Grin Technologies Ebike Basic Manual

The

Grin Technologies

Basics Ebike Guide

© July 2013, Grin Technologies Ltd.

Prepared and Illustrated by: Adam Burvill

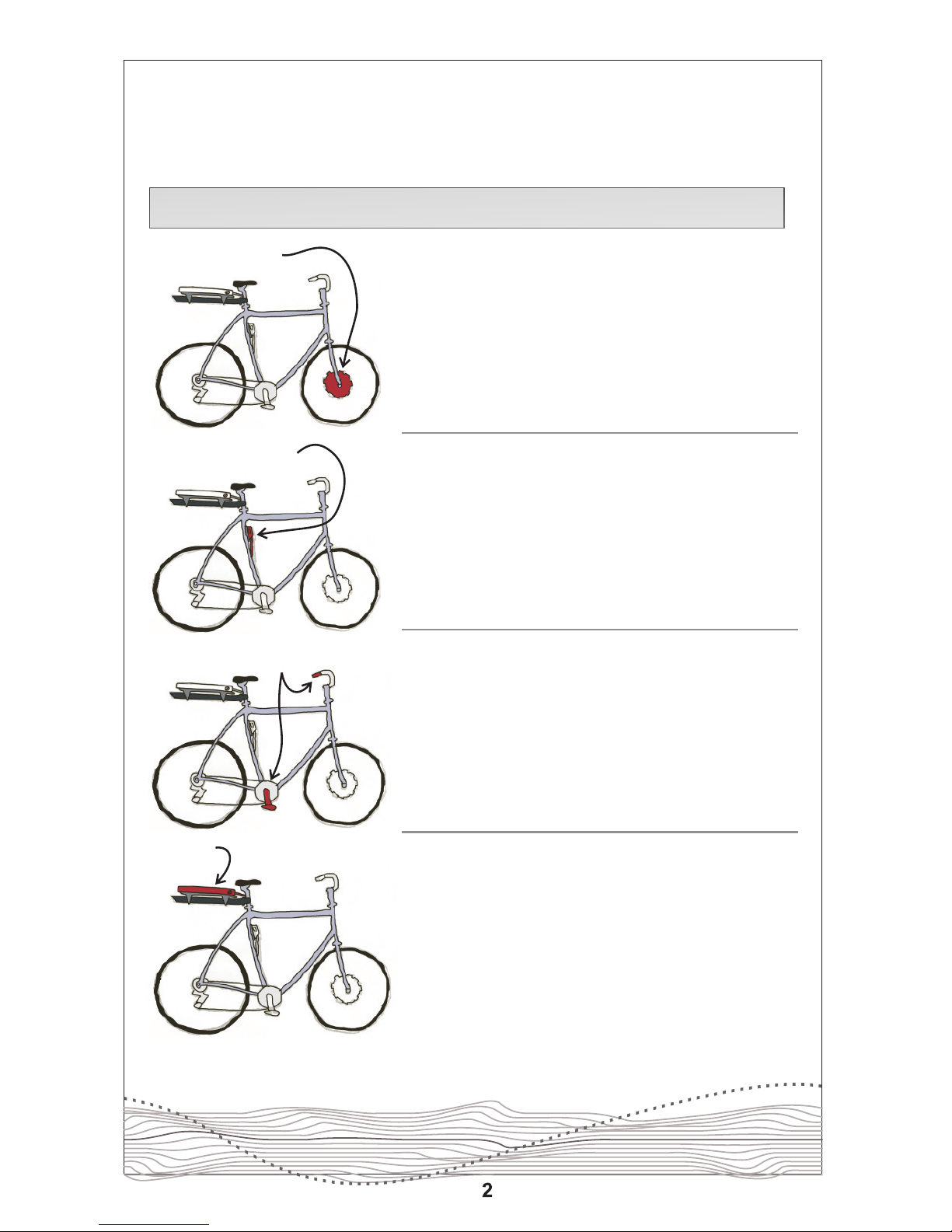

An electric bike normally comprises 4 key components:

We mostly sell hub motor conversion kits where the

motor is built inside the bike wheel and the axle of the

motor is secured in the bicycle dropouts. The axle is

fixed to the bicycle fork and then when you provide

power to the motor the "rotor" part of the motor spins,

which then spins the bicycle wheel itself.

The motor controller delivers and regulates power to

the motor, controls how fast the motor spins (via a

throttle normally) and converts the DC (direct current)

type of electricity the battery provides into the AC

(alternating current) electricity needed to spin the hub.

The throttle is normally mounted on the handlebars of

the bike and a twisting action tells the motor controller

to supply more power. Some electric bikes have a

pedal assist system (PAS) instead whereby your

pedaling effort is sensed and this tells the motor

controller to provide a certain level of assist power.

The battery is where the system gets its power from.

Nowadays most ebike batteries are lithium batteries,

similar to those found in laptops but are about 10x the

size. The battery is usually recharged by a charger

plugged into a mains power outlet. A battery weighing

around 4kg can provide upwards of 20-40km range with

speeds of 30-40kph depending on how much the rider

pedals.

Electric Motor

Motor Controller

Throttle/Pedal Assist

Battery

Electric bikes are a new and promising alternative form of urban transportation. They provide

all the advantages of a regular bicycle while eliminating one of the bicycle’s main drawbacks,

lack of power. You can pedal normally and just use the motor to help out on hills and

headwinds, or use the motor all the time just to make riding easier and faster.

3

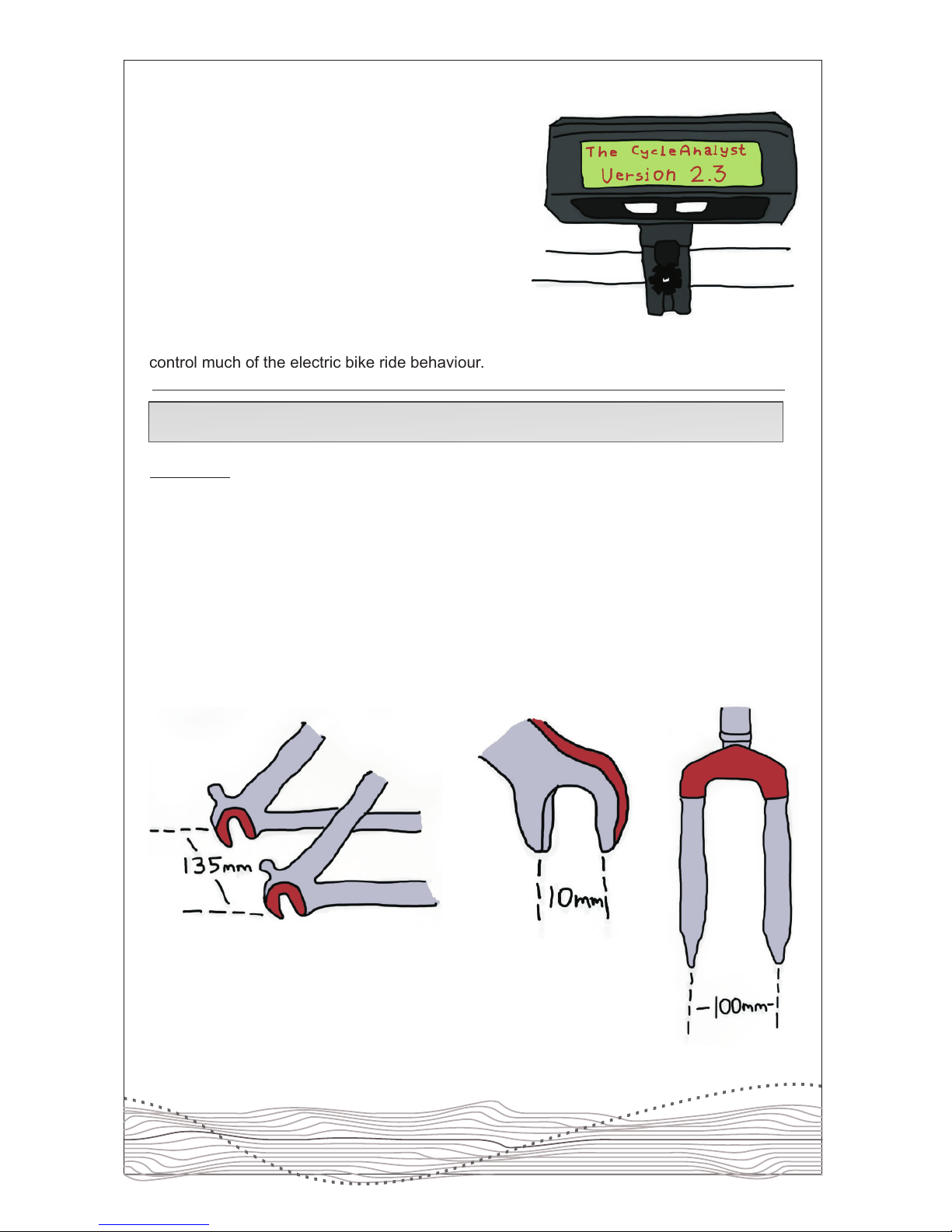

Many electric bikes also come with a display console

so that you can view the performance of the ebike

whilst riding. At Grin Technologies we design and

manufacture the Cycle Analyst: it allows you to keep

track of the vehicle's battery usage and performance

characteristics, and with the more recent Version 3

model you can also monitor the throttle, the motor

temperature, control pedal assist systems and much

more. The Version 3 Cycle Analyst effectively

becomes the “brains” of the ebike, and is able to

control much of the electric bike ride behaviour.

Considerations when buying an electric bike conversion:

Will it fit?

Our goal at Grin is to make ebike conversion parts as compatible as possible with regular

bike standards. To that end all of our front hub motors have 100mm dropout width which is

the industry standard for front forks and they fit in the vast majority of bikes. The rear

wheels have 135mm axle spacing, which is standard for most bikes as well. Occasionally

if you want to fit a larger 7, 8 or 9 speed freewheel on a rear motor then you need to space

out the axle with some washers but most bike frames can be widened a few mms to

accommodate this. We have also taken the time to create complete engineering diagrams

for nearly all the hub motors we sell and these can help confirm the fit.

Our front motor axles are 12mm diameter machined to 10mm on the flats,

whilst the rears are 14mm diameter and 10mm on the flats. This means

they will fit in most bike dropouts but in about half the forks out there a

small amount of filing is required to make the dropout slot wide enough to

fit the axle. If you have lawyer lips you might also need a C washer so

that the motor nuts can be tightened flat against the dropout.

4

Front vs Rear:

?ease of installation: a front tends to be easier than a rear

?weight distribution: with the battery normally mounted at the rear of the bike a front

motor can help with more even weight distribution

?traction: front motors are limited in how much power they can deliver to the wheel on

loose gravel roads without skidding since most of the weight is on the rear.

?discreteness: rear motors can be hidden with panniers to look more subtle

For the most part you won't notice a huge difference between front and rear installations

but a few factors to consider include:

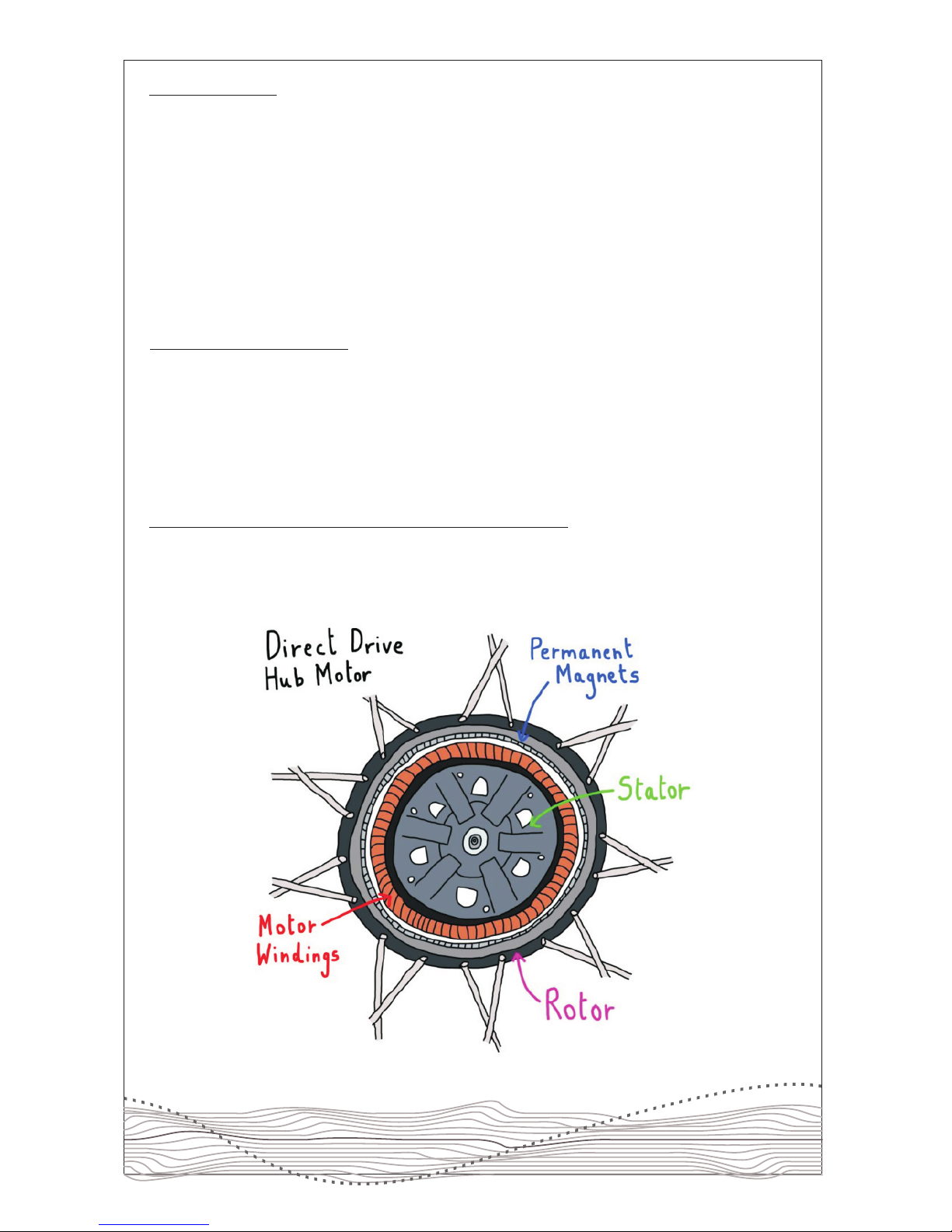

With a direct drive hub motor, you have the capability to use the hub as an engine brake as

well, and have the motor to slow you down while charging up the batteries a bit in the

process. The amount that regenerative braking recharges the battery can’t really

compensate for the battery discharge over the course of an ebike trip, usually about 5-10%

recaptured, but it is definitely useful for saving wear and tear on the brake pads.

Regenerative Braking:

In a normal direct drive motor the motor is always mechanically engaged which means you

feel a slight resistance when turning the wheel. It amounts approximately to the difference

between riding with a slick road tire and a knobby mountain bike tire.

Direct Drive And Internally Geared Hub Motors:

Loading...

Loading...