Grifco Gld-sdo User Manual

OPERATOR

SUPPLIED WITH GRIFCO

MONITORED ENTRAPMENT

PROTECTION

OPERATOR

SUPPLIED WITH GRIFCO

MONITORED ENTRAPMENT

PROTECTION

INSTRUCTION MANUAL

LS-Drive

GLD-SDO

LS-Drive Operator

GLD-R2.4M

Rail for (max) 2.4m High Door

GLD-R3.0M

Rail for (max) 3.0m High Door

Model GLD-SDO

Commercial Sectional Door Operator

• THIS OPERATOR IS TO BE INSTALLED AND SERVICED BY A TRAINED TECHNICIAN ONLY

• This operator is compatible with Security+ 2.0® accessories

Chamberlain Australia Pty Ltd

Unit 1, 75 Epping Rd North Ryde NSW 2113

Ph: 1800 GRIFCO

www.grifco.com.au

Ref: 114A4934B

SAFETY SYMBOL AND SIGNAL WORD REVIEW

This commercial sectional door operator has been designed and tested to offer safe service provided it is installed, operated, maintained

and tested in strict accordance with the instructions and warnings contained in this manual.

WARNING

When you see these Safety Symbols and Signal Words on the

following pages, they will alert you to the possibility of serious

Mechanical

WARNING

injury or death if you do not comply with the warnings that

accompany them. The hazard may come from something

mechanical or from electric shock.

Electrical

When you see this Signal Word on the following pages, it will alert

CAUTION

you to the possibility of damage to your commercial door and/or

the commercial door operator if you do not comply with the

cautionary statements that accompany it.

THESE ARE IMPORTANT SAFETY INSTRUCTIONS. FOLLOW ALL INSTRUCTIONS AS INCORRECT

INSTALLATION CAN LEAD TO SEVERE INJURY OR DEATH

Keep commercial door balanced. Sticking or binding doors must be

repaired. Commercial doors, door springs, pulleys, brackets and their

hardware are under extreme tension and can cause serious personal

injury. Do not attempt to loosen, move or adjust them. Call for commercial

door service.

Do not wear rings, watches or loose clothing while installing or servicing a

commercial door operator.

To avoid serious personal injury from entanglement, remove all ropes

connected to the commercial door before installing the door operator.

Installation and wiring must be in compliance with your local building and

electrical codes. Connect the power supply cord only to properly earthed

mains.

Permanently fasten all supplied labels adjacent to the wall control as a

convenient reference and reminder of safe operating procedures.

Disengage all existing commercial door locks to avoid damage to

commercial door. Install the wall control (or any additional push buttons) in

a location where the commercial door is visible during operation . Do not

allow children to operate push button(s) or remote transmitter(s). Serious

personal injury from a closing commercial door may result from misuse of

the operator.

Activate operator only when the door is in full view, free of obstructions

and operator is properly adjusted. No one should enter or leave the

building while the door is in motion.

An electrician must disconnect electric power to the commercial door

operator before making repairs or removing covers.

Moisture and water can destroy the electronic components. Make sure

under all circumstances that water moisture or storage moisture cannot

penetrate the electronics. The same applies for openings and cable

entries.

After the installation a final test of the full function of the system and the

full function of the safety devices must be done.

When operating a biased-off switch, make sure that other persons are

kept away.

The operator cannot be used with a driven part incorporating a wicket

door (unless the operator cannot be operated with the wicket door open).

Motor may become hot during operation. Appropriate clearance and/or

shielding should be supplied by the installer to ensure any cabling, wiring

and/or other items cannot come in contact with the motor. If temperature

rise exceeds 50°C all fixed wiring insulation must be protected, for

example, by insulating sleeving having an appropriate temperature rating.

If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualified persons in order to avoid a hazard.

Do not allow children to play with operator wall controls or remote

controls. Keep remote controls away from children.

WARNING: Important safety instructions

It is important for the safety of persons to follow all instructions.

SAVE these instructions

The actuating member of a biased-off switch is to be located within direct

sight of the door but away from moving parts. Unless it is key operated, it

is to be installed at a minimum height of 1500mm and not accessible to

the public.

Make sure that people who install, maintain or operate the door follow

these instructions. Keep these instructions in a safe place so that you can

refer to them quickly when you need to.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

Use the commercial sectional door operator for its intended purpose. The

GLD-SDO operator is designed lifting spring-balanced sectional doors.

2

INTRODUCTION

CONTENTS

SAFETY SYMBOL AND SIGNAL WORD REVIEW .........................................................................................................2

INTRODUCTION ..............................................................................................................................................................3

OPERATOR SPECIFICATIONS ...............................................................................................................................................................4

OPERATOR OVERVIEW .........................................................................................................................................................................5

CONTROL PANEL OVERVIEW ...............................................................................................................................................................5

CARTON INVENTORY ............................................................................................................................................................................6

TOOLS REQUIRED ................................................................................................................................................................................6

HARDWARE PROVIDED ........................................................................................................................................................................6

INSTALLATION ................................................................................................................................................................7

CONNECT RAIL TO OPERATOR ...........................................................................................................................................................7

TIGHTENING THE CHAIN ......................................................................................................................................................................7

FASTENING RAIL TO OPERATOR .........................................................................................................................................................7

HEADER BRACKET POSITIONING ........................................................................................................................................................8

INSTALL HEADER BRACKET .................................................................................................................................................................8

POSITION THE OPERATOR ...................................................................................................................................................................9

MOUNT THE OPERATOR TO THE CEILING ..........................................................................................................................................9

FASTEN THE DOOR BRACKET .............................................................................................................................................................9

ATTACH DOOR ARM TO TROLLEY .....................................................................................................................................................10

TESTING AND OPERATING THE MANUAL RELEASE .........................................................................................................................10

COMMISSIONING .........................................................................................................................................................11

PROGRAMMING TRAVEL LIMITS AND FORCE SETTINGS .................................................................................................................11

INSTALL THE ENTRAPMENT PROTECTION SYSTEM .........................................................................................................................12

SETTING TIMER-TO-CLOSE (TTC) ......................................................................................................................................................13

TYPES OF SECURITY +2.0 TRANSMITTERS .......................................................................................................................................14

COMMISSIONING REMOTE TRANSMITTERS .....................................................................................................................................15

MAINTENANCE AND CARE ..........................................................................................................................................16

USING YOUR OPERATOR ...................................................................................................................................................................16

TROUBLESHOOTING ....................................................................................................................................................17

DIAGNOSTICS ...............................................................................................................................................................18

SERVICE AND REPAIR PARTS.....................................................................................................................................19

CHAMBERLAIN LIMITED WARRANTY .........................................................................................................................20

3

INTRODUCTION

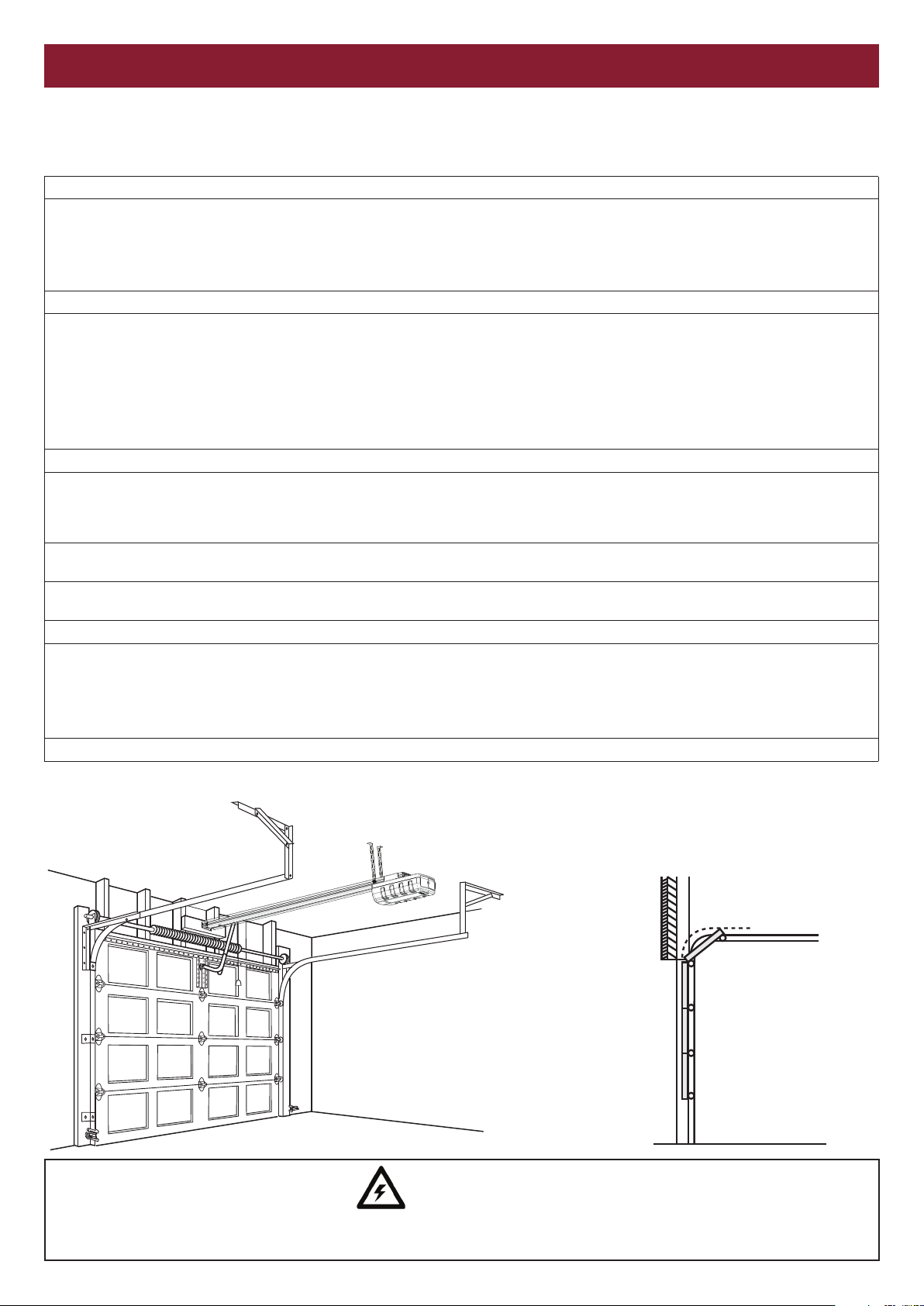

OPERATOR SPECIFICATIONS

Power Specifications

Main AC Power Supply 230-240 Vac 50Hz

Max. Pull Force 1,200N

Power 225W

Operating Temperature +5°C to +40°C

Door Specifications

Max Door Height 3.0m

Max Door Weight 160kg

Max Lift under Spring Tension 20kg

Normal Torque 8Nm

Maximum Door Area Commercial Spring-Balanced Sectonal Doors up to 15m²

Max. Door Cycles 50 cycles / day

Dimensions

Operator Length 370mm Rail Length GLD-R2.4M: 3,222mm / GLD-R3.0M: 3,822mm

Operator Height 100mm Rail Height 46.5mm

Operator Width 200mm Rail Width 88mm

Total installed dimensions GLD-R2.4M: 3,372mm (L) x 150mm (H) x 200mm (W)

GLD-R3.0M: 3,972mm (L) x 150mm (H) x 200mm (W)

Compliance AS/NZS 60335-1

AS/NZS 60335-2-103

Transmitter Specifications

Hand Transmitters 64 devices

Keypad Transmitters 2 devices

Operator Frequency 433.30 / 433.92 / 434.54 MHz

Transmitter Management Compatible with STAR1000EVO (accessory sold separately)

Usage Indoor Use Only

TYPICAL DOOR INSTALLATION

Door Types

Commercial spring-balanced sectional

door with curved track, up to 3.0m

high and up to 15m² in area.

WARNING

A 240V General Purpose Outlet (GPO) ie. Power Point must be available in close proximity to the operator.

This fitting is not part of the operator hardware and must be supplied by the consumer.

4

INTRODUCTION

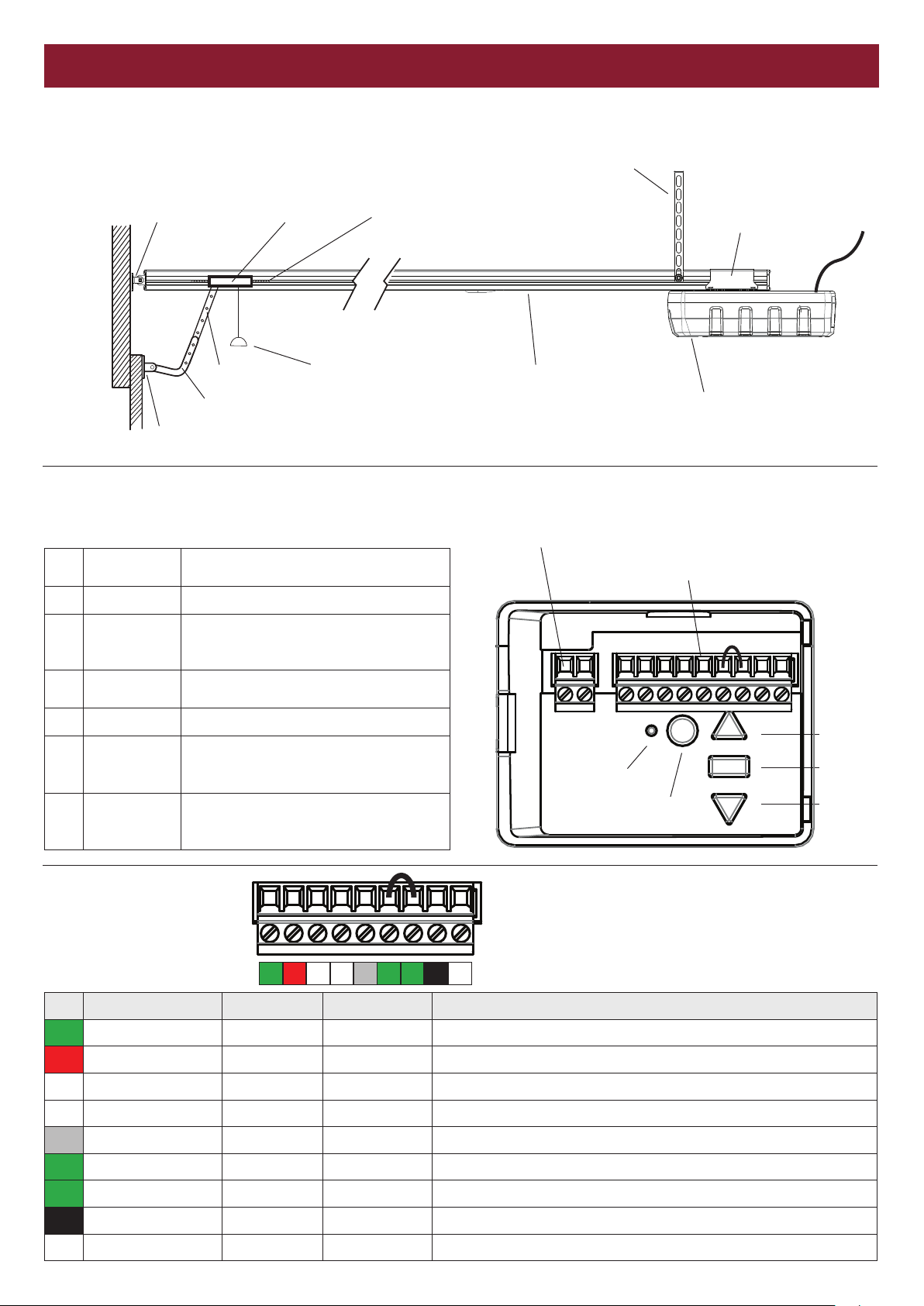

OPERATOR OVERVIEW

4

Header Bracket Trolley

Door arm Manual Release

J-Bar

Door Connection Bracket

CONTROL PANEL OVERVIEW

Control Panel is accessible under the cover on the rear of the operator.

1. Up Button

2. Prog Button Used to program door limits and other features

3. Down Button

4. Learn Button

5. Indicator LED Used to indicate various programming modes

External

6.

Accessory

Power

7. Terminal Blocks

Used for initial programming, driving the door

up and for displaying diagnostic codes - Digit 1

Used for initial programming, to drive the door

down and for displaying diagnostic codes Digit 2

Used for programming remote access devices

and manual learning of forces

30 Vdc 50mA available. Constant supply (no

low standby) unregulated.

Used to configure external accessories. See

chart below for the function of each terminal

block.

Chain

Hanging bracket

Rail

6. External Accessory Power (30V DC)

7. Terminal Blocks

5. Indicator LED

4. Learn Button

Operator Mounting

Bracket

Power

cord

Operator

1. Up

2. Stop

3. Down

Terminal Block Functions

0 1 2 2 3 4 5 6 7

No. Function Colour Polarity Comment

0 E-Serial port Green +ve Serial Communication Input

1 Trigger input Red +ve Dry Contact input for access control accessories

2 Ground White -ve Common terminal for access control accessories

2 Ground White -ve Common terminal for Safety Beams

3 Safety Beam Grey +ve Safety Beam Input: (compatible with supplied safety beams only)

4 Emergency Stop Green +ve Dry Contact input for Emergency Stop N/C

5 Emergency Stop Green -ve Common terminal for Emergency Stop

6 24Vdc power supply Black +ve Accessory power output: (24 Vdc 150 mA) while door is in motion (regulated)

7 24Vdc power supply White -ve Accessory power output: (24 Vdc 150 mA) while door is in motion (regulated)

5

INSTALLATION

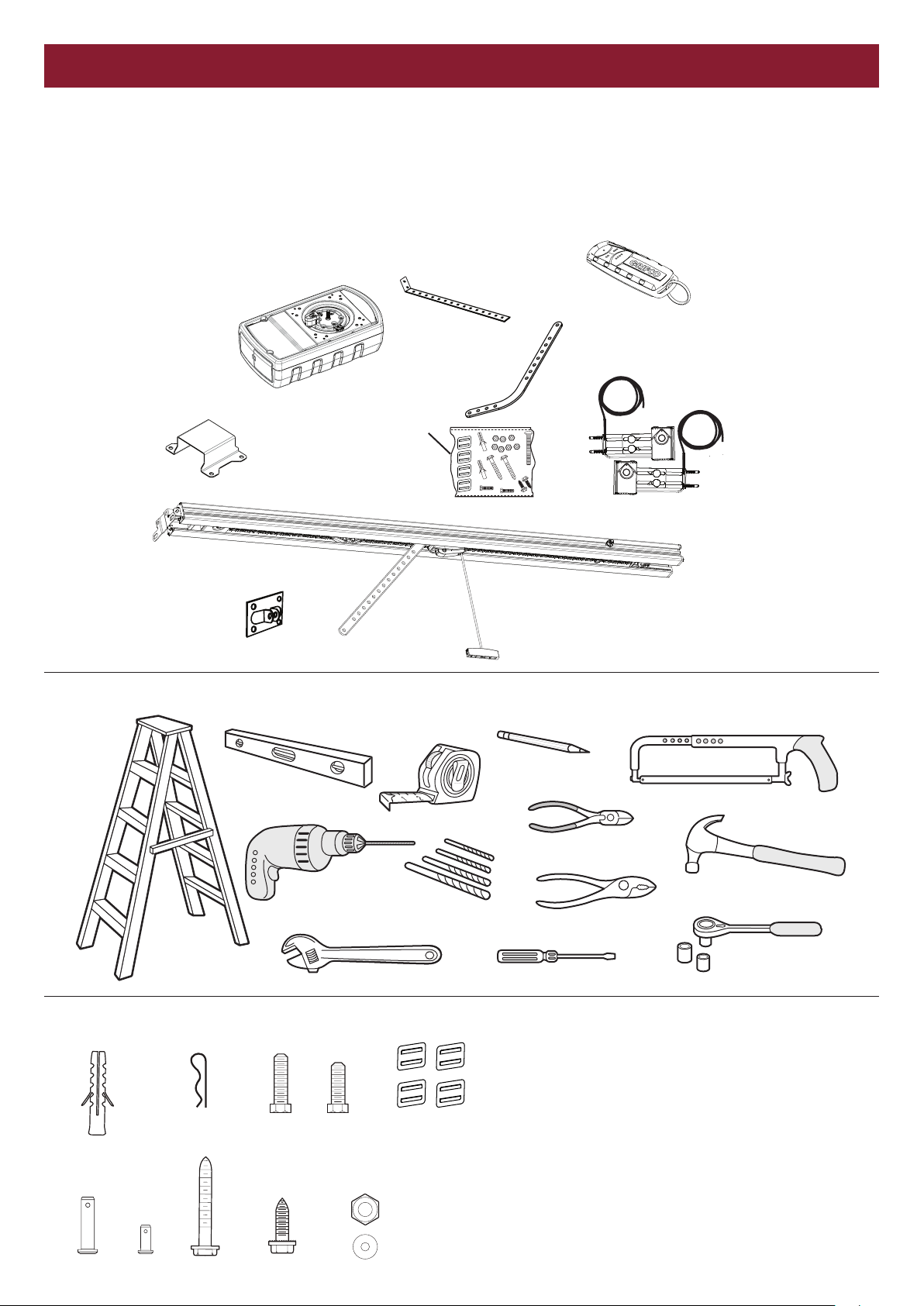

CARTON INVENTORY

NOTE

The commercial sectional door operator is supplied in two separate cartons.

GLD-SDO contains the operator, fitting hardware and accessories.

GLD-R2.4M or GLD-R3.0M contain the complete, assembled rail and some hardware.

Hanging Brackets

Grifco 4-Channel

Transmitter

Operator

Operator Mounting

Bracket

Header Bracket

Door Connection

Bracket

TOOLS REQUIRED

Cable

Clips x 4

Mounting

Hardware

Door arm

J-Bar

Safety Beams

Rail

Manual Release

HARDWARE PROVIDED

(1) 4x

(5) 1x (6) 2x (7) 4x (8) 8x

(1) Wall plug

(2) R clip

(3) Hexagonal head screw M8x25

(4) Hexagonal head screw M8x20

(5) Clevis pin 8mm

(4) 2x (11) 4x(3) 2x(2) 3x

(9) 4x

(10) 4x

6

(6) Clevis pin 6mm

(7) Screw ST6 x 50 mm

(8) Screw ST6,3 x 18 mm

(9) Nut M8

(10) Flat washer M8

(11) Cable Clips

Loading...

Loading...