Page 1

Grindmaster 115 and 250 Series

Coffee Grinders

Operation and Instruction Manual

for

Models 115A, 115AB, 250, 250A, 250AB, 250-3A,

250RH-2 & 250RH-3

Table of Contents

Installation Instructions ..................................2

Set-up Procedures..........................................2

How to Operate ............................................2

Timer Adjustment ..........................................3

Grind Selector™ ............................................4

Coffee Grind Profile, Grind Adjustment ........5

Current, Protection, Circuit Breaker................5

Lubrication ....................................................5

Cleaning Instructions ....................................6

Removal and Reinstallation

of Upper Hopper Assembly ............................6

Shear Disc Replacement ................................7

Troubleshooting Guide................................8-9

Exploded Views ......................................10-18

Wiring Diagrams ....................................19-22

Grindmaster Corporation™

4003 Collins Lane

Louisville, Kentucky 40245 USA

(502) 425-4776

(800) 695-4500 (USA & Canada only)

(800) 568-5715 (Technical Service)

FAX (502) 425-4664

www.grindmaster.com

© Grindmaster Corporation, 1998

Printed in the USA

0108 Form # GR-373-04

Part# 85358

Prior authorization must be obtained from

Grindmaster Corporation for all warranty claims.

Model 250

Model 115

Model 250RH-2

Page 2

Page 3

115 & 250 Series Coffee Grinders Page 2

Installation Instructions

For Models 115A, 115AB, 250, 250A, 250AB, & 250-3A:

1. Please read this manual before operating the grinder.

2. Carefully remove grinder from carton.

3. Place grinder in position on shelf, counter or flat surface.

4. Plug grinder into 120V, 15A, grounded, electrical outlet. Do not use an extension cord.

5. Grind a small amount of whole bean coffee following operating instructions as described in this manual.

6. If there is any problem, consult the Troubleshooting Guide in this manual and also on the back of your grinder.

7. If you still cannot correct a problem, call Grindmaster Corporation’s Technical Service Department for help,

(502) 425-4776 or (800) 695-4500 (USA & Canada only) 8 AM - 6 PM EST.

For Models 250RH-2 & 250RH-3:

1. Please read this manual before operating the grinder.

2. Remove the flat cardboard insert. Remove the cardboard insert on top of the

grinder. Next, remove the small box next to the grinder (hopper enclosed).

Next, remove corner supports and then remove the grinder. Lastly, remove the

second hopper.

3. Place grinder in position on shelf, counter or flat surface.

4. Plug grinder into 120V, 15A, grounded, electrical outlet. Do not use an

extension cord.

5. Fill hoppers with whole bean coffee and place on grinder. Make sure the base

of each hopper is seated in its designated area (see Figure A). See

“Removal and Reinstallation of Hopper Assembly” section on page 6 for

detailed instructions.

6. Grind a small amount of whole bean coffee following operating instructions as

described in this manual.

7. If there is any problem, consult the Troubleshooting Guide in this manual and

also on the back of your grinder.

8. If you still cannot correct a problem, call Grindmaster Corporation’s Technical

Service Department for help:

(502) 425-4776 or (800) 695-4500 (USA & Canada only) 8 AM - 6 PM EST.

Instructions

Your new coffee grinder is easy to operate and maintain. Before you place it in service, please have all personnel

familiarize themselves with these instructions; then keep this manual in a convenient place for ready reference.

Set-up Procedures

1. You, the user, must determine the quantity of coffee you want to dispense as various types of coffee and

brewing equipment require different quantities to obtain a quality cup of fresh ground, fresh brewed coffee.

Note: Because of the inherent properties of some decaffeinated coffee, it may be necessary to dispense a slightly greater

amount to achieve the desired level of flavor extraction as in regular coffee. This should be evaluated based on the coffee

you use as well as the brewing equipment used.

2. Adjust the timer inside the grinder if necessary, to dispense the desired weight of ground coffee (see Timer Adjustment

Section on page 3). All grinders are factory set to deliver approximately 2 ounces of ground coffee. This weight is

approximate, as the density of all coffee beans is not the same. The only way to ensure the desired portion is being

dispensed is to weigh the coffee after it has been ground.

3. The grind texture can be adjusted, if necessary, to a finer or coarser grind (see “Grind Adjustment” section on page 5).

The grind is factory set to deliver a standard autodrip grind.

How to Operate

1. Fill the hopper with the appropriate amount of whole bean coffee.

250RH Models: Place full hoppers on machine making sure the base of each hopper is seated in designated area.

(Refer to Figure A)

2. Place the brew basket with coffee filter on rails (or basket arms).

3. Choose the type of coffee you wish to grind by pressing the rocker selection switch.

4. Push the start button on the front of the grinder.

5. When grinder stops, remove the brew basket.

Figure A

correct

incorrect

Page 4

Timer Adjustment

The timer is preset at the factory, but should adjustments be required, follow the instructions below to set the grind times.

Note: The grinder power must remain ON for timer adjustments.

Digital Grinder Timer Adjustments (All Models)

1. To access timer, remove the timer cover by removing the mounting screws and pulling the cover away from the casing.

2. To light up the display on the board and check the time setting, depress either one of the two square buttons located next to

the display one time.

3. To change the displayed setting, press and hold either the left or right square button until the desired setting is reached. The

left button lowers the displayed value; the right button increases the displayed value. The time values are set in seconds and

tenths of a second.

4. Refer to chart above for approximate timer settings.

Note: For accuracy you must weigh the coffee and make appropriate adjustments.

5. In order to store this desired value you must press the grinder start switch once.

Note: If start switch is not pushed, the last value stored will be used when you return to grinding mode.

6. Once the timer is adjusted, reinstall the timer cover.

Page 3 115 & 250 Series Coffee Grinders

AMOUNT TIME AMOUNT TIME

DESIRED SETTING DESIRED SETTING

(OZ.) (SECONDS) (OZ.) (SECONDS)

0.5 1.0-1.3 6 13.0-15.8

1.0 2.1-2.6 7 15.2-18.4

1.5 3.2-3.9 8 17.4-21.1

2.0 4.3-5.3 9 19.5-23.7

2.5 5.4-6.6 10 21.7-26.3

3.0 6.5-7.9 12 26.1-31.6

3.5 7.5-9.2 14 30.5-36.9

4.0 8.6-10.5 16 34.8-42.1

5.0 10.8-13.2 18 39.2-45.0

Page 5

115 & 250 Series Coffee Grinders Page 4

Grind Selector™

For Models 115AB and 250AB:

Models equipped with a Grind Selector™ are designated with a “B” at the end of the model number (Model 115AB & 250AB). If

your grinder is equipped with a Grind Selector™, refer to the following information:

The Grind Selector™ allows you to set the grinder to coarse or fine on any of the 250AB four grind selections:

regular small, regular large, decaf small, or decaf large.

The following are some recommended use conditions:

Coarser Settings Regular Settings

Larger portions - 8 oz or more Smaller portions - 7 oz. or less

(urns) (bottle brewers or airpots)

Decaffeinated coffee Regular coffee

The fine grind setting on this grinder has been pre-set at the factory to deliver coffee ground to normal drip

specifications. Should you wish to make an adjustment please follow these steps:

To Adjust the Fine Grind

For Models 115AB and 250AB:

Tools Required: Adjustable Wrench, Phillips Screw Driver, Large Blade Screwdriver

1. Unplug grinder.

2. Remove upper front plate.

3. Loosen the fine grind adjusting screw lock nut (see Figure B).

4. Hold solenoid shut while turning adjusting screw clockwise to

make the grind finer, counter-clockwise to make the grind coarser

(see Figure B). We recommend that you do not turn the

adjusting screw more than two notches on the scale before

testing the new grind setting.

NOTE: Be sure that when adjusting the grind that you do not adjust too fine, causing the burrs to touch each other (a sound of

metal scraping metal). This could cause damage to the burrs or motor.

5. After the adjustment has been made, tighten adjusting screw lock nut. Do not allow the fine grind adjusting screw to expose

more than three threads on the outer side of the arm or it could loosen during operation.

6. Assemble front plate to front of the grinder.

To Adjust the Coarse Grind

For Models 115AB and 250AB:

Tools Required: Adjustable Wrench, Phillips Screw Driver, Large Blade Screwdriver

1. Unplug grinder.

2. Remove upper front plate.

3. Loosen the fine grind adjusting screw lock nut (see Figure C).

4. Pull the solenoid plunger toward you until it contacts the coarse

grind adjusting screw (see Figure C). Then turn the adjusting

screw clockwise to make the grind finer, counter-clockwise to

make the grind coarser. We do not recommend that you turn the

adjusting screw more than one and a half turns before testing the new grind setting.

5. After the adjustment has been made, tighten the adjusting screw lock nut.

6. Assemble front plate to front of grinder.

Figure B: Fine Grind Adjustment

Figure C: Coarse Grind Adjustment

Fine grind

adjustment

screw

Coarse grind

adjustment screw

Page 6

Page 5 115 & 250 Series Coffee Grinders

Coffee Grind Profile

Before shipment, this grinder has been tested with coffee and has been accurately adjusted to deliver a

standard autodrip grind.

The Grinding Burrs are made of an extremely hard and wear resistant alloy. From time to time, grind

adjustments (see instructions below) may be necessary as the burrs wear. If the grind runs coarser than

expected after normal adjustment and the grind time has increased, the burrs may have excess wear and should be

replaced. The burrs are warranted for 3 years or 30,000 pounds of coffee. See your warranty for details. New burrs should

always be installed as a pair, never one or the other, as they are accurately ground and lapped in pairs. Old burrs cannot be

resharpened.

Grind Adjustment

For Models 115A, 250, 250A, 250RH-2, 250RH-3

Tools Required: Phillips and Large Blade Screwdrivers, Pliers

In order to adjust the grind follow these steps: (see Figure D)

1. Remove Upper Front Plate by removing the four screws in the corners.

2. Loosen Adjusting Screw Lock Nut by turning counter clockwise.

3. Turn slotted Adjusting Screw clockwise to make grind finer or

counter-clockwise to make grind coarser. Generally a 1/8 to 1/4 turn

will provide the desired adjustment.

Note: Use dial on grinder cap as reference. Do not turn more than

one notch before testing new Grind Adjustment.

4. After adjustment has been made, tighten Adjusting Screw Lock Nut.

5. To visually inspect grind adjustment, test grind a small portion of coffee

and re-adjust if necessary.

Note: Adjusting the grind may alter the portion of coffee dispensed. After grind adjustment,

weigh portion and adjust, if necessary (see “How to Adjust the Portion”).

Current

It is absolutely essential that full voltage and amperage always be available as it takes full power to grind

coffee. NEVER connect to an overloaded line or a two or three way plug, otherwise serious damage to the motor may result.

Do not use an extension cord.

Protection

This grinder is equipped with both a circuit breaker and a shear disc to protect motor and burrs if a foreign object, such as a

nail or rock, gets into the coffee.

Circuit Breaker

This grinder is equipped with a circuit breaker to protect the motor from overloading. When the circuit breaker operates, the

reset button will pop out approximately 1/4” which cuts off the power to the grinder. The reset button is located above the

power cord on the back of the grinder. To reset the circuit breaker, push the reset button in. You will hear a click as it resets.

If the grinder does not operate after resetting the circuit breaker, there may be an obstruction in the grinding mechanism that

is stalling the motor. In this case, the Grinder Head should be cleaned out as described in the Shear Disc Replacement

section of this manual.

Lubrication

All bearings have been oiled for life. No further oiling is necessary.

Figure D: Grind Adjustment

Adjusting Screw

Lock Nut

(86340)

Adjusting Screw

(86341)

Grinder Cap

(87131)

Page 7

Cleaning Instructions

The outside of the machine can be cleaned with a damp cloth or common household polishing wax. Grinding parts should

be cleaned with a stiff brush or dry cloth. Do Not Use Water. See “Shear Disc Replacement” for instructions on assembling

and disassembling of grinder parts. Before reassembling, wipe motor shaft with 2 or 3 drops of common household lubricating oil in the area of feedworm engagement to make assembly easier.

For Models 250RH-2, 250RH-3:

Regular usage of the coffee hoppers will cause oils to accumulate on the inner surface, requiring occasional cleaning.

1. Remove hopper from grinder and empty all beans.

2. Use a soft, damp cloth with a small amount of liquid soap and clean hopper. Use a clean, damp cloth to remove the

soap residue. Do not immerse or fill hopper with water.

3. Allow hopper to completely air dry before refilling with beans.

4. Once the hopper is dry, refill with whole bean coffee, cover and replace on grinder.

Shipping Bracket Removal

NOTE: Shipping bracket must be removed prior to removal of

upper hopper assembly.

Models 250, 250A and 250AB are equipped with shipping bracket.

Remove bracket prior to installation. (see Figure E)

Tools Required: 1 Phillips screwdriver.

1. Using the Phillips screwdriver, remove the screws and the bracket

located at the back of the grinder.

2. Do not discard the screws and bracket. The bracket should be re-installed

on the grinder prior to transporting or shipping.

Removal and Reinstallation of Hopper Assembly

For Models 250, 250A, 250AB, 250-3A:

1. Remove Upper Front Plate by removing the four screws in the corners

(Shipping bracket must be removed prior to removal of upper

hopper assembly. See instructions and diagram above.)

2. Lift Upper Hopper Assembly while rotating the Assembly slightly

upward (see Figure F).

3. Pull the Assembly forward, toward front of unit and out.

4. To reinstall hopper, ensure the Drive Pins are in vertical position.

(see Figure G)

5. Ensure that Drive Links are in horizontal position.

6. Insert the rear slots of the Upper Hopper Assembly into the rear tabs

of the motor bracket.

7. Rotate assembly downward.

8. Reassemble Upper Front Plate.

9. Put the (4) screws back into Upper Front Plate and tighten.

For Models 250RH-2, 250RH-3:

1. To remove hoppers, grasp hopper by handle and lift up

approximately 1/4” and pull hopper back and out of

grinder. The bottom bean shut off valve will close

automatically, preventing spillage of beans.

2. Once hopper is removed, it can be refilled or cleaned if necessary.

3. To reinstall hopper, grab by handle and set bottom back of hopper on

left or right side of grinder, making sure that the drive link is properly

oriented (see Figure G).

4. Push hopper all the way back until it settles in it’s designated space (see Figure A).

NOTE: Hopper must be in place in order for that side of the grinder to operate.

115 & 250 Series Coffee Grinders Page 6

Figure F: Upper Hopper Assembly

Removal and Reinstallation

Figure E: Shipping Bracket Removal

Figure G: Positioning of the

Drive Pins and Drive Links

Model 250

shipping bracket

The bracket may be

left on grinder, but

must be removed

prior to servicing.

Page 8

Page 7 115 & 250 Series Coffee Grinders

Shear Disc Replacement

If the motor should run and no coffee is dispensed, the shear disc release may have operated. Should this occur,

perform the following operations in the sequence given (see Figure H).

Tools Required: Phillips Head Screwdriver and Pliers

1. Unplug machine.

2. Remove the Upper Front Plate of the grinder to provide access to the grinder mechanism.

3. Remove the Grind Cap by taking out the 2 Thumb Screws.

4. Pull out the Revolving Burr and Feedworm Assembly. Clean out the Grinder Head, removing all coffee particles

from inside of the Grinder Head and the Grinder Cap so that it can be reset properly.

5. Check that no obstruction has been caught on the surface of the teeth of either burr.

6. Remove the Shear Cap and broken pieces of the Shear Disc. You are now ready to reassemble the grinder

mechanism.

7. Slide the Burr and Feedworm Assembly back onto the Motor Shaft making certain that the tongue of the shaft

engages the slot in the Shear Drive.

8. Insert a new Shear Disc by aligning the slot in the Shear Drive with the slot in the hub of the Feedworm.

9. Reassemble the Shear Cap and Grinder Cap. Make certain the Grinder Cap is screwed on tight and is sealed

properly against the head, not angled or mis-aligned. Otherwise a proper grind cannot be obtained.

10. Reassemble the Upper Front Plate. Your grinder is now ready to grind.

Figure H: Motor Assembly

Adjusting Nut

(86340)

Decal, Coarse-Fine

(84884)

Shear Cap

(86355)

Shear Disc

(86123)

Burr Set

(85281W)

Tension Spring

(86118)

Thrust Collar

(86304)

Grind Head

(84171S)

Gasket, Hopper Foam

(88211)

Motor

(86419)

Nut

(86864)

Machined Spout (86218)

Deflector (86220)

Screw (86217)

Gasket, Portioner to Head

(71419)

Adjusting Screw

(86341)

Thumb Screw

(86819)

Bearing, Adjusting

(86140)

Grind Cap

(87131)

Shear Drive

(86154)

Feedworm

(85185K)

Screw

(86812)

Screw

(86148)

Spring, Chaff Mixing

(86146)

Revolving

Burr

Page 9

115 & 250 Series Coffee Grinders Page 8

Troubleshooting Guide

The following procedures must be performed by a qualified service technician.

CAUTION: Unplug the machine before cleaning or servicing the unit.

Problem Possible Cause Solution

Grinder will not start when START

button is pushed

• Plug not in outlet properly

• No power to outlet

• Circuit breaker has tripped

• Install plug in outlet

• Check outlet with lamp or radio to verify

outlet has power.

• Reset circuit breaker by pushing in reset

button until you hear a click

Grinder runs or hums but no

coffee is dispensed

• Shear disc is broken

• Obstruction in opening to grinding

chamber

• Auger has stalled (Models 250,

250A

250RH-2 & 250RH-3 only).

• 250RH Models: Hoppers not properly in

place

• Replace shear disc. See “Shear Disc

Replacement” section or instructions on

inside of upper front plate.

• Remove hopper and clear obstructions.

• Clean auger

• Make sure hoppers are seated in their

allocated area

Excessive amount of chaff flying

about

• Defective chaff mixer spring

• Static electricity

• If bent, broken, or missing,

replace spring.

• If stuck open with coffee, clean coffee to

free spring

• Tighten all nuts, bolts, and screws and

verify outlet is grounded.

Quantity of coffee dispensed each

throw is not the same

• Auger stalls (Models 250, 250A,

250RH-2, and 250RH-3 only)

• Timer delay is not working or running

long enough

• Defective timer

• Refer to problem as listed below in this

Troubleshooting Guide.

• See “Timer Adjustment” section

• Check the length of time the grinder

runs

• If time varies more than plus or minus

1%, replace timer.

Knobs do not operate smoothly • Coffee beans or bean dust may have

clogged carrier

• With machine unplugged, clean carrier

Auger does not turn • Coffee beans or bean dust may have

jammed auger

• 250RH Models: Hopper not properly

seated

• With machine unplugged, clean auger

opening

• Make sure hopper is seated in its

designated area (see Figure A)

Auger will not operate • Motor or link is binding

• Auger motor has burned out

• Wiring harness to motor is loose

• 250RH Models: Hopper not properly

seated

• Check all alignment of link and motor.

Check tightness of motor mounting

screws.

• Replace motor

• With machine unplugged, check to see

if wires are connected to motor

• Make sure hopper is seated in its

designated area (see Figure A)

Circuit breaker continuously trips • Insufficient current due to use of

extension cord

• Insufficient current due to overloaded

line

• Grind setting needs adjustment

• Plug unit directly into outlet. Do not use

extension cord.

• Designate single line for grinder. Do not

use multi-outlet box.

• Adjust grind to coarser setting (see

“Grind Adjustment” section)

continued on next page

Page 10

Page 9 115 & 250 Series Coffee Grinders

If you still need help, call our Service Department at (502) 425-4776 or (800) 695-4500 (USA & Canada only)

(Monday through Friday 8am-6pm EST) or an authorized service center in your area. Please have the model

and serial number ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all

warranty claims.

Troubleshooting Guide for Grind Selector™ Mechanism

(Models 115AB and 250AB)

The following procedures must be performed by a qualified service technician.

Problem Possible Cause Solution

Loud grating noise • Burrs are touching each other on fine

grind setting

• Readjust fine grind setting, see “To

Adjust Fine Grind” section

Rumbling noise • Thrust bearing rotating inside flange

bearing

• Replace thrust bearing and shear cap

Chattering or buzzing noise • Solenoid may have failed to seat or

close fully (Models 115AB &

250AB only)

• Check alignment of solenoid and

shift arm

• Also check the tightness of the solenoid

mounting screws

Loud vibration noise during grinding

when Grind Selector™ is not activated

• Cotter pin in the thumb screw linkage

may be vibrating

• Attempt to spread flanges of cotter pin

or replace cotter pin

Grind Selector™ fails to activate • Wiring harness loose

• Solenoid has burned out (Models 115AB

& 250AB only)

• WITH MACHINE UNPLUGGED, check

wiring harness connections to see if

they are secure on the timer terminals

• Replace solenoid

Page 11

115 & 250 Series Coffee Grinders Page 10

Models 115A, 115AB, 250, 250A, 250AB & 250-3A Exploded Views

(refer to pages 11-14)

Page 12

Page 11 115 & 250 Series Coffee Grinders

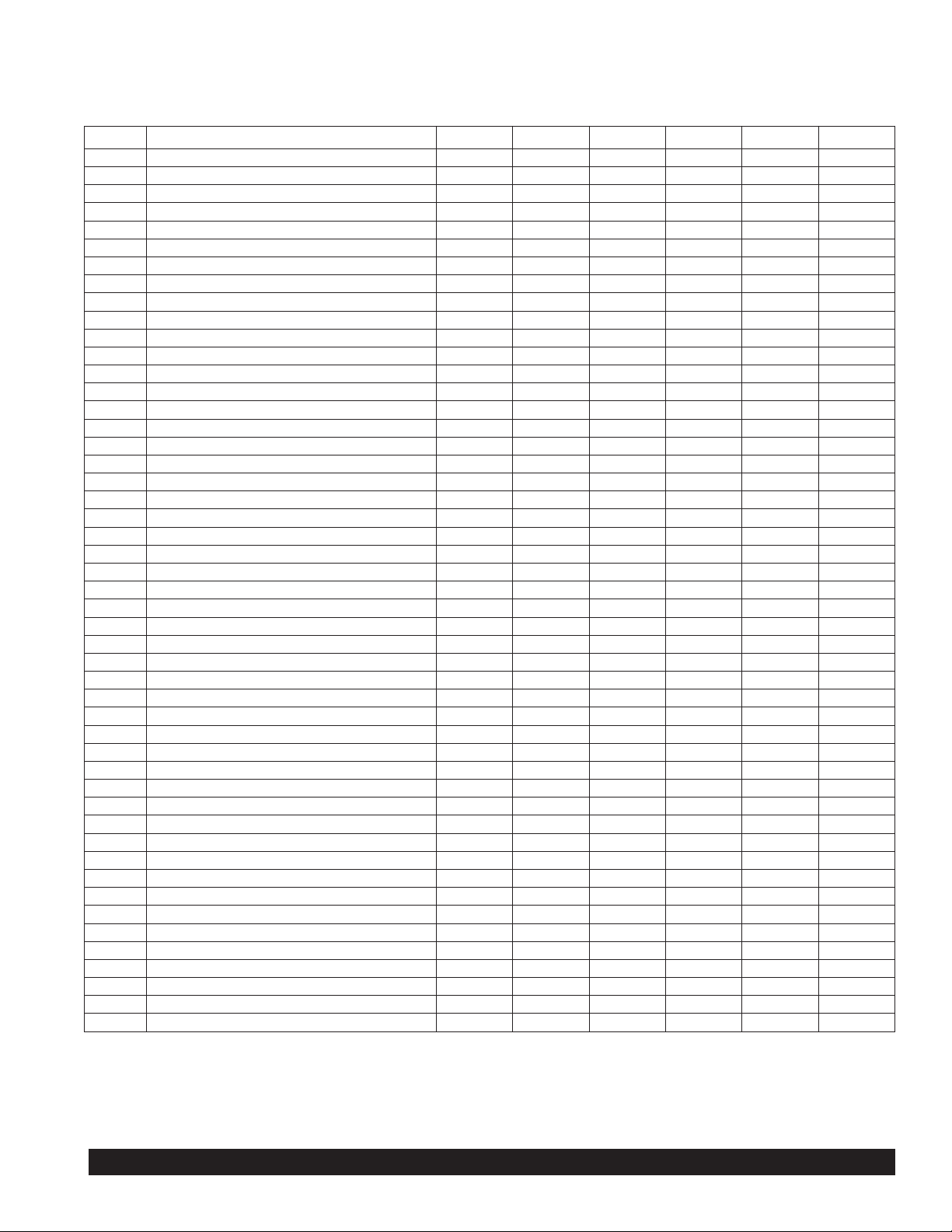

Exploded View Parts List - 115V

Models 115A, 115AB, 250, 250A, 250AB & 250-3A

Item No. Description 115A 115AB 250 250A 250AB 250-3A

1 HARNESS, 115/250 A & AB 86037 86037 86037 86037 86037 86037

2 HARNESS, 250 SERIES DIGITAL AUGER 86125 86125 86125 86125

3 HARNESS, DIGITAL SWITCH 86122 86122 86121 86117 86117 86117

4 FOOT, RUBBER 100/250 86034 86034 86034 86034 86034 86034

5 BASE 86309 86309 86309 86309 86309 86309

6 BRACKET, TINNERMAN ANGLE 86863 86863 86863 86863 86863 86863

7 250 LID ASSEMBLY 89103 89103 89103 89103

8 SCREW, #8 X 3/8 PH PN SMS T/B 410 SS 89113 89113

9 LID, BACK SS 86013 86013

10 SCREW, 6-32 X 1/4 PH PN HD 86801 86801

11 LID, FRONT SS 86014 86014

12 NUT, 6-32 ACORN LOCK 86848 86848

13 HINGE, PLATED 86316 86316

14 PARTITION, HOPPER 86041 86041 86041 86041

15 SCREW, 8-32 1/2 SL BD HD NYLON 86087 86087 86087 86087

16 NUT, 8-32 NYLON LOCK 86086 86086 86086 86086

17 SCREW, #8 X 3/8 PH PN SMS T/B 410 SS 89114 89114

18 HOPPER 86010K 86010K 86010K 86010K 86010K 86010K

19 WINDOW, HOPPER 86102 86102 83152 83152 83152 83152

20 HOPPER, SUPPORT 86008 86008

21 HOPPER 86192 86192

22 FRONT HOPPER SUPPORT 86196K 86196K

23 GASKET, HOPPER 86228 86228

24 SCREW, 8-32 X 3/8" HEX PEM 83182 83182 83182 83182

25 LINK, DRIVE 83368 83368 83368 83368

26 WASHER, NYLON 83141-01 83141-01 83141-01 83141-01

27 HOPPER, AUGER W/ SPOUT 83150 83150 83150 83150

28 ADAPTER, DRIVE 80019 80019 80019 80019

29 SPRING, AUGER 86046 86046 86046 86046

30 FUNNEL, AUGER 83134 83134 83134 83134

31 MOTOR, AUGER 115V 86050 86050 86050 86050

32 BRACKET, MOTOR 86042-01 86042-01 86042-01 86042-01

33 GASKET, HOPPER 83081 83081 83081 83081

34 NUT, TINNERMAN 1/4 - 20

86864 86864

86864 86864 86864 86864

35 MOTOR, 1/2HP 115V

86419K 86419K

86419K 86419K 86419K 86419K

36 SCREW, 8-32 X 3/8 PH TR HD M/S 410 SS

82097 82097

82097 82097 82097 82097

37 HEAD, GRIND

84171S 84171S

84171S 84171S 84171S 84171S

38 COLLAR, THRUST

86304 86304

86304 86304 86304 86304

39 SPRING, TENSION

86118 86118

86118 86118 86118 86118

40 BURR (SET)

85281WK 85281WK

85281WK 85281WK 85281WK 85281WK

41 SCREW, #10-32 X 5/16

86812 86812

86812 86812 86812 86812

42 FEEDWORM

85185T 85185T

85185T 85185T 85185T 85185T

43 DRIVE, SHEAR

86154 86154

86154 86154 86154 86154

44 SHEAR DISC

86123 86123

86123 86123 86123 86123

45 COVER, SHEAR

86355 86355

86355 86355 86355 86355

46 BEARING, ADJUSTING

86140 86140

86140 86140 86140 86140

47 GRIND, ADJUST PIN

86341 86341

86341 86341 86110 86341

48 GRIND, CAP

87131 86112

87131 87131 86112 87131

49 NUT, 5/8-18 BRASS ADJUST SCREW

86340

86340 86340 86340

50 SCREW, 5/16-18 X 1 THUMB T/S ZINC

86819

86819 86819 86819

51 GRIND SHIFT ASSEMBLY

89003

89003

52 SCREW, 8-32 X 5/8 PH TR M/S ZINC

86899

86899

53 NUT, 8-32 KEPS ZINC PLATED

86810

86810

54 BRACKET, COARSE STOP

86115

86115

55 SCREW, GRIND ADJUST 5/8-18 X 3/8

86 111

86 111

Page 13

115 & 250 Series Coffee Grinders Page 12

Exploded View Parts List - 115V (cont.)

Models 115A, 115AB, 250, 250A, 250AB & 250-3A

Item No. Description 115A 115AB 250 250A 250AB 250-3A

56 NUT, 1/4-20 X 7/16 HEX JAM ZINC PLATED 86892 86892

57 WASHER, FLAT 1/4 - ZINC PLATED 86824 86824

58 SPRING, TENSION 86118 86118

59 SHIFT, ARM 86114 86114

60 SCREW, 1/4-20 X 3/4 THUMB ZINC 86089 86089

61 SOLENOID, GRIND SHIFT 120V 60HZ 86073-01 86073-01

62 SCREW, #8 X 1/4 PH TR HD SMS T/B 410 SS 89116 89116

63 HARNESS, SOLENOID 86048 86048

64 PIN, COTTER 3/32 X 1 ZINC PLATED 86853 86853

65 BRACKET, SOLENOID MTG 86116 86116

66 NUT, 8-32 KEPS ZINC PLATED 86810 86810

67 ASSEMBLY, GRIND SHIFT HINGE A225-28-1 86107 86107

68 SCREW, 8-32 X 3/8 SL BD HD M/S ZINC 86807 86807

69 SCREW, #8 X 1/4 PH TR HD SMS T/B 410 SS 89116 89116 89116 89116 89116 89116

70 SCREW, 5/16-18 X 1 SL FIL HD M/S 86887 86887

71 PLATE, FRONT 86007 86007 86007 86006 86006 86006

72 SWITCH, DECAF / REGULAR ROCKER 86075 86075 86075 86075

73 SWITCH,PORTION ROCKER 86075 86075 86075 86075 83231

74 SWITCH, ROCKER START 83339 83339 83339 83339 83339 83339

75 CAPACITOR, 115V W/ BRACKET 86144 86144 86144 86144 86144 86144

76 SCREW, 8-32 X 1/2 86808 86808 86808 86808 86808 86808

77 SPRING, CHAFF MIXER 86146 86146 86146 86146 86146 86146

77 SPRING, W/ CHAFF SUPPRESSION 86235 86235 86235 86235 86235 86235

78 SCREW, 4-40 X 1/4 PH PN HD ZINC 86148 86148 86148 86148 86148 86148

79 DEFLECTOR 86220 86220 86220 86220 86220 86220

80 GASKET, HOPPER FUNNEL 83105 83105 83105 83105 83105 83105

81 STANDOFF, REVERSE EDGEMOUNT 61266 61266 61266 61266 61266 61266

82 SPOUT 86218 86218 86218 86218 86218 86218

83 SCREW, 8-32 X 3/8 PH RD HD 86217 86217 86217 86217 86217 86217

84 BRACKET, CONTROL BOARD 86038 86038 86038 86038 86038 86038

85 BOLT, 1/4-20 HX HD 86872 86872 86872 86872 86872 86872

86 BUSHING, HEYCO OPEN / CLOSED 86039 86039 86039 86039 86039 86039

87 DIGITAL, TIMER 86138 86138 86138 86138 86138 86138

88 SPRING, BASKET ARM 86508 86508 86508 86508 86508 86508

89 NUT, WHIZLOCK 1/4-20 87049 87049 87049 87049 87049 87049

90 SPACER 87026 87026 87026 87026 87026 87026

91 ARM, BASKET LEFT 71014 71014 71014 71014 71014 71014

92 ARM, BASKET RIGHT 71013 71013 71013 71013 71013 71013

93 SCREW, 5/16 X 1 HEX SOC SHLDR 87024 87024 87024 87024 87024 87024

94 SPACER 87025 87025 87025 87025 87025 87025

95 CASING 86011K 86011K 86012K 86012K 86012K 86012K

96 CIRCUIT BREAKER, 10A 86618 86618 86618 86618 86618 86618

97 POWER CORD, 115VAC 86222 86222 86222 86222 86222

98 STRAIN RELIEF 86071 86071 86071 86071 86071

99 SCREW, #10 X 1/2 PH TR HD T/AB 410 SS 86859 86859 86859 86859 86859

100 PLATE, LOWER FRONT 86003 86003 86003 86003 86003

101 PLATE, SAFETY SHIELD 87032K 87032K 87032K 87032K 87032K 87032K

102 MOTOR MOUNT ASSEMBLY 86995 86995 86995 86995 86995

103 SCREW, 10-32 X 5/16 SL BD HD M/S ZINC 86812 86812 86812 86812 86812

Page 14

Exploded View Parts List - 230V

Models 115A, 115AB, 250, 250A, 250AB & 250-3A

Item No. Description 115A 115AB 250 250A 250AB 250-3A

1 HARNESS, 115/250 A & AB 86037 86037 86037 86037 86037 86037

2 HARNESS, 250 SERIES DIGITAL AUGER 86125 86125 86125 86125

3 HARNESS, DIGITAL SWITCH 86122 86122 86121 86117 86117 86117

4 FOOT, RUBBER 100/250 86034 86034 86034 86034 86034 86034

5 BASE 86309 86309 86309 86309 86309 86309

6 ANGLE BRACKET, GRINDER BASE 88862 88862 88862 88862 88862 88862

7 250 LID ASSEMBLY 89103 89103 89103 89103

8 SCREW, #8 X 3/8 PH PN SMS T/B 410 SS 89113 89113

9 LID, BACK SS 86013 86013

10 SCREW, 6-32 X 1/4 PH PN HD 86801 86801 86801 86801 86801 86801

11 LID, FRONT SS 86014 86014

12 NUT, 6-32 ACORN LOCK 86848 86848 86848 86848 86848 86848

13 HINGE, PLATED 86316 86316

14 PARTITION, HOPPER 86041 86041 86041 86041

15 SCREW, 8-32 1/2 SL BD HD NYLON 86087 86087 86087 86087

16 NUT, 8-32 NYLON LOCK 86086 86086 86086 86086

17 SCREW, #8 X 3/8 PH PN SMS T/B 410 SS 89114 89114

18 HOPPER 86010K 86010K 86010K 86010K 86010K 86010K

19 WINDOW, HOPPER 86102 86102 83152 83152 83152 83152

20 HOPPER, SUPPORT 86008 86008

21 HOPPER 86192 86192

22 FRONT HOPPER SUPPORT 86196K 86196K

23 GASKET, HOPPER 71419 71419

24 SCREW, 8-32 X 3/8" HEX PEM 83143 83143 83143 83143

25 LINK, DRIVE 83368 83368 83368 83368

26 WASHER, NYLON 83141-01 83141-01 83141-01 83141-01

27 HOPPER, AUGER W/ SPOUT 83150 83150 83150 83150

28 ADAPTER, DRIVE 80019 80019 80019 80019

29 SPRING, AUGER 86046 86046 86046 86046

30 FUNNEL, AUGER 83134 83134 83134 83134

31 MOTOR, AUGER 230V 86000 86000 86000 86000

32 BRACKET, MOTOR 86042-01 86042-01 86042-01 86042-01

33 GASKET, HOPPER 83081 83081 83081 83081

34 NUT, TINNERMAN 1/4 - 20 86864 86864 86864 86864 86864 86864

35 MOTOR, 1/2HP 230V 50 HZ 86421 86421 86421 86421 86421 86421

36 SCREW, 8-32 X 3/8 PH TR HD M/S 410 SS 82097 82097 82097 82097 82097 82097

37 HEAD, GRIND 84171S 84171S 84171S 84171S 84171S 84171S

38 COLLAR, THRUST 86304 86304 86304 86304 86304 86304

39 SPRING, TENSION 86118 86118 86118 86118 86118 86118

40 BURR (SET) 85281W 85281W 85281W 85281W 85281W 85281W

41 SCREW, #10-32 X 5/16 86812 86812 86812 86812 86812 86812

42 FEEDWORM 85185T 85185T 85185T 85185T 85185T 85185T

43 DRIVE, SHEAR 86154 86154 86154 86154 86154 86154

44 SHEAR DISC 86123 86123 86123 86123 86123 86123

45 COVER, SHEAR 86355 86355 86355 86355 86355 86355

46 BEARING, ADJUSTING 86140 86140 86140 86140

47 GRIND, ADJUST PIN 86341 86110 86341 86341 86110 86341

48 GRIND, CAP 87131 86112 87131 87131 86112 87131

49 NUT, 5/8-18 BRASS ADJUST SCREW 86340 86340 86340 86340 86340 86340

50 SCREW, 5/16-18 X 1 THUMB T/S ZINC 86819 86819 86819 86819 86819 86819

51 GRIND SHIFT ASSEMBLY 230VAC 89005 89005

52 SCREW, 8-32 X 5/8 PH TR M/S ZINC 61305 61305

53 NUT, 8-32 KEPS ZINC PLATED 86810 86810

54 BRACKET, COARSE STOP 86115 86115

55 SCREW, GRIND ADJUST 5/8-18 X 3/8 86111 8 6111

Page 13 115 & 250 Series Coffee Grinders

Page 15

Exploded View Parts List - 230V (cont.)

Models 115A, 115AB, 250, 250A, 250AB & 250-3A

Item No. Description 115A 115AB 250 250A 250AB 250-3A

56 NUT, 1/4-20 X 7/16 HEX JAM ZINC PLATED 86892 86892

57 WASHER, FLAT 1/4 - ZINC PLATED 86824 86824

58 SPRING, TENSION 86118 86118

59 SHIFT, ARM 86114 86114

60 SCREW, 1/4-20 X 3/4 THUMB ZINC 86089 86089

61 SOLENOID, GRIND SHIFT 230V 50HZ 86534-02K 86534-02K

62 SCREW, #8 X 1/4 PH TR HD SMS T/B 410 SS 89116 89116 89116 89116 89116 89116

63 HARNESS, SOLENOID 86048 86048

64 PIN, COTTER 3/32 X 1 ZINC PLATED 86853 86853 86853 86853 86853 86853

65 BRACKET, SOLENOID MTG 86116 86116

66 NUT, 8-32 KEPS ZINC PLATED 86810 86810

67 ASSEMBLY, GRIND SHIFT HINGE A225-28-1 86107 86107

68 SCREW, 8-32 X 1/2 PH TR ZINC 86809 86809

69 SCREW, #8 X 1/4 PH TR HD SMS T/B 410 SS 89116 89116 89116 89116 89116 89116

70 SCREW, 5/16-18 X 1 SL FIL HD M/S 86819 86819

71 PLATE, FRONT 86007 86007 86007 86006 86006 86006

72 SWITCH, DECAF / REGULAR ROCKER 86075 86075 86075 86075

73 SWITCH,PORTION ROCKER 86075 86075 86075 86075 83231

74 SWITCH, ROCKER START 70445 70445 70445 70445 70445 70445

75 CAPACITOR, 230V W/ BRACKET 86179 86179 86179 86179 86179 86179

76 SCREW, 8-32 X 1/2 86808 86808 86808 86808 86808 86808

77A SPRING 86141 86141 86141 86141 86141 86141

77 SPRING, CHAFF MIXER 86146 86146 86146 86146 86146 86146

77 SPRING, W/ CHAFF SUPPRESSION 86235 86235 86235 86235 86235 86235

78 SCREW, 4-40 X 1/4 PH PN HD ZINC 86148 86148 86148 86148 86148 86148

79 DEFLECTOR 86220 86220 86220 86220 86220 86220

80 GASKET, PROPORTIONER TO HEAD 71419 71419 71419 71419 71419 71419

81 STANDOFF, REVERSE EDGEMOUNT 61266 61266 61266 61266 61266 61266

82 SPOUT 86218 86218 86218 86218 86218 86218

83 SCREW, 8-32 X 3/8 PH RD HD 86217 86217 86217 86217 86217 86217

84 BRACKET, CONTROL BOARD 86038 86038 86038 86038 86038 86038

85 BOLT, 1/4-20 HX HD 86872 86872 86872 86872 86872 86872

86 BUSHING, HEYCO OPEN / CLOSED 86039 86039 86039 86039 86039 86039

87 DIGITAL, TIMER 86139 86139 86139 86139 86139 86139

88 SPRING, BASKET ARM 86508 86508 86508 86508 86508 86508

89 NUT, WHIZLOCK 1/4-20 87049 87049 87049 87049 87049 87049

90 SPACER 87026 87026 87026 87026 87026 87026

91 ARM, BASKET LEFT 71014 71014 71014 71014 71014 71014

92 ARM, BASKET RIGHT 71013 71013 71013 71013 71013 71013

93 SCREW, 5/16 X 1 HEX SOC SHLDR 87024 87024 87024 87024 87024 87024

94 SPACER 87025 87025 87025 87025 87025 87025

95 CASING 86011K 86011K 86012K 86012K 86012K 86012K

96 CIRCUIT BREAKER, 5A 83107 83107 83107 83107 83107 83107

97 POWER CORD, 1.5MM CE 61453 61453 61453 61453 61453 61453

98 STRAIN RELIEF 86071 86071 86071 86071 86071 86071

99 SCREW, 8-32 X 3/8 PH T/H 410SS 82097 82097 82097 82097 82097 82097

100 PLATE, LOWER FRONT 86003 86003 86003 86003 86003 86003

101 PLATE, SAFETY SHIELD 87032K 87032K 87032K 87032K 87032K 87032K

102 MOTOR MOUNT ASSEMBLY 86995 86995 86995 86995 86995 86995

103 SCREW, 10-32 X 5/16 SL BD HD M/S ZINC 86812 86812 86812 86812 86812 86812

104 WASHER, LCK #8 INT ZNC PLTD 86822 86822 86822 86822 86822 86822

115 & 250 Series Coffee Grinders Page 14

Page 16

Page 15 115 & 250 Series Coffee Grinders

Models 250RH-2 and 250RH-3 Exploded View

Page 17

115 & 250 Series Coffee Grinders Page 16

Models 250RH-2 and 250RH-3 Removable Hopper Exploded View

Models 250RH-2 and 250RH-3 Casing Assembly Exploded View

Page 18

Page 17 115 & 250 Series Coffee Grinders

Models 250RH-2 and 250RH-3 Digital Timer Assembly Exploded View

Models 250RH-2 and 250RH-3 Front Plate Assembly Exploded View

Page 19

115 & 250 Series Coffee Grinders Page 18

Models 250RH-2 and 250RH-3 Motor Mount Assembly (120V)

Exploded View

Models 250RH-2 and 250RH-3 Auger Motor Mount Assembly

Exploded View

Page 20

Models 250RH-2 and 250RH-3 Wiring Diagram

Page 19 115 & 250 Series Coffee Grinders

Page 21

115 & 250 Series Coffee Grinders Page 20

115A, 115AB & 250 Series Wiring Diagram 115V

Page 22

115A &115AB/120V Wiring Diagram

Page 21 115 & 250 Series Coffee Grinders

Page 23

115 & 250 Series Coffee Grinders Page 22

115A &115AB/120V Wiring Diagram

Page 24

Grindmaster® Coffee Grinders and Brewers • PrecisionBrew™ Brewing Systems • Espressimo® Espresso Machines

Crathco® Hot Beverage Dispensers • Crathco® Cold and Frozen Beverage Dispensers • AMW Coffee and Tea Systems

Tel (502) 425-4776 • Fax (502) 425-4664 • 1-800-695-4500 (USA & Canada only)

P.O. Box 35020 • Louisville, KY 40232 • USA

www.grindmaster.com • email: info@grindmaster.com

0108 Form # GR-373-04

Part # 85358

© Grindmaster Corporation™, 1998

PRINTED IN USA

Loading...

Loading...