Grifco GSD-SDO, GSD-R2.4M, GSD-R3.6M, GSD-RKIT Instruction Manual

Model GSD-SDO

Chamberlain Australia Pty Ltd

Unit 1, 75 Epping Rd North Ryde NSW 2113

Ph: 1800 638 234

www.grifco.com.au

Ref: 01-38727D

• THIS OPERATOR IS TO BE INSTALLED AND SERVICED BY A TRAINED TECHNICIAN ONLY

• This operator is compatible with Security+ 2.0® accessories

OPERATOR

REQUIRES GRIFCO

MONITORED ENTRAPMENT

PROTECTION

OPERATOR

REQUIRES GRIFCO

MONITORED ENTRAPMENT

PROTECTION

Commercial Sectional Door Operator

With Integral Battery Back Up

GSD-SDO

DC Operator

GSD-R2.4M

Rail for 2.4m Door

GSD-R3.6M

Rail for 3.6m Door

GSD-RKIT

Hardware Kit for

Custom Rail Length

up to 6m

INSTRUCTION MANUAL

2

WARNING:

Important safety instructions

It is important for the safety of persons to follow all instructions.

SAVE these instructions

WARNING

CAUTION

WARNING

This commercial door operator has been designed and tested to offer safe service provided it is installed, operated, maintained and tested

in strict accordance with the instructions and warnings contained in this manual.

Mechanical

Electrical

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock.

When you see this Signal Word on the following pages, it will alert

you to the possibility of damage to your commercial door and/or

the commercial door operator if you do not comply with the

cautionary statements that accompany it.

Keep commercial door balanced. Sticking or binding doors must be

repaired. Commercial doors, door springs, pulleys, brackets and their

hardware are under extreme tension and can cause serious personal

injury. Do not attempt to loosen, move or adjust them. Call for commercial

door service.

Permanently fasten all supplied labels adjacent to the wall control as a

convenient reference and reminder of safe operating procedures.

Activate operator only when the door is in full view, free of obstructions

and operator is properly adjusted. No one should enter or leave the

building while the door is in motion.

An electrician must disconnect electric power to the commercial door

operator before making repairs or removing covers.

The actuating member of a biased-off switch is to be located within direct

sight of the door but away from moving parts. Unless it is key operated, it

is to be installed at a minimum height of 1500mm and not accessible to

the public.

Make sure that people who install, maintain or operate the door follow

these instructions. Keep these instructions in a safe place so that you can

refer to them quickly when you need to.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

If the operator is installed at a height less than 2.5 metres from floor level

or any other level from which the operator can be accessed (eg

mezzanine) the installer is responsible to fit guards to the operator to

prevent access to the chain drive.

Use the commercial door operator for its intended purpose. The GSDSDO S-Drive operator is designed lifting spring-balanced sectional doors.

Disengage all existing commercial door locks to avoid damage to

commercial door. Install the wall control (or any additional push buttons) in

a location where the commercial door is visible during operation . Do not

allow children to operate push button(s) or remote transmitter(s). Serious

personal injury from a closing commercial door may result from misuse of

the operator.

Do not wear rings, watches or loose clothing while installing or servicing a

commercial door operator.

To avoid serious personal injury from entanglement, remove all ropes

connected to the commercial door before installing the door operator.

After the installation a final test of the full function of the system and the

full function of the safety devices must be done.

When operating a biased-off switch, make sure that other persons are

kept away.

The operator cannot be used with a driven part incorporating a wicket

door (unless the operator cannot be operated with the wicket door open).

Motor may become hot during operation. Appropriate clearance and/or

shielding should be supplied by the installer to ensure any cabling, wiring

and/or other items cannot come in contact with the motor. If temperature

rise exceeds 50°C all fixed wiring insulation must be protected, for

example, by insulating sleeving having an appropriate temperature rating.

THESE ARE IMPORTANT SAFETY INSTRUCTIONS. FOLLOW ALL INSTRUCTIONS AS INCORRECT

INSTALLATION CAN LEAD TO SEVERE INJURY OR DEATH

Installation and wiring must be in compliance with your local building and

electrical codes. Connect the power supply cord only to properly earthed

mains. If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in order to

avoid a hazard.

Moisture and water can destroy the electronic components. Make sure

under all circumstances that water moisture or storage moisture cannot

penetrate the electronics. The same applies for openings and cable

entries.

SAFETY SYMBOL AND SIGNAL WORD REVIEW

3

CARTON INVENTORY

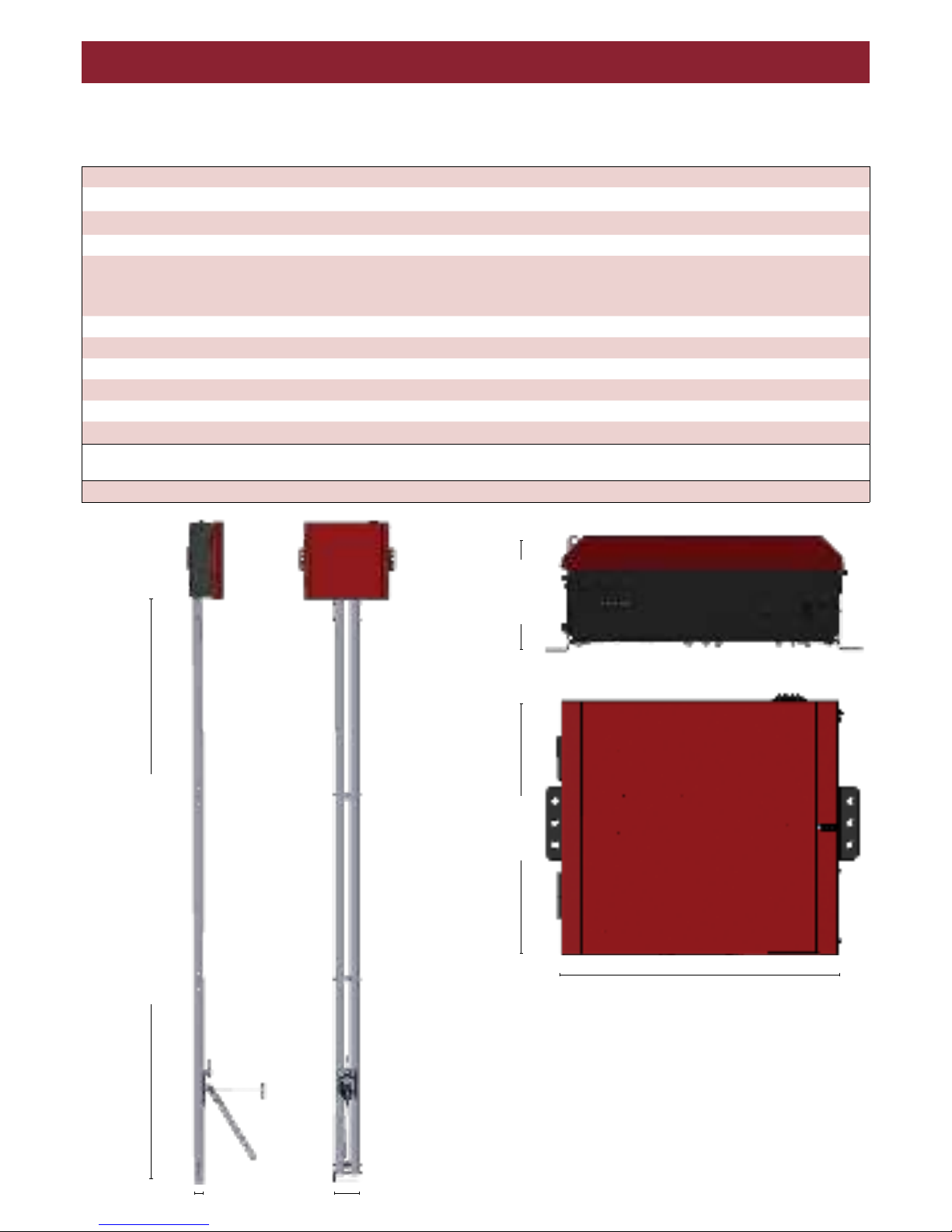

GSD-SDO DC Operator

GSD-R2.4M 2.4 m Rail

GSD-R3.6M 3.6 m Rail

GSD-RKIT Rail Kit for Custom Length

(6m max)

Battery 12 Vdc 7AH (2)

INTRODUCTION

CONTENTS

NOT SHOWN:

Door Bracket

J-Bar

Fasteners

Documentation Packet

Chain

SAFETY

SAFETY SYMBOL AND SIGNAL WORD REVIEW ..................... 2

INTRODUCTION 3

CARTON INVENTORY ................................................................ 3

OPERATOR SPECIFICATIONS ................................................... 4

OPERATOR OVERVIEW ............................................................. 5

CONTROL BOARD OVERVIEW .................................................. 6

EXPANSION BOARD OVERVIEW ............................................... 7

INSTALLATION 8

CONNECT RAIL TO OPERATOR ............................................... 8

MOUNT THE OPERATOR .......................................................... 8

ELECTRICAL CONNECTION AND DOOR ATTACHMENT .......... 9

CONNECT BATTERIES .............................................................. 9

DISCONNECT BATTERIES ......................................................... 9

COMMISSIONING 10

LIMIT SETTING......................................................................... 10

TYPES OF MONITORED ENTRAPMENT PROTECTION ........... 11

SELECTION OF ENTRAPMENT PROTECTION SYSTEM ......... 11

COMMISSIONING ENTRAPMENT PROTECTION SYSTEMS ... 12

FORCE SETTING AND FINE ADJUSTMENT............................. 13

TYPES OF SECURITY +2.0 TRANSMITTERS ........................... 14

COMMISSIONING REMOTE TRANSMITTERS ......................... 15

ACCESSORY WIRING ............................................................ 17

CONNECTING ACCESS CONTROL ACCESSORIES ............... 17

CONNECTING EXTERNAL CONTROL DEVICES ...................... 17

MISECLLANEOUS WIRING ...................................................... 18

OPERATION 18

RESET BUTTON ...................................................................... 18

OPERATOR ALARM ................................................................. 19

MANUAL DISCONNECT........................................................... 19

EXPANSION BOARD 20

AUXILIARY RELAYS ................................................................. 20

WIRING ACCESSORIES TO THE EXPANSION BOARD ........... 21

MAINTENANCE 22

MAINTENANCE CHART ........................................................... 22

BATTERY MAINTENANCE ....................................................... 22

TROUBLESHOOTING 23

VIEWING DIAGNOSTIC CODES ............................................... 23

DIAGNOSTIC CODES CHART .................................................. 25

CONTROL BOARD LEDS ......................................................... 27

TROUBLESHOOTING CHART .................................................. 28

SERVICE AND REPAIR PARTS ................................................ 30

WIRING DIAGRAM 31

CHAMBERLAIN LIMITED WARRANTY 32

4

OPERATOR SPECIFICATIONS

Main AC Power Supply 230-240 VAC 50Hz, 400W

Rated Load (R/T) 270N (Continuous)

System Operating Voltage 24 VDC Transformer Run / Battery Backup

Accessory Power 24 VDC, 500 mA max. for ON and SW (switched)

Maximum Door Heights (Rail Part No.) 2.4m (GSD-R2.4M)

3.6m (GSD-R3.6M)

6.0m (GSD-RKIT - rail angle not supplied)

Maximum Door Weight 315.5 kg balanced door

Maximum Door Area 26m²

Travel Speed 20cm per second

Maximum Duty Cycle Continuous

Operating Temperature +5°C to +40°C

Expansion Board Included

Compliance AS/NZS 60335-1

AS/NZS 60335-2-103

Usage Indoor Use Only

INTRODUCTION

2.4 m Rail GSD-R2.4M: 3,380 mm

3.6 m Rail GSD-R3.6M : 4,580 mm

146 mm

490 mm

445 mm 200 mm

50 mm

5

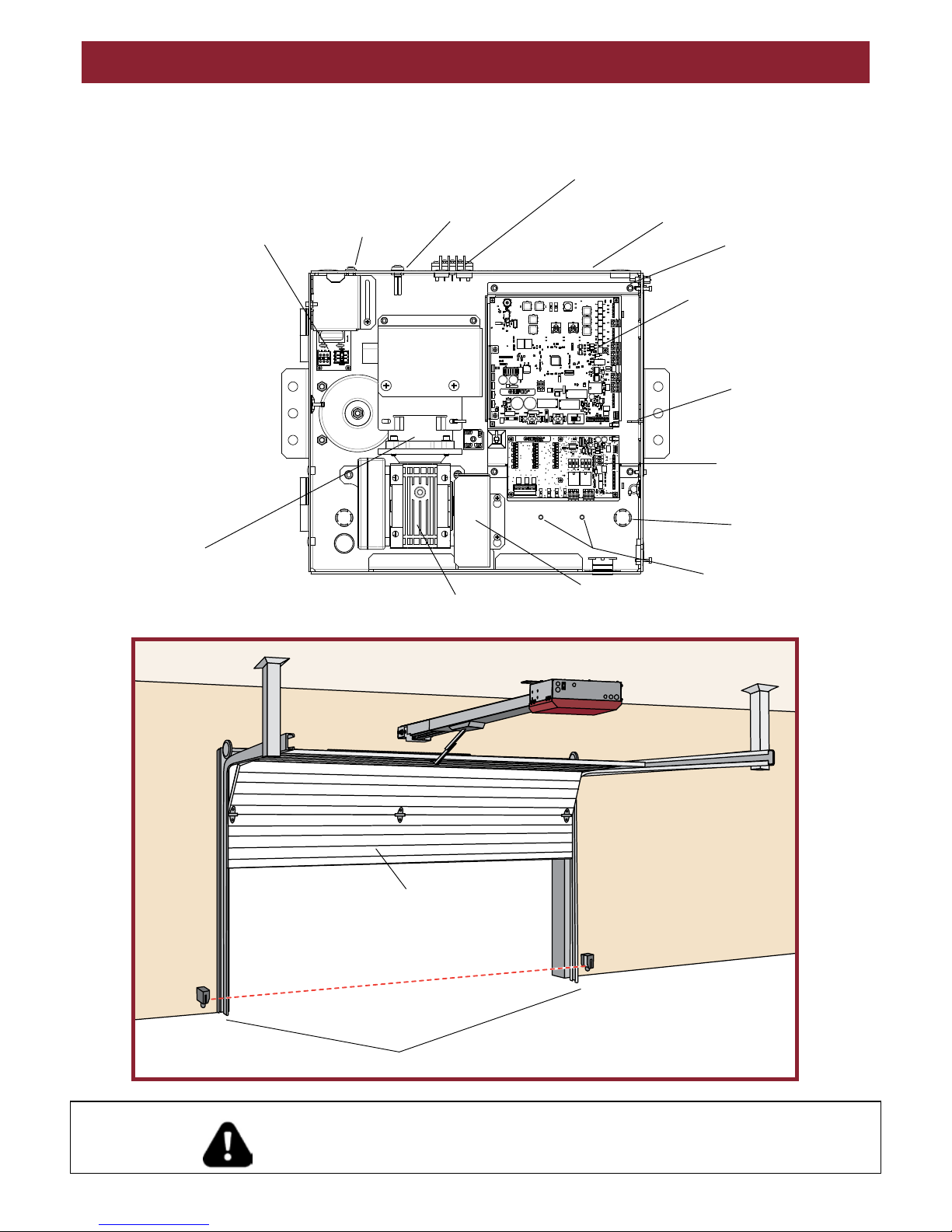

EXPANSION

BOARD

CONDUIT ENTRY /

EXIT TOP OF

OPERATOR

GSD-STAR1000EVO

MOUNTING

(NOT INCLUDED)

LOCKABLE LID

CHAIN GUARD

MOTOR

GEAR BOX

CONTROL BOARD

CONDUIT ENTRY / EXIT

REAR OF OPERATOR

ANTENNA CONNECTION

RESET BUTTON

ACCESS CONTROL DEVICE

EXTERNAL TERMINAL BLOCK

AC POWER

SWITCH

EMI BOARD

INTRODUCTION

PE Beams (Sold Separately)

Make sure the door opens and closes smoothly.

Door should stay in the open position when

springs are properly balanced.

WARNING

Always wear protective gloves and eye protection when changing

the battery or working around the battery compartment.

OPERATOR OVERVIEW

6

CONTROL BOARD OVERVIEW

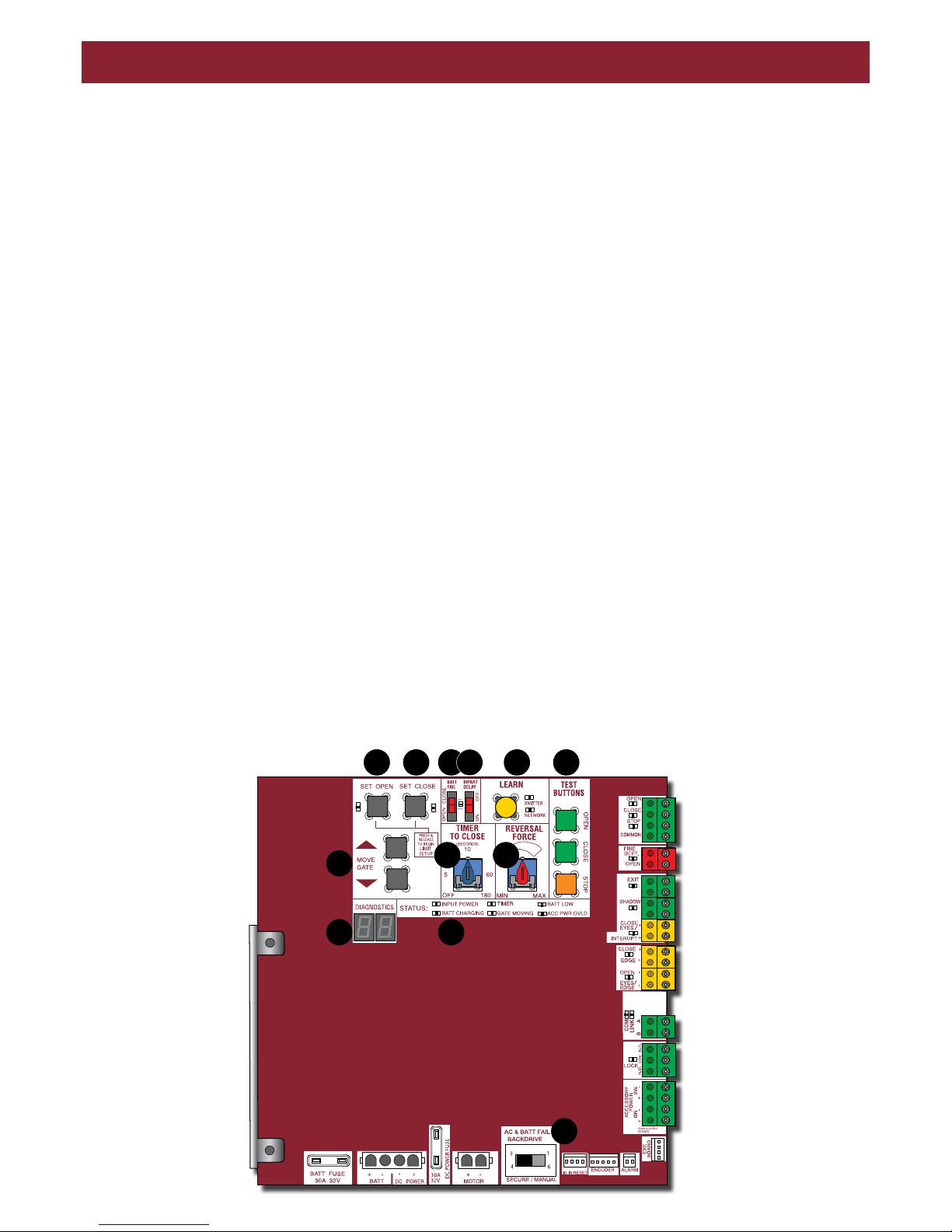

1. SET OPEN Button: The SET OPEN button sets the OPEN limit. See Adjust Limits section

2. SET CLOSE Button: The SET CLOSE button sets the CLOSE limit. See Adjust Limits section.

3. MOVE GATE Buttons: The MOVE GATE buttons will either open or close the door when the operator is in Limit setting mode.

See Adjust Limits section

4. BATT FAIL:

• When AC power is OFF and battery voltage is critically low the door will latch at a limit until AC power is restored or Batteries

voltage increases

• Option select switch set to OPEN forces door to automatically open and then latch at the OPEN limit until AC power is restored or

battery voltage increases

• Option select switch set to CLOSE forces door to latch at CLOSE limit if at CLOSE limit or on next CLOSE Command until AC

power restored or battery voltage increases

• Constant pressure on a hard command input overrides to open or close the gate/door

• Critically low battery is less than 23V

5. BIPART DELAY Switch: Not used in this application, ensure switch remains in OFF position

6. LEARN Button: The LEARN button is for programming remote transmitters and the network.

7. TIMER-TO-CLOSE dial: The TIMER-TO-CLOSE (TTC) dial can be set to automatically close the door after a specified time period.

The TTC is factory set to OFF. If the TTC is set to the OFF position, then the door will remain open until the operator receives another

command from a control. Rotate the TIMER-TO-CLOSE dial to the desired setting. The range is 0 to 180 seconds, 0 seconds is OFF

NOTE: Any radio command, single button control, or CLOSE command on the control board prior to the TTC expiring will close the

door. The TTC is reset by any signals from the open controls, loops, close edges, and close photoelectric sensors (IR’s)

8. REVERSAL FORCE dial: The REVERSAL FORCE dial adjusts the force. See Force Adjustment section

9. TEST BUTTONS: The TEST BUTTONS will operate the door (OPEN, STOP and CLOSE)

10. STATUS LEDs: The STATUS LEDs indicate the status of the operator. See Status LED Chart in the Troubleshooting section

11. Diagnostic Code Display: The diagnostic code display will show the operator type, firmware version, and diagnostic codes. The

operator type will display as "Gd" followed by a "24" which indicates the operator type as GSD-SDO. The firmware version will show

after the operator type, example "1.2"

12. BACKDRIVE Switch: MUST BE set to SECURE

1 2 4 5 6

7 8

9

10

12

11

3

INTRODUCTION

7

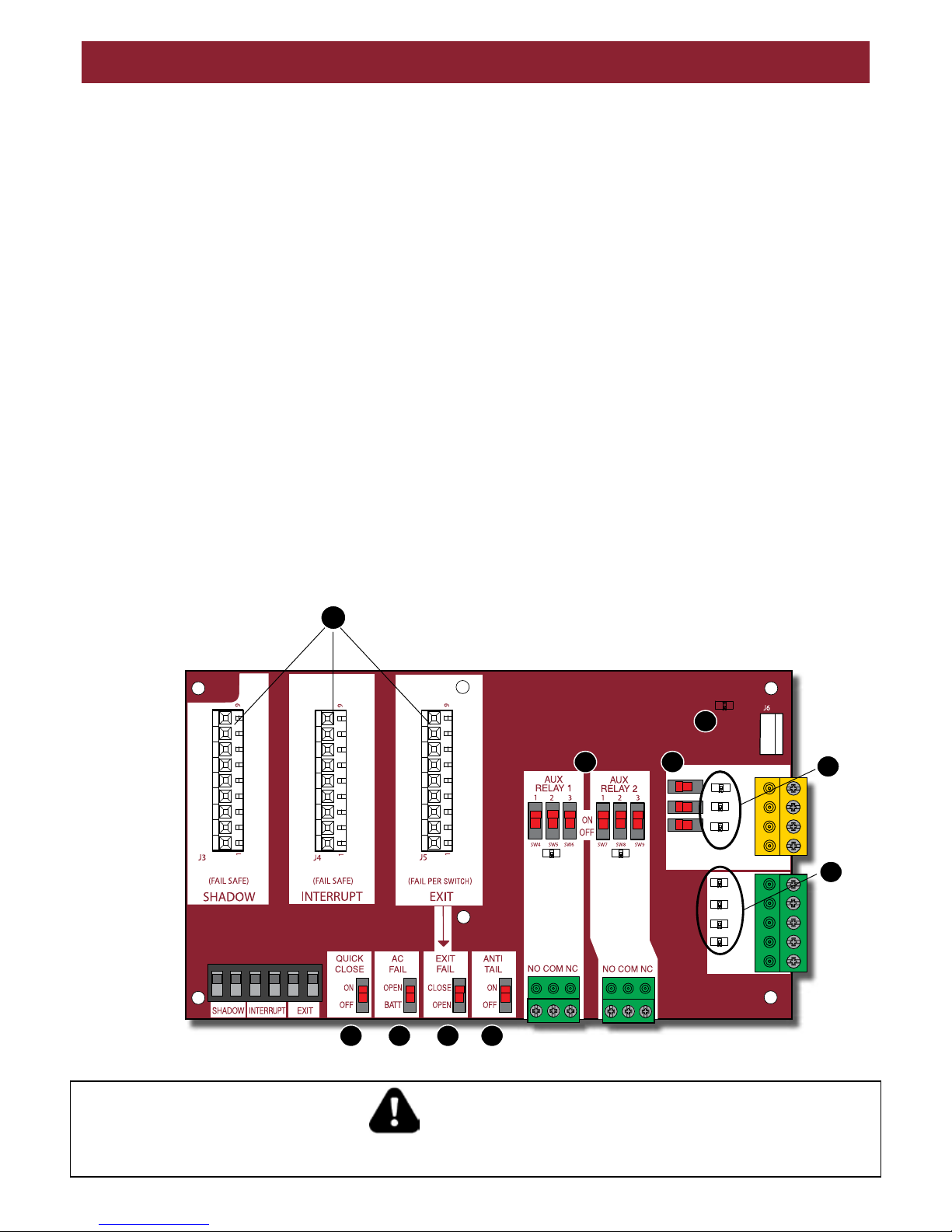

EXPANSION BOARD OVERVIEW

SBC

OPN

CLS

STP

COM

EYE

ONLY

EYE/

EDGE

EYE/

EDGE

COM

1

2

3

OPEN

CLOSE

TO MAIN

BOARD

POWER

10

1 2 3 4

5 6

7

9

8

1 QUICK CLOSE Switch:

OFF: No change to the door's normal operation.

ON: When CLOSE EYES/Interrupt loop is deactivated it causes

an opening or a stopped door to close (ignores the Timer-to Close).

2 AC FAIL Switch:

OPEN: Loss of AC power will cause the door to open

approximately 15 seconds after AC power fail and remain OPEN

until AC power is restored (enabling the Timer-to-Close).

BATT: With loss of AC power, door will remain in present position

and operator is powered from batteries.

3 EXIT LOOP FAIL Switch:

OPEN: if the EXIT plug-in loop detector detects a fault, then

the door will open and remain open until fault is cleared.

CLOSE: The plug-in EXIT loop detector faults are ignored (EXIT

loop is faulted and inoperative

4 ANTI-TAIL Switch:

OFF: When CLOSE EYES/Interrupt loop is activated it causes a

closing door to stop and reverse.

ON: When CLOSE EYES/Interrupt loop is activated it causes a

closing door to pause. Once the vehicle is clear the door will

continue to close.

5 AUX RELAY Switches: Set the AUX RELAY switches as need-

ed to obtain the desired function as shown on pages 20-21.

6 EYE/EDGE Switches: Set the EYE/EDGE switches as needed

to obtain the desired OPEN or CLOSE functionality.

7 1, 2, and 3 LEDs: LEDs indicating the status of the EYE/EDGE

inputs. Also used to check the firmware version of the expansion

board:

1. Locate the 1, 2, and 3 LEDs on the expansion board.

2. Disconnect AC/DC power to the main control board for 15

seconds.

3. Connect power. The 1, 2, and 3 LEDs will flash in sequence

until the main control board firmware revision is displayed.

When the green POWER LED glows solid the LED 1 will flash

the version number, then stop, then the LED 2 will flash the

revision number (for example: For version 5.1 when the green

POWER LED is solid the LED 1 will flash 5 times, then stop,

then the LED 2 will flash once).

8 MAIN BOARD Input: Input Connection for the main board

connector.

9 Input LEDs: LEDs indicating the status of the SBC, OPN, CLS,

and STP inputs.

10 Loop Detector Inputs: Inputs for the Plug-In Loop Detectors

WARNING

To AVOID damaging the circuit board, relays or accessories, DO NOT connect more than 42 Vdc (32 Vac) to the

AUX relay contact terminal blocks.

INTRODUCTION

8

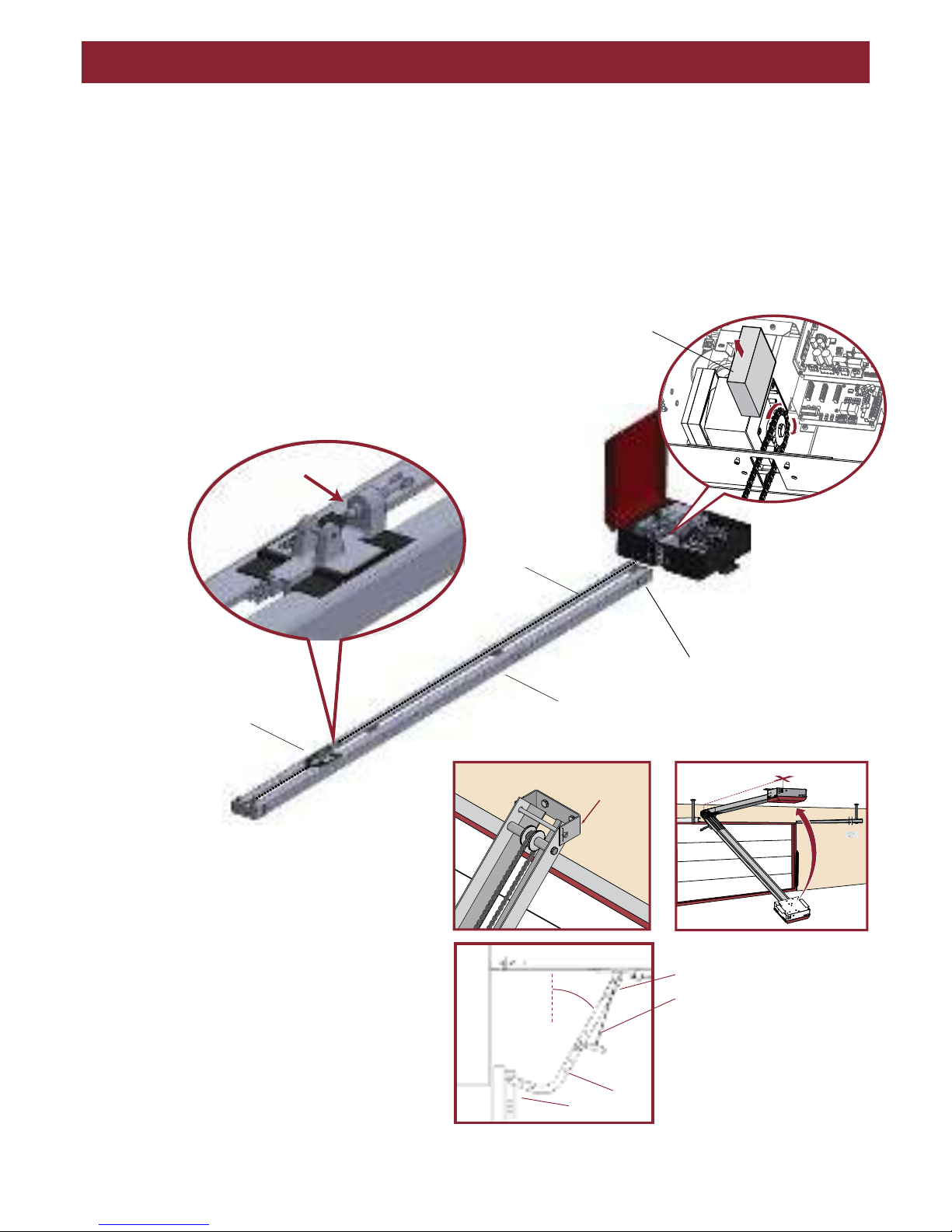

Chain Guard

Trolley

Rail

Chain

STEP 1

CONNECT RAIL TO OPERATOR

BEFORE INSTALLATION, ENSURE THE OPERATOR IS SUITABLE FOR THE TYPE AND SIZE OF THE DOOR. ENSURE THE

TEMPERATURE RANGE MARKED ON THE OPERATOR IS SUITABLE FOR THE LOCATION OF THE INSTALLATION.

ENSURE THAT THE DRIVEN PART IS IN GOOD MECHANICAL CONDITION, CORRECTLY BALANCED

AND OPENS AND CLOSES PROPERLY.

INSTALLATION

1

2/7

4

6

3

5

STEP 2

MOUNT THE OPERATOR

1. With the door closed, mark the centre of the door on the

wall above the door

2. Open the door and mark the centre of the door on the

ceiling. Ensure height of the rail has the correct clearance

with the door in the open position (see diagram right)

3. Close the door, mount the header bracket and rail

assembly to the wall. Make sure the header bracket is in

the centre of the door opening

4. Lift the operator and align with the centre mark on the

ceiling. Temporarily support the operator

5. Attach operator to ceiling using lateral mounting brackets.

Ensure at least 1 fixing on either side of the operator

6. Attach the door bracket to the door

7. Attach the push arm to the trolley, test emergency release

rope is operational. Attach the J-bar to the push arm

8. Attached J-bar to door bracket after following STEP 3 on

the next page

Header Bracket

J-bar

20°

Door Bracket

Push Arm

NOTE: U-shape bracket

with square holes

indicates the end of the

rail that connects to

the operator.

Emergency Release Rope

NOTE: Trolley can not be

moved independantly of chain.

For attaching the J-bar to the

door bracket, trolley needs to

be positioned by using the

operator. Follos STEP 3 on the

next page.

NOTE: Lateral mounting plates are provided with multiple holes.

Alternate holes to the installation can be used to temporarily suspend

the operator (with ropes, hooks etc not provided) during mounting.

1. Position the operator and rail as shown below

2. Open the cover and remove the chain guard

3. Secure the rail to the operator with the square-neck bolts and Nylock nuts provided.

NOTE - Do not use washers with these nuts

4. Cut the cable ties securing the chain

(The trolley should be approximately 1m from the end of the rail)

5. Remove tensioner nut (shown as (6) below) and wrap the chain around the

output sprocket

6. Reconnect the tensioner nut and tighten until chain hangs approx 10mm

below horizontal

7. Replace chain guard

9

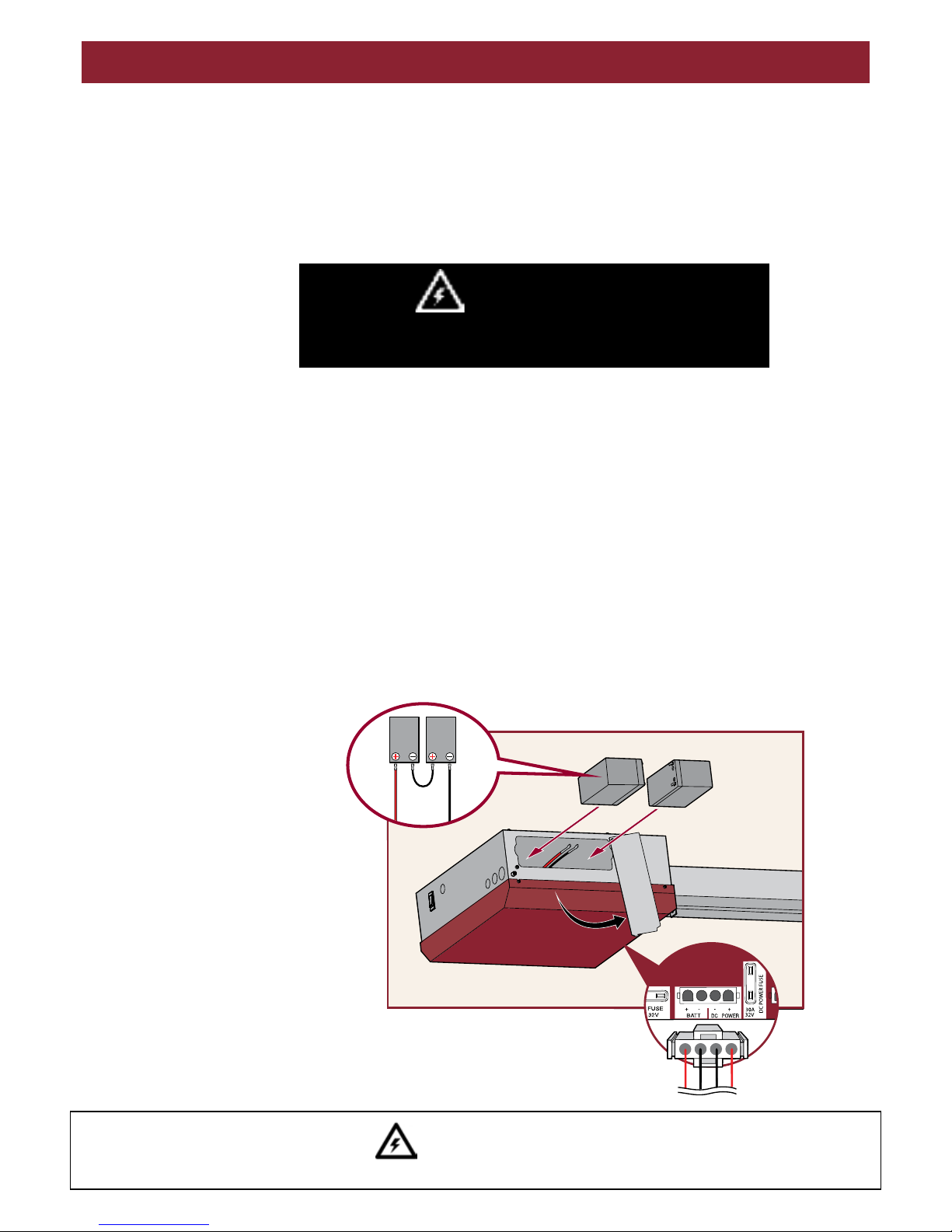

STEP 3

ELECTRICAL CONNECTION AND DOOR ATTACHMENT

STEP 4

CONNECT BATTERIES

DISCONNECTING BATTERIES

Connect the operator to the mains power supply using the pre-connected mains plug to a 10A general power outlet

NOTE: After electrical connection, J-bar can be attached to door bracket by activating the operator. Press the "MOVE

GATE" buttons to position the trolley / J-bar assembly so it can be attached to the door bracket. Push arm should be

approx 20° from vertical

The batteries are charged in the circuit by the integrated transformer. The batteries are for battery backup

1. SEE WARNING! Unplug the J15 plug labelled BATT on the control board by squeezing the plug and pulling it from the control

board. This disconnects the ac/dc power to the control board

2. Loosen the screws on the battery cover and rotate out of the way

3. Connect the red wire to the positive (+) terminal on one battery and connect the black wire to the negative (-) terminal

on the other battery

4. Connect the black jumper (included with the batteries) between the positive (+) terminal of one battery to the

negative (-) terminal of the other battery

5. Insert the batteries as shown

6. Reattach the battery cover

7. Insert the J15 plug back into the control board. This will power up the control board. NOTE: You may see a

small spark when plugging the J15 plug into the board

8. Turn ON AC power at the wall switch

9. Turn ON the AC power switch on the rear of the operator

1. Turn OFF the AC power switch on the rear of

the operator

2. Turn OFF the power at the wall switch

3. SEE WARNING Remove the J15 plug from the

control board

4. Loosen the screws on the battery cover and

rotate out of the way

5. Carefully remove batteries and disconnect all

wires from the battery terminals

6. Dispose of used batteries responsibly

7. Follow instructions above to connect new

batteries

OPERATOR WILL NOT FUNCTION WITHOUT

GRIFCO BATTERIES CONNECTED

INSTALLATION

Black jumper

provided with

batteries

Black Wire (-)

Red Wire (+)

J15 Plug

1/7

9

2/6

3

4

5

WARNING

Batteries are supplied charged. When batteries are connected the operator is fully functional without AC power connected.

NOTE: Batteries are supplied fully charged.

They are automatically charged when

operator is connected to mains power.

WARNING

FAILURE TO DISCONNECT J15 PLUG LABELLED BATT WILL RESULT

IN POTENTIAL SHOCK HAZARD (FOLLOW STEP 4, POINT 1)

10

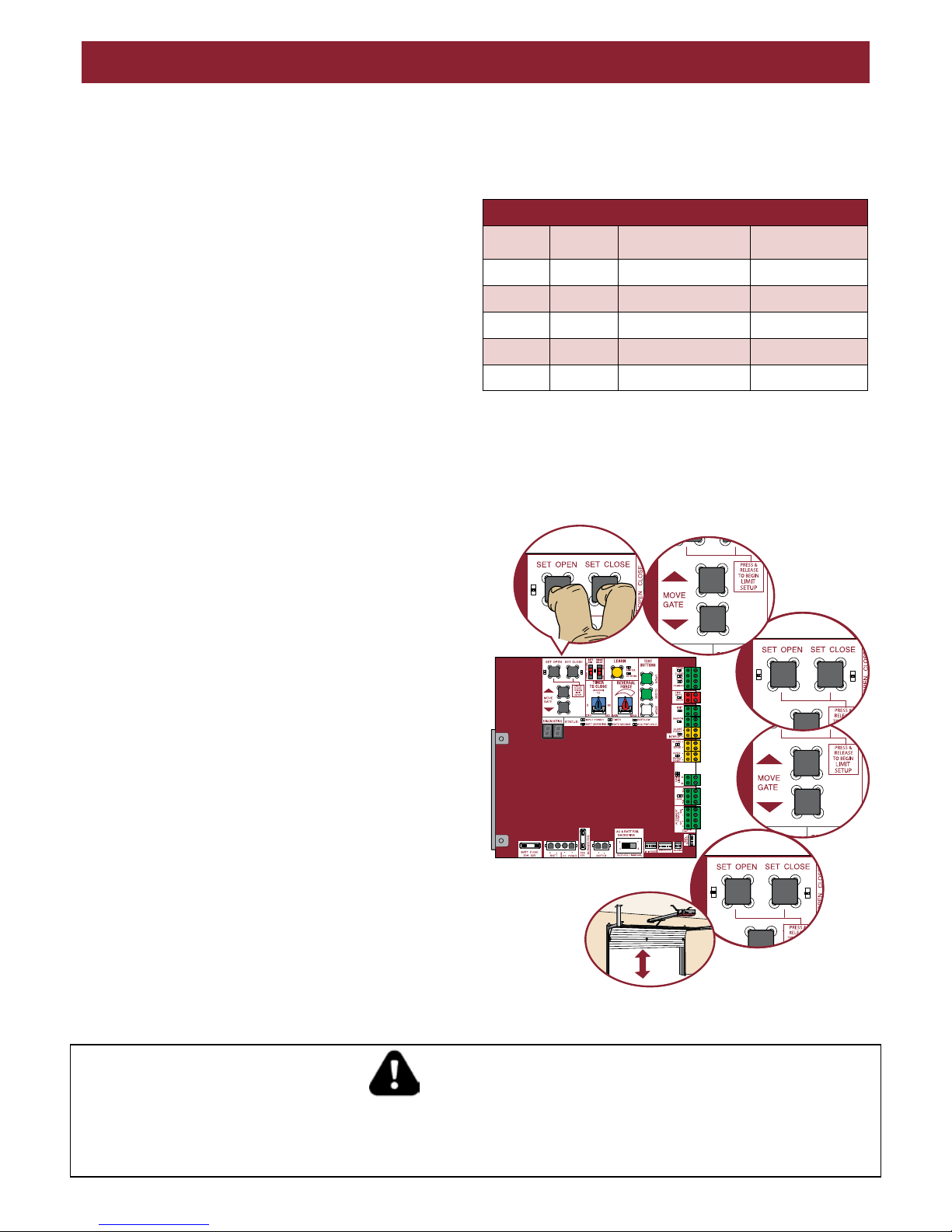

The door MUST be attached to the operator before setting the limits

and force.

1. Press and release the SET OPEN and SET CLOSE buttons

simultaneously to enter limit setting mode

2. Press and hold one of the MOVE GATE buttons to move the

door to the open or close limit

3. Press and release the SET CLOSE or SET OPEN button

depending on which limit is being set

4. Press and hold one of the MOVE GATE button to move the door

to the other limit

5. Press and release the SET CLOSE or SET OPEN button

depending on which limit is being set

6. Cycle the door open and close by pressing the green "TEST

BUTTONS" (Open and Close). This automatically sets the force

When limits are set properly the operator will automatically exit limit

setting mode.

INTRODUCTION

Your operator is designed with electronic controls to make travel

limit and force adjustments easy. The adjustments allow you to

program where the door will stop in the open and close position.

The electronic controls sense the amount of force required to open

and close the door.

The force is adjusted automatically when you program the limits but

can be fine tuned using the REVERSAL FORCE dial on the control

board (refer to Fine Tune the Force section) to compensate for

environmental changes.

The limit setup LEDs (located next to the SET OPEN and SET

CLOSE buttons) indicate the status of the limits, refer to

the table below.

LIMIT SETTING

LIMIT SETUP LEDS

SET OPEN

LED

SET CLOSE

LED

OPERATOR MODE EXPLANATION

OFF OFF NORMAL MODE Limits are set

BLINKING BLINKING LIMIT SETTING MODE Limits are not set

BLINKING ON LIMIT SETTING MODE Open limit is not set

ON BLINKING LIMIT SETTING MODE Close limit is not set

ON ON LIMIT SETTING MODE Limits are set

1

2

3

4

5

WARNING

• NEVER increase force beyond minimum amount required to

move door.

• NEVER use force adjustments to compensate for a binding or

sticking door.

• If one control (force or travel limits) is adjusted, the other control

may also need adjustment.

The limits can be set using the control board (below) or a remote transmitter (refer to Limit Setup with a Remote Transmitter in the

Programming section). Setting the limits with a remote transmitter requires a 3-button transmitter programmed to OPEN, CLOSE, and STOP.

NOTE: The Test Buttons on the control board will not work until the limits have been set.

COMMISSIONING

Loading...

Loading...