Gripe Rite GR309EDV Operating Manual And Parts List

OPERATING MANUAL AND PARTS LIST

MODEL GR309EDV ELECTRIC COMPRESSOR

www.grip-rite.com

TABLE OF CONTENTS

Table of Contents..........................................................................1

Safety Symbols .............................................................................2

Safety Instructions........................................................................3

Specifications................................................................................5

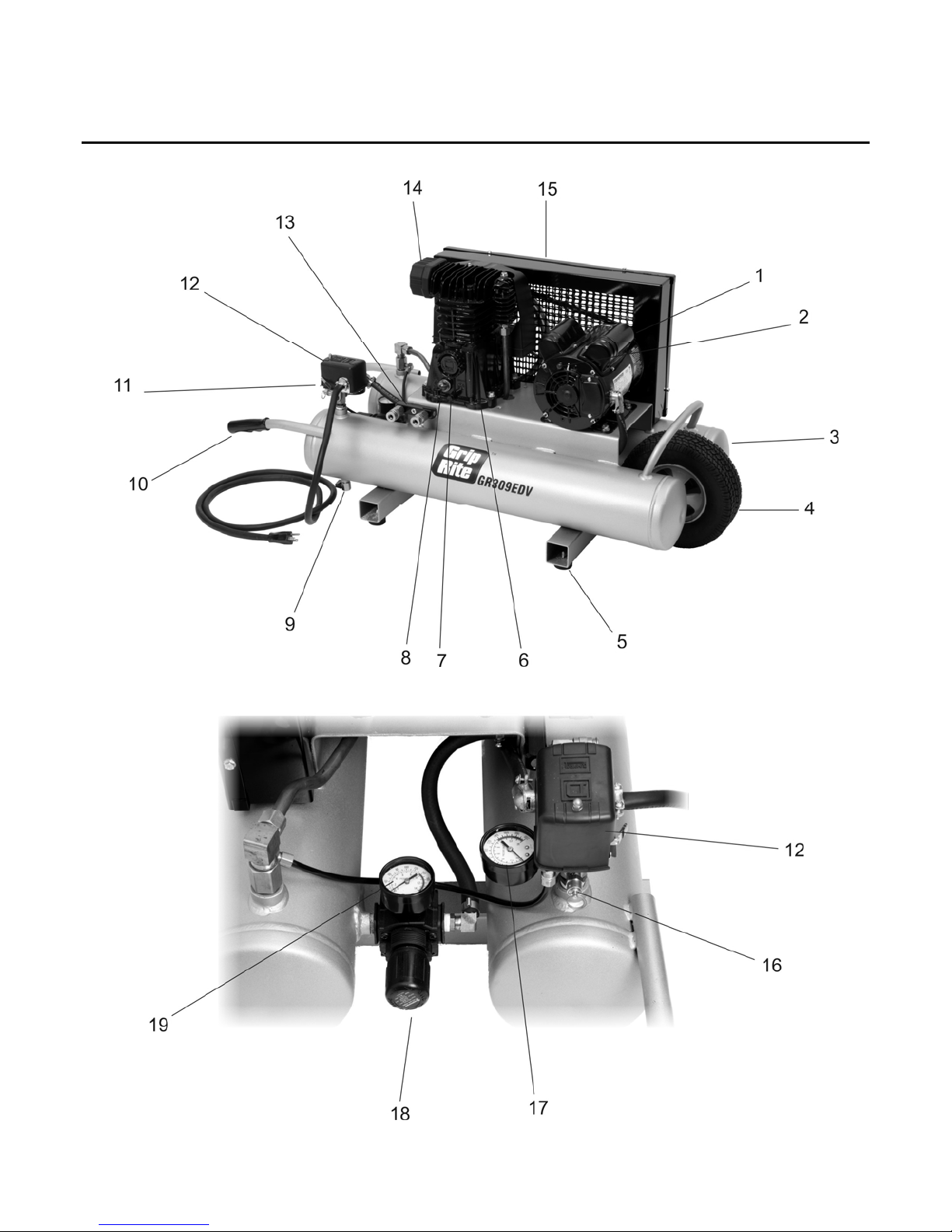

Compressor Description ..............................................................6

Compressor Parts Description.....................................................7

Set Up............................................................................................. 8

Operation.......................................................................................9

Maintenance ................................................................................10

GR309EDV Compressor Schematic ......................................... 11

GR309EDV Compressor Parts List - Tank/Frame.....................12

GR309EDV Compressor Schematic - Pump .............................14

GR309EDV Compressor Parts List - Pump............................... 15

Troubleshooting..........................................................................16

Storage......................................................................................... 19

Warranty.......................................................................................20

WARNING

This manual contains important safety and operating instructions that must be followed.

You must read and understand this manual before operating this compressor. Failure

to follow all instructions can result in serious injury to operator and bystanders, or

damage to compressor and attachments.

1

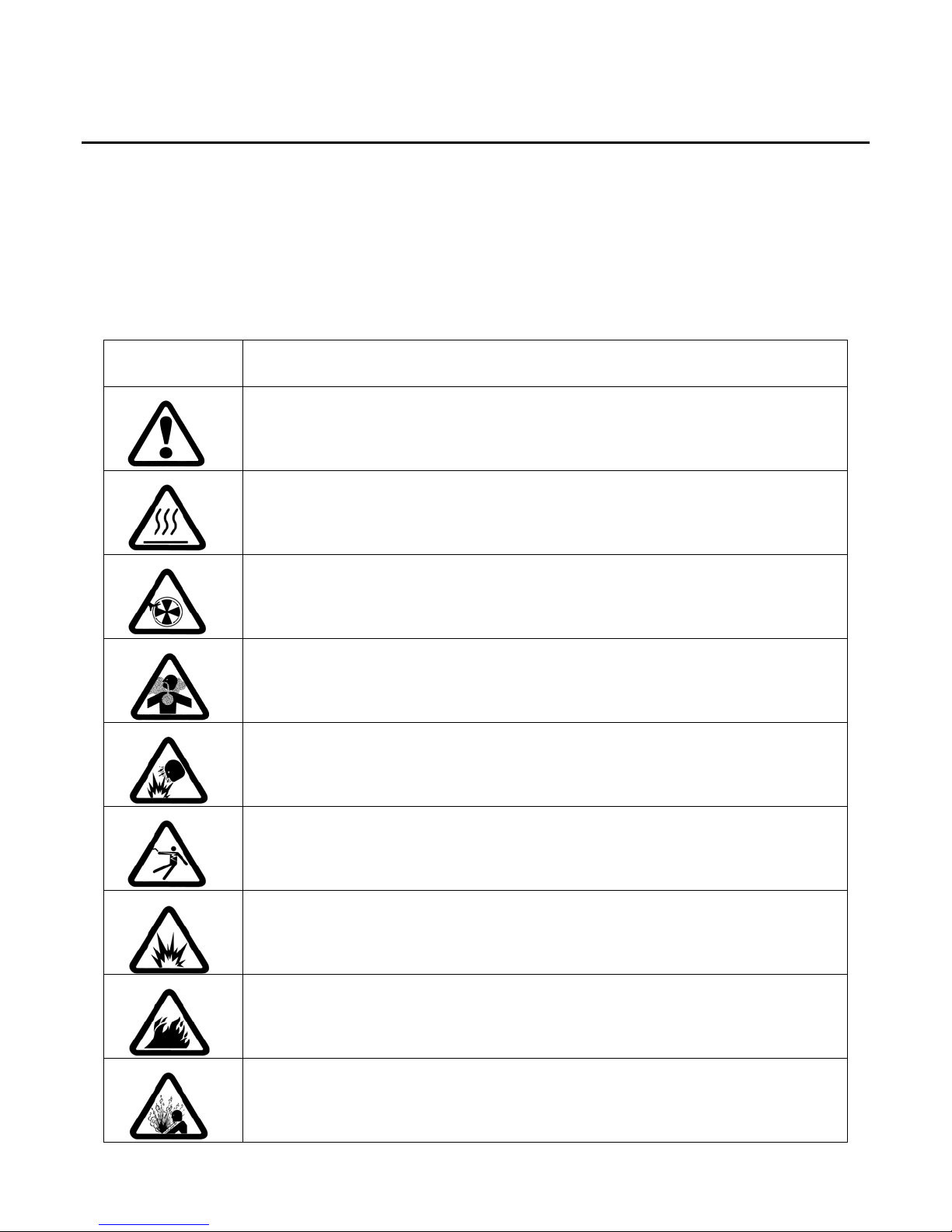

SAFETY SYMBOLS

The safety symbols used on the compressor’s safety labels and in this manual provide an

important visual reminder of basic safety rules, and the hazards that may arise if all safety and

operating instructions are not followed. Make sure you understand the meaning of each of

these symbols, and protect yourself and others by obeying all safety and operating instructions

on warning labels and in this manual.

SYMBOL DESCRIPTION

SAFETY ALERT SYMBOL

Calls attention to important safety information and provides an alert to

potential safety hazards.

HOT SURFACE HAZARD

Hot surfaces can cause serious burn injury if touched. Let unit cool before

handling.

MOVING PARTS/ENTANGLEMENT HAZARD

Contact with moving parts can cause serious injury. Keep guards and

protective covers in place.

INHALATION HAZARD

Compressed air can contain carbon monoxide or other harmful gases. Do

not use compressor to provide air for breathing.

BURST HAZARD

Over-pressurization caused by tampering with controls can cause serious

injury or death from explosion.

SHOCK HAZARD

Contact with live electrical components can cause shock, serious injury, or

death from electrocution. Use a properly grounded power source.

EXPLOSION HAZARD

Electrical sparks from unit can ignite flammable liquids and vapors. Use

compressor in a well ventilated area free from explosive vapors.

FIRE HAZARD

Keep compressor 20’ feet away from spray area when spraying flammable

materials. Operate unit away from obstructions that could block ventilation.

HIGH PRESSURE AIR HAZARD

Release of pressurized air can cause serious injury if directed against body.

Never use air pressure higher than recommended for tool or accessory.

2

SAFETY INSTRUCTIONS

WEAR ANSI Z87.1 (In Canada, CSA Z94.3-99) APPROVED EYE PROTECTION - Always

wear approved eye protection equipment that provides both front and side eye protection when

operating or servicing the compressor.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING PRESSURE OF

AIR-POWERED TOOLS OR OTHER EQUIPMENT BEING USED - Spray guns and other low

to medium pressure equipment can burst, causing serious injury to user and bystanders.

Read and follow all manufacturers' pressure recommendations before connecting tools,

sprayers, or other equipment to compressor. Use extreme care when using the compressor

with tires, inner tubes, and other inflatables, as excessive pressure or rapid inflation can cause

these items to burst.

DO NOT OPERATE IF FLAMMABLE VAPORS ARE PRESENT - The electric motor and

pressure switch may produce sparks, which can ignite flammable vapors and cause fire or

explosion. Flammable vapors from gasoline, solvents, adhesives, and other chemicals may

drift some distance from the source, or build up in low areas. Operate the compressor only in

well-ventilated areas that are free of flammable vapors.

DO NOT TOUCH COMPRESSOR MOTOR, HEAD, OR TUBING WHEN UNIT IS

OPERATING - Normal compressor operation will cause tubing and other components to

become extremely hot. Contact with hot parts can cause serious burns. Allow unit to cool

before handling or performing service.

NEVER DIRECT COMPRESSED AIR AT ANY BODY PARTS - Compressed air can penetrate

skin, or force dirt and debris into eyes, causing serious injury. Never place hands or body

parts over the air discharge opening of a pressurized nozzle or fitting. Use care when

connecting and disconnecting air hose to attachments, pneumatic tools, and other air-powered

devices.

KEEP FLAMMABLE SPRAYS AWAY FROM SPARKS AND OTHER SOURCES OF

IGNITION - Spraying flammable liquids such as oil-base paints, sealers, and finishes near

sparks, open flame, and other sources of ignition such as pilot lights, appliances, water heaters,

furnaces, etc. can result in explosion and fire. Turn off all pilot lights, and avoid using

electrical appliances, heaters, torches, and other equipment that may produce sparks or flame.

Keep compressor as far away from spraying area as possible by using an air hose of sufficient

length to prevent spray mist from being ignited by electrical sparks from compressor operation.

DO NOT OPERATE IN THE RAIN OR IN WET AREAS - Operating an electric compressor in

wet conditions can result in severe shock or electrocution. Operate only in dry conditions,

using a properly grounded power outlet that conforms to local and national electrical code

requirements. An outlet with ground-fault circuit interrupter (GFCI) protection is

recommended for use outdoors or in garages, and may be required by local electrical codes.

3

SAFETY INSTRUCTIONS

DO NOT TAMPER WITH COMPRESSOR PRESSURE SWITCH SETTINGS - The pressure

switch settings set at the factory provide the maximum safe operating pressure recommended

for this compressor. Altering these settings can result in over-pressurization, risk of tank,

hose, and pneumatic equipment failure, and serious injury to operator and bystanders.

USE AIR HOSE RATED FOR 150 PSI OR GREATER - Air hose must be rated to safely

handle maximum compressor pressure. Air hose that does not meet minimum pressure

requirements can rupture, releasing high pressure air. Replace a cracked or leaking air hose

immediately to prevent serious injury from contact with high pressure air streams.

SHUT OFF COMPRESSOR AND RELIEVE TANK PRESSURE BEFORE SERVICING UNIT –

Never perform service or maintenance on any part of the compressor while the unit is running

or tanks are pressurized. Open tank drains slowly to allow air to escape, and keep clear of air

stream.

DO NOT MODIFY COMPRESSOR – Altering the compressor in any way may create a serious

safety hazard, and result in serious injury to operator and bystanders. If compressor does not

work properly, stop using unit immediately. Return unit to an authorized service center for

repairs if problem cannot be remedied by following troubleshooting instructions in this manual.

DO NOT USE COMPRESSED AIR FROM THE UNIT FOR BREATHING PURPOSES - Air

produced by this compressor may contain poisonous exhaust gases from the engine, and is

not suitable for breathing purposes.

DO NOT LEAVE COMPRESSOR RUNNING UNATTENDED - Shut compressor off when done,

and disconnect air hoses to prevent unauthorized use of compressor. Drain air tanks if unit is

to be stored or transported.

CONNECT COMPRESSOR POWER CORD ONLY TO A PROPERLY GROUNDED POWER

OUTLET USING AN APPROVED 3-PRONG GROUNDED EXTENSION CORD - Using an

improperly grounded outlet or extension cord can result in shock or electrocution. Electrical

wiring, outlets, extension cords, and current protection devices such as fuses and circuit

breakers must meet local electrical and safety codes, as well the requirements of the National

Electrical Code. A ground-fault circuit interrupter (GFCI) device may be required for

compressor use outdoors, in garages, and in damp locations.

USE AN EXTENSION CORD THAT IS PROPERLY SIZED - Using an undersize cord can

result in overheating of cord and short-circuiting, resulting in fire and damage to property. Use

a UL-listed extension cord rated to safely handle the power requirements of the compressor.

Cord Length Wire Gauge Size

Up to 25 ft. 12 ga.

Up to 100 ft. 10 ga.

Up to 150 ft. 8 ga.

Up to 250 ft. 6 ga.

4

SPECIFICATIONS

DESCRIPTION SPECIFICATIONS

Horsepower Running/Peak 1.5/3.0

Motor 115/230V 1 Ph 17/8.5 A

Capacity

Tanks 2

Air Storage Capacity 9 Gallons

Maximum Air Pressure 135 PSI

CFM 7.2 cfm @ 100 PSI

Pressure Switch Settings

Pressure Switch - ON 100 PSII

Pressure Switch - OFF 130 PSI

Compressor Pump

Cylinders 2

Compression Stage 1

Motor

Lubrication Splash

Oil Type Non-detergent Mineral Oil

SAE 10W - 30W

ISO 32 - 100

Crankcase Aluminum

Bearings Ball

Cylinders Cast Iron

Valves Stainless Steel

Head Aluminum

Filter Canister

Dimensions

Weight 140 Lbs.

Shipping Weight 162 Lbs.

Size ( L X W X H) 46" X 19" X 24"

5

COMPRESSOR DESCRIPTION

6

Loading...

Loading...