GrillMaster 720-0783 User Manual

ITEM / ARTÍCULO / RÉF # 30237516

LP GAS GRILL (pages 1-25)

PARRILLA A GAS LP (página 26-50)

GRIL AU GAZ DE PÉTROLE

LIQUÉFIÉ (page 51-75)

MODEL / MODELO / MODÈLE # 720-0783

WARNING

To reduce the risk of fire, burn hazard or other injury,

read the manual carefully and completely before

using your grill.

WARNING

FOR OUTDOOR USE ONLY.

Version No. 19000373A2

Note to Consumer/Nota para el usuario/Note destinée à l’utilisateur

Leave this Owner’s Manual in a convenient place for future reference.

Deje este Manual del Usuario en un lugar conveniente para referencia en el futuro.

Rangez ce manuel de l’utilisateur dans un endroit pratique pour une consultation future.

Example only: SERIAL # ________ MFG. DATE ________ PURCHASE DATE: _________

Questions, problems, missing parts? Before returning to your retailer, call our customer service

department at 1-800-648-5864, 8 a.m. - 5 p.m., EST, Monday – Friday.

Visit our website at: www.grillmasterbbqs.com

WARNING

This grill is not intended to be installed in or on

recreational vehicles and/or boats.

®

vicinity of this or any other

Table of Contents

vicinity of this or any other

Warranty----------------------------------------------Precautions-------------------------------------------Package Contents List-----------------------------Hardware Contents---------------------------------Preparation-------------------------------------------Parts Diagram ---------------------------------------Parts List-----------------------------------------------Assembly Instructions------------------------------Lighting Instructions--------------------------------Cleaning and Maintenance-----------------------Troubleshooting-------------------------------------Cooking Instructions--------------------------------Grill Cooking Chart----------------------------------

2

2-4

5-6

7

7

8

9

10-19

20-21

22

23

24

25

Grill Warranty

One-Year Limited Warranty on stainless steel and

other parts.

If this grill fails due to a defecting material or

workmanship within one year from the date of

purchase, call 1-800-648-5864 to arrange for free

repair (or replacement if repair proves impossible).

For five years from the date of purchase, any

stainless steel burner that rusts through will be

replaced free of charge. After the first year from the

date of purchase, you pay for labor if you wish to

have it installed.

All warranty coverage excludes igniter batteries and

grill part paint loss, discoloration or rusting, which are

either expendable parts that can wear out from

normal use within the warranty period, or are

conditions that can be the result or normal use,

accident or improper maintenance.

All warranty coverage is void if this grill is ever used

for commercial or rental purposes.

All warranty coverage applies only if this grill is used

in Canada.

GrillMaster® logo is a registered trademark of

Sunbeam Products, Inc. used under license.

Precautions

!

WARNING

Failure to comply with these instructions could

result in a fire or explosion that could cause

serious bodily injury, death, or property damage.

WARNING

!

Your grill will get very hot. Never lean over the

cooking area while using your grill. Do not touch

cooking surfaces, grill housing, lid or any other

grill parts while the grill is in operation, or until the

gas grill has cooled down after use.

Failure to comply with these instructions may

result in serious bodily injury.

!

WARNING

1. Do not store or use gasoline or

other flammable liquids or

vapors in the vicinity of this or

any other appliance.

2. An LP cylinder not connected for

use shall not be stored in the

appliance.

DANGER

!

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away

from the appliance and

immediately call your gas

supplier or your fire department.

Grill Installation Codes

The installation must conform with local codes or,

in the absence of local codes, with either the

national fuel gas code, ANSI Z 223.1/NFPA S4,

Natural gas and propane installation code, CSA

B149.1, or propane storage and handling code,

B149.2, or the standard for Recreational vehicles,

ANSI A 119.2, and CSA Z240 RV series

recreational vehicle code, as applicable.

LP gas grill models are designed for use with a

standard 20 lb. Liquid Propane Gas tank, not

included with grill. Never connect your gas grill to

an LP gas tank that exceeds this capacity.

2

Precautions

dust cap on the cylinder valve outlet that is

A tank of approximately 12 inches in diameter by 18-1/2

inches high is the maximum size LP gas tank to use.

You must use an OPD gas tank which offers an

Overfill Prevention Device.

This safety feature prevents the tank from being

overfilled which can cause malfunction of the LP gas

tank, pressure regulator and/or grill.

The LP gas tank must be constructed and marked in

accordance with specifications of the U.S. Dept. of

Transportation (DOT). In Canada, the LP gas tank must

meet the National Standard of Canada ,CAN/CSA-B339 ,

Cylinders, spheres and Tubes for Transportation of

Dangerous Goods and Commission .

1. The LP gas tank must have a shutoff valve,

terminating in an LP gas supply tank valve outlet, that is

compatible with a Type 1 tank connection device. The LP

gas tank must also have a safety relief device that has a

direct connection with the vapor space of the tank.

2. The tank supply system must be arranged for vapor

withdraw.

3. The LP gas tank used must have a collar to protect the

tank valve.

Have your LP gas tank filled by a reputable

propane gas dealer and visually inspected and requalified at each filling.

Do not store a spare LP gas tank under or near

this appliance.

Never fill the tank beyond 80 percent full. If this

information is not followed exactly a fire causing

death or serious injury may occur.

Always keep LP gas tanks in an upright position.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this gas grill.

Do not subject the LP gas tank to excessive heat.

Never store an LP gas tank indoors. If you store

your gas grill in the garage or other indoor

location, always disconnect the LP gas tank first

and store it safely outside.

Always keep the LP cylinder at

90° (upright) orientation to

provide vapor withdraw.

Place dust cap on cylinder valve outlet whenever

the cylinder is not in use. Only install the type of

Proper Placement and Clearance of Grill

Never use your gas grill in a garage, porch, shed,

breezeway or any other enclosed area. Your gas grill is

to be used outdoors only, at least 24 inches from the

back and side of any combustible surface. Your gas grill

should not be used under overhead combustible

construction . Do not obstruct the flow of ventilation air

around the gas grill housing.

Do not install this outdoor gas grill in or on recreational

vehicles or boats.

Keep outdoor gas grill area clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

Do not obstruct the flow of combustion and ventilation

air. Check for this each time prior to using grill.

Never connect an unregulated LP gas tank to your gas

grill. The gas pressure regulator assembly supplied

with your gas grill is adjusted to have an outlet

pressure of 11” water column (W.C.) for connection to

an LP gas tank.

Only use the pressure regulator and the hose

assembly supplied with your gas grill. Replacement

pressure regulators and hose assemblies must be

those specified in this manual.

provided with the cylinder valve. Other types of

caps or plugs may result in leakage of propane.

LP gas tanks must be stored outdoors in a well-

ventilated area and out of reach of children.

Disconnected LP gas tanks must not be stored in

a building, garage or any other enclosed area.

When your gas grill is not in use the gas must be

turned off at the LP gas tank.

The pressure regulator and hose assembly must

be inspected before each use of the grill. If there

is excessive abrasion or wear or if the hose is cut,

it must be replaced prior to the grill being used

again.

Keep the gas pressure regulator hose away from

hot grill surfaces and dripping grease. Avoid

unnecessary twisting of hose. Visually inspect the

hose prior to each use for cuts, cracks, excessive

wear or other damage. If the hose appears

damaged do not use the gas grill. Call 1-800-6485864 for a replacement hose.

Never light your gas grill with the lid closed or

before checking to ensure the burner tubes are

fully seated over the gas valve orifices.

Never allow children to operate your grill.

3

WARNING

connected to your grill. For help with this procedure

connected to your grill. For help with this procedure

!

A strong gas smell, or the hissing sound of gas

indicates a serious problem with your gas grill or

the LP gas tank. Failure to immediately follow the

steps listed below could result in a fire or

explosion that could cause serious bodily injury,

death, or property damage.

Shut off gas supply to the gas grill.

Turn the control knobs to OFF position.

Put out any flame with a proper fire

extinguisher.

Open grill lid.

Get away from the LP gas tank.

Do not try to fix the problem yourself.

If odor continues or you have a fire you can not

extinguish, call your fire department. Do not call

near the LP gas tank because your telephone is

a form of electrical device and could create a

spark resulting in fire and/or explosion.

NOTE: The normal flow of gas through the pressure

regulator and hose assembly can create a humming

noise. A low volume of noise is perfectly normal and

will not interfere with operation of the grill. If humming

noise is loud and excessive you may need to purge

air from the gas line or reset the pressure regulator

excess gas flow device. This purging procedure

should be done every time a new LP gas tank is

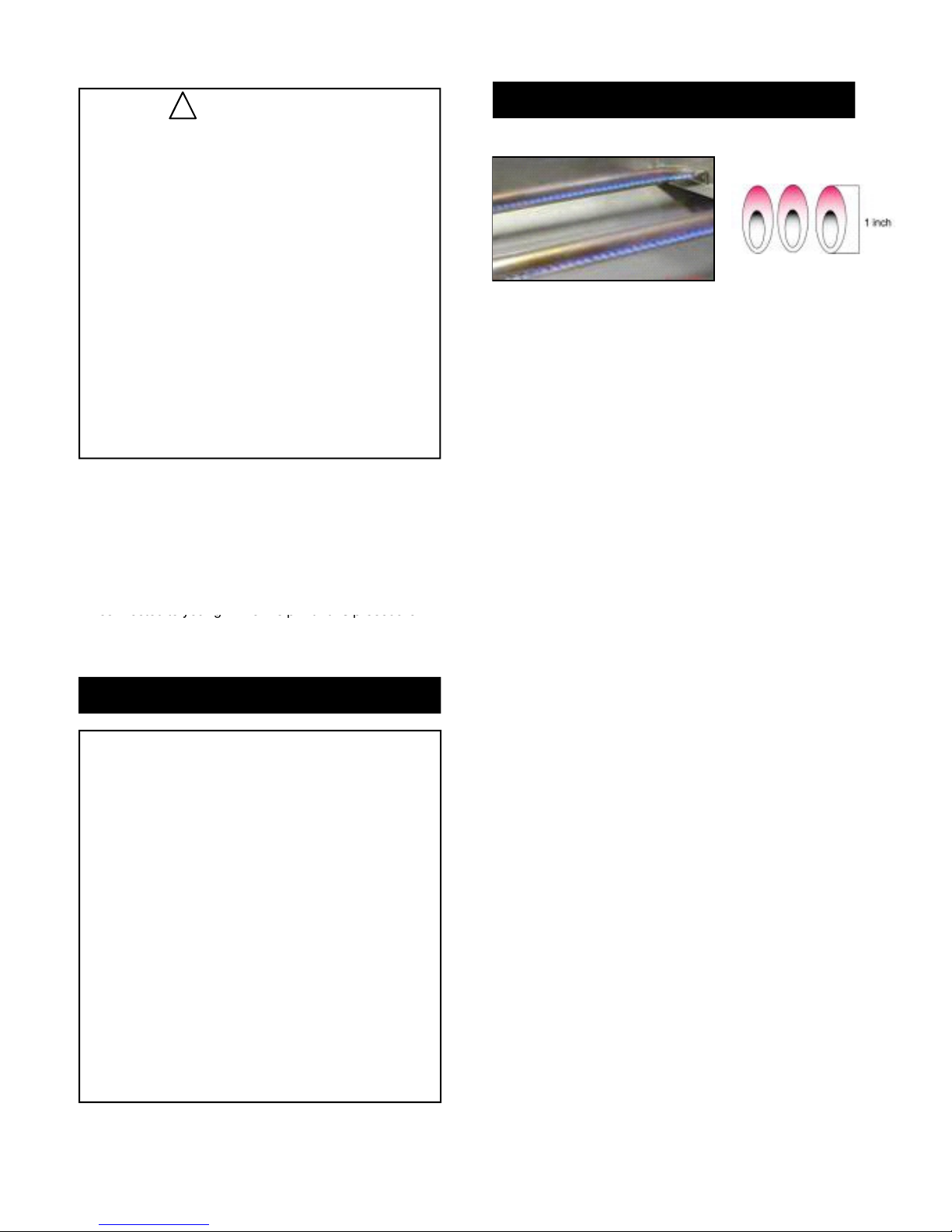

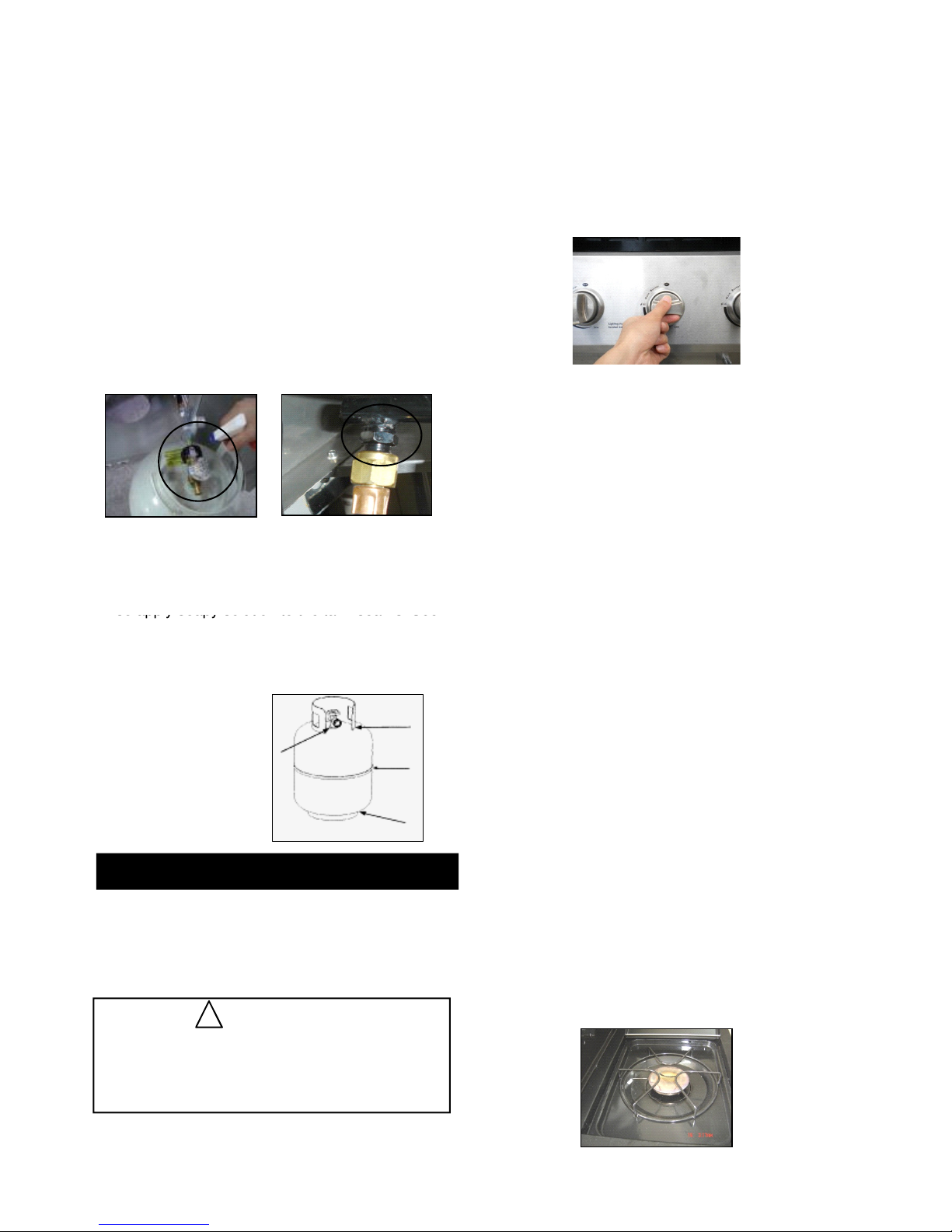

Burner Flame Check

Visually check the burner flames prior to each use. The

flames should look like picture, if they do not, refer to the

Cleaning Burner Tubes and Burner Ports, see page 22 of

this manual.

refer to page 20, item 4 of “If Grill Still Fails To Light”,

or call the Grill Information Center at 1-800-648-5864.

CAUTION: Beware of Flash-Back

CAUTION: Spiders and small insects occasionally

spin webs or make nests in the grill burner tubes

during transit and warehousing. These webs can lead

to gas flow obstruction which could result in a fire in

and around burner tubes. This type of fire is known as

“FLASH-BACK” and can cause serious damage to

your grill and create an unsafe operating condition for

the user.

Although an obstructed burner tube is not the only

cause of “FLASH-BACK”, it is the most common

cause.

To reduce the chance of “FLASH-BACK”, you must

clean the burner tubes before assembling your grill,

and at least once a month in late summer or early fall

when spiders are most active. Also perform this burner

tube cleaning procedure if your grill has not been used

for an extended period of time.

See Cleaning Burner Tubes and Burner Ports on page

22.

4

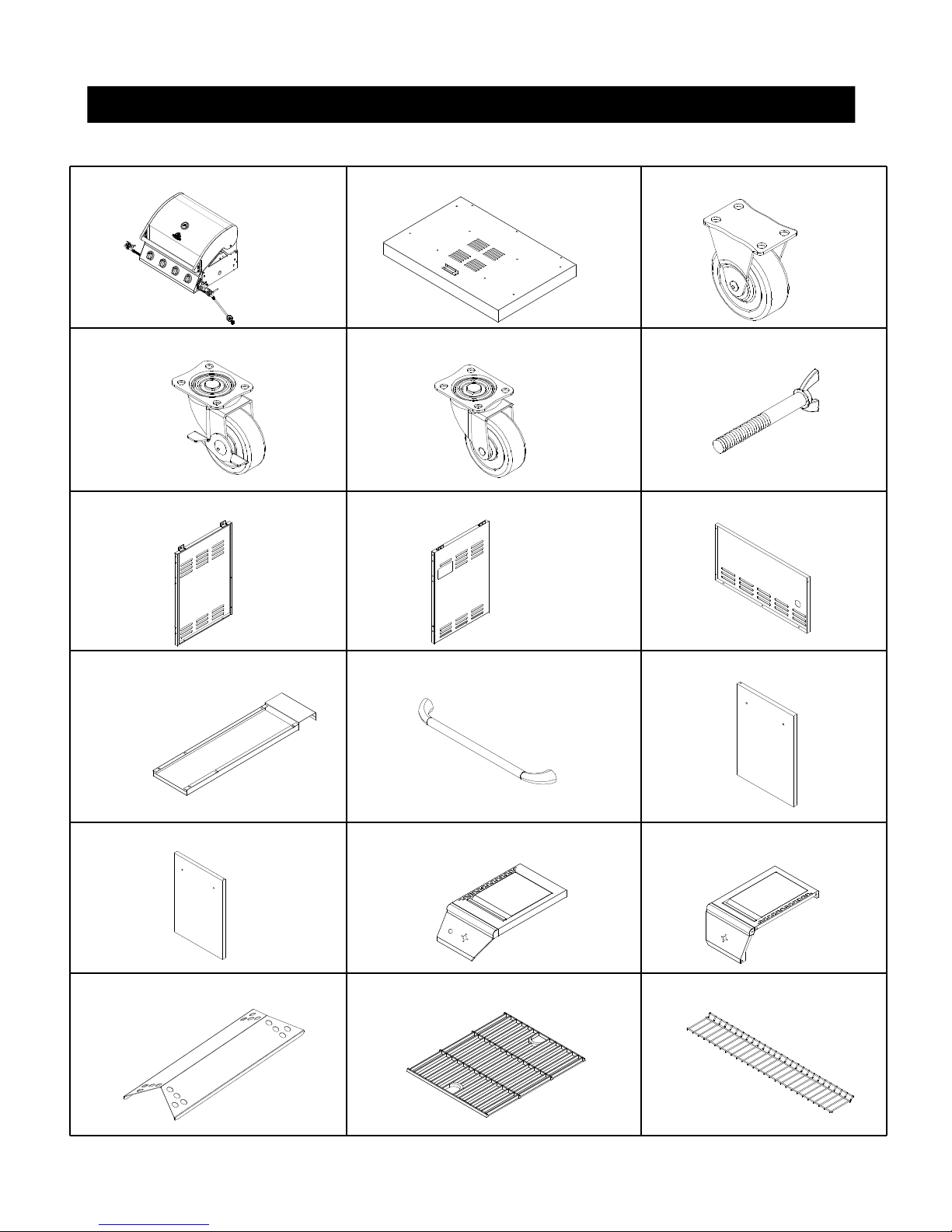

Package Contents List

A. Firebox --- 1pc. B. Bottom Panel --- 1pc. C. Caster --- 2pcs.

D. Swivel Caster with Brake --- 1pc. E. Swivel Caster --- 1pc. F. Tank Tray Bolt --- 1pc.

G. Side Panel, Left --- 1pc. H. Side Panel, Right --- 1pc. I. Back Panel --- 1pc.

J. Sear Side Burner Grease Tray --1pc.

M. Door Right --- 1pc. N. Regular Side Burner Bowl Assembly

K. Door Handle --- 2pcs. L. Door, Left --- 1pc.

Frame with Side Burner Control Panel

--- 1pc.

O. Left Sear Side Burner with

Side Shelf Front Panel --- 1pc.

P. Heat Diffuser --- 4pcs. R. Cooking Grid --- 2pcs. S. Warming Rack --- 1pc.

5

T. Bezel --- 2pcs. U. Control Knob --- 2pcs. V. AA Size Alkaline ---1pc.

W. Grease Tray --- 1pc. X. Grease Cup --- 1pc. Y. Manual Lighting Stick --- 1pc.

Z. Cart Frame --- 1pc. A1. Sear Side Burner Cooking

Grid --- 1pc.

C1. Regular Burner Cooking --- 1pc. D1. Triangle Bracket, Right ---

1pc.

B1. Gas Tank Tray --- 1pc.

E1. Triangle Bracket, Left --- 1pc.

6

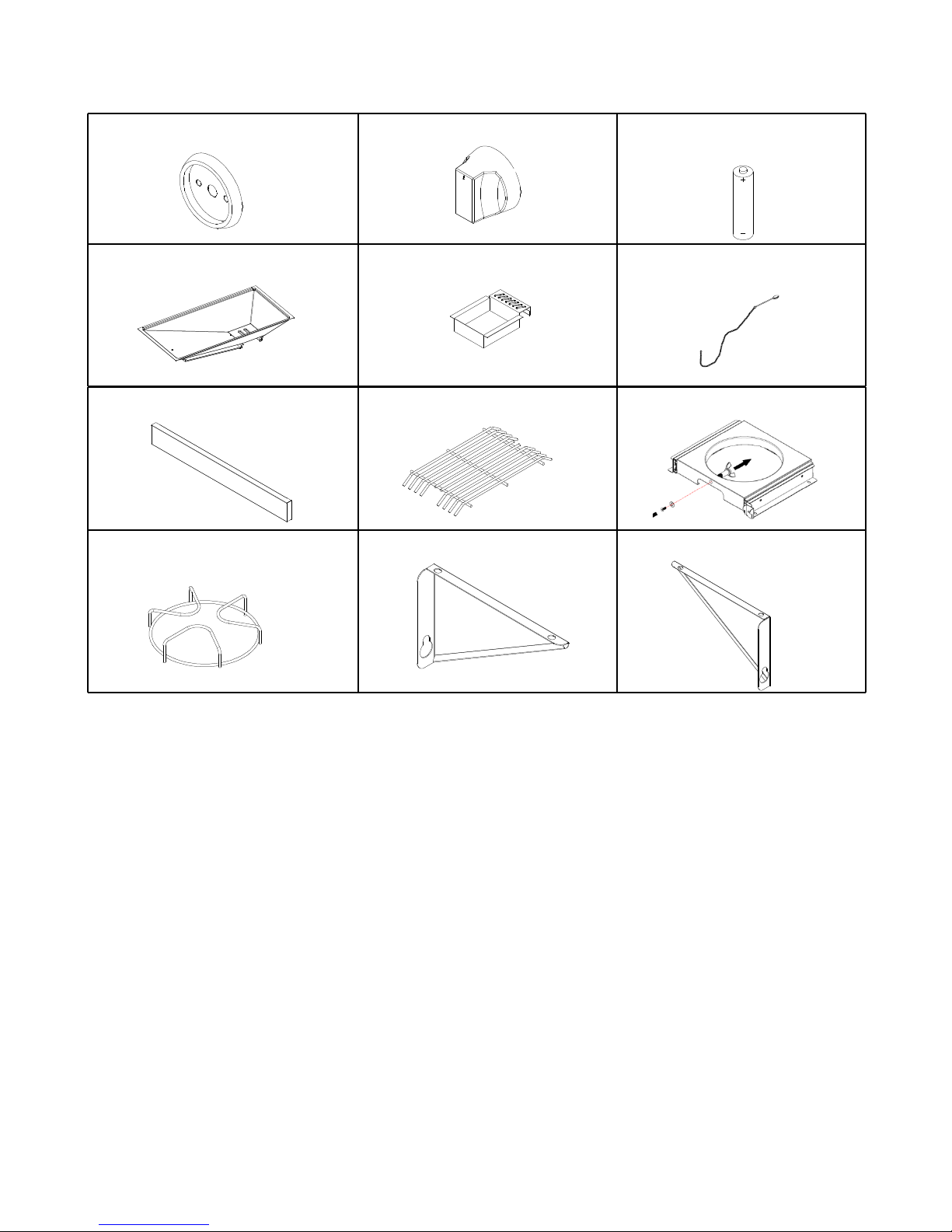

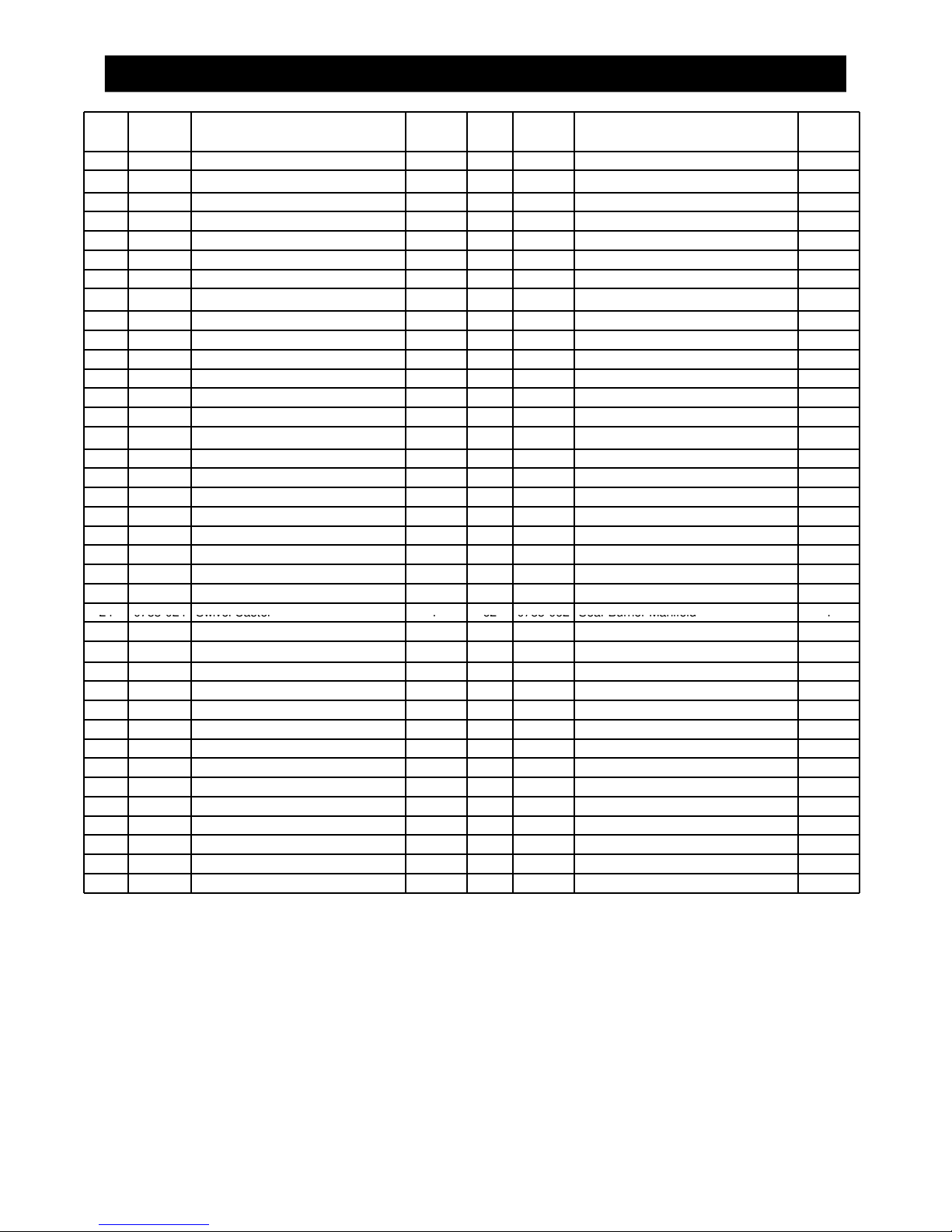

Hardware Contents

Item Description Specification Quantity

Truss Head Screw

AA 1/4'' x 15mm

24pcs.

Truss Head Screw

BB

1/4'' x 10mm 4pcs.

Truss Head Screw

CC 5/32'' x 8mm 27pcs.

Flat Head Screw

DD 5/32'' x 8mm

8pcs.

Lock Washer

20pcs.EE 1/4''

Lock Washer

FF 5/32'' 11pcs.

Preparation

Before beginning assembly, make sure all parts are present. Compare parts with package contents list and

diagram above. If any part is missing or damaged, do not attempt to assemble the product. Contact

customer service at 1-800-648-5864 for replacement parts.

• Tools required for assembly:

Phillips Screwdriver (not included) and Hex Wrench (not included).

Phillips Screwdriver Hex Wrench

• Note: The left and right sides of the grill are on your left and right as you face the front of the grill.

7

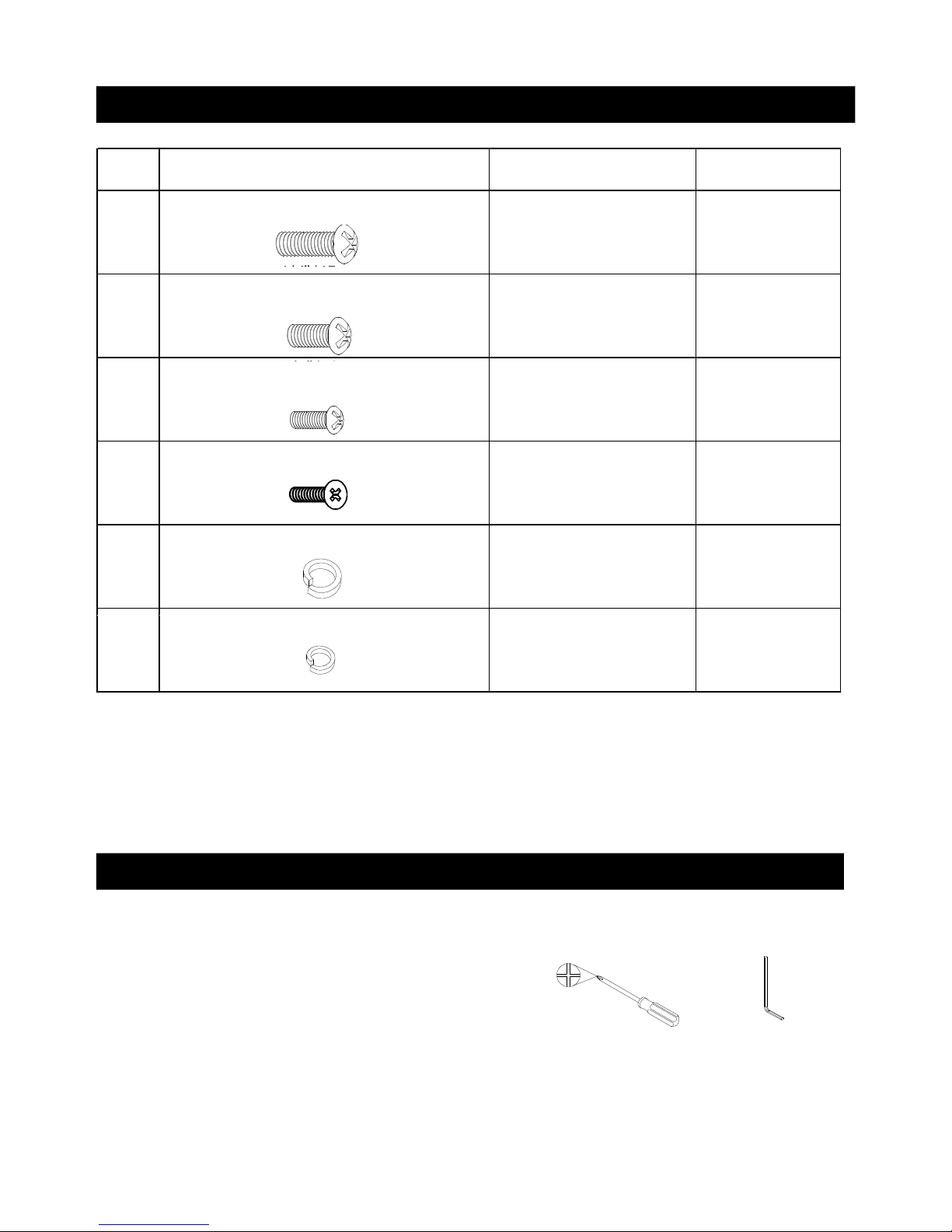

Parts Diagram

4

3

5

0

1

1

1

8

1

7

4

3

5

0

1

1

1

8

1

7

0

3

0

0

7

0

5

0

9

0

8

1

6

0

6

5

1

1

8

1

9

6

2

0

7

1

5

6

0

0

7

6

2

1

5

5

8

4

0

1

6

0

2

5

9

0

6

4

0

6

1

4

1

0

0

7

4

5

3

5

2

5

1

3

7

0

7

6

5

7

5

6

4

5

5

0

6

4

5

9

4

8

4

7

4

6

0

1

4

4

0

1

3

1

6

9

3

9

3

6

3

3

0

6

8

2

6

2

1

2

8

2

9

3

1

3

3

3

2

2

4

2

9

3

5

3

4

7

4

6

2

9

7

0

2

3

3

2

5

2

7

4

7

0

7

3

8

1

7

1

8

6

3

4

2

4

1

6

6

0

2

2

3

0

8

Parts List

24

0783-024

Swivel Caster

1620783-062

Sear Burner Manifold

1

KEY# PARTS DESCRIPTION

1 0783-001 Main Lid 1 39 0783-039 Slide 2

2 0783-002 Main Lid Screw 2 40 0783-040 Side Burner Gas Valve 1

3 0783-003 Temperature Gauge Housing 1 41 0783-041 Side Shelf Control Panel, Right 1

4 0783-004 Temperature Gauge 1 42 0783-042 Side Burner Pipe Assembly 1

5 0783-005

6 0783-006 Hood Buffer 4 44 0783-044 Side Burner Shelf 1

7 0783-007 R Shape Pin 10 45 0783-045 Side Burner Cooking Grate 1

8 0783-008 Sear Burner Lid 1 46 0783-046 Side Burner Lid 1

9 0783-009 Sear Burner Cooking Grate 1 47 0783-047 Gas Tank Heat Shield 1

10 0783-010 Control Panel Support Bracket, Left 1 48 0783-048 Grease Tray 1

11 0783-011 Pulse Igniter Module 1 49 0783-049 Grease Box 1

12 0783-012 Regulator, LP 1 50 0783-050 Main Burner Igniter Wire A 1

13 0783-013 Side Burner Manifold 1 51 0783-051 Main Burner Igniter Wire B 1

14 0783-014 Side Burner Flex Gas Line 2 52 0783-052 Main Burner Igniter Wire C 1

15 0783-015 Main Manifold 1 53 0783-053 Main Burner Igniter Wire D 1

16 0783-016 Main Control Panel 1 54 0783-054 Main Burner 4

17 0783-017 Bezel 6 55 0783-055 Flame Tamer 4

18 0783-018 Control Knob 6 56 0783-056 Cooking Grid with Hole 2

19 0783-019 Sear Burner Bowl Assembly 1 57 0783-057 Warming Rack 1

20 0783-020 Side Shelf Control Panel, Left 1 58 0783-058 Main Burner Gas Valve 4

21 0783-021 Side Panel, Left 1 59 0783-059 Sear Burner 1

22 0783-022 Side Panel, Right 1 60 0783-060 Sear Burner Igniter Wire 1

23 0783-023 Swivel Caster with Brake 1 61 0783-061 Sear Burner Gas Valve 1

Side Burner Lid Hinge Rod, Left

QUANTI

KEY# PARTS DESCRIPTION

TY

2 43 0783-043 Side Burner Igniter Wire 1

QUANTI

TY

25 0783-025 Bottom Panel, LP 1 63 0783-063 Side Burner Bowl Assembly 1

26 0783-026 Tank Tray Bolt 1 64 0783-064 Sear Burner Grease Tray 1

27 0783-027 Caster 2 65 0783-065 Side Shelf Bracket, Left 1

28 0783-028 Cart Frame, Front 1 66 0783-066 Side Shelf Bracket, Right 1

29 0783-029 Door Magnet 2 67 0783-067 Side Burner Lid Hinge Rod, Right 2

30 0783-030 Door Hinge 4 68 0783-068 Tank Tray Slide Block Plate 1

31 0783-031 Front Door, Left 1 69 0783-069 Tank Tray Bracket A 1

32 0783-032 Front Door, Right 1 70 0783-070 Tank Tray Bracket B 1

33 0783-033 Door Handle 2

34 0783-034 Lighting Rod 1

35 0783-035 Lighting Rod Cover 1

36 0783-036 Tank Tray 1

37 0783-037 Control Panel Support Bracket,Right 1

38 0783-038 Back Panel 1

Important: Use only parts listed above. When ordering

parts, providing the following information:

If you are missing hardware or have damaged

parts after unpacking grill, call 1-800-648-5864

for replacements.

• Model #

• Serial # (found inside the front panel of your grill)

• Part Number (see PART# in chart)

To order replacement parts after using grill, call:

1-800-648-5864.

• Part Description

• Quantity of parts needed

9

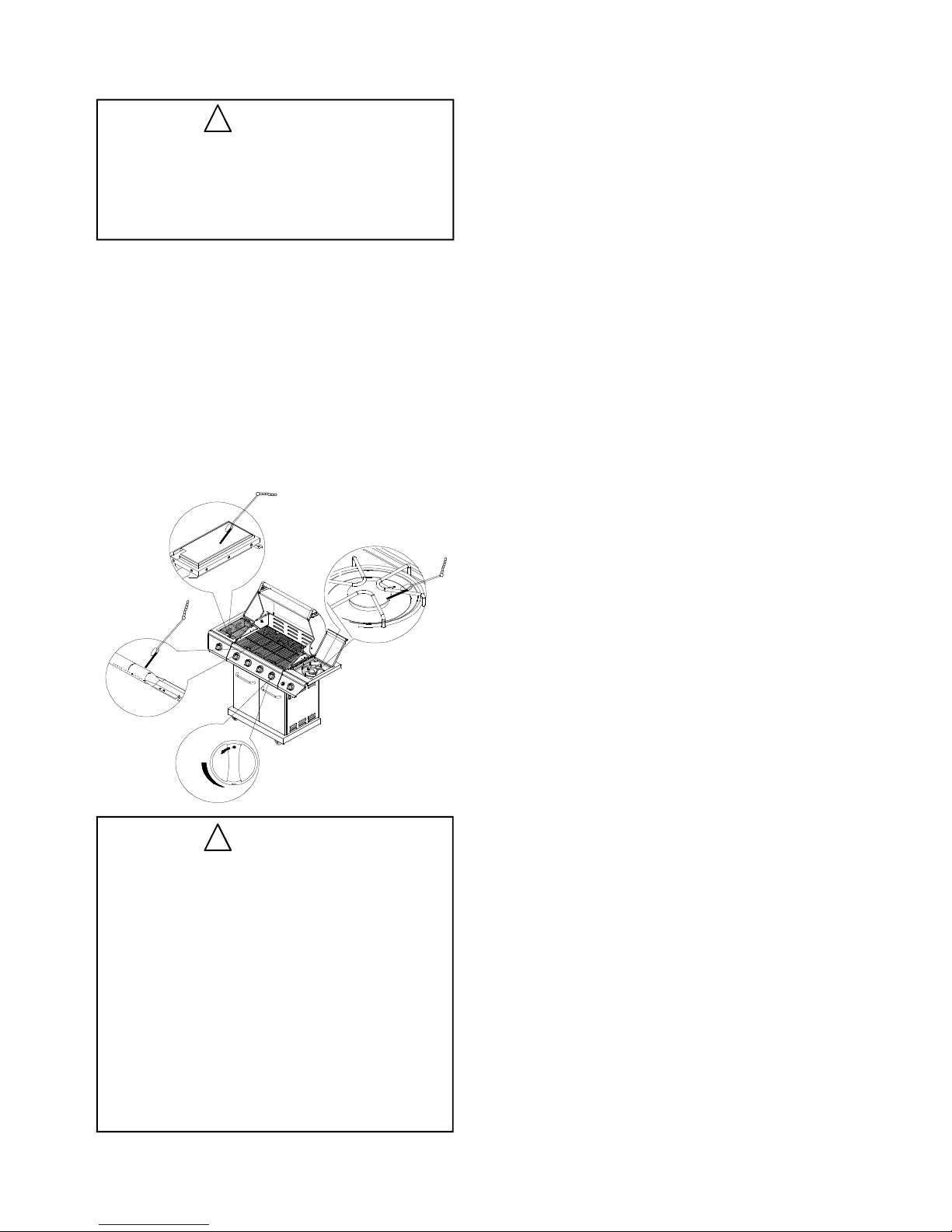

Assembly Instructions

Fig.1

CAUTION: While it is possible for one person to

assemble this grill, obtain assistance from another

person when handling some of the larger, heavier

pieces.

Note: Be sure to slide grease tray out of back of grill

head and remove all packaging from tray.

1. Use the parts list to check that all parts have been

included.

2. Inspect the grill for damage as you assemble it. Do

not assemble or operate the grill if it appears

damaged. If there are damaged or missing parts

when you unpack the shipping box, or you have

questions during the assembly process, please call

1-800-648-5864.

For Assembly Questions, call 1-800-648-5864

8AM – 5 PM EST, Monday through Friday.

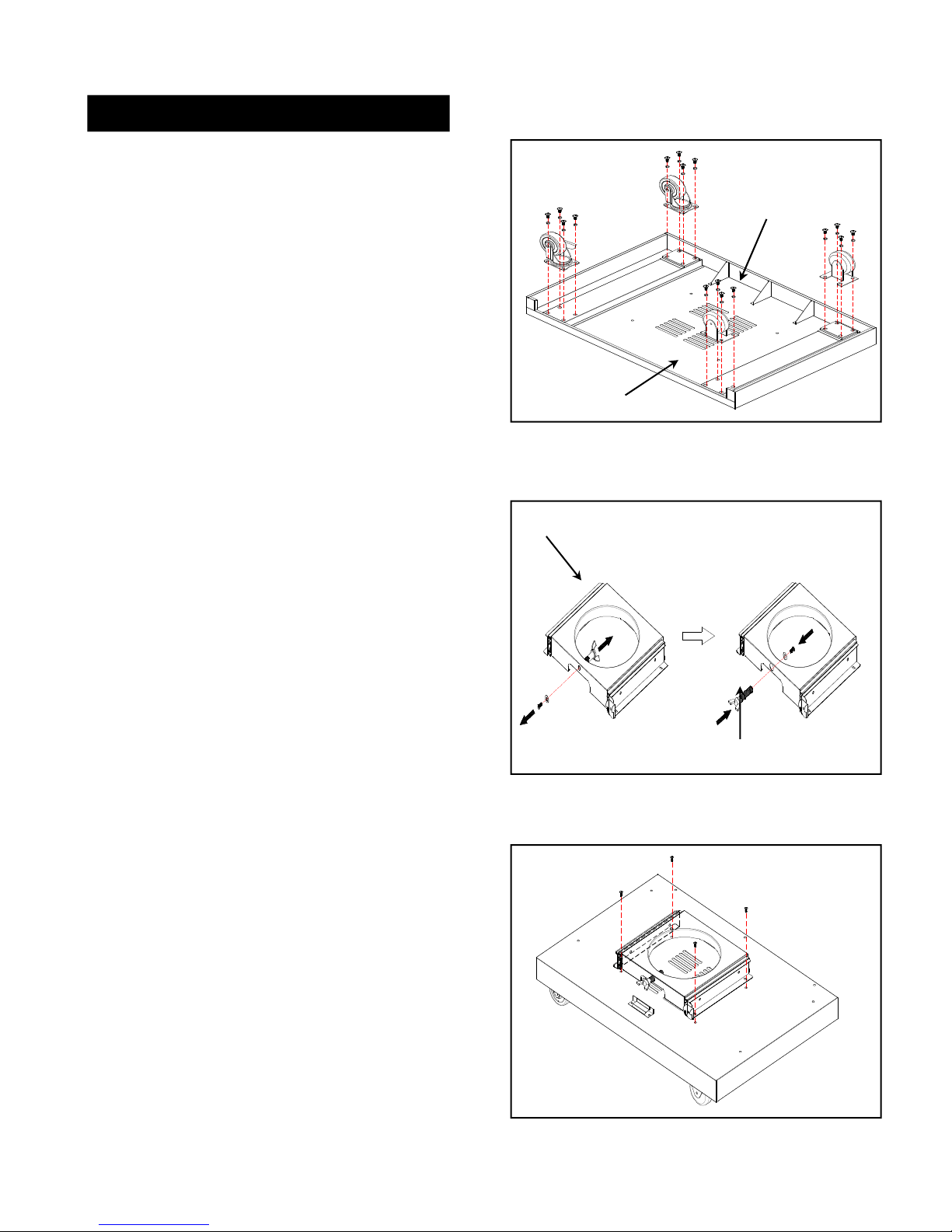

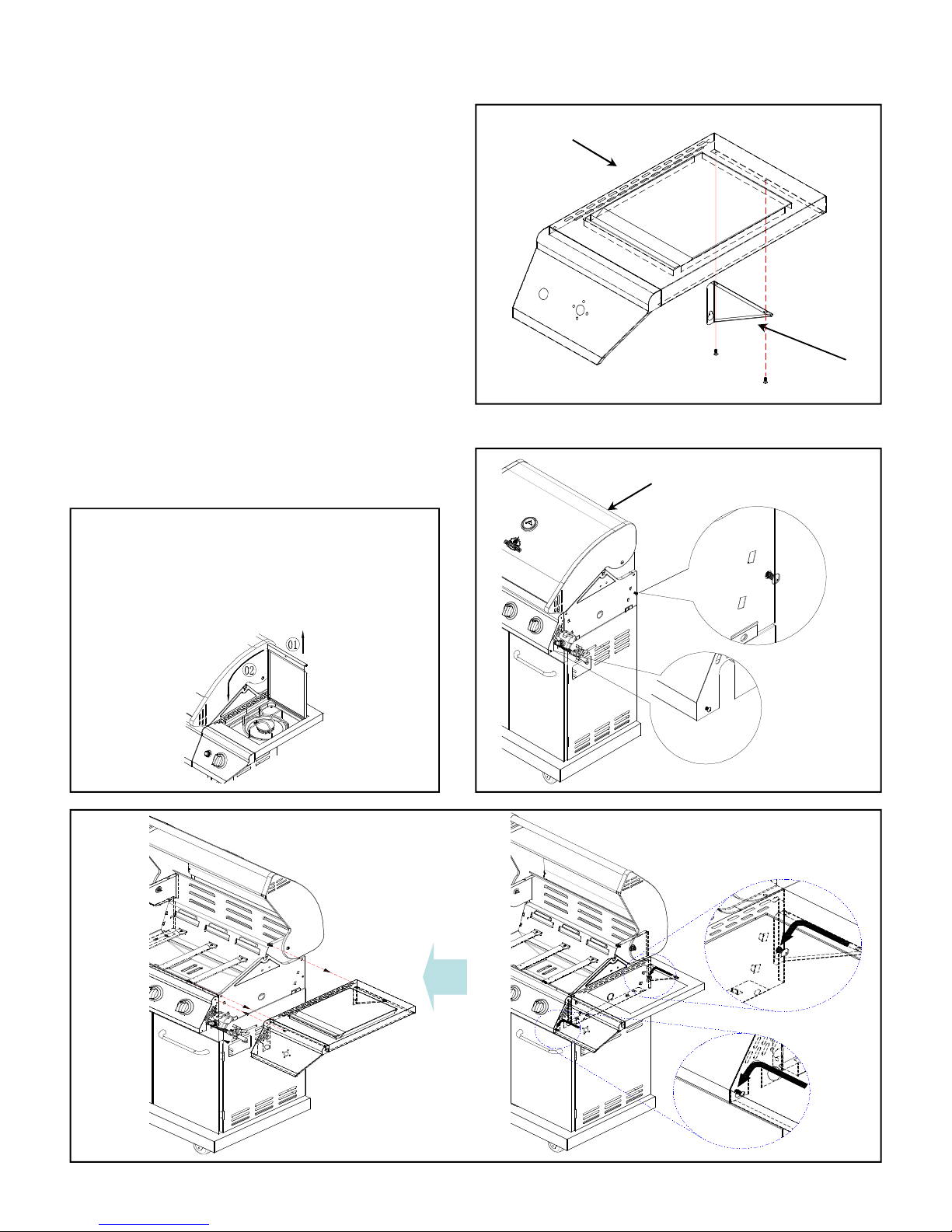

1. Assembling Grill Cart

D

Fig.2

B1

E

B

C

C

a) Attach four casters to bottom panel (B) using (16)

Truss head screws (AA), (16) Lock washers (EE),

Note: (D) is swivel caster with brake, (E) is swivel

caster, (C) are straight casters. See Fig.1.

Hint: For ease of cast assembly, turn bottom panel

upside down.

b) Loosen screw and washer which is attached to tank

bolt from outside of gas tank tray seat (B1). Remove

bolt from inside and insert the bolt from outside, of

tank tray. Re-attach screw and washer from inside

the tank tray. See Fig.2.

c) Attach assembled gas tank tray to bottom panel (B)

using (4) Truss head screws (CC). See Fig.3.

F

Fig.3

10

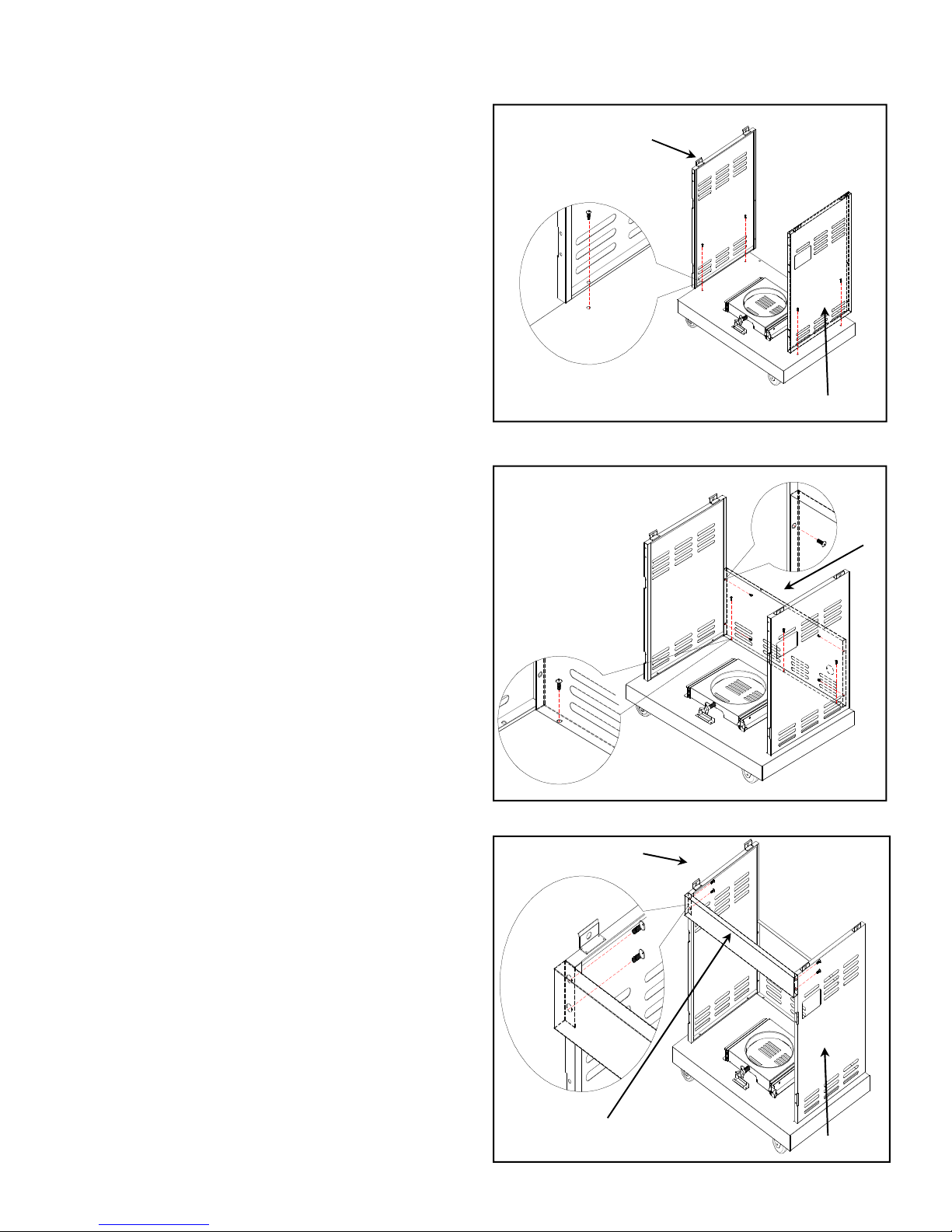

Fig.4

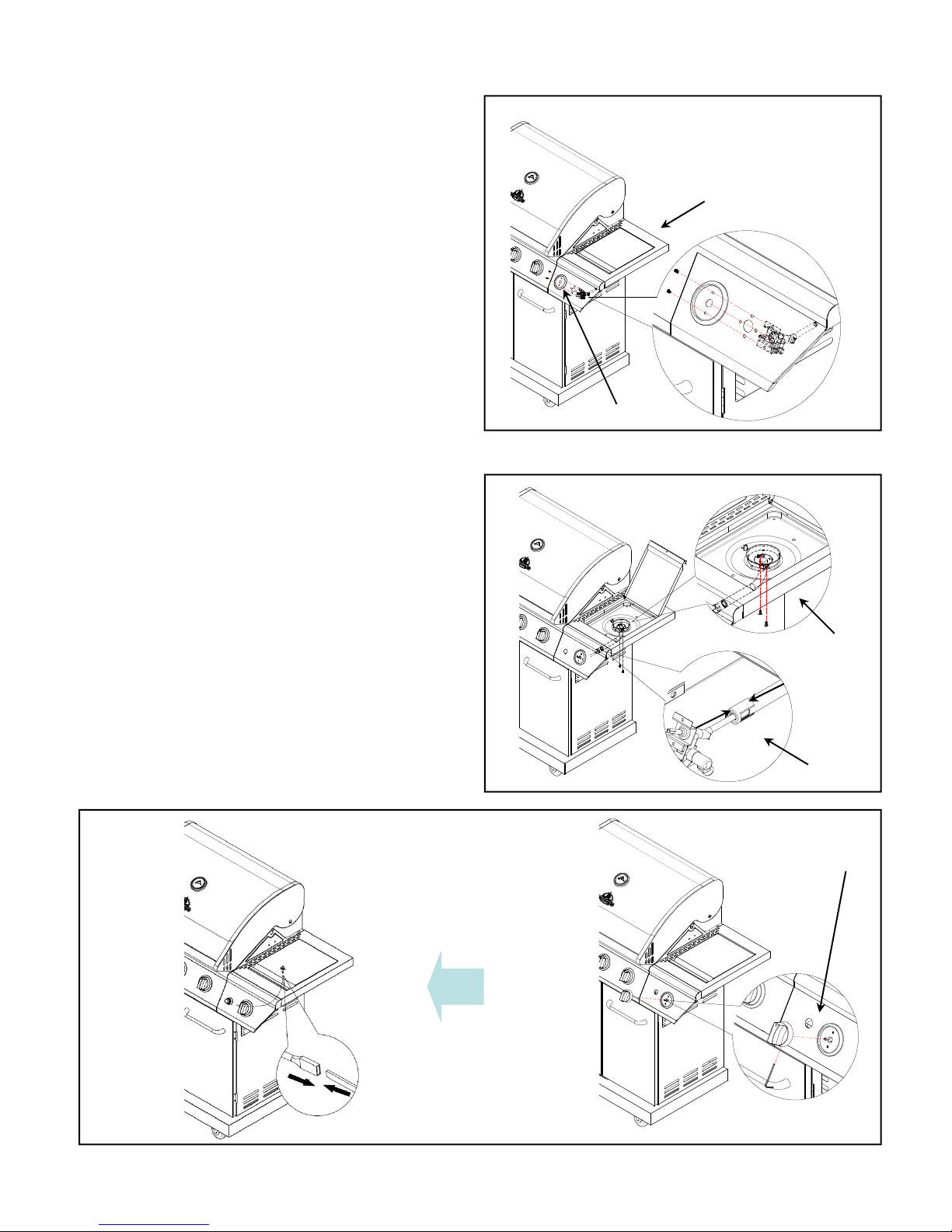

(d) Attach left & right side panels (G & H) to bottom panel

(B) using (4) Truss head screws (CC) with (4) Lock

washers (FF). See Fig.4.

(e) Attach back panel (I) to bottom panel (B) using (7)

Truss head screws (CC) with (7) Lock washers (FF).

See Fig.5.

G

H

Fig.5

I

(f) Attach cart frame bar (Z) to both side panels (G & H)

using (4) Truss head screws (BB) with (4) Lock

washers (EE) from inside. See Fig.6.

11

Fig.6

G

Z

H

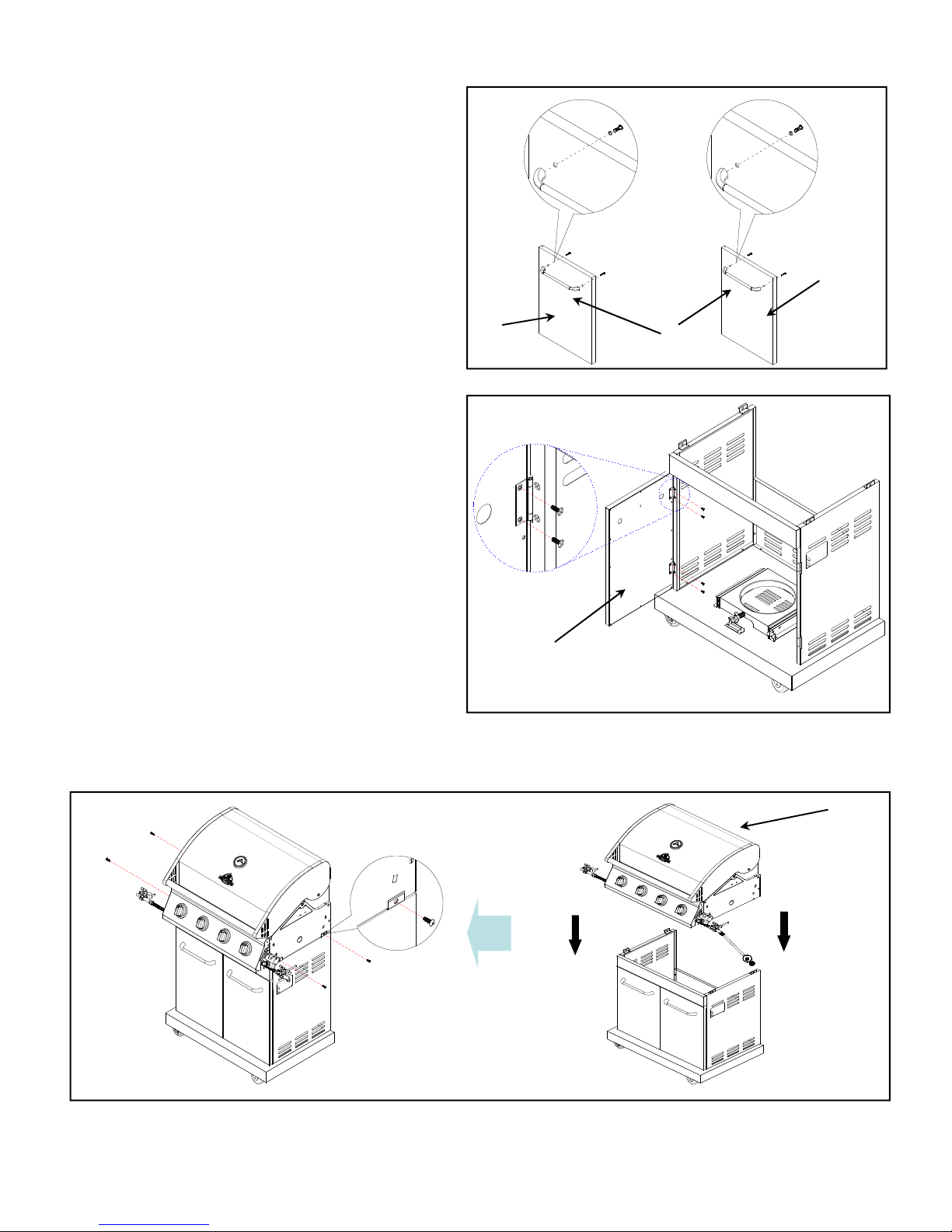

(g) Attach door handle (K) to left door (L) using (2)

Truss head screws (CC). Repeat to assemble the

other door handle to right door (M). See Fig.7.

(h) Attach two doors (L & M) to side panels (G & H)

using (8) flat head screws (DD). See Fig.8.

Fig.7

M

2. Firebox Assembly

(a) Be sure grill cart doors are closed to stabilize cart.

Remove Firebox (A) from carton. Place onto cart

as shown. See Fig.9.

CAUTION: Firebox is heavy. To avoid injury,

obtain the help of an assistant for this step.

Also, make sure doors remain closed when

placing Firebox onto cart. DO NOT open doors

until Firebox is securely mounted to cart.

(b) Attach firebox (A) to left and right side panels (G &

H) using (4) Truss head screws (AA). See Fig.10.

L

Fig.8

K

L

L

Fig.10

12

Fig.9

A

3. Side Burner Assembly

Instruction: Lift lid straight up before closing. See

(a) Attach Triangle Bracket, right (D1) to side burner

(N) using (2) Truss head screws (CC). See Fig.11.

(b) Loosen (2) preinstalled head screws from right

side of Firebox (A) as shown. Do not screw out

fully; leave ¼ extended for shelf assembly. See

Fig.12.

(c) Through side burner shelf keyholes, hang side

burner shelf (N) on two loosened screws. See Fig.

13A.

(d) Using (2) Truss head screws (AA), attach side

burner shelf (N & D1) to Firebox from inside the

firebox. Insert (1) Truss head screws (CC) to

attach the side burner shelf front panel to the

control panel. See Fig.13B. Fully tighten the two

loosened screws to secure shelf to firebox.

SIDE BURNER LID OPERATION

Fig.11

N

D1

Fig.12

A

Featuring two-step lift and release side burner lids

to avoid lid closing unexpectedly.

below illustration:

Fig.13B

Fig.13A

13

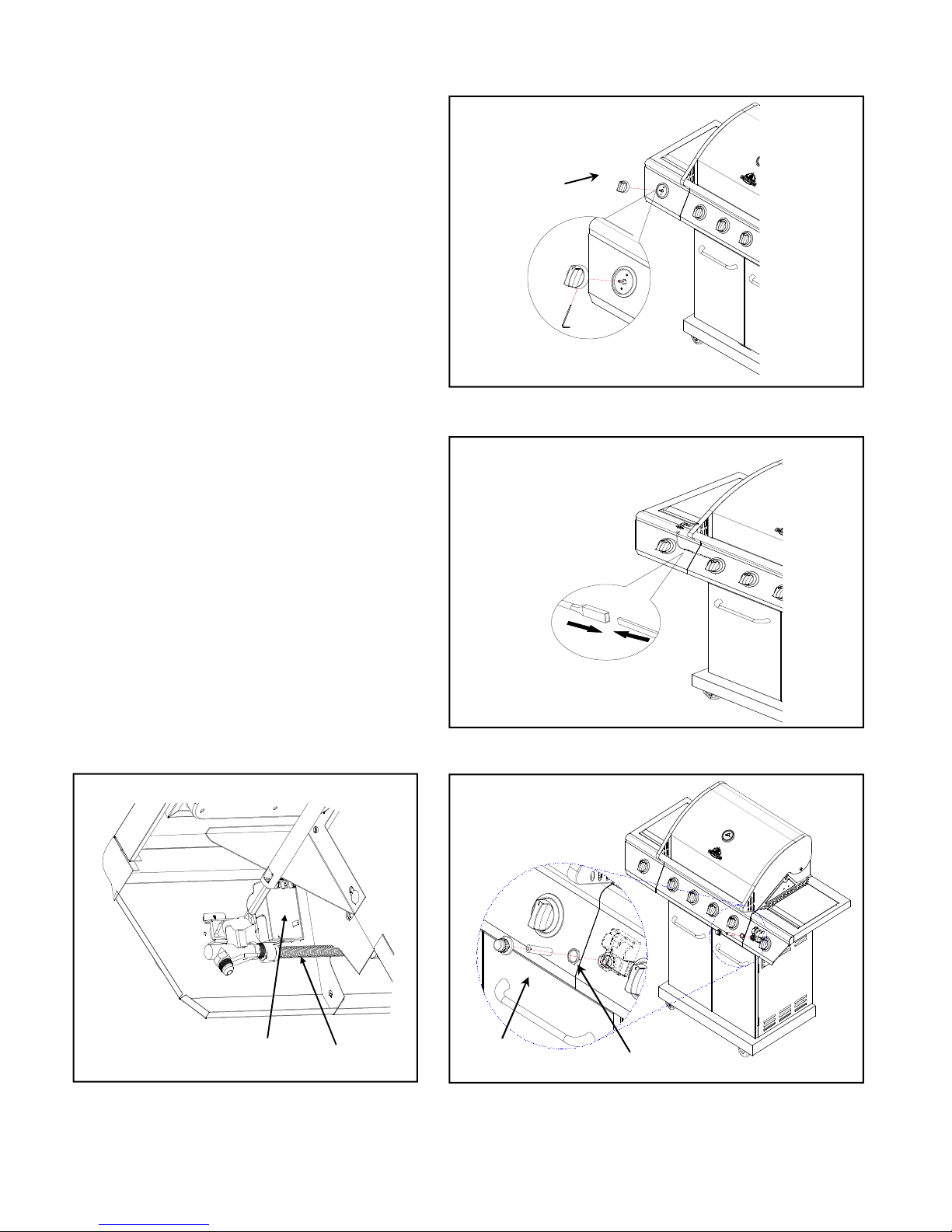

4. Side Burner Valve Assembly

(a) Remove two screws from side burner control valve

face. Insert side burner valve control stem through

hole in side burner control panel. Place bezel (T)

over side burner valve control stem. Secure bezel

to control panel and valve with 2 screws removed

above. See Fig.14.

(b) Insert side burner tube over side burner valve

orifice.

See Fig.15A1. Use two Truss head screws (CC)

attaching side burner (N) to shelf to make room to

install side burner valve. See Fig.15A2.

Fig.14

N

(c) Push control knob (U) onto valve control stem, and

tighten using hex wrench. See Fig.16.

(d) Plug ignition wire into igniter wire hanging from

electrode on underside of burner. See Fig.17.

T

Fig.15

A2

A1

Fig.16Fig.17

U

14

5. Sear Side Burner Assembly

Fig.18

(a) Attach Triangle Bracket, left (E1) to side burner

(O) using (2) Truss head screws (CC). See

Fig.18.

(b) Loosen (2) preinstalled head screws from left

side of Firebox (A) as shown. Do not screw out

fully; leave ¼ extended for shelf assembly. See

Fig.19.

(c) Through side burner shelf keyholes, hang side

burner shelf (O) on two loosened screws. See

Fig.20.

(d) Using (2) Truss head screws (AA) attach side

burner shelf (O & E1) to grill head from inside

the firebox. Insert (1) Truss head screws (CC)

attach the side burner shelf front panel to the

control panel, see Fig.21. Fully tighten the two

loosened screws to secure shelf to firebox.

O

E1

Fig.19

Fig.20Fig.21

15

6. Sear Side Burner Valve Assembly

side burner lids to avoid lid closing

(a) Remove the side burner igniter. See Fig.22.

Remove two screws at the back of side burner

bowl, see Fig.23, then pull out of side burner. See

Fig.24.

(b) Remove two screws from side burner control

valve face. Insert side burner valve control stem

through hole in side burner control panel. Place

side burner control knob bezel (T) over side

burner valve control stem. Secure bezel to control

panel and valve with 2 screws removed above.

See Fig.25.

(c) Insert side burner over side burner valve orifice.

See Fig.26. Use the two previously removed side

burner screws to reattach side burner to side

burner shelf.

(d) Replace igniter and tighten two screws at the

back of burner.

Fig.22

Fig.23

Fig.24

SIDE BURNER LID OPERATION

Featuring two-step lift and release

unexpectedly.

Instruction: Lift lid straight up before

closing. See below illustration:

Fig.25

T

Fig.26

16

(e) Push control knob (U) onto valve control stem,

and tighten use hex wrench. See Fig.27.

(f) Plug ignition wire into igniter wire hanging from

electrode on underside of burner. See Fig.28.

7. Igniter and Battery Assembly

(a) Remove igniter cover and lock washer from

igniter. Insert igniter through from back of side

burner control panel, secure lock washer from

front of side burner control panel. See Fig.29.

(b) Install battery (V) into ignition box with positive

terminal facing outward.

(c) Replace the ignition battery cap after the

battery has been installed. See Fig.29.

Fig.27

U

Fig.28

Note: Make sure the igniter is assembled

with the wires upward in order that the wires

are away from manifold enough.

See illustration below:

Igniter Manifold

Fig.29

v

l ock washer

Lock Washer

17

8. Side Burner Grates Assembly

10.

Installing

Cooking Components

Replace both grates to each side burner. See

Fig.30.

9. Grease Cup Assembly

From the back, pull out grease trays (W & J),

remove any packaging materials from it, then insert

grease cup (X) into grease tray (W) as shown in

Fig.31. Push grease trays back into grill.

Fig.30

Fig.31

(a) Place heat diffusers (P) over burners as shown.

Diffuser ends insert into channels on front and

back of firebox. See Fig.32.

(b) Evenly space cooking grids (R) on the ledge above

heat diffusers. See Fig.32.

To obtain sear marks in cooked meat, be sure to

insert grids so that side with four corner feet faces

down.

(c) Insert legs of warming rack (S) into the holes in the

top of firebox side panels. See Fig.32.

Fig.32

J

W

P

X

S

R

18

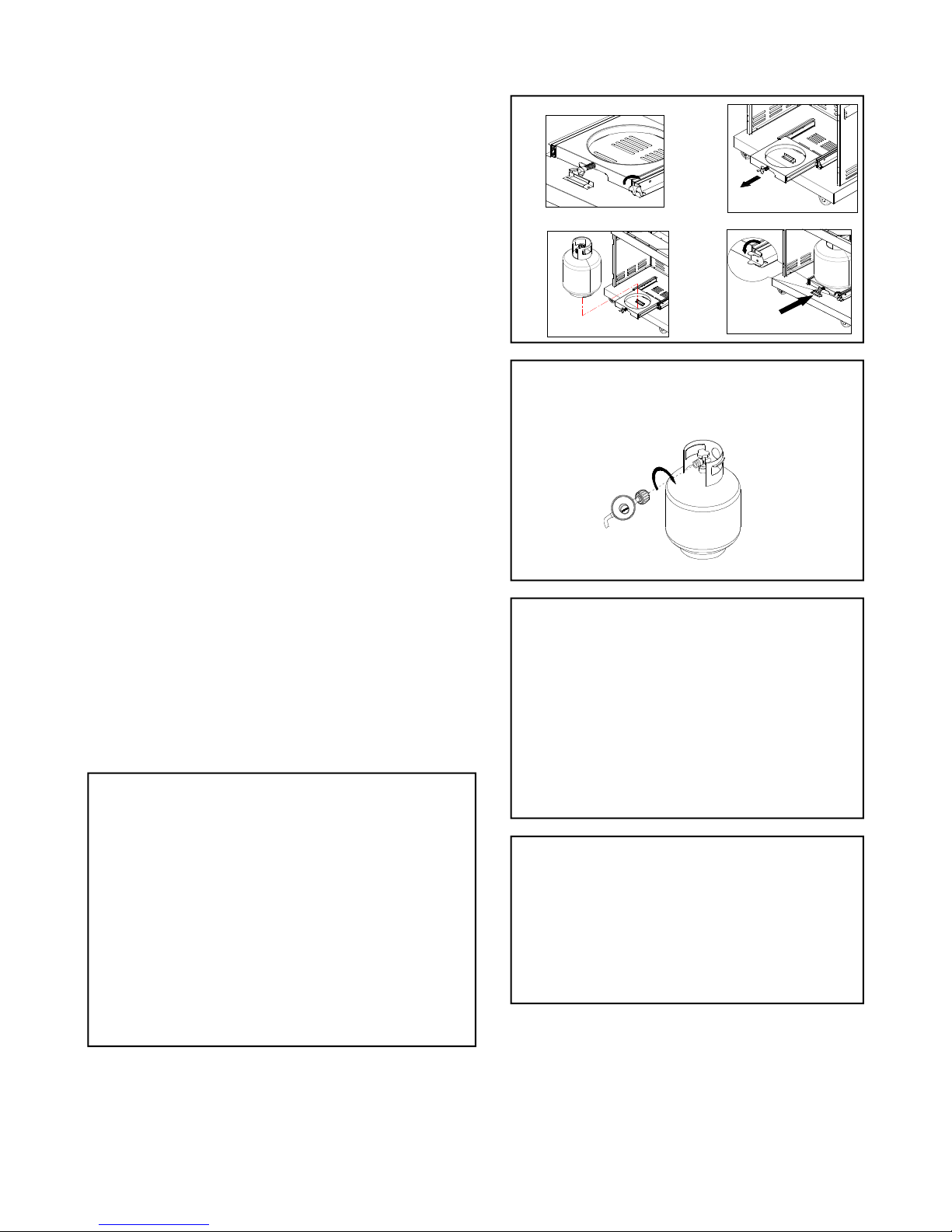

11. Connecting LP Gas Tank to LP Grill

leaks before attempting to light your grill (

see

page

Congratulations

Fig.33

(a) From front of the cart, turn the locker to the right and

pull out of tank tray seat, place foot ring of 20 lb tank

into the hole in bottom panel. Make sure the tank

valve is in OFF position. Use the tank bolt to secure

the tank in a fixed position, turn locker to left. See

Fig.33.

(b) Check the tank valve to ensure it has proper external

mating threads to fit the hose and pressure regulator

assembly provided.

(c) Make sure all burner valves are in OFF position.

(d) Inspect the valve connection port and pressure

regulator assembly. Look for damage or debris.

Remove any debris. Inspect hose for damage. Never

use damaged or plugged equipment.

(e) When connecting pressure regulator and hose

assembly to tank valve, hand tighten quick coupling

nut clockwise to a full stop. See Fig.34. Do not use a

wrench to tighten because it could damage the quick

coupling nut and result in a hazardous condition.

a

c

Fig.34

b

d

Pressure Regulator

Connection

(f) Slowly open tank valve fully (counterclockwise). Use

a soapy water solution to check all connections for

20 for gas leak check instructions). If a leak is found,

turn tank valve off and do not use your grill until the

leak is repaired.

CAUTION: When the appliance is not in use, gas

must be turned off at the supply tank.

DISCONNECTING THE LIQUID PROPANE

CYLINDER

Turn the grill burner valves “OFF” and make sure the

grill is cool.

Turn the Liquid Propane Cylinder valve “OFF” by

turning clockwise until it stops.

Detach the pressure regulator assembly from the

cylinder valve by turning the quick coupling nut

counterclockwise.

Place dust cap on cylinder valve outlet whenever the

cylinder is not in use. Only install the type of dust cap

on the cylinder valve outlet that is provided with the

cylinder valve. Other types of caps or plugs may

result in leakage of propane.

Your GrillMaster® gas grill is now ready for use.

Before the first use and at the beginning of each

season (and whenever the LP gas tank has

been changed):

1. Read all safety, lighting and operating

instructions.

2. Check gas valve orifices, burner tubes and

burner ports for any obstructions.

3. Perform gas leak check according to

instructions found on page 20 of the manual.

Important

Before cooking on your grill the first time, wash

cooking grids and cooking rack with warm ,

soapy water. Rinse and dry thoroughly. Season

with cooking oil regularly. After cooking is

completed, turn grill to HIGH setting for 3 to 5

minutes to burn off excess grease or food

residue.

19

•

Also apply soapy solution to the tank seams. See

Checking for LP gas leaks

•

Also apply soapy solution to the tank seams. See

USING THE SIDE BURNERS:

Never test for leaks with a flame. Prior to first use, at

the beginning of each season, or every time your LP

gas tank is changed, you must check for gas leaks.

• Make a 50/50 (soap/water) mild soap solution.

• Turn the control knobs to full OFF position; then turn

gas ON at supply tank.

• Apply the soap solution with a clean brush to all gas

connections. See below. If growing bubbles appear

in the solution the connections are not properly

sealed. Check each fitting and tighten or repair as

necessary.

3. Be sure all gas connections are securely

tightened.

4. Turn on gas supply.

5. Open the grill main lid.

6. Push and turn any main burner control knob to

HIGH position. Push Electronic Ignition button

for 3 to 5 seconds to light burner.

Gas Connection Leak Check

• If you have a gas connection leak you cannot repair,

turn gas OFF at supply tank, disconnect fuel line

from your grill and call 1-800-648-5864 or your gas

supplier for repair assistance.

below. If growing bubbles appear, shut tank OFF

and do not use or move it! Contact an LP gas

supplier or your fire department for assistance.

Gas Tank Leak Check

Lighting Instructions

Grill Lighting Instructions for Main Burners

1. Do not smoke while lighting grill or checking gas

supply connections.

2. Be sure that LP gas tank is sufficiently full.

WARNING

!

Failure to open grill lid during the lighting

procedure could result in a fire or explosion

that could cause serious bodily injury, death,

or property damage.

7. If the burner does not light after 5 seconds, turn

knob to OFF. Turn gas OFF at LP tank and

wait 5 minutes for gas to clear. Then turn gas

ON at tank and repeat step 5

8. If burner still does not light, see Match Lighting

section and If Grill Still Fails to Light section on

the following page.

9. To light additional burners, turn burner knob(s)

to HIGH. Push and hold electronic ignition

button to light burner. Adjust knob(s) to desired

setting.

Inspect the gas supply hose prior to turning the gas

“ON”. If there is evidence of cuts, wear or abrasion,

it must be replaced prior to use. Do not use the

side burner if the odor of gas is present.

WARNING: Always keep your face and body as

far away from the burner as possible when

lighting.

LIGHTING INSTRUCTIONS FOR SIDE BURNERS

• Open side burner lid fully.

• Push and turn side burner knob to HIGH position.

Push and hold Electronic Ignition button for 3-5

seconds to light burner.

• If the side burner does not light after 5 seconds,

turn knob to OFF. Turn gas OFF at LP tank and

wait 5 minutes for gas to clear. Then turn gas

ON at tank and repeat step 2.

• If burner still does not light, see Manually

Lighting Your Grill by Match section and If Grill

Still Fails to Light Section on the following page.

20

!

purge air from the gas line or reset the pressure

WARNING

Never lean over the grill cooking area while

lighting your gas grill. Keep your face and body a

safe distance (at least 18 inches) from the

cooking grid surface when lighting your grill by

match.

Manually Lighting Your Grill by Match

1. Insert a match into the manual lighting stick.

2. Follow steps 1 through 9 of the Lighting

instructions on page 20.

If Grill Still Fails To Light

1. Check gas supply and connections for leaks.

Check that all wire connections are secure.

2. Repeat basic lighting procedure. If your grill still

fails to operate, turn the gas off at source, turn

the control knobs to OFF, then check the

following:

Misalignment of burner tubes over orifices

Correction: Reposition burner tubes over

orifices.

3. Light the match and extend the lighting stick to

cooking grid surface.

4. Turn the desired control knob to the HIGH

position setting to release gas. The burner

should light immediately.

OFF

IGNITE / H IGH

LOW

!

WARNING

Should a “FLASH-BACK” fire occur in/or

around the burner tubes, follow the

instructions below. Failure to comply with

these instructions could result in a fire or

explosion that could cause serious bodily

injury, death, or property damage.

Shut off gas supply to the gas grill.

Turn the control knobs to OFF position.

Put out any flame with a proper fire

extinguisher.

Open grill lid.

Once the grill has cooled down, clean the

burner tubes and burners according to the

cleaning instructions found on page 22.

Plugged orifice

Correction: Remove burners from grill,

carefully lift each burner up and away from gas

valve orifice. Remove the orifice from gas valve

and gently clear any obstruction with a fine wire.

Then reinstall all orifices, burners, and cooking

components.

3. If an obstruction is suspected in grill burner

valves, please call for repair service at 1-800648-5864.

4. If the grill still does not light you may need to

regulator excess gas flow device. Note: This

procedure should be done every time a new LP

gas tank is connected to your grill.

To purge air from your gas line and/or reset the

pressure regulator excess gas flow device:

Turn all control knobs to the OFF position.

Turn off the gas at the tank valve.

Disconnect pressure regulator from LP gas tank.

Let unit stand for 5 minutes.

Reconnect pressure regulator to the LP gas tank.

Turn the tank valve on slowly until ¼ to ½ open.

Open the grill lid.

Push and turn any control knob to HIGH.

Turn control knobs to HIGH until all the burners

are lit.

You may start to use the grill.

5. If all checks or corrections have been made and

you still have questions about operating your

gas grill, call the Grill Information Center at

1-800-648-5864

21

Cleaning and Maintenance

Burning

-

off the grill after every use will keep it ready

Step 1. Remove screw which locks ignite wire.

To ensure a proper working unit the following proper

care and maintenance is suggested.

Cleaning Cooking Grids

We suggest you wash your cooking grids in a mild

soap and warm water solution. You can use a wash

cloth or soft brush to clean your cooking grids.

Cleaning Heat diffusers

Periodically you should wash the heat diffusers in a

soap and warm water solution. Use a soft brush to

remove stubborn burnt-on cooking residue. The heat

diffusers should be dry before you reinstall them.

Cleaning Grease Tray

The grease tray should be emptied and wiped down

periodically and washed in a mild detergent and

warm water solution. A small amount of sand or cat

litter may be placed in bottom of grease tray to

absorb the grease.

Check the grease tray frequently, don’t allow excess

grease to accumulate and overflow out of the grease

tray.

Annual Cleaning of Grill Interior

Cleaning Exterior Stainless Steel Surfaces

Weathering and extreme heat can cause exterior

stainless steel surfaces to turn tan in color. Machine oils

used in manufacturing process of stainless steel can also

cause this tanning color. Use a stainless steel cleaner to

polish stainless steel surfaces of your grill. Never use

abrasive cleaners or scrubbers because they will scratch

and damage your grill.

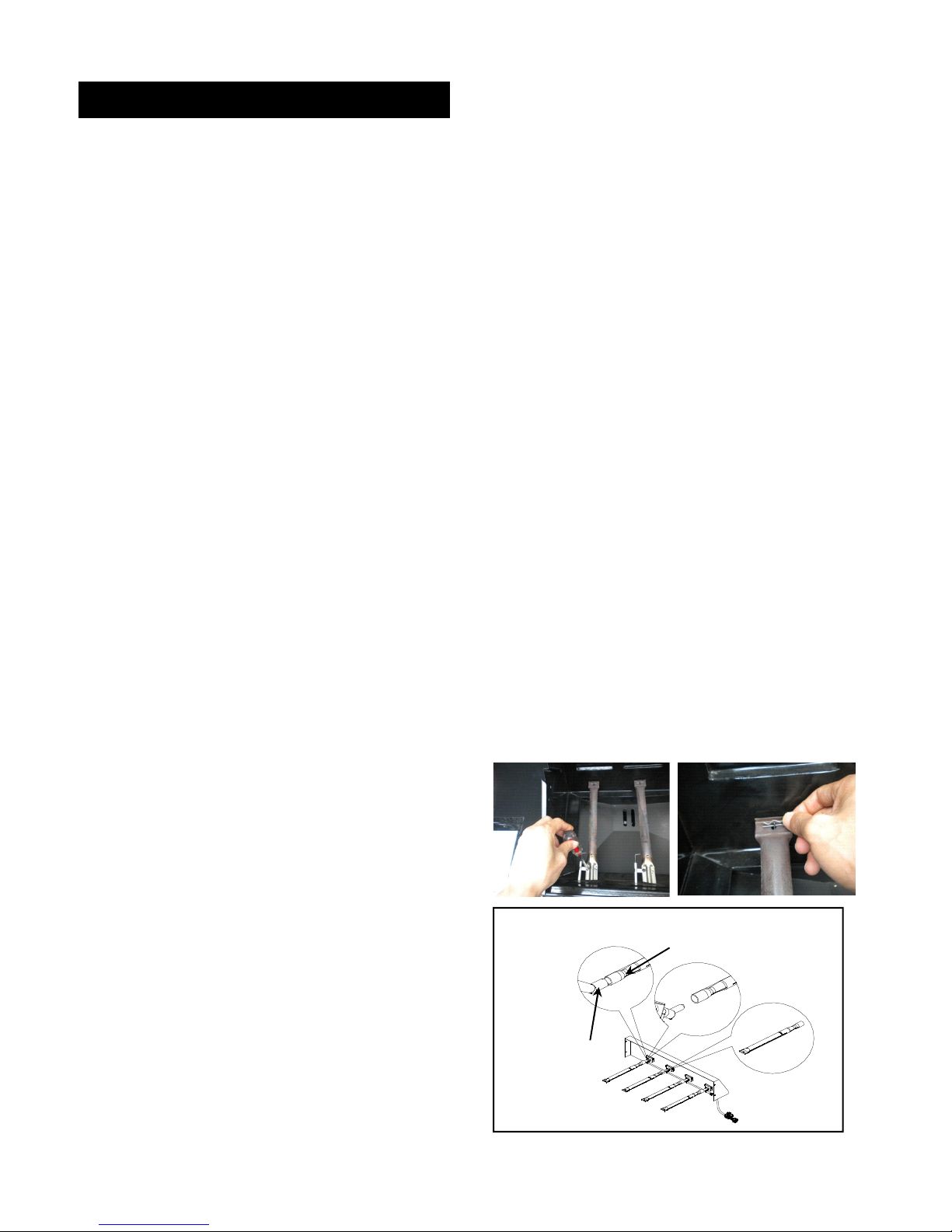

Cleaning Burner Tubes and Burner Ports

To reduce the chance of “FLASH-BACK” the procedure

below should be followed at least once a month in late

summer or early fall when spiders are most active or

when your grill has not been used for a period of time.

1. Turn all burner valves and gas tank valve to off

position.

2. Detach the LP gas pressure regulator assembly from

your gas grill.

3. Remove cooking grids, heat diffusers, and grease

tray from the grill.

4. Remove the screws from the underside of each

burner and lift the burners up and away from the gas

valve orifice.

5. Using a bent stiff wire in the shape of a hook , air

hose or a bottle brush, run it through the burner tube

and inside several times to remove any debris.

6. Replace burners, see illustration below.

for your next use. However, once a year you should

give the entire grill a thorough cleaning to keep it in

top operating condition. Follow these steps.

1. Turn all burner valves to full OFF position.

2. Turn LP gas tank valve to full OFF position.

3. Detach LP gas hose and pressure regulator

assembly from your gas grill. Inspect for any

damage and replace as necessary with

manufacturer replacement part number found on

parts list.

4. Remove and clean heat diffusers, cooking grids

and grill burners.

5. Cover each gas valve orifice with aluminum foil.

6. Brush inside and bottom of grill with a nylon

brush, and wash with a mild soap and warm

water solution. Rinse thoroughly and let dry.

7. Remove the aluminum foil, then reinstall heat

diffusers, and cooking grids.

8. Reconnect gas source and observe burner

flame for correct operation.

Cleaning Exterior Surface

We suggest you wash your grill using a mild soap

and warm water solution. You can use a wash cloth

or sponge for this process. Do not use abrasives or

a brush that might remove finish during the cleaning

process.

Step 2. Take off R clip which fixes burner at the end side.

Step 3. Locate the new burner onto the orifice.

(a) Insert the burner over the main burner gas valve.

(b) Make sure the orifice stud (C1) is inside the burner

venture (D1) as shown in Fig.35.

Step 4. Secure the main burner on the back wall using R

clip, and fix on ignite wire.

Fig.35

D1

C1

22

Clean wires and/or electrode by rubbing with

WARNING

Clean wires and/or electrode by rubbing with

!

The location of the burner tube with respect to the

orifice is vital for safe operation. Check to ensure

the orifice is inside the burner tube before using the

gas grill. If the burner tube does not fit over the

valve orifice, lighting the burner may cause

explosion and/or fire.

2. Clean any clogged ports with a stiff wire, such as

an open paper clip.

3. Inspect each burner for damage (cracks or holes)

and if such damage is found, order and install a new

burner. After installation check to ensure that gas

valve orifices are correctly placed inside the ends of

the burner tubes.

Regardless of which burner cleaning procedure you

use, we recommend you also complete the following

steps to help prolong burner life.

1. Use a fiber pad or nylon brush to clean the entire

outer surface of each burner until free of food residue

and dirt.

Spiders and insects can nest inside the burners of

the grill and disrupt gas flow. This very dangerous

condition could cause a fire behind the valve panel,

thereby damaging the grill and making it unsafe for

operation. Inspect the grill at least twice a year.

WARNING

!

Troubleshooting

BEFORE CALLING FOR SERVICE

If the grill does not function properly, use the following check list before calling for service.

You should inspect the burners at least once a year or immediately after any of the following

conditions occur:

PROBLEMS WHAT TO DO

Grill won’t light when the control knob is

rotated.

Check to see if LP tank is empty.

alcohol and clean swab.

Wipe with dry cloth.

Make sure the wire is connected to

electrode assembly.

Check to see if other burners operate. If so,

check the gas orifice on the malfunctioning

burner for an obstruction.

Burner flame is yellow or orange, in

combination with the odor of gas.

Low heat with knob in “HIGH” position.

Refer to Cleaning Burner Tubes and Burner

Ports on page 22. If problem still exists,

please call 1-800-648-5864

1. Make certain the problem is isolated to

only one burner. If it appears so, clean the

orifice and burner, clearing ports of any

obstruction.

2. Check for a bent or kinked fuel hose.

3. Make sure the air shutter is properly

adjusted.

4. Check for proper gas supply and

pressure.

5. Pre-heat the grill for a full 15 minutes.

6. If using LP gas, check for an empty tank.

23

Loading...

Loading...