Tele Web Controller

Telecontrol Module through the WEB

USER MANUAL

grifo

®

ITALIAN TECHNOLOGY

http://www.grifo.it http://www.grifo.com

Tel. +39 051 892.052 (a. r.) FAX: +39 051 893.661

Tele Web Controller

, GPC®, grifo®, are trade marks of grifo

Via dell' Artigiano, 8/6

40016 San Giorgio di Piano

(Bologna) ITALY

E-mail: grifo@grifo.it

Rel. 5.00 Edition 27 October 2004

®

Tele Web Controller

Telecontrol Module through the WEB

USER MANUAL

Can be driven through Internet using a normal Web Browser (e. g.

Internet Explorer, Netscape, ecc.) from anywhere in the world.

Access to all the on-board resouces through Password protected Web

pages. Can manage up to 32 Optocoupled Inputs and 24 Outputs

buffered by transistor or relay, visualized by LEDs on board. Each

signal has its own identification Label, that the user can change via

Web. Signals status is reported by graphics on the Web page. Optional

Web page to manage a Real Time Clock backed with Lithium battery.

Optional Web page to manage a Data Logger that can save data in

Excel compatible format. Optional Web page to manage eventual

Black Outs date and time memorization (available only matched with

real time clock). Optional Web page to manage Analog Inputs.

Connection to internet thorugh on-board Ethernet interface. IP

address can be changed dynamilically, even when the server is

working. Wide range of power supply. Development system provided

with IDE. Powerful programming language PCode to optimize CGI

Scripts and control directly all the hardware interfaces and all the

protocols supported. Supported protocols: TCP/IP, BOOTP, SMTP,

HTTP, PING, UDP. Wide range of example programs. PicoWeb

development software can be used with Win95/98/Win2k and XP.

Complete documentation in PDF format that explains every detail

about instalaltion, development and finalization of application program.

grifo

®

ITALIAN TECHNOLOGY

http://www.grifo.it http://www.grifo.com

Tel. +39 051 892.052 (a. r.) FAX: +39 051 893.661

Tele Web Controller

, GPC®, grifo®, are trade marks of grifo

Via dell' Artigiano, 8/6

40016 San Giorgio di Piano

(Bologna) ITALY

E-mail: grifo@grifo.it

Rel. 5.00 Edition 27 October 2004

®

DOCUMENTATION COPYRIGHT BY grifo® , ALL RIGHTS RESER VED

No part of this document may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language or computer language, in any form or

by any means, either electronic, mechanical, magnetic, optical, chemical, manual, or

otherwise, without the prior written consent of grifo

®

.

IMPORTANT

Although all the information contained herein have been carefully verified, grifo

assumes no responsability for errors that might appear in this document, or for damage

to things or persons resulting from technical errors, omission and improper use of this

manual and of the related software and hardware.

®

grifo

reserves the right to change the contents and form of this document, as well as

the features and specification of its products at any time, without prior notice, to obtain

always the best product.

For specific informations on the components mounted on the card, please refer to the

Data Book of the builder or second sources.

SYMBOLS DESCRIPTION

In the manual could appear the following symbols:

Attention: Generic danger

®

Attention: High voltage

Attention: ESD sensitive device

Trade Marks

, GPC®, grifo® : are trade marks of grifo®.

Other Product and Company names listed, are trade marks of their respective companies.

ITALIAN TECHNOLOGY grifo

®

GENERAL INDEX

INTRODUCTION ........................................................................................................................ 1

FIRMWARE VERSION .............................................................................................................. 3

GENERAL INFORMATION ...................................................................................................... 4

INTERNET INTERFACE ...................................................................................................... 6

OUTPUT SECTION OF ZBR ................................................................................................ 6

OUTPUT SECTION OF ZBT ................................................................................................ 6

INPUT SECTION OF ZBT AND ZBR .................................................................................. 6

POWER SUPPLY SECTION ................................................................................................. 6

TECHNICAL FEATURES .......................................................................................................... 8

GENERAL FEATURES .......................................................................................................... 8

PHYSICAL FEATURES......................................................................................................... 8

ELECTRIC FEATURES......................................................................................................... 9

INSTALLATION ........................................................................................................................ 10

MATERIAL REQUIRED ..................................................................................................... 10

POWER SUPPLY .................................................................................................................. 10

SOFTWARE INSTALLATION ............................................................................................ 12

LOW LEVEL CONFIGURATION...................................................................................... 12

ZBX MAPPING ADDRESS............................................................................................. 15

HIGH LEVEL CONFIGURATION..................................................................................... 16

UTILIZATION ........................................................................................................................... 17

LOGIN .................................................................................................................................... 17

OUTPUT COMMANDS ....................................................................................................... 18

INPUT COMMANDS............................................................................................................ 18

LABELS MANAGEMENT .................................................................................................. 20

REAL TIME CLOCK MANAGEMENT (OPTIONAL) ................................................... 20

DATA LOGGER MANAGEMENT (OPTIONAL) ............................................................ 20

ANALOG INPUTS MANAGEMENT (OPTIONAL) ........................................................ 22

PERSONALIZATIONS ............................................................................................................. 23

PERSONALIZATION OF ICONS....................................................................................... 24

PERSONALIZATION OF HTML PAGES ......................................................................... 24

APPENDIX A: ALPHABETICAL INDEX ............................................................................ A-1

GMB HR168 & GMM AC0 Rel. 3.00

Page I

grifo

®

ITALIAN TECHNOLOGY

FIGURE INDEX

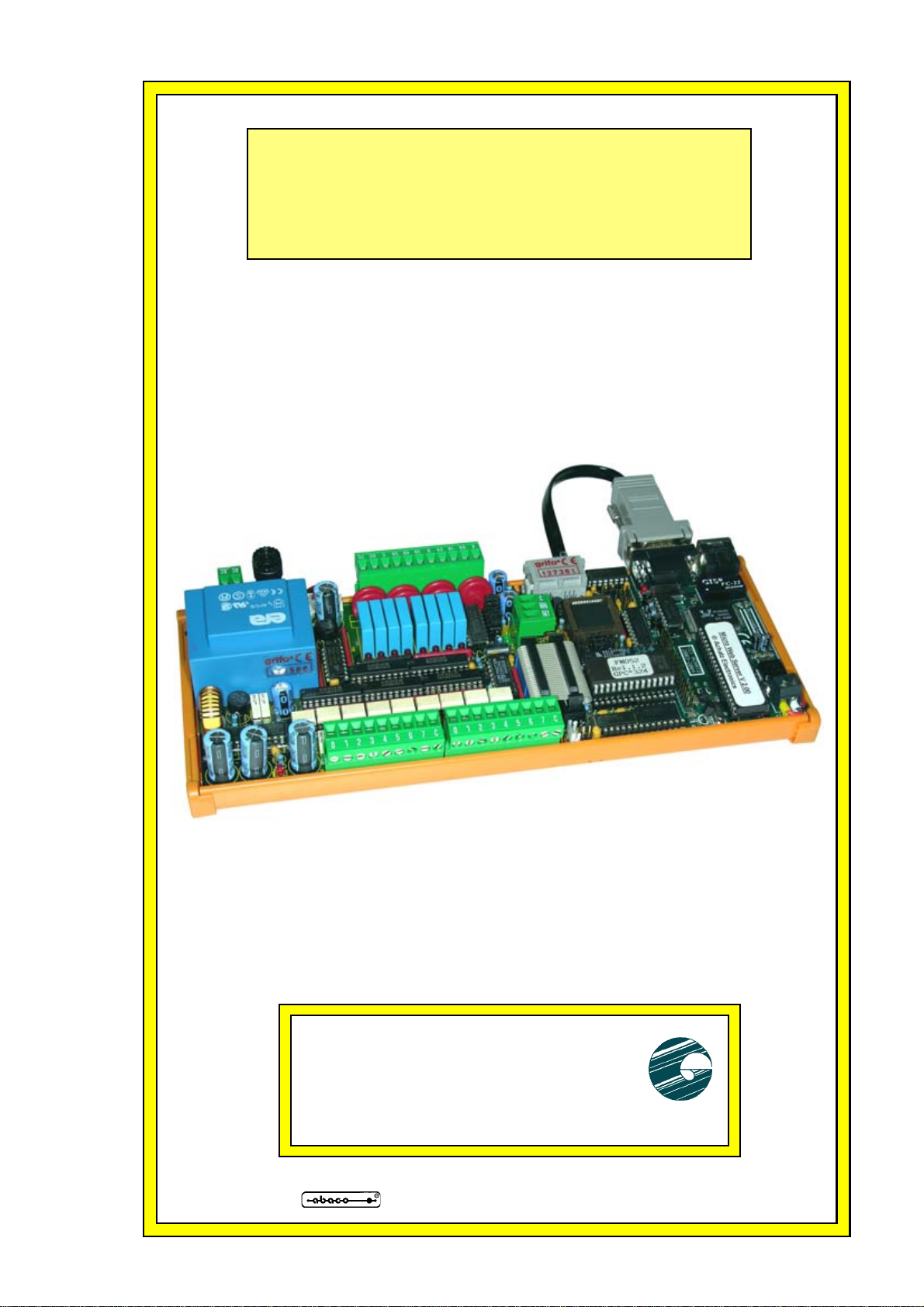

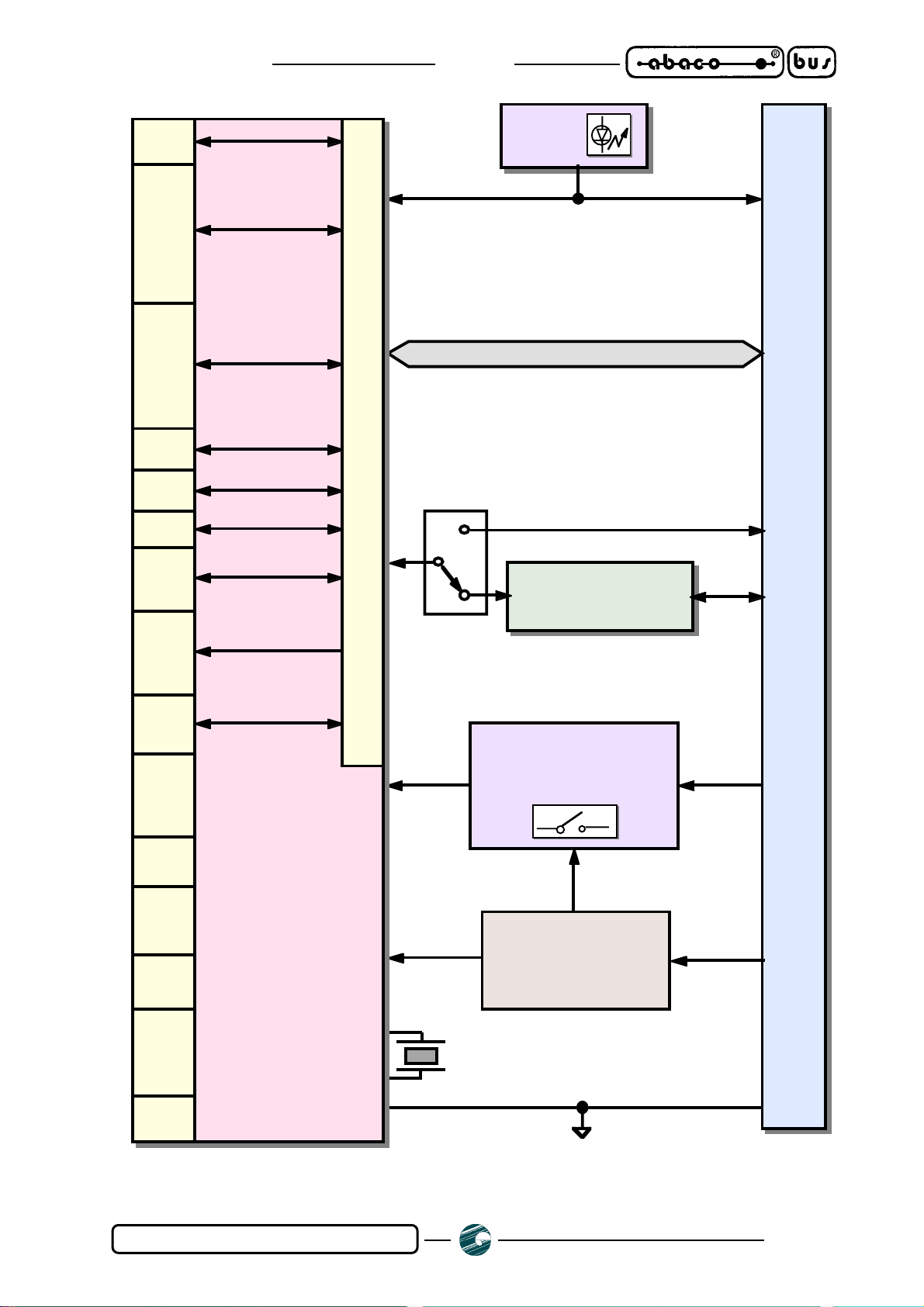

FIGURE 1: BLOCKS DIAGRAM ............................................................................................................ 5

FIGURE 2: PHOTO OF TELE WEB ...................................................................................................... 7

FIGURE 3: SNAPSHOT OF MICRO WEB SERVER ............................................................................... 11

FIGURE 4: SNAPSHOT OF ZBR 168 ................................................................................................ 1 1

FIGURE 5: MICRO WEB SERVER COMPLETE DELIVERY.................................................................... 13

FIGURE 6: LOW LEVEL CONFIGURATION .......................................................................................... 14

FIGURE 7: ZBX MAPPING ADDRESS.................................................................................................. 15

FIGURE 8: SNAPSHOT OF A GPC® 324D......................................................................................... 15

FIGURE 9: LOGIN ........................................................................................................................... 17

FIGURE 10: COMMANDS PAGE OF ZBX 168..................................................................................... 19

FIGURE 11: LABELS MANAGEMENT ................................................................................................. 19

FIGURE 12: CHANGE SIGNALS NAMES.............................................................................................. 21

Page II

GMB HR168 & GMM AC0 Rel. 3.00

ITALIAN TECHNOLOGY grifo

®

INTRODUCTION

The use of these devices has turned - IN EXCLUSIVE WAY - to specialized personnel.

This device is not a safe component as defined in directive 98-37/CE.

Pins of Modules are not provided with any kind of ESD protection. They are connected directly to

their respective pins of microcontroller. Modules are affected by electrostatic discharges.

Personnel who handles Modules is invited to take all necessary precautions to avoid possible

damages caused by electrostatic discharges.

The purpose of this handbook is to give the necessary information to the cognizant and sure use of

the products. They are the result of a continual and systematic elaboration of data and technical tests

saved and validated from the manufacturer, related to the inside modes of certainty and quality of

the information.

The reported data are destined- IN EXCLUSIVE WAY- to specialized users, that can interact with

the devices in safety conditions for the persons, for the machine and for the enviroment, impersonating

an elementary diagnostic of breakdowns and of malfunction conditions by performing simple

functional verify operations , in the height respect of the actual safety and health norms.

The informations for the installation, the assemblage, the dismantlement, the handling, the adjustment,

the reparation and the contingent accessories, devices etc. installation are destined - and then

executable - always and in exclusive way from specialized warned and educated personnel, or

directly from the TECHNICAL AUTHORIZED ASSISTANCE, in the height respect of the

manufacturer recommendations and the actual safety and health norms.

The devices can't be used outside a box. The user must always insert the cards in a container that

rispect the actual safety normative. The protection of this container is not threshold to the only

atmospheric agents, but specially to mechanic, electric, magnetic, etc. ones.

To be on good terms with the products, is necessary guarantee legibility and conservation of the

manual, also for future references. In case of deterioration or more easily for technical updates,

consult the AUTHORIZED TECHNICAL ASSISTANCE directly.

Tele Web Controller Rel. 5.00

Page 1

grifo

®

ITALIAN TECHNOLOGY

To prevent problems during card utilization, it is a good practice to read carefully all the informations

of this manual. After this reading, the user can use the general index and the alphabetical index,

respectly at the begining and at the end of the manual, to find information in a faster and more easy

way.

Page 2

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

FIRMWARE VERSION

The present handbook is reported to the firmware installed on Tele-Web.

The firmware name is Tele Web Controller, so this manual describers version 1.0 of Tele Web

Controller.

In addition, this manual describes the basic version of the firmware, that is the version without the

several options like Real Time Clock, data logger, analog inputs, etc.

The working of the several options is described in specific manuals delivered only when the option

itself is purchased.

Tele Web Controller Rel. 5.00

Page 3

grifo

®

ITALIAN TECHNOLOGY

GENERAL INFORMATION

Tele-Web by grifo® is a hardware structre that allows to drive through Internet an Input/Output

peripheral module type grifo® ZBR or ZBT using a commin Web Browser.

Just assigning Tele-Web an IP address makes possible to reach it from anywhere in the world through

the network, regardless of the distance.

The module is made of three components enclosed in a plastic container that allows to mount on

standard Omega rail DIN 46277-1 and 46277-3.

Tele-Web can be optionally provided with a Real Time Clock capable to manage date and time, and

that can memorize timestamps of eventual black outs.

In addition, local SRAM can be used as a circular stack to make a data logger (optional), that can

memorize events (e.g. status of inputs and outputs, etc.) with timestamp at a regolable frequency and

even save the memory content to the PC in a Excel compatible format.

There is also an option to feature eight analog inputs, that can be read through the Web interface and

can be manage by the data logger.

Peripheral modules are provided with relays outputs (ZBR) or NPN transistor outputs (ZBT) in a

variable number according to the model, and optocoupled inputs, also these in a variable number

according to the model.

Overall features of union Tele-Web are:

- Can be driven through Internet using a normal Web Browser (e. g. Internet Explorer,

Netscape, ecc.) from anywhere in the world.

- Access to all the on-board resouces through Password protected Web pages.

- Can manage up to 32 optocoupled inputs and 24 outputs buffered by transistor or relay,

visualized by LEDs on board.

- Each signal has its own identification Label, that the user can change via Web. Signals

status is reported by graphics on the Web page.

- Optional Web page to manage a real time clock backed with Lithium battery.

- Optional Web page to manage a Data Logger that can save data in Excel compatible

format. - Optional Web page to manage eventual Black Outs date and time memorization

(available only matched with real time clock).

- Optional Web page to manage Analog Inputs. Connection to internet thorugh on-board

Ethernet interface.

- IP address can be changed dynamilically, even when the server is working.

- Wide range of power supply. Development system provided with IDE.

- Powerful programming language PCode to optimize CGI Scripts and control directly all

the hardware interfaces and all the protocols supported.

- Supported protocols: TCP/IP, BOOTP, SMTP, HTTP, PING, UDP. Wide range of

example programs.

- PicoWeb development software can be used with Win95/98/Win2k and XP.

- Complete documentation in PDF format that explains every detail about instalaltion,

development and finalization of application program.

Here follows a description of the board's functional blocks, with an indication of the operations

performed by each one. To easily locate such section on verify their connections please refer to figure

1.

Page 4

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

6 Lines

CCU

7 Lines

ANALOG

COMPARATOR

2 Lines

COUNTER

PWM, TIMER

2 Lines

I2C

2 Lines

INT

4 Lines

SPI

2 Lines

UART

LED

1 signals

20 signals

Internal MUX

2 signals

(TTL serial line)

RS 232 DRIVER

protection ±15 kV

KEYPAD

I/O

PORT

DOG

WATCH

RTC

8 KB

FLASH

RAM

768 B

512 B

EEPROM

8 Lines

23 Lines

CPU

28 pins socket CN1

WORKING MODE

SELECTOR

(RUN/DEBUG)

WIDE RANGE

POWER SUPPLY

SECTION

2.6 ÷ 20 Vdc

P89LPC932

CLK

Tele Web Controller Rel. 5.00

FIGURE 1: BLOCKS DIAGRAM

Page 5

grifo

®

ITALIAN TECHNOLOGY

INTERNET INTERFACE

Internet interface is module Micro Web Server, a real HTTP server based on the resources of a

microcontroller and capable to connect to any local network or router through the Ethernet interface.

This module features several on board resources, for a complete description please refer to the Micro

Web Server.

In detail, RS 232 interface of Micro Web Server is used to communicate to GPC® control card and

to reach the resources of other peripheral modules.

OUTPUT SECTION OF ZBR

This section can feature 4, 8 ,16 or 32 latched output signals, according to the model ordered.

Each output signal is visualized through a LED and controls a 3 A relay, normally open, provided

with MOV 24 Vac noise suppressor.

These signals can be completely driven by the icons on the commands Web page, which also show

the outputs status using a different color.

Clicking on the icon of a signal complements its status.

OUTPUT SECTION OF ZBT

This section can feature 4, 8 ,16 or 32 latched output signals, according to the model ordered.

Each output signal is galvanically isolated, visualized through a LED and controls a not continuous

4 A Open Collector 45 Vdc Darlington Transistor, provided with suppression diode.

These signals can be completely driven by the icons on the commands Web page, which also show

the outputs status using a different color.

Clicking on the icon of a signal complements its status.

INPUT SECTION OF ZBT AND ZBR

This section can feature 8, 16, 24 or 32 input signals, according to the model ordered.

Each input signal is galvanically isolated by type NPN optocouplers and visualized through a LED.

Above mentioned optocouplers must be supplied through a tension +Vopto generated by on board

supply section.

Different status of each input is indicated using different colors.

POWER SUPPLY SECTION

Tele-Web features an efficent power supply circuitery that can accept a wide range of input tensions

and generates the required +5 Vdc voltage to supply output and logic sections in every load condition

and also generates the +Vopto voltage required by the Input optocouplers.

Please refer to ZBx manual for further information.

Page 6

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

FIGURE 2: PHOTO OF TELE WEB

Tele Web Controller Rel. 5.00

Page 7

grifo

®

ITALIAN TECHNOLOGY

TECHNICAL FEATURES

GENERAL FEATURES

On board resources: 1 Ethernet interface 10 Mbit/sec

from 4 to 24 digital transistor or relays outputs

from 8 to 32 optocoupled inputs

1 Real Time Clock (optional)

8 analog inputs for A/D converter (optional)

Memories: 2 KBytes FLASH EPROM for code (on TWC)

502 Bytes RAM for user data (on TWC)

502 Bytes EEPROM for user data (on TWC)

32 KBytes serial EEPROM for code and HTML (on TWC)

24 KBytes RAM for data logger (optional)

CPU: on GPC®, depends on the model ordered (*)

on TWC, Atmel 90S8515

Clock frequency: on GPC®, depends on the model ordered

on TWC, 8 MHz

PHYSICAL FEATURES

Size: 72 x 155 x 109 mm + length of ZBx (**)

Weight: 260 g + weigth of ZBx (**)

Connectors: CON1: plug 8 ways 90 degreeses for Ethernet 10BaseT

X3: D-type 9 ways 90 degreeses for RS 232

CN3A: D-type 9 ways 90 degreeses for RS 232

CN3B: D-type 9 ways 90 degreeses for RS 232

several quick release screw terminal connector (**)

Temperature range: from 0 to 50 centigrad degreeses

Relative humidty: 20% up to 90% (without condense)

(*) For further information, please refer to manual of GPC® ordered

(**) For further information, please refer to manual of ZBx ordered

Page 8

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

ELECTRIC FEATURES

Power supply: depends on ZBx ordered (**)

Current consumption: 5 mA + GPC® consumption (*) + ZBX consumption (**)

Analog inputs range: optional feature, depends on GPC® ordered (*)

Analog inputs impedance: optional feature, depends on GPC® ordered (*)

(*) For further information, please refer to manual of GPC® ordered

(**) For further information, please refer to manual of ZBx ordered

Tele Web Controller Rel. 5.00

Page 9

grifo

®

ITALIAN TECHNOLOGY

INSTALLATION

This chapter describes the hardware and software structure and all the steps to take for connecting

it to the netword, configure the PC and become operational.

MATERIAL REQUIRED

Tele-Web is made of three modules, all included in delivery:

-Micro Web Server; this modules is the interface to Ethernet network, in addition it runs the

TCP/IP stack and the HTTP server, it also stores HTML pages and images

- GPC®; this is the bridge between Micro Web Server and peripheral module, it runs the proper

telecontrol firmware (read the inputs, sets the outputs, etc.)

-ZBR/ZBT; this is the peripheral module featuring optocoupled inputs and relay or transistor

NPN (or PNP) outputs in a variable number, according to the model

This additional material not included in delivery is also required:

- Power supply cable

- 10BaseT type 5 Ethernet cable (straight or crosslink, ask the netword administrator)

- Serial line plug cable to connect the PC (grifo® listing code CCR.plug9F)

POWER SUPPLY

To supply the structure, it is enough to connect CN2 of ZBx peripheral module to the power supply

source.

According to the ZBx model and its configuration, power supply source can be quite different.

Please refer to ZBx manuals for further information.

Page 10

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

FIGURE 3: SNAPSHOT OF MICRO WEB SERVER

®

FIGURE 4: SNAPSHOT OF ZBR 168

Tele Web Controller Rel. 5.00

Page 11

grifo

®

ITALIAN TECHNOLOGY

SOFTWARE INSTALLATION

Tele-Web includes the complete delivery of Micro Web Server, shown in figure 5.

This delivery includes the Micro Web Server development CD and the sources of Tele Web Controler

firmware (TWC11.c, TWC11.mak, TWC11.pwp, IP plus all the files with *.htm and *.gif extension).

To install the basic developmnet system, it is enough to unzip the content of file pwdev.zip, that can

be found in the Micro Web Server development CD, into a folder.

NOTE: The resulting pathname must not contain space characters.

Example: unzip into the folder C:\pwdev\ is OK.

unzip into the folder C:\Web Software\ is wrong.

In the rest of the manual, the selected folder for software installation is C:\pwdev\.

After unzipping, to complete the installation, the following commands must be typed in a DOS

window or in the commands prompt:

C:>set PWDEV=C:\PWDEV

C:>set PATH=%PATH%;%PWDEV%\bin

Whenever the DOS window or the commands prompt is closed, the previous commands must be

typed again.

For greater comfort, the commands can be written in a batch file.

LOW LEVEL CONFIGURATION

Tele-Web is delivered already configured and ready to work.

The low level configuratin allows to specify:

-Which ZBR/ZBT peripheral module is used

- The password to access the system

The final user may want to change the low level configuration to modify the sytem password.

To change other elements of the low level configuration may lead to system malfunctions.

Please remark that any change to the configuration is immediatly reversible, except the labels

deletion.

Page 12

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

FIGURE 5: MICRO WEB SERVER COMPLETE DELIVERY

Tele Web Controller Rel. 5.00

Page 13

grifo

®

ITALIAN TECHNOLOGY

TO ENTER THE LOW LEVEL CONFIGURATION:

1. Connect the serial line of Tele-Web (connector plug CN3A of GPC® module) to a terminal

emulator or to a PC disconnecting the serial cable and connecting a plug serial cable (code of

grifo® listing CCR.plug9F)

2. On the PC, start a terminal emulator and configure it for 19200 Baud, 8 bit of data, 1 stop bit,

no parity

3. Switch off supply of Tele-Web

4. Enable low level configuration (see next table)

5. Supply Tele-Web

6. From the screen that appears on terminal emulator, select A

7. Type old password

8. Type new password

9. Exit from menu

10. Switch off supply of Tele-Web

11. Enable normal working mode (see next table)

12. Disconnect the plug cable to the PC, reconnect the cable already present before and supply the

Tele-Web

GPC®

CARD

Enable configuration mode Enable normal working mode

Page 14

GPC®

324D

J1 Open J1 Connected

FIGURE 6: LOW LEVEL CONFIGURATION

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

ZBX MAPPING ADDRESS

To make the ZBx module reachable from the tele control firmware it is essential that its address on

ABACO® I/O BUS is the correct one for the GPC® module used.

For further information about ABACO® I/O BUS and about mapping addresses please refer to the

manuals of GPC® and ZBx modules used.

Table of correct addresses is:

GPC®

CARD

GPC®

324D

Base Address

of ZBx

JAddr Jumpers group

00H All jumpers connected

FIGURE 7: ZBX MAPPING ADDRESS

FIGURE 8: SNAPSHOT OF A GPC® 324D

Tele Web Controller Rel. 5.00

Page 15

grifo

®

ITALIAN TECHNOLOGY

HIGH LEVEL CONFIGURATION

Before proceeding here, assure to have taken all the steps described in the paragraph “Software

Installation”.

High level configuration allows to set the IP address of Web interface.

In order to to this, it is essential to connect CON1 of Micro Web Server to the Ethernet local network

through an appropriate cable and obtain a free IP address.

If specialized personnell is managing the network, ask the network administrator.

IP addres is assigned executin the SETIP command in the DOS window or command prompt of a

PC connected to the same network of Tele-Web and changing the content of the file called IP in the

sources folder of Tele Web Controller.

For example, if the free IP obtained is 192.168.168.123, the command to type is:

SETIP 0:1:2:3:4:5 192.168.168.123

While in the file called IP just replace “192.168.168.123” to the address already present.

In the same DOS window or command prompt, to make the Tele-Web visible to the PC, type:

ROUTE ADD 192.168.168.123 <Address of PC>

Being, like in the previous example, the address of Tele-Web 192.168.168.123.

To obtain the address of PC, you may execute the utility winipcfg and find the address of Ethernet

adapter or ask the netword administrator.

This latter command must be retyped whenever the DOS window or a command prompt is closed.

After doing this, the command:

PING 192.168.168.123

should receive a response from the Tele-Web.

In this case, the system is ready for working.

Page 16

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

UTILIZATION

LOGIN

Before any other operation, server authentication is required (login).

Assiming 192.168.168.123 as the IP assigned to the Tele-Web, run the preferred browser (e.g.

Internet Explorer, Opera, Netscape, etc.) and type in the addres box:

http://192.168.168.123.

By default, no passowrd is set in the system as it is delivered.

Tele-Web responds with the page shown in figure 9, type the password (if present) in the specific

test obx or press immediatly the button if no password is set.

NOTE: For further information about how to set the password, please refer to paragraph “LOW

LEVEL CONFIGURATION”.

If the (optional) password it typed correctly, Tele-Web enables the commands page, from which it

is possible to control all the features of the application described in the paragraph “GENERAL

INFORMATION”.

If the password is not typed correctly, the Tele-Web enters in a idle mode for about one minute,

during which any command is ignored.

This way, illegal access attempts are heavily obstacolated.

Tele Web Controller Rel. 5.00

FIGURE 9: LOGIN

Page 17

grifo

®

ITALIAN TECHNOLOGY

OUTPUT COMMANDS

Entering the commands page, it is possible to control the status of transistor or relays outputs and

optocoupled inputs of ZBR/ZBT module.

Commands page is shown in figure 10, it is automatically updated every 5 seconds.

If the peripheral module installed is not ZBR/ZBT 168, you may see a different number of inputs and

outputs respect to figure 10.

Each signal features a 31 characters long label printed near the icon that shows the signal status.

When delivered, Tele-Web has all the labels set to a null string, to set them please refer to paragraph

“LABELS MANAGEMENT”.

When an output is enabled (relay contact closed or transistor conducting), this fact is indicated

painting in red its label and showing the image stored in the file called “on.gif”.

By default, the image shows the writing “ON”.

When an output is disabled (relay contact open or transistor not conducting), it is indicated showing

the image stored in the file called “off.gif”.

By default, the image shows the writing “OFF”.

To modify the images “on.gif” and “off.gif” please refer to paragraph “PERSONALIZATIONS”.

To complement the status of an output, it is enough to click on the corresponding icon.

So, clicking on the icon of an output enabled, this will be disabled, and viceversa.

INPUT COMMANDS

Entering the commands page, it is possible to control the status of transistor or relays outputs and

optocoupled inputs of ZBR/ZBT module.

Commands page is shown in figure 10, it is automatically updated every 5 seconds.

If the peripheral module installed is not ZBR/ZBT 168, you may see a different number of inputs and

outputs respect to figure 10.

Each signal features a 31 characters long label printed near the icon that shows the signal status.

When delivered, Tele-Web has all the labels set to a null string, to set them please refer to paragraph

“LABELS MANAGEMENT”.

When an optocoupled input is enabled (contact closed), this fact is indicated painting in green or

yellow (whether the bit belongs to a high byte or not) its label and showing the image stored in the

file called “on.gif”.

By default, the image shows the writing “ON”.

When an input is disabled (contact open), it is indicated showing the image stored in the file called

“off.gif”.

By default, the image shows the writing “OFF”.

To modify the images “on.gif” and “off.gif” please refer to paragraph “PERSONALIZATIONS”.

Page 18

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

FIGURE 10: COMMANDS PAGE OF ZBX 168

FIGURE 11: LABELS MANAGEMENT

Tele Web Controller Rel. 5.00

Page 19

grifo

®

ITALIAN TECHNOLOGY

LABELS MANAGEMENT

Clicking the link “Change signals names” you may access the signals names management page.

Modules ZBR/ZBT of grifo® feature up to 24 relays or transistor outputs and up to 32 optocoupled

inputs.

The page shows all the 56 signals and their names even if the hardware used does not feature them

because the firmware manages all the names in any case.

To change the name of a signal, just click on it with the mouse (as in figure 12), write the new name

in the textbox and pres sthe button.

The result will be immediatly visible in this page and in the commands page.

REAL TIME CLOCK MANAGEMENT (OPTIONAL)

An optional version of grifo® Tele-Web features a Real Time Clock backed by a Lithium battery

and capable to manage day, month, year, hour, minutes and seconds.

Managenent of time is performed through a comfortable specific Web page available only for who

orders this option and described in detail in a specific manual.

Shortly, the above mentioned Web page allows to read and set date and time and to save or load such

settings to/from a file on the PC.

DATA LOGGER MANAGEMENT (OPTIONAL)

An optional version of grifo® Tele-Web features a data logger that uses the GPC® module local

memory backed by a Lithium battery.

This option can be ordered together with the previous one, to make possible to store a timestamp

matched with other data.

Managenent of data logger and ring buffer memory content is performed through a comfortable

specific Web page available only for who orders this option and described in detail in a specific

manual.

Shortly, the above mentioned Web page allows to get and set the sampling frequency and the

presence of a timestamp, to reset or to read the content of the memory and to save or load such settings

to/from a file on the PC.

In detail, content of memory can be saved in a Excel compatible format, with cell names decideable

by the user.

Page 20

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

FIGURE 12: CHANGE SIGNALS NAMES

Tele Web Controller Rel. 5.00

Page 21

grifo

®

ITALIAN TECHNOLOGY

ANALOG INPUTS MANAGEMENT (OPTIONAL)

An optional version of grifo® Tele-Web features eight analog inputs.

Managenent of analog inputs is performed through a comfortable specific Web page available only

for who orders this option and described in detail in a specific manual.

Shortly, the above mentioned Web page allows to read the inputs, to enable or disable the saving of

the inputs to the (optional) ring buffer memory and to save the contente of this memory in a Excel

compatible format, with cell names decideable by the user.

Page 22

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

PERSONALIZATIONS

To personalize the Tele-Web, a good knowledge of C programming language, of Micro Web Server

scripting language PCode and grifo® hardware is required.

If you want a custom firmware in short times, please contact grifo® directly through our Web sites

http://www.grifo.it or http://www.grifo.com.

Before continuing, instructions descibed in paragraphs “SOFTWARE INSTALLATION” and

“HIGH LEVEL CONFIGURATION” must be followed.

To make any kind of changes to the content of HTML pages or to the behaviour of firmware it is

essential to recompile the software project.

Software project is made of two modules:

-GPC® software module: it is written in C using the compiler µC/51; this part of firmware

receivs commands through the GPC® RS 232 serial line (connector CN3A) and manages

outputs, inputs and all other features

-Micro Web Server software modul: it is written in PCode and compiled using the sofware

development tools of Micro Web Server (please refer to chapter “SOFTWARE

INSTALLATION”); it manages the Internet interface of the system, user commands and Web

response pages

The compilation procedure is beyond the purposes of this manual, pleare refer to Micro Web Server

specific documentation for further information.

The user can easily change some graphic elements of the project, following paragraphs give some

information about this purpose.

Changing the behaviour of the firmware is more complex and requires a deep study of the project

and of the development system, in specific of the following files:

-PDF document pwproj.pdf, in sub-folder /docs of Micro Web Server installation folder

-PDF document pw1_pcode.pdf, in sub-folder /docs of Micro Web Server installation folder

- Source code of Micro Web Server software module: TWC11.pwp

- Source code of GPC® software module: TWC11.c

The first two files contain detailed instructions on how to make a Micro Wev Server software project

and to write PCode scripts.

Other two files contain several comments that explain how the modules work, allowing to understand

and so to change their behaviour.

Further information about compiler µC/51 can be found at: http://www.wickenhaeuser.de.

Further information about Micro Web Server firmware development system can be found at:

http://www.picoweb.net and http://www.achatz.nl.

Tele Web Controller Rel. 5.00

Page 23

grifo

®

ITALIAN TECHNOLOGY

PERSONALIZATION OF ICONS

Tele-Web, in the basic version without options, uses three icons:

1. To show the status ON of an input or an output, the corresponding image is on.gif

2. To show the status OFF of an input or an output, the corresponding image is off.gif

3. To show that an input or an output is not available, the corresponding image is na.gif

To personalize them, just replace these images with the ones you want without changing their

names, and to recompile the project.

PERSONALIZATION OF HTML PAGES

Tele-Web, in the basic version without options, uses three Web pages:

1. TWCMain.htm for login

2. TWCCommands.htm for commands management

3. TWCLabels.htm for labels management

All the elements of HTML language (tags) can be changed by an HTML experienced user, without

changing the files names.

In specific, name enclose in back-quotes (for example: `list_lables.cgi`) are required for the project

correct working and must never be changed.

For further information, please refer to PDF documents pwproj.pdf and pw1_pcode.pdf, in subfolder

/docs of Micro Web Server installation folder.

Page 24

Tele Web Controller Rel. 5.00

ITALIAN TECHNOLOGY grifo

®

APPENDIX A: ALPHABETICAL INDEX

SYMBOLS

+VOPTO 6

10BASET 10

A

A/D CONVERTER, OPTIONAL 8

ANALOG INPUTS 9

ANALOG INPUTS MANAGEMENT (OPTIONAL) 22

C

CLOCK 8

CONNECTORS 8

CPU 8

CURRENT CONSUMPTION 9

D

DARLINGTON 6

DATA LOGGER MANAGEMENT (OPTIONAL) 20

DATA LOGGER, OPTIONAL 8

E

EEPROM 8

EPROM 8

ETHERNET 6, 8, 10

G

GPC®10

H

HIGH LEVEL CONFIGURATION 16

HTTP 6

I

INPUT 6

INPUT COMMANDS 18

INTERNET 6

IP ADDRESS 16

GMB HR168 & GMM AC0 Rel. 5.00

Page A-1

L

LABELS MANAGEMENT 20

LED 6

LOGIN 17

LOW LEVEL CONFIGURATION 12

M

MICRO WEB SERVER 6, 10

MOV 6

N

NPN 6, 10

O

OPEN COLLECTOR 6

OPTOCOUPLERS 6

OUTPUT 6

OUTPUT COMMANDS 18

grifo

®

ITALIAN TECHNOLOGY

P

PASSWORD 12, 14, 17

PERSONALIZATION OF HTML PAGES 24

PERSONALIZATION OF ICONS 24

PERSONALIZATIONS 23

PNP 10

POWER SUPPLY 6, 10

R

RAM 8

REAL TIME CLOCK MANAGEMENT (OPTIONAL) 20

REAL TIME CLOCK, OPTIONAL 8

RELATIVE HUMIDTY 8

RELAY 6, 8

RESOURCES 8

S

SERIAL EEPROM 8

SETIP, COMMAND 16

SIZE 8

SOFTWARE 12

Page A-2

GMB HR168 & GMM AC0 Rel. 5.00

ITALIAN TECHNOLOGY grifo

T

TEMPERATURE RANGE 8

TRANSISTOR 6, 8

V

VERSION 3

W

WEIGHT 8

Z

ZBR 6, 10, 18

ZBT 6, 10, 18

®

GMB HR168 & GMM AC0 Rel. 5.00

Page A-3

grifo

®

ITALIAN TECHNOLOGY

Page A-4

GMB HR168 & GMM AC0 Rel. 5.00

Loading...

Loading...