WINE MAKING MACHINES

MANUAL

INSTRUCTION, USE AND MAINTENANCE

MOTORIZED GRAPE CRUSHER AND

DESTEMMER

Art. DMS/DMC/DMCSI/DMCI

2016-ENG

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

2 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

Dear Customer,

Via Mantova, 1

26034 Piadena (CR), Italia

Tel. +39 0375/98601

Fax +39 0375/980879

e-mail: info@grifomarchetti.com

www. grifomarchetti.com

GRIFO

MACCHINE ENOLOGICHE S.n.c.

di Marchetti Giordano & C.

GB

Thank you for choosing a GRIFO product, which has always had a

name for reliability, sturdiness and functionality.

We are pleased to give you this manual so as to enable you to operate

the machine, in the safest and most efficient way.

We invite you to read this technical manual carefully and to show it to

anyone who will use the machine, as well as the person who installs it and

carries out maintenance work.

We are at your complete disposal for any further information you may

need and will consider any proposals in order to make this manual evermore

complete for the safety requirements for which it is intended.

Our best wishes and enjoy working with Grifo products!

GRIFO Macchine enologiche S.n.c.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

3 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

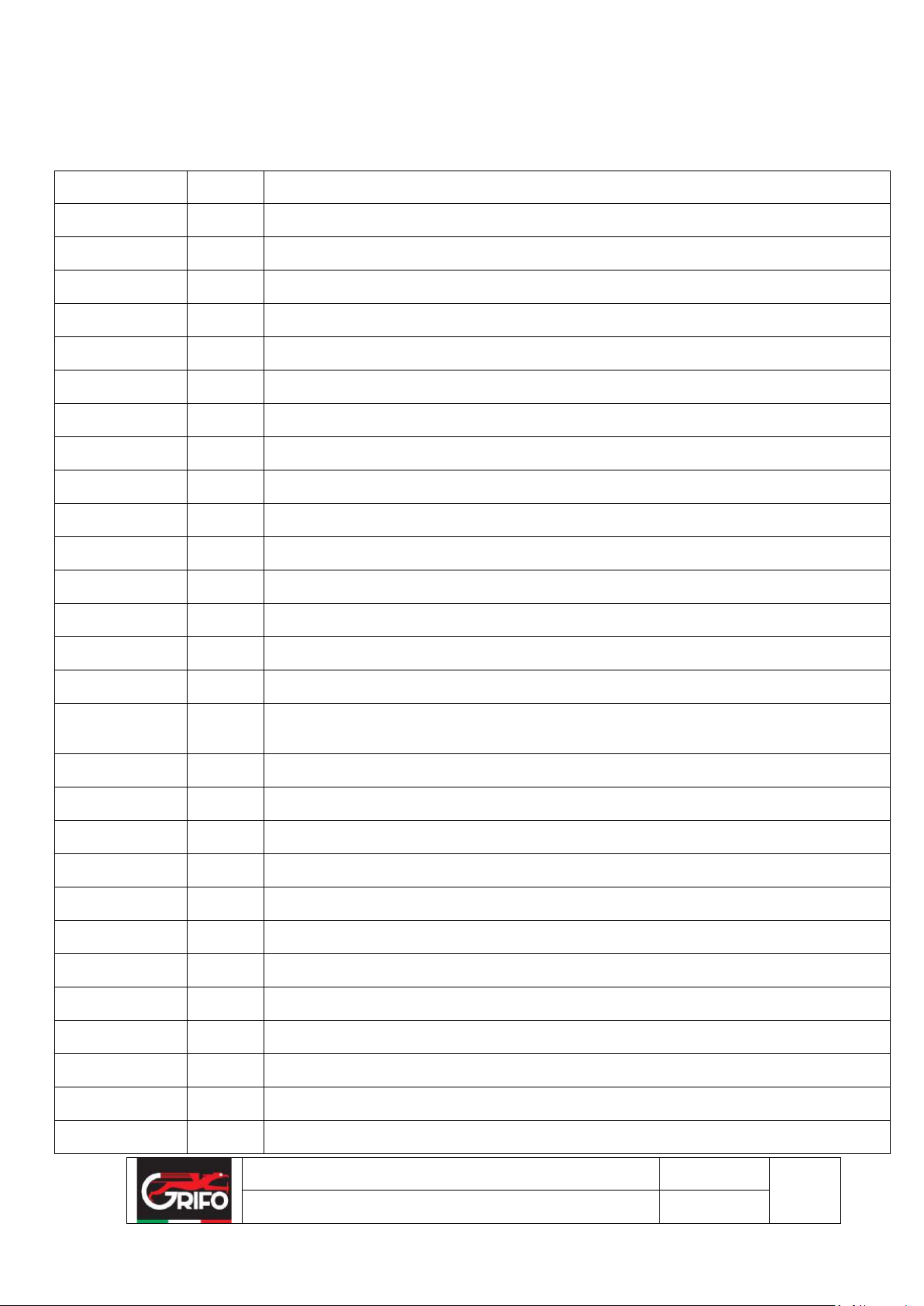

Index

Edition

2016

Revision

00

File name

Manuale DMS – DMC – DMCSI - DMCI

GB

EC Declaration of Conformity .................................................................................................................4

1. INTRODUCTION ................................................................................................................................5

1.1 Contents ......................................................................................................................................... 5

1.2 Consegnes and conservation of the manual ................................................................................... 5

1.3 Responsability ............................................................................................................................... 6

1.4 Manual update ............................................................................................................................... 6

1.5 Guarantee ....................................................................................................................................... 7

2. MACHINE DETAILS..........................................................................................................................7

2.1 Machine description and functioning ............................................................................................ 7

2.2 Correct use ................................................................................................................................... 11

2.3 Directives and standards .............................................................................................................. 11

2.4 Technical informations ................................................................................................................ 12

3. SAFETY .............................................................................................................................................12

3.1 General informations ................................................................................................................... 12

3.2 Risks and preventive measures .................................................................................................... 13

4. INSTALLATION ...............................................................................................................................15

4.1 Preparation for installation .......................................................................................................... 15

4.2 Transport, unloading and installation .......................................................................................... 15

4.3 Positioning ................................................................................................................................... 16

4.4 Electrical connections .................................................................................................................. 18

4.5 Lubrication................................................................................................................................... 18

5. USO ....................................................................................................................................................19

5.1 Preliminary operations ................................................................................................................. 19

5.2 Starting up.................................................................................................................................... 20

5.3 Instructions in case of blocking ................................................................................................... 21

5.4 Taking out of service ................................................................................................................... 21

6. MAINTENANCE AND DISPOSAL .................................................................................................22

6.1 Maintenance, inspections and controls ........................................................................................ 22

6.1.1 Lubrication and controls ........................................................................................................... 23

6.1.2 Spare parts ................................................................................................................................ 23

6.2 Demolition ................................................................................................................................... 23

7. ATTACHMENTS (drawings and components) ........................ Errore. Il segnalibro non è definito.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

4 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

EC Declaration of Conformity

(Directive 2006/42 CE, Annex II, A)

GRIFO MACCHINE ENOLOGICHE S.n.c.

di Marchetti Giordano & C.

Via Mantova, 1

26034 Piadena (CR)

Italia

DECLARES THAT

The machine MOTORIZED GRAPE CRUSHER AND DESTEMMER

Model DMS, DMC, DMCSI, DMCI

Conforms to Directives 2006/42/EC (Machines), 2006/95/EC (Low-voltage) and 2004/108/EEC

(Electromagnetic Compatibility);

Conforms to the standards EN 953, EN 13850, EN 60204-1.

Name and address of the person authorized to compile the technical file:

Giordano Marchetti

Via Mantova, 1

26034 Piadena (CR)

Italia

Identity and signature of the person empowered to draw up the declaration on behalf of the

manufacturer

Rosa Busi

Place and date of the declaration

Piadena (CR), 02 January 2016

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

5 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

1. INTRODUCTION

Pay maximum attention to the instructions marked by this symbol

keeping scrupulously to what is specified.

Indications and useful tips for manipulation, mounting and installation,

use and maintenance operations.

Operations or behaviour absolutely forbidden

Continue in the indicated, operating sequence

The manual constitutes an integral part of the machine and as such must

be conserved for all the life of the machine and passed on to any user or

successive owner

GB

1.1 Contents

This manual contains a description of the technical characteristics and functioning of

the MOTORIZED GRAPE CRUSHER AND DESTEMMER, Mod. DMS, DMC,

DMCSI, DMCI, as well as instructions of installation, use and maintenance.

This instruction manual uses the following symbols.

1.2 Consigns and conservation of the manual

This publication refers to use, transport, installation and maintenance operator.

The manual must be kept by the manager in a suitable place in order for it to be

always available for consultation in the best state of conservation.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

6 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

1.3 Responsibility

Before operating the machine it is obligatory to read what is specified

in the manual

The only configurations and destination of use allowed by the

manufacturer are those expressly stated in the manual.

GB

The guarantee of the well functioning and full conformity performance of the machine

to its foreseen service, is strictly dependent on the correct application of all the

instructions in this manual.

In reference to the above indicated in this instruction manual, GRIFO Macchine

Enologiche S.n.c. declines every responsibility in the case of:

in observation of the instructions regarding installation, use and maintenance

printed in this manual;

inadequacy of the plant engineering and environmental conditions in which the

machine is used,

non authorized modifications to the machine

use by unauthorized or untrained personnel

1.4 Manual update

This manual is an integral part of the machine.

Any modifications that are made to any successive machines do not oblige the

manufacturer to carry out any intervention or adaptation to the machine already on

the market.

Any supplement to the manual that the manufacturer considers necessary to send to

the user should be kept together with the manual of which it will be integral part.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

7 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

1.5 Guarantee

The guarantee of the machine covers the first twelve months of

operation. In case of non immediate use, the guarantee expires on

the eighteenth month from its delivery.

The guarantee does not cover transportation of the machine, which

is the purchaser’s responsibility, and the guarantee will be invalid if

machine use does not conform to what is indicated in this manual.

GB

Conditions other than those specified may be defined in the contractual phase.

2. MACHINE DETAILS

2.1 Machine description and functioning

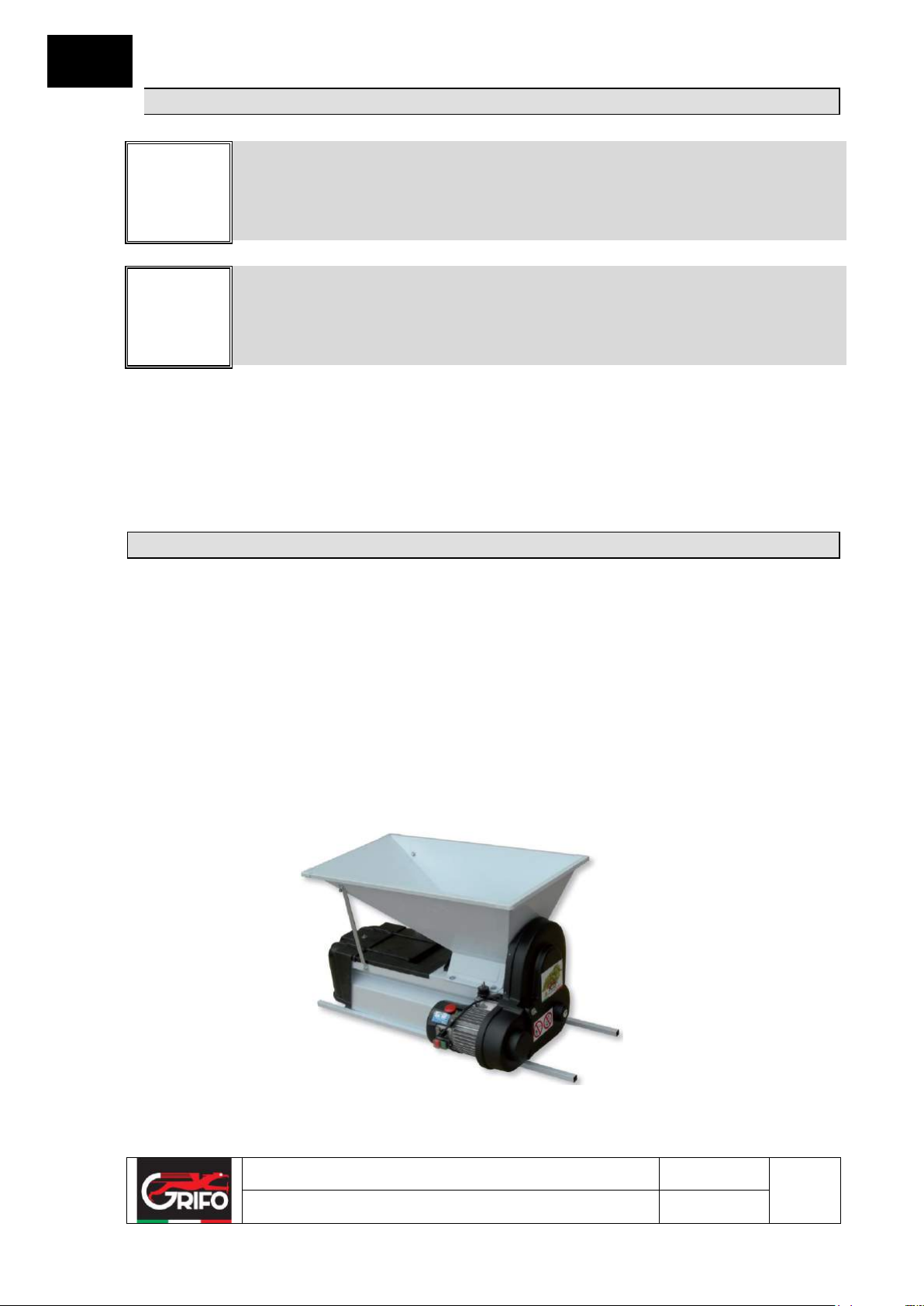

MOTORIZED GRAPE CRUSHER MACHINE AND DESTEMMER, Models DMS,

DMC, DMCSI and DMCI is a machine for crushing grapes, designed and built for use

in small and medium-sized wine-making companies. The models which this manual

refers to are different only for the material used for their production, painted steel or

stainless steel; the names in the manual of the models are as follows:

GRAPE CRUSHER AND DESTEMMER (DMS)

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

8 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

GRAPE CRUSHER AND DESTEMMER (DMC)

GB

SEMI STAINLESS STEEL GRAPE CRUSHER AND DESTEMMER (DMCSI)

STAINLESS STEEL GRAPE CRUSHER AND DESTEMMER (DMCI)

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

9 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

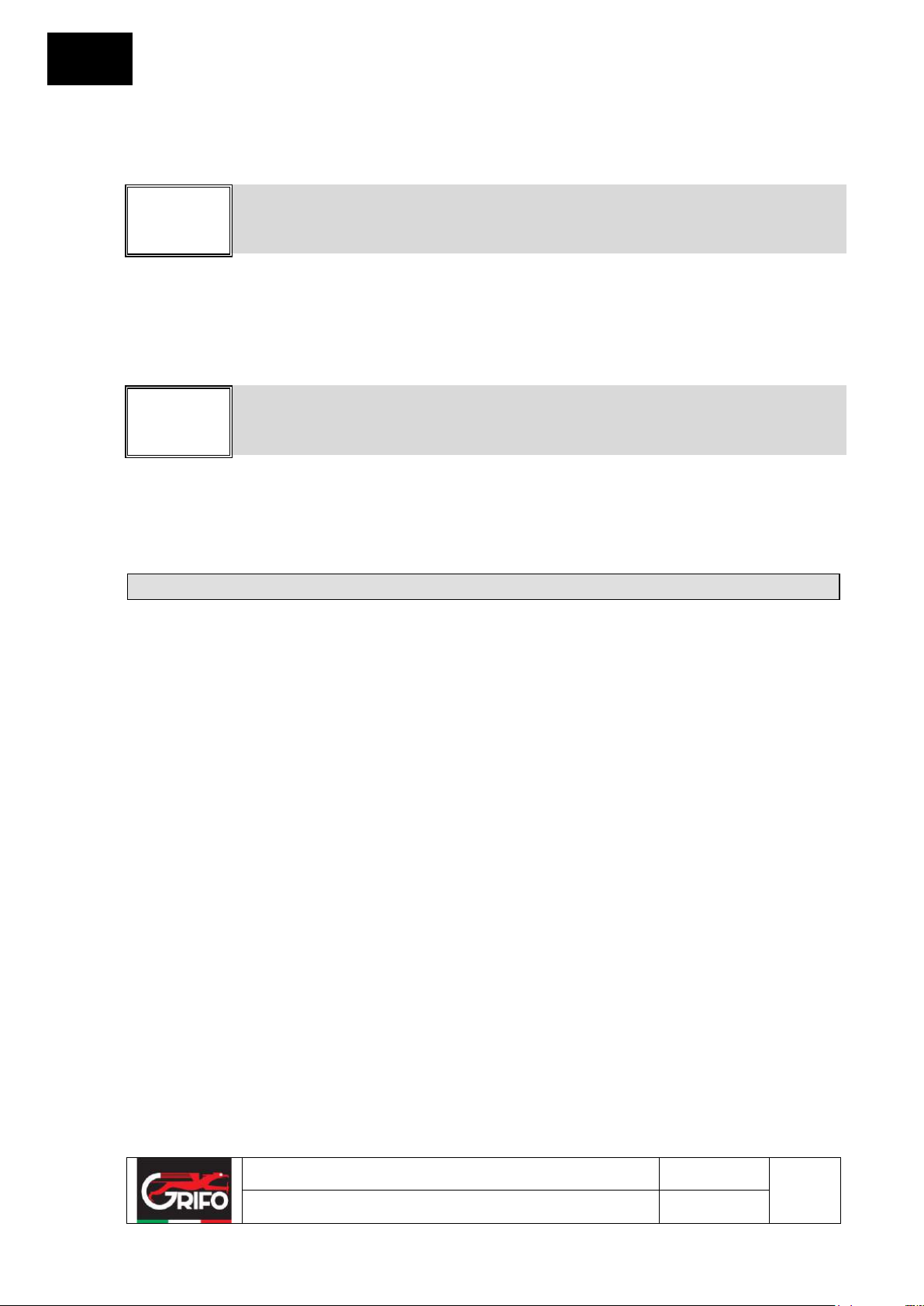

Auger feed

Crushing

rollers

GB

The machine consists of a loading hopper, which contains the grapes to be

destemmed. At the bottom of the loading hopper, there is a auger feed that pushes

the grapes towards two rollers that will crush them.

It then conducts them into the lower part where, thanks to a circular movement, the

destemmer shaft paddles separate the grapes from the stems. The grapes, together

with the freshly squeezed must, fall into the lower bin through the grate situated

inside the machine.

The destemmer shaft is manufactured in such a way that through its helical

movement, the welded paddles on it push the stems to the output shoot.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

10 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

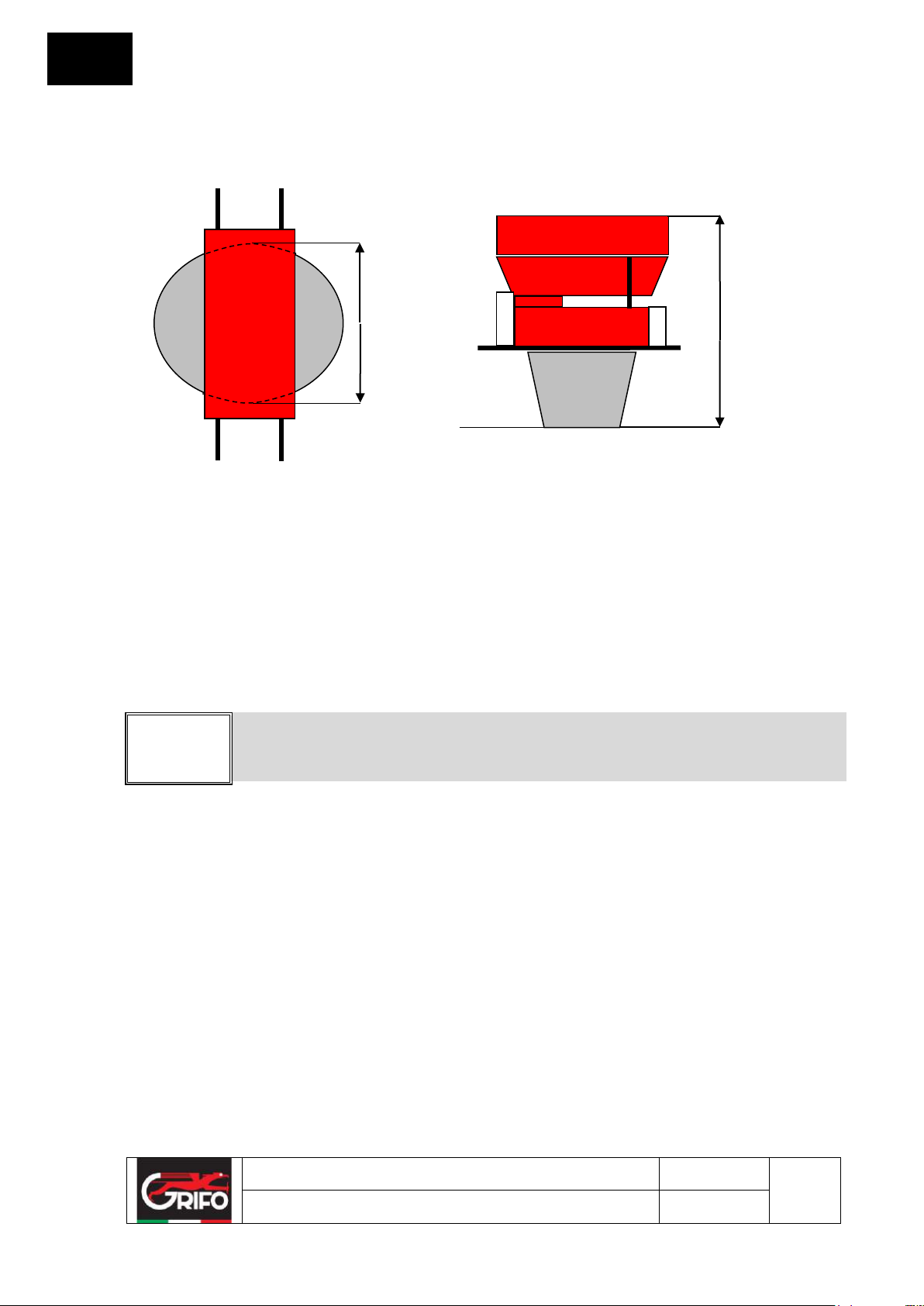

Fig. 1 Main parts of the MOTORIZED GRAPE CRUSHER AND DESTEMMER

Loading guard

Loading

hopper

Accepted

output

Transmission guard

Crushed

grape exit

Destemmer guard

Sustaining

bars

Motor and

controls

GB

On top of the hopper, a protective box (supplied) must be placed in order to avoid

upper limbs coming into contact with the destemmer and rollers.

The machine must be positioned above a container, which collects the crushed

grapes according to the instructions described in chapter 5.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

11 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

2.2 Correct use

Any variations of the conditions of use of the machine both in terms

of use and materials processed must be considered as a new use of

the machine under the directive 98/37/CE and therefore relieves the

manufacturer of any responsibility.

GB

The MOTORIZED GRAPE CRUSHER AND DESTEMMER, Mod. DMS, DMC,

DMCSI, DMCI is a crusher-destemmer machine used for grape processing. The

operations of the machine are:

grape crushing by means of two rollers positioned inside the hopper

Destemming i.e. separating the grapes from their discarded stems by means

of a destemmer shaft inside the machine..

2.3 Directives and standards

The MOTORIZED GRAPE CRUSHER AND DESTEMMER, Mod. DMS, DMC,

DMCSI, DMCI is designed and manufactured according to European Directives

2006/42 CE (Machines), 2006/95/CE (Low voltage), 2004/108/CE

(Electromagnetically Compatibility) and according to standards EN 953, EN 13850,

EN 60204-1.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

12 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

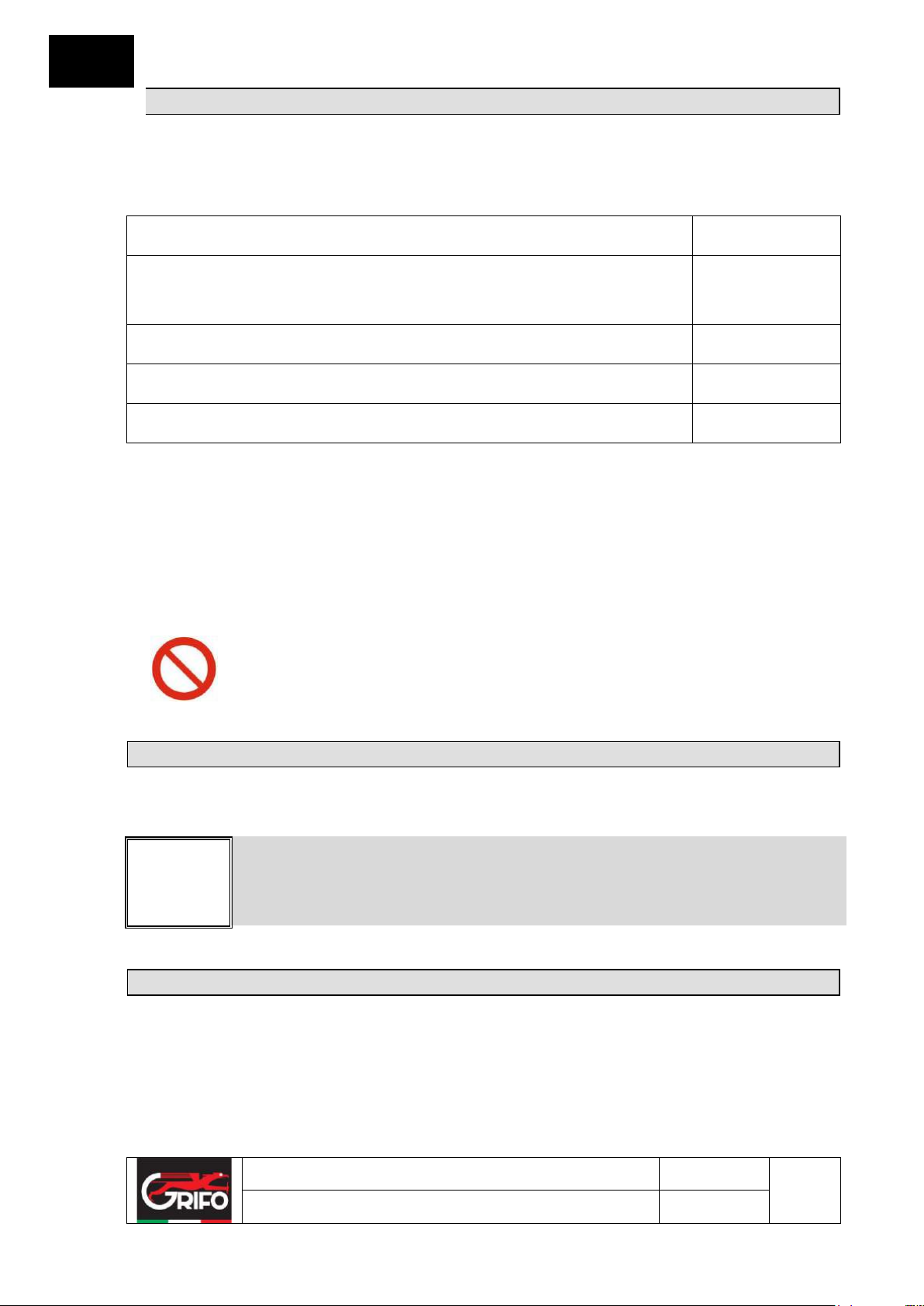

2.4 Technical informations

maximum overall dimensions

Height 600 mm - Width 600 mm - Length 1200 mm

weight

54 kg

engine power

0.75 kW

hopper dimensions

900 x 500 mm

diameter of alluminium rollers

220 mm

engine speed

1400 rpm (revolutions per minute)

hourly production

1500 Kg.

voltage and frequency

220 V – 60 Hz

operating temperature

5° ÷ 45° C

noise level

less than 70 dBA

GB

The basic characteristics of the machine and those required by the environment for

correct functioning are reported in Table 1.

Table 1 Technical data of the MOTORIZED GRAPE CRUSHER AND DESTEMMER

3. SAFETY

3.1 General informations

Within the obligation of information and training of workers foreseen by current

legislation, the company employer, management and the authorized users operating

the MOTORIZED GRAPE CRUSHER AND DESTEMMER Model DMS, DMC,

DMCSI, DMCI must supply personnel who will carry out operations of installation, use

and maintenance all the necessary information in order to guarantee their safety

while using the machine.

In particular, they must request and control that

all workers assigned to the abovementioned operations must scrupulously

conform to the procedures in this manual and the general accident prevention

measures foreseen by current regulations.

no different operations must be carried out other than those specified by the

manufacturer.

no tampering or modifications to the machine must be made and the machine is

used exclusively in its original configuration.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

13 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

3.2 Risks and preventive measures

- - Insure that the machine is stable in particular with reference to the

compatibility between the dimensions of the support rods and those of

the container above which the machine is place. (par. 4.3).

- - Use safety boots with steel toe-caps.

- - Stop the machine in case of intervention on the moving parts.

- - Do not remove the protective case.

GB

The machine is designed to eliminate or reduce the risks for the people who will use

it. The preventive measures for a safe use of the machine are the following:

Machine falling

Moving parts

Fig. 2 Hazardous moving parts

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

14 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

Machine moving

- - Move the machine with at least two people.

- - Regularly control the integrity of wires and make necessary

replacements.

- - Protect wires and engine from humidity.

- - Carry out any maintenance work with the machine turned off.

- - Authorize only skilled personnel to work on the electrical parts.

- - Control that the voltage is the same as that indicated on the machine

identification plate.

Positioning

The machine must be placed so as not to obstruct the

movement of men or equipment, and in such a way as to

guarantee that all the points requiring the presence of an

operator are easily accessible

Environment

Environmental conditions (temperature, humidity, magnetic

fields, etc.) must be such as to guarantee the correct

functioning of the electrical components.

Noise

The noise level of this machine is inferior to 70 dBA. The

distribution of jobs of the operators must be such to insure

exposure to noise remains within the limits allowed by current

legislation.

Any tampering with parts, and in particular parts connected with the

safety of the machine, will relieve the manufacturer of any civil or

criminal liability in the case of accidents.

GB

Electrical equipment

The evaluation of the correct place of use of the machine is the user’s responsibility.

Some useful tips regarding this are the following;

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

15 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

4. INSTALLATION

Grifo Macchine Enologiche does not accept any responsibility for

damages from transport. The goods are supplied ex-factory.

GB

4.1 Preparation for installation

Before installing the machine it is necessary to control the suitability of the place

where it will be located. It being understood that such evaluation must consider the

specific conditions of the location, some important general controls are the following:

Check the overall dimensions of the machine, leaving a distance of at least 70

cm from any type of fixed obstacle (walls, columns, walkways) to allow the

operator to move without impediments. Check that the foreseen location of the

machine does not interfere with any other machinery.

Check the suitability of flooring in terms of stability, cleanliness and slope.

Insure constant, uniform lightning to avoid risks due to shaded areas.

If the machine is positioned near to transit zones, you must place suitable

barriers around it for protection of accidental bumps with trolleys, trucks etc.

If it is located on intermediate floors, elevated floors or raised platforms, check

that the maximum carrying capacity is more than the overall weight of the

machine and any other accessories such as lifting equipment etc. always

considering an adequate safety factor.

4.2 Transport, unloading and installation

The machine is supplied already assembled into its operating configuration so the

risks due to movement concern the whole machine.

Transport must be by qualified transporters able to guarantee the correct movement

of the transported materials.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

16 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

On receipt, control the integrity of the different parts of the machine and check that

Check that the consignment corresponds to the order

specifications.

Pay maximum attention when moving the machine, respecting what

is set out in current regulations and in any safety procedures.

GB

the necessary parts for installation are not missing.

Complaints relative to the goods must be made in writing, to GRIFO Macchine

Enalogiche S.n.c. within 15 days from receipt of delivery.

Any moving of the machine must be done by two adults holding the four support

tubes at its extremes.

4.3 Positioning

When positioning the MOTORIZED GRAPE CRUSHER AND DESTEMMER, Model

DMS, DMC, DMCSI, DMCI, other than respecting the general conditions in

paragraphs 3.2 and 4.1, particular attention must be paid to the dimensional

compatibility between the support tubes and the container over which the machine is

placed.

The container must be placed in such a way that the grape stems, coming out of the

machine, fall outside of it.

The containers used must have the same shape and dimensions as to guarantee the

stability of the machine. The distance between resting points must not be more than

850mm (Fig. 3).

When positioning the machine you must choose the height so as to guarantee

accessibility to the destemmer and rollers situated at the bottom of the hopper. With

regards to this, a protective case is provided to screw onto the hopper itself.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

17 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

Bearing in mind that the case provided has a height of 450 mm, the top end of this

For your safety, put the protective case as shown.

Minimum

850 mm

Minimum

1600 mm

GB

must be at a height not inferior to 1600 mm.

Fig. 3 Dimensional limits in the positioning

The user should also be careful to guarantee machine stability when positioning. For

this purpose, adjustable feet to fix to the support tubes are supplied in order for the

machine to remain secured to the container on which it is placed.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

18 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

4.4 Electrical connections

It is obligatory to connect the machine to an earthed wall plug.

The plant must be fitted with an emergency safety cutout switch.

In case the use of an extension cable is necessary, it is advisable to

use an electric 1.5 mm cable for lengths of up to 20 m and a 2.5 mm

cable for over 20m.

GRIFO Macchine Enologiche S.n.c. decline all responsibility for

damages to people or things caused by failure to comply to the

installation instructions set out in this section.

GB

Connection to the mains is done by simply inserting the plug. The corresponding wall

plug must correspond to what is set in the safety regulations.

The simplicity of the connection must not make you underevaluate the importance of

respecting general security measures for electricity. Therefore it is important to:

control that the mains voltage is the same as that indicated on the engine plate

before using check the integrity of the electric cable and in case of damage it

must be replaced

avoid leaving the cable exposed to collisions, passage of people or vehicles or

any other situation that could be a threat to its integrity

protect the cable, plug-wall socket connection and any other electric parts from

humidity

4.5 Lubrication

The machine does not need particular servicing. Before starting it up you should

check oil levels, as indicated in chapter 6.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

19 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

5. USE

Cleaning of the machine, taking care not to wet the engine.

Control the state of connections to the power mains.

Control that inside the machine there are no foreign bodies that could

impede its correct functioning.

Control the presence of all protective covers.

Check the correct functioning of the controls, in particular the emergency

stop.

In the case when preliminary controls do not have positive

results, you must action the emergency stop, unplug the machine

and warn the department manager.

GB

5.1 Preliminary operations

Before starting up the machine you must check that all moving parts have been

lubricated, then periodically you should control the state of lubrication and make any

necessary interventions. For the instructions of use see paragraph 6.1.1.

The following controls must be made before starting of every work session

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

20 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

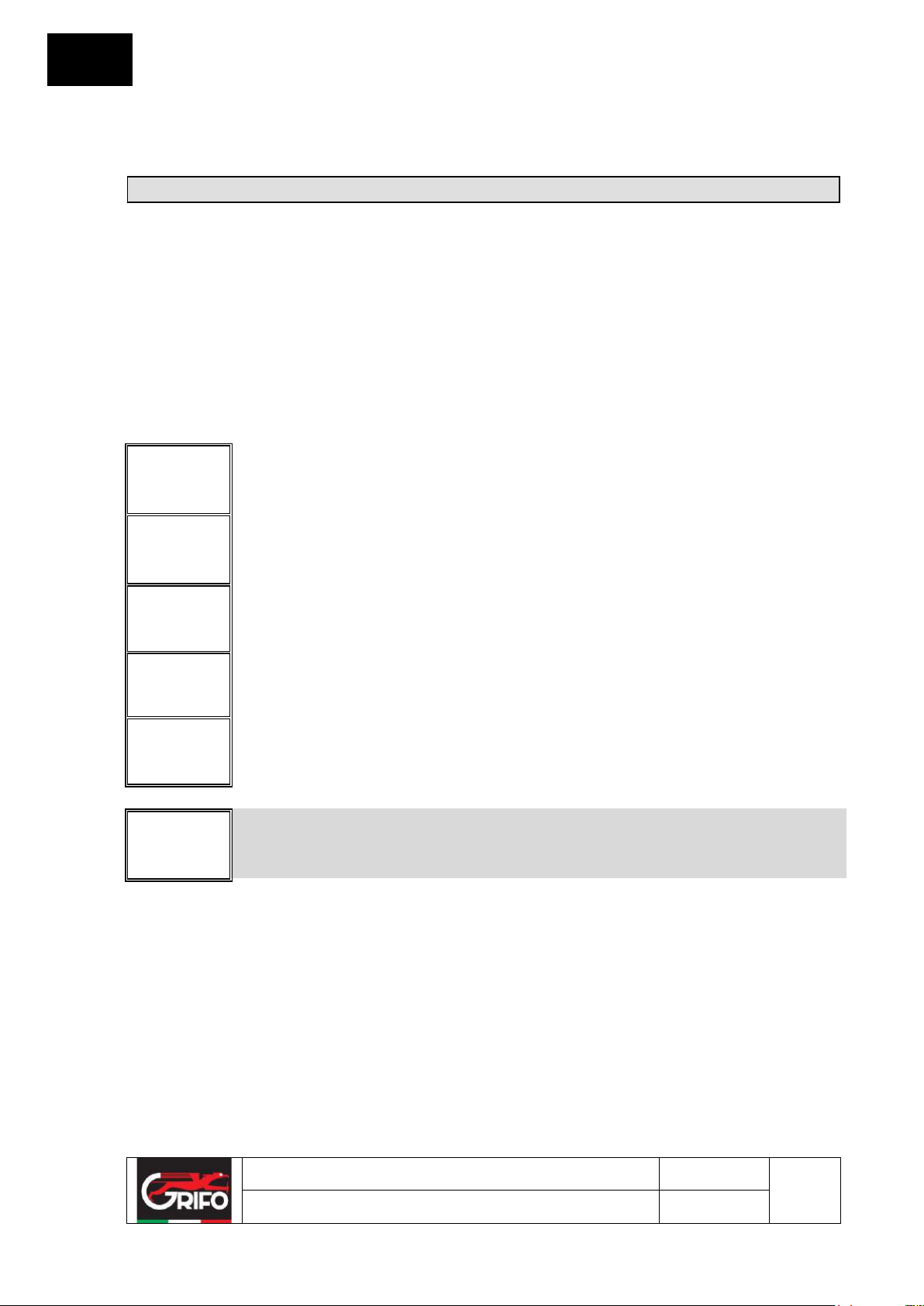

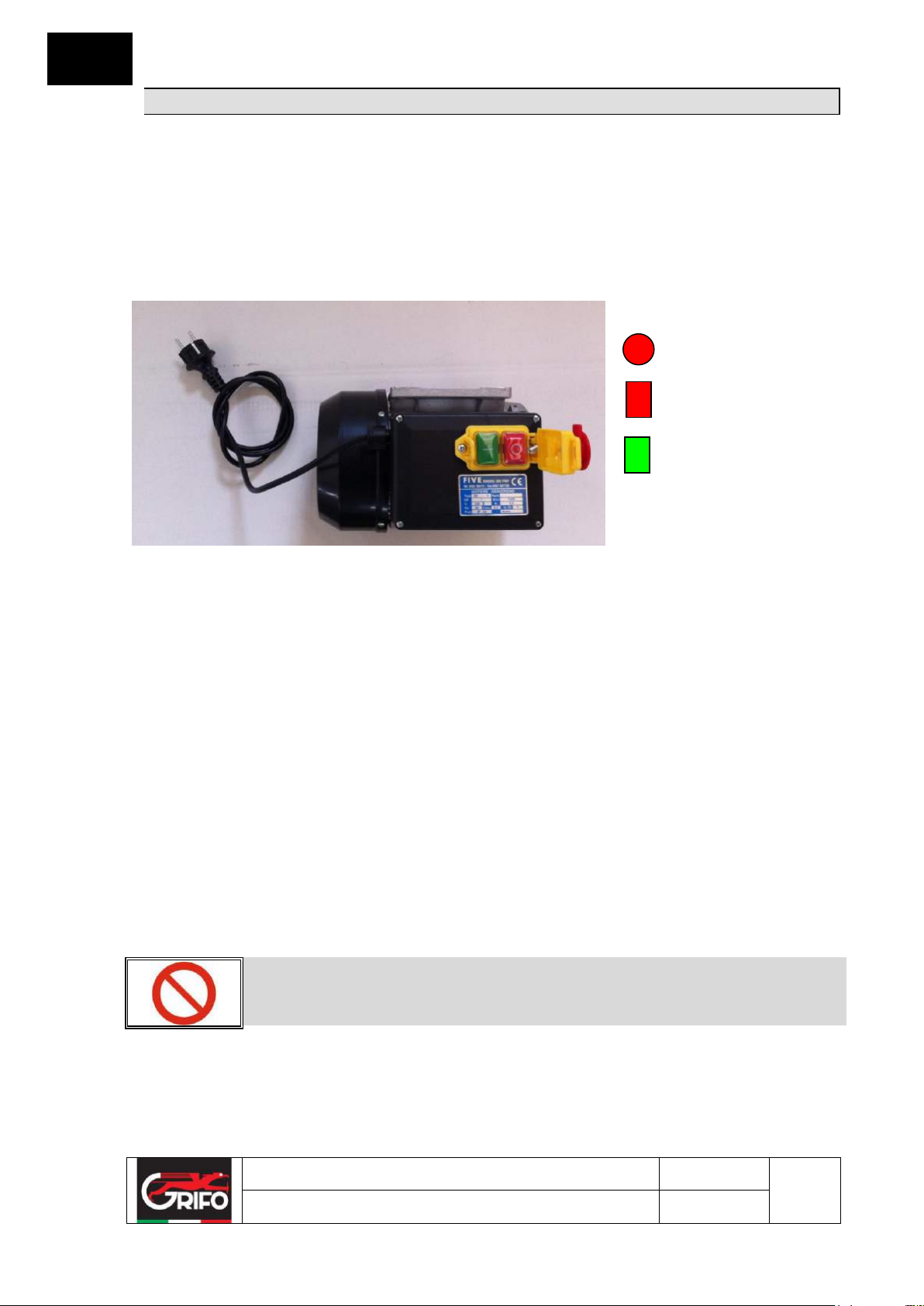

5.2 Starting up

It is forbidden to put your hands near to the moving parts, in

particular the output shoot of the grape stems.

Start

Stop

Emergency stop

GB

Following the preliminary controls, you can turn on the machine by activating the start

button placed on the control board. After the engine is started, insert the bunches of

grapes into the hopper that, by means of the agitator, will be taken to the rollers

where the crushing takes place.

Fig. 4 Controls

Once crushed it passes to where the rotating shaft is that separates the grapes from

the bunch destemming them. The stems exit from the rear part of the machine while

the grape, passing through the grate, is ready for fermentation.

The dimensions of the output shoot of the stems are determined by safety and

functional needs, in order to favor the expulsion of the stems. In the case of abnormal

accumulation of the stems that could obstruct the output shoot, you must turn the

machine off (disconnect from the mains), and only then, see to freeing the output

shoot.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

21 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

5.3 Instructions in case of blocking

Before doing any attempt to remove materials that could be the

cause of the blocking, you must disconnect the machine.

Use gloves.

When the machine is started up after a period of being in storage,

you must follow carefully all the instructions in chapters 3, 4 and

5.

GB

If the machine is correctly used, the power of the electric motor is enough to prevent

any blocking. Anyway, in case of blocking it’s necessary to remove its cause.

5.4 Taking out of service

To turn off the machine it is sufficient to activate the stop button.

In case of setting aside or taking out of service for a long time, it is necessary:

1. Disconnect the machine from the electricity power mains.

2. Cover it and possibly place it in a storage warehouse.

For restarting the machine you must proceed as indicated in paragraphs 5.1 and 5,2

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

22 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

6. MAINTENANCE

Any maintenance must be carried out by authorised personnel

when the machine is disconnected from the power mains.

In order to manage the machine in a correct, precise way, it is

advisable to register all maintenance work taking care to indicate the

date and type of work carried out.

A non-toxic, non-polluting detergent must be used for cleaning

operations.

GB

6.1 Maintenance, inspections and controls

With careful maintenance parts subject to wear have a longer life.

To guarantee a safe and efficient functioning of the machine maintenance should be

programmed and carried out thoroughly and punctually.

The main operations of general maintenance work to be carried out are described as

follows.

The frequency of these depends on the conditions of use of the machine.

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

23 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

6.1.1 Lubrication and controls

OPERATION

FREQUENCY

A thorough cleaning of the hopper and rollers, paying attention not to wet

the engine

After every grape

crushing session

Oiling of all engine transmission parts

Monthly

Oiling of roller shafts through the holes situated on each support

Monthly

Oiling of destemmer shaft and paddle type auger supports

Monthly

In any case it is forbidden to dissemble the engine. In case of

necessity, please contact GRIFO Macchine Enologiche S.n.c. or

the authorized dealer.

The use of unauthorized spare parts, different from those

supplied by GRIFO Macchine Enologiche or the authorized dealer

entail the forfeiture of the guarantee, as well as the Declaration of

Conformity of the machine.

GB

Before starting up the machine and in later on, periodically you must check the state

of lubrication of the movable parts of the machine (see par. 5.1)

The elimination of oil must be done according to the current laws in the countries

where the machine is in use. During oiling operations care must be taken that the oil

does not dirty the elements that come into contact with the grapes and crushed

grapes. The position of the lubrication points has been studied to facilitate these

operations.

6.1.2 Spare parts

All spare parts are available from GRIFO Macchine Enologiche S.n.c. or from the

authorized dealer.

6.2 Demolition

In the case the machine has to be demolished, it must be dismantled in uniform parts

and such parts must be separately disposed of according to current laws.

2016-ENG

Tipo Documento

Manuale Istruzioni Diraspatrice DMS-DMC-DMCSI-DMCI

Anno

2012

Pagina

24 di 27

Nome File

1_Manuale DMS - DMC - DMCSI - DMCI - INGLESE

Revisione

0

7. ALLEGATI (schemi e componenti)

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

25 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

26 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

SPARE PARTS art. DMC/DMCI/DMCSI

CODE

POS.

DESCRIPTION

SP-DMC-001

1

Upside protection

SP-DMC-002A

2A

Cassone auger painted model “DMC”

SP-DMC-002B

2B

Cassone screw steel model “DMCI / DMCSI”

SP-DMC-003A

3A

Auger painted power

SP-DMC-003B

3B

Auger steel supply

SP-DMC-004

4

Inclined support for auger

SP-DMC-005

5

Caisson supporting irons

SP-DMC-006

6

Stalk output cover to stalk separator

SP-DMC-007

7

Nylon loading hopper gear

SP-DMC-008

8

Large roller gear

SP-DMC-009

9

Small roller gear

SP-DMC-010

10

Gear series for destemmer Motor

SP-DMC-011

11

Roll left for destemmer Motor

SP-DMC-012

12

Right roller

SP-DMC-013

13

Couple rollers for destemmer Motor

SP-DMC-014

14

Pair of rubber rollers

SP-DMC-015

15

Roller set supports (n° 4 pz.)

SP-DMC-016

16

Toothed chain

SP-DMC-017

17

Chain

SP-DMC-018A

18A

Cash machine painted

SP-DMC-018B

18B

Stainless cash machine

SP-DMC-019

19

Set cage nuts 8 MA

SP-DMC-020A

20A

Tree painted Destemmer

SP-DMC-020B

20B

Tree stemmer stainless

SP-DMC-021

21

Segger at the end mast Destemmer

SP-DMC-022

22

Internal steel plate for destemmer shaft

SP-DMC-023

23

Bearing

SP-DMC-024

24

Door bearing support

Document

Manuale DMS – DMC – DMCSI - DMCI

Year

2016

Page

27 of 27

File name

Manuale DMS – DMC – DMCSI - DMCI

Revision

0

SP-DMC-025

25

Full support (support bearing + bearing)

SP-DMC-026

26

Spacer for destemmer shaft

SP-DMC-027

27

Pignone

SP-DMC-028

28

Destemmer shaft pulley

SP-DMC-029A

29A

Stainless steel grid holes ø 2.5 cm

SP-DMC-029B

29B

Small holes grid ø holes 1 cm

SP-DMC-030

30

Plastic caps

SP-DMC-031A

31A

Motor CE Hp 1 230/50 int. 0-1 con fungo

SP-DMC-031B

31B

Motor Hp 1 230/50 int. 0-1 con spina schuko

SP-DMC-031C

31C

Motor Hp 1 240/50 int. 0-1 con fungo and plug Australia

SP-DMC-031D

31D

Motor Hp 1 110/60 int. 0-1 con fungo and USA plug

SP-DMC-031E

31E

Motor trifase Hp 1 380/50 int. 0-1 con fungo and skinned endings

SP-DMC-032

32

Small motor pulley

SP-DMC-033

33

V-belt (A34)

SP-DMC-034

34

Lives 8x100 MA

SP-DMC-035

35

Motor plate

SP-DMC-036

36

tensioner bolt 8x50 MA

SP-DMC-037A

37A

Switch CE con fungo Hp 1

SP-DMC-037B

37B

Normal switch 0-1

SP-DMC-038

38

Fan cover for motor Hp 1

SP-DMC-039A

39A

Capacitor Mf 30 with bipolar cable

SP-DMC-039B

39B

Capacitor Mf 30 con cavetti + occh.

SP-DMC-040

40

Controcarter per “DMC – DMCI – DMCSI”

SP-DMC-041

41

Carter gears for “DMC – DMCI – DMCSI”

SP-DMC-042

42

Carter + controcarter diraspatrice a motore

SP-DMC-024

24

Door bearing support

SP-DMC-025

25

Full support (support bearing + bearing)

SP-DMC-026

26

Spacer for destemmer shaft

SP-DMC-027

27

Pignone

SP-DMC-028

28

Destemmer shaft pulley

SP-DMC-029A

29A

Stainless steel grid ø fori 2,5 cm

Loading...

Loading...