Grill-Max 30 SCBDE, 30 SCBD, 30 SCHD, 30 SCHDE, 45 CHD Installation And Operation Instructions Manual

...Page 1

¸

¸

¸

®

ROLLER GRILLS

MODELS

30 CBD, CBDE, CHD, CHDE,

SCBD, SCBDE,SCHD, SCHDE

45 CBD, CHD, SCBD,

SCBDE, SCHD

50 CBD, CBDE,CHD,CHDE,

SCBD, SCBDE, SCHD, CHDE

75 CBD, CBDE, CHD,CHDE,

SCBD, SCBDE, SCHD, SCHDE, SCHDEP

Innite and Electronic Controls

Bun Drawer & Heated Bun Drawer

Installation and

Operation

Instructions

2M-Z9666 Rev. G 3/02/12

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business 8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (314) 678-6303

Fax: (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

TABLE OF CONTENTS

PAGE NUMBER

GENERAL SAFETY INFORMATION 3

GENERAL INSTALLATION INFORMATION 4

Connection Load 4

GENERAL OPERATING INSTRUCTIONS 5

Cleaning 6

ELECTRONICALLY CONTROLLED:

Start-up, Heating & Programing 7

WARRANTY 8

WIRING DIAGRAM 9 - 12

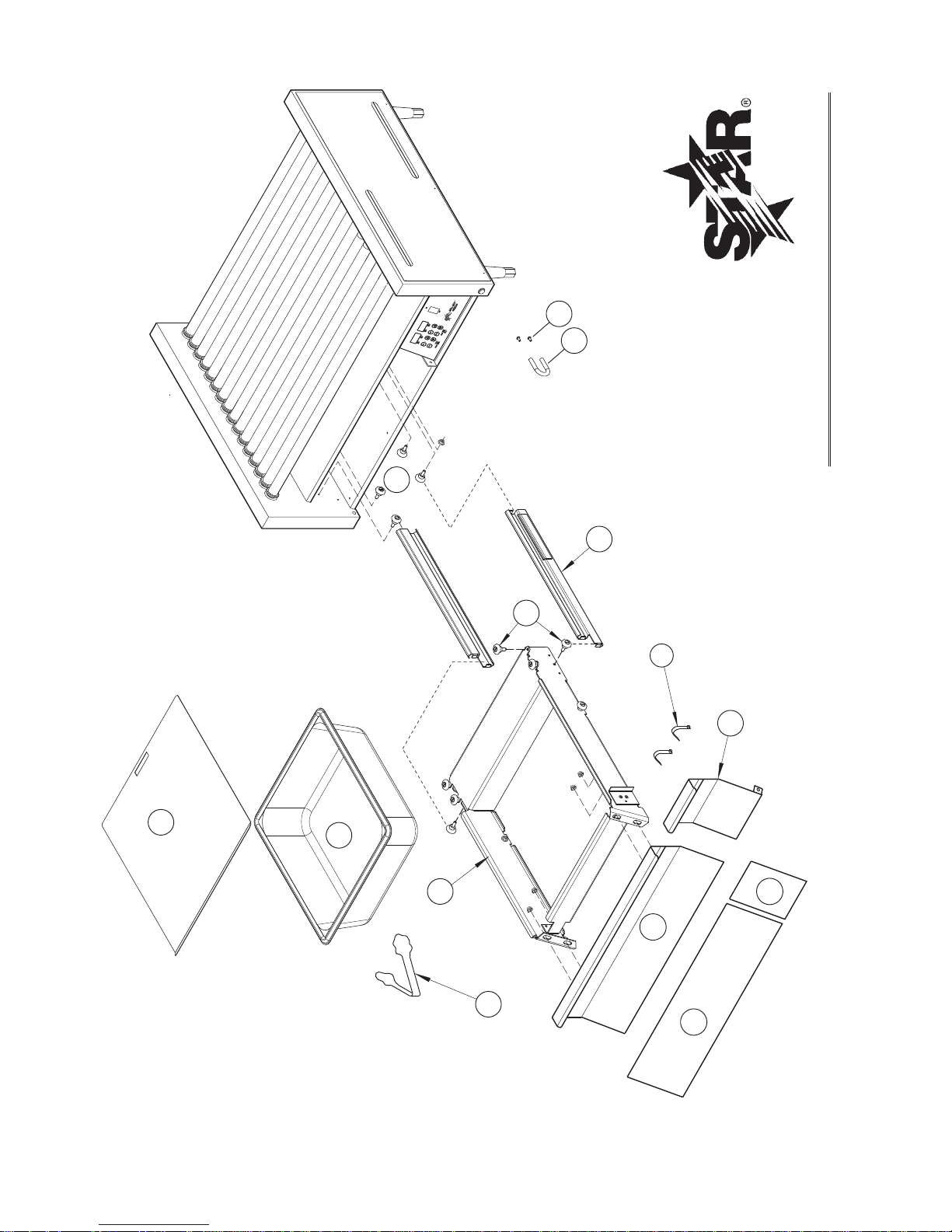

EXPLODED VIEW 14 - 15

PARTS LIST

30 MODEL SERIES 16 - 17

45 MODEL SERIES 18 - 19

50 MODEL SERIES 20 - 21

75 MODEL SERIES 22 - 23

CAUTION

GENERAL SAFETY INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand the

units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This

unit has been tested and carefully packaged to insure delivery of your unit in perfect condition. If

equipment is received in damaged condition, either apparent or concealed, a claim must be made with

the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials for inspection. The carrier will make

an inspection and will supply necessary claim forms.

3

Page 4

GENERAL INSTALLATION INFORMATION

The grill should be connected to a wall type receptacle, a direct line or individual branch circuit. An

individual branch circuit is preferred. If connected to an overloaded circuit the grill will not operate

properly. The unit should be level when installed. Models equipped with bun boxes must be level to

utilize the self-closing feature of the bun drawer. Adjustable 4-inch legs are standard on the 75 series

and available for all other models.

This grill is equipped for the voltage shown on the nameplate. It will operate on alternating current

only, however, the specied voltage must be applied.

CONNECTION LOAD:

INFINITE CONTROL

MODEL SERIES WATTAGE

30CBD, 30SCBD 1150

30CHD, 30SCHD 1230

45CBD, 45SCBD 1650

45CHD, 45SCHD 1730

50CBD, 50SCBD 1535

50CHD, 50SCHD 1635

75CBD, 75SCBD 1730

75CHD, 75SCHD 1830

MODEL SERIES WATTAGE

30CBDE, 30SCBDE 1150

30CHDE, 30SCHDE 1230

45CHDEP 1650

50CBDE, 50SCBDE 1535

50CHDE, 50SCHDE 1635

75CBDE, 75SCBDE 1730

75CHDE, 75SCHDE 1830

75SCHDEP 1920/2560

ELECTRONIC CONTROL

WARNING

DO NOT CONNECT TO DIRECT CURRENT (DC).

IMPORTANT

UNLEVEL UNITS COULD RESULT IN HAVING PRODUCT TRAVEL FROM ONE

SIDE TO THE NEXT, OVER A PERIOD OF TIME.

4

Page 5

GENERAL OPERATING INSTRUCTIONS

For specic information regarding ELECTRONIC GRILL OPERATION see page 7.

The main switch located on the control panel controls all the power to the unit. With the main switch

on, the rollers will turn, heat will be supplied to the bun box, but no heat will be supplied to the rollers

unless the heat controls are turned on. The switch is lighted to indicate when the unit is turned on.

For exibility the heating section of the grill is divided into two individually controlled heat sections.

The right control regulates the heat to the rear section and the left control regulates the heat to the

front section. On Innite control grills a signal light is provided above each heat control and

indicates when the heated section is on. An additional light is provided on the end housing of the unit

that indicates the position of the main power switch.

All units are equipped with an easily removed bun pan which can be removed by lifting out of the

open bun drawer. This makes daily cleaning of the pan easy.

It is necessary to remove the bun drawer before attempting to remove the drip tray when access to

the rear of the unit is obstructed. To remove the bun drawer, rst allow the unit to cool, remove bun

pan, then grab the drawer by both sides and pull it out all the way.

Lift the front to unhook the drawer slide from rear drawer roller. Pull the drawer the remainder of the

way out. Use caution not to drop the drawer when reaching the end of the drawer slide travel.

To reinsert the drawer, rst hook the drawer slide over the rst right side roller then push the drawer

in until the second roller drops in, doing one side at a time. Repeat for left side rollers. Reinsert bun

pan. Do not operate the grill without the drip tray in place.

COOKING

The heat controls provide an innite range of settings for a wide variety of food products and

installation conditions. The size, content and shape of the product and the installation of any sanitary

food shields or sneeze guards will determine the proper heat setting. The National Sanitation

Foundation requires that perishable foods be kept at 140°F or above during

serving periods. Do not keep the food product on a low setting for more than two hours. The product

should be kept refrigerated until ready for use. Cooking time will vary depending on the starting

temperature and the quality of the product. For best results when cooking hot dogs use a hot dog

made for grilling.

Operating the bun drawer requires lling the pan with fresh buns and removing the stale buns as

required. The heated bun drawer is not meant to toast the buns and the temperature is not adjustable.

NO WATER IS REQUIRED OR RECOMMENDED.

CAUTION

CAUTION

USE ONLY PLASTIC OR COATED UTENSILS FOR HANDLING THE FOOD PRODUCT.

METAL WILL SCRATCH THE ROLLER COATING AND AFFECT THE ABILITY TO

CLEAN THE ROLLERS.

INTERNAL DRAWER COMPONENTS & DRAWER CAVITY ARE HEATED. ALLOW THE

DRAWER & CAVITY TO COOL DOWN BEFORE SERVICING OR CLEANING. DO

NOT USE STEEL WOOL OR ABRASIVE CLEANERS ON THE ROLLERS.

SCRAPES WILL VOID THE WARRANTY. USE CAUTION WHEN CLEANING

A HOT GRILL TO PREVENT BURNS OR BODILY INJURY.

5

Page 6

CAUTION

CLEANING

Before cooking for the rst time, wash the rollers with mild soap and water using a soft cloth. Do

not use metal utensils when cooking. Scratches and scrapes will hamper the ability to easily clean

the rollers. Never use steel wool or abrasive cleaners on the rollers. This will damage the nish and

the roller bearings. The rollers clean most easily when hot. Use caution when cleaning to prevent

burns and bodily injury. Clean the rollers with a clean wet cloth. Wipe from the ends to the center to

prevent forcing debris into the roller seals. Do not allow the food product to build up and bake onto

the roller surface. The exterior of the unit should be cleaned using a mild detergent or non-abrasive

cleaner. Clean the entire unit daily to insure long life and satisfactory performance as well as to

maintain an attractive appearance. Do not clean with water jet equipment.

When cleaning the interior bun drawer compartment, remove the bun drawer (see General Operating

Instructions on page 5) and clean with mild detergent and warm water.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a local service company for service or required

maintenance. Replacement cord sets must be purchased from Star Manufacturing International, Inc.

6

Page 7

PAT. # 6,782,802 PAT. # 6,707,015

MADE IN

U.S.A.

PAT. # 6,393,971

Seal-Max

DURATEC

PAT. # 6,782,802 PAT. # 6,707,015

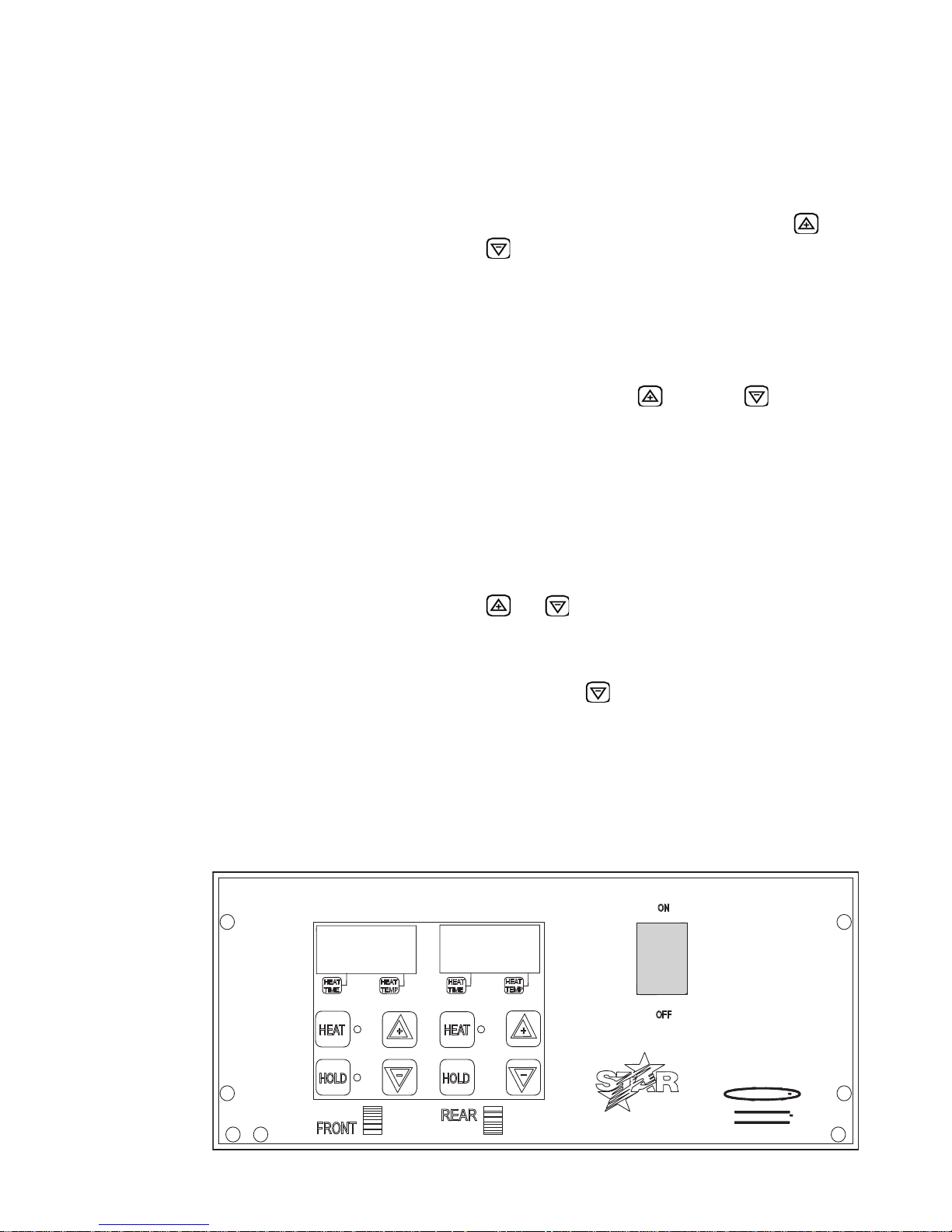

OPERATING PROCEDURES FOR ELECTRONIC GRILLS

START-UP

When initially turning on power to the electronically

controlled grill, it will be in the HOLD mode. The

display will ash until the set point temperature is

reached. The grill will beep once when it is up to

temperature. Innite controlled grills have no notication when operating temperature is reached.

HEATING

The size, content, and shape of the product and the

installation of any sanitary food shields or sneeze

guards will determine the proper heat setting. The

National Sanitation Foundation requires that all

perishable foods be kept at 140°F or above during

serving periods.

The product should be kept refrigerated until ready

to use. Heating times vary depending on the starting

temperature and the qualities of the product. For

best results, use a hot dog made for grilling.

Before cooking for the rst time, wash the rollers

with mild soap and water using a soft cloth. When

the electronic controlled grills are initially turned on,

the displays will ash the HOLD temperature until

the grill reaches that set point.

With the grill preheated to the hold temperature,

load with the desired product and press the HEAT

button. The grill will then go into the heat mode and

the displays will ash until the HEAT temperature is

reached. After the heating cycle, the grill will beep

four times and the food product will be at the serving

temperature.

PROGRAM

The electronic controls provide programmable HEAT

and HOLD settings for a variety of food products and

installation conditions.

To program the electronic roller grill:

1. With the grill on, push and hold the up and down

arrows at the same time, on the side you wish to

program for three seconds until the alarm beeps once

and the display blanks.

2. To set the heat temperature and/or heat time, push the

heat button. The last saved heat time will be displayed

and the HEAT LED will ash and HEAT TIME indicator will

be ON. Use the up and down buttons to adjust

to the desired time, then press the HEAT button again.

The HEAT TIME LED indicator will turn off and the HEAT

TEMP LED indicator will now be on. When programming the HEAT temperature is complete, push the HEAT

button one more time to exit the programming mode.

3.To set the hold temperature, repeat step 1 above then

push the HOLD button. The last saved hold temperature

will be displayed and HOLD LED will be ON. Use the

and buttons to adjust to the desired temperature,

then press the HOLD button again to exit programming

mode.

4.To turn the heat off to the front or rear section, press

and hold the for that section for 3 seconds. "OFF"

will be displayed. To turn the section back on, press the

HEAT or HOLD button.

NOTE:

Based on the product being heated, some

experimentation is required to nd the optimal HEAT

temperature and HEAT time to bring the product up

to temperature in an acceptable amount of time.

7

Page 8

2M-4497-2 10/2010

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of

the unit.

LIMITED EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is chargeable to

the customer.

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

* The Model 510FD Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

Page 9

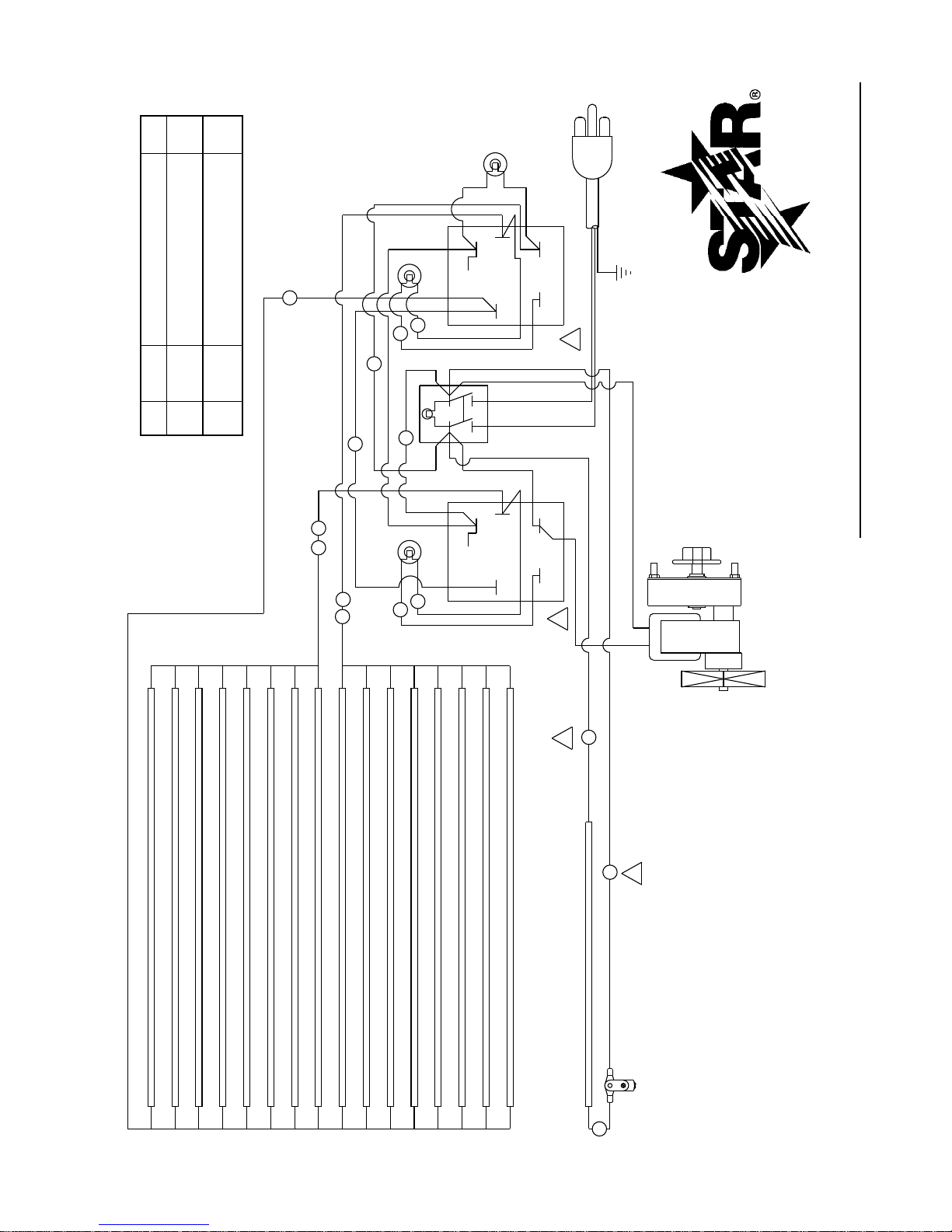

STAR MANUFACTURING INTERNATIONAL INC.

SK2095 Rev B 1/13/2011

75SCHB7-240/120V WIRE DIAGRAM

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

PILOT

H1

L1

H2 H2

PILOT

H1

L1

7

7

L2

3

7

4

7

L2

1

1

2

2

REAR FRONT

F

R

(AS VIEWED FROM REAR OF PANEL)

BUN BOX ELEMENT

4

3

7

B

A

A

B

A

1/04/05

UPDATE WIRING OF WIRES 3 & 4,

REMOVE WIRE NUTS & CE PLUG

RFA

B

1/13/2010

UPDATING PILOT LIGHTS AND

INFINITE CONTROLS

MCT

DESCRIPTION OF CHANGEDATELTR DR

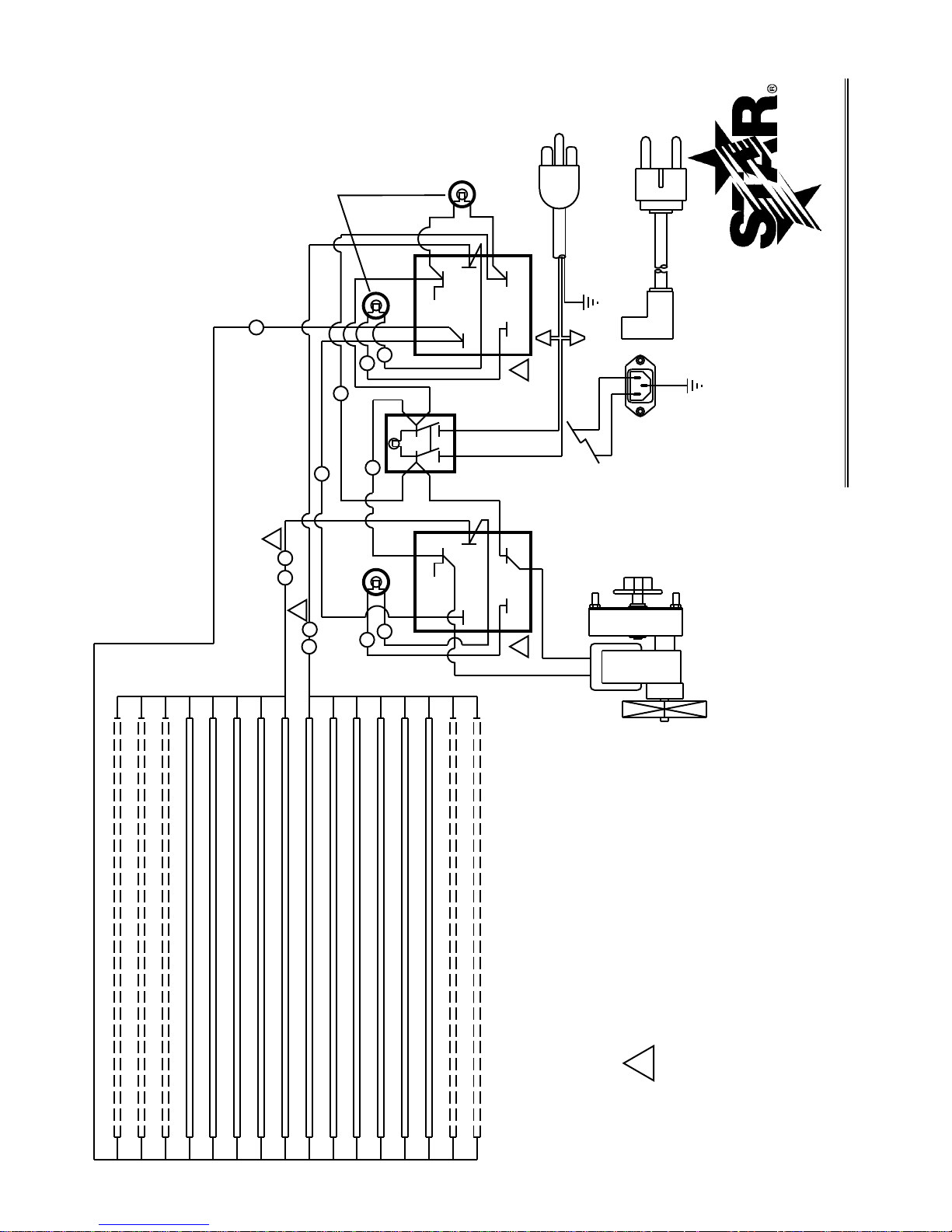

Page 10

ALL MODELS EXCEPT

20, 20S, 30D, 30SD - 230V

MODEL:

RG SERIES, INFINITE CONTROLS

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

STAR MANUFACTURING INTERNATIONAL INC.

SK1646 Rev E

1/13/2011

D

P2

H1

L1

H2 H2

P2

H1

L1

7

7

L2

3

7

4

7

L2

1

1

2

2

REAR FRONT

F

R

B

B

(AS VIEWED FROM REAR OF PANEL)

E E

PILOT

LIGHT

Page 11

NEUTRAL

LINE

FRONT GRILL

REAR GRILL

REAR

FRONT

1

2

3

7

4

F

R

9

F

R

BLACK

WHITE

RIBBON

CABLE

120V AND 240V MODELS

230V MODELS

CONTROL BOARD

POWER BOARD

POWER

SWITCH

SENSOR

BUN BOX ELEMENT

6

10

11

12

MODEL:

RG SERIES, HEATED BUN BOX,

ELECTRONIC CONTROLS

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

STAR MANUFACTURING INTERNATIONAL INC.

SK2171 Rev A

5/08/2006

5

8

PILOT LIGHT

MOTOR

Page 12

NEUTRAL

LINE

FRONT GRILL

REAR GRILL

REAR

FRONT

1

2

6

3

7

4

F

R

9

F

R

BLACK

WHITE

120V AND 240V MODELS

230V MODELS

CONTROL BOARD

POWER BOARD

POWER

SWITCH

SENSOR

5

8

PILOT LIGHT

MOTOR

MODEL:

RGE SERIES,

ELECTRONIC CONTROLS

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

STAR MANUFACTURING INTERNATIONAL INC.

SK1913 Rev A

5/08/2006

Page 13

1

3

4

41

42

38

37

9

18

17

20

10

13

MOUNT SPRING BETWEEN

FRAME & ARM HOLES

14

5

35

2

8

12

11

39

56

57

40

11

10

15

16

6

7

5

32

22

36

33

34

23

31

30

24

INFINITE CONTROLS

ELECTRONIC CONTROLS

NAMEPLATE

43

40

19

33

31

30

25

REFER TO THE PARTS LIST SPECIFIC TO YOUR MODEL FOR MORE DETAIL INFORMATION.

STAR MANUFACTURING INTERNATIONAL INC.

SK2180 Rev. C 11/28/2011

27

26

Page 14

48

52

53

54

55

46

50

51

49

58

59

REFER TO THE PARTS LIST SPECIFIC TO YOUR MODEL FOR MORE DETAIL INFORMATION.

STAR MANUFACTURING INTERNATIONAL INC.

SK2181 9-15-11

47

45

47

Page 15

PARTS LIST March 2, 2012, Rev G

Grill-Max Roller Grills

30 HD/BD Series

Key

Number

1 A5-RG30106 1 BODY ASSY ALL

2 A5-Z2185 1 DRIP TRAY ALL

3 A5-Z8409 1 BACK-CHAIN RETAINER SPACER ALL

4 A5-Z8410 1 ANGLE CHAIN RETAINER UPPER ALL

5 A5-Z2169 2 SIDE PANEL ALL

6 2N-Z2178 11 ELEMENT 120V 30/45 120V

2N-Z2194 11 ELEMENT 230V 30/45 230V

7 A5-Z6719 1 CHAIN GUIDE ALL

8 2P-Z2242 1 CHAIN ALL

9 PS-RG3077 11 ROLLER ASSY CHROME ALL

PS-RG3078 11 ROLLER ASSY POLY (HI-GRIP) ALL

10 2P-Z8392 3 IDLER SPROCKET ALL

11 2A-Z8017 3 BUSHING, IDLER ALL

12 A5-RG2042 1 ARM ASSY- CHAIN TENSIONER ALL

13 2P-Z8074 1 EXTENSION SPRING ALL

14 2P-Z8317 1 MOTOR SPROCKET ALL

15 PS-RG5069 1 KIT MOTOR 120V 120V

PS-RG5070 1 KIT MOTOR 230V 30/45 230V

16 A5-RG2046 1 MOTOR MOUNTING ASSY ALL

17 A5-RG2036 1 CORD ASSY 120V 120V

2E-Z0512 1 CORD SET EUR 10AMP 230V

A5-RG50111 1 CORDSET AY, CEE 7-7 30SCHD-230V

18 2K-Y3240 1 CORD BUSHING ALL

19 2K-8043 1 BUSHING HEYCO SB-875-10 120V

2E-Y9227 1 CORD INLET IEC320 10 AMP 230V

20 A5-Z5335 1 BOTTOM COVER PLATE ALL

21 2P-Z1540 2 HOLE PLUG, 5/16” DIA. ALL

22 A5-Z9344 1 MOUNTING BRACKET ALL

23 2J-Z2195 2 CONTROL 120V

2J-Z2192 2 CONTROL 230V

24 2K-Z1971 9 SPACERS 30CBDE/CHDE/SCBDE/SCHDE

25 PS-RG5087 1 KIT 2E-Z5565 REPLACEMENT, 120V/240V 30CBDE/CHDE/SCBDE/SCHDE,

2E-Z13638 1 ELECTRONIC CONTROL, RG 120V 30CBDE/CHDE/SCBDE/SCHDE,

A5-Z13640 1 ELECTRONIC CONTROL, RG 230/240V 230/240V

26 PS-RG5093 1 KIT SERVICE, FRONT PROBE REPL 30CBDE/CHDE/SCBDE/SCHDE,

2J-Z13632 1 THERMISTOR, FRONT, .250 DIA. 30CBDE/CHDE/SCBDE/SCHDE,

27 2J-Z13633 1 THERMISTOR, REAR, .125" DIA 30CBDE/CHDE/SCBDE/SCHDE

30 A5-Z9519 1 CONTROL PANEL 30CBD/SCBD/CHD/SCHD

A5-Z9523 1 CONTROL PANEL 30CBDE/CHDE/SCBDE/SCHDE

31 2M-Z9628 1 CONTROL PANEL LABEL 30CBD/CHD

2M-Z9626 1 CONTROL PANEL LABEL 30SCBD/SCHD

2M-Z9627 1 CONTROL PANEL LABEL 30CBDE/CHDE

2M-Z9625 1 CONTROL PANEL LABEL 30SCBDE/SCHDE

32 2J-Z2329 3 PILOT LIGHT RED 30CBD/SCBD/CHD/SCHD

2J-Z2329 1 PILOT LIGHT RED 30CBDE, 30CHDE

2J-Z3157 3 PILOT LIGHT YELLOW 30CBD 230V

33 2E-Z1858 1 SWITCH-RED LIGHTED ALL

2E-Z3156 1 SWITCH-YELLOW LIGHTED 30CBD 230V

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

manf before 11/2010

manf after 11/2010

manf before 11/2010

manf after 11/2010

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

1

2

Page 16

PARTS LIST March 2, 2012, Rev G

Grill-Max Roller Grills

30 HD/BD Series

MODEL

Key

Number

34 2R-Z1854 2 KNOB W/SET SCREW 30CBD/SCBD/CHD/SCHD

35 A5-Z2509 4 PANEL-INSULATOR ALL

36 2P-Z6455 22 TUBE SEAL, SOLID ALL

37 2I-Z2175 22 ORING SEAL ALL

38 2P-Z2174 22 TUBE GUIDE ALL

39 2R-Z5846 4 FOOT-ROLLER GRILLS ALL

40 2K-Z2895 2 ANTI SHORT BUSHING ALL

41 A5-Z7650 1 ELEMENT RETAINER - UPPER ALL

42 A5-Z7656 1 ELEMENT RETAINER - LOWER 30CBD/SCBD/CHD/SCHD

A5-RG30139 1 ELEMENT RETAINER ASSY - LOWER 30CHDE/SCHDE/CBDE/SCBDE/

43 2N-Z2181 1 ELEMENT BUN BOX 30CHD/CHDE/SCHD/SCHDE

44 2T-Z8346 1 THERMOSTAT 115F-RG W/HB 30CHD/CHDE/SCHD/SCHDE

45 2P-Y9176 2 SNAP-BUTTON ALL

46 A5-RG30110 1 CONTROL PANEL DOOR ASSY ALL

47 2P-Z0315 12 DRAWER ROLLER, BEARING ALL

48 A5-RG30109 1 BUN DRAWER FRAME ASSY ALL

49 2R-Z9393 1 SET 14” DRAWER SLIDES ALL

50 2D-Z5898 1 PAN 2/3 X 4” DEEP ALL

51 A5-Z9538 1 PAN COVER, BUN BOX 30CHD/CHDE/SCHD/SCHDE

52 2P-Z0584 1 TONGS ALL

53 A5-RG30105 1 BUN DRAWER DOOR ASSY ALL

54 2M-Z9397 1 LABEL, DRAWER ALL

55 2M-Z9398 1 LABEL, CONTROL PANEL DOOR ALL

56 2C-Z5182 1 SCREW, THUMB-1/4-20 X 1/2 30CHDE/SCHDE/CBDE/SCBDE/

57 A5-Z13072 1 HD ELEMENT GUARD 30CHDE/SCHDE/CBDE/SCBDE/

NI 2E-Z8414 1 WIRE SET 30CBDE/SCBDE

NI 2E-Z9386 1 WIRE SET 30CHDE/SCHDE

NI 2E-Z8320 1 WIRE SET 30CBD/SCBD

NI 2E-Z8118 1 WIRE SET 30CHD/SCHD

NI PS-Z3018 -- TUBE ASSEMBLY SLEEVE

Part

Number

Per

Unit

Description & Model Designation

CHDE/SCHDE

CHDE/SCHDE

CHDE/SCHDE

Number

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

2

2

Page 17

PARTS LIST November 28, 2011, Rev G

Grill-Max Roller Grills

45 HD/BD Series

Key

Number

1 A5-RG4562 1 BODY ASSY ALL

2 A5-Z2186 1 DRIP TRAY ALL

3 A5-Z8411 1 BACK-CHAIN RETAINER SPACER ALL

4 A5-Z8412 1 ANGLE CHAIN RETAINER UPPER ALL

5 A5-Z2265 2 SIDE PANEL ALL

6 2N-Z2178 16 ELEMENT 120V 30/45 ALL

2N-Z2194 16 ELEMENT 230V 30/45 230V

7 A5-Z6615 1 CHAIN GUIDE - LOWER ALL

8 2P-Z2266 1 CHAIN ALL

9 PS-RG3077 16 ROLLER ASSY CHROME ALL

PS-RG3078 16 ROLLER ASSY POLY (HI-GRIP) ALL

10 2P-Z8392 3 IDLER SPROCKET ASSEMBLY ALL

11 2A-Z8017 3 BUSHING, IDLER ALL

12 A5-RG2042 1 ARM ASSY- CHAIN TENSIONER ALL

13 2P-Z8074 1 EXTENSION SPRING ALL

14 2P-Z8317 1 MOTOR SPROCKET ALL

15 PS-RG5069 1 GEAR MOTOR 120V ALL

16 A5-RG2063 1 MOTOR MOUNTING ASSY ALL

17 2E-Z0512 1 CORD SET EUR 10AMP 230V

A5-RG2036 1 CORD ASSY 120V ALL

A5-RG2041 1 CORD SET ASSY 120V CSA 120VC

18 2K-Y2968 1 BUSHING - HEYCO 7W-2 120VC

2K-Y3240 1 CORD BUSHING ALL

19 2K-8043 1 BUSHING HEYCO SB-875-10 ALL

20 A5-Z5335 1 BOTTOM COVER PLATE ALL

22 A5-Z9344 1 MOUNTING BRACKET ALL

23 2J-Z2192 2 INFINITE CONTROL 240V 230V MANUAL

2J-Z2195 2 INFINITE CONTROL 120 VOLT ALL MANUAL

PS-RG3091 1 SERVICE KIT,RG CNTL PB/PR 45SCHDE

24 2K-Z1971 9 SPACERS 45SCHDE

25 2E-Z13638 1 ELECTRONIC CONTROL, RG 120V 45SCHDE, manufactured after

A5-Z13640 1 ELECTRONIC CONTROL, RG 230/240V 230/240V

PS-RG5087 1 KIT 2E-Z5565 REPLACEMENT, 120/240V 45SCHDE, manufactured before

26 2J-Z13632 1 THERMISTOR, FRONT, .250 DIA. 45SCHDE, manufactured after

PS-RG5093 1 KIT SERVICE, FRONT PROBE REPL 45SCHDE, manufactured before

27 2J-Z13633 1 THERMISTOR, REAR, .125" DIA 45SCHDE

30 A5-Z9519 1 CONTROL PANEL ALL

31 2M-Z9628 1 LABEL, CONTROL PANEL INFINITE ALL

32 2J-Z2329 3 PILOT LIGHT RED ALL

2J-Z3157 3 PILOT LIGHT YELLOW 230V

33 2E-Z1858 1 SWITCH-RED LIGHTED ALL

2E-Z3156 1 SWITCH-YELLOW LIGHTED 230V

34 2R-Z1854 2 KNOB W/SET SCREW ALL

35 A5-Z2510 4 PANEL-INSULATOR ALL

36 2P-Z6455 32 TUBE SEAL, SOLID ALL

37 2I-Z2175 32 ORING SEAL ALL

38 2P-Z2174 32 TUBE GUIDE ALL

39 2R-Z5846 4 FOOT-ROLLER GRILLS ALL

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

11/2010

11/2010

11/2010

11/2010

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 2

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

Page 18

PARTS LIST November 28, 2011, Rev G

Grill-Max Roller Grills

45 HD/BD Series

Key

Number

40 2K-Z2895 2 ANTI SHORT BUSHING ALL

2K-Z2895 3 ANTI SHORT BUSHING 230V

41 A5-Z6619 1 ELEMENT RETAINER - UPPER ALL

42 A5-Z6622 1 ELEMENT RETAINER - LOWER ALL

43 2N-Z2181 1 ELEMENT BUN BOX 120V 45CH/SCH

44 2T-Z8346 1 THERMOSTAT 115F-RG W/HB 45CH

45 2P-Y9176 2 SNAP-BUTTON ALL

46 A5-RG30110 1 CONTROL PANEL DOOR ASSY ALL

47 2P-Z0315 12 DRAWER ROLLER W/SCREW ALL

48 A5-RG30109 1 BUN DRAWER FRAME ASSY ALL

49 2R-Z9393 1 SET 14” DRAWER SLIDES ALL

50 2D-Z5898 1 PAN 2/3 X 4” DEEP ALL

51 A5-Z9538 1 PAN COVER, BUN BOX 45CH/SCH

52 2P-Z0584 1 TONGS ALL

53 A5-RG30105 1 BUN DRAWER DOOR ASSY ALL

54 2M-Z9397 1 LABEL, DRAWER ALL

customer provided 1 LABEL, DRAWER 45SCBDEP, 45SCBDE4P

55 2M-Z9398 1 LABEL, CONTROL PANEL DOOR ALL

customer provided 1 LABEL, CONTROL PANEL DOOR 45SCBDEP, 45SCBDE4P

56 2C-Z5182 1 SCREW, THUMB-1/4-20 X 1/2 45CH/SCH

57 A5-Z11753 1 HD ELEMENT GUARD 30/45 45CH/SCH

58 2V-Z13052 1 TONG HOLDER CERTAIN MODELS

59 2C-1512 2 SCREW 10X24X3/8 RHP STL CERTAIN MODELS

NI 2E-Z8118 1 WIRE SET 45CHD/SCHD

NI 2E-Z8320 1 WIRE SET 45CBD/SCBD

NI PS-Z3018 -- TUBE ASSEMBLY SLEEVE ALL

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

2

2

Page 19

PARTS LIST September 15, 2011, Rev G

Grill-Max Roller Grills

50 HD/BD Series

Key

Number

1 A5-RG5053 1 BODY ASSY ALL

2 A5-Z2305 1 DRIP TRAY ALL

3 A5-Z8409 1 BACK-CHAIN RETAINER SPACER ALL

4 A5-Z8410 1 ANGLE CHAIN RETAINER UPPER ALL

5 A5-Z2169 2 SIDE PANEL ALL

6 2N-Z2179 11 ELEMENT 120V 50

2N-Z2193 11 ELEMENT 230V 230V, 230/5

7 A5-Z6719 1 CHAIN GUIDE ALL

8 2P-Z2242 1 CHAIN ALL

9 PS-RG7562 11 ROLLER ASSY CHROME ALL

PS-RG7563 11 ROLLER ASSY POLY (HI-GRIP) ALL

PS-RG7598 11 ROLLER ASSY POLY (SMOOTH) 50SCBDESW

10 2P-Z8392 3 IDLER SPROCKET ASSEMBLY ALL

11 2A-Z8017 3 BUSHING, IDLER ALL

12 A5-RG2042 1 ARM ASSY- CHAIN TENSIONER ALL

13 2P-Z8074 1 SPRING ALL

14 2P-Z8317 1 MOTOR SPROCKET ALL

15 PS-RG5069 1 MOTOR-120 VOLT KIT

PS-RG5070 1 MOTOR-230 VOLT KIT 230V

A5-Z14583 1 MOTOR, 240V, 50 HZ 50SCBD-230/5

16 A5-RG2046 1 MOTOR MOUNTING ASSY ALL

17 2E-Z0512 1 CORD SET , CONT. EUR 10A 230V

A5-RG2036 1 CORD ASSY 120V 50CBDE/CHDE/SCHDE/SCBDE-120V

A5-RG2041 1 CORD SET ASSY 120V 50CBD/SCBD/CHD/SCHD/SCBDE-CSA

18 2E-Y9227 1 INLET IEC320 10 AMP 230V, 230/5

2K-Y3240 1 CORD BUSHING ALL

2K-Y2968 1 BUSHING - HEYCO 7W-2 SCBDE-CSA

19 2K-8043 1 BUSHING HEYCO SB-875-10 ALL

20 A5-Z5335 1 BOTTOM COVER PLATE ALL

22 A5-Z9344 1 MOUNTING BRACKET ALL

23 PS-RG5095 2 INFINITE CONTROL 240V 230V

2J-Z2195 2 INFINITE CONTROL 120V 50CHD/CBD/SCHD/SCBD

PS-RG3091 1 ELECTRONIC CONTROL 120V 50CBDE/CHDE/SCBDE/SCHDE

24 2K-Z1971 9 SPACERS 50CBDE/CHDE/SCBDE/SCHDE

25 PS-RG5087 1 KIT 2E-Z5565 REPL, 120/240V 50CBDE/CHDE/SCBDE/SCHDE

manufactured before 11/2010

2E-Z13638 1 ELECT CONTROL, RG 120V 50CBDE/CHDE/SCBDE/SCHDE

manufactured after 11/2010

A5-Z13640 1 ELECT CONTROL, RG 230/240V 230/240V

26 PS-RG5093 1 KIT SERVICE, FRNT PROBE REPL 50CBDE/CHDE/SCBDE/SCHDE

manufactured before 11/2010

2J-Z13632 1 THERMISTOR, FRONT, .250 DIA. 50CBDE/CHDE/SCBDE/SCHDE

manufactured after 11/2010

27 2J-Z13633 1 THERMISTOR, REAR, .125" DIA 50CBDE/CHDE/SCBDE/SCHDE

30 A5-Z9392 1 CONTROL PANEL 50CHD/CBD/SCHD/SCBD

A5-Z9526 1 CONTROL PANEL BDE/HDE 50CBDE/CHDE/SCBDE/SCHDE

31 2M-Z9613 1 CONTROL PANEL LABEL 50SCBDE/SCHDE

2M-Z9614 1 CONTROL PANEL LABEL 50CBDE/CHDE

2M-Z9615 1 CONTROL PANEL LABEL 50SCHD/SCBD

2M-Z9616 1 CONTROL PANEL LABEL 50CHD/CBD

32 2J-Z2329 1 PILOT LIGHT RED 50CBDE/CHDE/SCBDE/SCHDE

2J-Z2329 3 PILOT LIGHT RED 50CHD/CBD/SCHD/SCBD

2J-Z3157 3 PILOT LIGHT 250V AMBER 230V, 230/5

33 2E-Z1858 1 SWITCH-RED LIGHTED ALL

2E-Z3156 1 SW DPST 20A/125V ORG LGHT 230V, 230/5

34 2R-Z1854 2 KNOB W/SET SCREW 50CHD/CBD/SCHD/SCBD

35 A5-Z2509 4 PANEL-INSULATOR ALL

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

1

2

Star Manufacturing International, Inc.

Page 20

PARTS LIST September 15, 2011, Rev G

Grill-Max Roller Grills

50 HD/BD Series

Key

Number

36 2P-Z6455 22 TUBE SEAL, SOLID ALL

37 2I-Z2175 22 ORING SEAL ALL

38 2P-Z2174 22 TUBE GUIDE ALL

39 2R-Z5846 4 LEGS ALL

40 2K-Z2895 2 ANTI SHORT BUSHING

2K-Z2895 3 ANTI SHORT BUSHING 230V, 230/5

41 A5-Z7650 1 ELEMENT RETAINER - UPPER ALL

42 A5-RG30139 1 ELEMENT RET + THERM MOUNT 50CBDE/CHDE

A5-Z7656 1 ELEMENT RETAINER - LOWER 50CHD/CBD/SCHD/SCBD

43 2N-Z2178 1 ELEMENT, BUN BOX 120V 50CHD/CHDE/SCHD/SCHDE

2N-Z2194 1 ELEMENT, BUN BOX 230V 230V

44 2T-Z8346 1 THERMOSTAT 115F-RG W/HB 50CHD/CHDE/SCHD/SCHDE

45 2P-Y9176 2 SNAP BUTTONS ALL

2P-Y9176 4 SNAP BUTTONS 50SCBDESW120

46 A5-RG5047 1 CONTROL PANEL DOOR ASSY ALL

47 2P-Z0315 12 DRAWER ROLLER W/SCREW ALL

48 A5-RG5048 1 BUN DRAWER FRAME ASSY ALL

49 2R-Z9393 1 SET 14” DRAWER SLIDES ALL

50 2D-Z5899 1 PAN FULL X 4” DEEP ALL

51 A5-Z9539 1 HD PAN COVER 50CHD/CBD/SCHD/SCBD

52 2P-Z0584 1 TONGS ALL

2P-Z0584 3 TONGS 50SCBDESW120

53 A5-RG5046 1 BUN DRAWER DOOR ASSY ALL

54 2M-Z9395 1 LABEL, DRAWER ALL

customer provided 1 LABEL, DRAWER 50SCBDEP, 50SCBDE4P

55 2M-Z9396 1 LABEL, CONTROL PANEL DOOR ALL

customer provided 1 LABEL, CONTROL PANEL DOOR 50SCBDEP, 50SCBDE4P

56 2C-Z5182 1 SCREW, THUMB-1/4-20 X 1/2 50CHD/CHDE/SCHD/SCHDE

57 A5-Z13072 1 HD ELEMENT GUARD 30/45 50CHD/CHDE/SCHD/SCHDE

58 2V-Z13052 1 TONG HOLDER CERTAIN MODELS

59 2C-1512 2 SCREW 10X24X3/8 RHP STL CERTAIN MODELS

NI 2E-Z8118 1 WIRE SET 50CHD/SCHD

NI 2E-Z8320 1 WIRE SET 50CBD/SCBD

NI 2E-Z8414 1 WIRE SET 50CBDE/SCBDE

NI 2E-Z9386 1 WIRE SET 50CHDE/SCHDE

NI PS-Z3018 -- TUBE ASSEMBLY SLEEVE

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

2

2

Page 21

PARTS LIST May 31, 2011, Rev G

Grill-Max Roller Grills

75 HD/BD Series cont'd

Key

Number

1 A5-RG7580 1 BODY ASSY ALL

2 A5-Z2306 1 DRIP TRAY ALL

3 A5-Z8411 1 BACK-CHAIN RETAINER SPACER ALL

4 A5-Z8412 1 ANGLE CHAIN RETAINER UPPER ALL

5 A5-Z2265 2 SIDE PANEL ALL

6 2N-Z2193 16 ELEMENT 230V 50/75 240V, CE50

2N-Z2982 16 ELEMENT 120V 105 W 120V

7 A5-Z6615 1 CHAIN GUIDE ALL

8 2P-Z2266 1 CHAIN ALL

9 PS-RG7562 16 ROLLER ASSY CHROME

PS-RG7563 16 ROLLER ASSY POLY (HI-GRIP)

PS-RG7598 16 ROLLER ASSY POLY (SMOOTH) 75SCBDESW

10 2P-Z8392 3 IDLER SPROCKET ALL

11 2A-Z8017 3 BUSHING, IDLER ALL

12 A5-RG2042 1 ARM ASSY- CHAIN TENSIONER ALL

13 2P-Z8074 1 EXTENSION SPRING ALL

14 2P-Z8317 1 MOTOR SPROCKET ALL

15 PS-RG5070 1 GEAR MOTOR 240V

PS-RG5069 1 GEAR MOTOR 120V

A5-Z14583 1 MOTOR, 240V, 50 HZ 75SCBDE-CE50

16 A5-RG2046 1 MOTOR MOUNTING ASSY ALL

17 A5-RG2034 1 CORD SER 240V W/TERMINALS 240V

A5-RG2041 1 CORD ASSY 120V 120V

2E-Y9251 1 CORD SET CONT EEUR 16AMP 75SCBDE-CE50

18 2K-Y3240 1 CORD BUSHING ALL

19 2K-8043 1 BUSHING HEYCO SB-875-10 ALL

20 A5-Z5335 1 BOTTOM COVER PLATE ALL

22 A5-Z9344 1 MOUNTING BRACKET ALL

23 2J-Z2192 2 CONTROL 230/240 VOLT 240V

2J-Z2195 2 CONTROL 120 VOLT 120V

24 2K-Z1971 9 SPACERS 75CBDE/CHDE/SCBDE/SCHDE

25 PS-RG5087 1 KIT 2E-Z5565 REPL, 120/240V 75CBDE/CHDE/SCBDE/SCHDE,

manufacture before 11/2010

25 2E-Z13638 1 ELCTRN CONTROL, RG 120V 75CBDE/CHDE/SCBDE/SCHDE

manufactured after 11/2010

25 A5-Z13640 1 ELCTRN CONTROL, RG 230/240V 75CBDE/CHDE/SCBDE/SCHDE

manufactured after 11/2010

26 PS-RG5093 1 KIT SRV, FRONT PROBE REPL 75CBDE/CHDE/SCBDE/SCHDE,

manufacture before 11/2010

2J-Z13632 1 THERMISTOR, FRONT, .250 DIA. 75CBDE/CHDE/SCBDE/SCHDE

manufactured after 11/2010

27 2J-Z13633 1 THERMISTOR, REAR, .125" DIA 75CBDE/CHDE/SCBDE/SCHDE

30 A5-Z9526 1 CONTROL PANEL 75CBDE/CHDE/SCBDE/SCHDE

A5-Z9392 1 CONTROL PANEL 75CBD/CHD/SCBD/SCHD

31 2M-Z9616 1 CONTROL PANEL LABEL 75CHD/CBD

2M-Z9615 1 CONTROL PANEL LABEL 75SCHD/SCBD

2M-Z9614 1 CONTROL PANEL LABEL 75CBDE/CHDE

2M-Z9613 1 CONTROL PANEL LABEL 75SCBDE/SCHDE

32 2J-Z2329 1 PILOT LIGHT RED 75CBDE/CHDE/SCBDE/SCHDE

2J-Z2329 3 PILOT LIGHT RED 75CBD/CHD/SCBD/SCHD

2J-Z3157 1 PILOT LT 250V AMBER NEON 75SCBDE-CE50

33 2E-Z1858 1 SWITCH-RED LIGHTED ALL

2E-Z3156 1 SW DPST 20A/125V ORG LIGHT 75SCBDE-CE50

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Part

Number

MODEL

Number

Per

Unit

Description & Model Designation

1

2

Star Manufacturing International, Inc.

Page 22

PARTS LIST May 31, 2011, Rev G

Grill-Max Roller Grills

75 HD/BD Series cont'd

Key

Number

34 2R-Z1854 2 KNOB W/SET SCREW 75CBD/CHD/SCBD/SCHD

35 A5-Z2510 4 PANEL-INSULATOR ALL

36 2P-Z6455 32 TUBE SEAL, SOLID ALL

37 2I-Z2175 32 ORING SEAL ALL

38 2P-Z2174 32 TUBE GUIDE ALL

39 2R-Y5092 4 LEGS 4”, BLACK PLASTIC ALL

40 2K-Z2895 2 ANTI SHORT BUSHING ALL

2K-Z2895 3 ANTI SHORT BUSHING 240V, 75SCBDE-CE50

41 A5-Z6619 1 ELEMENT RETAINER - UPPER ALL

42 A5-RG4582 1 ELEMENT RET + THERM MOUNTS 75CBDE/CHDE/SCBDE/SCHDE

A5-Z6622 1 ELEMENT RETAINER - LOWER 75CBD/CHD/SCBD/SCHD

43 2N-Z2178 1 ELEMENT, BUN BOX 120V 75CHD/CHDE/SCHD/SCHDE

44 2T-Z8346 1 THERMOSTAT 115F-RG W/HB 75CHD/CHDE/SCHD/SCHDE

45 2P-Y9176 2 SNAP BUTTON ALL

46 A5-RG5047 1 CONTROL PANEL DOOR ASSY ALL

47 2P-Z0315 12 DRAWER ROLLER W/SCREW ALL

48 A5-RG5048 1 BUN DRAWER FRAME ASSY ALL

49 2R-Z9393 1 SET 14” DRAWER SLIDE ALL

50 2D-Z5899 1 PAN FULL X 4” DEEP ALL

51 A5-Z9539 1 HD PAN COVER 50/75 75CHD/CHDE/SCHD/SCHDE

52 2P-Z0584 1 TONGS ALL

2P-Z0584 3 TONGS 75SCBDESW120

53 A5-RG5046 1 BUN DRAWER DOOR ASSY ALL

54 2M-Z9395 1 LABEL, DRAWEE ALL

55 2M-Z9396 1 LABEL, CONTROL PANEL DOOR ALL

56 2C-Z5182 1 SCREW, THUMB-1/4-20 X 1/2 75CHD/CHDE/SCHD/SCHDE

57 A5-Z13072 1 HD ELEMENT GUARD 30/45 75CHD/CHDE/SCHD/SCHDE

NI 2E-Z8414 1 WIRE SET 75CBDE/SCBDE

NI 2E-Z9386 1 WIRE SET 75CHDE/SCHDE

NI 2E-Z8320 1 WIRE SET 75CBD/SCBD

NI 2E-Z8118 1 WIRE SET 75CHD/SCHD

NI PS-Z3018 -- TUBE ASSEMBLY SLEEVE

NI 2E-Y9253 1 INLET IEC 320 16 AMP 75SCBDE-CE50

Number

Part

MODEL

Number

Per

Unit

Description & Model Designation

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Star Manufacturing International, Inc.

2

2

Page 23

Page 24

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Loading...

Loading...