Page 1

1104 Form # AM-324-03

American Metal Ware®Hot Water Boiler

Installation, Operation & Service Manual

For

Models 815, 830, 850

Gas

Electric Steam

Special Features

After completing installation and set-up, the

equipment owner should keep this manual for

future reference.

© Grindmaster Corporation™, 1995

PRINTED IN USA

Grindmaster Corporation™

4003 Collins Lane

Louisville, Kentucky 40245 USA

(502) 425-4776

(800) 695-4500 (USA and Canada only)

(800) 568-5715 (technical service only)

FAX: (502) 425-4664

www.grindmaster.com

X

TABLE OF CONTENTS

General Description.................................1

Installation...............................................1

Thermostat..............................................4

Adjustment..................................4

Service Instructions.................................5

Dual Level Control...................................6

Troubleshooting.......................................7

Solenoid Valve

Safety Instructions.....................11

Installation..................................11

Disassembly..............................12

Assembly...................................12

Troubleshooting.........................12

Cleaning....................................12

Testing.......................................12

Repair Kits.................................12

Coils..........................................12

Parts List...............................................13

Page 2

Page 1 American Metal Ware Hot Water Boiler

Electric Models

815, 830, 850

Equipped with Option 46 Automatic Refill

Option 39 Low Water Cut-Off System

General Description

This unit is a high temperature hot water boiler. It consists of a non-pressure, vented water

compartment into which is installed an electric immersion heater thermostatically controlled through

a contactor relay, to keep the water always at the desired brewing temperature. Automatic refill

maintains water level in water compartment. All control system components are enclosed in a

stainless steel housing on the right end of the urn:

A master ON-OFF switch shuts off entire unit, including heater circuit: Separate low water cutoff

system protects heater and entire unit from damage.

Installation

1.

2.

3.

4.

5.

IMPORTANT TO ALLOW 6" CLEAR SPACE TO RIGHT ON CONTROL BOX FOR

ACCESS. Urn should be level, both front to back and left to right.

CONNECT WATER LINE. 3/8" NPT water inlet located at right end. Provide shutoff valve and

union in supply line near urn. Cold or hot water may be used, but hot water will give greater gallon per hour capacity. We strongly recommend the use of copper or aluminum tubing to provide

flexibility and avoid strain on the unit. 3/8" O.D. Tubing is recommended.

CONNECT URN TO ELECTRIC POWER. Check to be sure that name plate marking of voltage

phase and number of wires matches supply lines. Remove cover on control housing. Terminal

block for line connections located in housing on right end. See drawing, as required. It is recommended that a fused disconnect switch be installed near urn. Urn body must be grounded

either through metallic conduit or else by means of ground wire. An experienced electrician

should be responsible for the installation of the unit, and its associated supply line. NOTE:

Neutral wire required on all single phase and on 208 volt 3 phase power supplies to operate

120volt AC control circuit. Do not replace cover until completion of installation.

FILL WATER COMPARTMENT. Turn on water supply and electric service to urn. Turn master

switch on. Do NOT turn on thermostat until water shows in gauge glass (approximately 6 minutes). When water shows, remove adhesive WARNING label from thermostat knob. Turn

thermostat knob maximum clockwise to BREW position. Pilot light over knob should light

showing heater power on. Water compartment will fill automatically to stop-full level, and should

reach operating temperature approximately 45 minutes later. When the pointer on thermometer

approaches the "W" in the blue BREW zone, unit is ready for operation.

REFILL RATE ADJUSTMENT. To gain maximum capacity of the boiler, and shorten heat

recovery time, adjust the water inlet flow regulator (located inside the control box) according

to the chart provided. Turning the threaded adjustment shaft clockwise increases the flow

rate, counterclockwise will decrease it.

Page 3

American Metal Ware Hot Water Boiler Page 2

TO CHECK REFILL RATE, allow water to fill to stop/full level automatically; then turn off master

switch. Draw off 1 gallon of water from faucet. Turn master switch back on and time how long it

takes for the water level to come up to stop/full mark again. Compare time with chart provided

and adjust accordingly.

Installation (cont.)

5)

*Factory setting

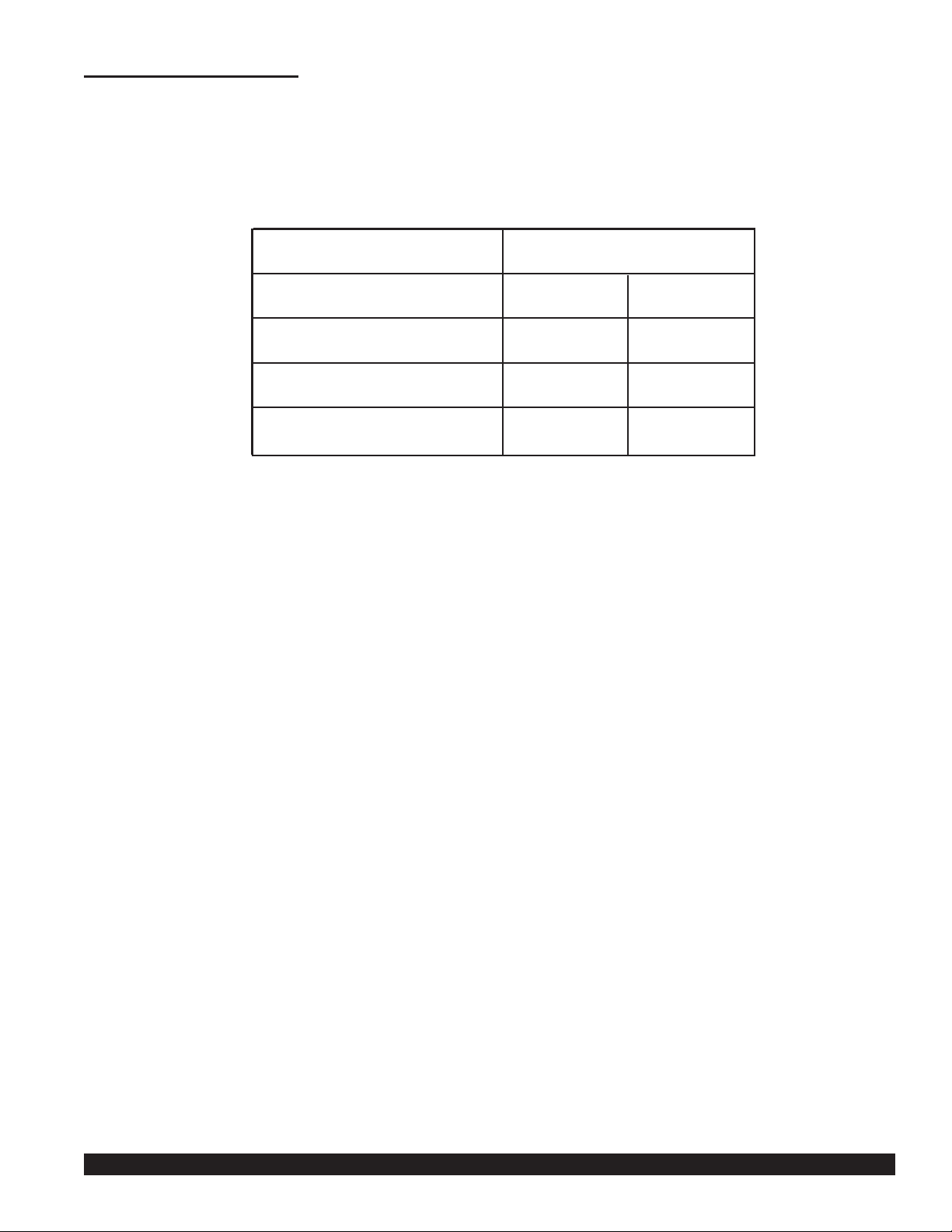

HEATER SIZE

(OR EQUIV. STEAM USE)

5.5KW/208 Volt or

7KW/240 Volt

12KW

15KW

COLD WATER*

CONNECTION

3min. 30sec.

1min. 50 sec.

1min. 25sec.

TIME TO REFILL 1 GALLON

HOT WATER

CONNECTION

1min. 25sec.

45sec.

35sec.

Page 4

Page 3 American Metal Ware Hot Water Boiler

Page 5

American Metal Ware Hot Water Boiler Page 4

Thermostat

Factory set so that knob on BREW setting holds unit at brewing temperature toward HIGH end of

brew zone on thermometer dial. Then, if turned back to HOLD position, thermostat should cycle

on and off and hold at LOW 'end of BREW zone on thermometer.

Thermostat Adjustment

1.

2.

If water temperature is below HIGH end of BREW zone on thermometer dial with knob on

BREW setting, remove knob by pulling straight outward. Using a small screwdriver, insert in

hole in center of shaft, turn slotted screw counter-clockwise until red pilot light goes on.

Check to see that water in unit holds at HIGH end on BREW zone on thermometer and

does not

boil.

If water boils with thermostat knob set at the BREW position, remove knob by pulling

straight outward. Using a small screwdriver, insert into hole in center of shaft, turn slotted

screw clockwise until red pilot light goes out. Hold shaft so it does not turn while adjusting

screw. Add cold water and check that heat comes back on (Pilot light glows), and that thermostat cycles at temperature at HIGH end of BREW zone on thermometer dial.

If thermostat will not cycle, replace entire control.

Page 6

Page 5 American Metal Ware Hot Water Boiler

Service Instructions

PROBLEM: THERMOSTAT DIAL TURNED TO BREW AND WATER IN COMPARTMENT REMAINS COLD

POSSIBLE CAUSE

1.

2.

PROBLEM: WATER BOILS CONTINUOUSLY WITH THERMOSTAT DIAL ON POSITION BREW OR HOLD.

POSSIBLE CAUSE

1.

2.

3.

Set knob on BREW and remove knob by pulling outward. Using

small screwdriver in center of shaft, turn slotted screw clockwise

until pilot light goes out. Check holding temperature by adding

cold water. Red light should come on, and water heat up to HI

end of BREW zone on thermometer dial and then shut off.

NO

BOILING.

If impossible to get control to cycle on and off and control

temperature, replace entire control. Be sure to drain water in urn

below level at which bulb enters urn. Also shut off all power

before service is attempted.

Relay must click on and off. If it sticks, replace.

Thermostat out of

calibration.

Thermostat is inoperative.

Fluid has leaked out of

diastat assembly of

thermostat.

Relay sticking in closed

position.

No power at urn.

Power at urn, but no power

at heater terminals.

Check main switch, Check main fuses. (3 on 3 phase power, 2

on single phase power). Check that Pilot Light by On-Off switch

is ON.

Check control circuit fuse. Check that pilot light over thermostat

dial is lighted with dial set to BREW. Check that water level is at

FULL mark on water gauge glass. NOTE: If urn is equipped with

Option 39, Low Water Cut-off System, level in gauge glass

should be minimum 2 inches showing to have power ON to

control circuit. Check low water cut-off and auto refill system and

replace if necessary. Check that contactor clicks on and off as

thermostat dial is turned from BREW to OFF. Check control

transformer if so equipped. Lastly, check for voltage at heater

terminals. If OK, check for broken or loose wire on terminal. If

necessary, replace heater.

Page 7

American Metal Ware Hot Water Boiler Page 6

Dual Level Control

Auto Refill And Low Water Cutoff System

I)

II)

Dual Level Control: What it does:

Description and Operation of Dual Level Control System:

A.

B.

C.

A.

AUTO REFILL of the water compartment to keep the tank filled with water.

When water is used, the fill valve opens automatically to let

in more. The fill valve closes when the water level reaches full.

LOW WATER CUTOFF to prevent burn out of the electric immersion heater when

there is not enough water to cover it. When low water occurs,

the heat automatically switches off. The heat stays off until

more water is added.

A device called a DUAL LEVEL CONTROL keeps the tank filled with water and

turns off the heat when water is low by simultaneously monitoring two

different water levels.

Components

1. DUAL LEVEL CONTROL -

2. ELECTRODE ASSEMBLY -

3. METAL ENCLOSURE (TANK BODY)

switches power to both the thermostat and

water inlet solenoid valve by sensing changes

in water level.

consists of a high (short) and a low (extra long)

sensing electrode, or probe, molded in an epoxy

body.

provides a common (ground) connection for the

electrode circuit.

HIGH

RED WIRE

GREEN WIRE

TRANSFORMER

RELAYS

FILL HEAT

MN

120VAC

PROBES

HI XL C

PRINTED CIRCUIT

RED WIRE

HIGH

LOW

GREEN WIRE

LOW

SIDE MOUNTED PROBES

TOP MOUNTED PROBES

Page 8

Page 7 American Metal Ware Hot Water Boiler

II)

III) Quick Service Check of Dual Level Control System:

Description and Operation of Dual Level Control System (continued)

B. Operation

W

ater Level Action

1) Below both electrodes 1)

2) Rises to low electrode 2)

above heater coils

3) Rises to high electrode 3)

4) Falls below high electrode only 4)

5) Falls below low electrode 5)

(Same as condition no. 1)

1)

2)

3)

Both “HI” and “XL” electrode circuits open.

Dual Level Control turns power on to fill

valve and keeps power off to thermostat.

“XL” electrode circuit closes. Power to

thermostat turned on. Power to fill valve

remains on.

“HI” electrode circuit closes. Dual Level

Control turns power off to fill valve and

continues power to thermostat.

“HI” electrode circuit opens. “XL” circuit

stays closed. After a few seconds delay,

power to fill valve is turned on.

“XL” electrode circuit now opens. Power to

thermostat is turned off. Power to fill valve

remains on.

All

wire secure and properly connected.

Clean the electrodes. Lime (mineral scale) build-up can interfere with the operation of any

liquid level control system.

Check the common (ground) connection. A little looseness or dirt can cause erratic

operation.

Thermostat

Fill Solenoid

Valve

OFF

ON

O

Thermostat

Fill Solenoid

Valve

ON

ON

O

O

O

Thermostat

Fill Solenoid

Valve

ON

OFF

Thermostat

Fill Solenoid

Valve

ON

ON

Page 9

American Metal Ware Hot Water Boiler Page 8

A)

B)

C)

Overfilling of water

tank when power is

off.

Overfilling of water

tank only when power

to unit is on.

Auto refill fails to

fill water tank.

PROBLEM

IV) Trouble Shooting Auto Refill, Low Water Cutoff, and Dual Level Control System

POSSIBLE CAUSE SERVICE CHECK REMEDY

1)

2)

1)

2)

3)

4)

1)

2)

Fill solenoid valve leaking

due to dirt or scale holding

valve open, or worn

plunger seat.

Fill solenoid valve

installed backwards.

High electrode coated

with scale, or faulty.

Missing or faulty

common connection for

electrode circuit (“C”

terminal to metal

enclosure).

Fill valve connected to

“HEAT” terminal.

Dual Level printed

circuit board faulty.

No power at equipment.

No water at equipment.

Visual. Water entering

tank continuously, and

usually slowly.

Visual.

Jumper from “HI” terminal

to metal enclosure stops

fill.

Jumper “C” terminal

(next to XL) to metal

enclosure stops fill.

Visual.

Jumper from “HI” to “C”

does not stop fill.

Nothing operates on

machine.

“Crack” fitting at

water inlet for pressure

check.

Disassemble and clean out. May

require new plunger assembly. Caution

is advised to avoid damage to valve.

See valve instruction sheet.

On valves without integral strainer:

Install so that port marked “IN” is

connected to outside fresh water

supply.

On valves with integral strainer:

Install so that arrow points in

direction of tank, away from fresh

water supply.

Remove electrode assembly. Clean both

electrodes. If still no remedy and

connections are good, replace assembly.

Make good secure connection. May

require cleaning or replacement.

Connect “BLACK” wire lead to “FILL”

terminal.

Replace Dual Level Control.

Make sure main switch(es), fuse(s),

circuit breaker(s) provide power to

unit, that machine’s circuit

breaker is OK and power switch, if

provided, is on.

Make sure all water supply line

valves are open.

Page 10

Page 9 American Metal Ware Hot Water Boiler

C)

D)

Auto refill fails to

fill water tank

(continued).

Auto Refill is erratic.

PROBLEM

IV) Trouble Shooting Auto Refill, Low Water Cutoff, and Dual Level Control System (continued)

POSSIBLE CAUSE SERVICE CHECK REMEDY

3)

4)

5)

6)

7)

8)

1)

2)

3)

Water strainer clogged.

No power on Dual

Level Control.

Fill solenoid valve

clogged with scale

or frozen closed.

Fill solenoid valve

coil inoperative

Electrodes shorting to

ground.

Dual Level Control

faulty.

Electrode shorting to

ground completely or

intermittently.

Loose connection.

Dual Level Control

faulty.

Water pressure before

strainer and not after.

Check for 120V AC across

“H” and “N” terminals.

Disassemble.

Jumper from “FILL”

terminal to “H” terminal

does not start fill.

Tank fills with electrode

wire disconnected from

“HI” terminal.

Tank does not fill

with electrode wire

disconnected from “HI”

terminal.

Tank fills with

electrode wire

disconnected from “HI”

terminal

Visual. Check for “C” and

“HI” probe terminals as well

as “FILL.” Also check

neutral (white) wire at valve.

Tank does not fill with

electrode wires disconnected

from “XL” and “H” terminals.

Remove and clean micromesh screen

filter located in water strainer.

If voltage missing or incorrect,

check wiring for looseness, breaks,

and proper connections.

Clean out and/or replace plunger

assembly or entire valve. May require

new coil. Caution is advised to avoid

damage to valve. See valve instruction

sheet.

Replace coil. Also check for frozen

plunger. See valve instruction sheet.

Replace electrode assembly. If no

remedy, check for improper wiring

(cut insulation) or electrode tips

touching metal.

Replace Dual Level Control.

Replace electrode assembly.

Push wire lead connector securely

onto terminal(s). Replace connector

if wire is frayed or broken.

Replace Dual Level Control.

Page 11

American Metal Ware Hot Water Boiler Page 10

NOTE: The level control board works on the principle that water is conductive and with some pure water installations, an

increased senseitivity may be required in the level control system. Consult factory if this be the case.

If you still need help, call our service department at (800) 568-5715 Ext. 3 or (505) 425-4776 (Monday through Friday,

8 am - 6 pm EST) or an authorized service center in your area. Please have the model number and serial number s ready so that

accurate information may be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all warranty claims.

E)

F)

Tank fills with water,

but heat does not come

on.

No water in tank, but

heat comes on (heater

damage likely).

PROBLEM

IV) Trouble Shooting Auto Refill, Low Water Cutoff, and Dual Level Control System (continued)

POSSIBLE CAUSE SERVICE CHECK REMEDY

1)

2)

3)

4)

5)

1)

2)

3)

Thermostat off.

Thermostat inoperative

or out of calibration.

Power relay or

contactor inoperative.

Low electrode faulty

or covered with lime

scale.

Dual Level Control

faulty.

Thermostat and fill

valve connected to

wrong terminals on

Dual Level Control .

Electrode(s) shorting

to ground.

Dual Level Control

faulty.

Visual.

Jumper across thermostat

terminals causes heat to

come on.

Check for voltage

(120V AC) across coil

terminals.

Jumper from “XL”

terminal to metal

enclosure allows unit

to heat.

Jumper from “XL”

terminal to “C” does not

cause unit to heat.

Visual

Disconnecting wire

(white) from “C” probe

terminal provides low

water heat cutoff and

tank fill.

Heat comes on with no

probe wires (HI, XL, C)

connected.

Make sure knob is turned fully clockwise.

Recalibrate thermostat. If no remedy, or ther-

mostat does not cycle, replace.

If correct voltage, replace coil or entire device.

If not correct voltage, check for loose wires,

improper wiring or other cause.

Clean electrodes. Check wiring. If still no

remedy, replace electrode assembly.

Replace Dual Level Control.

Thermostat (brown wire) must be

connected to “HEAT” and fill valve (black wire)

to “FILL”.

Replace electrode assembly. If no

remedy, check for improper wiring (cut insula-

tion for instance), or electrode tips touching

metal inside tank.

Replace Dual Level Control.

Page 12

Page 11 American Metal Ware Hot Water Boiler

Read installation instructions- thoroughly. Failure to comply can

result in valve failure or system damage or personal injury.

Do not use solenoid valves on applications or fluid media not

specifically cataloged without prior approval of Alco Engineering

Department.

WARNING: DO NOT USE WITH FLAMMABLE OR EXPLOSIVE

FLUIDS OR GASES. DO NOT USE IN EXPLOSIVE

ATMOSPHERES.

Use on these elements can result in product damage or

personal injury.

Use of solenoid valves on applications not specifically cataloged

can result in valve failure and/or system damage or personal

injury. Do not utilize a solenoid valve on any system where the

system pressure can exceed the safe working pressure of the

valve.

CAUTION:

Do not utilize a solenoid valve as a safety shut off.

Do not exceed MOPD (Maximum Operating Pressure

Differential) or valve may fail to open when energized.

6.

7.

8.

9.

10.

11.

1.

2.

3.

4.

5.

CAUTION: Always disconnect power source and depressurize

the system before working on solenoid valve or system. If the

power disconnect is out-of-sight, lock it in the open position and

tag to prevent unexpected applications of power.

Direction of flow must correspond to flow Direction Schematics.

Before energizing valve, be sure source voltage and frequency

matches that on coil. Do not energize coil unless coil is securely

attached to valve. See Coil Installation Instructions.

Prolonged use in excessive ambient temperature or humidity

may damage coils.

Do not dent or bend or use enclosing tube as lever. A damaged

enclosing tube may result in coil burnout or inoperative valve.

Foreign matter in the valve may result in seat leakage, sticking

open or closed, or coil burnout. To prolong valve life and ensure

system cleanliness use a strainer.

Safety Instructions

ATTENTION: Read carefully before attempting to install,

operate or service your Alco solenoid valve. Retain for

future reference.

For ease of installation, an Alco solenoid valve can be installed in

any position...gravity does not affect its operation.

NOTE:

Although all valves can be operated in any position,

by mounting the valve upright there is less chance of

malfunction caused by the collection of foreign material.

The solenoid coil can be rotated 360

O

for ease of wiring. If possible

do not reduce thelength of the solenoid coil wire leads, so that if it

becomes necessary to remove coil at a later date (for valve cleanout,

etc), wire leads will not have to be disconnected.

To allow for removal of the solenoid coil without removing the valve from

its piping, allow at least 2 inches of clearance above the solenoid.

Be sure valve is installed so that its flow arrow on valve body corresponds to direction of flow through piping.

1.

2.

3.

4.

Before removing coil from valve, disconnect electrical power

source. Failure to do so will cause coil to burn out.

Verify coil type, voltage and frequency. This information appears

on the coil nameplate.

Place coil over the enclosing tube. Coil may be rotated 360

O

for

easy wiring. It is recommended that coil lead connections be

soldered on D.C. and 24V - 50/60 Hz. applications.

Install valve nameplate. Pull tab on valve nameplate and peel off

paper backing to expose adhesive. Stick nameplate on top of coil

housing and press nameplate down firmly. If installing

replacement coil, use valve nameplate supplied with valve. Press

nameplate down firmly.

Install voltage nameplate and coil retainer. Press coil retainer

down firmly to secure coil.

Be sure your wiring conforms to all local and national electric codes.

For dual voltage coils, refer to the wiring schematic label on side

of coil.

The coil circuit of each solenoid valve should be protected by

adequate fuses.

1.

2.

3.

4.

5.

Wiring

1.

2.

3.

WARNING

If not properly grounded, a hazard of electrical shock may exist.

Install and ground unit in compliance with National, state, and local

electrical codes.

Installation

Valve and Solenoid Position

Coil Installation Instructions

FLUID TEMPERATURE RATING F

O

Elastomer

Code

B

P

N

F

T

V

Coil Code

AMG, AMC

180

250

180

180

250

AHG, AHC

385

Identify valve elastomer code and coil code from valve model

number and reference rating from table.

Valves are rated for use on air or other non-hazardous, non-toxic

fluids, water and other aqueous, non-hazardous fluids, and steam.

INSTALLATION AND SERVICE

INSTRUCTIONS

FOR

202CB and 204CD Series

General Purpose Solenoid Valve

53.20.10

May 1983

Supd’s 3-80

Page 13

American Metal Ware Hot Water Boiler Page 12

Diassembly

Disassemble in the same general order as indicated in exploded-view

illustrations except as noted in the following steps:

1.

2.

3.

Notes: Do NOT Lose Nameplate, as it is extremely

important if it becomes necessary to order

a parts kit, coil or duplicate valve .

Assembly

1.

2.

3.

Troubleshooting

1.

2.

Cleaning

As with all valves, it may become necessary to clean them

periodically to keep them in peak operating condition. Any cleaning

methods or fluids used should be compatible with valve materials.

Inspection

1.

2.

Testing

1.

2.

3.

4.

5.

Repair kits

The following Repair Kits are available:

Coils

1. Junction box (AMG) is supplied as standard on all valves.

2. The following coil housings are available:

a. Conduit Connection (AMC) c. Open Frame (AMF)

b. GROMMET 113" Leads (AML) d. Spade Connection (AMS)

3. Use only Alco coils on Alco valves.

All moving parts and elastomers should be clean in appearance

without permanent set springs should be free of corrosion. If any

appear damaged, replace them with a parts kit which contains all

moving parts necessary to rebuild valve to an "as new" condition.

Inspect enclosing tube assembly for wear, exterior dents or other

conditions which would impair free movement of the poppet

and/or plunger assembly. Its interior should be clean and free

from any obstructions. Be especially critical of its valve seat.

Apply correct voltage to valve solenoid and cycle solenoid several times. A distinct click should be heard each time the solenoid

is energized.

Pressurize valve and check for leaks.

Note: Alco solenoid valves are equipped with a

contlnuous-duty solenoid coil,which when energized

for an extended period of time becomes hot to the

touch...this is a safe operating temperature. Any

excessive heating will be indicated by smoke and

odor of burning coil Insulation.

Are all system relays operating?

Is system source pressure as specified?

Are all system components free from obstructions?

Check system fuses, electrical wiring and system source voltage

as specified.

Is flow direction arrow on valve the same as system flow

direction?

Assemble in the reverse general order of disassembly.

Lubricate gasket and "O" ring sparingly with a compatible

lubricant such as a Silicon base lubricant.

All moving parts, must move freely over the full length of its

intended travel.

De-pressurize valve and disconnect electrical power source.

To remove solenoid coil:

Insert small screwdriver into gap in voltage nameplate. Slide

screwdriver tip under coil retainer and snap off. If replacing coil,

use knife to separate adhesive-backed valve nameplate from coil.

Keep valve nameplate.

To remove collar, use service tool X11981-1 shown in Figure 1.

VALV E

SERIES

202CB -B

202CB -F

202CB -N

202CB -P

202CB -T

202CB -V

VALV E

SERIES

204CD -B

204CD -F

204CD -N

204CD -P

204CD -T

204CD -V

KIT

PART NO.

K-1072

K-1075

K-1073

K-1076

K-1077

K-1074

KIT

PART NO.

K-1063

K-1066

K-1067

K-1064

K-1068

K-1065

VALV E

SERIES

204CD -B

204CD -V

204CD -T

204CD -P

KIT

PART NO.

K-1162

K-1164

K-1167

K-1166

For 1/4” Orifice Only

COIL RETAINER

NAME PLATE

COIL ASSEMBLY

COLLAR

“O” RING (K)

ENCLOSING TUBE

PLUNGER AND

SPRING ASSEMBLY (K)

GASKET (K)

BODY

SERVICE

TOOL (K)

(K) INDICATES ITEMS INCLUDED IN REPAIR KIT

ALCO CONTROLS DIVISION • EMERSON ELECTRIC CO.

P.O. BOX 12700 • ST. LOUIS, MISSOURI 63141 • 314-569-4500

CUSTOMER SERVICE • 314 569 4666

Figure 1

Page 14

Page 13 American Metal Ware Hot Water Boiler

Parts List

815, 830, 850 - Electric, Gas or Steam Heat

AMW Part # Description

522004 Aluminum Gauge Shield Only for 815 - 5/8” x 13”

522006 Aluminum Gauge Shield Only for 830 - 5/8” x 16”

522010 Aluminum Gauge Shield Only for 850 - 5/8” x 20”

522034 Gauge Glass Only for 815 - 5/8” x 13”

522036 Gauge Glass Only for 830 - 5/8” x 16”

522129 Gauge Glass Only for 850 - 5/8” x 20”

522030 Aluminum Bracket for Gauge Shield

522026 Upper Gauge Glass Washer

522027 Lower Gauge Glass Washer

A-682 Gauge Shield Cap for Plug-in Cleanout Cap

A-1132 Plug-in Cleanout Cap w/Vent Hole

522094 Water Faucet

522102 Silicone Seat Cup for Faucet

532064 Water Line Strainer

506001 Thermometer

549-000 Dual Liquid Level Control

712-017 Electrode Assembly for 815, 830

712-007 Electrode Assembly for 850

505021 Adjustable Water Flow Regulator (1/4- NPT)

504001 Thermostat

515017 Red Pilot Light

537-060 Solenoid Valve, Water Inlet

537-061 Repair Kit for Solenoid

515012 On-Off Master Switch

Electric Heat Only

514009 Heater Contactor - 3 Pole

514005 Heater Contactor - 4 Pole Control

515043 Control Circuit Transformer

515072 Circuit Breaker

535-____ Heater -- specifiy model and serial number, voltage, watts and phase

S

team Heat Only

506009 Steam Solenoid Valve - 10-40 PSI

506014 Repair Kit for Steam Solenoid

506016 Replacement Coil Only for Steam Solenoid

532027A Steam Strainer

Gas Heat Only

504002 Gas Solenoid Valve

504024 Thermocouple

504038 TS11K Gas Safety Valve

504026 Coil for Gas Solenoid

504023 Pilot Burner with Orifice - Natural Gas

504025 Pilot Burner with Orifice - L.P. Gas

505007 Gas Pressure Regulator - Natural Gas

505039 Gas Pressure Regulator - L.P. Gas

IMPORTANT: Give Model Number and Serial Number when ordering

Page 15

American Metal Ware Hot Water Boiler Page 14

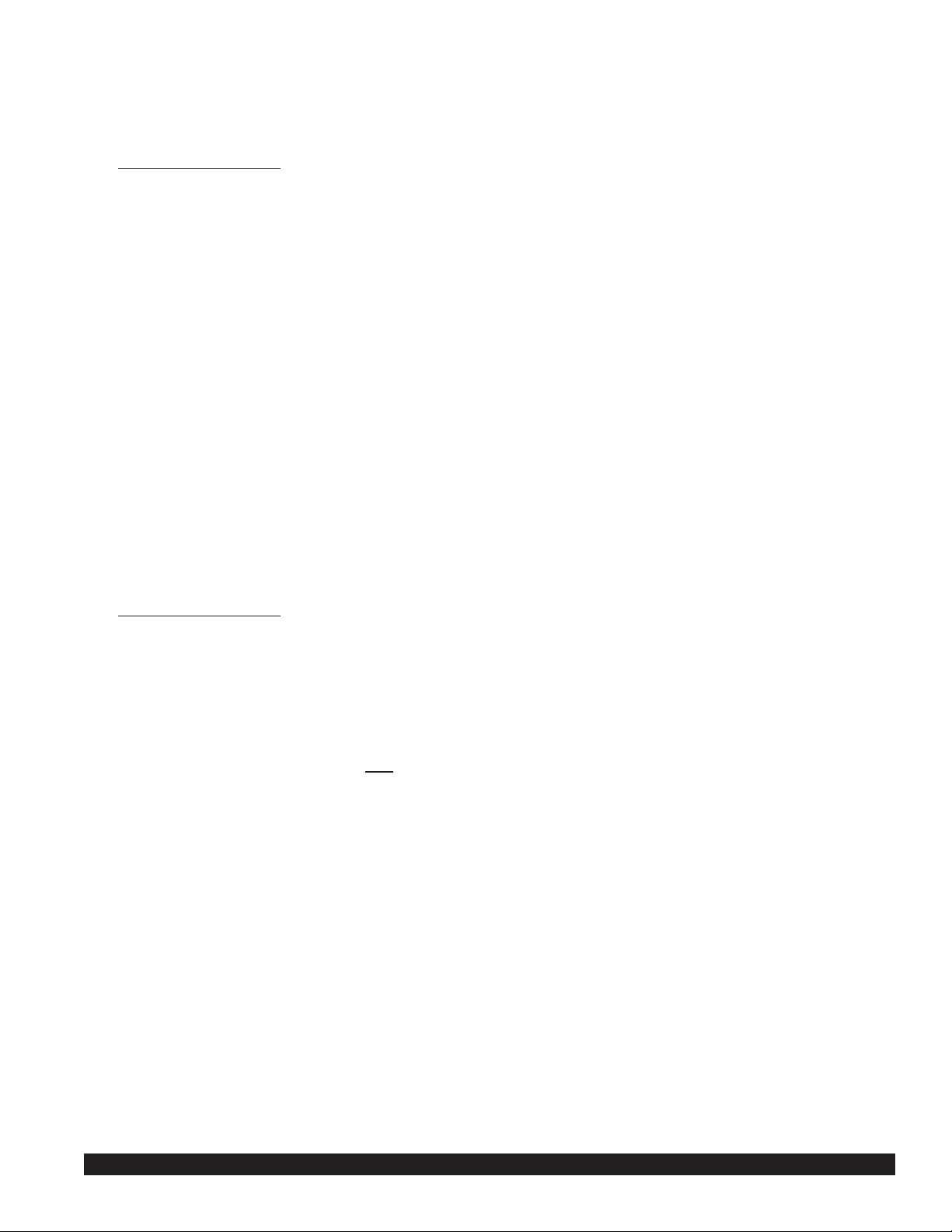

RED

HEAT

FILL H

H

XL

HI

C

GREEN

Page 16

Grindmaster® Coffee Grinders and Brewers • Espressimo® Espresso Machines • Crathco® Hot Beverage Dispensers

Crathco® Cold and Frozen Beverage Dispensers • American Metal Ware® Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

Loading...

Loading...