Page 1

Operation and Instruction Manual

for

Models 5512 & 5512E

Crathco®Beverage Freezers

Operator’s Safety Precautions . . . . . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Product Tips . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Consistency Control . . . . . . . . . . . . . . . . . .9-10

Care & Cleaning . . . . . . . . . . . . . . . . . . . .11-15

Maintenance . . . . . . . . . . . . . . . . . . . . . . .15-16

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . .17

Freezer Specifications . . . . . . . . . . . . . . . .18-19

Troubleshooting Guide . . . . . . . . . . . . . . .20-21

Exploded Views . . . . . . . . . . . . . . . . . . . . .22-30

Wiring Diagrams . . . . . . . . . . . . . . . . . . . .31-41

Refrigeration Schematic . . . . . . . . . . . . . . . . .42

Grindmaster Corporation

4003 Collins Lane

Louisville, KY 40245-1643

Phone (502) 425-4776

800-695-4500 (USA & Canada only)

(800) 568-5715 (technical service only)

Fax (502) 425-4664

www.grindmaster.com

TABLE OF CONTENTS

0106 Form #WH-332-04

Part #W0600138

© Grindmaster Corporation, 2000

PRINTED IN USA

Model 5512

Prior authorization must be obtained from

Grindmaster Corporation for all warranty

claims.

Page 2

Page 3

Crathco®5512 Manual Page 3

Operator's Safety Precautions

1. Read and understand the operating instructions in this manual thoroughly.

2. Note all warning labels on the freezer. If any warning labels are missing or damaged replace them immediately.

3. Do not wear loose fitting garments or jewelry which could cause a serious accident.

4. Stay alert at all times during operation.

5. Keep operating area clean.

6. Do not operate freezer if any excessive noise or vibration occurs. Contact your authorized service agent.

Installation

Shipment & Transit

The freezer has been operated and tested at the factory. Upon arrival the complete freezer must be thoroughly

checked for any damage which may have occurred in transit.

Note: A Tip (N) Tell warning device is placed on each shipping carton at the factory. If the arrow tip is blue, the carton

has been tipped in transit.

Removal from Carton and Pallet

1. Remove staples or cut cardboard box around the stapled area.

2. Pull the cardboard box up off machine.

3. Remove the Styrofoam packing and the plastic bag.

4. Remove both side panels with screwdriver.

5. Use a wratchet with a 3 inch extension and a 7/16 socket to remove the shipping bolts (connecting the machine

to the pallet) located on both sides of the frame bottom plate.

6. Supporting all four sides, lift machine up and place in appropriate area.

THE CARRIER IS RESPONSIBLE FOR ALL DAMAGE IN TRANSIT WHETHER VISIBLE OR CONCEALED. DO

NOT PAY THE FREIGHT BILL until the freezer has been checked for damage. Have the carrier note any visible damage on the freight bill. If concealed damage and/or shortage is found later, advise the carrier within 10 days and

request inspection. The customer must place any claim for damage and/or shortage with the carrier. Grindmaster

Corporation cannot make any claims against the carrier.

CAUTION: IF EQUIPPED WITH SPINNER DO NOT LIFT UNIT BY SPINNER SHAFT TO AVOID SERIOUS

DAMAGE TO SPINNER.

Figure A

!

Page 4

Page 4 Crathco®5512 Manual

Installing Y

our Unit

CAUTION: Do not alter or deform the plug in any way. Altering or deforming plug may damage unit

and will void warranty! Receptacle NEMA 6-20R required for Model 5512.

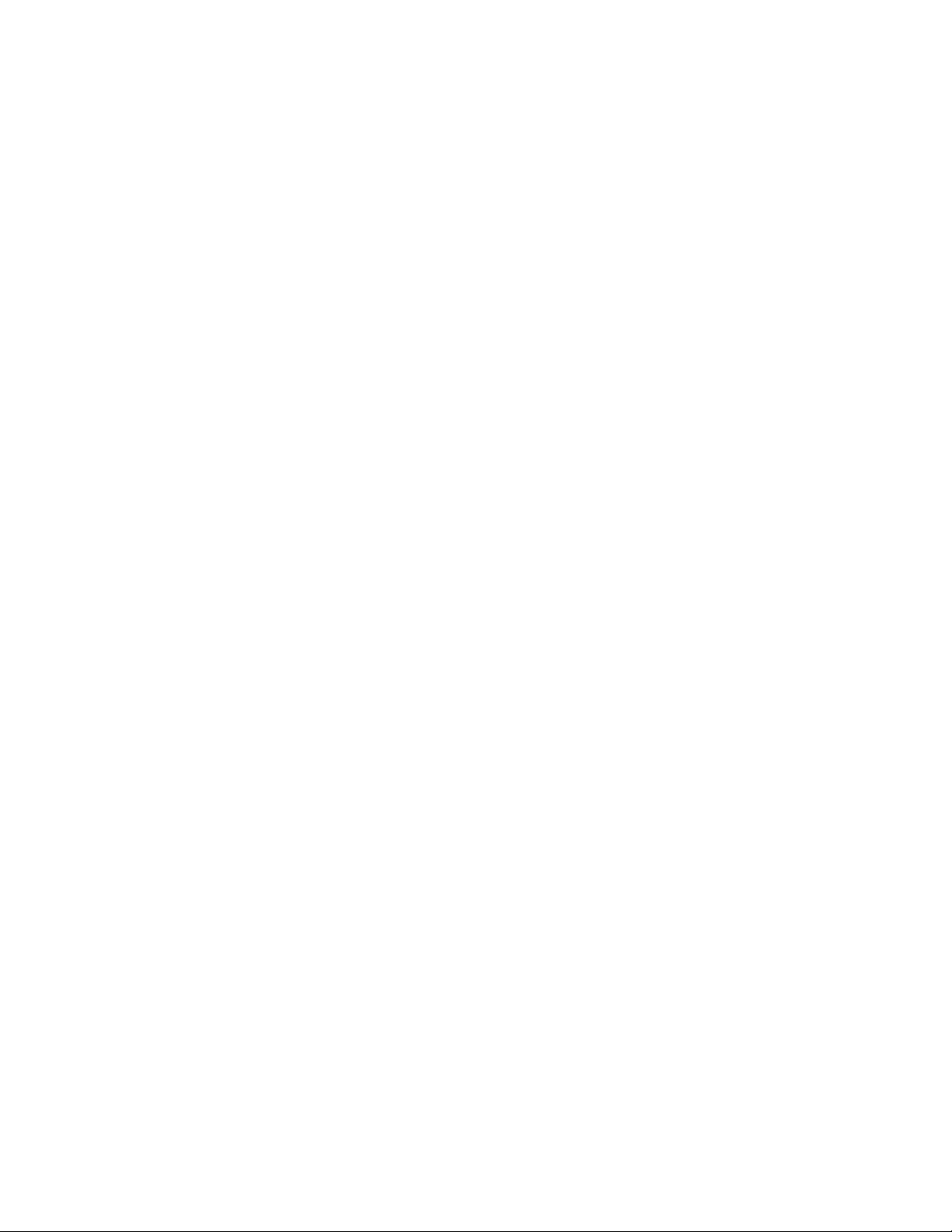

1. Place freezer in a location that allows adequate space at each side and above

for proper air circulation. Minimum clearance is: 6” (15 cm) on both sides, 4”

(10 cm) at back, and 8" (20 cm) above the freezer. See figure B.

CAUTION:

Failure to allow adequate ventilation will void the warranty

and reduce freezer performance.

2. Place the freezer on the self-sealing rubber pad on a level counter that is

stable and strong enough to safely support its weight (276 lbs/124.2 kg). If

equipped with legs instead of pad, install legs by screwing them into the four

leg holes on the bottom of the unit. (Leg Kit Part #W089.0220 (4) 4” Legs.)

3. Place On-Off-Clean switches in OFF position.

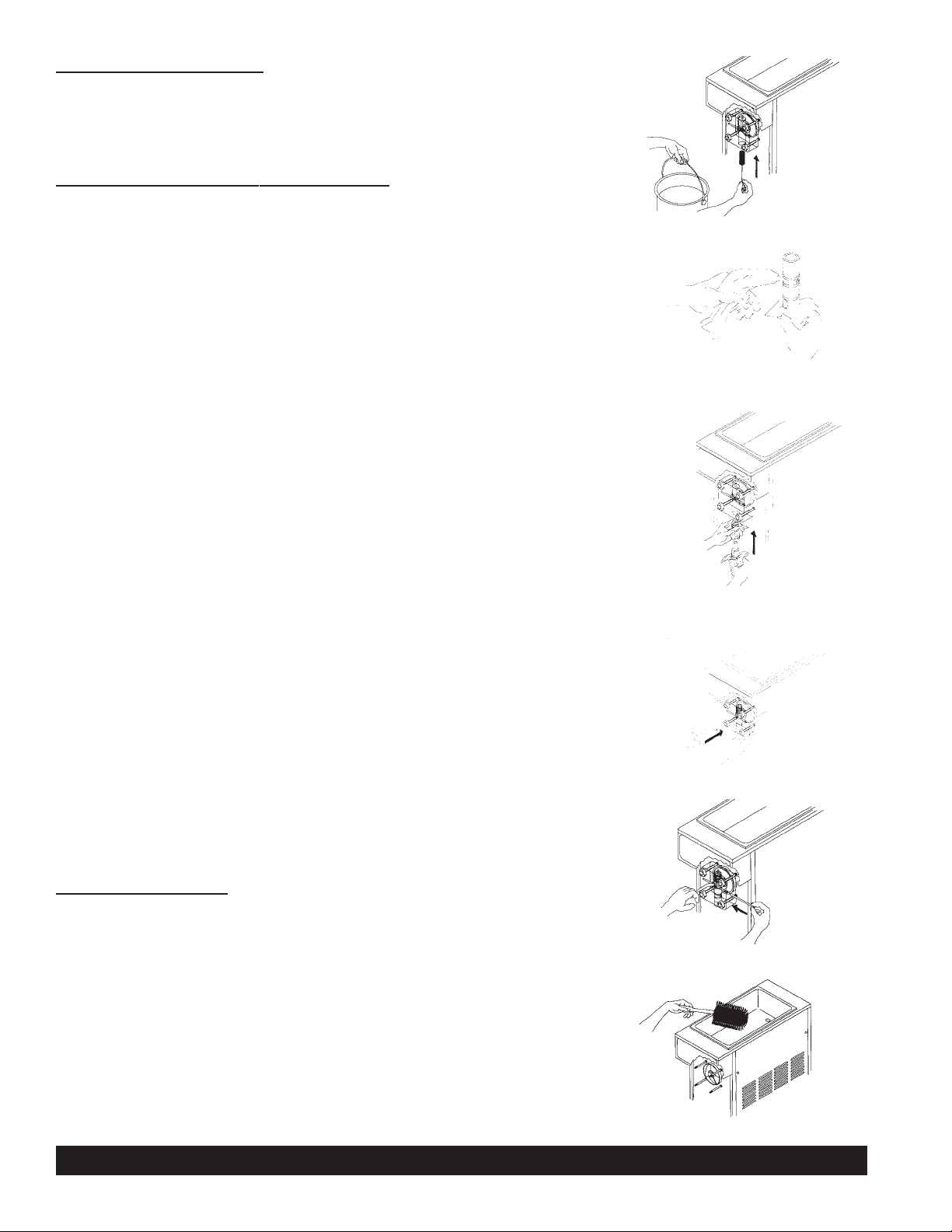

4. Install header by removing all four screws from the electrical box cover.

Carefully remove electrical box cover. Place the header (transparency)

between the clear and opaque plates (plastic lens). Slip the electrical

box cover back on to machine and reinsert the four screws.

(See Figure C)

5. Install the standard one piece carb tube by placing it in the hole in the

hopper. If your unit is equipped with a two piece smoothie/shake carb

tube place the solid piece in the hole in the hopper with the hole facing

front to back. Then place the carb tube sleeve over the solid piece, lining

up one of the holes with the hole in the solid piece. (Select the larger

hole for thickest products).

6. Connect the power cord to a properly grounded DEDICATED

20 Amp circuit.

IMPORTANT: See Autofill Installation for information on set up of

remote fill control and proportioning pump assembly.

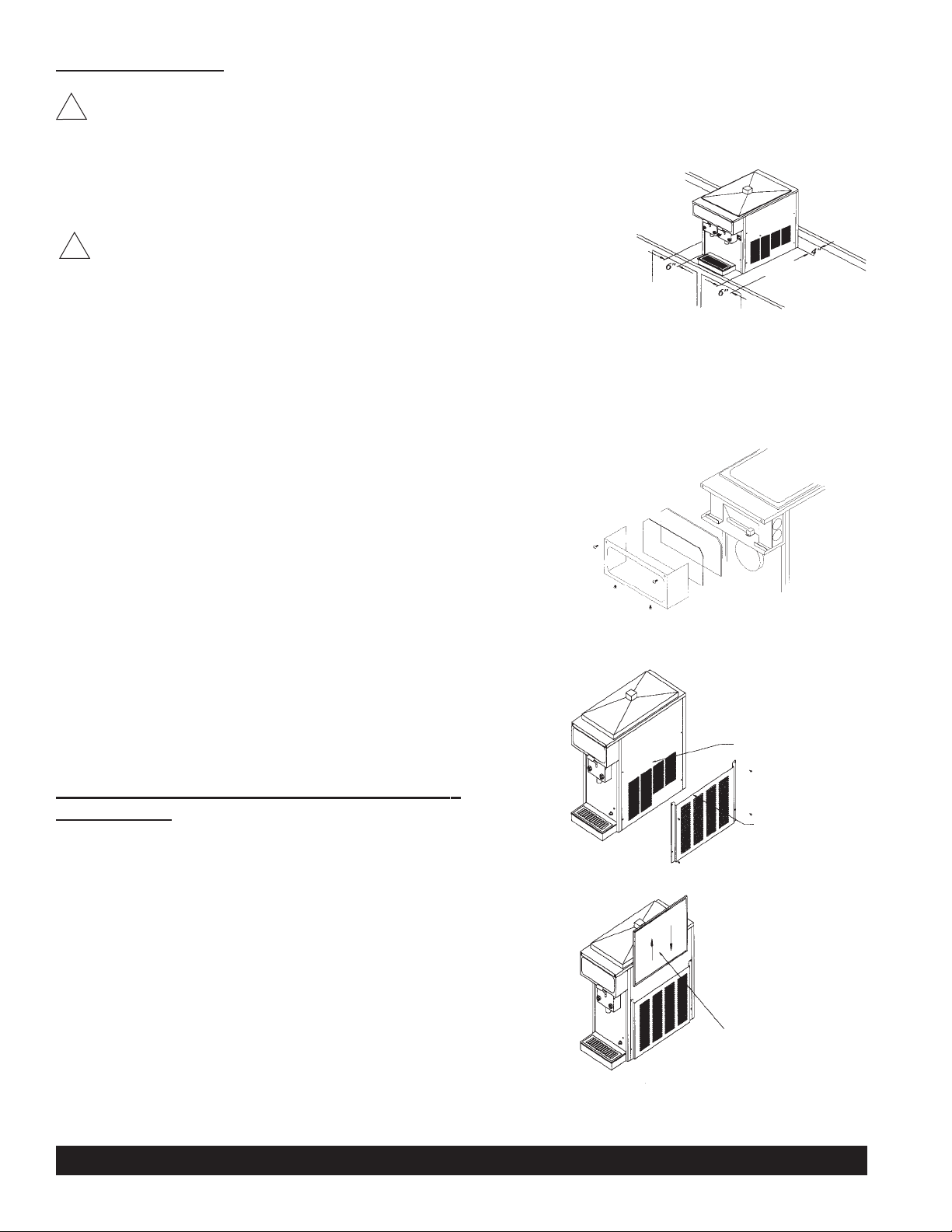

Installation of Concealed Air Filter Accessory

Kit (optional) (Part #’s W0890200 Stainless Steel, W0890208 Black)

1. Remove the four screws that hold the right side panel on the

machine.

2. Install the filter panel over the existing side panel and reinstall

screws. (See Figure D)

3. Open top cover of filter cover by raising and rotating away from the

existing panel.

4. Slide filter into top of filter cover with removal clip up and the air

flow arrows facing the existing panel. (See Figure E)

5. Push filter down until flush with the top of the cover.

6. Close the top cover by rotating the top back toward the existing

cover and pushing down once it is in place.

Figure C

Figure D

Figure E

INSTALL THE FILTER

PANEL OVER THE

EXISTING SIDE PANEL

& RE-INSTALL SCREWS.

P/N: W0520101, COMES

IN KIT # W0890220

FILTER PANEL

P/N: W0631805 FILTER

SLIDE THE FILTER IN BEHIND THE FILTER PANEL, &

IN FRONT OF THE EXISTING SIDE PANEL.

TO CHANGE REMOVE, CLEAN, & OR REPLACE.

!

Figure B

Proper air

clearance

!

Page 5

Crathco®5512 Manual Page 5

Installation of Exposed Filter Accessory Kit (optional) (Part #W089.0206)

1. Remove the four panel screws.

2. Pull the bottom of the panel out.

3. Run a bead of the silicone adhesive at the inside back of the bottom

filter channel. (2)

4. Install the channel over the end of the side panel so the adhesive in

the channel contacts the bottom edge of the side panel.

5. Put the panel with the channel added, back in place on the machine and reinstall the two lower panel screws.

6. Apply silicone adhesive to the length of the top edge of the upper filter channel (1) before installing, then wipe off

any excess.

7. Install the upper channel using the upper panel screws.

8. Slide filter (3) in from the front with the arrows pointing toward the existing panel. The thick wire side of the filter

should face outward.

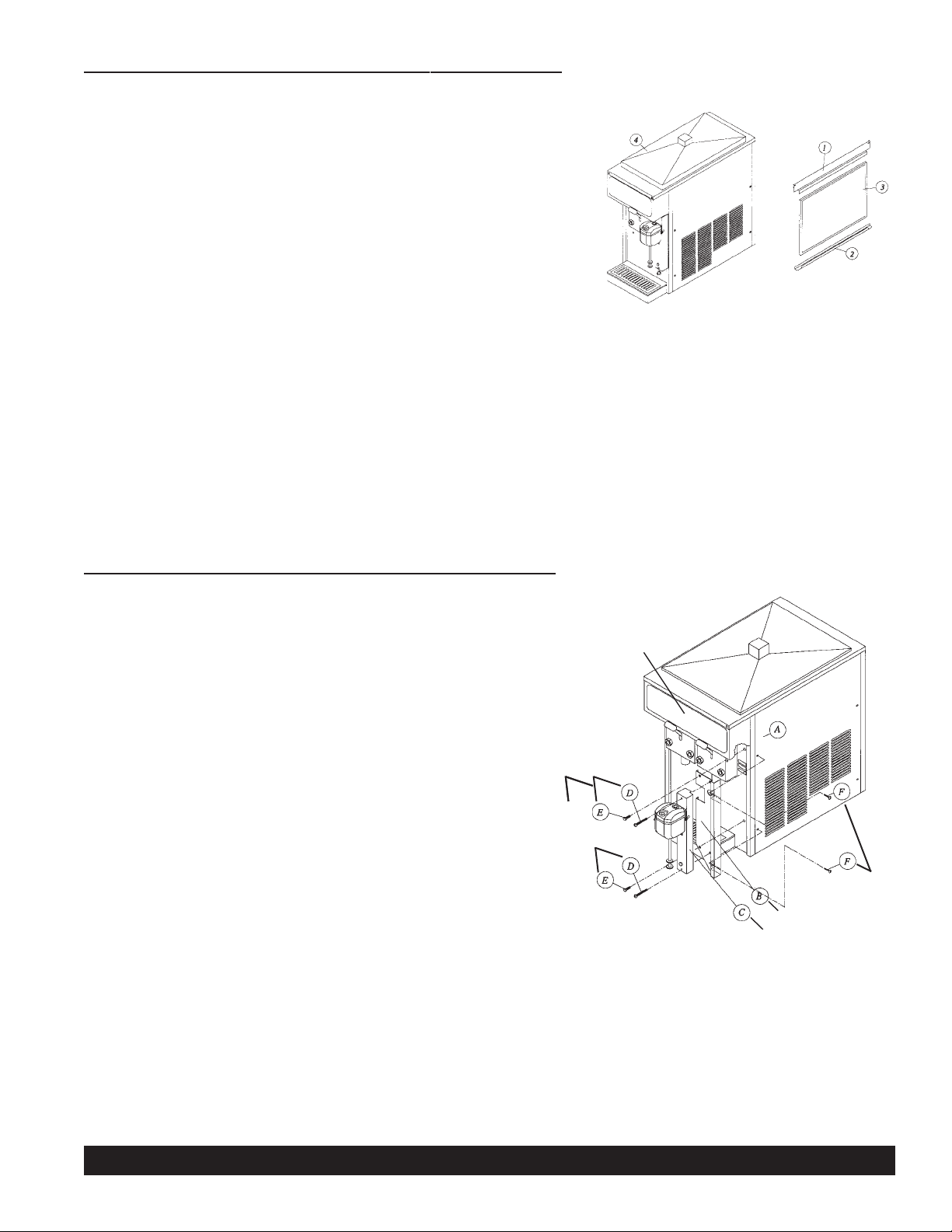

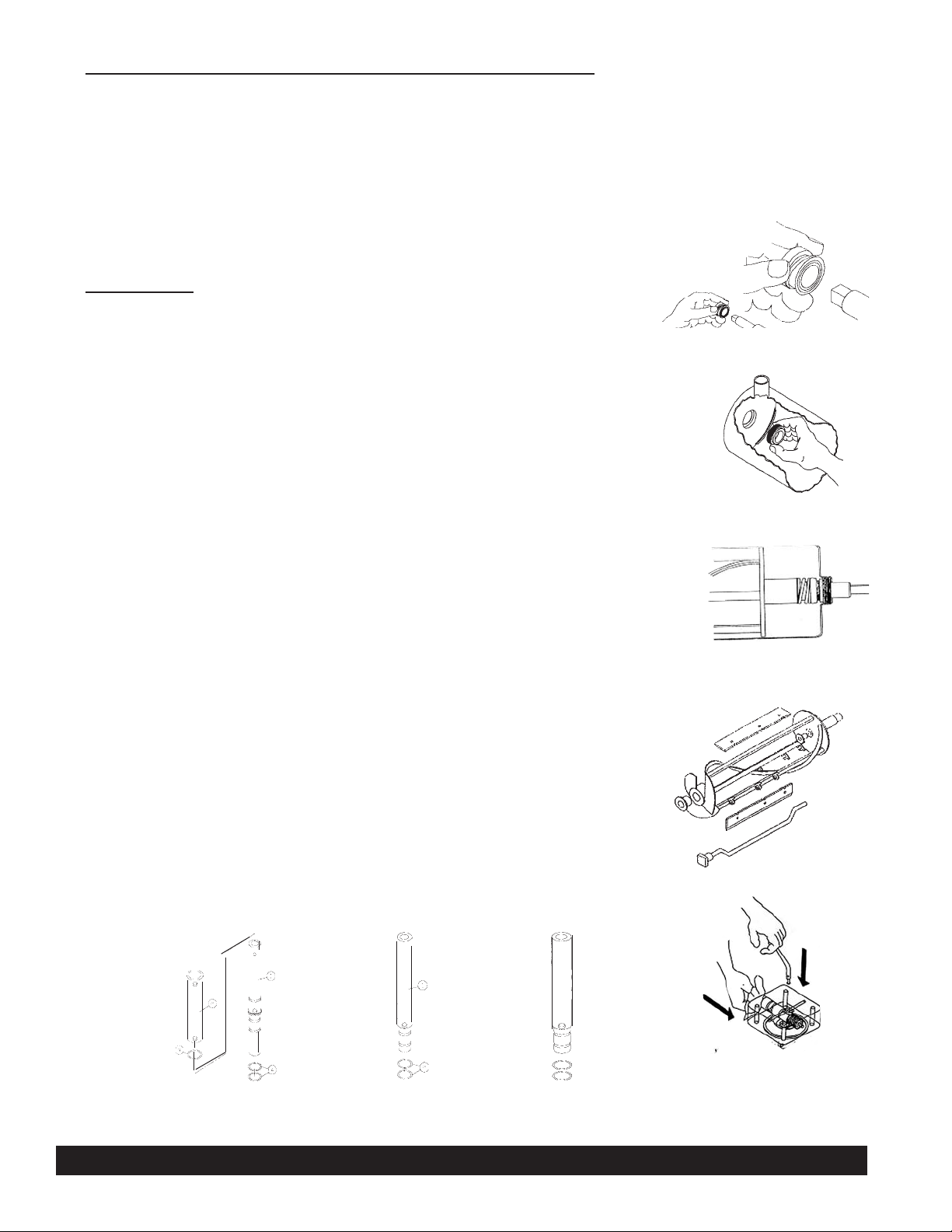

Installation of Spinner/Mix

er Accessory Kit (optional)

(W047119 5512 Spinner Mount Bracket)

1. Turn to "OFF" and unplug the freezer from the electrical power

source.

2. Remove the existing panel screws (F).

3. Install (B) to the front panel of (A) using the cap screws (E).

4. Re-install existing panel screws (F) through the

obround holes in the spinner mount bracket (B).

5. Install the spinner (C) using mounting screws (D).

6. Connect white and brown wire from the spinner (C) to the

red wire from the electrical box using the blue wire nut

provided.

7. Connect white and blue wire from the spinner (C) to the blue wire

from the electrical box using the blue wire nut provided.

8. Connect green and yellow wire from the spinner (C) to the green wire from the electrical box using the blue wire

nut provided.(See Figure G)

9. See the spinner-wiring diagrams on page 37 to locate spinner wire connections.

Figure F

Electrical box

Spinner Mounting Bracket

Spinner

Mounting Screws

Mounting Screws

Panel Screws

Figure G

Page 6

Page 6 Crathco®5512 Manual

Operation & Adjustments

How to Operate:

1) Sanitize unit following the cleaning instructions on page 12.

2) Fill hopper with product. Allow barrel to fill with product to the proper level, then install carb tube.

3) Turn power switch (toggle switch located underneath the electrical box) to "on" position.

4) Turn mode switch (rocker switch located next to power switch) to “freeze” position.

5) Allow product to freeze in barrel.

6) To dispense product pull down valve handle and release when done.

7) If product consistency is not as desired, adjust per the instructions on page 10.

Mix Considerations - General

Freezing characteristics are affected by the amount of sweeteners and solids in the mix. The amount of sweeteners

and solids is called BRIX. BRIX can be measured with an instrument called a refractometer. A BRIX reading of

between 11 and 14 will provide optimum freezer operation. Mixes with this brix level will freeze down to a smooth,

uniform consistency. Mixes with too high a brix level will take longer to freeze down and will yield a soft wet frozen

product. Mixes with too low a brix level will have larger ice crystals and will have a tendency to dispense slowly.

NOTE: Always take BRIX measurements using mix that has been thoroughly blended, before it is frozen. Always

allow frozen mix to thaw thoroughly before taking a reading

Alcohol content also affects product freezing characteristics and may prevent the freezer from serving a product at

proper thickness.

For maximum output capacity always pre-chill mix before adding it to the freezer. Pre-chilled mix gives the freezer a

head start on the freezing process and will speed both initial freeze down and recovery time. It is normal for output

capacity to decrease when warm mix is added, or when the freezer is operated in a warm area

Carburetor Assembly

Your new freezer uses a metering device, known as a carburetor, to feed the proper ratio of mix and air into the

freezing cylinder. For products such as diary based shake mixes, the proper mix to air ratio is generally accepted to

be two parts mix to one part air. This proportion yields a finished product that is both tasty and profitable. At this ratio,

one gallon of liquid mix will yield a volume of one and one-half gallons of frozen product. This 50% increase in volume from liquid to frozen product is referred to as OVERRUN.

The carburetor is a tube with a hole, or series of holes, bored through the side. It is located in the hopper and fits in a

hole that leads to the freezing cylinder. Air flows into the freezing cylinder through the top of the tube and mix flows in

through a smaller hole in the side of the carb tube. The size of the mix inlet is balanced with the viscosity (thickness)

of the liquid mix and product draw rate, in such a way that the proper amount of mix is fed into the freezer cylinder to

blend with air at just the right ratio. Mix viscosity varies by mix type, mix temperature and mix age. Different serving

rates also demand different feed rates. Grindmaster Corporation’s carburetor has an outer sleeve that can be rotated

to line up with different hole sizes to provide ideal overrun under all operating conditions.

You will need to experiment to determine how much mix to add to the freezing cylinder at start-up. This can be done

by watching the level of mix though the clear plastic dispensing valve when filling the hopper. When the correct

amount of mix feeds into the freezing cylinder install the carburetor tube in the "Off" position (outer sleeve set

between any two holes) and turn the freezer "ON" to freeze down to proper consistency.

Page 7

Crathco®5512 Manual Page 7

Overrun

Overrun is the increase in product volume, expressed as a percentage, resulting from the entrapment of air in liquid

mix as it is frozen.

The rotating dasher blends air into the mix as it is frozen resulting in increased frozen product volume. For example,

if one gallon (1) (4.4 liters) of liquid mix is poured into a freezer and one and a half gallons (1/2) (6.6 liters) of frozen

product is drawn out, the result is a fifty percent volumetric increase, or a fifty (50%) percent “overrun”.

Why is overrun important? The introduction of air into the finished frozen product is essential from two stand

points...taste and profitability. Frozen product with a low percentage of overrun costs more to serve, appears wet and

is heavy. The introduction of air makes the finished frozen product taste richer. Too much air causes the finished

product to be too light and fluffy, making it less satisfying and adversely affecting sales.

The optimum percentage of overrun varies from one type of mix to another, but 50% overrun seems to be a good

average. The ingredients in some mixes take on and hold air easier.

Overrun also effects profitability. For example, an increase from 25% to 50% overrun represents a mix savings of

17%.

Uniform overrun insures consistent portion costs. If overrun is allowed to drop, it will cost more to serve a portion of

finished product.

Computing Overrun

1. Weigh an empty cup.

2. Weigh this cup filled with liquid mix, subtract the weight of the cup.

NOTE: Repeat this step only when changing mix sources, as mix weight will vary slightly from one supplier to

another.

3. Draw a heaping cup of frozen product that contains no air pockets. NOTE: Use a spatula or other device to help

fill the cup completely. Avoid tamping the cup as this artificially reduces overrun.

4. Use a straight edge to scrape off excess product flush with the rim of the cup and weigh the cup.

5. Subtract the cup weight and use the overrun formula to determine overrun.

For Example:

If a full cup of liquid mix weighs 23 ounces and a full cup of frozen product weighs 15-1/2 ounces, then:

NOTE: Several companies manufacture scales that automatically read out the overrun for one pint samples. A scale

of this type is a valuable tool and should be part of any well run operation. A trick is to place the empty cup on the

scale and zero it out first, this will then automatically eliminate the weight of the cup from the calculation.

Overrun has a major impact on the size of the finished frozen portion. As the percentage of overrun (air in the frozen

product) increases, the size of the finished portion also increases, yet the portion weight remains the same. For

example, an increase from 25% to 50% overrun will yield a 20% larger portion. Customers equate size with

perceived value so proper overrun will result in increased customer satisfaction. Experiment with carburetor settings

to achieve optimum overrun and product quality with each mix. Some products such as Cappuccino taste better with

low overrun. Experiment with different carburetor settings to find the ideal combination for each product.

x 100 = OVERRUN

x 100 = 48.4% Overrun

Weight of Liquid Mix (Minus) Weight of Frozen Product

Weight of Frozen Product

23 - 15-1/2

15-1/2

Page 8

Page 8 Crathco®5512 Manual

Standby Switch

The "STANDBY" switch allows the operator to retain optimum product quality and conserve energy during extended

non-draw periods. The Stand-by mode keeps the mix in the hopper at a safe storage temperature and allows the

product in the freezing cylinder to return to a refrigerated liquid state. Switching back to "ON" quickly returns the

product in the freezing cylinders to proper serving consistency.

At the start of the “STANDBY” period:

1. Fill the hoppers with fresh mix.

2. Select the “STANDBY” mode...the front panel “STANDBY” lights will illuminate.

3. Turn the carburetor outer tubes to the OFF position (between any two holes). This will prevent any mix from

flowing into the freezing cylinder and reducing overrun. NOTE: Loss of overrun is one of the main reasons for

soft, wet looking frozen product.

At the end of the “STANDBY” period:

1. Turn the carburetor tubes back to their original setting.

2. Turn the switches to the “FREEZE” position. The FREEZE lights will illuminate.

3. When the freezer cycles off by reaching the desired temperature you are ready to start serving.

IMPORTANT: The STANDBY SWITCHES should not be used in lieu of cleaning and sanitizing procedures

specified by local regulatory agencies.

Mix Low Function

This model will sense when the mix is low in the hopper. The mix low light will illuminate continuously for 2 minutes.

After 2 minutes the light will begin to blink off and on for the next 8 minutes. The buzzer in the mix out circuit is 2 minutes off and 5 seconds (or 5 beeps) on for a total of 10 minutes. At the end of the 10-minute time the buzzer is out of

the circuit and the light will illuminate fully again. After the 10-minute cycle the mix out safety function is activated

making the unit inoperable. The machine is placed into the standby mode to prevent any damage to the machine

from running dry of product. The unit can be reset back to the freeze mode by simply adding mix into the hopper.

1. If the unit is low in mix or the unit shuts down due to extended mix low condition (“Mix Low” safety function has

activated), refill hopper with fresh product. The unit will automatically revert back to its original operation mode.

2. If the mix low safety function has activated disabling the unit, and the product has not been added for an

extended period of time - verify the product is okay for re-use. If it is not, use fresh product to restart the

unit. Empty the unit of old product and follow sanitizing (page 12) and start up procedures (page 6).

Product Tips

The Model 5512 was designed to dispense a wide variety of frozen beverages including smoothies, frozen

cappuccino, shakes, and frozen cocktails. These products can be served in consistencies ranging from thin to fairly

thick. For optimum long term freezer reIiability, it is recommended that product thickness not be set too thick.

Two types of white plastic dispensing valve plungers are available. One style, P/N W0480462, is used to serve thin to

medium products such as cappuccino and cocktails. This plunger has one horizontal outlet slot. The other plunger,

P/N W0480463, is used to serve thicker product such as shakes and smoothies and has two horizontal outlet slots.

These plungers are interchangeable.

Over an extended period of time some products, such as frozen cocktails that contain alcohol and lemonade, have a

tendency to separate, or stratify. Separation of product in the mix storage hopper can result in frozen product quality

inconsistencies.

Page 9

Crathco®5512 Manual Page 9

Product Tips (cont.)

Some cappuccino or latte’ mixes contain dairy products which can spoil if not refrigerated. If the freezer is to be

turned off at night these products must be removed from the freezer. Contact your local health department regarding

their regulations regarding proper mix handling and storage.

Consistency Control - Overview

CAUTION: SHOCK HAZARD! THIS ADJUSTMENT REQUIRES REMOVAL OF THE ELECTRICAL BOX

COVER AND SHOULD BE MADE BY A QUALIFIED SERVICE TECHNICIAN.

An electronic circuit board, mounted inside the front electrical box, controls the consistency (thickness) of the frozen

product in the “Freeze” setting, and controls the freezing cylinder and storage hopper temperature in the “StandBy”

mode.

The “freeze” mode consistency setting adjusts the frozen product thickness. In the “freeze” mode, as the liquid mix in

the cylinder freezes, it becomes harder for the motor to turn the dasher assembly. The control board senses the

amount of energy that the drive motor consumes as it rotates the dasher assembly through the product in the cylinder. The control board will turn the compressor and barrel solenoid valve off at the proper consistency. The drive

motor will continue to run for 45 seconds after the compressor is cycled off. This is called the blending cycle. After the

blending cycle is complete the drive motor also is shut off. The drive motor and compressor will run together at any

time refrigeration is required in the barrel. The compressor will run independently for the hopper if required. The hopper is controlled by temperature. The thermistor will signal the board and the board will start the compressor and

open the hopper solenoid valve.

The unit will remain off until either the timer in the control board (either 10 or 15 minutes dependent upon which

value is selected) restarts the drive motor. In this case the drive motor will run for 45 seconds and if no refrigeration

is required the drive motor will then shut off. If refrigeration in the barrel is required the freeze cycle is repeated as

well as the blending cycle. The unit will also restart the drive motor if the plunger is raised. The plunger switch will

start the drive motor and remain on as long as it is held open. After the plunger is closed the drive motor will continue to run for 45 seconds.The compressor will start, and barrel solenoid valve will open. If refrigeration is required during this time the freeze cycle and blend cycle will follow.

In the “standby” mode, the control board senses the temperature of the product in the barrel. The drive motor is

cycled on time only. It will operate for 2 minutes ON then 18 minutes OFF as long as it is in “standby”. The compressor and drive motor are cycled independently for the barrel in the “standby” mode. Once the barrel thermistor signals

to the board, the board will start the compressor and the barrel solenoid valve will open as refrigeration is required. It

will continue to run until satisfied. The plunger switch is disabled and the drive motor will not start when the plunger is

opened. The hopper is still controlled by temperature. If the thermistor signals a raise in temperature the compressor

will start and the hopper solenoid valve will be opened. It will continue to run until satisfied.

In the “clean” mode the drive motor will run continuously. (The compressor will not run in the “clean” mode.) This is

for emptying out product for cleaning purposes.

CAUTION: SHOCK HAZARD! THIS ADJUSTMENT REQUIRES REMOVAL OF THE ELECTRICAL BOX

COVER AND SHOULD BE MADE BY A QUALIFIED SERVICE TECHNICIAN.

The electronic control has three adjusters; one to set the “Freeze” mode product consistency (thickness), one to set

the “StandBy” mode cylinder temperature and one to set the “StandBy” mode hopper temperature. The “Freeze”

mode consistency setting adjusts frozen product thickness. Always adjust this control to deliver a frozen product that

is as thin (soft) as possible yet is still acceptable to the customer.

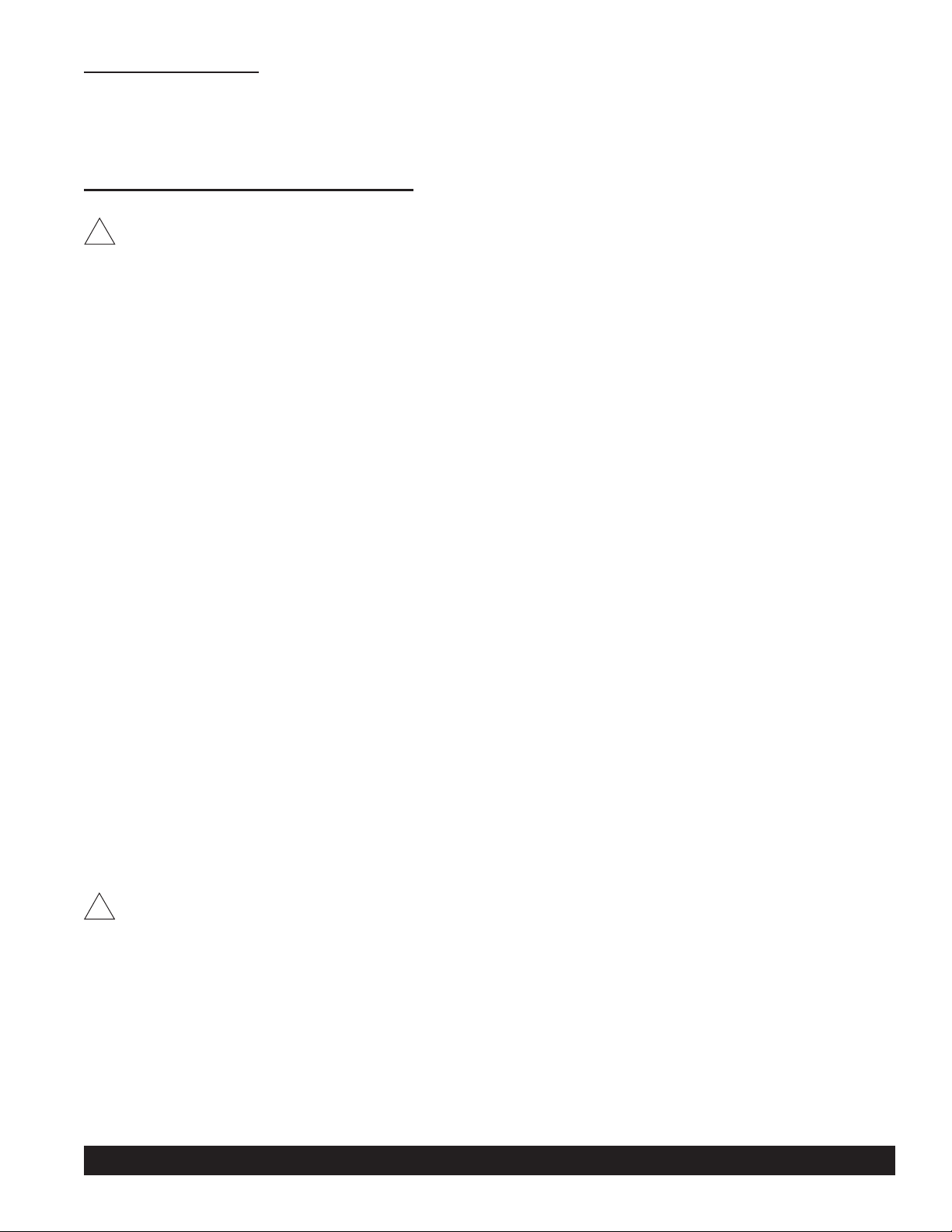

There are eleven (11) lights on the circuit board that indicate the following: (See Figure H )

BARREL (D1) - Illuminated when the freezing cylinder (barrel) has achieved the pre-set temperature in the

"Stand- by" mode.

HOPPER (D2) - Illuminated when the hopper has achieved the pre-set temperature in the "StandBy" mode.

!

!

Page 10

Page 10 Crathco®5512 Manual

Consistency Control -Overview (cont.)

WASH (D3) - Illuminated when the mode switch is in the wash or "Clean" position.

FREEZE (D4) - Illuminated when the mode switch is in the "Freeze" mode.

DISPENSE (D5) - Illuminated when the dispensing valve is open calling for both the compressor and drive

motor to operate.

GREEN CONSISTENCY (D6) - Off when the motor and compressor are off. Illuminated when the

compressor and dasher are bringing product to preset consistency. Blinks as preset consistency is

achieved and then goes out.

RED CONSISTENCY (D7) - Blinks as preset product consistency is approached. Glows steadily when

preset consistency is achieved and then goes out.

COIL (D8) - Compressor contactor energized

COIL (D9) - Drive motor coil energized

COIL (D10) - Hopper refrigeration solenoid coil energized

COIL (D11) - Freezing cylinder refrigeration solenoid

coil energized

Product Consistency Adjustment

1. Remove the Front electrical box cover.

2. If the product in the cylinder has been frozen for more

than 30 minutes, draw out 16 ounces (1/2 liter) before

checking consistency.

3. Turn the consistency control knob, (see figure H) located at the right center of the circuit board, clockwise

to achieve a colder setting (thicker product) or counterclockwise to achieve a less cold setting (less thick product).

CAUTION: THIS CONTROL SETTING IS VERY SENSITIVE SO ALWAYS MAKE SMALL ADJUSTMENTS. IF

YOU VISUALIZE THIS CONTROL AS A CLOCK FACE WITH THE ADJUSTER SET ALL THE WAY COUNTER-CLOCKWISE IT WOULD BE 5:00. A RECOMMENDED SETTING IS 7:00. THIS WOULD BE THE WARMEST SETTING THE

MACHINE HAS. A ONE HOUR CHANGE WILL MAKE A NOTICEABLE DIFFERENCE IN PRODUCT CONSISTENCY.

4. When making adjustments to a thicker (colder) setting, dispense approximately 16 ounces (1/2 liter) of product and

recheck consistency after the compressor has cycled off.

5. If the consistency is still not correct, repeat steps 2 and 3.

Freezing Cylinder Temperature Adjustment

1. Remove the front electrical box cover.

2. For a colder setting, turn the “Barrel” control adjuster, located at the right top left of the circuit board, counter clock-

wise. (see figure H)

CAUTION:

THIS CONTROL SETTING IS VERY SENSITIVE SO ALWAYS MAKE SMALL ADJUSTMENTS. IF

YOU VISUALIZE THIS CONTROL AS A CLOCK FACE, A ONE HOUR CHANGE WILL MAKE A NOTICEABLE DIFFERENCE IN FREEZING CYLINDER PRODUCT TEMPERATURE. A RECOMMENDED SETTING IS 11:00.

Hopper

Temperature Adjustment

1. Remove the front electrical box cover.

For a colder setting, turn the “Hopper” control adjuster, located at the right top left of the circuit board, counter

clockwise. (see figure H)

Figure H

!

!

Page 11

Crathco®5512 Manual Page 11

CAUTION: THIS CONTROL SETTING IS VERY SENSITIVE SO ALWAYS MAKE SMALL ADJUSTMENTS. IF

YOU VISUALIZE THIS CONTROL AS A CLOCK FACE, A ONE HOUR CHANGE WILL MAKE A NOTICEABLE

DIFFERENCE IN HOPPER PRODUCT TEMPERATURE. A RECOMMENDED SETTING IS 11:00.

Care & Cleaning

NOTE: Each time the freezer is disassembled, all internal freezer components must be thoroughly washed, scoured

and sanitized using procedures recommended by your local health department. In lieu of local health department recommendations, use a three compartment sink; one compartment to wash parts in detergent, one compartment to

rinse, and one to sanitize.

Drain and Rinse

1. If the freezer is empty, proceed to Cleaning Following Complete Disassembly of Unit or Daily Cleaning

Procedure. If the freezer is full of product, turn the mode switch to “CLEAN”.

2. On freezers using the optional electric pump and tank assembly and optional Remote Fill Control, turn the switch

on the Remote Fill Control to “OFF” and unplug the pump.

3. On freezers using the optional Remote Fill Control and Proportioning Pump, turn off the water valve on the

Proportioning pump, using the valve next to the inlet pressure regulator.

4. Open the front dispensing valve and drain all product from the freezer. Close the dispensing valve and turn freezer switches to “OFF”.

NOTE: Use approximately 2-1/2 gallons (10 liters) (per side) of cool water to rinse product out of the freezer.

5. Remove the carb tubes and pour water into the storage hopper. Allow the water

to fill the freezing cylinders.

6. Turn the freezer panel switches to “CLEAN” for 5 minutes. Open the dispensing

valves and drain the water from the freezer.

Dail

y Cleaning Procedure

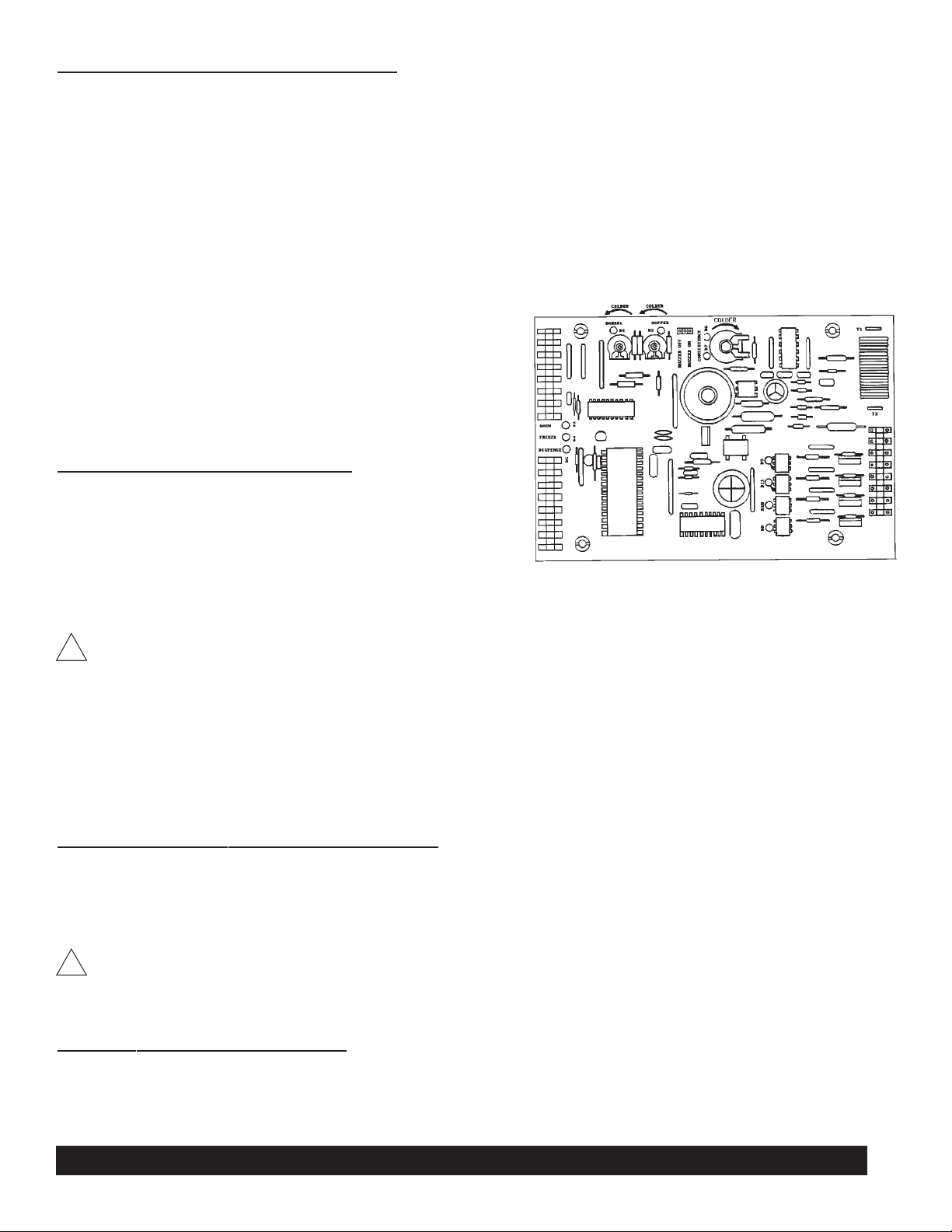

1. Pull out valve handle retaining pin, while supporting the valve plunger from bottom. Push up on the valve plunger and remove the stainless handle. Slide the

valve plunger and spring downward to remove. Remove the “O” Rings from the

plunger assembly as shown in figure I. Repeat disassembly for the other side.

NOTE: The best way to remove an “O” Ring is to first wipe off all of the lubricant

using a clean paper towel. Pinch the “O” Ring upward with a dry towel between

your index finger and thumb. When a loop is formed in the “O” Ring, roll it out of the

groove with your other thumb. Always remove the “O” Ring farthest from the end of

the plunger first. See figure J.

2. Take all components to the cleaning area.

3. Carefully inspect the “O” rings and replace if necessary.

Cleaning Carb

uretor, Dispensing Valve and Plunger Assembly

1. Prepare 1 gallon solution of hot tap water and a good grade of dish washing

detergent.

2. Thoroughly wash valve plunger, spring, carburetor assembly and all “O” Rings

in detergent solution.

Figure I

!

Figure K Clean Valve Body

Figure J Ring Removal

Page 12

Page 12 Crathco®5512 Manual

Care & Cleaning (cont.)

3. Using medium sized brush (supplied with freezer) clean the bottom of the

valve body and the inside of the plunger bore with detergent solution taking

care to remove all remaining lubricant (see figure K). Repeat for other side.

Sanitizing Carb

uretor and Valve Components

1. Re-assemble carburetor assembly installing the two “O” Rings at the

bottom of the carb tube.

2. Place the carburetor assembly in the bottom of the hopper.

3. Replace “O” Rings on valve plunger and lay plunger assembly on a clean piece

of paper towel.

4. Prepare a minimum of 4 gallons (15 liters) of sanitizing solution (Stera Sheen

Green Label or equivalent) following the manufacturer’s instructions.

NOTE: Add 4 ounces of Stera Sheen to 4 gallons (15 liters) of 120° Fahrenheit

(50° Centigrade) water to achieve a concentration of 100 parts per million.

5. Dip the medium sized brush (supplied) into the sanitizing solution and

sanitize the inside bore of the dispensing valve (see figure L).

6. Place a small amount of sanitary lubricant onto a piece of clean paper

toweling (see figure M).

7. Use a clean piece of paper toweling to pick up the small end of the valve

plunger assembly. Apply the lubricant on the other piece of paper toweling

to the “O” Rings on the valve plunger assembly (see figure N).

8. Slide the valve plunger spring over the small end of the valve plunger

and, using another clean piece of paper toweling, pick up the valve plunger

at the outlet end and insert plunger and spring into the valve body (see

figure N).

9. Push up on the valve plunger and insert the stainless steel handle (see

figure O).

10. Insert the dispensing valve handle retaining pin (see figure P). Repeat

procedure for other side.

Sanitizing and Refilling

1. Pour sanitizing solution into the mix storage hopper and allow the solution to

fill freezing cylinder. Use a large brush (supplied) to sanitize all hopper

surfaces (see figure Q).

2. Turn panel switch to “CLEAN” and allow freezer to run for 20 minutes.

3. Open dispensing valve and drain solution. Allow the auger to push remaining

sanitizer out of the freezing cylinder.

4. Place a small amount of sanitary lubricant onto another piece of clean paper

toweling (see figure R).

Figure L Sanitize Valve Body

Figure N Installing Plunger and

Spring

Figure M Lubricate Plunger

Figure P Insert Retaining Pin

Figure O Insert Valve Handle

Figure Q Sanitize Hopper

Page 13

Crathco®5512 Manual Page 13

Sanitizing & Refilling (cont.)

5. Use a clean piece of paper toweling to pick up the large end of the carburetor

from the bottom of the hopper taking care not to touch the sanitized carburetor

with your bare hands.

6. Apply the lubricant on the other piece of paper toweling to the two “O” Rings on

the bottom of the carburetor assembly (see figure S).

7. Place the lubricated carburetor assembly on a clean piece of paper toweling.

8. Use either fresh product or mix new product according to manufacturer’s instructions.

9. Fill mix storage hopper with product.

10. Open dispensing valve. Pour product into the hopper and allow this product to

chase out any remaining sanitizer.

11. Watch the product flowing out of the dispensing valve and close the Valve when

the sanitizer remaining in the cylinder has been purged by the new mix.

12. Use a clean piece of paper toweling to insert the sanitized carburetor assembly

into the inlet hole in the hopper (see figure T).

13. Fill mix storage hopper with fresh product.

14. Turn front panel switch to “ON”. Allow approximately 20 to 30 minutes for the

freezer to reach proper consistency. Repeat procedure for other side.

Cleaning Following Complete Disassembly of Unit

1. Remove knobs and carefully remove the front dispensing valve assembly.

2. Disassemble the dispensing valve assembly by removing the retaining pin,

pushing up on the plunger assembly and pulling out the handle. This will allow

the plunger assembly, complete with O-Rings, to be removed as a unit. Remove

the spring. Remove the O-Rings from the plunger assembly and back of the

dispensing valve body. (See Figure T.)

NOTE: The best way to remove an O-Ring is to first wipe off all of the lubricant using

a clean paper towel. Pinch the O-Ring upward with a dry towel between your index finger and thumb. When a loop is formed in the O-Ring, roll it out of the groove with your

other thumb. Always remove the O-Ring farthest from the end of the plunger first. (See

Figure U).

NOTE: Carefully inspect the O-Rings and replace if necessary.

3. Remove the dasher assembly taking care to avoid damaging the rear seal assembly at the back of the freezing cylinder.

4. Remove stationary portion of the shaft seal assembly from the back end of the

freezer cylinder. This is accomplished by reaching into the cylinder and pulling seal

out with your index finger. (See Figure V).

5. Slide the rotary seal off the the auger shaft. Inspect both seal components carefully for nicks or cracks. Replace seal if defective.

NOTE: To prevent leakage both surfaces of the seal must be smooth with no chips or

cracks. Wash all components in a detergent solution, sanitize and allow to air dry.

Figure R Lubricate Carb Tube

Figure S Carb Tube

Figure T Exploded View of

Dispensing Valve

Figure U O-Ring Removal

Figure V Remove stationary

part of seal

Page 14

Page 14 Crathco®5512 Manual

Cleaning Following Complete Disassembly of Unit (cont.)

IMPORTANT: After disassembly, thoroughly scour each part of the freezer in a

warm mild detergent solution including the inside of the freezing cylinder and the

mix storage hopper. Rinse each part with clean water. Prepare a minimum of 3

1/2 gallons (13 liters) of sanitizing solution (Divorsol CX or equivalent) following

the manufacturer's instructions.

NOTE: Add 3 ounces (85.4 mg) of Divorsol CX to 3 1/2 gallons (13 liters) of 120°F

(50°C) water to achieve a concentrations of 200 parts per million. Dip or wipe

each part in sanitizing solution and allow them to dry on clean paper toweling.

Reassembly

1. Wet the inner rubber lip of the rotary portion of the seal and the back end of

the auger shaft with water. Slide rotary portion of assembly onto the auger

shaft, RUBBER FIRST, with the smooth sealing surface toward the back of

the auger. (see figure W)

2. Insert the stationary portion of the seal into the grooved rubber boot with the

polished surface facing out (forward). Lubricate the grooved exterior portion of

the boot and insert it straight back into recess at the back of the freezing cylinder, RUBBER FIRST. (see Figures X & Y)

NOTE: If the circular portion of the seal is white, make sure that the groove is

toward the rubber (back of freezer).

3. Reassemble the dasher assembly, as shown in Figure Z. Insert the larger

front and smaller rear white plastic bearings into dasher, then slip in the stator

rod. Carefully and slowly guide the auger into the freezing

cylinder taking care not to damage the seal assembly. Turn auger shaft

until it engages the square drive coupling.

4. Reassemble the dispensing valve assembly as shown on Figure AA. Thoroughly

wash and sanitize all components, lubricate the inside bore of valve body with

a thin film of food grade sanitary lubricant. Reinstall the

O-Rings on the plunger assembly and lubricate the entire plunger.

Reassemble the valve and replace the retainer pin. Inspect and lubricate the

large O-Ring and refit it into the rear of the valve assembly. Install the valve

assembly on the front studs and tighten knobs until they are finger tight. Do

not use tools to tighten knobs.

5. Disassemble the carburetor assembly and remove the O-Rings. Wash and

sanitize all parts.

6. Reinstall and lubricate the O-Rings and slip on the outer tube if equipped.

(See Figure BB.) Repeat reassembly on the other side.

Figure X Installing the

stationary portion seal

Figure Y Seal Assembly

installed correctly

Figure W Re-assemble rotary

portion of seal as shown

Figure Z

Figure AA

Thick product carb tube

(W0471136)

Figure BB

Low overrun

carb tube

(W0472060)

Standard carb tube

(W0471076)

Page 15

Crathco®5512 Manual Page 15

Sanitizing and Refilling

1. Prepare a minimum of 3-1/2 gallons (13 liters) of sanitizing solution (Divorsol CX or equivalent) following the

manufacturer's instructions.

NOTE: Add sanitizer to 3-1/2 gallons of water (warm) to achieve a concentration of 200 parts per million.

2. Pour sanitizing solution into the mix storage hopper and allow the solution to fill freezing cylinder. Use a brush to

clean the hopper sides and bottom. (Repeat steps 1 & 2 for opposite side.)

3. Turn panel switch to "CLEAN" and allow freezer to run for 5 minutes.

4. Open dispensing valve and drain solution. Turn freezer to "CLEAN" for a few seconds to allow the auger to

push remaining sanitizer out of the freezing cylinder.

5. If you are using a concentrated product, mix the product according to the manufacturer's instructions.

6. Open dispensing valve. Pour product into the hopper and allow this product to chase out any remaining sanitizer.

Watch the product flowing out of the dispensing valve and close the valve when the new mix has purged the sanitizer remaining in the cylinder.

7. Sanitize and install the carburetor. (Figure R). Refill mix hopper.

8. Turn front panel switch to "ON". Allow approximately 20 to 30 minutes for the freezer to reach proper

consistency. Repeat on other side.

Maintenance

WARNING!

Disconnect power for maintenance. Do not attempt to perform maintenance on the freezer

until electrical power has been disconnected.

Suggested Weekly Maintenance

1. Clean, lubricate and sanitize the freezer following guidelines in Care and Cleaning on page 11.

2. Clean the exterior of the freezer using a soft wet cloth.

Suggested Monthly Maintenance

How to Clean Exposed Filter:

1. Slide exposed filter out of the rails by pulling forward on the filter. It is recommended to remove the filter by using

the palm of your hand and applying even pressure to the face of the filter.

2. Clean filter with liquid soap and water.

3. Soak filter for 15 minutes.

4. Rinse filter with heavy stream of water, opposite the direction of air flow. Allow filter to dry.

5. Slide the filter into the rails until the filter contacts the stop on the top rail.

!

Page 16

Page 16 Crathco®5512 Manual

How to Clean Concealed Filter:

1. For concealed filters lift lid and pull up on filter tab to remove filter.

2. Clean filter with liquid soap and water.

3. Soak filter for 15 minutes.

4. Rinse filter with heavy stream of water, opposite the direction of air flow. Allow filter to dry.

5. Slide filter into top of filter cover with removal clip up and the air flow arrows facing the existing panel.

CAUTION: Disconnect power for maintenance. Do not attempt to perform maintenance on the freezer

until electrical power has been disconnected.

How to Clean Condenser

NOTE: Loss of refrigeration efficiency will result if condenser is allowed to become dirty. Excessive compressor run

time or loss of capacity is a good indication that the condenser needs to be cleaned.

1. Disconnect electrical power.

2. Remove side panels.

3. Place a damp towel over the side of condenser opposite the fan motor.

4. Use compressed air or CO

2

to blow out dirt from the fan side of the condenser.

5. An alternate cleaning method is to use a condenser brush and a vacuum cleaner.

CAUTION: Procedure can create a loud noise.

Ann

ual Maintenance

1. Disconnect electrical power.

2. Clean condenser.

3. Remove dispensing valve assembly and replace all “O” Rings. (See Care and Cleaning)

4. Remove dasher assembly, inspect stator bearings and replace shaft seal set. (See Care and Cleaning)

5. Remove rear panel and inspect “V” belt.

6. Inspect the drive shaft square hole for wear (rounding out).

7. Check drive shaft and motor shaft bearings for excessive wear.

8. Replace side and back panels. Re-connect power supply.

!

!

Page 17

Crathco®5512 Manual Page 17

Belt Adjustment

CAUTION: UNPLUG THE MACHINE BEFORE PERFORMING ANY ADJUSTMENTS. THIS PROCEDURE

MUST BE DONE BY A QUALIFIED TECHNICIAN.

Check the belt tension. The proper belt deflection is 1/2" over all. If the deflection is more than 1/2" the motor

will need to be lowered. If the deflection is less than 1/2" the motor will need to be raised. Follow this procedure

to adjust the motor to achieve proper belt tension.

1. Unplug the machine and remove both side and the rear panels.

2. Locate the motor flange bearings. These are the pillow block bearings that hold the motor to the cradle. The

motor is double shafted and the shaft extends through a bearing on each end. The bearing is held to the motorcradle by two allen bolts on each bearing.

3. Loosen the allen bolts on each bearing. Do not loosen the setscrews that hold the bearing collar to the

motor shaft.

4. Lower the motor or raise the motor as needed. The motor must be kept level from front to back. Do not

lower or raise only one end of the motor. This will result in excessive belt wear and belt noise.

5. Tighten all four allen bolts down. Align the motor pulley with the top pulley if needed.

6. The motor pulley should be in alignment with the large (driven) top pulley. Use a straight edge along the top

pulley.

7. If the pulleys are not in alignment, remove the setscrew from the motor pulley and move either in or out as

needed.

8. Reinstall the setscrew. Use non-permanent loc-tite on the setscrew and tighten it back down on the motor

shaft. Please be sure the setscrew is tightened down flat on the motor shaft.

9. Return the unit back to service.

!

Figure CC

Page 18

Page 18 Crathco®5512 Manual

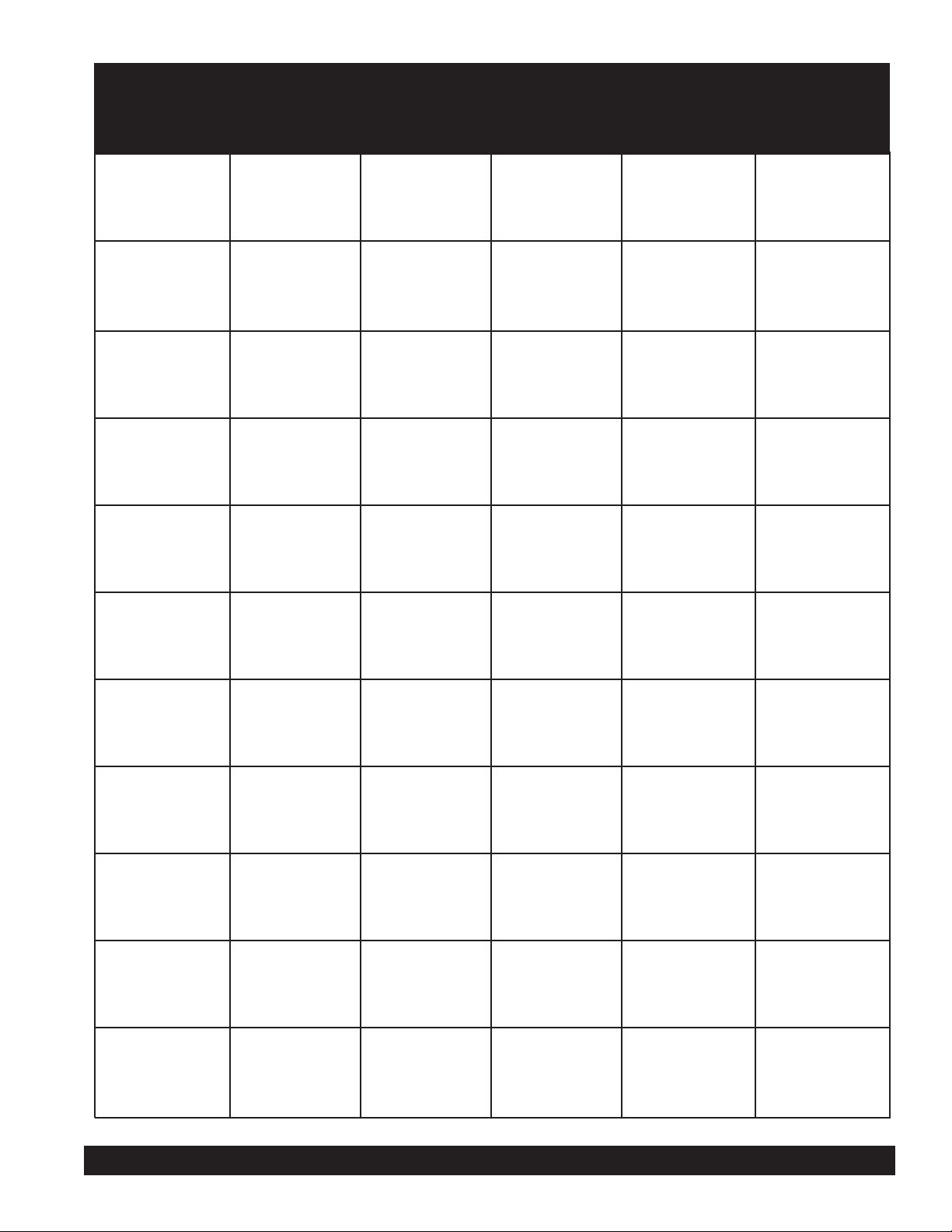

MODEL 5512

Circuit NEMA #

Electrical

Drive Motor

1/2 hp, Capacitor Start / Run

1 hp

Air Cooled

260 lbs. (118 kg)

3 gallons (11.35 liters) per side

1 1/2 gallons (5.7 liters) per side

See Serial Number Plate

See Serial Number Plate

275 to 350psi (19 to 25 k/cm)

35psi (2.5 k/cm)

Compressor

Cooling

Actual Weight

Mix Hopper Capacity

Freezing Cylinder Cap.

Refrigerant

Refrigerant Charge

High Side (approximate operating pressure)

Low Side (approximate operating pressure)

208 volt, 60 Hz, 1 Phase

Dedicated 20 Amp circuit

MODEL 5512E

Circuit NEMA #

Electrical

Drive Motor

Compressor

Cooling

Weight

Mix Hopper Capacity

Freezing Cylinder Cap.

Refrigerant

Refrigerant Charge

High Side (approximate operating pressure)

Low Side (approximate operating pressure)

High Side Design Pressure

Low Side Design Pressure

See Serial Number Plate

1.5 gallons (5.7 liters) per side

3 gallons (11.35 liters) per side

260 lbs. (118 kg)

Air Cooled

1 hp

1/2 hp

220/240 volt, 50Hz, 1 Phase

Dedicated 16 Amp circuit

NA

See Serial Number Plate

275 to 350psi (19 to 25 k/cm)

35psi (2.5 k/cm)

520psi

174psi

6-2OR

Freezer Specifications

Low Side Design Pressure)

High Side Design Pressure)

520psi

174psi

Freezer Specifications

Page 19

Crathco®5512 Manual Page 19

Par t

Description

Monthly

Every

3 Months

Every

6 Months

Annually

Quantities

to be

Replaced

Shaft seal

Inspect &

replace if

necessary

2

Inspect &

replace if

necessary

2

Inspect &

replace if

necessary

2

Inspect &

replace if

necessary

4

Inspect &

replace if

necessary

2

Inspect &

replace if

necessary

2

Inspect &

replace if

necessary

2

X

Thick Product

plunger:4

Standard Product

plunger:6

X 4 or 6

Inspect &

replace if

necessary

Maximum 1

Inspect &

clean if

necessary

Maximum 1

Drive shaft

Drive belts

Scraper blades

on dasher

Square cut

o-ring on valve

body/face plate

Front stator

flange bearing

Rear stator

flange bearing

Dispense valve

o-rings

Carb tube o-rings

Cleaning brush

Condenser

Refer to the Crathco Frozen Beverage Parts Price List when ordering the above parts

Page 20

Page 20 Crathco®5512 Manual

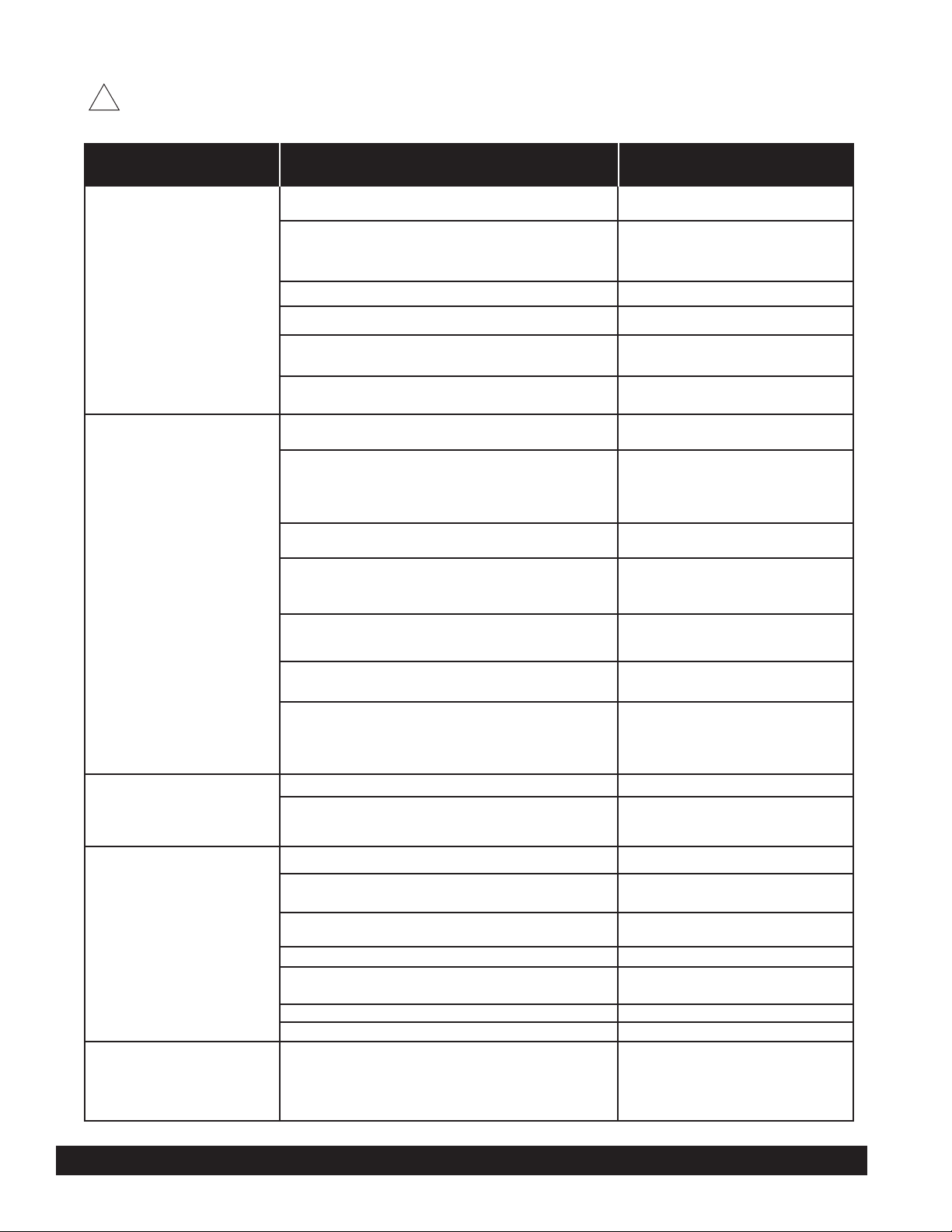

Freezer will not run or Freezer not plugged in Plug in machine

freeze down

Circuit breaker tripped or fuse Reset breaker or

blown replace fuse

Freezer in "CLEAN" position Switch to "FREEZE"

Dasher or blades not installed Install dasher and blades

Obstructed cooling air flow Allow 6"(15cm) on sides

Freezer in Standby mode Switch to "FREEZE"

Product too soft Improper consistency control setting Readjust consistency control

Mix soft, no overrun Product broken down

Drain and refill with

fresh mix

Carburetor set incorrectly Readjust carburetor

Extended non-draw period Use "STANDBY" during slow

business periods

Improper product taste Check date code. Use

only fresh mix

Used rerun/leftover mix Use only fresh mix

Frozen product too fluffy and icy Draw out 1 quart (1 liter),

(Product frozen too long, low draw) dispose of product.

Allow product to refreeze.

Frozen product too Consistency control set too firm Readjust consistency control

stiff, or freezer runs Dispensing valve not fully closed Close valve, lubricate

continuously properly

Frozen product not Power switch OFF Turn Power Switch to ON

dispensing Insufficient mix in storage hopper, Refill storage hopper

light on, beeper

Carburetor in off position, Set carburetor to proper hole

between holes size

Carburetor inlet hole clogged Unclog carburetor

Foam buildup, liquid mix cannot Remove foam from hopper

feed properly using sanitized utensil

Drive belt broken or off of pulley Replace or repair

Machine in STANDBY mode Set switch to FREEZE

Liquid coming out of Worn, defective or improperly Replace and lubricate per

drain tube, front of installed seal manual

freezer

PROBLEM PROBABLE CAUSE SOLUTION

Troubleshooting Guide

Only a qualified service technician should perform electrical and mechanical adjustments

or repairs. Always disconnect power before attempting any maintenance procedures.

!

Page 21

Crathco®5512 Manual Page 21

Excessive dispensing Worn or defective O-Rings Replace and lubricate at

valve leakage each cleaning

Scraping sound during Frozen product scraping off of Normal sound during freeze

freeze down cylinder walls down, goes away when

product is frozen to proper

consistency

Clicking sound Low voltage Connect freezer to dedicated

circuit of proper rating

Extension cord or improperly sized Connect freezer directly to

electrical wire power source using properly

sized wiring.

Thumping sound from Worn drive belt Replace belt

inside freezer

PROBLEM PROBABLE CAUSE SOLUTION

If you still need help, call our service department at (800) 695-4500 (USA & Canada only) or (502) 425-4776 (Monday

through Friday, 8 am - 8 pm EST) or an authorized service center in your area. Please have the model and serial

numbers ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all

warranty claims.

Page 22

Page 22 Crathco®5512 Manual

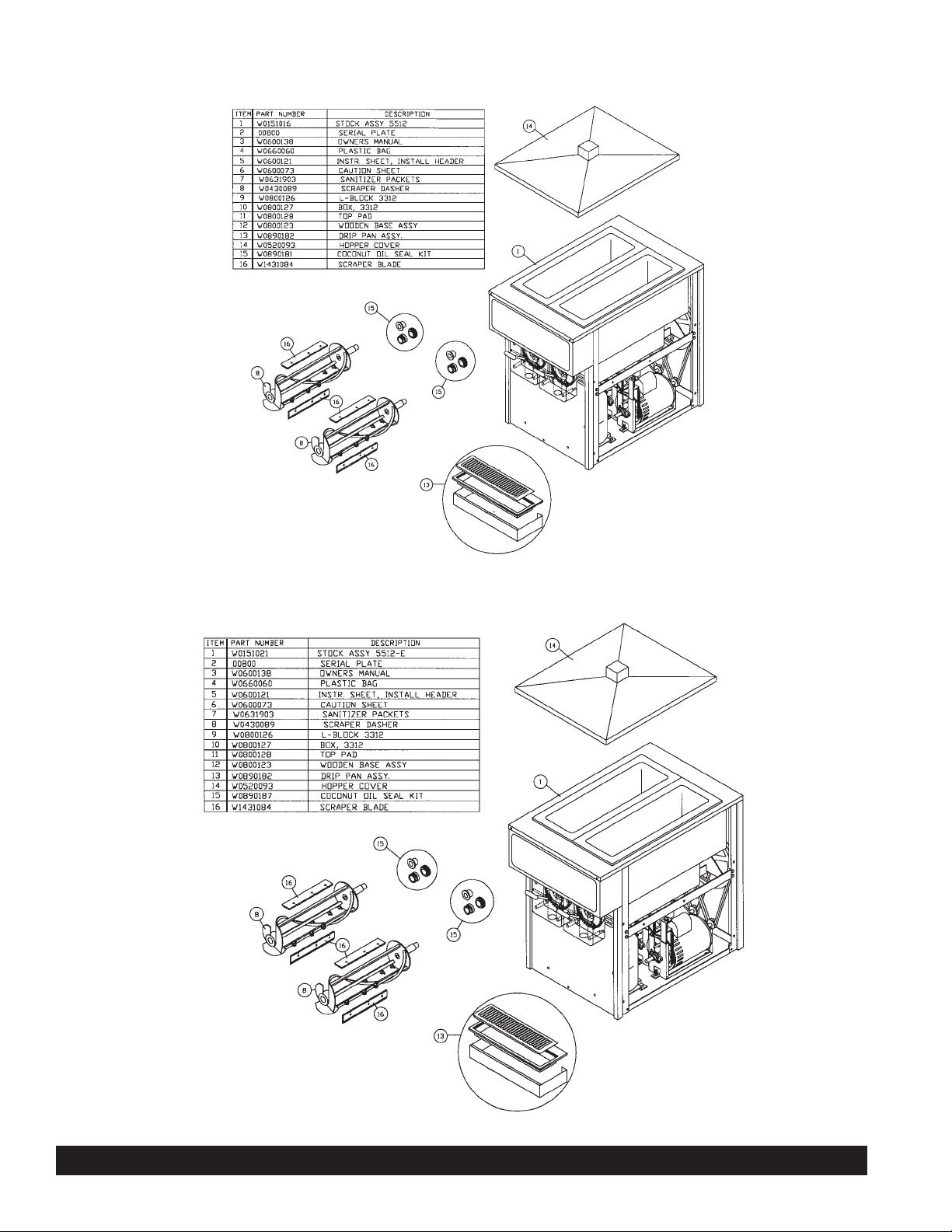

Exploded View Model 5512 Final Assembly

Exploded View Model 5512-E Final Assembly

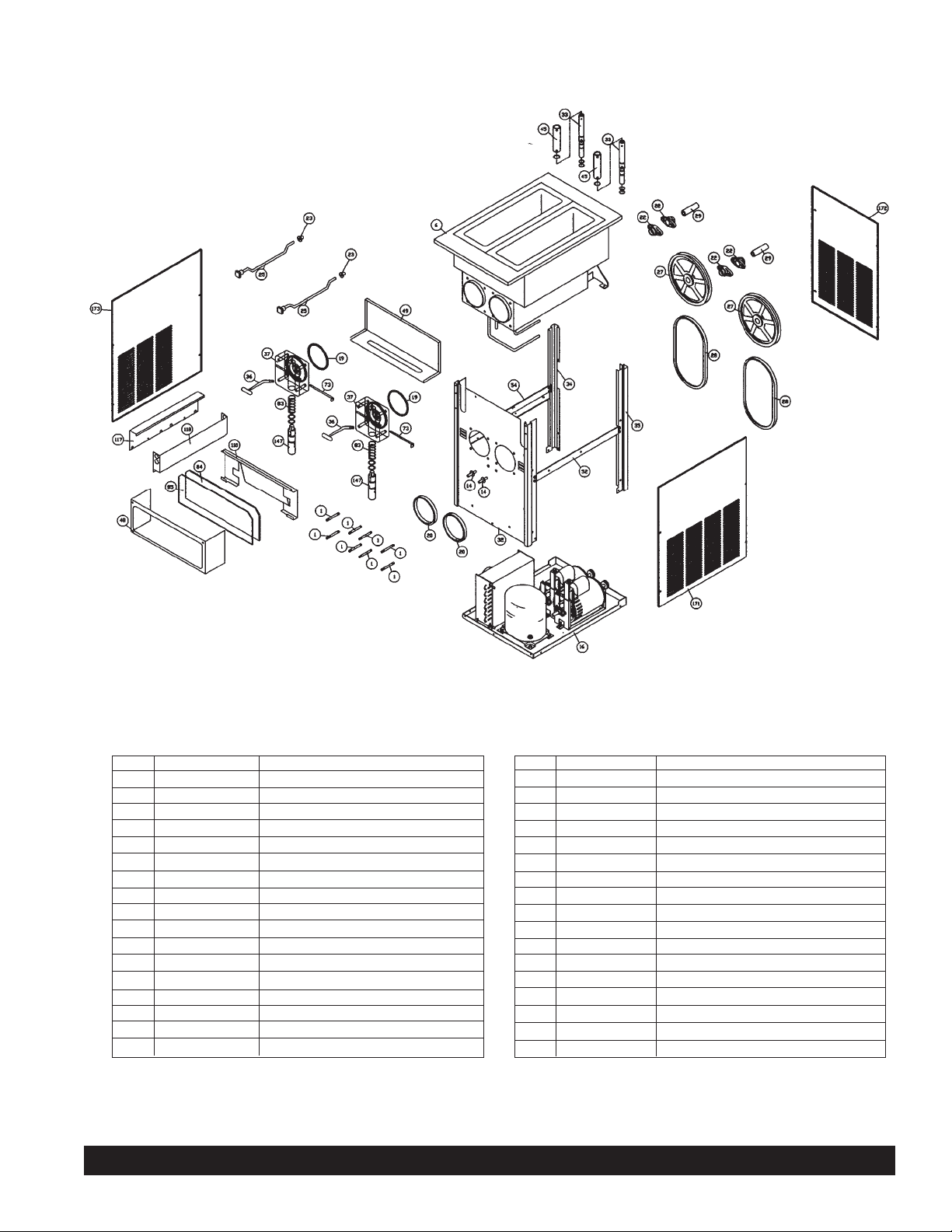

Page 23

Crathco®5512 Manual Page 23

Exploded View Model 5512 Stock Assembly

Item Part Number Description

173 W0520081 PANEL, LH

172 W0520080 PANEL, REAR

171 W0520082 PANEL, RH

147 W0572411 LEFT ELEC. BOX HARNESS

118 W0572371 RELAY BOX

117 W0572372 RELAY BOX COVER

110 W0572358 LIGHT REFLECTOR

85 W0631621 FRONT DISPLAY LENS CLEAR

84 W0631620 FRONT DISPLAY LENS

83 W0631230 VALVE SPRINGS

73 W0611728 FAS PIN

54 W0211213 LH CENTER SHELF ANGLE

52 W0211212 RH CENTER SHELF ANGLE

48 W0572298 ELECTRICAL BOX COVER

45 W0471134 SLEEVE STANDPIPE

37 W0480450 VALVE BODY

36 W0480445 VALVE HANDLE

Item Part Number Description

35 W0211206 RH FRAME LEG

34 W0211205 LH FRAME LEG

33 W0471128 CARBORATOR ASSY

32 W0211225 FRONT PANEL 5512

29 W0451067 SLUSH DRIVE SHAFT

28 W0450209 BELTS

27 W0450053 SHEAVE

25 W0430028 STATOR WELDMENT

23 W0430024 BLIND FLANGE BEARING

22 W0380025 FLANGE BEARING

20 W0340058 BARREL GASKET

19 W0340055 O-RING FOR VALVE BODY

16 W0211224 BASE ASSEMBLY

15 W0650913 CIRCUIT BOARD

14 W0211112 DRAIN TUBE FITTING

6 W0201427 EVAPORATOR FOAM ASSY.

1 W0110013 VALVE STUDS

Page 24

Page 24 Crathco®5512 Manual

Exploded View Model 5512-E Stock Assembly

Item Part Number Description

173 W0520083 PANEL, LH

172 W0520084 PANEL, REAR

171 W0520082 PANEL, RH

147 W0572411 LEFT ELEC. BOX HARNESS

118 W0572371 RELAY BOX

117 W0572372 RELAY BOX COVER

110 W0572358 LIGHT REFLECTOR

85 W0631621 FRONT DISPLAY LENS CLEAR

84 W0631620 FRONT DISPLAY LENS

83 W0631230 VALVE SPRINGS

73 W0611728 FAS PIN

54 W0211213 LH CENTER SHELF ANGLE

52 W0211212 RH CENTER SHELF ANGLE

48 W0572298 ELECTRICAL BOX COVER

45 W0471134 SLEEVE STANDPIPE

37 W0480450 VALVE BODY

36 W0480445 VALVE HANDLE

Item Part Number Description

35 W0211206 RH FRAME LEG

34 W0211205 LH FRAME LEG

33 W0471128 CARBORATOR ASSY

32 W0211225 FRONT PANEL 5512

29 W0451067 SLUSH DRIVE SHAFT

28 W0450209 BELTS

27 W0450053 SHEAVE

25 W0430028 STATOR WELDMENT

23 W0430024 BLIND FLANGE BEARING

22 W0380025 FLANGE BEARING

20 W0340058 BARREL GASKET

19 W0340055 O-RING FOR VALVE BODY

16 W0211229 BASE ASSEMBLY

15 W0650913 CIRCUIT BOARD

14 W0211112 DRAIN TUBE FITTING

6 W0201427 EVAPORATOR FOAM ASSY.

1 W0110013 VALVE STUDS

Page 25

Crathco®5512 Manual Page 25

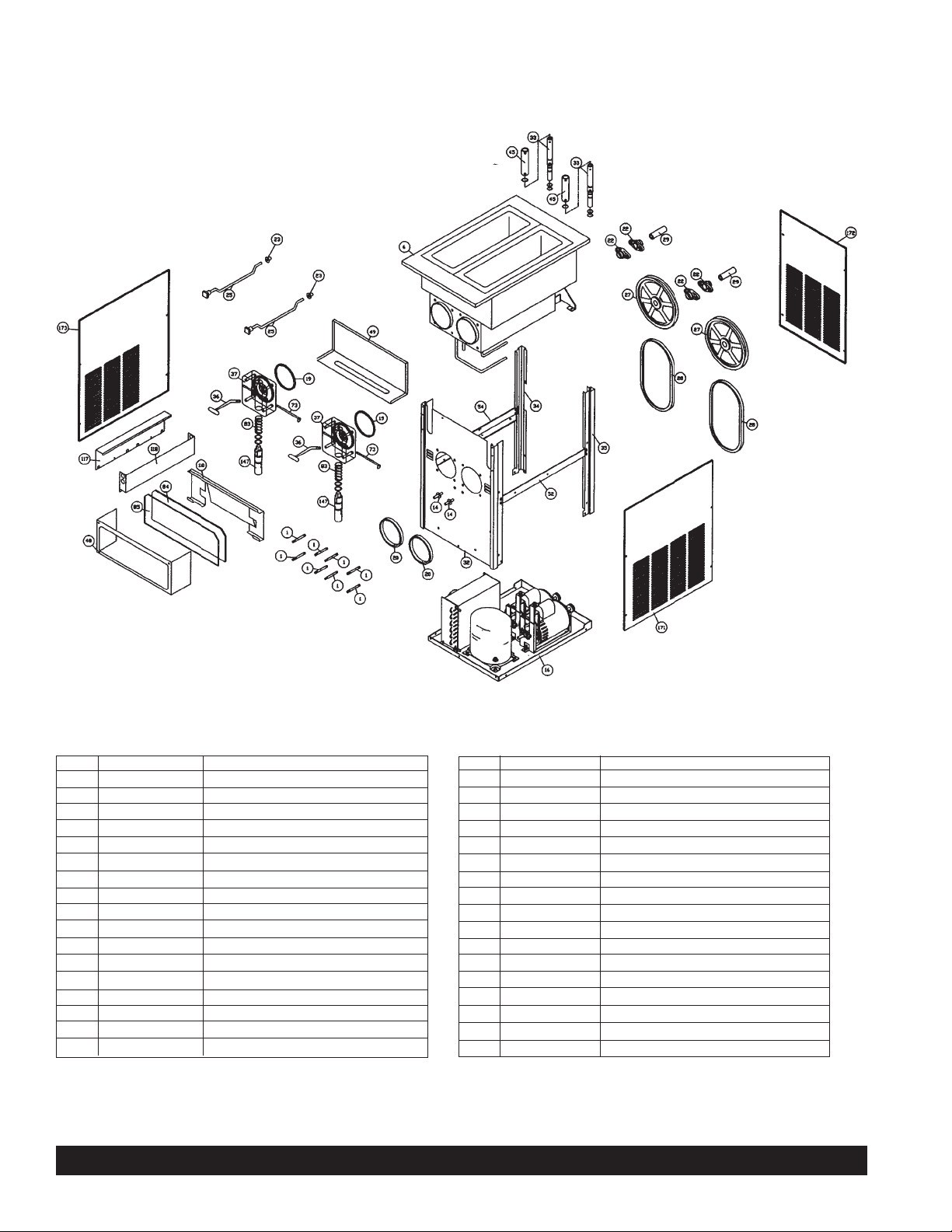

Exploded View Model 5512 Base Assembly

Item Part Number Description

24 W0340111 RUBBER BUMPER

23 W0611246 1/4 LOCKWASHER

22 W0611235 3/16 FLAT WASHER

21 W0611082 5/16-18 FLANGE NUT

20 W0611074 1/4-20 HEX NUT

19 W0611055 10-24 HEX NUT

18 W0610559 1/4-20 X 1 CAP SCREW

17 W0610264 10-24 X 1/4 TRUSS HD.

16 W0610110 #8 X 3/8 PAN HD.

15 W0451000 PULLEY

14 W0380009 FLANGE BEARING

13 W0321022 MOTOR ASSEMBLY

Item Part Number Description

12 W0321013 MOTOR ADJ. NUT

11 W0320221 FAN BLADE

10 W0320220 FAN MOTOR

9 W0211204 FRAME BOTTOM PLATE

8 W0210169 MOTOR CRADLE

7 W0201080 FAN SHROUD

6 W0200413 COMPRESSOR GROMMET

5 W0200412 COMPRESSOR SPACER

4 W0200411 FAN MOUNT BRACKET

3 W0200256 CONDENSER

2 W0200133 COMPRESSOR

1 W0321025 MOTOR STOP BRACKET

Page 26

Page 26 Crathco®5512 Manual

Exploded View Model 5512-E Base Assembly

Item Part Number Description

24 W0340111 RUBBER BUMPER

23 W0611246 1/4 LOCKWASHER

22 W0611235 3/16 FLAT WASHER

21 W0611082 5/16-18 FLANGE NUT

20 W0611074 1/4-20 HEX NUT

19 W0611055 10-24 HEX NUT

18 W0610559 1/4-20 X 1 CAP SCREW

17 W0610264 10-24 X 1/4 TRUSS HD.

16 W0610110 #8 X 3/8 PAN HD.

15 W0451000 PULLEY

14 W0380009 FLANGE BEARING

13 W0321023 MOTOR ASSEMBLY

Item Part Number Description

12 W0321013 MOTOR ADJ. NUT

11 W0320221 FAN BLADE

10 W0320216 FAN MOTOR

9 W0211204 FRAME BOTTOM PLATE

8 W0210169 MOTOR CRADLE

7 W0201080 FAN SHROUD

6 W0200413 COMPRESSOR GROMMET

5 W0200412 COMPRESSOR SPACER

4 W0200411 FAN MOUNT BRACKET

3 W0200256 CONDENSER

2 W0200134 COMPRESSOR

1 W0321025 MOTOR STOP BRACKET

Page 27

Crathco®5512 Manual Page 27

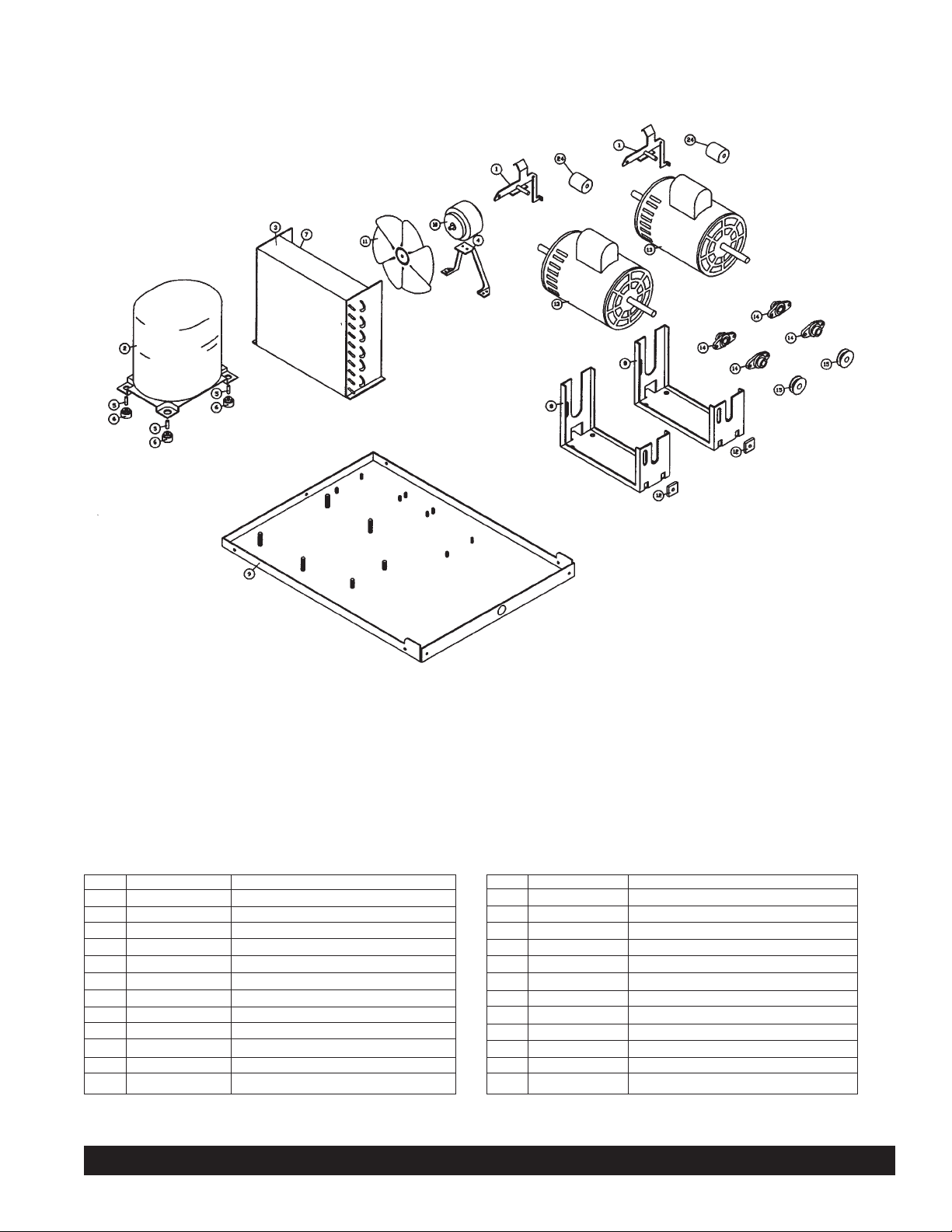

Exploded View Model 5512 Base Assembly Refrigeration

Item Part Number Description

34 W0650428 HIGH PRESSURE CUTOUT, 500#

33 W0201417 HOT GAS LINE 1/4”

32 W0201416 HOT GAS LINE 3/8”

31 W0201415 ACCESS VALVE LINE

30 W0201414 SUCTION LINE

28 W0201412 R.H. EXPANSION VALVE LINE

27 W0201411 EXPANSION VALVE LINE

26 W0201410 CONDENSER/DRIER LINE

25 W0201409 DRIER LINE

24 W0201408 L.H. EXP. VALVE LINE

23 W0201407 R.H. EXP. VALVE LINE

22 W0201406 L.H. SOLENOID LINE

21 W0650112 FILTER DRIER

20 W0201405 R.H. SOLENOID LINE

19 W0201404 BARREL SOLENOID LINE

18 W0201403 HOPPER SOLENOID LINE

Item Part Number Description

17 W0620101 1/4” COUPLING

16 W0620110 1/4” ELBOW

15 W0620103 3/8” STRAIGHT COUPLE

14 W0201402 FILTER/HOPPER SOLE LINE

13 W0201401 SOLENOID ELL’S.

12 W0200133 COMPRESSOR

11 W0200256 CONDENSER

9 W0620125 1/2” STRAIGHT COUPLING

8 W0620127 1/2” COPPER ELBOW

7 W1650002 SOLENOID VALVES

6 W0200314 CAPILLARY TUBE

5 W0620105 1/4” STREET ELBOW

4 W0650501 ACCESS VALVE

3 W0620102 1/4 X 1/4 X 1/4 TEE

2 W0650104 AUTOMATIC EXPANSION VALVES

1 W0201400 CAPILLARY CONNECTORS

Page 28

Page 28 Crathco®5512 Manual

Exploded View Model 5512 Base-E Assembly Refrigeration

Item Part Number Description

34 W0650428 HIGH PRESSURE CUTOUT, 500#

33 W0201417 HOT GAS LINE 1/4”

32 W0201416 HOT GAS LINE 3/8”

31 W0201415 ACCESS VALVE LINE

30 W0201414 SUCTION LINE

28 W0201412 R.H. EXPANSION VALVE LINE

27 W0201411 EXPANSION VALVE LINE

26 W0201410 CONDENSER/DRIER LINE

25 W0201409 DRIER LINE

24 W0201408 L.H. EXP. VALVE LINE

23 W0201407 R.H. EXP. VALVE LINE

22 W0201406 L.H. SOLENOID LINE

21 W0650112 FILTER DRIER

20 W0201405 R.H. SOLENOID LINE

19 W0201404 BARREL SOLENOID LINE

18 W0201403 HOPPER SOLENOID LINE

Item Part Number Description

17 W0620101 1/4” COUPLING

16 W0620110 1/4” ELBOW

15 W0620103 3/8” STRAIGHT COUPLE

14 W0201402 FILTER/HOPPER SOLE LINE

13 W0201401 SOLENOID ELL’S.

12 W0200134 COMPRESSOR

11 W0200256 CONDENSER

9 W0620125 1/2” STRAIGHT COUPLING

8 W0620127 1/2” COPPER ELBOW

7 W1650002 SOLENOID VALVES

6 W0200314 CAPILLARY TUBE

5 W0620105 1/4” STREET ELBOW

4 W0650501 ACCESS VALVE

3 W0620102 1/4 X 1/4 X 1/4 TEE

2 W0650104 AUTOMATIC EXPANSION VALVES

1 W0201400 CAPILLARY CONNECTORS

Page 29

Crathco®5512 Manual Page 29

Exploded View Probe Assembly

S.S PROBE - W0572362

ACETAL DELRIN SLEEVE - W0572361

ADD SILICON SEALANT TO BACK OF SLEEVE ONLY

MACHINE SCREW - W0610299

INTERNAL TOOTH LOCKWASHER - W0611224

RING EYE TERMINAL

FLAT WASHER - W0611241

PLASTIC SPACER - W0572360

HOLE IN REAR OF HOPPER PAN

Page 30

Page 30 Crathco®5512 Manual

1

2

Rough Side

of Ceramic

Smooth

Shiny Side

CRATHCO MACHINE ASSEMBLY

CHECK LIST

(W0631230)

Page 31

Crathco®5512 Manual Page 31

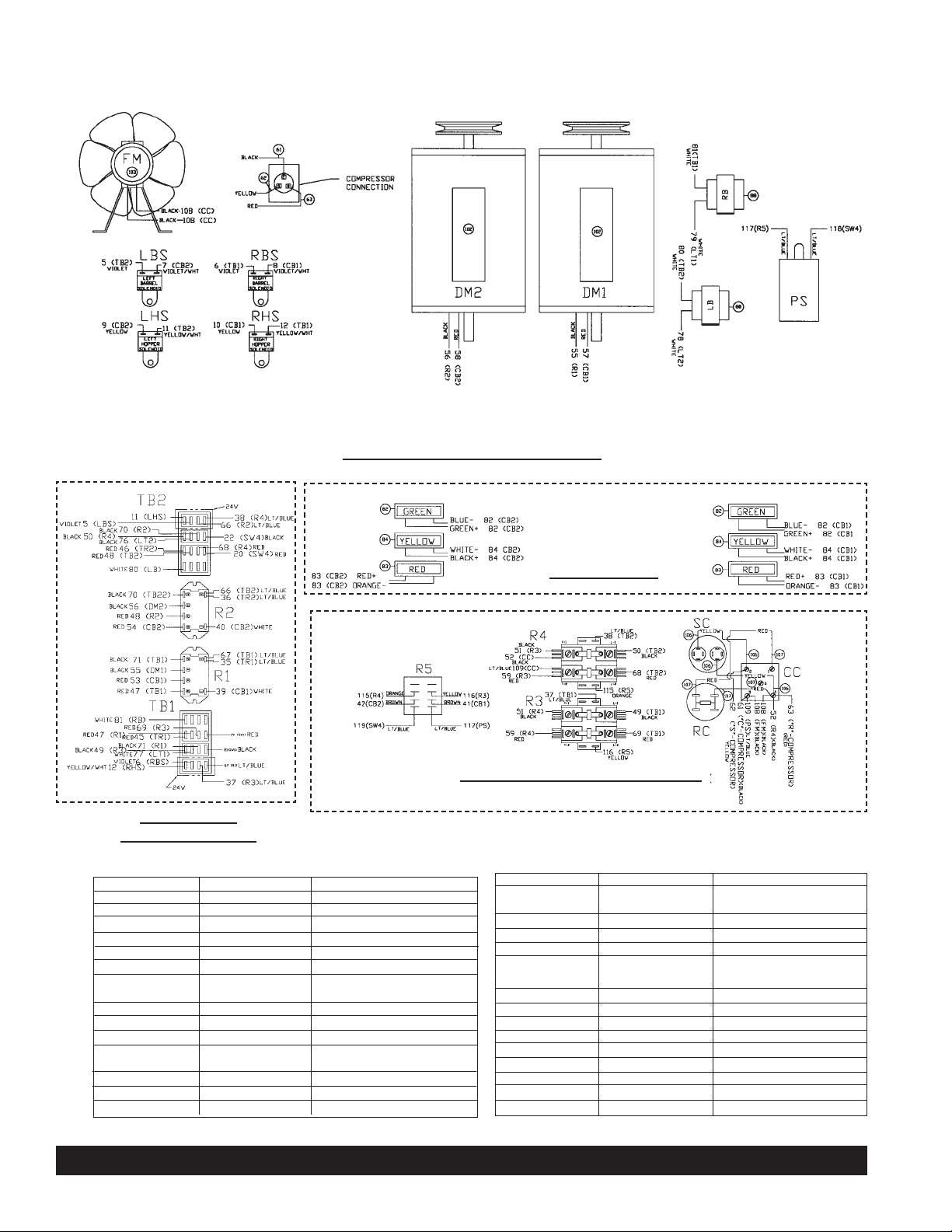

Exploded View Model 5512 Electrical Components

5512 ELECTRICAL COMPONENT

FRONT PANEL

UPPER LEFT

ELECTRICAL BOX

LO

WER LEFT ELECTRICAL BOX

Item Part Number Description

LHS & RHS W1650002 HOPPER SOLENOIDS

LBS & RBS W1650002 BARREL SOLENOIDS

PS W0650428 HIGH PRESSURE CUT-OUT

FU1-4 W1570616 FUSE HOLDERS

FM W0320216 FAN MOTOR

DM1 & DM2 W0321022 DRIVE MOTORS

101 W0570712 POWER CORD REQUIRE 2

WIRE NUTS & 1 W0570308

100 W0570916 RELAY SWITCH

R1 & R2 W0570677 SWITCHING RELAYS

R3 & R4 W0570655 CONTACTORS

TR1 & TR2 W0570873 TRANSFORMERS REQUIRE 2

W0570205

SW2 & SW3 W0570939 MODE SWITCHES

SC W0570672 START CAPACITOR

RC W0570673 RUN CAPACITOR

Item Part Number Description

SW1 & SW4 W0570940 ON/OFF SWITCH WITH 2

W1571507 FUSE HOLDERS

CC W0570880 COMPRESSOR RELAY

FU2 & FU4 W0570823 3.2 AMP FUSE

CB1 & CB2 W0650910 CIRCUIT BOARDS

FU1 & FU3 W0570842

5.0 AMP FUSE WITH 2

W1571507 FUSE HOLDERS

RB & LB W0570053 BALLASTS

LT1 & LT2 W0570055 FLUORESCENT BULBS

LT1 & LT2 W0570054 LIGHT SOCKETS

TB1 & TB2 W0570235 4 CIRCUIT TERMINAL BLOCK

84 W1570010 AMBER INDICATOR LIGHT

83 W1570011 RED INDICATOR LIGHT

82 W1570012 GREEN INDICATOR LIGHT

R5 83106 CONTACTOR RELAY

Page 32

Page 32 Crathco®5512 Manual

Exploded View Model 5512-E Electrical Components

FRONT PANEL

UPPER LEFT

ELECTRICAL BOX

5512-E ELECTRICAL COMPONENT

LOWER LEFT ELECTRICAL BOX

Item Part Number Description

LHS & RHS W1650002 HOPPER SOLENOIDS

LBS & RBS W1650002 BARREL SOLENOIDS

PS W0650428 HIGH PRESSURE CUT-OUT

FU1-4 W1570616 FUSE HOLDERS

FM W0320216 FAN MOTOR

DM1 & DM2 W0320031 DRIVE MOTORS

101 W0570714

POWER CORD REQUIRE 2

WIRE NUTS & 1 W0570308

100 W0570916 SERVE SWITCH

R1 & R2 W0570677 SWITCHING RELAYS

R3 & R4 W0570655 CONTACTORS

TR1 & TR2 W0570873 TRANSFORMERS REQUIRE 2

W0570205

SW2 & SW3 W0570939 MODE SWITCHES

SC W0570672 START CAPACITOR

RC W0570673 RUN CAPACITOR

Item Part Number Description

SW1 & SW4 W0570940 ON/OFF SWITCH WITH 2

W1571507 FUSE HOLDERS

CC W0570880 COMPRESSOR RELAY

FU2 & FU4 W0570823 3.2 AMP FUSE

CB1 & CB2 W0650913 CIRCUIT BOARDS

FU1 & FU3 W0570842

5.0 AMP FUSE WITH 2

W1571507 FUSE HOLDERS

RB & LB W0570053 BALLASTS

LT1 & LT2 W0570055 FLUORESCENT BULBS

LT1 & LT2 W0570054 LIGHT SOCKETS

TB1 & TB2 W0570235 4 CIRCUIT TERMINAL BLOCK

84 W1570010 AMBER INDICATOR LIGHT

83 W1570011 RED INDICATOR LIGHT

82 W1570012 GREEN INDICATOR LIGHT

R5 83106 RELAY CONTACTOR

Page 33

Crathco®5512 Manual Page 33

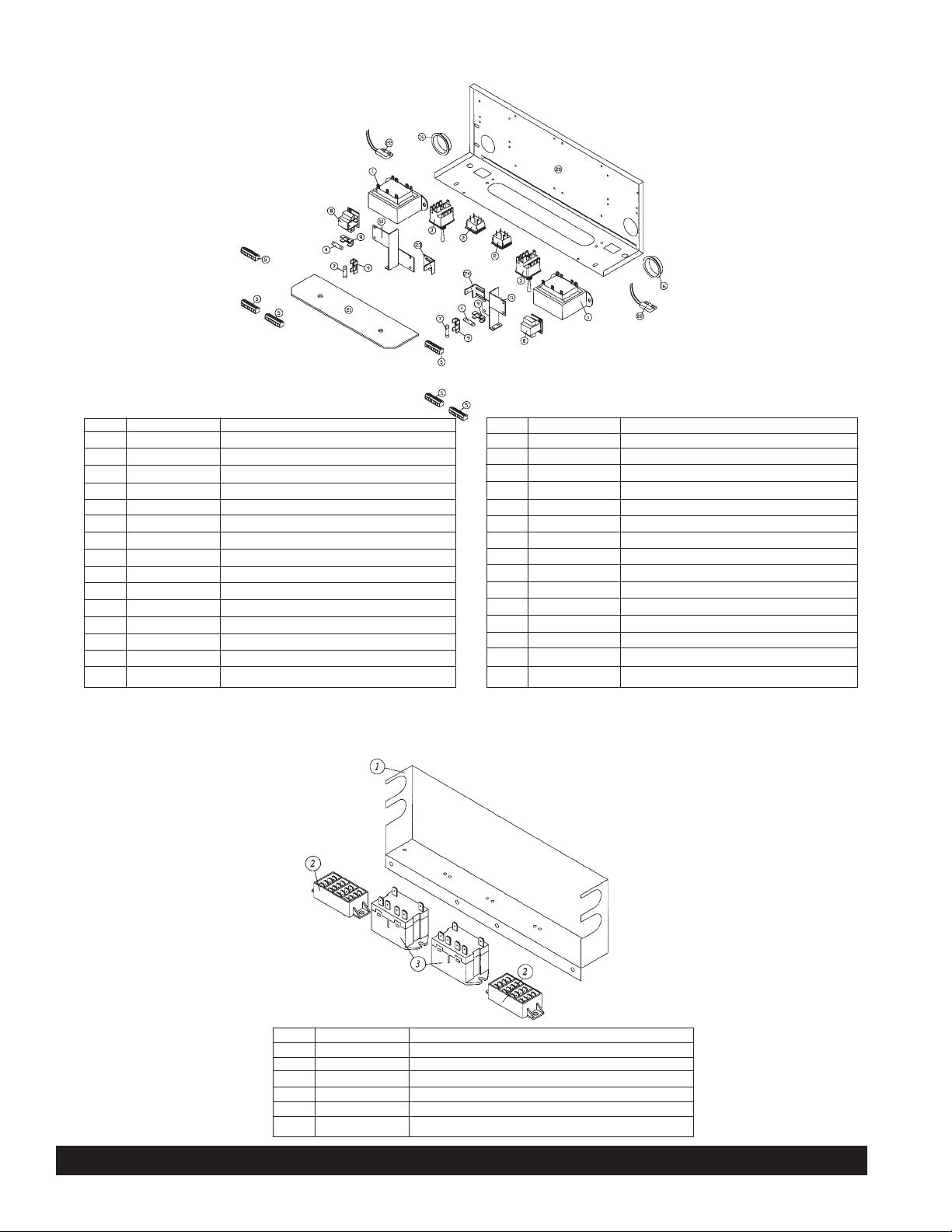

Model 5512 Electrical Components Front Electrical Box

Page 34

Page 34 Crathco®5512 Manual

Model 5512-E Electrical Components Front Electrical Box

Page 35

Crathco®5512 Manual Page 35

Model 5512 Contactor Box

Model 5512-E Contactor Box

Item Part Number Description

1 W0572373 CONTACTOR BOX

2 W0570655 CONTACTORS

3 W0570618 COMPRESSOR RELAY

4 W0570617 RUN CAPACITOR

5 W0570619 START CAPACITOR

6 83106 RELAY

7 W0630802 CABLE TIE, 7.375” NATURAL (NOT SHOWN)

8 W0610264 SCRW, 10-24 X 1/4 TRUSS HD PH

(NOT SHOWN)

9 W0340110 RUBBER GROMMET

10 W0610014 6.32 X 1/ 4 BINDING HEAD PHILLIPS (NS)

11 W0610138 SCRW, 8-32 X 1/4 RND HD SLT

(NOT SHOWN)

12 W0572417 COMPRESSOR COMPONENT BUNDLE

(NOT SHOWN)

13 W0572413 LEFT REAR HARNESS (NOT SHOWN)

Item Part Number Description

1 W0572373 CONTACTOR BOX

2 W0570655 CONTACTORS

3 W0570880 COMPRESSOR RELAY

4 W0570673 RUN CAPACITOR

5 W0570672 START CAPACITOR

6 83106 RELAY

7 W0630802 CABLE TIE, 7.375” NATURAL (NOT SHOWN)

8 W0610264 SCRW, 10-24 X 1/4 TRUSS HD PH

(NOT SHOWN)

9 W0340110 RUBBER GROMMET

10 W0610014 6.32 X 1/ 4 BINDING HEAD PHILLIPS (NS)

11 W0610138 SCRW, 8-32 X 1/4 RND HD SLT

(NOT SHOWN)

12 W0572417 COMPRESSOR COMPONENT BUNDLE

(NOT SHOWN)

13 W0572413 LEFT REAR HARNESS (NOT SHOWN)

Page 36

Page 36 Crathco®5512 Manual

Models 5512 & 5512-E Electrical Box

Models 5512 & 5512-E Relay Box

Item Part Number Description

1 W0572371 RELAY BOX

2 W0570235 TERMINAL BLOCK

3 W0570677 SOLID STATE RELAY

4 W0610131 SCREW, 8-32 X 1/4” SELF THRD PH

5 W0572410 RELAY BOX HARNESS (NOT SHOWN)

6 W0572416 RELAY BOX WIRE BUNDLE (NOT SHOWN)

Item Part Number Description

29 W0572415 ELECTRIC BOX WIRE BUNDLE

28 W0572414 RIGHT ELECTRICAL BOX HARNESS

27 W0572412 RIGHT SIDE HARNESS

26 W0572411 LEFT ELECTRICAL BOX HARNESS

25 W0570206 TERM, 2-520184-2 RECEPTACLE

24 W0572703 SERVE SWITCH BRACKET

23 W0572700 SERVE SWITCH BRACKET

22 W0570916 REED SWITCH (NORMALLY OPEN)

21 W0631630 LIGHTED ELECTRICAL BOX LENS

20 W0572357 ELECTRICAL BOX

19 W1631508 WIRE SADDLE

18 W0630804 WIRE TIE

17 W0630801 CABLE TIE

16 W0630008 HEYCO BUSHING

15 W0611037 6-32 HEX NUT ZINC PLATED

Item Part Number Description

14 W0611038 8-32 X 1/4 ROUND HD. SLOTTED

13 W0610131 8-32 X 1/4 SELF THREADING PHILLIPS

12 W0610019 6-32 X 1/4 PAN HD. SCREW

11 W0572702 LIGHT BRACKET R.H

10 W0572701 LIGHT BRACKET L.H.

9 W1570616 FUSE BLOCK

8 W0570044 LIGHT SOCKET, 5512

W0570054 LIGHT SOCKET, 5512-E

7 W0570842 FUSE, 5.0 AMP

6 W1570701 CABLE, 6 CONDUIT GREY

5 W1570214 TERMINAL STRIP, 8 POSITION

4 W0570823 FUSE 3.2 AMPS

3 W0570940 TOGGLE SWITCH

2 W0570939 ROCKER SWITCH

1 W0570659 TRANSFORMER

Page 37

Crathco®5512 Manual Page 37

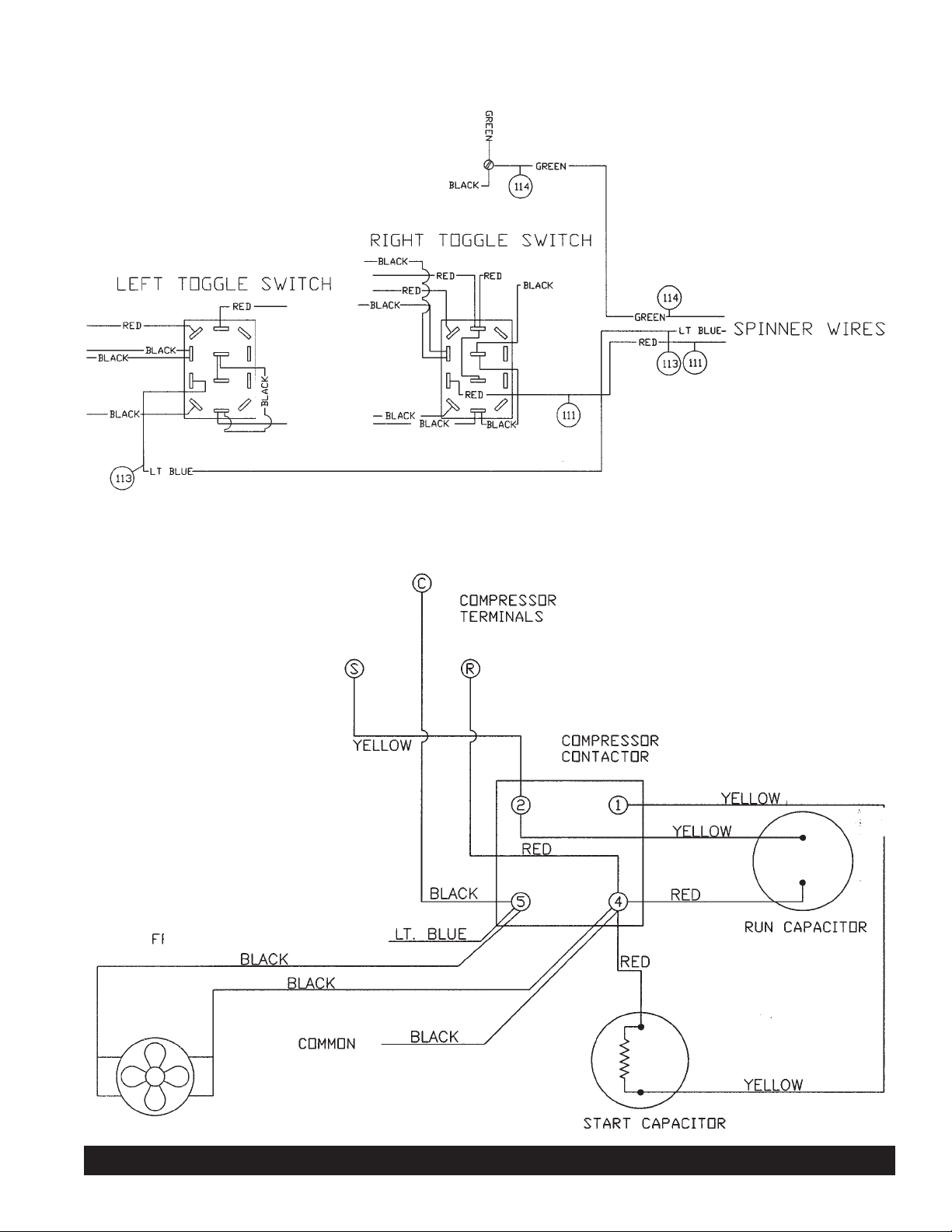

Models 5512 & 5512-E Spinner Wire Hookup

Models 5512 & 5512-E Compressor Contact Detail

Page 38

Page 38 Crathco®5512 Manual

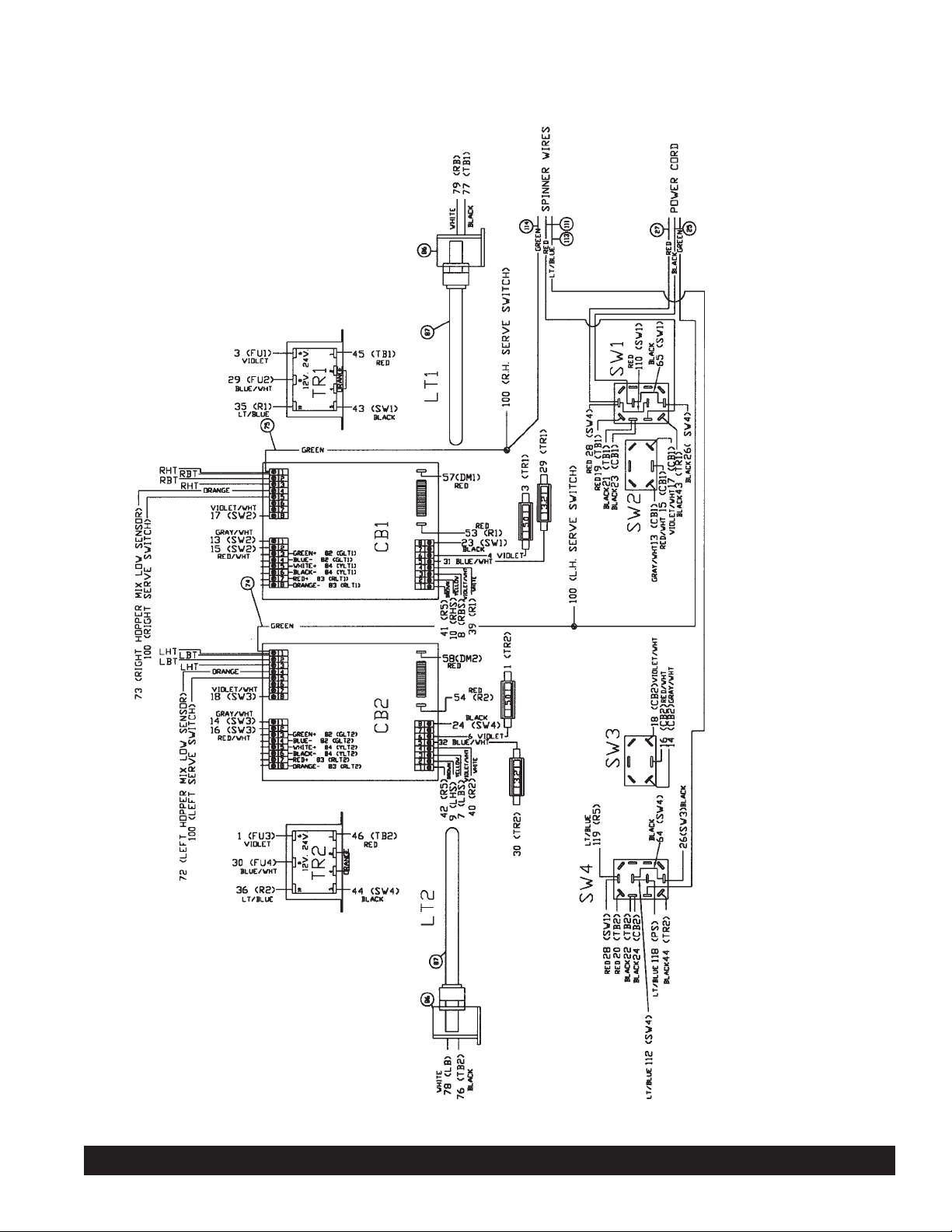

Model 5512 Ladder Diagram

Page 39

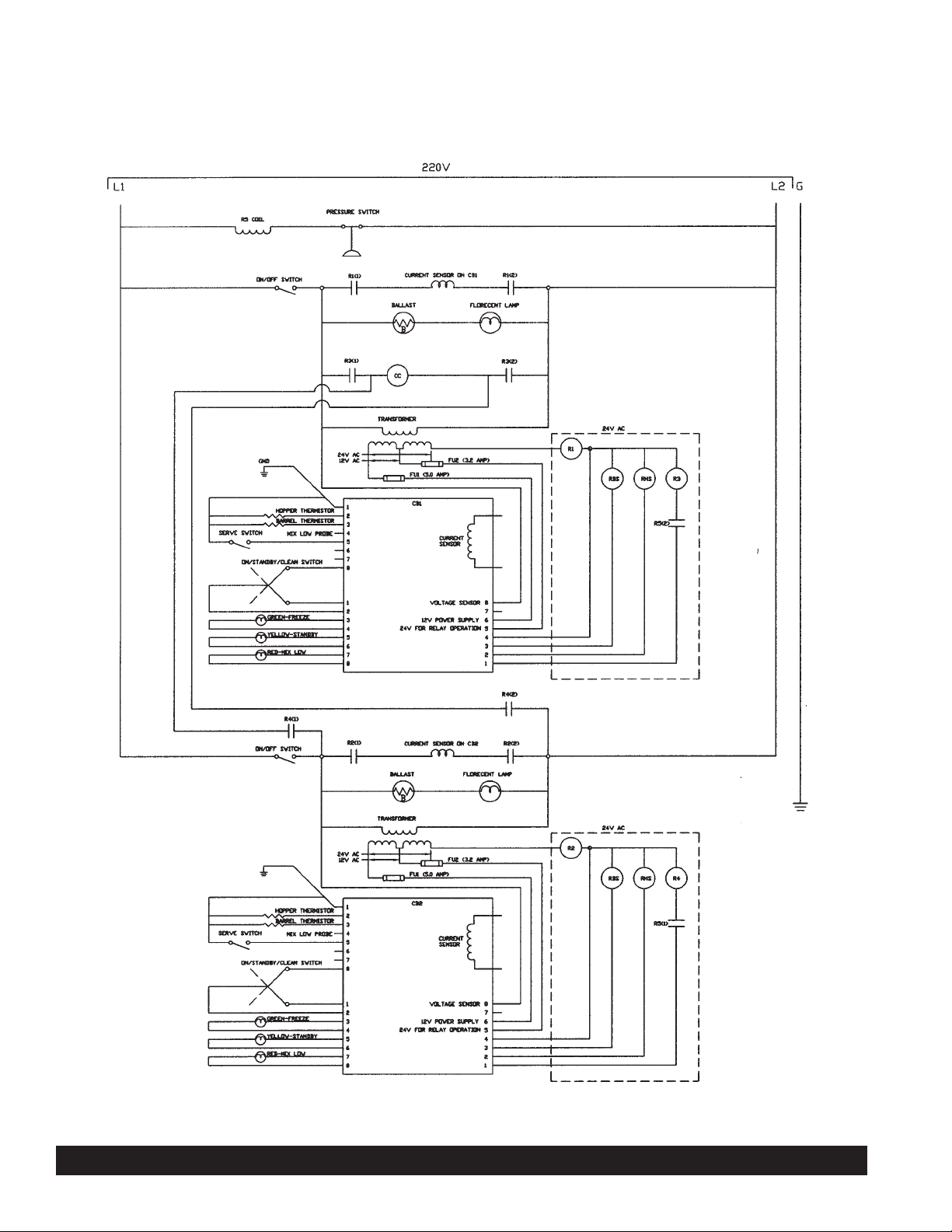

Crathco®5512 Manual Page 39

Model 5512-E Ladder Diagram

Page 40

Page 40 Crathco®5512 Manual

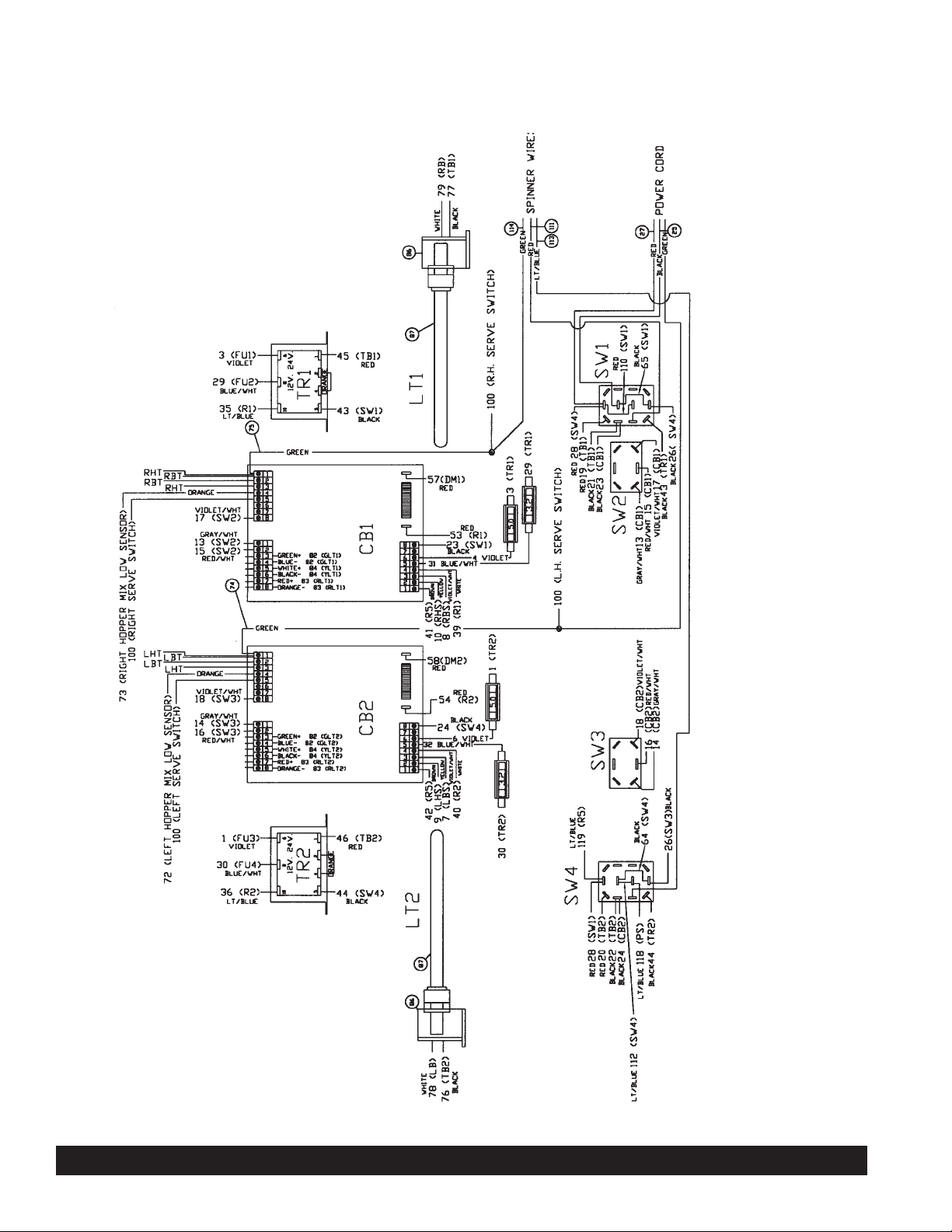

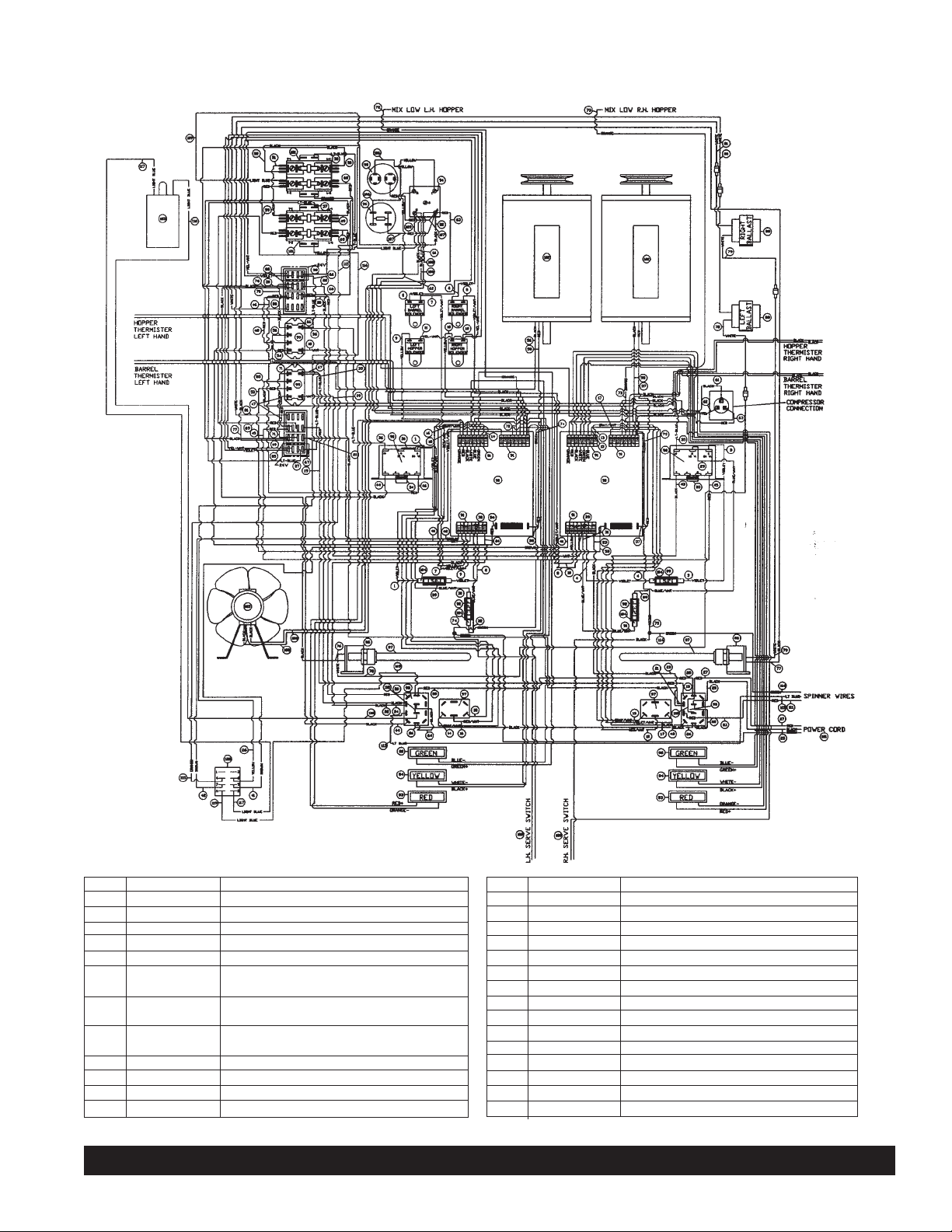

Model 5512 Wiring Diagram

Item Part Number Description

121 W0570655 CONTACTORS

120 83106 RELAY CONTACTOR

105 W0650428 HIGH PRESSURE CUT-OUT

104 W1570616 FUSE HOLDERS

103 W0320220 FAN MOTOR REQUIRE 2 W0570308

102 W0321022 DRIVE MOTORS REQUIRE

4 W0570205 2 W0570206 & 1 W0570308

101 W0570712 POWER CORD REQUIRE

2 WIRE NUTS & 1 W0570308

100 W0570916 SERVE SWITCH REQUIRE

1 EA. W0570308

99 W0570677 SOLID STATE RELAYS

98 W0570659 TRANSFORMERS REQUIRE 2 W0570205

97 W0570939 MODE SWITCHES

96 W0570619 START CAPACITOR

Item Part Number Description

95 W0570617 RUN CAPACITOR

94 W0570618 COMPRESSOR RELAY

93 W0570940 ON/OFF SWITCH

92 W0570823 3.2 AMP FUSE

91 W0570217 TERMINAL CONNECTORS (ORANGE)

90 W0650910 CIRCUIT BOARD

89 W0570842 5.0 AMP FUSE

88 W0570047 BALLASTS

87 W0570043 FLUORESCENT BULBS

86 W0570044 LIGHT SOCKETS

85 W0570235 4 CIRCUIT TERMINAL BLOCK

84 W1570010 AMBER INDICATOR LIGHT

83 W1570011 RED INDICATOR LIGHT

82 W1570012 GREEN INDICATOR LIGHT

Page 41

Crathco®5512 Manual Page 41

Model 5512-E Wiring Diagram

Item Part Number Description

121 W0570655 CONTACTORS

120 83106 RELAY CONTACTOR

105 W0650428 HIGH PRESSURE CUT-OUT

104 W1570616 FUSE HOLDERS

103 W0320216 FAN MOTOR REQUIRE 2 W0570308

102 W0320031 DRIVE MOTORS REQUIRE

4 W0570205 2 W0570206 & 1 W0570308

101 W0570714 POWER CORD REQUIRE

2 WIRE NUTS & 1 W0570308

100 W0570916 SERVE SWITCH REQUIRE

1 EA. W0570308

99 W0570677 SOLID STATE RELAYS

98 W0570873 TRANSFORMERS REQUIRE 2 W0570205

97 W0570939 MODE SWITCHES

96 W0570672 START CAPACITOR

Item Part Number Description

95 W0570673 RUN CAPACITOR

94 W0570880 COMPRESSOR RELAY

93 W0570940 ON/OFF SWITCH

92 W0570823 3.2 AMP FUSE

91 W0570214 TERMINAL CONNECTORS (ORANGE)

90 W0650913 CIRCUIT BOARDS

89 W0570842 5.0 AMP FUSE

88 W0570053 BALLASTS

87 W0570055 FLUORESCENT BULBS

86 W0570054 LIGHT SOCKETS

85 W0570235 4 CIRCUIT TERMINAL BLOCK

84 W1570010 AMBER INDICATOR LIGHT

83 W1570011 RED INDICATOR LIGHT

82 W1570012 GREEN INDICATOR LIGHT

Page 42

Page 42 Crathco®5512 Manual

Models 5512 & 5512-E Refrigeration Schematic

Page 43

Page 44

Grindmaster® Coffee Grinders and Brewers • PrecisionBrew™ Brewing Systems • Espressimo® Espresso Machines

Crathco® Hot Beverage Dispensers • Crathco® Cold and Frozen Beverage Dispensers • AMW Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

Loading...

Loading...