CRYOTherm #4500 Users Manual

Page 1

Description:

The Model 4500 CRYOTherm Single-Tank Console provides comfortable and convenient of cold hydrotherapy.

Water in the tank is precisely maintained at selected temperatures with a hermetic refrigeration system and electronic

temperature control.

Specifications:

Weight / Tanks Empty 1,950 Pounds

Weight / Tanks Full 6,186 Pounds

Tank Dimensions 48” L x 94” W x 28” D

Tank Capacity 508 Gallons

Temperature Range

Tank Construction 12 Gauge, Type 304 Stainless Steel

Exterior Construction Dupont Cameo White Corian

Voltage 208-240/120 Volt, Single Phase, 60 Hertz

Full Load Amperage 28 Amps

Circuit Breaker 2 Pole, 40 Amp, GFI

Refrigeration Capacity 2.25 Ton

Pump 1 HP, Dual Speed

Hydrotherapy Jets Six per Tank

40° F to 60° F

Please read thoroughly before use and retain for later reference

Grimm Scientific Industries, Inc. Tel: 800-223-5395

P.O. Box 2143, Marietta, OH 45750 Fax: 740-374-5745

www.grimmscientific.com e-mail: grimm@ee.net

090205-R0

CRYOTherm #4500 Users Manual

Page 2

Important Safeguards:

The following safety precautions should always be followed when using CRYOTherm.

1. Use CRYOTherm only as directed in this manual. Improper use can cause injury.

2. Do not plug CRYOTherm into any electrical outlet that is not protected by a ground fault interrupter and matches

the voltage and amperage specification.

3. Do not modify the power cord in any way or use with any type extension cord.

4. Maintain CRYOTherm as described in this manual. Improper maintenance can cause injury.

5. Use only Grimm-approved parts or service. Improper parts or service can cause injury.

6. Do not utilize warm or hot water treatment where there is hemorrhaging or swelling.

7. Advise patients to refrain from adjusting controls, and never leave patients alone.

8. Thoroughly clean the tanks with a disinfectant between treatments, particularly after treating open lesions (see

“Maintenance” section of this manual).

9. An antibacterial agent added when filling the tanks helps prevent or reduce infection.

10. Keep loose material (bandages, gauze, washcloths, etc.) out of tanks as they can block pump intakes.

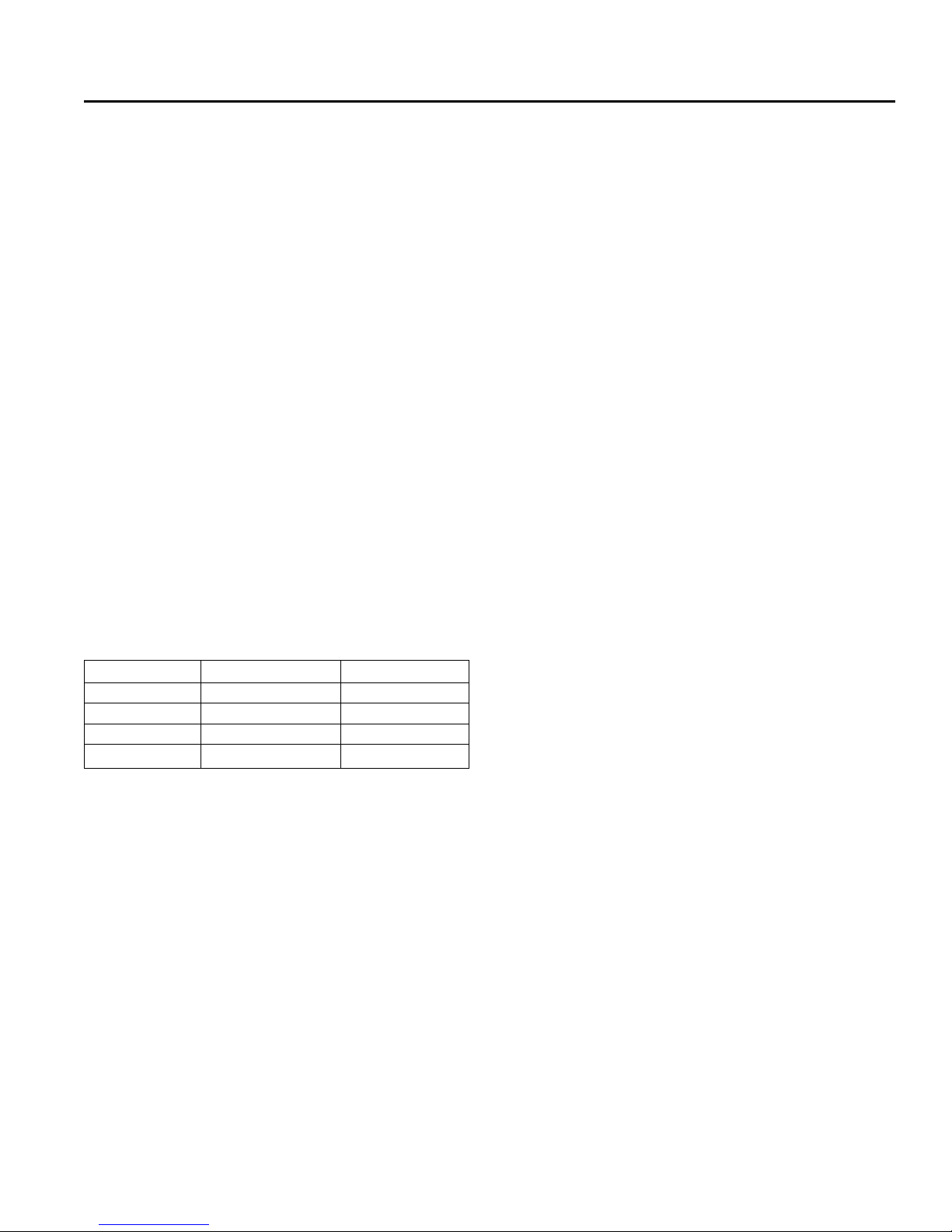

Water Temperature Terminology:

Very Cold

Cold

Warm

Hot

Very Hot

40° F to 55°F 5° C to 13° C

55° F to 60°F 13° C to 16° C

90° F to 98°F 32° C to 37° C

98° F to 104°F 37° C to 40° C

104° F to 110°F 40° C to 43° C

090205-R0

CRYOTherm #4500 Users Manual

actual water temperature to reading the

Page 3

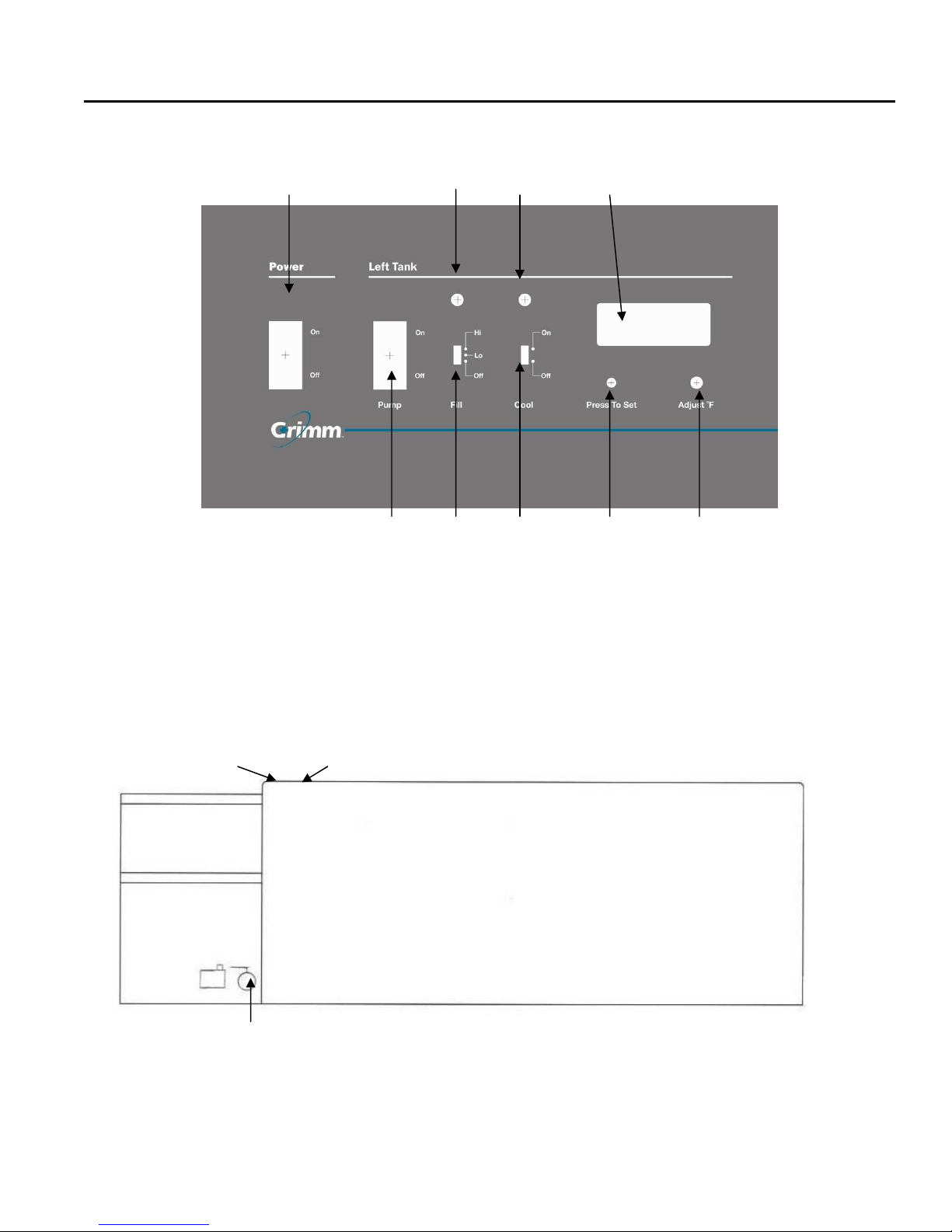

Control Functions:

1 3 6 7

4 2 5 8 9

1. Power Switch - Activates all electrical components.

2. Fill Switch - Activates automatic water level control.

3. Fill LED - Indicates when tank is filling.

4. Pump Switch - Activates dual speed circulation pump.

5. Cool Switch - Activates cooling temperature control.

6. Cool LED - Indicates temperature control is asking for cooling.

7. Digital Display - Displays water temperature and temperature control setting.

8. Press-To-Set Button - Switches digital display from reading the

temperature control setting.

9. Adjust Slot - Adjusts (use small screwdriver supplied) temperature control settings when Press-To-Set button

is pressed.

10 11

12

10. High Speed Button - Switches pump speed from low to high for 20 minutes.

11. Air Control - Controls air supply to hydrotherapy jets while pumps are running.

12. Drain Valve - Manually drains tank. Power switch should be switched off.

090205-R0

CRYOTherm #4500 Users Manual

Page 4

Installation:

1. Site Preparation

The attached Spec Sheet indicates the utilities necessary for installation of the CRYOTherm. Consideration should

also be made for the 6,186-pound load this unit will place on the floor and building structure.

2. Level CRYOTherm

Fifteen 5/8-11 stainless steel hex head leveling feet are provided to give uniform support. Thread these into the frame

before positioning the unit. Place a level on the top Corian surface and level the CRYOTherm.

3. Drain Connections

A 1-1/2-inch copper drain connection is provided. This should be positioned over an open, trapped floor drain with an

adequate air gap. Refer to local plumbing codes for specific requirements.

4. Cold Water Supply Connection

A ¾” NPT connection is provided for connection to the cold water supply. An internal backflow preventer protects the

supply and requires annual inspection. This supply fills the tank and cools the condensing unit.

When the supply pressure fails, the high-pressure cutout on the refrigeration system will trip making it necessary to

press the reset button (see #13 under control functions) after the pressure is restored.

5. Electrical Connection

Power requirements for the Model 4500 CRYOTherm are 208-240/120 volt, single-phase, 60 hertz, 28 amps.

Only plug the CRYOTherm into a voltage-matched NEMA 14-50A 3-pole, 4-wire grounding outlet that is properly

grounded, polarized, and ground-fault-circuit-interrupter (GFCI) protected.

Use professional electrical assistance and follow the National Electrical and local codes as a minimum.

090205-R0

CRYOTherm #4500 Users Manual

Page 5

Operation:

1. Operator Considerations

Operators should have a working knowledge of clinical hydrotherapy and cryotherapy procedures. They should also

have a complete understanding of the procedures described in this manual, the ability to operate the CRYOTherm,

and assist patients.

2. Fill Tanks

If prescribed, add an antibacterial agent to the water at this time. Follow the antibacterial agent manufacturer’s

directions for use.

With Fill, Pump, and Cool switches “Off” on both tanks and drain valves “Closed” press Power Switch to “On”. Now

press Fill switches to “On” and allow water level to rise. An automatic level switch located behind the overflow grille

will control the water level just below the overflow pipe height. These level controls have a ten-second delay with the

under-level condition to avoid valve chatter.

3. Switch Pump “On” and Adjust Hydrotherapy Jets

When tanks are full, turn Air Control Valve to “Min” and press Pump switch to “On”. Pumps will begin circulating the

water. Pump must be left on at all times for proper operation of the temperature control. Without circulation ice will

form on the tank walls.

Tank has six adjustable hydrotherapy jets. When the 1-horsepower, dual-speed pump is switched “On” it circulates

water through these jets in the low-speed mode. Press the black “Hi” button over the Pump switch for high-speed

hydrotherapy. After 20-minutes the pumps will resume low-speed operation automatically. Turn Air Control valve to

“Max” for more vigorous aerated hydrotherapy.

4. Select Temperature

The temperature is adjustable from 40°F to 60°F. To set the temperature press the black Press-To-Set button and

the digital display will switch from reading the water temperature to indicating the set point temperature. Using the

small screwdriver supplied, adjust the set point to the desired temperature. When the button is released, the digital

display will immediately return to reading the actual water temperature. Press the Cool switch to “On” and the

CRYOTherm will seek the set point temperature and control at that point.

5. Patient Loading

CRYOTherm is ergonomically designed to accommodate all size patients and support them either standing in the

tanks or sitting anywhere on the Corian surfaces.

090205-R0

CRYOTherm #4500 Users Manual

Page 6

Maintenance:

1. Clean Regularly

After patient use, clean the tanks thoroughly with a disinfectant and inspect for contaminates, particularly after treating

open lesions.

Note…The entire CRYOTherm should be inspected, cleaned, and disinfected at least once a week.

Caution…When cleaning CRYOTherm wear protective gloves.

2. Disinfection Procedure:

a) Turn Power switch “Off” and drain tanks before disinfection.

b) Apply solution of diluted bleach (1/4 cup bleach to one gallon water) or EPA approved intermediate level

disinfectant with cloth or sponge. Wet surface thoroughly and allow to remain wet for ten minutes.

c) Rinse with clean water to reduce residue of disinfectant on the surfaces to a non-toxic level.

d) Examine tank walls, exterior surfaces, and associated components for damage and visual cleanliness.

3. Culturing

Routine culturing of the tanks should be done. Guidelines for culturing can be obtained through clinical laboratory or

hospital infection control department.

4. Replace Filter:

Filter should be changed following a positive culture or when circulation is impaired.

a) Turn Power switch “Off” and drain tanks before replacing filters.

b) Open top air relief valve and remove drain valve to allow water to drain from filter housing.

c) Remove filter housing top and any collected debris from bottom of the filter housing.

d) Reinstall new filter cartridge in filter housing. Be sure o-ring is in place on threads.

e) Clean o-ring. For ease of future disassembly, apply a very light film of silicone lubricant to o-ring and threads.

f) Screw filter housing with o-ring into filter head. Do not over tighten. Tighten drain valve and top air relief

valve.

090205-R0

CRYOTherm #4500 Users Manual

Page 7

Service:

1. Trouble Shooting

Problem Possible Cause

Nothing happens when Power switch is switched “On”.

Power cord unplugged.

GFCI breaker tripped.

CRYOTherm won’t cool.

Ice forms on tank walls. Pump switch turned “Off”.

Water circulation impaired.

2. One Year Warranty

The CRYOTherm warranty applies to purchaser and any subsequent owner. Grimm Scientific Industries, Inc.

(warrantor) warrants this product to be free from defects in material and workmanship under normal use for one year

from the date the product is shipped. The warrantor may opt to replace the product, rather than repair it. This

warranty does not cover damage resulting from accidents, improper use, or maintenance of this product, and in no

case shall warrantor’s liability exceed the original purchase price paid for the product. This warranty is expressly in

lieu of all other express warranties.

3. Repairs

Should repairs be needed on your CRYOTherm, simply call the factory and ask to speak with a service technician.

We will repair it free during the first year and quote a nominal parts and labor fee after the warranty expires.

4. Inspection & Calibration

Every year a qualified service technician should check the CRYOTherm. Temperature control calibration should be

verified with a certified mercury thermometer, electrical system tested for grounding and leakage current. Grimm can

provide this service.

5. Call 1-800-223-5395

All Grimm products are sold and serviced directly by the factory. Call us toll-free Monday through Friday, 8:00 a.m. to

5: p.m. EDT about your thermal therapy needs. We are often available before and after hours so call us anytime.

Check refrigeration compressor high pressure cut out

reset button.

Check pump suction fittings for debris.

Check filters cartridges.

090205-R0

Loading...

Loading...