Griffco Valve CCG Glass User Manual

Griffco Valve Inc.

Y-STRAINER

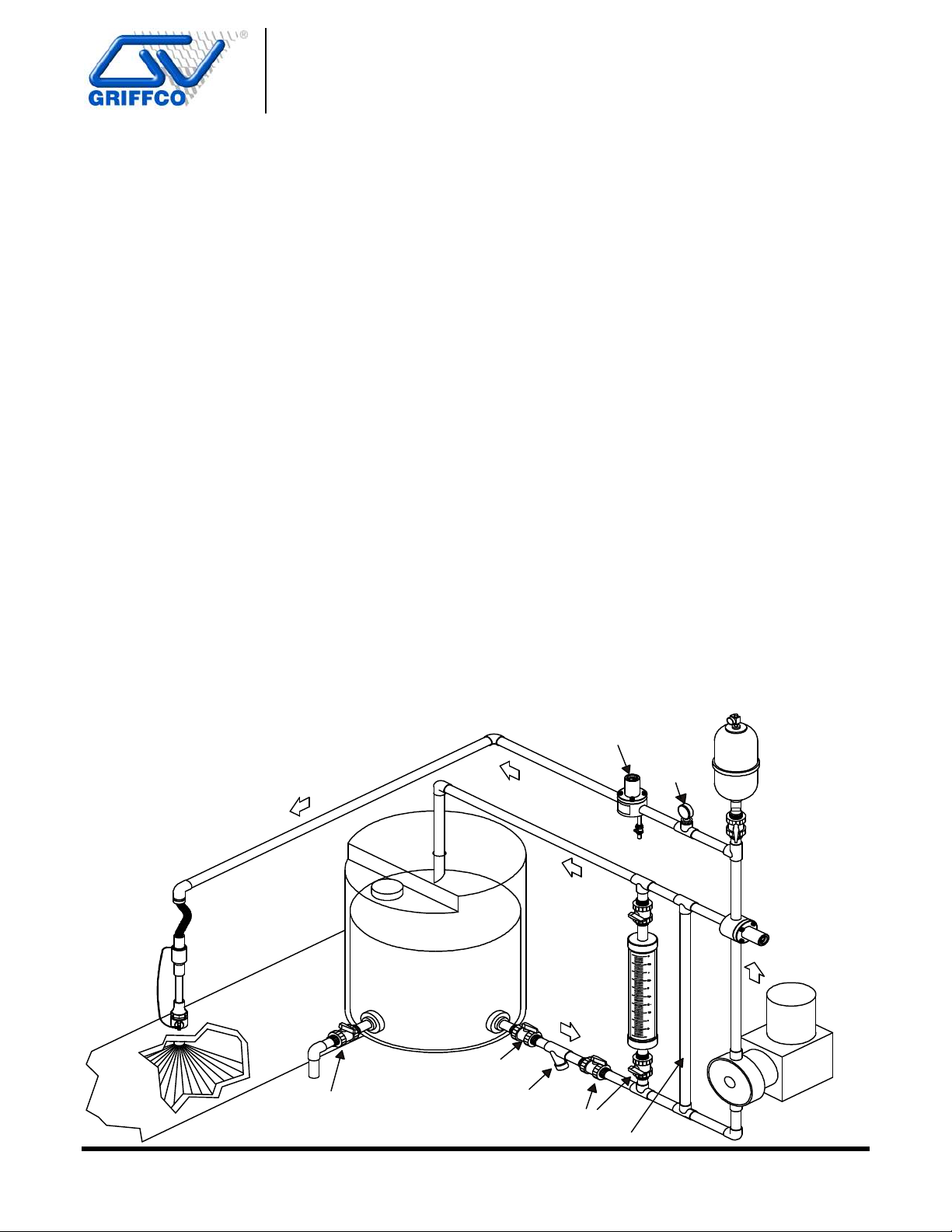

TYPICAL INSTALLATION

6010 N.Bailey Ave, Ste 1B

Amherst,NY 14226

Phone:1 800-474-3326

Fax:1 716-835-0893

GLASSCALIBRATION CYLINDERS

Operating Instructions:

Install the calibrationcylinder in thesuctionline tothe chemical meteringpump. Ensure thatthe cylinder is

vertical. Two (2)isolating ball valvesmust be install in thesuctionlineasperthe drawing below.The topofthecylinder

shouldbevented back to thetopofthe chemicalcontainer or to drain. A 12” length offlexablehoseshouldbeinstallon

thetop ofthecylinder if it is to be hardpiped intothesystem.

There aretwo(2)methodsof using the calibrationcylinder, measuringvolume orrateofflow.Beforestarting the

calibrationmakesure the pumpisprimed.

Method 1 - Rate of Flow:(Using theUSGPHscale)

Open isolatingvalves1 and2 to fillthecylinder

tothetop mark on thescale. (0 USGPH)

Close isolatingvalve(1) inthe suctionline.

Leaveisolating valve (2) open.

Switch on thechemical feedpump for 30

seconds. Switch off thepump.

Thereadingintheright sideofthe cylinderisa

directreadout in USGPH.

If thereading is not thedesired rateofflow

adjustthe pumpvolumeandrepeat the

processuntil thecorrect rateofflowis

achieved.

Method 2 – Volumetric:(Using the mL Scale)

Open isolatingvalves1 and2 to fillthecylinder

tothetop mark on thescale. (0 mL )

Close isolatingvalve(1) inthe suctionline.

Leaveisolating valve (2) open.

Switch on thechemical feedpump for a

measured drawdowntime.Shut off thepump.

Thevolumedisplacedfromthe cylindercanbe

read on theleftside thecylinder scaleinmL.

If thereading is not thedesired rateofflow

adjustthe pumpvolumeandrepeat the

processuntil thecorrect rateofflowis

achieved.

To convert toLPHorGPH useoneofthe

followtwoformulas

LPH=(volume÷drawdowntime) x3.6

GPH=(volume÷drawdowntime) x 0.952

Oncethedesired pump dosing volumehasbeen setclose isolating valve (2) and openisolation valve(1) toresume

normalpumping operation.

Note: Maximum sealed cylinder pressure is 15 feet of water column.

GRIFFCO BACK PRESSURE / ANTI-SYPHON VALVE

C/W OPTIONAL PRIMING VALVE

PRESSURE

GAUGE

PULSATION

DAMPENER

INJECTION

VALVE

DRAIN

VALVE

GRIFFCO PRESSURE

RELIEF VALVE

GRIFFCO

CALIBRATION

CHEMICAL

CONTAINER

SHUT OFF VALVE

ISOLATING BALLVALVES

OPTIONAL PRESSURE RELIEF PIPING

CYLINDER

1

2

CHEMICAL

FEED PUMP

CALL 1 - 800 - GRIFFCO Bulletin# CAL7003-2011

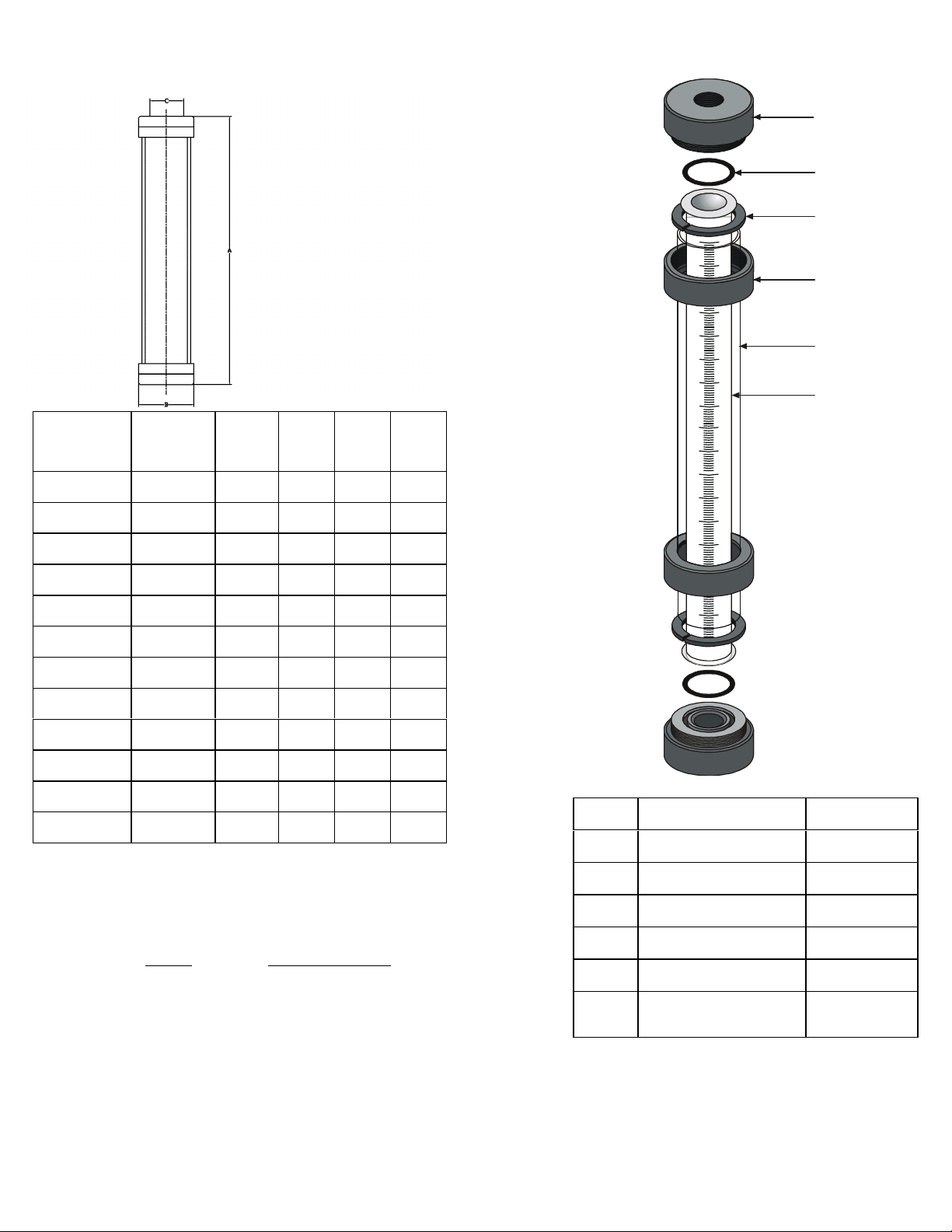

Dimensions:

6

5

Component Drawing:

1

2

3

4

Capacity

(mL)

30

100

200

500

1,000

2,000

3,000

4,000

5,000

7,000

10,000

20,000

* 2,000mL w/ PTFE End Cap ONLY, Dim A = 26 in

* 4,000mL w/ PTFE End Cap ONLY, Dim A = 38 in

Size

(USgph)

Scale

(mL)

A

(in)

B

(in)

.95 1 14 1.4 1/4

3.2 2 15 2.5 1/2

6.4 2 21 2.5 1/2

16 5 15 3.5 3/4

32 5 27 3.5 3/4

63 10 27* 5.0 1

95 10 21 7.5 1 1/2

127 10 39* 5.0 1

160 10 29 7.5 1 1/2

225 10 39 7.5 1 1/2

320 20 27 9.15 2

640 20 39 9.15 2

C

(in)

Codes for Ordering Glass Calibration Cylinders:

CCG □□□□□ □

1 2

1 = Size 2 = End Cap Material

0030 - 30 mL

0100 - 100 mL P - PVC

0200 - 200 mL CP - CPVC

0500 - 500 mL PP - Polypro

1000 - 1000 mL T - PTFE

2000 - 2000 mL K - PVDF

4000 - 4000 mL M - 316 SS

10000 - 10000mL A - Alloy 20

20000 - 20000 mL

Ref # Part # - Size - Mtrl Description

1 PC-001-_____ - ___ End Cap

2 PC-002-_____ - V O-Ring

3 PC-003-_____ - PVC Split Ring

4 PC-004-_____ - PVC Nut

5 PC-005-_____ - CAB Shield

6 PC-006-_____ - GL Glass

Tube

1

Shield not available on 10 & 20,000 mL sizes.

2

Viton O-Ring is standard, other by request.

When ordering parts please specify size and

material code.

2

1

Website: www.griffcovalve.com Email: sales@griffcovalve.com

Loading...

Loading...