Grifco U-Drive GUDK-RSO-H053M, GUD-MK-07, GSB-600, U-Drive GUDK-RSO-H073M, GUD-H053M Instruction Manual

...

Chamberlain Australia Pty Ltd

PO Box 1446, Lane Cove

NSW 1595, Australia

Phone toll free 1800 474 326

D-M-RSO-040A 06/11/18

Chamberlain New Zealand Ltd

PO Box 100-221

North Shore 0745, New Zealand

Phone toll free 0800 653 667

THIS OPERATOR IS TO BE INSTALLED AND SERVICED BY A TRAINED TECHNICIAN ONLY

Compatible with GLMe2 eDrive +2.0 Wall Control

INSTRUCTION MANUAL

U-Drive

Operator for Non Spring-Balanced

Roller Shutters

www.grifco.com.au

www.grifco.co.nz

2

WARNING:

Important safety instructions

It is important for the safety of persons to follow all instructions.

SAVE these instructions

WARNING

CAUTION

WARNING

This commercial door operator has been designed and tested to offer safe service provided it is installed, operated, maintained and

tested in strict accordance with the instructions and warnings contained in this manual.

Mechanical

Electrical

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock.

When you see this Signal Word on the following pages, it will

alert you to the possibility of damage to your commercial door

and/or the commercial door operator if you do not comply with

the cautionary statements that accompany it.

THESE ARE IMPORTANT SAFETY INSTRUCTIONS. FOLLOW ALL INSTRUCTIONS AS INCORRECT

INSTALLATION CAN LEAD TO SEVERE INJURY OR DEATH

Keep commercial door maintained. Sticking or binding

doors must be repaired. Commercial doors, brackets and

their hardware are under extreme tension and can cause

serious personal injury. Do not attempt to loosen, move or

adjust them. Call for commercial door service.

Where applicable, permanently fasten all supplied labels

adjacent to the wall control as a convenient reference and

reminder of safe operating procedures.

Disengage all existing commercial door locks to avoid

damage to commercial door. Install the control (or any

additional push buttons) in a location where the commercial

door is visible during operation . Do not allow children to

operate push button(s) or remote control(s). Serious personal

injury from a closing commercial door may result from misuse

of the opener.

Activate opener only when the door is in full view, free of

obstructions and opener is properly adjusted. No one should

enter or leave the building while the door is in motion.

An electrician must disconnect electric power to the

commercial door opener and control before making repairs or

removing covers.

The actuating member of a biased-off switch is to be located

within direct sight of the door but away from moving parts.

Unless it is key operated, it is to be installed at a minimum

height of 1500mm and not accessible to the public.

Make sure that people who install, maintain or operate the

door follow these instructions. Keep these instructions in a

safe place so that you can refer to them quickly when you

need to.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play

with the appliance.

If the opener is installed at a height less than 2.5 meters

from floor level or any other level from which the unit can

be accessed (eg mezzanine) the installer is responsible to fit

guards to the opener to prevent access to the chain drive.

Ensure that the temperature range marked on the operator is

suitable for the location. Ensure that entrapment due to the

opening movement of the of the driven part is avoided.

Unbalanced roller shutter doors require a Suitable AntiDrop device to catch the door in the event a a failure of

the drive system., such as the GRIFCO GSB-600.

Do not wear rings, watches or loose clothing while

installing or servicing a commercial door opener.

To avoid serious personal injury from entanglement,

remove all ropes connected to the commercial door

before installing the door control.

Installation and wiring must be in compliance with your

local building and electrical codes. Connect the power

supply cord only to properly earthed mains if applicable.

Moisture and water can destroy the electronic components.

Make sure under all circumstances that water moisture or

storage moisture cannot penetrate the electronics. The

same applies for openings and cable entries.

After the installation a final test of the full function of the

system and the full function of the safety devices must

be done.

When operating a biased-off switch, make sure that other

persons are kept away.

The opener cannot be used with a driven part

incorporating a wicket door (unless the opener cannot be

operated with the wicket door open).

Motor may become hot during operation. Appropriate

clearance and/or shielding should be supplied by the

installer to ensure any cabling, wiring and/or other items

cannot come in contact with the motor. If temperature

rise exceeds 50°C all fixed wiring insulation must be

protected, for example, by insulating sleeving having an

appropriate temperature rating.

3

SAFETY INSTRUCTIONS ............................................................................................. 2

TYPICAL INSTALLATION ............................................................................................. 4

SPECIFICATIONS ..................................................................................................... 5-9

Specifications Table ..................................................................................................................... 5

Dimensions ................................................................................................................................... 6

Contents .......................................................................................................................................7

Selection Guide ........................................................................................................................ 8-9

INSTALLATION ..................................................................................................... 10-17

Install Wall Brackets ...................................................................................................................10

Install Door Drum .......................................................................................................................10

Install Flange Bearing ................................................................................................................10

Install Safety Brake Angle .......................................................................................................... 11

Install Safety Brake ....................................................................................................................11

Select Mounting Configuration .................................................................................................. 12

Select In-Board or Out-Board Mounting Configuration ........................................................... 13

Install Operator Mounting Plate ................................................................................................13

Mount Operator to Wall Bracket ...............................................................................................14

Install Sprocket...........................................................................................................................14

Install Drive Chain ......................................................................................................................15

Electrical Installation ............................................................................................................ 16-17

COMMISSIONING ................................................................................................. 18-19

Setting Limits .............................................................................................................................. 18

Manual Setting of Door Position ...............................................................................................19

MAINTENANCE ......................................................................................................... 20

TROUBLESHOOTING ............................................................................................ 21-22

CHAMBERLAIN LIMITED WARRANTY ....................................................................... 24

TABLE OF CONTENTS

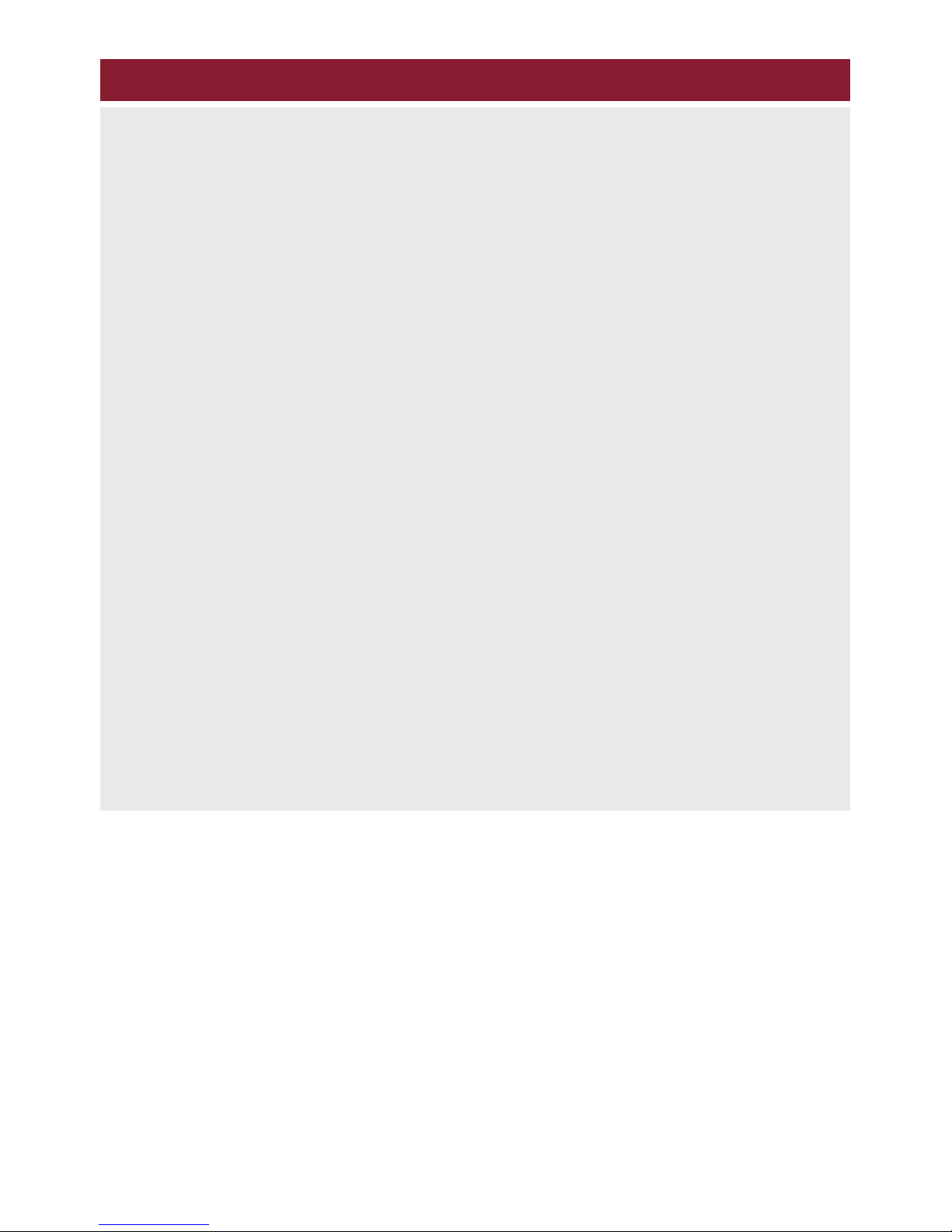

The U-Drive can be operated with a standard

GLMe2 Series controller, or one of our standard

reversing starters. The mechanical limit system

and high torque output make this an ideal solution

for high-cycle non spring-balanced roller shutters

and grilles.

This manual details the mechanical installation of

the U-Drive system and safety brake. For all other

electrical connections please refer to the

respective controller’s manual.

4

TYPICAL INSTALLATION

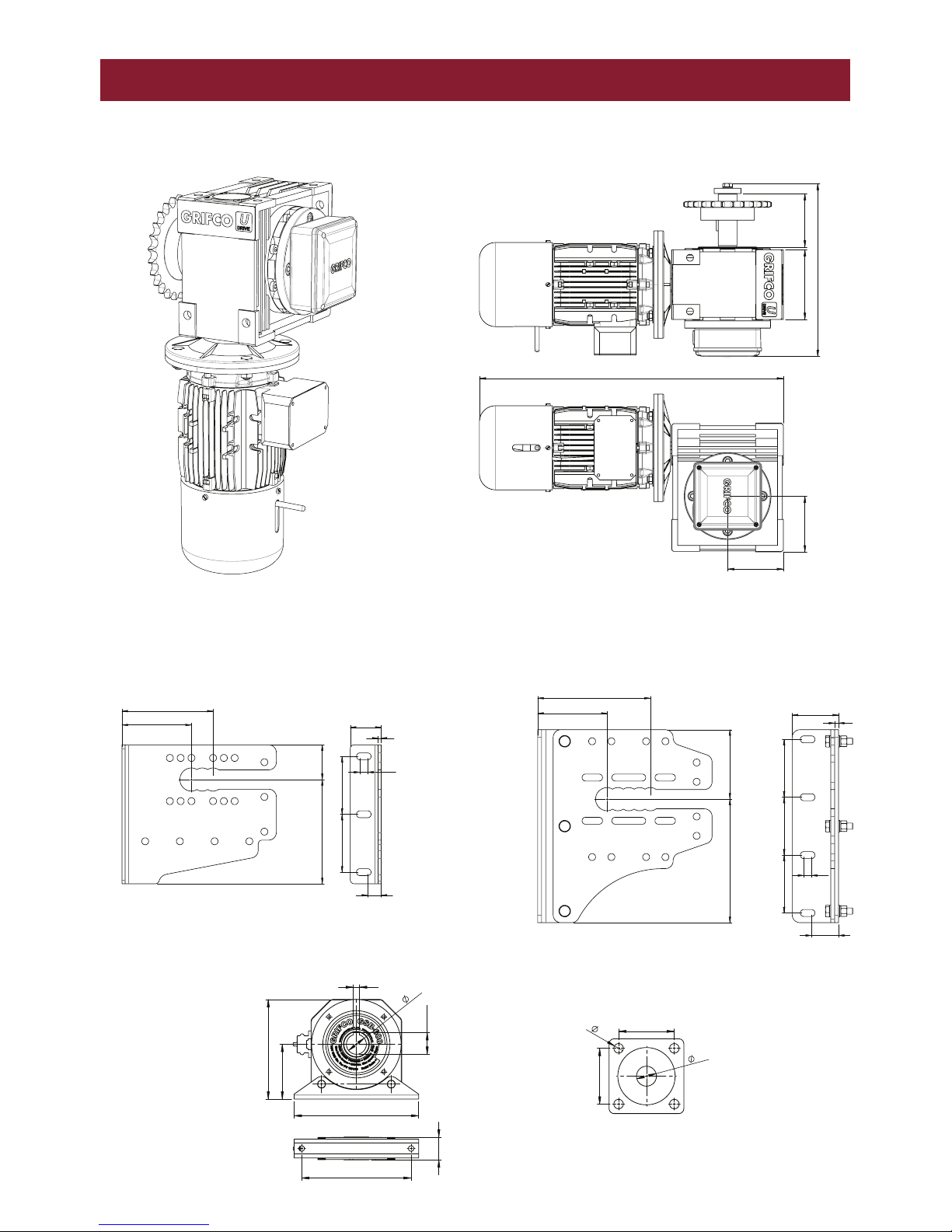

INSTALLATION OF GUDK-RSO-H073M SHOWN

5

SPECIFICATIONS

* Note: Door size indication only based on standard door weights and dimensions, it remains the

responsibility of the installer to confirm maximum drum torque and system mass before installation.

GUD-H053M

GUD-MK-05

GUD-H073M

GUD-MK-07

Peak Opener Torque 180 Nm 260 Nm

Peak Drum Torque 600 Nm 600 Nm

Max Bracket capacity (Pair) 574 kg 800 Kg

Power 0.5 Hp 0.75 Hp

Full Load Current 1.8 A 2 A

Volts (AC) 415 V 415V

Phase 3 3

Max safety brake speed 16 rpm 16 rpm

Output shaft speed 14 rpm 14 rpm

Limits 2 x N/C Micro Switch 2 x N/C Micro Switch

Rated Load 110N.m @ RUN TIME = 7.6min 183N.m @ RUN TIME = 10min

Drive Sprocket supplied 25T 12B 25T 12B

6

SPECIFICATIONS

GUD-H053M / GUD-H073M

GUD-MK-05

GSB-600 FLANGE BEARING

GUD-MK-07

554

104

104

322

130 99.5

180 MIN

180 320

292 MAX

120

10

150 150 150

70

20

180 MIN

180 320

292 MAX

120

10

150 150 150

70

20

180 MIN

90 270

236 MAX

150 150

20

35

80

8

110

200

250

40

12

43.3

220

46

40

19

112

112

40

19

112

112

7

SPECIFICATIONS

CONTENTS

GUD-H053M

A. Motor and gearbox assy with limits and output shaft

B. 25T sprocket

C. Operator mounting plate

D. Drive chain 12B (Not shown)

E. Operator fastener kit (Not shown)

F. Manual (Not shown)

GUD-H073M

A. Motor and gearbox assy with limits and output shaft

B. 25T sprocket

C. Operator mounting plate

D. Drive chain 12B (Not shown)

E. Operator fastener kit (Not shown)

F. Manual (Not shown)

GUDK-RSO-H073M - COMPLETE CONTENTS

GUDK-RSO-H053M - COMPLETE CONTENTS

GUD-MK-05

A. Wall bracket LH

B. Wall bracket RH

C. Safety brake angle

D. Flange bearing

E. Flange bearing fastener kit (Not shown)

F. Safety brake fastener kit (Not shown)

G. Wall bracket fastener kit (Not shown)

GSB-600

Safety Brake

GSB-600

Safety Brake

GUD-MK-07

A. Wall angle x 2

B. Wall bracket x 2

C. Safety brake angle

D. Flange Bearing

E. Flange Bearing Fastener kit (Not shown)

F. Safety Brake Fastener kit (Not shown)

G. Wall Bracket Fastener kit (Not shown)

A.

A.

B.

B.

C.

C.

C.

C.

A.

A.

B.

B.

D.

D.

8

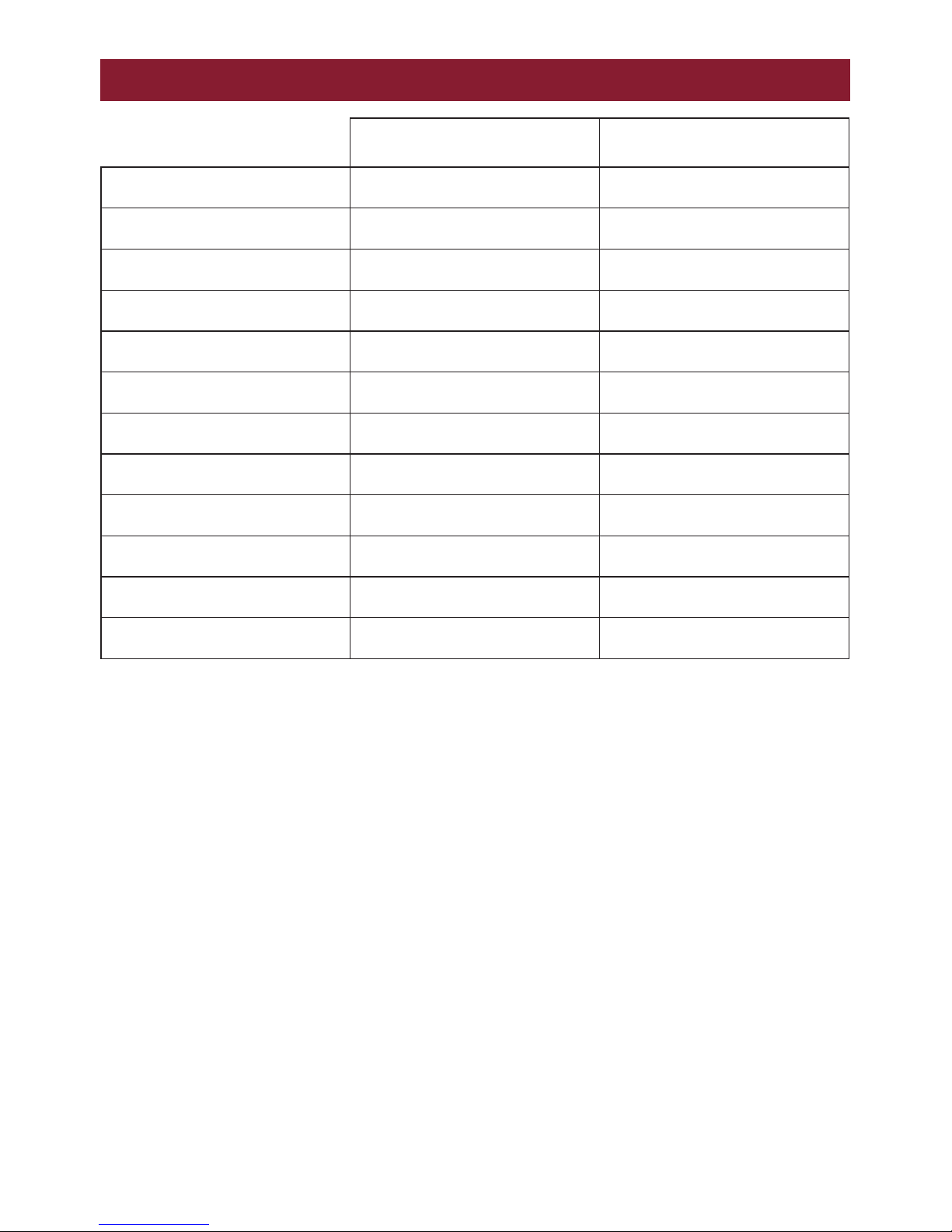

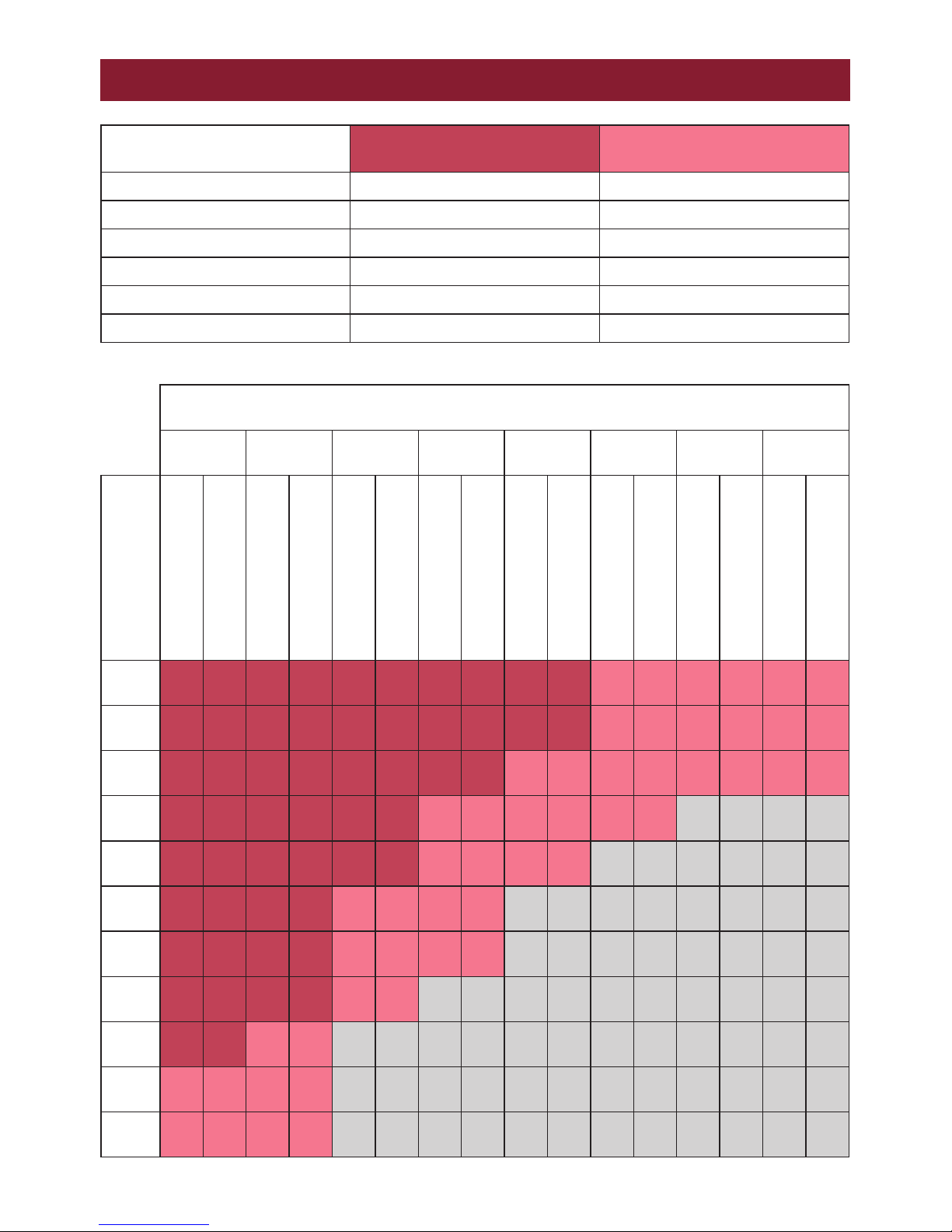

SELECTION GUIDE 60% DUTY

Door Height (Drum Axis to Floor)

2.5m 3m 3.5m 4m 4.5m 5m 5.5m 6m

Door Width

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

Drum Sprocket Teeth

Drum Speed Rpm

3m 35 10.0 35 10.0 35 10.0 35 10.0 35 10.0 35 10.0 36 9.7 40 8.8

3.5m 35 10.0 35 10.0 35 10.0 35 10.0 40 8.8 37 9.5 42 8.3 46 7.6

4m 35 10.0 35 10.0 35 10.0 40 8.8 37 9.5 42 8.3 47 7.4 54 6.5

4.5m 35 10.0 35 10.0 40 8.8 37 9.5 42 8.3 47 7.4 N/A N/A N/A N/A

5m 35 10.0 38 9.2 44 8.0 41 8.5 46 7.6 N/A N/A N/A N/A N/A N/A

5.5m 35 10.0 41 8.5 39 9.0 45 7.8 N/A N/A N/A N/A N/A N/A N/A N/A

6m 38 9.2 45 7.8 43 8.1 50 7.0 N/A N/A N/A N/A N/A N/A N/A N/A

6.5m 41 8.5 50 7.0 46 7.6 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

7m 44 8.0 43 8.1 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

7.5m 38 9.2 46 7.6 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

8m 41 8.5 50 7.0 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A

60% DUTY GUD-H053M

GUD-MK-05

GUD-H073M

GUD-MK-07

Drum Diameter 168 mm 168 mm

Curtain Mass 14 kg/m2 14 kg/m2

Max System Mass 574 KG 800 KG

Max Door Size 20 m2 24 m2

Max Torque 180 Nm 220 Nm

Max Cycle Time 60s 60s

Loading...

Loading...