5 to extension number 4. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 5 must be supported by a suitable support stand or rostrum.

25. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

26. In turn, connect 4 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pins.

Note: Support the second and fourth parallelogram rod with the parallelogram

support located on sections 2 and 4 and secure with the locking pin as shown

on page 10.

27. Connect the angle adjuster to the end of the 200cm / 6’ 6” extension number 5.

Release the angle adjuster by removing the safety pins from the side of the angle

adjuster. Secure the angle adjuster to extension number 5 with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

28. Connect the last 200cm / 6’ 6” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

29. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

30. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

31. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

32. Connect 2 Rigging Support Brackets to the Rigging Support Brackets on section 2.

Ensure that the locking pins are inserted fully.

33. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

34. Connect another 2 standard rigging rods to the Rigging Rod Connectors on the

second 2 standard rigging rods. Ensure that the locking pins are inserted fully.

35. Connect another 2 standard rigging rods to the third 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

36. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 4.

Ensure that the locking pins are inserted fully.

37. Connect a Rigging Rod Connector to each of the fourth Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets on section 4 as shown on page 10.

38. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 5. Ensure that the locking pins are inserted fully.

39. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

40. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

2 and section 4 as shown on page 10.

Page: 24

Page 26

GF-16 Crane System Instruction Manual

41. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

42. Remove the support stand or rostrum supporting the counterweight bucket section.

43. Then unlock the friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 25

Page 27

Version 10

GF-16 Crane System Instruction Manual

Front extension arms required 5 x 200 cm / 6' 6” + 1 x 100 cm / 3’ 3”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1834 cm / 60’ 2”

Maximum Euro-adapter height 1130 cm / 37'

Lift capacity (working load) 1 pers + accessories 130 kg / 286 lbs

Counterweight required for max. load 1330 kg / 2926 lbs

Counterweight required to balance empty arm 658 kg / 1447 lbs

Crane weight (excluding dolly and weights) 896 kg / 1975 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 1225 cm / 40’ 2”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section number 3.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

15. Connect 2 turnbuckles to the bottom connection on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

16. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

17. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

18. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 2.

Ensure that the locking pins are inserted fully.

19. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

20. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 3. Ensure that the locking pins are inserted fully.

21. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

22. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

3 as shown on page 10.

Page: 26

Page 28

GF-16 Crane System Instruction Manual

23. Connect the 200cm / 6’ 6” extension number 4 to extension number 3. Slip the

connection flanges into each other and secure with the provided safety pin.

24. Connect the 200cm / 6’ 6” extension number 5 to extension number 4. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 5 must be supported by a suitable support stand or rostrum.

25. Connect the 100cm / 3’ 3” extension to extension number 5. Slip the connection

flanges into each other and secure with the provided safety pin.

26. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

27. In turn, connect 4 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pins.

Note: Support the second and fourth parallelogram rod with the parallelogram

support located on sections 2 and 4 and secure with the locking pin as shown

on page 10.

28. Connect the 100cm / 3’ 3” parallelogram rod to the last parallelogram connection and

secure it with the provided safety pin.

29. Connect the angle adjuster to the end of the 100cm / 3’ 3” extension. Release the

angle adjuster by removing the safety pins from the side of the angle adjuster. Secure

the angle adjuster to the 100cm / 3’ 3” extension with a removed safety pin.

Tip: The angle adjuster has two sidewise safety pins. These are either used for

the angle adjusters transport position or to secure the connections between

angle adjuster and extension as well as angle adjuster and platform.

30. Connect the 100cm / 3’ 3” parallelogram rod to the rod on the angle adjuster and

secure it with the provided safety pin.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

31. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

32. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

33. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

34. Connect 2 Rigging Support Brackets to the Rigging Support Brackets on section 2.

Ensure that the locking pins are inserted fully.

35. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

36. Connect another 2 standard rigging rods to the Rigging Rod Connectors on the

second 2 standard rigging rods. Ensure that the locking pins are inserted fully.

37. Connect another 2 standard rigging rods to the third 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

38. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 4.

Ensure that the locking pins are inserted fully.

39. Connect a Rigging Rod Connector to each of the fourth Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets on section 4 as shown on page 10.

40. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the

rigging connectors on section 5. Ensure that the locking pins are inserted fully.

41. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

Page: 27

Page 29

GF-16 Crane System Instruction Manual

straight line and should not bend or dip.

42. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

2 and 4 as shown on page 10.

43. Connect the platform to the angle adjuster and secure with the removed safety pin

from the side of the angle adjuster. Ensure that the platform is level.

Tip: The angle adjuster has an integrated leveller. By turning it, the vertical plate

on the angle adjuster can be set to a perfect right angle. Correct setting of

the angle adjuster enhances the crane’s balance.

44. Remove the support stand or rostrum supporting the counterweight bucket section.

45. Then unlock the tilt friction.

Before operation, all locking pins, locking screws etc should be inspected to ensure

that all assembly sections are securely fastened.

Read “Balancing the crane arm” on page 44.

Page: 28

Page 30

Version 11

GF-16 Crane System Instruction Manual

Front extension arms required 6 x 200 cm / 6' 6”

Rear extension arm required 1 x 192 cm / 6' 3”

Lift range 1954 cm / 64’ 1”

Maximum Euro-adapter height 1217 cm / 39' 11”

Lift capacity (working load) camera + accessories 85 kg / 187 lbs

Counterweight required for max. load 974 kg / 2142 lbs

Counterweight required to balance empty arm 518 kg / 1139 lbs

Crane weight (excluding dolly and weights) 846 kg / 1865 lbs

Dolly weight (unit weights see page 46) 244 kg / 536 lbs

Arm reach (pivot to camera head mount) 1286 cm / 42’ 2”

Length of rear end (pivot to outside of bucket) 278 cm / 9’ 1”

Continue from § 12, page 6

13. Connect the 200cm / 6’ 6” extension number 2 to extension number 1. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 2 must be supported by a suitable support stand or rostrum.

Tip: To avoid the sections jamming or getting stuck make sure that the sections

are joined parallel. Using a small amount of lubricant also helps. We suggest

rubbing the joints with an oiled rag prior to assembly.

14. Connect the 200cm / 6’ 6” extension number 3 to extension number 2. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Move the support stand or rostrum to support section number 3.

The “Rigging Harness Assembly” is described on page 9. After reading and

following the instructions, please proceed as follows.

15. Connect 2 turnbuckles to the bottom connection on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

16. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

17. Connect 2 standard rigging rods to the first 2 rigging rods. Ensure that the locking

pins are inserted fully.

18. Connect 2 Rigging Support Brackets to the Rigging Rod Connections on section 2.

Ensure that the locking pins are inserted fully.

19. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

20. Connect 2 standard rigging rods to the Rigging Rod Connectors and in turn to the to

the rigging connectors on section 3. Ensure that the locking pins are inserted fully.

21. Hand tighten the rods by turning the turnbuckles until the rods are taut, then secure

the turnbuckles with the locking nut as seen on page 9.

Attention: The rigging system when taut as well as the crane arm, should run in a

straight line and should not bend or dip.

Page: 29

Page 31

GF-16 Crane System Instruction Manual

22. When the Rigging Rods are taut and running in a straight line, insert the locking pin

connecting the Rigging Rod Connectors into the Rigging Support Brackets on section

2 as shown on page 10.

23. Connect the 200cm / 6’ 6” extension number 4 to extension number 3. Slip the

connection flanges into each other and secure with the provided safety pin.

24. Connect the 200cm / 6’ 6” extension number 5 to extension number 4. Slip the

connection flanges into each other and secure with the provided safety pin.

Note: Section 5 must be supported by a suitable support stand or rostrum.

25. Connect the Remote Extension to 200cm / 6’ 6” extension number 5. Slip the

connection flanges into each other and secure with the provided safety pin.

26. Connect a 200cm / 6’ 6” parallelogram rod to the parallelogram connection on the

middle section and secure it with the provided safety pin.

27. In turn, connect 4 x 200cm / 6’ 6” parallelogram rods to the first parallelogram

connection and secure them with the provided safety pin.

Note: Support the second and fourth parallelogram rod with the parallelogram

support located on sections 2 and 4 and secure with the locking pin as shown

on page 10.

28. Connect the Remote Extension parallelogram rod to the last parallelogram connection

and secure it with the provided safety pin.

29. Support the Remote Extension parallelogram rod with the parallelogram support

located on the Remote Extension and secure with the locking pin as shown on

page10.

30. Connect the Remote Bracket as described on page 43.

Tip: The Remote Bracket has an integrated leveller. By turning it, the Remote

Bracket can be set to a perfect right angle. Correct setting of the angle

adjuster enhances the crane’s balance.

31. Connect 2 turnbuckles to the top connection on the front side of the rigging harness.

Ensure that the locking pins are inserted fully.

32. Connect 2 standard rigging rods to the turnbuckles on the front side of the rigging

harness. Ensure that the locking pins are inserted fully.

33. Connect another 2 standard rigging rods to the first 2 standard rigging rods. Ensure

that the locking pins are inserted fully.

34. Connect 2 Rigging Support Brackets to the Rigging Support Brackets on section 2.

Ensure that the locking pins are inserted fully.

35. Connect a Rigging Rod Connector to each of the second Rigging Rods ensuring that

the locking pins are inserted fully. Fit the Rigging Rod Connectors into the Rigging

Support Brackets as shown on page 10.

36. Connect another 2 standard rigging rods to the Rigging Rod Connectors on the

second 2 standard rigging rods. Ensure that the locking pins are inserted fully.

37. Connect another 2 standard rigging rods to the third 2 standard rigging rods. Ensure