GRIGGIO GC 95/1, GC 95/2RRT, GC 110/1, GC 95/2RR, GC 110/2RRT Instructions Manual

...

GC

?5/1

l

GC

95/2RR

r

GC

95/2RRT

GC

110/1

WIDE

TNSTRUCTIONS

-

GC

BELT

1'10/2RR

r

SANDING

GC

110/2RRT

MACHINE

SPARE

PARTS

7\

\,.,r

GRIGGIO

WOODW.ORKING

((

MACHINERY

Vio Co'

'lel.049/9200920

f,ìtp:l¡*w..griggio.com

Brion,

FoxO49l920l433

Reschigliono

1

-

3501

40

ITALY

(PD)

E-moil:info@griggio'cc

c!

Table

Contents:

of

General

1.

1.1.

1.2-

1.3.

1.4.

'1.5.

'1.6.

1.7.

1.8.

1.9.

WarrantY

Application

General

Machine

ldentification

Applicable

Specifications.........

Possible

Standard

1.10.

Technical

2.

2.1.

2.2.

3.

3.1.

3.2.

3.3.

4.

4.1

4.2

4.3.

Emergency

Description

Safety

Safety

Safety

Safety,rulesformaintenance..""

lnstallation

Transportation

Unpacking

Placement

4.4.

4.5.

4.6.

4.7.

4.8.

4.9.

5.

Power

Connecting

Connecting

Working

Operators

Machine

5.1.

5.2.

5.3.

Adjustingthe

5.4.

5.5.

Adjusting

5.6.

Operation

6.

6.1.

6.2.

6.2.1

6-2.2

6.3.

6.4.

6.5.

6.6.

6.7.

6.8.

6.9

Maintenance

7.

Cleaning

8.

8.1

1.

8.1

lnformation...'......-..

Operating

of

safety

application

machine

Customequipment.'......'....'

description

information....'.........

rules

rules

.............

lnstalling

Replacing

Replacing

Controlling

Centering

Contro-l

Calibration

Zero

Changing

Automatic

Manualwheel

Starting

Stopping

Catinraäng

Calibrating,

Automatic

Maintenance

Conveyor

the

connection..-.....

conditions...'

adjustments.........."'

of the

Panel'......

setting......'-

the

the

information..'.'.."""

..........'

of the

documentation..-....

machine..'.""""

configurations.""""

machine

equþrnent

of

for

for

and

of

compressed

suction....

the

the

and

the

the

of

accessories

of

safety

the

moving

set-up

.........

cleaning

machine...

the

machine.

sanding

pad

...."......"1'

height

sanding

loading

machine

tab'le

of

aã¡usting

lifting

the

description

the

and

belt"""'

working

belt

conveyor"""""""'

"..'.

system

the

of

of

.'..

.......'...

the

'.."'

...'......."

positioning

machine

machine

the

sanding

and

presanding,

control

rePairs

and

machine

schedule

Manual

"""

""""""'

machine"

""""""'

equipment"""""'

machine

operation

machine.

the

air

'

rollers"""

oscillation

tension""

read-out"""

measurement

of

unit

table

the

solid

of

sanding

and

Pad""'

3

of the machine.....

of the

wood

on

on

sanding

'

RT

the

RRT

the

belt....

machine

machine

5

5

5

6

7

7

7

I

I

I

I

0

1

.......

0

1

.

8.1.2.

8.1.3.

8.1.4.

8.1.5.

8.1.5.1.

8.1.5.2.

8.1.6.

8.1.7_

8.2.

8.3.

8.4.

8.5.

9.

Remedies

9:1.

9.2.

1A.

Tightening

Gearbox

Greasing

Belts

lnspection

Replacing

Storing

sanding

lnspection

Moving

Laying

Liquidating

the

up

Dangerous

of

Possible

Quality

defects

of

work

Spare parts.

the

chain

of loading

bolts

on

the table

and

adjustment

the belts

belts

of

emergency

machjne..........

the

machine

the

machine

situations

defects

deterioration

of table

and table

lift...........

....

........

and

for

an

extended

.............

1if.t.........

|ift........

of belts.

safety

devices

period.

..23

..23

..24

..24

..25

,.25

,,25

.25

.26

.26

.27

.28

4

f .

General

lnformation

a)

I .1 .

The

product

Warrantv

product

shall

b) Warranty

material

or

c) Warranty

operation

during

transport

d) Should the

consequential

e) File

f)

g)

Model

Serial Number

all warranty

may be

Warranty

warranty

A duly

performed

completed

has

been tested

maintain declared

applies

workmanship

doesn't

instructions,

machine

shall

repair.

to

apply to

or forces of nature.

darnages

claims dJrect$

by any

be extended

Warranty Card

priorto

properties

all defects

defects

unauthorized intrusion,

be installed

injuries.

or

professional

by

shipment.

preventing

caused

improperly,

with

the

repair

the time

must

accompany

The manufacturer

while

the warranty

the use

of

by improper

or force

we shall

manufacturer.

shop.

for

which

the

a submitted

Manufacturcls

remains

product

the

haridling,

major,

not

Repairs

such

be responsible

product

warranty

seal

warants

in force.

due

disregard

as

outside

remained

claim.

and

signature

that

the

to faulty

of

damage

for

any

warranty

under

Date of sale:

1.2. Application

Tlris manual has

delivered

environment

information for

for a safe and

The

manual is

for

easy orientation.

Please read it

reference.

Some

model, since

The manufacturer

incorporated in

Operations and

writing.

goods.

and

correct

economical

organized in

carefully

information

the

new models.

applications not

of Operatinq

been

Manual includes

compiled by the

lt contains basic

manner in

and safe

before

and drawings

reviews the Manual

which the machine

service. Furthermore,

operation

Chapters

you

may not

information for all

listed

Manual

manufacturer

infiormation

during

the

pertaining

start

using

be applicable specifically

continuously

here require

qualified

for

of the

equipment

operators.

should

it includes

planned

to details

service life

particular

of

machine,

the

manufactured models.

updates

and

the manufacturer's

and is

lt

be used,

the text

of the

subþct

and file

to

the

it with

prior

part

of the

describes

the

including

of

regulations

machine.

matters,

it for

modifications

firture

pur,chased

approval in

all

Notice

to

adhered

the

that

following regulation.

the

consequence.

recommends

to,

serious

5

injury

proceed

to

Should

or death to the

exclusively

the regulation

according

operator

be not

may

be

d

Warning

machine

environmental, or economical

that improper

may

cause

procedures

injury, machine

or application

damages.

of

the

breakdown,

Gnnara

1.3.

The machine

Safety, horuever,

Non-adherence

yourself

The use

mind

Be extra

Prior

Prior

readiness.

Prior

befrore

For

main

General

precept.

From

has

as

well

at

all

to starting

to

to maintenance

you

switching

switch

cleanliness

experience

etc., ate

working"

gears,

international

Always

Never

Never

button

tie

use

work

start

Warning

Non-adherence

to the machine.

I safet i.n rmati

been

depends

to

the following

as other

of any

times.

careful

any

deactivate

to 0

v fo

designed to

great

to a

oeople.

kind of machine

wtren

the machine

work,

the

position,

getting

install

and clean

safety elements.

machine off

shut

of

the

we found that

often

causes of injuries.

your

up

your

up

safety

goggles

with

too small

the

machine, unless

sleeves,

free

rules.

or eye

or too

demanding

may

due considerations

cause minor injuries

(ln

guaran-tee

degree on

outmost

you.

safety regulations

represents

ready

read carefulty

and

for

any work

check

up, make

for set-up

off cornpressed

machine and the floor

personal

Therefiore,

remove

flowing hair,

protectors.

large

all safiety

pieces.

certain risks

the Operating Manual.

all safety

sure the

or dismantling of

air, and lock.,

items

your

necktie

and wear work shoes

elements have been

during

and/or damage

-

safety and

represents danger of injury

optimal

that

performance.

have

to be kept in

work.

elements in their functíonal

machine

around is an important

like rings,

remove

so

is at

a complete stop

part,

any

watches,

them before

that it doesn't

switch

safety

bracelets,

you

start

enter the

prescribed

properly

activated.

to

the

by

6

1.4,

M

appl[c

e

R

a semi-automatic

is

BS

of lacquer,

similar

and

operations.

ldentific

1.5.

)

m sfmr

ProÍM

wr}@t

@

ìf*

Parts

G@s.r¡

¡4

ilP

Applicable

1.6.

of the

- electrical

pneurnatic

-

and sanding

materials.

lt

ion

IL

((

túff

æ

ffi

ffi

documentation

Operating

schematic

circuit

Manual

schematic

machine

pieces made

of

also

may

the

of

macfiine

The

attached

are

used

be

to the

finishing

for

of solid

used

may

wood,

whetting

for

e

be identified

stand.in

work,

rear

the

calibration,

surface treatment

wood-particle

lacquered

the manuúacturing

by

machine.

the

of

boards,

planks,

boards between

label

7

1.7.

Specificati

Max.

working

Min.

working

Max.

working

Diameter

Length

Speed

Speed

Nominalvoltage

Main

Forwarding

Table

Pneumatic

Air

intake

Min.

suction

Min.

suction

Diameter

Machine

Weight

Level

Level

Dust

emanation

of

working

of the

of

the

of

the

electric

electric

lifting

of

of

electric

circuit pressur€

air

capacity

of

suction

dimensions

(as

to

and

appoíntment)

noise

acoustic

ons

width

width

width

rollers

sanding

sanding

forwarding

motor power

speed

selected

pressure

belt

belt

motor

motor

hose

L

x W

configuration

belt

power

power

x

mm

mm

mm

m.m

mm

m.s-r

m.min-1

Vl\z

KW

KW

KW

(MPa)

bar

dm3.min-r

m.sec-1

m3.hod-r

mm

H

rnm

kg

(A)

dB

(A)

dB

mg.m'

-?

950

33

160

180

1900

18

4,519

400/50

7.5

0.3/0.55

0,25

6(0,6)

20-30

28

3100

120

f

395x1

730-890

95

81

0,57

320x1950

1100

160

180

1900

18

4,519

400t50

7.5

a,55t1

0,25

(0,6)

6

20-30

zB

3500

120

1395x1

930-

1120

96

82

0,64

470x1

9S0

Certificate

The

listed

Although

cannot

affect

sources

there

be

real

of

values

is

used

for

exposure

noise,

such

are

emission

correlation

reliabb

vatues

determination

as

the

values

between

to

the workers

nurnber

and

emission

possible

of

of

machines,

are

not

and

include

etc.

necessarily

""porré

required

conditions

further

safe

values,

of

the

working

such

steps.

Factors

rorLrrláp,

values.

values

that

;pr*

I

1.8

GC

12

Possible

RR

machine

RT

/1

GC

confiqurations

GC

/2

RRT

Standard

1.9.

Rubberized

-

-

ca[ibrating

Sh

-

80

- sanding

Sh

- 50

- Motorized

- Rubberized

- SafetY

Two

-

gate

feeding

working

table

Pressing

the

at

sPeeds

machine

roller

roller

roHer

lift

rollers

machine

accessories

inPut

.Pneumaticcontrolledoscillationofthesandingbelt

working

- Brake

Start

-

Mechanical

-

of

star-delta

- Ampermeter

_

såiåðtabte

Working

-

Holderlor

-

ópét"ting,

-

Construction

-

1.10.

units

Gust

s,bft

the

Maintenance,

units

õonnection

table

gauging

set

hose

of

semi-hard

or

by

r-rp

to

sanding

êuction

and

;;l-"Opoin'tment

uipme

eq

om

(manua¡y

elevation

pad

for

-

belts

opening

Set-up

line

in

controlled)

and

RT

connection

Manual..

valid

with

RRT

.

configuration

^-

standards'

CE

kW

lncreased

Extended

iectr¡cal

f

Electronic

Àutomatic

controlled

Pad

motor

table

sta

table

table

power

*iti'rói1"rc

rt.étar-delta,

positioning

positioning

PneumaticallY

11

autom

15kW,

kW,

'oearings

on

display

tfte

to

ati

18'5

the

at

ntro

co

ly

cal

thickness

input

lled

material

of

Padcontrolledpneumaticallywithautomaticcontrol

pneumatic

Soft

etowing

Automãtic

of

pad with

sanding

centeriñg

belts

the

of

adjustable

longer

for

feeding

firmness

life

belt

I

and

output

to

the

machine

2.Tec

h

nic

al

des

c ript

on

of

the

machi

ne

2.1.

Emergency

Push

stop'

and

2.2.

The

situations

a)

b)

c)

d)

e)

fl

g)

h)

¡)

Two

one

safety

Folding

Lockable

the

Blocking

main

Door

Automatic

the

limit,

-sanding

loose,

sanding

set

limits.

umit

during

Position,

switch

specific

cw'

The

remove

worker,

activate

the

electrical

Emer

equipment

button

on

for

such

the

cover

equipment

gate

main

padlock

sr,vitch

dur.ing

of

doois

in

switches'

brake.

emergency

and

some

belt

and

stops

belt position

switch

its

.of

positioning

blocked

set-up

switches

and

store

well

versed

the

switch

box.

encv

eoui

for

emergency

buttonsãre

at

the

protects

at

the

mate¡:ial

switch.

repair.s!

ón

the,,ofif"

Accídeñtal

position.

stops

stop

búüon,

other

safety

tension

the

"*¡'t"tl

machine,

switch

table

or

position

by

the

by

lock

maintenance

are

out

safely.

in

The

in

the

its

original positio"

þme

stopping

td

the

stopping

instatted

rear

of

the

the

entry

Prevents

the

electrical

opening

the'macñin

efectricat

devices.

prevents

åhourd

stops

limits

motor.

allows

operations.'lnsert

of

service

deactivation

operation

escrip

machine

oñ

machin".

operator

to

unauthorized

of

of

tne

the

box.

side

tion

in

the

machine.

machine

in"

and

machine.

The

doors

rs

"y.t

power

ttre

the

extreme

It

blocks

for..tenporary

in

this

and

inier,ruption,

the

machine

oeit

machine

rurtner

póéition

oi

swiicher

funciion

pri"i

Ëreat.

top

iå

case

of

one

-

shaped

the

starting.

door

stops

w¡th¡ir

from

when

and

moyement

¡rwvtrrvrrr

release

key

in

io

r"y

of

start.

danger.

All

systems

;"iË

button

machine

Lock

may

rrrqv

be

ve

the

running

a

fime

lim¡t.

drop

being

the

vibrating

bottom

towards

of

door

the

switch

r."ðtiuåì"

Àê

¿ãne

trí"

rããn¡ne.

The

switch

of

the

front

control

is

red.

against

the

main

opened

vp

machine.

lt

¡n

ä¡i'pi"JJr;ff"Ë;

started

positions

rL'Yr

contacts

lock

turn

only

is

dangerous

switch

only

is

activated

with

belt

of

the

the

end

and

the

key

by

a

¡te

may

located

with

the

exceeds

trained

machine

paner,

w*h

the

by

belt

table

limit

dur:ing

twn

it

ccw,

also

inside

3.

Sa-f-etv

Read

3.1.

Lifting

suitable

workers.

ftlg

hoist,

the

Safetv

ger¡on

the

information

operating

rules

and

moving

equipment

-may

lift

t'uck,

be

or

Manuat

for

movinq

the

machine

that

has

present

any

other

carefutly

before

the

may

been

underneath

specified

rifting

or moving

starting

mach_ine

d.ole

g9

ror

a lifted

10

the

machine,

ysing

only

such

tÀis'[rrpo.",

machine

equipment.

or

and

in

its

proper

by

íts

vicinity,

set-up

and

trained

and

or

repair.

technically

and

skilled

near

the

3.2.

Safetv rules for

t-up

and

operation

of

the

ma!hi¡e

strictly

It is

Section

operator

The

wood

be older than

must

The operator

territory

Operate

Manual.

to startingthe

Prior

Never

Obserue

When

Unless

to

Prior

to starting the

Prior

working sections.

the

speed.

not allowed to

is

It

not touch

Do

working

forbidden to

1.3.

machining or a

of work.

the machine only

place your

proper

working,

protective

all

starting the machine

on heavy

perform other

must

must comply

illumination

prevent

adept

be

person instructed

years.

18

with

machine

hands

interfere

or other

unauthorized

safety

and

machine,

lnsert

with

of

runníng sanding

pieces.

physically

all safety

accordance

in

check

make

make

them

the

objects

work

the

personnel

devices

sure

sure

frst

electrical circuitry

the

and

belt

machine than

work on

and

by

regulations and

vicinity of the machine.

near the moving

area.

are functional,

that no objects

that machined

after

the

mentally.

him may operate

with

the

pressing

Only a

recommendations

frorn entering

do not

have been

pieces

machine

by untrained

rollers.

rules established for the

parts.

has

specified

person

the

trained in the

machine

of the

near the machine.

use the machine.

lefr in machine.

been

have

reached its full

people.

Be extremely

and listed

field

Strch workers

given

Operating

removed from

operating

careful when

in

of

d

3.3.

Safetv

Do not tet unqualified

Manual

before

machine.-Prior

4. lnstallation

Transportation

4.1.

Å*,

mln990 m

60%

ks(mln)

å

rules

you

workn

to

maintena.nce

for

personnel

start

working.

make

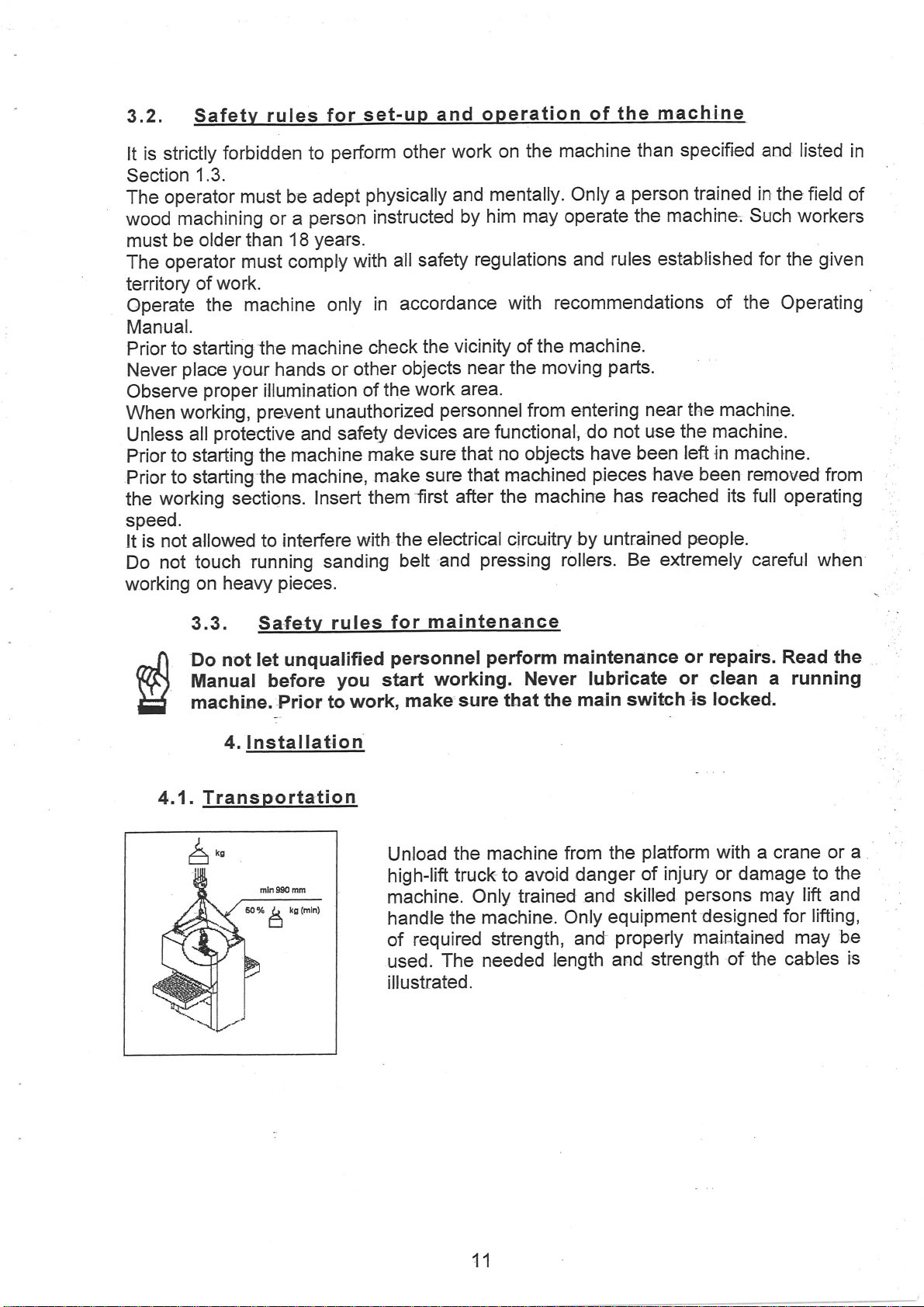

Unload

high-lift

the machine

truck to

machine.

handle

of

used.

illustrated.

the

required

The needed

perform

maintenance

Never lubricate

sure that the

from the

avoid danger

Only trained

machine.

strength,

Only

length

main

swiúch

platform

of

and skilled

equipment

properly

and

and

or repairs.

Read

or clean a running

is

locked.

with

a crane

injury or damage to

persons

designed for

maintained may

strength

may

of

the cables

the

or

the

lift and

lifting,

be

a

is

11

4.2.

Unpa

ckinq

and

cleanin

the

rnac

I ne.

Unpack

check

Remove

Wash

protective

prescribed

the

for

off conservation

4.3.

L max

*flr5

m

1,5 m

w

machine.

possible

wooden pads.

means

damage

and

Placement

rì

L

max

m

î

sustained

.film

obey

of

rules

the

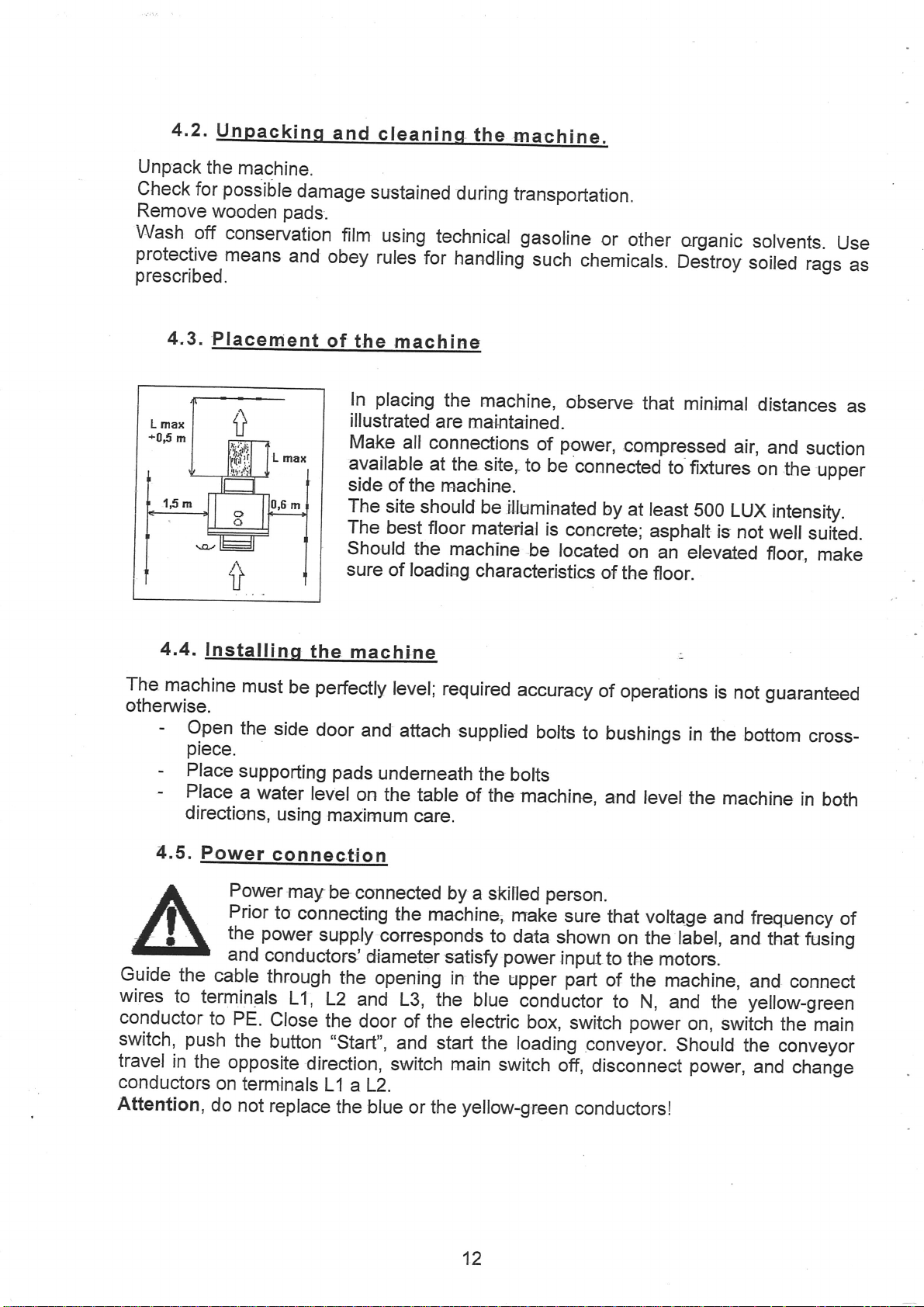

placing

ln

illustrated

Make

available

side

The

The

should

sure

during

using

technical gasoline

for

handling

machine

the

machine,

are

maintained.

all connections

at

the site,

of the

site

best

of loading

machine.

should be

floor

material

the

machine

characteristics

hansportation.

or

such

to

illuminated

be

observe

power,

of

be

connected

is

concrete;

focated

chemicals.

by

of

other

compr€ssed

that

organic

Deétroy

minimal

to fixtures

at

reast

sOo

asphalt

on

an

elevatcd

the

floor.

is

soiled

air,

LUX

not

solvents.

rags

distances

and

suction

on

the

upper

intensity.

well

suiied.

floor,

make

Use

as

as

4.4.

The

machine

otherwise.

-

Open

piece.

-

Place

-

Place

directions,

4.5.

Guide

wires

conductor

switch,

travel

conductors

Attention,

the

to

push

in

the

lnstallinq

must

the

side

supporting

a

water

using

Power

cable

terminals

to

on

do

connection

Powe

Prior

the

and

opposite

r

may

to

power

conductors

through

PE.

Close

the

button

terminals

not

replace

the

machine

perfectly

be

door

and

pads

level

on

maximum

be

connected

connecting

supply

the

L1,

L2

and L3,

the door of

"Start',,

direction,

L1 aL2.

the blue

level;

underneath

the

required

attach

table of

care.

the machine,

corresponds

dia

meter

opening in

the blue

the electric

and start

switch main

or the

accuracy

supplied

the

bolts

the

machine,

by

a skitled

make

to

data

the

power

upper

satisff

conductor

the

loading

switch

yellow-gr.een

of

bolts

to

person

sure

shown

inputto

part

box,

switch

conveyor.

off, disconneet

conductors!

:

operations

bushings

and

level

that

voltage

on

the label,

the

motors

of

the machine,

to N,

and the

power

on,

Should

is

not

in

the

the

machine

and

and

switch

power,

guaranteed

bottom

frequency

and

yellow-green

the

and

cross-

in

that

fusing

connect

the

main

conveyor

change

both

of

12

Loading...

Loading...