DESYS srl

BORING MACHINE Mod. GF 21G

GF 27G

GF 35G

SPARE PARTS INSTRUCTIONS

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Via Ca’ Brion, 40 - 35011 Reschigliano (PD) ITALY

Tel. 049/9200920 Fax 049/9201433

http://www.griggio.com E-Mail:info@griggio.com

GRIGGIO S.p.A.

WOODWORKING MACHINERY

MODEL

BORING MACHINES

GF21 spindles

GF27 spindles

GF35 spindles

MACHINE N°

YEAR OF MANUFACTURE

GRIGGIO S.p.A. WOODWORKING MACHINERY

Via Ca’ Brion, 40 - Reschigliano (PD) ITALY

Tel. 049. .9200920

Fax 049. .9201433

C.A.P. 35011

http://www.griggio.com

E-Mail:info@griggio.com

GRIGGIO S.p.A.

WOODWORKING MACHINERY

1

WE WOULD LIKE TO THANK YOU FOR

HAVING CHOSEN ONE OF OUR PRODUCTS

This manual contains all information, advice and warnings that our technicians deemed

essential to operate the machine properly.

It also contains routine maintenance rules, so that your machine will always be kept in

perfect working order.

We advise you to read this manual entirely before operating the machine for the first

time.

2

GRIGGIO S.p.A.

WOODWORKING MACHINERY

INDICE

1. CONFORMITY CERTIFICATE ......................................................................................... 4

2. SAFETY AND GENERAL SAFETY INFORMATION ........................................................ 4

2.1 USAGE AND MAINTENANCE ADVICE ................................................................. 4

2.2 MACHINE IDENTIFICATION ................................................................................. 4

3. OPERATIVE NOTES ....................................................................................................... 5

4. DESCRIPTION OF THE MACHINE .................................................................................5

4.1 APPLICABLE TOOLS ............................................................................................5

4.2 MACHINE PARTS ................................................................................................. 6

5. SUPPLIED EQUIPMENT ................................................................................................. 6

6. SAFETY DEVICES .......................................................................................................... 7

7. INDIVIDUAL SAFETY DEVICES ...................................................................................... 8

8. TECHNICAL SPECIFICATIONS ......................................................................................8

8.1 WEIGHT ................................................................................................................8

8.2 OVERALL SIZE ..................................................................................................... 8

8.3 MAX. SIZE OF PIECE TO BE BORED .................................................................. 8

8.4 ELECTRICAL CHARACTERISTICS ....................................................................... 8

8.5 TABLE SIZE .......................................................................................................... 9

8.6 INTERAXIAL DISTANCE BETWEEN SPINDLES .................................................. 9

8.7 NUMBER OF SPINDLES ....................................................................................... 9

8.8 INTERAXIAL DISTANCE BETWEEN FIRST & LAST SPINDLE ............................ 9

8.9 SPINDLE REVOLUTIONS ..................................................................................... 9

8.10 MAX. BORING DEPTH .......................................................................................... 9

8.11 WORKING PRESSURE ......................................................................................... 9

8.12 AIR CONSUMPTION ............................................................................................. 9

9. AUTHORISED USAGE .................................................................................................... 9

9.1 MATERIALS .......................................................................................................... 9

9.2 IMPROPER USAGE .............................................................................................. 9

10. SHIPMENT .................................................................................................................... 10

11. MACHINE SIZE .............................................................................................................10

12. INSTALLATION .............................................................................................................11

13. WORKING AREA ........................................................................................................... 11

14. ASSEMBLY AND PRELIMINARY STEPS TO OPERATE THE MACHINE

FOR THE FIRST TIME ................................................................................................... 12

15. CONNECTING THE MACHINE TO EXTERNAL ENERGY SOURCES .......................... 12

15.1 CONNECTION TO POWER SUPPLY MAINS .....................................................12

15.2 PNEUMATIC CONNECTION ............................................................................... 12

15.3 CONTROL PANEL ..............................................................................................13

16. CHECKS AND ADJUSTMENTS .................................................................................... 14

16.1. DISCONNECTIONG PROCEDURE ....................................................................14

16.2. PREVENTION CHECKS ...................................................................................... 14

16.3 BORING DEPTH ................................................................................................. 14

16.4 HOW TO ADJUST HEAD PARALLELISM ........................................................... 15

16.5 HOW TO POSITION SPINDLEHEAD HORIZONTALLY AND VERTICALLY……..15

16.6 HOW TO USE REFERENCE STOPS FOR STANDARD 0°-90°WOODWORKING …16

16.7 HOW TO USE EXTENSION FENCE .................................................................... 16

GRIGGIO S.p.A.

WOODWORKING MACHINERY

16.8 HOW TO USE REFERENCE PIN TO BORE SERIES OF HOLES ON LARGE

PIECES (OPTIONAL)…………………………………………………………………...17

16.9 HOW TO USE TRIANGULAR FENCE FOR 45° BORING AND SPLINE

(OPTIONAL)………………………………………………………………...………18

16.10 WOODWORKING EXAMPLES…………………………………………………….,….19

17. HOW TO START THE MACHINE .................................................................................. 21

17.1 WORKING CYCLE .............................................................................................. 21

18. MAINTENANCE ............................................................................................................ 21

18.1 MACHINE CLEANING (DAILY) ........................................................................... 21

18.2 RAILS CLEANING (WEEKLY) ............................................................................. 21

18.3 KINEMATICS CLEANING AND CHECKS (MONTHLY) ...................................... 21

18.4 EXTRAORDINARY MAINTENANCE .................................................................. 21

19.COMMON FAILURES – CAUSES AND SOLUTIONS .................................................... 22

19.1DRILLS ARE NOT TURNING……………………………………………………………..22

19.2 ENGINE IS RUNNING BUT DRILLS ARE NOT TURNING ................................. 22

19.3 BORED HOLE IS NOT PRECISE ....................................................................... 22

20. FAILURES THAT MIGHT OCCUR DURING MACHINE WORKING CYCLE…………….23

20.1 DRILLS LEAVING SCORCH MARKS ................................................................. 23

20.2BORED PIECES ARE NOT SET AT A 90° ANGLE TO TABLE………………………23

20.3 HEAD CANNOT ROTATE PROPERLY ............................................................... 23

20.4 HOLD DOWN CLAMPS CANNOT CLAMP WOOD PIECE ................................. 23

21 A. NOISE LEVEL ............................................................................................................ 23

21 B. DUST EMISSION ....................................................................................................... 23

22. PNEUMATIC SCHEME .............................................................................................. 24

23 A. ELECTRICAL SCHEME FOR GF21, GF27 (WITH ONE ENGINE) ............................. 24

23 B. ELECTRICAL SCHEME FOR GF 35 (WITH TWO ENGINES) ................................... 25

24. MACHINE IS PUT OUT OF COMMISSION ................................................................ 26

25. GUARANTEE CERTIFICATE ..................................................................................... 27

26. SPARE PARTS CATALOGUE…………………………………………………………...….29

3

4

GRIGGIO S.p.A.

WOODWORKING MACHINERY

1. CONFORMITY STATEMENT

Griggio S.p.A. declares that this Boring machine has been manufactured accurately, by using the best

techniques available to manufacture a quality product. We also declare that our boring machine com-

plies with EEC 89/392 Machines Guideline, as well as with the following standards:

EN 292/1

EN 292/2

EN 60240

EN 60240/1

EN 73/23 CE

IEC 408

The machine is hence commercialised with conformity mark:

GRIGGIO S.p.A.

Via Cà Brion,40 - 35011

Reschigliano (PD) ITALY

The President

2. SAFETY AND GENERAL SAFETY INFORMATION

2.1 USAGE AND MAINTENANCE ADVICE

In this manual we have considered all routine maintenance operations.

We advise you not to carry out any other working, repair or intervention than the ones envisaged in this

manual.

We suggest that you keep this manual with care and in a location where it can easily be found and consulted by the operator.

2.2 MACHINE IDENTIFICATION

The machine can be identified by means of the information written on the plate located in the front of the

machine on the left-hand side. When spare parts are ordered or advice is required to operate the machine or to carry out maintenance operations, always indicate the machine’s model number written on

the plate, as well as voltage and nationality.

It is absolutely forbidden to remove the plate or to change the information written on it.

On the Boring machine described in this manual, the following plate has been attached:

GRIGGIO S.p.A.

WOODWORKING MACHINERY

3. OPERATIVE NOTES

WOODWORKING MACHINES CAN BE DANGEROUS

1) To operate the machine safely and correctly, follow the indications contained in this manual care

fully and scrupulously.

2) The machine will have to be operated only by personnel who is both qualified and over 18. People

responsible for safety should make sure that the machine operator has read and fully understood all the

information contained in this manual.

3) Maintenance interventions must be carried out only by personnel who is both qualified and of age.

4) Personnel responsible for periodical and extraordinary servicing must have a good knowledge of

mechanics and electronics.

5) Keep away from any moving part in the machine.

Never touch the spindles and /or the drills when the machine is operational.

6) Never superimpose wood pieces to be worked. Always bore one piece at a time, after having adjusted the machine correctly.

5

REMOVING OR TAMPERING WITH SAFETY DEVICES MAY CAUSE SERIOUS ACCIDENTS. IT IS

FORBIDDEN TO REMOVE, EXCLUDE OR MODIFY SUCH DEVICES. PERIODICAL CHECKS

MUST BE CARRRIED OUT TO MAKE SURE THAT SAFETY DEVICES ARE ALWAYS IN GOOD

WORKING ORDER. ANY DEFECT OR POSSIBLE PROBLEM IS TO BE DEALT WITH IMMEDI-

ATELY.

4. DESCRIPTION OF THE MACHINE

Our Boring Machines have been manufactured to make a series of holes at a fixed 32-mm distance between centres on wooden pieces (with maximum precision).

The head has its fulcrum on the machine table and it can be tilted until a 90-degree angle. The pieces to

be bored are fed by the operator, who places them on the machine table. The operator will carry out the

required adjustments by pressing the control pedal before locking the pieces into place with the relevant

hold down clamps and starting boring operations.

The following parts make up the machine:

• A steel frame structure

• Spindlehead unit with transmission and drill spindles with quick-change seat (standard).

• Hold down clamps unit to clamp the piece to be cut in a vertical position.

• Pneumatic system for head positioning and head feed.

• Back stops so as to obtain the same vertical and horizontal boring distance

• Crank mechanism to adjust spindles height, equipped with mechanical counter and quick-depth de-

vice to adjust hole depth from 0 mm to 100 mm.

4.1 APPLICABLE TOOLS

Quick-change spindle drills with a 10mm-diameter shank L=20mm.

Drills up to 40mm-diametre outside the rack can be used; 100 mm maximum working length (attachment

is not taken into account).

6

GRIGGIO S.p.A.

WOODWORKING MACHINERY

4.2 MACHINE PARTS

1) Electric power line light

2) Switch to make the engine operational

3) Emergency pushbutton

4) Machine clamping

5) Lever-operated valve for head overturning piston.

6) Piston adjustment and drills feed speed

7) 45°Block pin

8) Back stops

9) Tilting degree dial for spindlehead

10) Fast-positioning safety hold down clamps

11) Clamping handle for hold down clamps rail

12) Table limiters

13) Clamping handle for limiters rails

14) Limiters exclusion device

15) Electric control board

16) Rack rotation clamping handle

17) Control handle for drills height from table

18) Drills depth adjustment for piece to be bored

19) Reference pin to repeat sets of holes (optional)

20) Lubrication-filter-regulator air unit

21) Drills feed cylinder

22) Spindlehead

23) Engine

24) Pneumatic control pedal

25) Electrical main switch

5. SUPPLIED EQUIPMENT

The machine comes with the following equipment to adjust the machine itself:

- 45-degree head position clamp

- Protractor scale to position the boring head

- Quick-positioning safety hold down clamps

- 4 T.E. wrenches sizes 6/7, 10/11, 12/13, 16/17.

- 7 hexagon ring wrenches sizes 2.5-3-4-5-6-8-10

- 5 quick-change bushes for cylindrical-shank drills 10 mm in diameter

- 3000mm extension fence with millimetrical scale and 4 oscillating stops

The following equipment is available on request:

- 45° Triangle for frame construction

- Central spline for 90° frames

- An additional extension fence with millimetrical scale (3000 mm max)

- Additional oscillating stops for extension fence

- Reference pin for line boring (2 pins maximum)

- Additional quick-change bushes for cylindrical shank drills 10 mm in diameter

GRIGGIO S.p.A.

WOODWORKING MACHINERY

7

6. SAFETY PROTECTION

The main risk is due to the revolving drills. To reduce this risk to the minimum, our machines have been

equipped with the following safety devices:

1) Emergency Pushbutton

It is located on the control board in the front part of the machine. When it is pressed, all machine movements are halted immediately.

2) Set of Plates

They contain an accurate description of safety precautions and indications on how to operate the machine and make it possible to identify the machine parts. One of these plates contains the identification

data and the serial number of the machine itself.

3) Side Protections

They prevent the operator from inserting his/her hands accidentally into the machine when the spindlehead is moving.

4) Safety hold down clamps (patented)

They remain either on the machine table surface or on the piece to be worked that has already been positioned, thus preventing the operator from accidentally placing his hands under one of them.

5) EL Safety Device

No-return coil to prevent accidental starting of the machine.

CAUTION SYMBOL: ALL OPERATIONS MARKED WITH THIS SYMBOL ARE

DANGEROUS FOR THE OPERATOR. AS A RESULT THE OPERATOR MUST

PAY THE GREATEST ATTENTION WHILE CARRYING THEM OUT.

8

GRIGGIO S.p.A.

WOODWORKING MACHINERY

7. INDIVIDUAL SAFETY DEVICES

Although safety devices used are valid, dangerous situations might occur resulting from:

- FALLING OR FLYING WOOD SPLINTERS WHILE PIECE IS BEING WORKED

- CLOTHING BEING TRAPPED IN MOVING PARTS OF THE MACHINE

- FIRE DANGERS

- ELECTRIC SHOCK DANGER

- RISK OF NOISE-RELATED DAMAGES

To prevent any risk occurring during positioning, installation, adjustment, usage, periodical and extraordinary maintenance operations, we advise you to wear:

- gloves (to handle machine parts, components and while replacing drills)

- anti-slip and anti-crush shoes

- goggles or face shields to protect against flying chips and splinters while the piece is being worked

or when the machine is being cleaned

Clothing must also be suitable to prevent

- trapping danger

- dragging danger

- crushing danger

- slipping danger

For further information and advice, please read chapter 3 “OPERATIVE NOTES”

8. TECHNICAL SPECIFICATION

8.1 WEIGHT

NET WEIGHT

Version. GF 21 320 Kg

Version. GF 27 360 Kg

Version. GF 35 444 Kg

8.2 OVERALL SIZE

Version. GF 21 1100 x 780 x 1300 mm

Version. GF 27 1200 x 780 x 1300 mm

Version. GF 35 1350 x 1040 x 1250 mm

8.3 MAXIMUM SIZE OF PIECE TO BE BORED

Version. GF 21 850 x 3000 mm

Version. GF 27 990 x 3000 mm

Version. GF 35 1308 x 3000 mm

Maximum thickness of piece to be drilled is 90 mm (all machine models)

8.4 ELECTRICAL CHARACTERISTICS

The electrical characteristics of the machines are:

- Supply voltage: 220/400 – 230/460 Volts

- Frequency: 50/60 Hz

- Number of current phases: 3

- Power: 1.5 kW (n.2 Hp) (Versions GF2132 GF2732)

2 X 1.5 kW (n.2 X 2 HP) (Version GF3532 – 2 Engines)

- Single-phase 220V (optional). For other voltage values please contact us.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

8.5 TABLE SIZE

Version GF 21 900 X 380 mm

Version GF 27 1050 X 380 mm

Version GF 35 1360 X 410 mm

8.6 INTERAXIAL DISTANCE BETWEEN SPINDLES

The interaxial distance between spindles is 32 mm.

8.7 NUMBER OF SPINDLES

Version GF 21 21 spindles

Version GF 27 27 spindles

Version GF 35 35 spindles

8.8 INTERAXIAL DISTANCE BETWEEN FIRST AND LAST SPINDLE

Version GF 21 640 mm

Version GF 27 832 mm

Version GF 35 1088 mm

8.9 SPINDLE REVOLUTIONS

Spindles revolutions are …2800 r.p.m. at 50 Hz

Spindles revolutions are …3300 r.p.m. at 60 Hz

8.10 MAXIMUM BORING DEPTH

Maximum boring depth is …100 mm.

8.11 WORKING PRESSURE

Working pressure is … 6/7 bar

8.12 AIR CONSUMPTION

Air consumption is …10L/Cycle

9

9. AUTHORISED USAGE

9.1 MATERIALS

This boring machine has been designed and manufactured to bore holes in the following materials:

- heart-wood

- M.D.F.

- Chip-wood boards, laminated wood, ennobled wood etc.

Maximum board thickness is 82 mm with maximum size indicated in paragraph 8.3

Other materials than the ones indicated above can be worked only after having received written approval by machine manufacturer. In particular it is forbidden to work materials containing toxic substances or substances that are hazardous for operator’s health and safety. It is also forbidden to bore

metals or substances that might impair the machine good performance of might cause fire or explosions.

- Any modification to the machine is forbidden without the written approval by the machine manufacturer.

- It is forbidden to tamper with the machine safety devices

9.2 IMPROPER USAGE

Any operation that does not comply with the indications given in this manual is to be regarded as improper usage.

Moreover:

WE ADVISE YOU NOT TO: lay tools against or on the machine during machine installation, usage or

maintenance operations for any reason whatsoever.

WE ADVISE YOU NOT TO: get on the machine or on any of its parts.

The manufacturer cannot be held responsible for any damage caused to people, animals, or objects

resulting from improper usage of the machine.

10

GRIGGIO S.p.A.

WOODWORKING MACHINERY

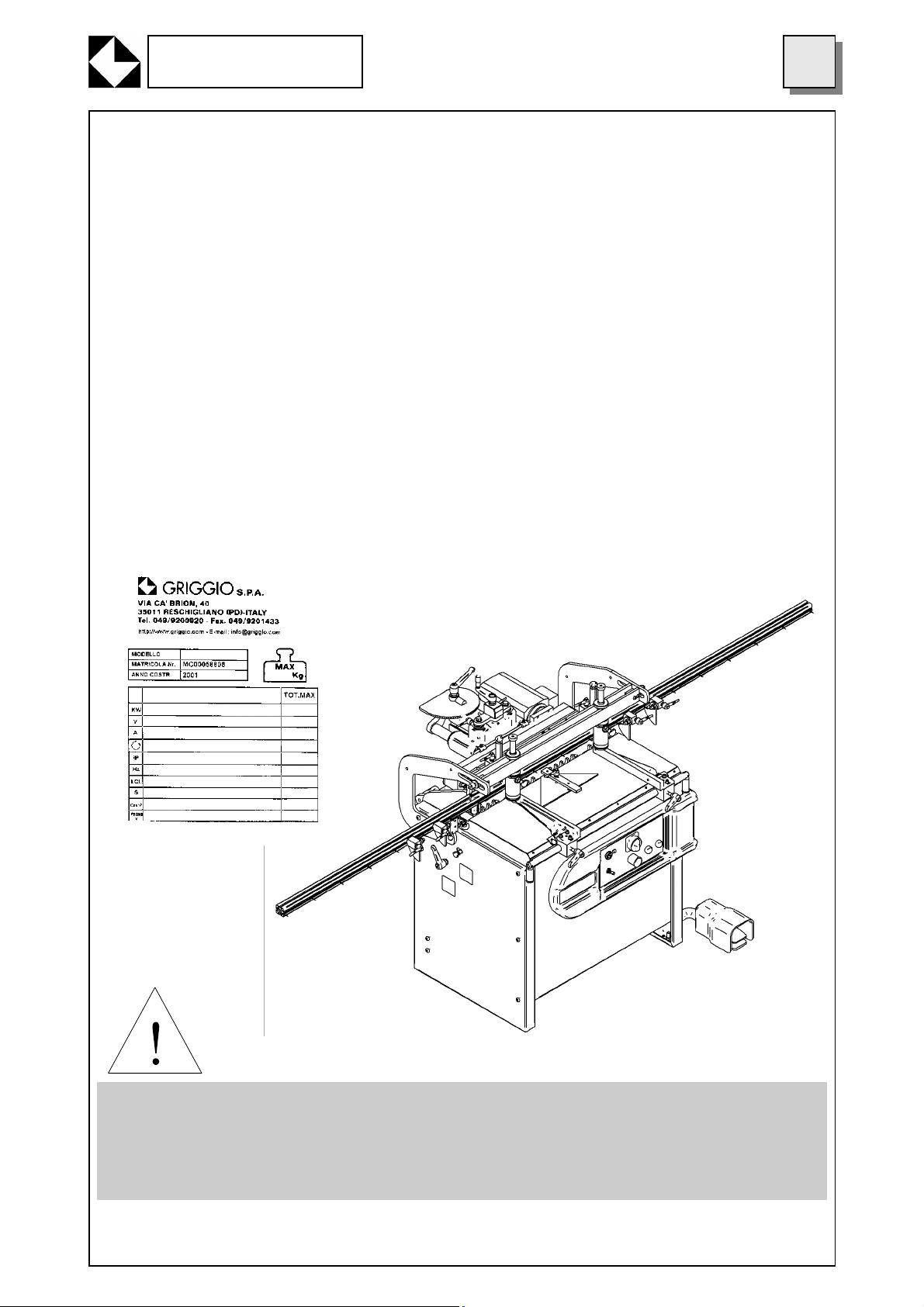

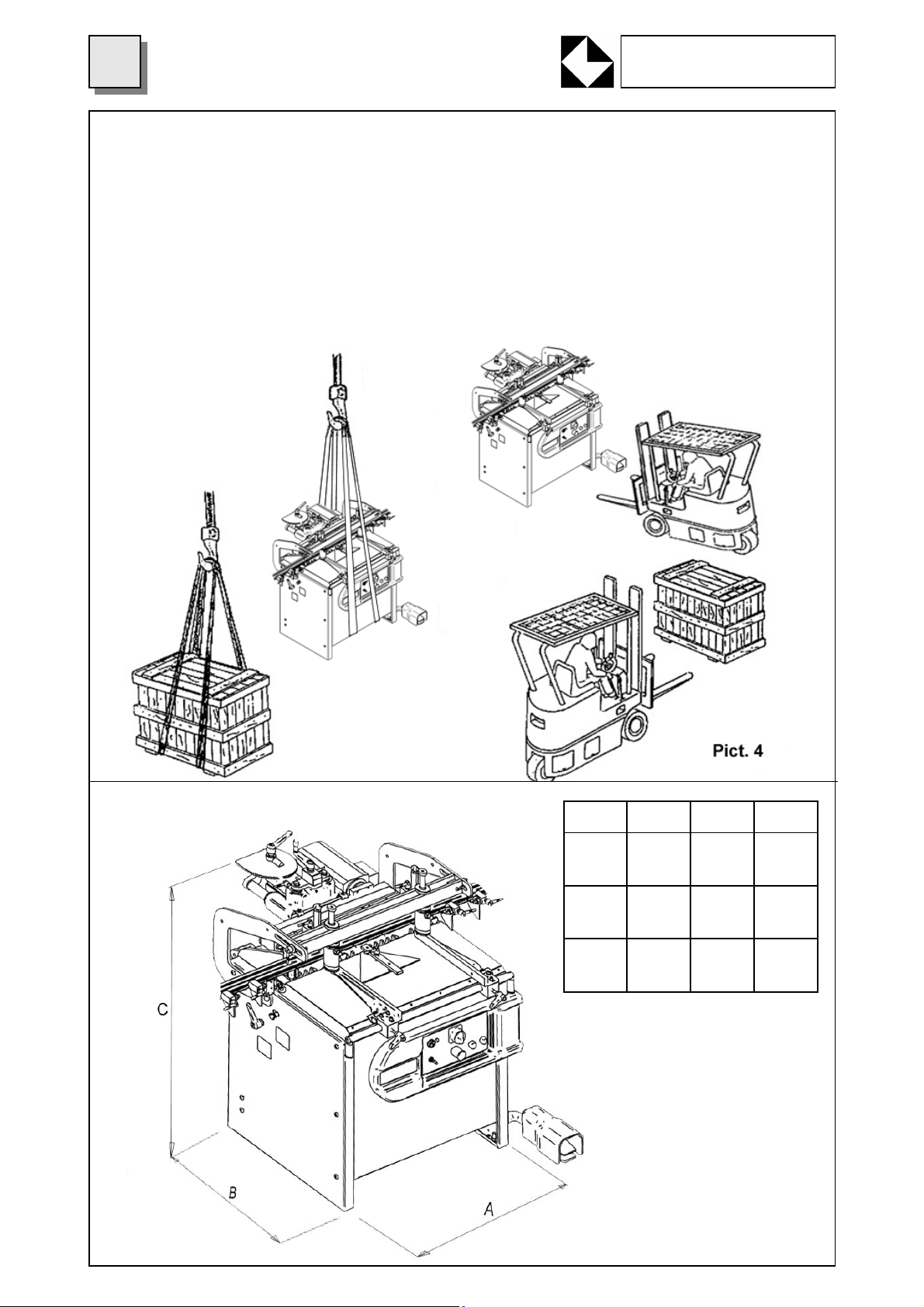

10. SHIPMENT

This boring machine is packed in a wooden box and/or in a cardboard and nylon box.

Machine handling is possible with:

- fork-lift trucks

- bridge cranes

- pallet trucks

Weight is indicated in paragraph 8.1 and hoisting points can be seen in the picture below. When the machine is handled it is necessary to make sure that the surrounding area is free from obstacles. If the machine is stored, it must be kept in a dry place, protected from rain, snow or dampness. During all handling operations, we advise you to pay great attention in order to prevent any damage to people, things

or to the machine itself.

11. MACHINE SIZE

Mod.

GF21

Mod.

GF27

Mod.

GF35

A B C

1100 780 1300

1200 780 1300

1480 1040 1250

Pict. 5

GRIGGIO S.p.A.

WOODWORKING MACHINERY

11

12. INSTALLATION

The machine must be installed on a surface strong enough to sustain its weight so as to prevent harmful

vibrations from impairing the good performance of the machine.

To guarantee maximum machine efficiency and safety, the surface where the machine is located must

be made of well-levelled concrete. If the surface does not meet such requirements, we advise you to

make a suitable one.

Place the machine in a room, in a suitable position to be used and to be easily connected to

- power supply network

- compressed air network

- suction plant

The location where the machine will be placed must be equipped with suitable lighting to execute working or maintenance operations.

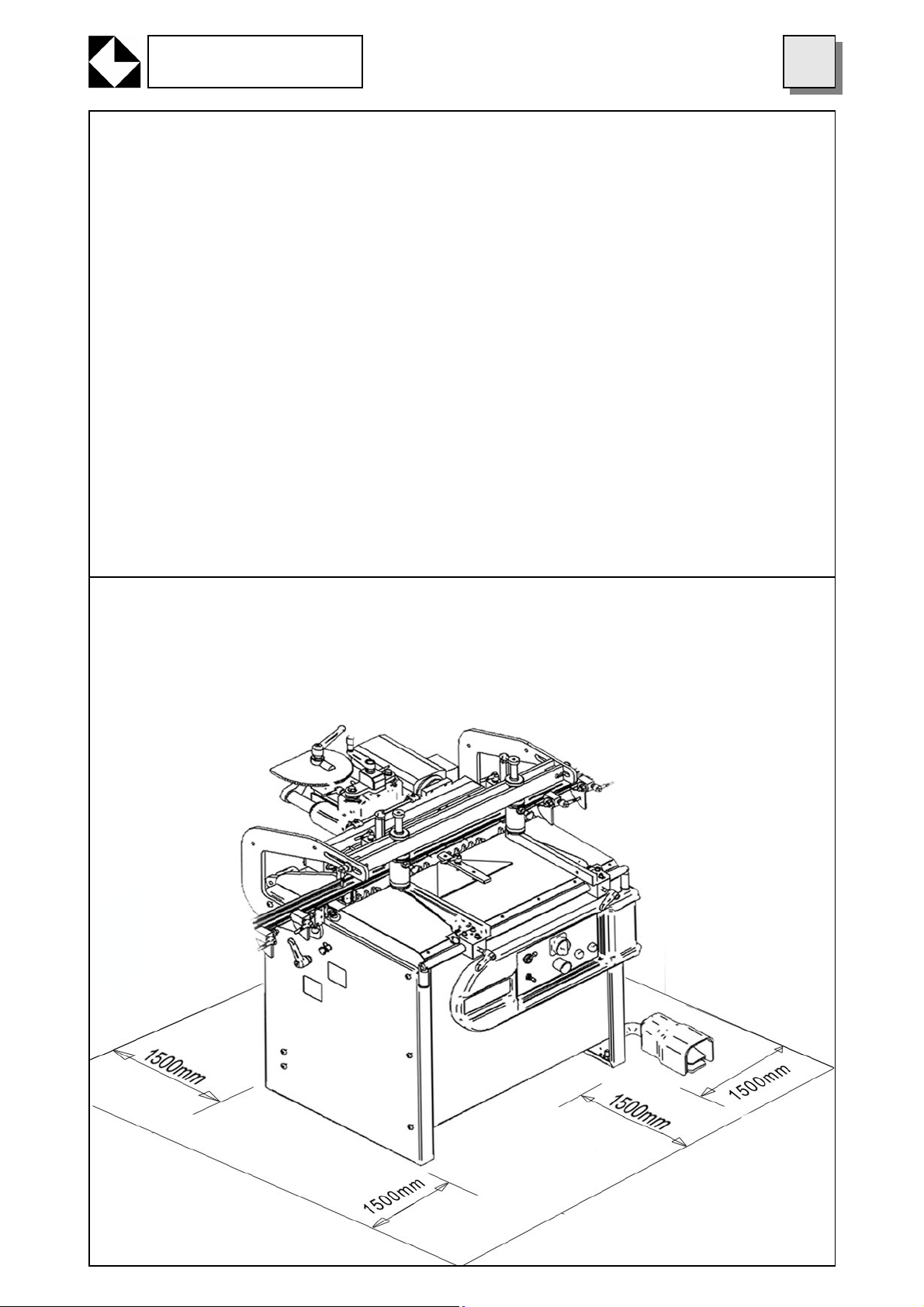

13. WORKING AREA

To be able to use the machine properly, the areas indicated in the picture below must be left free.

12

GRIGGIO S.p.A.

WOODWORKING MACHINERY

14. ASSEMBLY AND PRELIMINARY STEPS TO OPERATE THE MACHINE FOR

THE FIRST TIME

When the machine is delivered, it is partially assembled. It is therefore necessary to assemble those

pieces that are delivered disassembled for packaging reasons.

Before starting assembling operations, the purchaser must make sure that all machine parts are intact

and have not been damaged during shipment.

In particular, we advise you to check the most fragile components, such as electrical or mechanical

parts, pneumatic tubes or the machine’s safety devices.

When assembly operations are over, the machine must be cleaned by removing protective oil, so that

wood pieces do not get stained while being worked.

CAUTION: THE MACHINE IS SUPPLIED WITHOUT A SUCTION PLANT. TO KEEP DUST CONCENTRATION BELOW THE T.L.V. SET IN THE COUNTRY WHERE THE MACHINE IS LOCATED, THE

USER MUST INSTALL A SUITABLE SUCTION PLANT ACCORDING TO USAGE, MATERIAL AND

FREQUENCY OF USE.

Saw dust disposal

Saw dust and work scraps disposal is to be carried out in compliance with the regulations in force in the

country where the machine is used. We advise you to ask the relevant bodies of your country for the

relevant legislation so that you know what steps are to be taken.

15.CONNECTING THE MACHINE TO EXTERNAL ENERGY SOURCES

After assembling and installing the machine correctly, the machine has to be connected to:

- power supply mains

- compressed air system

15.1 CONNECTING THE MACHINE TO POWER SUPPLY MAINS

Engine (or Engines) voltage and frequency are indicated on the plate located on the engines.

The user’s electric installation must comply with CEI 64.8 (CENELEC HD 384, IEC 364-4-41) standards.

The electric installation must have:

- Equipotential earthing system

- Automatic protection devices installed on the machine and connected so as to guarantee that the

machine is automatically cut off from power supply in compliance with the above-mentioned standards.

Connection to the power supply is made with a three-phase plug (or with a single-phase plug according

to the board required).

Wire for the earthing system is yellow-green.

Allowed oscillation of electric voltage is +/- 10%

Connect the machine cable to the power supply mains.

Switch the machine on and make sure the machine‘s engines are revolving clockwise. Make sure that

spindles rotation matches the direction indicated on the spindlehead. (R= right L= left). If rotation direction does not match, invert connection cables to the engine.

Refer to the electrical diagrams enclosed in this manual.

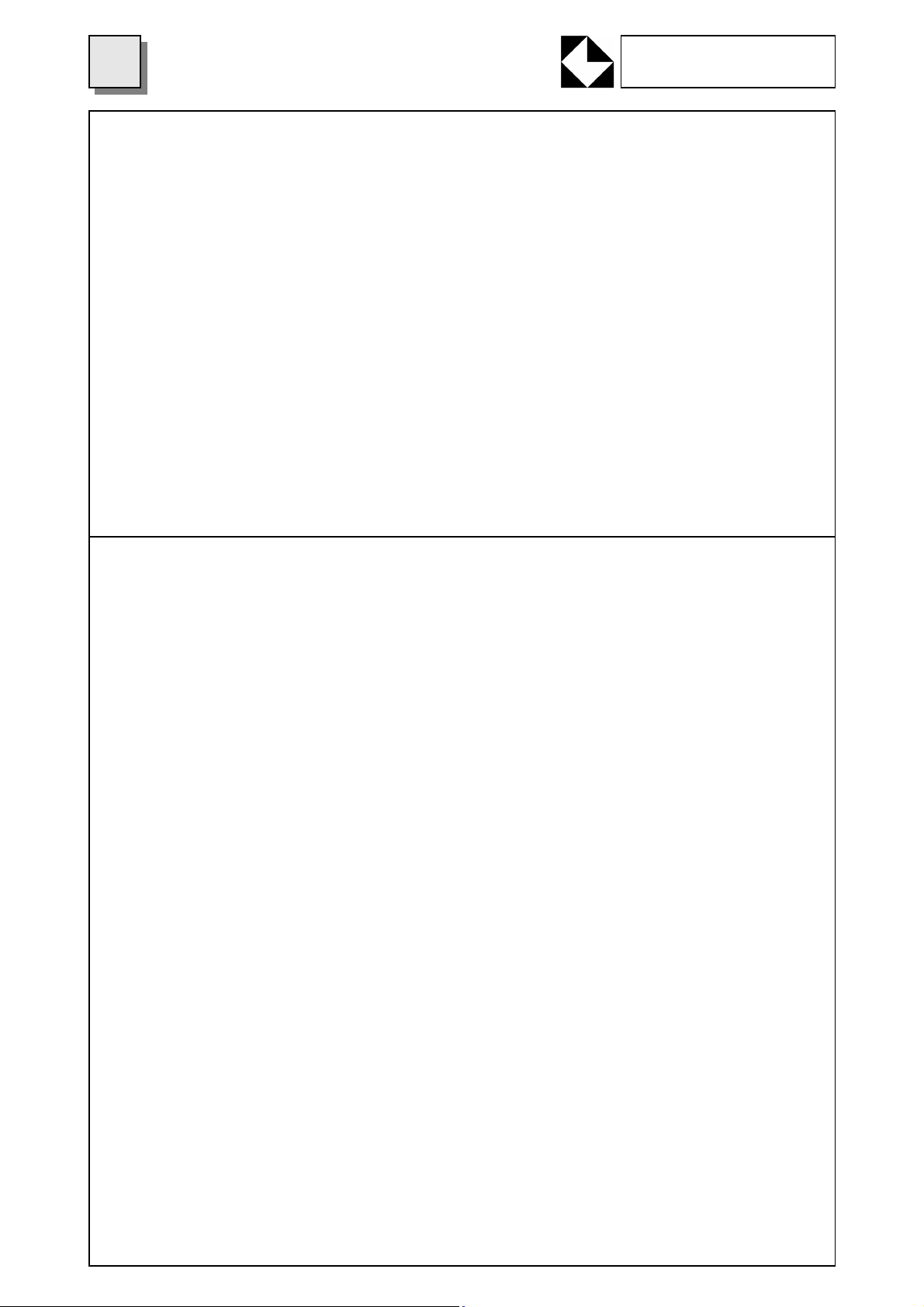

15.2 PNEUMATIC CONNECTION

1) Connect the machine to the compressed air system and make sure that the connection tube is compatible with the one provided alongside the machine itself and located on the lubrication-filter-regulator

unit at the back of the machine, in the lower left-hand side.

Pressure should range between 6 and 7 bar maximum.

1) The lubrication-filter-regulator unit is made up by:

A) A filter, whose function is to purify air from dust and humidity that might damage the valves or gaskets in pneumatic cylinders.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

B) A regulator that adjusts compressed air working pressure by keeping this value within the abovementioned limits.

C) A lubricator that puts a determined amount of oil into the system to lubricate cylinders, valves, gaskets and moving parts.

13

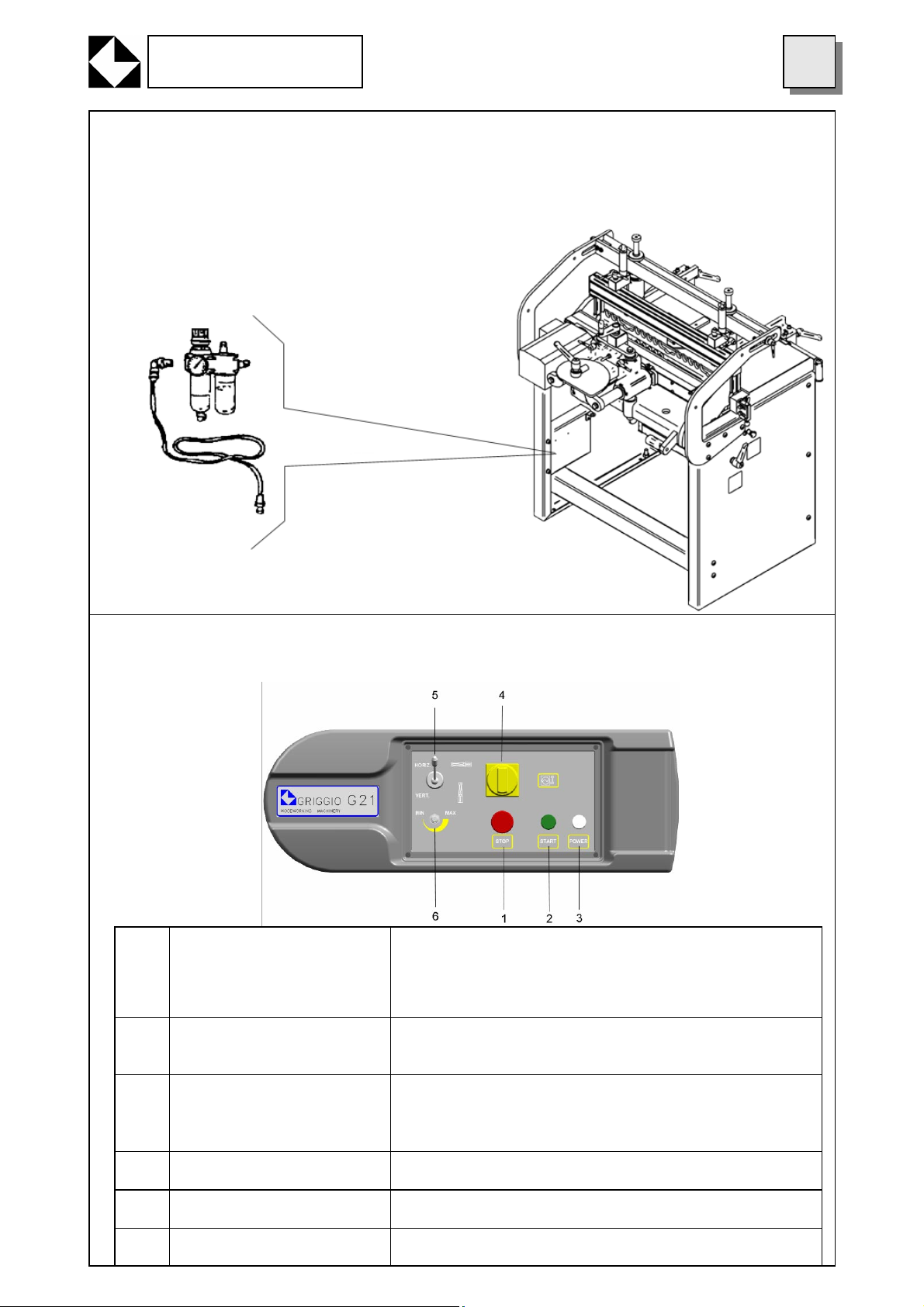

15.3 CONTROL PANEL

The control panel is located on the left-hand side of the machine:

EMERGENCY PUSHBUTTON TO HALT THE ENGINE (THE BUTTON IS

1

NOT AUTOMATICALLY RELEASED)

PUSHBUTTON WITH PILOT LIGHT TO MAKE EN-

2

GINE OPERATIONAL

1 - By pressing this button all electrical functions of the machine are switched off.

2 - To switch electric functions on, turn the mushroom

pushbutton in the direction indicated by the arrows.

1 - It gets the engine ready to be started and hence it gets

the spindles ready to rotate during the working cycle.

ON/OFF POWER INDICA-

3

TOR PILOT LIGHT

MAIN SWITCH 1 - It the switch is turned on power is supplied

4

HEAD UNIT OVERTURN-

5

ING VALVE

FEED SPEED ADJUST-

6

MENT

1 - If the light is on power is available.

2 – If the light is off power is not available.

1 – If the valve is switched on the head-unit is overturned

1 – It adjusts drills boring feed speed

14

GRIGGIO S.p.A.

WOODWORKING MACHINERY

16. CHECKS AND ADJUSTMENTS

WE ADVISE YOU TO DISCONNECT THE MACHINE FROM POWER SUPPLY AND FROM THE

PNEUMATIC SYSTEM WHENEVER YOU NEED TO SERVICE THE MACHINE ITSELF OR TO REPLACE DAMAGED OR WORN PARTS. IF THIS IS THE CASE, FOLLOW THE PROCEDURES INDICATED BELOW AND PAY ATTENTION TO THE ADVICE GIVEN IN CHAPTER 6 OF THIS MANUAL.

16.1 DISCONNECTING PROCEDURE

Before carrying out any maintenance intervention on the machine, follow this procedure:

1. Make sure the machine is in a suitable position to carry out the needed intervention. After having

fastened the machine mechanically in this position, disconnect the machine from power supply and from

the pneumatic system.

2. Make sure the machine is not connected to any other energy supply and that no residual power is

left.

It is essential that this procedure is carried out by a single person only, who will then have to make the

16.2 PREVENTION CHECKS

Make sure the area surrounding the machine is neat and clean and that no working scraps are left

around, such as saw dust and wood pieces.

MAKE SURE ALL SAFETY AND PROTECTION DEVICES ARE IN PLACE, IN GOOD WORKING ORDER AND READY FOR THE OPERATIONS THAT HAVE TO BE CARRIED OUT.

16.3 BORING DEPTH

To carry out the required boring, follow these procedures:

A) Insert suitable drills in the desired position on the spindlehead.

B) Turn the handle (1) to adjust the desired distance between drills and working table with spindlehead

at a 90° angle from table surface. Drill distance is indicated in mm. on the mechanical counter (2). Turn

the handle so that the screw is stretched in the required position at the required height, so that greater

boring precision is obtained. Drill height chosen depends on wood thickness, on the position of the hole

and on the diameter of the hole itself.

C) To set boring depth follow this procedure. Once the overall length value of the drill being used has

been found on the depth selection screw (3), it is possible to set (no calculation is needed) the actual

boring depth value. By unclamping the handle (4) and by turning the depth selection screw (3) until the

desired value, the pointer (5), which is also a magnifier, will indicate the chosen depth value. Tighten the

handle before starting boring operations.

D) Usually use a scrap wood piece to test the machine settings before boring a good piece of wood.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

16.4 HOW TO ADJUST HEAD PARALLELISM

To adjust head parallelism according to the working table:

- partially unscrew the screws (3) and operate alternatively on the screws (1) and screw nuts (2)

- position the drills parallel to the table

- tighten the screws very well (3)

15

16.5 HOW TO POSITION SPINDLEHEAD VERTICALLY AND HORIZONTALLY

To position the spindlehead at 90°, follow this procedure:

With spindlehead at 0°:

Unfasten the head by turning the handle (2) located on the left-hand side of the machine.

Operate on the boring head (3), by switching the lever (4) located at the front of the machine; lock the

head into position by tightening the handle (2).

To position the spindlehead at 0° do as follows:

With spindlehead at 90°:

Make sure the lever at the front of the

machine is also set at 90° and that the

pneumatic system is on (hence overturning lever must be active)

Unclamp spindlehead clamping handle

(2) on the left-hand side of the machine.

SELECT 0° POSITION WITH HEADPOSITIONING LEVER (4). ONCE THE

HEAD IS IN ITS NEW POSITION

CLAMP IT WITH THE CLAMPING HANDLE (2).

How to set Spindlehead at 45°

If the spindlehead is set at 0°:

- Make sure the head-overturning lever

(4) is also at 0° and that pneumatic pressure in the pneumatic system is correct.

- Insert lock at 45°in locking position;

- Clamp head-clamping handle (2);

- Lower head-rotating lever (4) located

in the front of the machine at 90°;

- Once the machine has been set at

45°, tighten the clamping handle until it is

clamped (2).

WARNING DANGER!

Follow the procedure described below very carefully.

!

PICT A

16

16.6 HOW TO USE REFERENCE STOPS FOR STANDARD 0°-90°WOODWORKING

Side rails and back stops are used to position the piece to be worked in a standard working cycle.

With spindlehead at 90° and spindle unit locked into position:

- Set side rails at the right distance from drills that will be used and fasten them.

- Position the hold-down cylinder (or hold-down cylinders) (3) on the table where the piece to be

worked will be located.

- Position the piece to

be bored against side limiters and use them as rails

to position the piece under

the hold down clamps and

right against the rack.

- Now position the stops

(2) over the piece to be

bored, lower stop reference block itself on the

piece, and clamp the stop

itself with the handle.

- The piece is in the right

position and it is now possible to start the working

cycle by pressing the pedal

that starts drills feed with

engine switched on (make

sure engine switch is on).

At the same time hold

down clamps will lock the

piece into position.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

When the first phase is over, release the pedal to release the piece and take the bored piece out of the

machine.

Unfasten the spindlehead unit and switch the overturning lever to reposition the spindlehead at 90°.

Once the head has been repositioned and locked into position, the second phase can begin:

- Position the piece that has to be joined to one that has just been worked against the side limiter under the hold down clamp (or hold down clamps) (3) and against the back stop block.

- Once you are sure the piece has been positioned correctly, press the pedal to activate hold down

clamp lock, drills rotation and drills feed.

- Once the pedal is released, the piece will be released and the working cycle will be over.

THE TWO PIECES THAT HAVE BEEN OBTAINED (0° -90°) ARE NOW READY TO BE JOINED

16.7 HOW TO USE EXTENSION FENCE (3000 MM STANDARD)

The extension fence is used to make a set of larger holes than the ones the machine can make or to

bore large pieces. To use the extension fence you usually have to exclude side limiters completely or

partially. To position the extension fence you usually have to exclude side limiters completely or partially

and to set the spindlehead at 90°. If you use the extension fence longitudinally, we advise you to exclude side limiters completely, since it is possible to use mobile reference stops on the extension fence

itself to position the piece to be worked. (The extension fence is provided with 4 mobile stops with positioning screws, stop screw and extension fence clamping device).

GRIGGIO S.p.A.

WOODWORKING MACHINERY

LONGITUDINAL POSITION OF EXTENSION FENCE:

- Unfasten the appropriate handles and turn side limiters over to bring them out of the table, making

sure they are under the working table.

- Once the working table has been cleared, position the extension fence against the back stops and

fasten it with the apposite screws.

- After positioning the extension fence longitudinally, by means of stop screw on the fence itself, use

back stops to find boring line parallel and distance between extension fence and drills line with drills

height handle.

- Lock the fence into position and the fence is now positioned correctly. By using the mobile stops it is

now possible to bore sections or repeat set of holes on long pieces.

- Add a suitable support for the fence and the board to be bored (i.e. a stand)

17

TRANSVERSAL POSITION OF EXTENSION FENCE:

To use the extension fence transversely, you have to fasten the fence to the side limiter with the apposite screws provided.

Follow this procedure:

- Position the extension fence along the inner side of the side limiter and lock it into position with the

stop screw on the extension fence itself.

- Once the extension fence has been positioned, exclude, if necessary, the other side limiter.

- It is now possible to use the mobile stops to co-ordinate the relative positions of the parts to be

bored on long pieces.

- Add a suitable support (i.e. a stand) for the fence and the piece to be bored.

18

16.8 HOW TO USE REFERENCE PIN FOR LINE BORING ON LARGE PIECES (optional)

As it can be complicated to use the extension fence to bore large pieces, our machines comes with a

reference pin. This reference pin can be used for line boring on a large wood piece with higher axial distance between first and last drill than the one obtainable with this type of boring machine. The reference

pin is aligned with the drills

axis and it fits into a slot under

the machine table once the

first series of holes has been

bored. To continue boring operations, the reference pin can

be used once again by turning

the knob to unlock the spring

that allows the reference pin to

come out. To make it possible

for another series of holes to

be bored, the reference pin

has to be inserted into one of

the holes that have just been

bored.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

16.9 HOW TO USE TRIANGULAR FENCE FOR 45° FRAMES (optional)

45° triangle can be very useful to manufacture 45°/45° frames very rapidly. Fasten the triangle on the

table in reference holes and clamp it in M8 central hole with the lever (2). In this way it is possible to lean

45-degree pieces to be bored and to join them with “dowel” wooden stakes. Machine spindlehead must

be set at 90°. When position is correct, the hold down clamp is over to piece to be worked. Proceed as

in a standard working cycle: press the control pedal to start the cycle and release the pedal at the end of

the cycle. Repeat the procedure on both sides of the triangle to obtain two specular frame pieces ready

to be joined.

HOW TO USE CENTRAL SPLINE FOR STRAIGHT 90° FRAMES (optional)

The spline is used to combine two pieces having 90°-angle sides (used mainly to make straight frames

rapidly)

- Fasten the spline (3) in the reference holes on the working table and fasten it with the lever (2).

- Position the pieces to be worked along the spline. It is now possible to start boring operations to assemble frames with “dowel” wooden stakes.

- For a correct

position the spindlehead must be at a

90° angle and the

hold down clamp

must be above the

piece to be bored.

Proceed as in a

standard working

cycle: press the control pedal to start the

cycle and release

the pedal at the end

of the cycle. Repeat

the procedure for

both sides of the

spline to obtain the

two bored parts of

the frame ready to

be joined.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

16.10 WOODWORKING EXAMPLES

19

20

GRIGGIO S.p.A.

WOODWORKING MACHINERY

GRIGGIO S.p.A.

WOODWORKING MACHINERY

17 HOW TO START THE MACHINE

The operator’s site and the control board are located in front of the electrical control panel of the machine.

17.1 WORKING CYCLE

After having programmed the machine, follow the instructions given in the following paragraph to start

the working cycle:

1) Turn the main switch (4), set it to position 1 and press MOTOR button (2). The corresponding light

will light up and the machine is ready to start the working cycle.

2) Press the pedal (A); the spindles will turn, the head will progress while the hold down clamps will

block the piece.

3) If the pedal is released, the head will return in its initial position and the spindles will stop.

4) Hold down clamps will release the block

Should you need to interrupt the working cycle, press the emergency pushbutton (1)

21

18. MAINTENANCE

Adequate servicing is a fundamental factor in guaranteeing longer life to the machine and to keep the

machine itself in good working order.

All maintenance operations must be carried out while the machine is switched off.

Always wear protective gloves and goggles.

18.1 MACHINE CLEANING (DAILY)

The machine and the working area must be kept clean from wood scraps or any other object that might

hamper the working cycle or might prevent the operator from easily reaching the machine itself. The machine must be cleaned daily. Make sure that material that is not needed to operate the machine does not

accumulate on the machine itself, thus preventing the machine from functioning safely and jeopardising

the operator during the every day working cycle.

18.2 RAILS CLEANING (WEEKLY)

Rails and slide shafts must be kept clean from working scraps since they might hamper movements of

the machine and damage its performance. Do not use detergents or lubricants.

ELECTRICAL CABLES CHECK:

Check electrical cables condition. Make sure they are not worn out or abraded.

18.3 KINEMATICS CLEANING AND CHECKS (MONTHLY)

Regularly check bearings and gears acoustically and visually inspect the spindlehead and all moving

parts

CAUTION – SLIPPING DANGER!

While cleaning the working area, mind working scraps and liquids on the floor around the ma-

!

chine, since they might cause the operator to slip.

of the machine (sliding shafts, overturning piston shaft etc.)

A

22

18.4 EXTRAORDINARY MAINTENANCE

- Make sure electrical system is safe.

- Check clamping of mechanical components.

- Check lubricating oil level in air-filtering unit and refill if necessary.

- Make sure the machine is lubricated regularly.

- Check air pressure. Line feed must be at 6 bar.

- Check condensate level and compressed air impurities settling in the transparent sump in the airpurification system.

- Make sure spindlehead is lubricated. We suggest that you use Castrol WP30 grease, Schell Alvania

EP2 grease, Agip grease or other similar lubricants.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

19. COMMON FAILURES - CAUSES AND SOLUTIONS

Some failure causes can be eliminated by the operator himself, while others failures need qualified personnel intervention. Here is a list of the most common failures, along with the correspondent service intervention.

CAUTION: Before carrying out any intervention you must strictly follow the cutting-off procedure described in chapter 16.

19.1 DRILLS ARE NOT TURNING

POSSIBLE CAUSE WHAT TO DO

A. The engine is not running - Press the engine operational button

- Release emergency pushbutton and check

fuses

- Check air pressure (to switch pressure switch

on)

B. The engine is burnt out - Replace the engine

19.2 ENGINE IS RUNNING BUT DRILLS ARE NOT TURNING

POSSIBLE CAUSE WHAT TO DO

A. Possible breakage in

-gears

-bearings

-replace them (call technical service)

19.3 IL FORO NON E’ PRECISO

POSSIBLE CAUSE WHAT TO DO

A. Drill is not clamped correctly -Check clamping. If it is correct call service inter-

vention.

B. Drills are worn - Replace or call technical service

C. Piece to be worked is not clamped correctly - Check hold down clamps, hold down clamps gas-

kets and working pressure

GRIGGIO S.p.A.

WOODWORKING MACHINERY

23

20. FAILURES THAT MIGHT OCCUR DURING MACHINE WORKING CYCLE

20.1 DRILLS LEAVING SCORCH MARKS

This problem might occur whenever the piece is not set at a 90° angle or whenever drills are worn.

Drills might also be turning in the opposite direction.

20.2 BORED PIECES ARE NOT SET AT A 90° ANGLE TO TABLE

This problem might be due to the fact that the drills have not been set at a 90° angle to the table. Check

angle of table limiters to rack as well as parallelism of drills line to table.

20.3 HEAD CANNOT ROTATE PROPERLY

If boring unit finds it difficult to reach other positions or cannot reach other positions altogether, check

hinge and shaft of overturning pneumatic piston.

20.4 HOLD DOWN CLAMPS CANNOT CLAMP WOOD PIECE

If hold down clamps cannot clamp pieces, check air pressure and connection tubes.

To solve these problems, we suggest that you contact GRIGGIO S.p.A. Post-sale Assistance Service or

your local dealer.

21. A. NOISE LEVEL

Assuming the machine is functioning properly and that tool balancing and sharpness are correct, noise

emissions can vary according to the material being worked, to drills diameter and to boring depth.

Length of time operators are expected to stay close to the machine can vary over the 8-hour working

day.

Other factors play a role in determining the exposition level, such as surrounding environment and other

sources of noise as well as the presence of other machines nearby. We advise you to inform operators

about risks resulting from a long exposition to noise and, if necessary, provide them with suitable individual protection devices.

The acoustic pressure level detected with a class-1 integrating noise meter at operator’s working position is 76.1dB (A).

This measurement has been carried out in compliance with ISO 3745 standard. During the measurement, the machine was functioning at steady state as far as pressure and speed were concerned, and

was drilling a wooden shaving panel with PVC covering.

The measurement has been carried out at a 1.5-m height in front of the machine at the operator’s working location.

The following reference measurements have been obtained by following the same procedure:

Acoustic pressure level in Atm.

dB(A):78.3

Acoustic power level

dB(A):93.3

21. B. DUST EMISSIONS

These are the results of a test carried out to determine the level of dust emissions during a non-stop

one-hour working span, while a 22 mm-thick fir panel with a PVC covering was being drilled.

Dust emission amounted to 13.9 mg/N cu.m at operator’s working location, which is at a 1.5-m height in

front of the machine.

24

22. PNEUMATIC SCHEME

1) ¼” Male quick-change

2) G ¼” lubrication-filterregulator unit

3) ¼” Wye

4) Wire muffler

5) Overturning lever Ø 30

6) G ¼”Flux Reg.

7) Overturning cylinder

8) 5/2 Pedal G ¼”

9) 1/8“ Pressure switch

10) G ¼”Flux reg.

11) Drill feed speed

12) Clamping clamps

GRIGGIO S.p.A.

WOODWORKING MACHINERY

23A. ELECTRICAL SCHEME FOR GF21 AND GF27 (WITH ONE ENGINE)

GRIGGIO S.p.A.

WOODWORKING MACHINERY

23B. ELECTRICAL SCHEME FOR GF35 (WITH TWO ENGINES)

25

I.G.: main switch;

RT ½: temperature relay;

C1/2: engine contactor;

PR: air pressure;

M1/2: driving shaft rotation;

F: main fuse.

26

GRIGGIO S.p.A.

WOODWORKING MACHINERY

24. MACHINE IS PUT OUT OF COMMISSION

If the machine has to be put out of commission, you will have to follow the following instructions strictly

so as to guarantee people’s safety and to protect the environment around the machine.

Therefore, after disconnecting the machine it is advisable to:

- Disassemble drills and put them in a suitable container, where they will be stored and protected from

damage.

- Disassemble electrical, pneumatic and hydraulic components so that they can be re-used after an

inspection or an overhaul.

- Empty oil out of hydraulic gearcase without spilling it into the environment.

- Disassemble all metallic components in the machine and divide them into separate groups according to material.

- Call a firm specialised in material regeneration and disposal (solid and liquid materials).

GRIGGIO S.p.A.

WOODWORKING MACHINERY

27

25. GUARANTEE CERTIFICATE

This machine has been manufactured in compliance with technological and safety standards and has un-

dergone a test on the manufacturer’s premises before being shipped.

GRIGGIO S.p.A. guarantees that the machine is in good working order and that it is a quality product ac-

cording to law requirements, for a 12-month period. The guarantee is not valid in case of improper usage

and servicing that do not comply with the regulations contained in this handbook and in case of adjustments

and modifications that have not been approved by the manufacturer. Guarantee terms concerning the ma-

chine’s working order are valid provided all indications given in this

USAGE AND MAINTENANCE HANDBOOK

are complied with.

Defective pieces will be replaced free of charge only after having ascertained that the machine has been

used correctly.

Complaints and service interventions covered by guarantee will only be accepted upon presentation of the

machine serial number engraved on the identification plate.

Upon receiving the machine, the purchaser must make sure that packages are whole and undamaged.

Unless otherwise agreed, the manufacturer is not responsible for damages caused to the machine during

shipment.

Should the packages be visibly damaged, we advise you to contact the shipment company immediately.

Our company will be available to provide all assistance required.

GUARANTEE AND ASCERTAINMENT COUPON

Type……………………………………...…………….Identification number………...………………

Name……………………………………………………………………………………………………..

Address…………………………………………………………………………………………………..

Postcode…………………...………………...Town……………………………………………………

Date of purchase…………………………….Dealer…..………………………………………………

Owner’s signature

……………………………………..

The owner of the machine hereby declares that he accepts the terms of guarantee and that he has ascertained that the machine is in perfect working order.

28

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Sale and Technical Service

GRIGGIO S.p.A

via Ca’ Brion, 40 - 35011 Reschigliano (PD) ITALY

Tel. 049/9200920 Fax 049/9201433

http://www.griggio.com E-Mail:info@griggio.com

GRIGGIO S.p.A.

WOODWORKING MACHINERY

26. SPARE PARTS CATALOGUE

29

30

TABLE 1 FRAME

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36200084 36200084

2 36222147 36222147

3 00000117 00000117

4 00018402 00018402

5 36222104 36222104

6 36222122 36222122

7 36222123 36222123

8 00018602 00018602

9 00000109 00000109

10 00004047 00004047

11 49900045 49900045

12 76200030 76200030

13 36200080 36700080

14 36222119 36222119

15 00018421 00018421

16 36222124 36222124

17 36200082 36200082

18 00018522 00018522

Frame Left Side

Clamping Block

D-En M 12

V-Te M 10 X 25

Electrical Box G Version

Clamping Plate

45° Threaded Bush

V-Tbei M 10 X 20

D-Es M 8

Gn 605 Screw M8 X 18 Type A

Supporting Plate

Rod With Clamping Slot Mod G

Patterned Front Cover

Vacuum Plastic Front Cover

V-Tspei M5x10

Clamping Hexagon

Frame Right Side

R-Cild M 10

1

1

4

6

1

1

1

10

1

1

1

1

1

1

12

1

1

6

19 36222120 36222120

20 36222121 36222121

21 00018523 00018523

22 00018403 00018403

23 00015224 00015224

24 00003947 00003947

25 00018501 00018501

26 36222117 36222117

27 00015223 00015223

28 36200086 36700086

29 36000087 36000087

30 00000017 00000017

31 00018297 00018297

32 00018531 00018531

33 00018290 00018290

34 00003104 00003104

35 0003303 0003303

Block Spacer

45° Stop Pin

R-Cild M 12

V-Te M 12x35

Flow Control G1-4 Pnmx Cod6.01.14n

Release Lever Krp-100 M12x60

D-En M 8

Plate Version G

Cover Lever D30 Pnmx Cod228.32.5-2-3vie

Table Back Cross Beam

Air Unit Plate

Galvan. Steel Washer Uni-6592, Ø Nom. Mm 5

Galvanised Tcbei-Screw M5x12

Deb M 4

Vcce-5931 M 4 X 12

Boteco 732-25 M8x16

Seeger Ring E 15

1

1

1

4

1

1

2

1

1

1

1

4

4

2

2

1

2

36 36222118 36222118

37 OPTIONAL OPTIONAL

38 36222105 36222105

39 00018521 00018521

40 00018307 00018307

41 36222116 36222116

Clamping Unclamping Plate Version G

Drill Holder

Control Board Sheet

R-Cild M 8

Vcce-5931 M 8x16

Overturning Plate Version G

1

1

1

2

2

1

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 1 FRAME

31

32

TABLE 2 MACHINE TABLE

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36222017 36722017

2 36222019 36722019

3 0003924 0003924

4 36000021 36000021

5 36000022 36000022

6 36000112 36000112

7 36001016 36001016

8 00004238 00004238

9 00018521 00018521

10 00005045 00005045

11 49900017 49900017

12 00005103 00005103

13 36222126 36222126

14 45400052 45400052

15 00150909 00150909

Table

Millimetrical scale

Release lever 563-65 M8 L16

Central spline

45° plate

Rotation pin

Bronze shimming ring

p-st 8 x 16 casehardened

r-cild M 8

plain bearing PAP 2530P10

pin spring

self-tapping screw 3.9x9.5 galvanised 6955

index disk

Degree plate

G-EICO M 8x20

1

1

1

1

1

1

2

4

5

2

1

6

1

1

6

16 49900014 49900014

17 49900015 49900015

18 00003923 00003923

19 00004303 00004303

20 49900016 49900016

21 00018405 00018405

22 36222125 36222125

23 00018302 00018302

Reference Pin

Reference Pin block

Boteco ball knob Art. 100-20 M5

Elastic pin Ø 4x14 6873

Reference Pin square

V-te M 8x16

Hollow rotation pin

Round-headed screw M6x10

1

1

1

1

1

4

1

1

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 2 MACHINE TABLE

33

34

TABLE 3 RACK

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36200005 36700005

2 00018608 00018608

3 00003940 00003940

4 00018307 00018307

5 36222148 36222148

6 36222129 36222129

7 36222127 36222127

8 00018311 00018311

9 00003305 00003305

10 00018522 00018522

11 00150803 00150803

12 00018501 00018501

13 00018405 00018405

14 36222128 36222128

15 36222129 36222129

Rack

V-tbei M 8X18

Boteco Sleeve 775-38 M12

V-tcei 8X16

90° Pawl

Hexagon stop

90° Stop cylinder screw

V-te M 10x35

A-Ela 12

R-cild M 10

G-EI M 8x10

D-en M 8

V-te M 8x 16

90° Stop screw

Hexagon Stop

1

2

1

10

1

1

1

4

4

4

2

2

1

1

1

16 36000105 36000105

17 00000169 00000169

18 00015205 00015205

19 36000106 36000106

20 7600002 7600002

21 36000126 36000126

22 36000125 36000125

23 00000117 00000117

24 00030507 00030507

25 36000108 36000108

26 00003462 00003462

Overturning Cylinder Lower pin

Gh-guk M 30x1.5

Overturning cylinder

Overturning Cylinder Upper pin

Cylinder Shaft fork

Threaded bush

Overturning cylinder new flange

D-en M12

V-TCEI M5x20

Overturning cylinder hinge

Oljembrons bearing S20x25x15

1

1

1

1

1

1

1

1

1

2

1

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 3 RACK

35

36

TABLE 4 LIMITERS

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36222139 36222139

2 36222134 36722134

3 36222136 36222136

4 36222135 36222135

5 00018521 00018521

6 00018531 00018531

7 00018290 00018290

8 36222137 36222137

9 00018340 00018340

10 00003936 00003936

11 00004239 00004239

12 36222131 36222131

13 36222132 36222132

14 00000035 00000035

15 00018325 00018325

Limiter Unit

Right limiter

Slide rail

Vertical Slide rail

r-cild M 8

DEB M 4

VCCE-5931 M 4 x 12

Left limiter

Socket head screw M8x25

Release lever KRP-80 M10 L30

Sp-K-28744 8x16

Right lens support

Left lens support

Washer with cone-shaped base G shape D12-30 SP 5

Round-headed screw M6x16

2

1

1

2

6

4

4

1

6

2

2

1

1

2

2

16 36222142 36222142

17 36222141 36222141

18 00550806 00550806

19 00018302 00018302

20 00018303 00018303

Lens D22

Contrast

V-tspei M 10x12

Round-headed screw M6x10

V-tcei M 6x20

2

2

2

2

5

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 4 LIMITERS

37

38

TABLE 5 SPINDLES UNIT

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36000047 36000047

2 00018314 00018314

3 36000043 36000043

4 00018524 00018524

5 36000042 36000042

6 36000045 36000045

7 00018523 00018523

8 00018403 00018403

9 00018522 00018522

10 00018313 00018313

11 36000044 36000044

12 00003960 00003960

13 00003942 00003942

14 36222046 36222046

15 36222097 36222097

16 00015206 00015206

17 00018315 00018315

Spiral stop support

VCCE-5931 M16X40

Spiral washer

r-cild M16

Spiral spigot

Lens support

r-cild M 12

V-te M 12x35

r-cild M 10

VCCE-5931 M 10x110

Plexiglas index

Counter

Botecoplast Lifting crank 216-80

Depth spiral stop

G-type Spiral plate

Drills feed cylinder

VCCE-5931 M 16x100

1

2

1

4

1

1

4

4

1

1

1

1

1

1

1

1

2

18 36222051 36222051

19 36000050 36000050

20 36000009 36000009

21 36000048 36000048

22 00003934 00003934

23 36000049 36000049

24 49900048 49900048

25 00004380 00004380

26 36000052 36000052

27 36000053 36000053

28 36000111 36000111

29 36000124 36000124

30 40000003 40000003

31 00000213 00000213

32 00018312 00018312

33* 00018455 00018455

34 00018419 00018419

Cross beam for hoisting screw (G)

Hoisting screw

Head support

Vertical guide shaft

Boteco 522-104 M10

Horizontal slide shaft

Back shaft contrast

s-el 4x26

Head-supporting plate

Rubber washer

Cylinder shaft extension

Spiral washer

Sintered bush

LI-PIA 5X5X10

V-TCEI m 10X60

G-EI M 5X6

V-tspei M 4x16

1

1

1

2

1

2

2

1

1

1

1

1

2

1

1

1

1

35 00003456 00003456

36 00003455 00003455

37 00018310 00018310

38 00003922 00003922

39 00005047 00005047

40 00000168 00000168

41 00018521 00018521

42 00018501 00018501

Ring INA AS 1730

Bearing INA AXK1730

V-tcei M 8x160

Release lever KRP-63 M8 L20

Plain bearing PAP 4020P10

Self-locking ring nut

r-cild M 8

D-en M 8

4

2

4

2

8

1

1

1

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 5 SPINDLES UNIT

39

40

TABLE 6 HOLD DOWN CLAMPS FRAME

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36200101 36200101

2 36200041 36700041

3 36000091 36000091

4 00018602 00018602

5 49900051 49900051

6 00018607 00018607

7 00003922 00003922

8 00018521 00018521

9 00018502 00018502

10 00018522 00018522

11 00018503 00018503

Right and left hold down clamps support

Cross beams

Spacing block

V-tbei M 10x30

Cross beam clamping washer

V-tbei M 8x60

Release lever KRP-63 M8 L20

r-cild M 8

Galvanised D-es M 8

r-cild M 10

D-en M 10

2

2

2

8

2

4

2

4

4

4

4

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 6 HOLD DOWN CLAMPS FRAME

41

42

TABLE 7 BACK STOP

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36222070 36722070

2 36222130 36222130

3 00003111 00003111

4 00004025 00004025

5 36222010 36222010

6 00003922 00003922

7 36000113 36000113

8 00018521 00018521

9 49900070 49900070

10 36222009 36222009

11 36000153 36000153

12 00018327 00018327

13 36222011 36222011

14 36222021 36222021

15 36222012 36222012

Back stop rail

Extruded thickness

Boteco 732-30 M8 L200

Release lever M8 L50

Back stop Shaft

Release Lever KRP-63 M8 L20

Small block for extension fence

r-cild M 8

Cap 8 80x40 – 0002602

Front Fence shaft

Thickness plate 36000153

V-tcei M 8x35

Right back stop trolley

Stops millimetrical scale

Left back stop trolley

1

2

2

1

2

3

4

2

2

2

2

6

1

2

1

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 7 BACK STOP

43

44

TABLE 8 HOLD DOWN CLAMPS

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 00003120 00003120

2 49970047 49970047

3 49970048 49970048

4 00000118 00000118

5 49970146 49970146

6 49970045 49970045

7 49900089 49900089

8 49900088 49900088

9 499700133 499700133

10 49970042 49970042

11 49970135 49970135

12 49970043 49970043

13 49970049 49970049

14 49900095 49900095

15 49970051 49970051

16 00001120 00001120

Boteco 119-32 M6

Wedge-shaped piston

Threaded cylinder

Nut M14-basso-5589

Piston spring

Clamping ring nut

Head pipe

Sliding head

Spacing hold down clamp

Piston cylinder cover

Shaft protection

Piston shaft

Upper head

Nylon bumper

Lower head

Piston gasket

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

17 00001121 00001121

18 49970040 49970040

19 49970041 49970041

20 00003393 00003393

21 49970052 49970052

22 49970053 49970053

23 00018420 00018420

24 00120404 00120404

25 00005103 00005103

Or Pneumax Cod R-1502.50.5

Piston cylinder

Hollow screw M 10

Seeger ring 50

Piston

Piston spring

VSCE-5933 M4x12

G-ipp M 4x4

Self-tapping screw 3.9x9.5 galvanised 6955

1

1

1

1

1

1

1

1

1

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 8 HOLD DOWN CLAMPS

45

46

TABLE 9 SPINDLEHEAD

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1 36222095 36722095

2 36200054 36700054

3 36000061 36000061

4 00018305 00018305

5 00003424 00003424

6 00018316 00018316

7 00000037 00000037

8 36200058 36700058

9 00018302 00018302

10 00000212 00000212

11 00000222 00000222

12 26000001 26000001

13 36000055 36000055

14 36000056 36000056

15 36000062 36000062

Spindles plate

Head unit

Quick-change bush

V-tcei M 6x90

Bearing 6001 2RS1

V-tcei M 8x85

Shimming washer

Head cover T/laser

Round-headed screw M6x10

Tongue 4x4x25

Flat tongue 5x5x50

Three-phase two-poles EM/63 engine 2HP

Connection plate

Engine connection

Steel gear Z 21

1

1

5

4

42

4

21

1

12

1

1

1

1

1

21

16 00000004 00000004

17 00000005 00000005

18 00003305 00003305

19 00018451 00018451

20 36000063 36000063

21 00018500 00018500

22 36000060 36000060

23 36000057 36000057

24 36000059 36000059

25 00018303 00018303

26 00003337 00003337

27 00000211 00000211

Knurled safety washer M8

Knurled safety washer M6

A-Ela 12

G-EI M 6x20

Bearing spacer

D-en M6

Driven spindle

Nylon connection

Driving spindle

V-tcei M 6x20

Internal ring 28

Flat tongue 4x4x12

4

4

21

2

21

2

20

1

1

4

42

20

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 9 SPINDLEHEAD

47

48

TABLE 10 EXTENSION FENCE

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Pos. Code 21G Code 27G Part name Quantity

1

2 36222145 36222145

3 00004030 00004030

4 00000037 00000037

5 00171204 00171204

6 36222144 36222144

7 00018521 00018521

8 36000113 36000113

9 00004021 00004021

10 36001078 36001078

11 36000103 36000103

12 36000100 36000100

13 36222022 36222022

14 36222023 36222023

15 00008905 00008905

36222143 36222143

3-meter extension fence with stops

Crescent stop

Release lever KRP 63 M8 L60

Shimming washer

VP-RL M 12x35

Stop casing

r-cild M8

Small block for extension fence

D-enaf M 12

Drift punch

Second millim. scale for extens. fence

First millimetrical scale for extension fence

Sec. Millim. scale for extens. fence XL

First millim. scale for extens. fence XL

Rivet D 2.4x6

1

4

4

8

4

4

4

6

4

2

1

1

1

1

20

GRIGGIO S.p.A.

WOODWORKING MACHINERY

TABLE 10 EXTENSION FENCE

49

50

35. SPARE PARTS ORDER FORM

EVERY PART OF THIS FORM MUST BE FILLED IN.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Customer

…………………………………………………………..

Address

…………………………………………………………..

…………………………………………………………..

Machine type Serial number

Date of

delivery

Date …………………………………………………….

Telephone

…………………………………………………………..

Fax

…………………………………………………………..

Table Rev. Quantity

NOTES

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………

N.B. Enclose a copy of each table where the ordered spare part is.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

Via Ca’ Brion, 40 - 35011 Reschigliano (PD) ITALY

Tel. 049/9200920 Fax 049/9201433

http://www.griggio.com E-Mail:info@griggio.com

Loading...

Loading...