Griffco Valve CC PVC User Manual

Griffco Valve Inc.

6010 N. Bailey Ave, Ste 1B

Amherst, NY 14226 USA

Phone: 1 800-474-3326

Fax: 1 716-835-0893

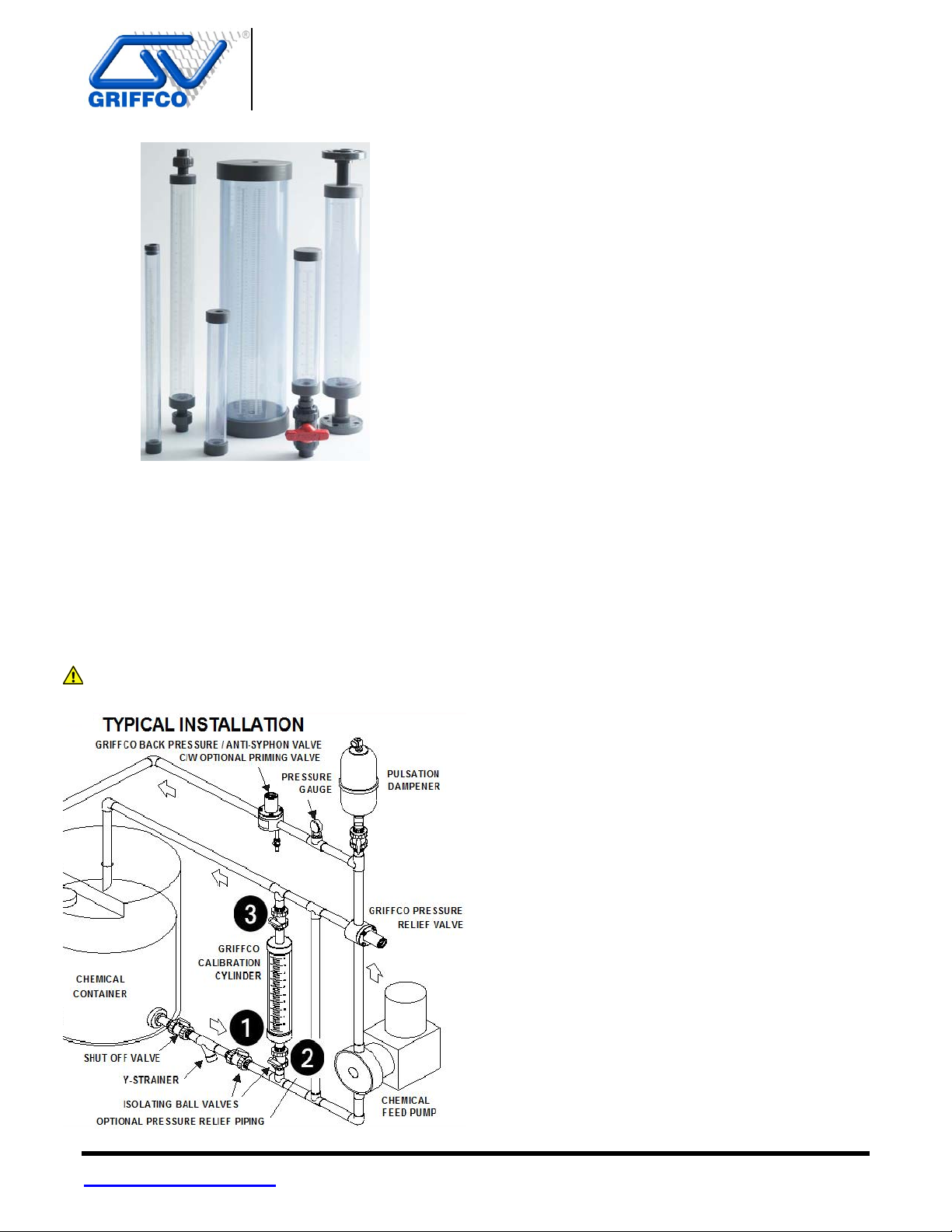

Installation Instructions:

Install the calibration cylinder in the suction line

before the chemical metering pump. Ensure that the

cylinder is vertical and level. For Sealed and EZClean configurations, two (2) isolating valves are

typically installed as per the drawing below. The top

of the cylinder should be vented back to the top of

the chemical container or to drain. The cylinder must

never be pressurized above 15 psi.

Caution! Max. cylinder pressure is 15 psi.

PVC CALIBRATION CYLINDERS

Installation & Operation Manual

Operating Instructions:

There are two (2) methods for using the calibration

cylinder, measuring volume or flow rate.

Method 1 – Volumetric. Any drawdown time may

be used: (Using the mL Scale)

1. Open isolating valves 1 and 2 to fill the cylinder to

the top mark on the scale (0 mL). Valve 3 is open

for venting.

2. Close isolating valve 1 from the tank on the suction

line. Leave isolating valves 2 and 3 on the

calibration cylinder open. Note the top needs to be

open to vent.

3. Turn on the chemical feed pump for a measured

drawdown time (seconds). Turn off the pump or

close valve 2 (first) and open valve 1 from the tank.

The volume displaced from the cylinder can be

read on the left side of the cylinder scale in mL. If

not starting at zero, subtract the starting reading

from the final reading.

4. To convert the mL reading into LPH or GPH use

one of the following two formulas:

LPH = 3.6 x [mL] ÷ Time (sec)

GPH = 0.951 x [mL] ÷ Time (sec)

5. If the reading is not the desired flow rate, adjust the

pump speed or stroke setting and repeat steps 1-4

until the correct flow rate is achieved.

6. Close valves 2 and 3 for normal system operation

and drain, or empty column.

Method 2 - Flow Rate, capacity based on 30 sec

drawdown time: (Using the USGPH scale)

1. Open isolating valves 1 and 2 to fill the cylinder to

the top mark on the scale (0 USGPH). Valve 3 is

open for venting.

2. Close isolating valve 1 from the tank on the suction

line. Leave isolating valves 2 and 3 on the

calibration cylinder open. Note the top needs to be

open to vent.

3. Turn on the chemical feed pump for 30 seconds.

Turn off the pump or close valve 2 (first) and open

valve 1 from the tank. The USGPH reading is on

the right side of the cylinder label. If not starting at

zero, subtract the starting reading from the final

reading.

4. If the reading is not the desired rate of flow adjust

the pump volume and repeat the process until the

correct rate of flow is achieved.

5. Close valves 2 and 3 for normal system operation

and drain, or empty column.

www.griffcovalve.com CALL 1 - 800 - GRIFFCO Bulletin # INSCC-5000-2014

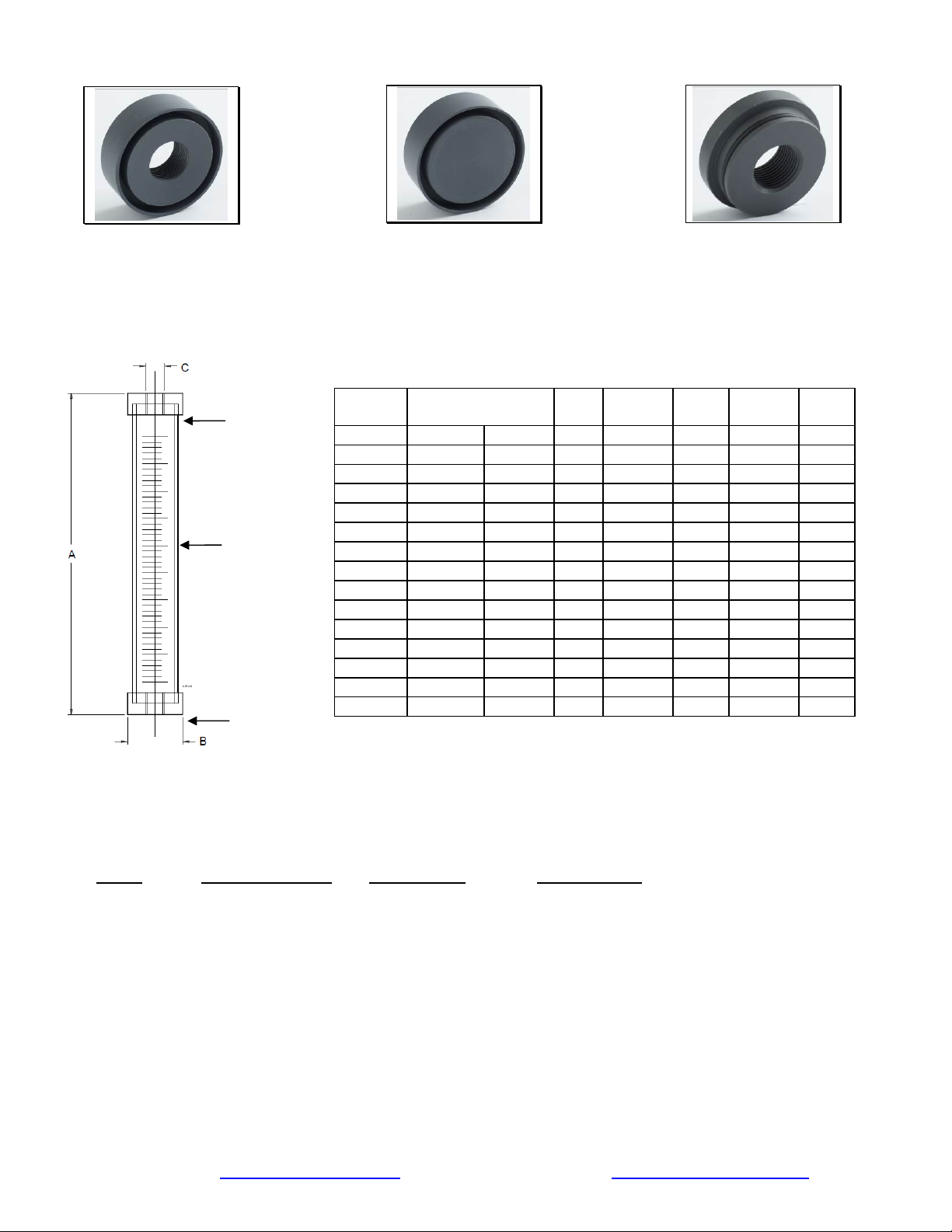

Description of models:

p

,

Sealed:

Top is glued to cylinder and contains a

vent or overflow connection. (FNPT).

Used in applications where there is a

positive suction head and a permanent

installation is desired.

Loose Cap: (Avail. up to 20,000 mL)

Top is loose and does not have a

connection in the top. Dust cover only.

Used in applications where there is no

positive suction head and the cylinder

must be filled from the top.

EZ-Clean: (Avail. 100 – 7000 mL

only)

Top is sealed with an O-ring and has a

vent connection, but removable for

easy cleaning. Used in applications

where frequent cleaning is required

such as polymer, alum, ferric chloride

or chlorine.

Top End

Ca

Clear PVC

Cylinder

Bottom

End Cap

Capacity

(mL) ◊

100

200

300

500

1,000

2,000

3,000

4,000

5,000

7,000

10,000

15,000

20,000

30,000

40,000

▲ Max Flow and gph scale are based on 30 second drawdown * Reference only

◊ For 60 sec draw down

Max Flow ▲

(USgph) (lph)

Scale

(mL)

Scale ▲

(gph)

A

(in)

3.17 12 1 .1 11 1.5 1/2

6.34 24 1 .1 19 1.5 1/2

9.51 36 5 .2 13 2.2 1/2

15.85 60 5 .2 13 2.5 3/4

31.70 120 5 .2 22 2.5 3/4

63.40 240 10 1 20 3.7 1

95.10 360 10 1 17 4.9 1 1/2

126.8 480 10 1 37 3.7 1

158.5 600 10 1 28 4.9 1 1/2

221.9 840 10 1 38 4.9 1 1/2

317.0 1200 100 5 25 6.95 2

475.5 1800 100 5 36 6.95 2

634.0 2400 100 5 47 6.95 2

952.0 3600 200 10 65* 9.5* 4

1,268.0 4800 200 10 77.5* 9.5* 4

double capacityin mL or flow size

Codes for Ordering PVC Calibration Cylinders:

B

(in)

C

(in)

CC □□□□ □ □ □

1 2 3 4

1 = Size 2 = Top End Cap Style 3 = Connections 4 = Oring Material

(Top Cap Only) (Union & EZ end cap orings)

0100 – 100 mL Blank – Sealed Blank – Threaded Blank – FKM (Viton

0200 – 200 mL L – Loose

0300 – 300 mL EZ – EZ Clean

0500 – 500 mL U – Union

1000 – 1000 mL

2000 – 2000 mL

3000 – 3000 mL

4000 – 4000 mL

5000 – 5000 mL

7000 – 7000 mL

10000 – 10000 mL

15000 – 15000 mL

20000 – 20000 mL

30000 – 30000 mL

40000 – 40000 mL

(up to 20000mL) S – Socket E - EPDM

(up to 7000mL) F – Flanged

(PTFE Encapsulated

or FFKM are available

upon request)

®

)

Website: www.griffcovalve.com email: sales@griffcovalve.com

Loading...

Loading...