Page 1

INSTALLATION, OPERATION and

MAINTENANCE MANUAL

MODEL ZF1, ZF2 and ZF3 rated 15, 25, 40 & 70 AMP

SINGLE and THREE PHAS E - 2 or 3 LEG CONTROL

SOLI DSTATE RELAY (SSR) POWE R CO NTROLS

UL/cUL FILE NUMBER – E151547

CSA FILE NUMBER – LR91210

CE – See last page of manual for CE Declaration of Conformity.

AMETEK HDR POWER S YS TEMS

3563 INTERCHANGE ROAD

COLUMBUS, OHIO 43204

TEL: 614-308-5500

TOLL FREE: 1-888-PWR-CNTL (797-2685)

FAX: 614-308-5506

Page 2

SCR Power Controls/Systems & Power Supplies

Dear Client:

On behalf of all of AMETEK HDR's employees, I want to take this opportunity to "thank you" for

purchasing an AMETEK HDR Power Systems' SCR Power Control.

We b el i ev e A METEK H DR rep resen ts the b es t overal l sol uti on to y our SCR Power C ontrol n ee ds i n

t he in du st ry toda y. We do this by pro viding a quality manufactured reliab le un it wit h fast, on- time

delivery and a competitive price.

All of our employees are dedicated to your success. If you have any questions, comments or

concerns, please call me toll free at 1-888-PWR-CNTL (797-2685).

Sincerely,

AMETEK HDR POWER SYSTEMS

George A. Sites

Vice President

GAS/be

3563 Interchange Road Columbus, OH 43204-1400 USA Telephone: 614-308-5500 1-888-PWR-C NTL FAX: 614-308-5506

Page 3

REVISION PAGE

Page Change Revision Date

28 1 Added EMC statement to EC Declaration 11-00

NOTE: ALL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

COPYRIGHT 2003 AMETEK HDR POWER SYSTEMS

Page 4

TABLE OF CONTENTS

Para.

Title Page

Section 1 - DESCRIPTION

1-1 Models Covered...................................................................................................1

1-2 General Description..............................................................................................1

1-3 Applications.........................................................................................................1

1-4 Specifications.......................................................................................................1

1-5 Options................................................................................................................2

1-6 Operation.............................................................................................................2

Section 2 - INSTALLATION

2-1 Mounting.............................................................................................................5

2-2 Line/Load Power Wiring......................................................................................5

2-3 Safety Issues........................................................................................................6

Section 3 - COMMAND SIGNAL CALIBRATION

3-1 Zero and Span Adjustments..................................................................................19

3-2 Command Indicator..............................................................................................19

3-3 Remote Manual Control.......................................................................................19

3-4 Process Command Signal.....................................................................................20

Section 4 - MAINTENANCE

4-1 Environmental Concerns ......................................................................................24

4-2 Line/Load Power Connections .............................................................................24

4-3 Troubleshooting Typical Symptoms.....................................................................24

Section 5 - SERVICE AND SPARE PARTS

5-1 Customer Service.................................................................................................26

5-2 Spare Parts...........................................................................................................26

5-3 Warranty..............................................................................................................26

i

Page 5

TABLES and ILLUSTRATIONS LIST

TABLES

Table

Title Page

1 Specifications............................................................................................................. 1

2 % Output Voltage at Various Input Command Levels................................................3

3 Fusing Requirements.................................................................................................. 6

4 Minimum/Maximum Currents .................................................................................... 7

ILLUSTRATIONS

Figure Title Page

1 Line/Load Power Wiring ZF1 Models........................................................................8

2 Line/Load Power Wiring ZF2 Models........................................................................8

3 Line/Load Power Wiring ZF3 Models........................................................................9

4 Outline & Mounting Dimensions – ZF1 15, 25 & 4 0A.............................................10

5 Outline & Mounting Dimensions – ZF1 70A............................................................11

6 Outline & Mounting Dimensions – ZF2 15, 25 & 40A .............................................12

7 Outline & Mounting Dimensions – ZF2 70A............................................................13

8 Outline & Mounting Dimensions – ZF3 15, 25 and 40A...........................................14

9 Outline & Mounting Dimensions – ZF3 70A............................................................15

10 24 VAC Transformer Dimensions & Schematic........................................................16

11 Single-Phase Fuse Block Dimensions.......................................................................17

12 Three-Phase Fuse Block Dimensions ........................................................................18

13 Remote Manual Control (-V) Models.......................................................................21

14 Process Command Signal (-V) Models.....................................................................22

15 Process Command Signal (-C) Models.....................................................................23

ii

Page 6

DRAWING LIST

Schematic, ZF1 15 Thru 40A (-C).................................................................................S2710000

Schematic, ZF1 15 Thru 40A (-V)................................................................................. S2710001

Schematic, ZF1 70A (-C).............................................................................................. S2710079

Schematic, ZF1 70A (-V)..............................................................................................S2710080

Schematic, ZF1-C Firing Circuit....................................................................................S2078000

Assembly, ZF1-C Firing Circuit....................................................................................M2078000

Schematic, ZF1-V Firing Circuit.................................................................................... S2079000

Assembly, ZF1-V Firing Circuit....................................................................................M2079000

Schematic, ZF2 15 thru 40A (-C)..................................................................................S2710017

Schematic, ZF2 15 thru 40A (-V)..................................................................................S2710018

Schematic, ZF2 70A (-C)..............................................................................................S2710081

Schematic, ZF2 70A (-V)..............................................................................................S2710082

Schematic, ZF2-C Firing Circuit....................................................................................S2081000

Assembly, ZF2-C Firing Circuit ....................................................................................M2081000

Schematic, ZF2-V Firing Circuit ................................................................................... S 2082000

Assembly, ZF2-V Firing Circuit ....................................................................................M2082000

Schematic, ZF3 15 thru 40A..........................................................................................S2710034

Schematic, ZF3 70A .....................................................................................................S2710083

Schematic, ZF3 Firing Circuit........................................................................................S2099148

Assembly, ZF3 Firing Circuit.........................................................................................M2099148

NOTE: If ful l si ze drawi ngs are required, contact HDR insi de sal es and r equ es t th e d es i re d d raw i n g(s )

by the drawing number listed above.

iii

Page 7

Section 1 - DESCRIPTION

1-1 MODELS COVERED

This manual covers the ZF1, ZF2 and ZF3 models rated 15, 25, 40 & 70 amperes and

their options.

1-2 GENERAL DESCRIPTION

The ZF1, 2 and 3 models are solid-state, single and three-phase, zero-fired (ZF)

So lid s t a t e R ela y p o w e r co n t r o ls wh ich will op e ra t e o n lin e vo lt a g es u p to 600 VAC.

They accept most all standard process comman d si gnal s and regul ate the outpu t v ol tage .

Zero and Span Multi -turn potentiometers are provi ded to ease calib ration. An i sol ated

base Solid-State-Relay (SSR) module is used for power switching in each controlled

phase. This module contains two SCRs connected back to back and a zero-cro ssing

detector. T he firing circuit is based on common integrat ed circuits that provides very

reliable operation. Terminals are provided to ease installation.

1-3 APPLICATIONS

A vari abl e tim e base f i rin g circui t is used to provide precise control of power to resi s ti v e

loads. These uni ts should n ever be used on i nducti ve l oads. However, they are v ers ati l e

enough to be used in pl ace of m echan ical contactors and mercury rel ays on dry e rs, kil n s ,

ovens, environmental chambers, extruders, molding equipment, and other types of

equipment which uses resistive heat.

1-4 SPECIFICATIONS

TABLE 1

CONTROL METHOD - Zero firing of back to back SCRs in each phase.

VOLTAGE RATING - Up to 600 VAC, 1 or 3 Ph., 50/60 Hz.

CURRENT RATING - 15, 25, 40 & 70 Arms.

COMMAND SIGNAL - 4-20 ma, 0-5 VDC/0-10 VDC, Manual Control.

ISOLATION - 2500 Vrms from line/load to command signal to ground.

ADJUSTMENTS – Zero and Span, Multi-turn.

AMBIENT TEMPERATURE – Operating, 0 to 50C; Storage, -10 to 70C.

AGENCY LISTING – 15, 25, 40A UL/cUL Listed, CSA Certified, CE Compliant.

70A UL/cUL, CE Compliant

1

Page 8

1-5 OPTIONS

Three opt ions are available: a Fuse Kit, a 24 VAC Contr ol Transformer for the -V

Models and heat sink thermostat(s).

The Fuse Kit (Option FK) consists of a Semi-Conductor Fuse and fuse block. It is the

user's respons ibilit y to mount this fus e kit.

The (-V) models require 24 VAC (3VA) control power. An appropriately sized

transformer (Option TX) is available with 120, 240, 400, 480 or 575 VAC primaries.

Over-temperature thermostats are mounted on each heat sink. Speci fy NO for n orm al l y

open or NC for no r mally closed.

1-6 OPERATION

The power is controlled by the switching action of two SCRs connected in a back to

back configuration in each controlled phase. The zero crossing detect or built into the

solid-state relay module sy nchronizes the gatin g of these SCRs with the line frequen cy

(either 50 or 60 HZ). The firing circuit provides timing pulses to the SSR proportional

to the command signal. T hese pulsed determine the output level. The output may be

adjusted by a voltage or current signal from a process controller. Zero and Span

controls all ow the user to calib rate the power controll er’s output to the process signal.

Termin al s are also avail ab l e for connection of a remote manual potentiometer on the (V) mo del.

The power controller regulates the output voltage by proportionally controlling the

number of AC cy cles “on” v ersus the n umber “off”. Because the voltage is “turned

on” at zero cr ossing, very little radio frequency interference (RFI) is generated and

WARNING

Hazardous vol tages exist at the power c ontr o ll e r

heat sinks and at the load at all times when the

input voltage is connec ted. This condi ti on ex i st s

even when the controller is set to deliver zero

output.

NOTE: On the (-V) models , the z ero c ontrol

can be used as a m anual c ontr ol, or a r em ote

manual control can be connected.

2

Page 9

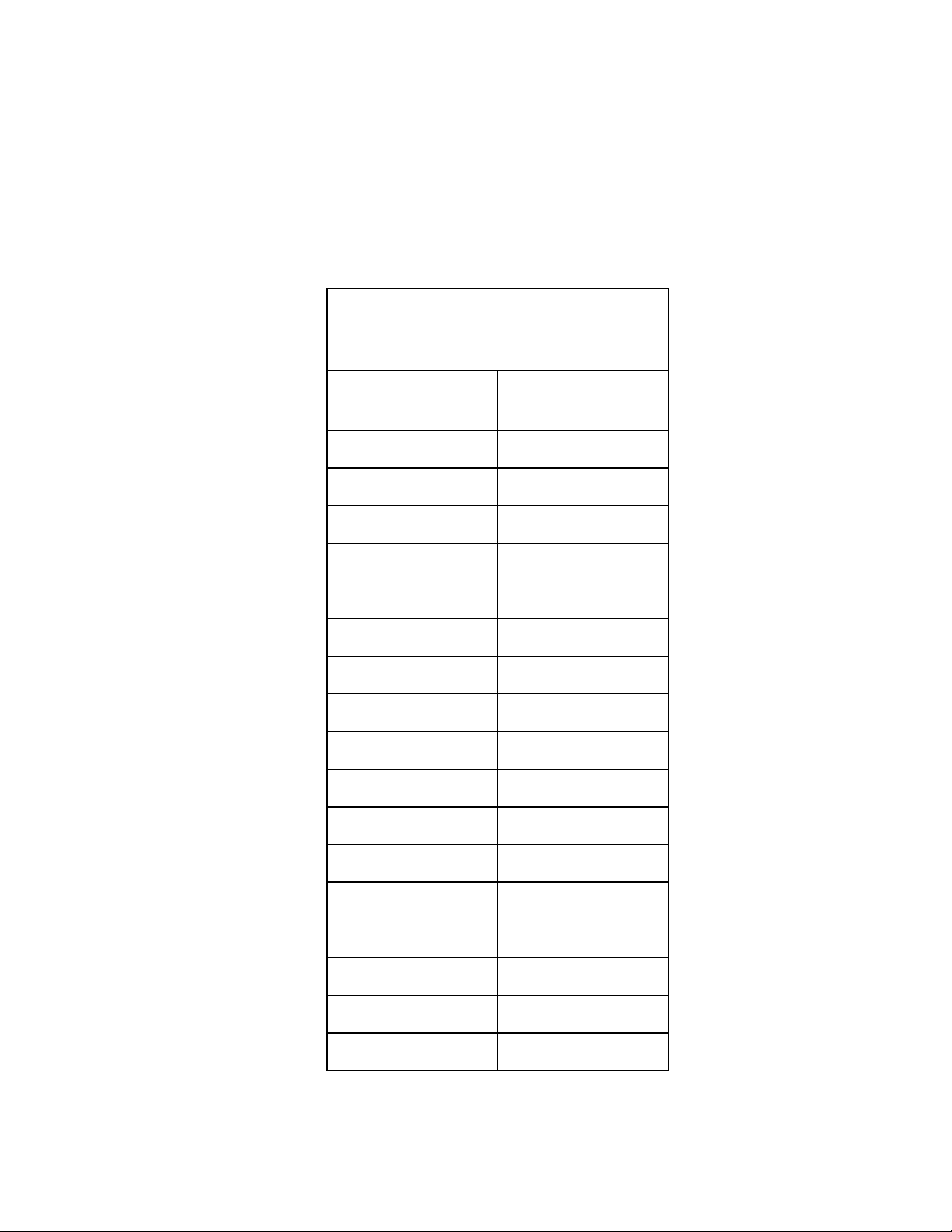

the power factor (PF) is n ear un ity. Keep in m ind that ZF units can only be used on

resistive loads. If an inductive load or a load with a large resistance change

(instantaneously or cold to hot) is being used, a phase fired (PF) power control

should be used.

TABLE 2

% OUTPUT VOLTAGE AT VARIOUS

INPUT COMMAND LEVELS

Ma

Input

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

%

Output Voltage

0

10

30

41

53

59

64

68

71

76

80

85

88

91

95

98

100

3

Page 10

Table 2 shows the percent output voltage at various i nput comm and si gnal l evel s. The

var iable time b ase firing c ircu it p icks the minimum len gth t ime base to maint ain as

constant a power level to the heating elements as possible. By doing this, thermal

shock and mech an i cal abus e to the heating elements i s reduced and the l i f e ex pectancy

of the element should increase.

NOTE: The percent o utput voltage for any given command signal

Is affected by the exact setting of the zero and span potentiometers.

Table 2 is to be used only as a reference.

4

Page 11

Section 2 - INSTALLATION

2-1 MOUNTING

Prior t o mounting, verify the voltage and current r ating of the power contr oller. The

inf ormation i s provided on the n amepl ate located on the left si de of the uni t. Determine th e

mounting dimensions from the outline drawing Figures 3, 4, 5, 6, 7 or 8. Mount the unit

with line/load terminals to the to p so that airflow is upward through the heat sink fins.

Ensure that airflow is unrestricted.

Mount the fuse kit and the 24 VAC control transformer as close as possible to the power

co ntr olle r. Refe r t o F igur e 10 for the c ont ro l tr ans forme r’s mou nting dimens ions and

schematic. Use Figures 11 and 12 for single and three-phase fuse block dimensions.

2-2 LINE/LOAD POWER WIRING

Connect the lin e/load usi ng appropriately si zed and i nsul ated wire/cabl e per any nati on al or

local codes based on the vo ltage and current rating of the power controller. Torque t he

line/load power connections to 25 in-lbs. minimum. Refer to Figures 1, 2 or 3 for all power

connections.

Branch circuit overcurrent protection is required to be

provided in accordance with the national and/or local

code of the inspecting authority or equivalent. If it is

desire d to protect the SC Rs, fast c lear ing sem iconductor

fuses must be added to t he system. Table 3 shows t he

fuse voltage, fuse current, fuse maximum I2T rating and

conditional shor t cir cuit cur rent (C SCA) rating for each

of t he p ower c ont rol’s ratings.

NOTE: a minimum rat ing of 75 °C wire is requ ired by

UL for all power connections to the power control.

WARNING

5

Page 12

TABLE 3

UNIT

CURRENT (A)

15A

25A

40A

70A

NOTE: The Conditional Short Circuit Current (CSCA) rating is the maximum current

the fuse can safely clear and this rating m ust be hi gher than the current the branch ci rcui t

can supply.

2-3 SAFETY ISSUES

The rated operational voltage of each power controller is shown on it’s nam eplate, i.e.

120V, 240V, 400V, 480V, or 575V. The power controller is designed to operate

between +10% and –15% of this rated operational vol tage in an Over Voltage Category

III environment.

Th e voltage drop across the swit ching semiconduct or wh ile in the conducting mode is

approxim ately 1.5 volts and is somewhat a f uncti on of current. To calculate the power

control’s power loss, multiply the load current times 1.5 time the number of controlled

phases.

FUSE

VOLTAGE

700

700

700

700

Power control units are not suitable to

provide isolation due to the use of

semiconductor s and other compon en ts th at

allow a small current to flow from line to

load even when the unit is in the nonconducting mode.

FUSE

CURRENT

20

30

50

80

WARNING

FUSE

I2T

157

427

950

4085

CSCA

200,000

200,000

200,000

200,000

6

Page 13

Th e minimu m o pe ra t ion al c ur re nt an d t he maximu m o ff st a te cu rr e nt for eac h un it is

shown in Table 4.

The power cont rols described in this instruction manual are designed to operate in a

pollution degree 2 environment.

TABLE 4

UNIT

CURRENT

(A)

15A

25A

40A

70A

MINIMUM

OPERATING

CURRENT

(ma)

100

100

100

100

MAXIMUM

OFF

CURRENT

(ma)

15

15

15

15

HAZARDS EXIST

DANGEROUS VOLTAGES EXIST

7

Page 14

Figure 1 – LINE/LOAD POWER WIRING ZF1 MODELS

Figure 2 – LINE/LOAD POWER WIRING ZF2 MODELS

8

Page 15

Figure 3 – LINE/LOAD POWER WIRING ZF3 MODELS

Figure 4 - OUTLINE and MOUNTING DIMENSIONS ZF1 - 15, 25 & 40A

9

Page 16

Figure 5 – OUTLINE and MOUNTING DIMENSIONS ZF1 – 70A

10

Page 17

Figure 6 – OUTLINE and MOUNTING DIMENSIONS ZF2 – 15, 25 & 40A

11

Page 18

Figure 7 – OUTLINE and MOUNTING DIMENSIONS ZF2 – 70A

12

Page 19

Figure 8 – OUTLINE and MOUNTING DIMENSIONS ZF3 – 15, 25 & 40A

13

Page 20

Figure 9 – OUTLINE and MOUNTING DIMENSIONS ZF3 – 70A

14

Page 21

15

Page 22

Figure 10 – 24 Vac Transformer

16

Page 23

Figure 11 – SINGLE-PHASE FUSE BLOCK DIMENSIONS

15/25 AMP

40/70 AMP

17

Page 24

Figure 12 – THREE-PHASE FUSE BLOCK DIMENSIONS

15/25 AMP

40/70 AMP

18

Page 25

3-1 ZERO AND SPAN ADJUSTMENTS

On (-V) models (voltage input) the Zero potentiometer has both positi ve and negati v e

voltages available making it usable as a manual or zero cont rol. By turning the Zero

control clockwise the unit's output voltage will increase proportionally to the

adjus tment. Tu rnin g it count er-c loc kwise will decrease the out put, or zero t he output

for a non-zero based command signal. Zero is mid rotation.

On (-C) models (4-20ma current input only) the Zero potentiometer has only the

negative vol tage available and, therefore, can only be used for zeroing the output for a

4-20ma comm and si gnal . Because the power controll er pul ls i t’s operating power from

the 4-20ma source, no other device can be series or parallel connected.

Th e S pa n p ot e nt io met er o n bo t h ( - V) & ( -C ) mo d els is u se d t o a dju st t he ma ximum

o ut put lev el. It will ad jus t fo r e ith er a re mot e ma nua l co nt ro l or a c omma nd sig nal

input. Clockwi s e adjustment i ncreases the output while counter-clockwise adj us tm ent

decreases the output. Due to some i nteraction between controls, i t may be neces sary to

repeat bot h t he zero and span adjustments.

3-2 COMMAND INDICATOR

The Command Indicator is a green Light Emitting Diode (LED) located between the

Zero and Span controls. The flash rate of this LED will vary in synchronization with the

o ut p u t o f t h e u n it . T he ra t e w ill be faste r wit h hig he r o utp u t s a nd slo w er w it h lo we r

outputs.

3-3 REMOTE MANUAL CONTROL (-V MODELS O NLY)

NOTE: A remote manual control cannot be used on a (-C) model.

Star t with th e Z e ro C on tr ol se t app r ox ima tely a t mid r ota tion a n d th e S pa n Control s e t

minimum (counter-clockwise). Connect a 5K ohm remote manual control as shown in

Figure 13. With the unit energized and the remote manual control fully counterclockwise, adjust the Zero Control until the unit is just off. Next turn the remote manual

contro l fully clockwise and adjust the Span Contro l until the desired output voltage is

reached. T his procedure may have to be repeated since some interaction between the

Zero and Span Controls ex ist. The exact setting of the zero and span controls can a f f ect

the linearity, so be as precise as possible.

Section 3 - COMMAND SIGNAL CALIBRATION

19

Page 26

3-4 PROCESS COMMAND SIGNAL

This procedure is similar to the Remote Manual Control procedure. Start with the Zero

Control set approximately at mid rotation and the Span Control set at minimum.

Conne ct the Com m and Sig nal wi th the (-) on term i na l 1 and th e (+) on term i n al 2. Ref e r

to Figure 14 for (-V) Models, and to Figure 15 for (-C) Models. Then energi ze the un i t.

Wit h the C omma nd S ig n a l a t minimu m, a d ju s t the Z e r o C ontr ol so t h e u n it is just off

(zero o utput voltage); next, with the Command Signal at full output, adjust the Span

Control so the output voltage is at the desired output level. Repeating this procedure

may be necessary due to so me interaction between the Zero and Span Contro ls.

NOTE: The (-V) models will accept a 0-5

VDC/0-10 VDC, 4-20 ma or a manual

control input. The (-C) model will only

accept a 4-20 ma input and cannot be

series or paralleled with other units.

20

Page 27

Figure 13 - REMOTE MANUAL CONTROL (- V) MODELS

21

Page 28

Figure 14 - PROCESS COMMAND SIGNAL (-V) MODELS

22

Page 29

Figure 15 - PROCESS COMMAND SIGNAL (-C) MODELS

23

Page 30

4-1 ENVIRONMENTAL CONCERNS

Alway s v erif y that the power control is m ounted in a cl ean, dust free en v i ron m en t. C l ea n

the heat sink(s) and printed circui t board periodical l y s o no dust or dirt accumulates on

the unit. Dust or dirt on the heat si nk f in s can preven t proper airf l ow and he at d i ss i pa ti on

causin g overheating of the sem i conductors. Conductive dust or dirt can cause shorts or

arcing, which can cause damage to the unit.

DISCONNECT ALL SOURCES OF POWER TO TH E POW ER CO NT ROLLER

PRIOR TO CLEANING. THE UNIT IS NOT SUITABLE FOR HOSE DOWN

CLEANING. USE VACUUM, B RUSH OR LOW PRESS URE AIR.

4-2 LINE/LOAD POWER CONNECTIONS

Periodically turn the power off to the ZF1 and ch eck for corrosion and ti ghtness of the

power co nnections. If any corrosion is evident, clean the cables and connectors and

reconnect them. Tighten them to 25 in-lbs.

4-3 TROUBLESHOOTING TYPICAL SYMPTOMS

Any o ne o f th e fo llo win g p ro ble ms c an be r ep air ed in t he fie ld. Any ot he r p ro ble ms

require returning the power controller to HDR for servicing.

1. Symptom - No output.

Cause - Open fuse or no 24 VAC control power on (-V) Models.

Solution - Disconnect the input po wer and check the fuse, replace the fuse if

faul ty. If the f use checks ok, verif y the 24 VAC control power on termi n al s 4 & 5

if the unit is a (-V) Mo del. If neither of these solve the problem, contact the

factory.

2. Symptom - Full o utput regard less of co mmand sig nal le vel.

Cause - Shorted SSR module or defective firing circuit.

Solution - Readjust the zero and span controls. If this does not help, di sconnect

the input power and remove the firing circuit. Re-energize, if the output is on

full, replace the SSR module. If the output is off, then most likely the firing

circuit is defective. Consult the factory.

Section 4 - MAINTENANCE

WARNING

24

Page 31

3. Symptom - T h e unit is not variable from 0 to full out put.

Cause - Defective firing circuit.

Solution - If neither of the first two symptom/solutions are the answer,

order a replacement firing circuit from the factory.

25

Page 32

5-1 CUSTOMER SERVICE

If you h ave operational p roble ms w hich can n ot be resolved using this manu al, please

contact the Se rvi ce Departm en t at AMETEK HDR . Our n orma l w ork hour s ar e 8 a. m .

to 3:30 p.m., U.S.A. EASTERN TIME ZONE, Monday through Friday.

TELEPHONE: 1-888-PWR-CNTL (797-2685) OR 614-308-5500.

Our answering machine at 614-308-5500 will an swer af ter hou r s a n d w e will

return your call the next working day.

FAX: 614-308-5506. 24 hours per day automatic answering.

EMERGENCY: Pager 1- 800-759- 8888, PI N # 1245473.

5-2 SPARE PARTS

Inside Sales should be contacted for any spare parts order whether routine or

emergency duri ng norm al workin g hours. Al l af ter hours requirem ents sh ou l d b e c al l e d

in on our 614-308-5500 answerin g m achi ne. Pl ease have as much in f orm a ti on av a i l ab l e

as possible pertaining to the model number, serial number, AMETEK HDR order

number and parts required. A purchase order number should be available.

5-3 WARRANTY

AMETEK HDR warrants that the equipment delivered will be fr ee fro m defe ct s in

workmanship and material for a period of five years from the date of shipment.

AMETEK HDR will re pa ir o r r ep lace, at AMETEK HDR's option, any part found

defective during proper and normal use, provided that written notice of the nature of

the defect is recei ved b y A METEK HD R w i th i n th e f iv e year wa rran ty pe ri od an d tha t

the cus tomer re turns th e part to AMETEK HDR f rei gh t pai d both w ay s. Th i s w a rra n ty

is not transf erable by t h e initial end us er.

AMETEK HDR MA KES N O OTHER WA RR ANTIES , EXPRE SS ED O R IM PL I ED

(INCLUDING, WITHOUT LIMITATION, MERCHANTABILITY, FITNESS FOR

PURPOSE, OR AGAINST INFRINGEMENT OF ANY PATENT) EXCEPT AS

EXPRESSLY PROVIDE D HE RE I N.

Section 5 - SERVICE AND SPARE PARTS

26

Page 33

THE REMEDY OF REPAIR OR REPLACEMENT IS CUSTOMER'S SOLE AND

EXCLUSIVE REMEDY AND WILL SATISFY ALL OF AMETEK HDR'S

LIABILITIES, WHETHER BASED ON CONTRACT, NEGLIGENCE, TORT,

PRODUCT LIABILITY, STRICT LIABILITY, OR OTHERWISE. IN NO EVENT

WILL HDR BE LIABLE FOR INCIDENT OR CONSEQUENT IAL DAMAGES,

NOR IN ANY EVENT SHALL HDR'S LIABILITY EXC EED THE UNIT PRICE OF

ANY DEFECTIVE PRODUCT OR P ART.

27

Page 34

WE: AMETEK HDR POWER SYSTEMS

3563 Interchange Road

Columbus, Ohio 43204 - USA

Declare under our sole responsibility that the products listed below and bearing the CE label:

Type: SCR power controllers with the following model designations and current ratings:

To which this declaration relates is in conformity with the technical requirements of the following

documents:

Title: Low-voltage switchgear No. IEC 947-5-1

and control gear Year: 1990-03

Low Voltage Directive No. IEC 73/23/EEC

Degrees of protection provided No. IEC 529-2nd Edition

by enclosures (IP Code): Year: 1989-11

Electromagnetic Compatibility No. IEC 89/336/EEC

(EMC) Year: 1989-05

(Environmental protection classification IP00 - for mounting ins ide an

enclosure)

Note

: Characteristics are according to manufactures specifications.

EC DECLARATION OF CONFORMITY

ZF1, ZF2, ZF3, PF1, PF3 - 15, 25, 40, 60, 70, 90,

120, 180, 225, 350, 500, 650, 800, 1000 and 1200A.

SHZF1, SHPF1 - 15, 30, 40, 60, 70, 90 and 120A

SHZF2, SHZF3, SHPF3 - 15, 25, 30, 60, 90, 120, 180 and 225A

SCZF1, SCPF1 - 15, 25, 40 and 65A

Year: 1973-02

Warning

All phase-fired (PF) controllers will require line filters

and possibly shielded cables to meet the EMC

requirements.

Name: George A. Sites

Declaration written in accordance with I.S.O. – IEC/22 Guide.

Title: Vice President

Date: November 9, 2000

28

Loading...

Loading...