Grieve Corporation VLT Installation Manual

VLT Micro Drive FC 51 Instruction Manual Contents

Contents

1. Safety

Safety Instructions 3

Approvals 3

General Warning 3

Avoid unintended Start. 4

Before Commencing Repair Work 4

2. Mechanical Installation

Before Starting 5

Mechanical Dimensions 6

3. Electrical Installation

How to Connect 7

Electrical Installation in General 7

EMC-correct Installation 8

Line Connection 9

Motor Connection 9

Control Terminals 11

3

5

7

Connecting to Control Terminals 11

Switches 12

Power Circuit - Overview 13

Load sharing/Brake 13

4. Programming

How to Program 15

Programming with MCT 10 15

Programming with LCP 11 or LCP 12 15

Status Menu 18

Quick Menu 18

Quick Menu Parameters 19

Main Menu 23

5. Parameter Overview

6. Troubleshooting

7. Specifications

15

25

29

31

Line Supply 31

Other Specifications 34

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

1

Contents VLT Micro Drive FC 51 Instruction Manual

Special Conditions 36

The Purpose of Derating 36

Derating for Ambient Temperature 36

Derating for Low Air Pressure 36

Derating for Running at Low Speeds 37

Options for VLT Micro Drive FC 51 38

Index

39

2

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

VLT Micro Drive FC 51 Instruction Manual 1. Safety

1. Safety

1.1.1. High Voltage Warning

The voltage of the adjustable frequency drive is dangerous whenever it is connected to AC line power. Incorrect installation of the

motor or adjustable frequency drive may cause damage to the equipment, serious injury or death. Consequently, it is essential to

comply with the instructions in this manual as well as local and national rules and safety regulations.

1.1.2. Safety Instructions

• Make sure the adjustable frequency drive is properly grounded.

• Do not remove line power connections, motor connections or other power connections while the adjustable frequency drive is connected to line

power.

• Protect users against supply voltage.

• Protect the motor against overloading in accordance with national and local regulations.

• The ground leakage current exceeds 3.5 mA.

• The [OFF] key is not a safety switch. It does not disconnect the adjustable frequency drive from line power.

1.1.3. Approvals

1

1.1.4. General Warning

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from line power.

Also make sure that other voltage inputs have been disconnected (linkage of DC intermediate circuit).

Be aware that there may be high voltage on the DC link even when the LEDs are turned off.

Before touching any potentially live parts of the VLT Micro Drive, wait at least 4 minutes for all sizes.

A shorter time is allowed only if indicated on the nameplate for the specific unit.

Leakage Current

The ground leakage current from the VLT Micro Drive FC 51 exceeds 3.5 mA. According to IEC 61800-5-1, a reinforced protective

ground connection must be ensured by means of a min. of 0.016 in² [10 mm²] Cu or an additional PE wire - with the same cable cross-

section as the line power wiring, which must be terminated separately.

Residual Current Device

This product can cause DC current in the protective conductor. If a residual current device (RCD) is used for extra protection, only an

RCD of Type B (time delayed) may be used on the supply side of this product. See also Danfoss Application Note on RCD, MN.90.GX.YY.

Protective grounding of the VLT Micro Drive and the use of RCDs must always follow national and local regulations.

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

3

1. Safety VLT Micro Drive FC 51 Instruction Manual

1

Motor overload protection is possible by setting par. 1-90,

market: ETR functions provide class 20 motor overload protection, in accordance with NEC.

Installation at high altitudes:

At altitudes higher than 6,600 feet [2 km], please contact Danfoss Drives regarding PELV.

Motor thermal protection

, to the value ETR trip. For the North American

1.1.5. IT Line

IT Line

Installation on isolated line power source, i.e., IT line power.

Max. supply voltage allowed when connected to line power: 440 V.

As an option, Danfoss offers line filters for improved harmonics performance.

1.1.6. Avoid unintended Start.

While the adjustable frequency drive is connected to line power, the motor can be started/stopped using digital commands, bus commands, references

or via the Local Control Panel.

• Disconnect the adjustable frequency drive from line power whenever personal safety considerations make it necessary to avoid unintended start

of any motors.

• To avoid an unintended start, always activate the [OFF] key before changing parameters.

1.1.7. Disposal Instructions

Equipment containing electrical components may not be disposed of together with domestic waste.

It must be separately collected with electrical and electronic waste according to local and currently valid leg-

islation.

1.1.8. Before Commencing Repair Work

1. Disconnect the FC 51 from line power (and external DC supply, if present.)

2. Wait for 4 minutes for the DC link to discharge.

3. Disconnect the DC bus terminals and brake terminals (if present)

4. Remove motor cable.

4

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

VLT Micro Drive FC 51 Instruction Manual 2. Mechanical Installation

2. Mechanical Installation

2.1. Before Starting

2.1.1. Checklist

When unpacking the adjustable frequency drive, make sure that the unit

is undamaged and complete. Make sure that the packaging contains the

following:

•VLT Micro Drive FC 51

•Quick Guide

Optional: LCP and/or de-coupling plate.

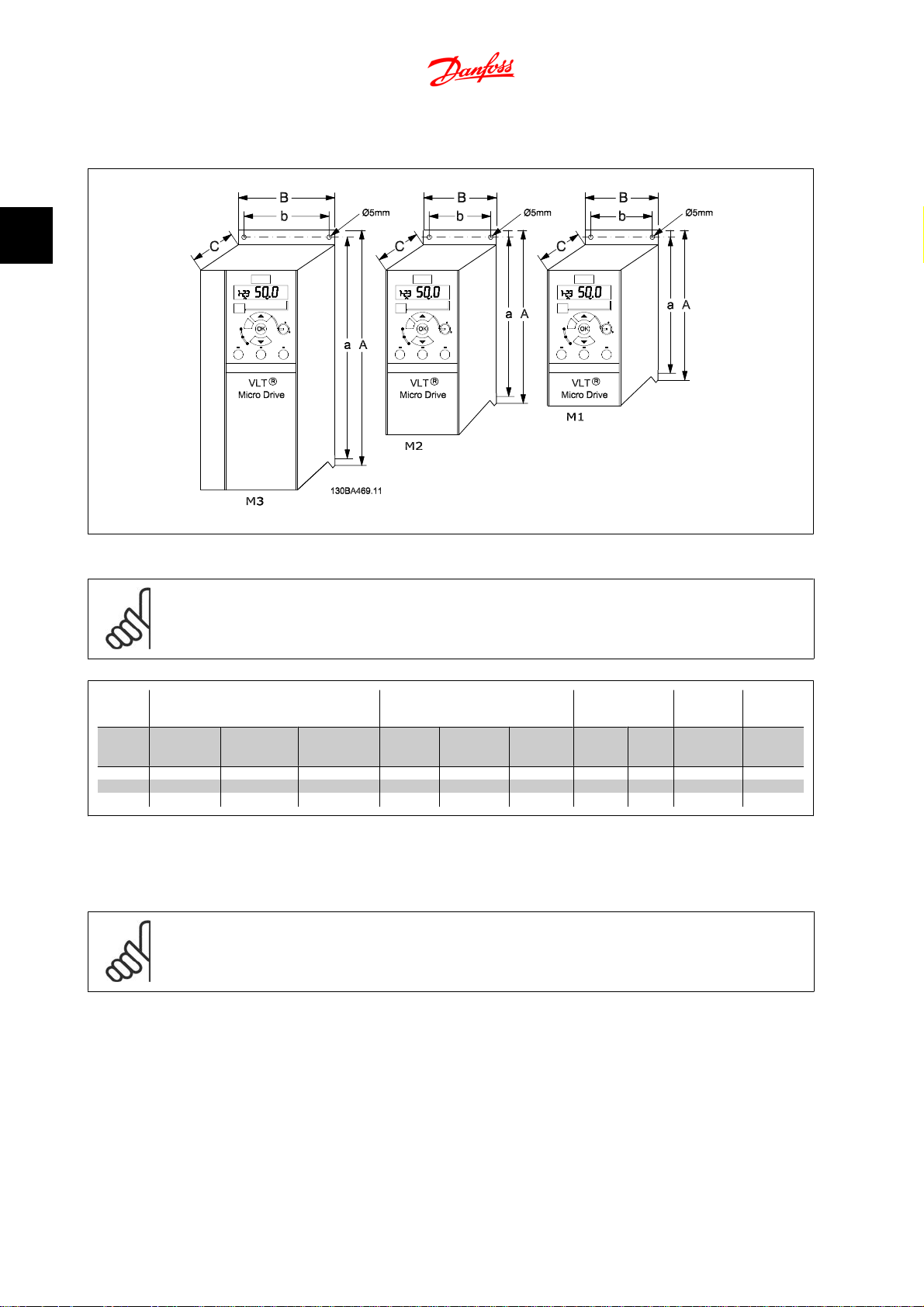

2.2. Side-by-Side Installation

2

2.1: Contents of box.

The Danfoss VLT Micro Drive can be mounted side-by-side for IP 20 rating units and requires 3.4 in. [100 mm] clearance above and below for cooling.

Regarding surroundings in general, please see chapter

2.2: Side-by-side installation.

7. Specifications

.

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

5

2

2. Mechanical Installation VLT Micro Drive FC 51 Instruction Manual

2.3.1. Mechanical Dimensions

2.3: Mechanical dimensions

NOTE

A template for drilling can be found on the flap of the packaging.

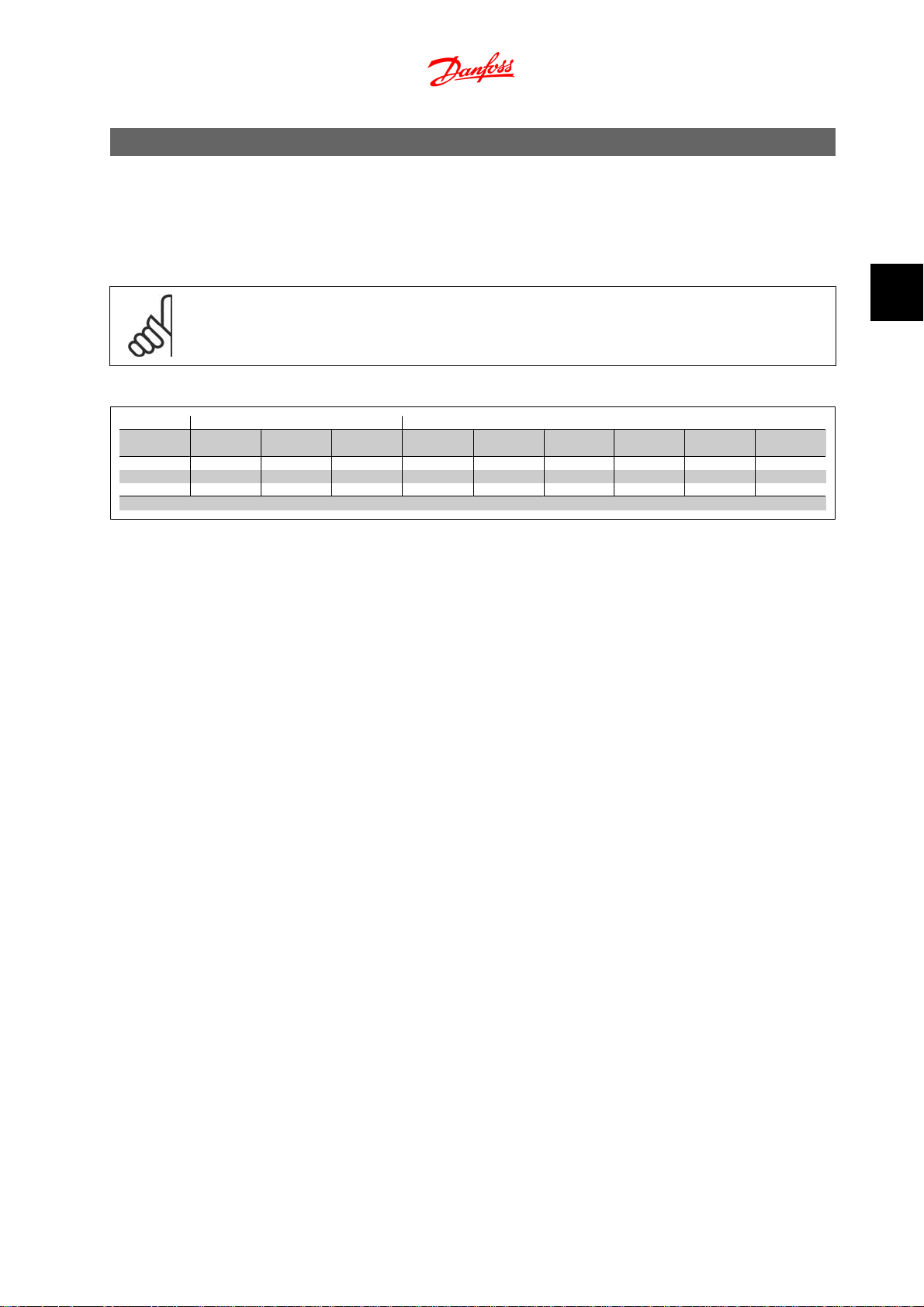

Power (kW) Height (mm) Width (mm)

Frame 1 X 200-240 V

M1 0.18 - 0.75 0.25 - 0.75 0.37 - 0.75 150 205 140.4 70 55 148 1.1

M2 1.5 1.5 1.5 - 2.2 176 230 166.4 75 59 168 1.6

M3 2.2 2.2 -3.7 3.0 - 7.5

3 X

200 -240 V

3 X

380-480 V

A (incl. de-

A

2) 2) 2) 2) 2) 2) 2)

coupling

plate)

a B b C Kg

Depth

(mm)

1)

2.1: Mechanical Dimensions

1)

For LCP with potentiometer, please add 0.3 in [7.6 mm].

2

These dimensions will be announced at a later point.

NOTE

DIN rail mounting kit is available for M1. Please use ordering number 132B0111.

Max.

Weight

6

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

VLT Micro Drive FC 51 Instruction Manual 3. Electrical Installation

3. Electrical Installation

3.1. How to Connect

3.1.1. Electrical Installation in General

NOTE

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper conductors

required, (140°-167° F [60°-75° C]) recommended.

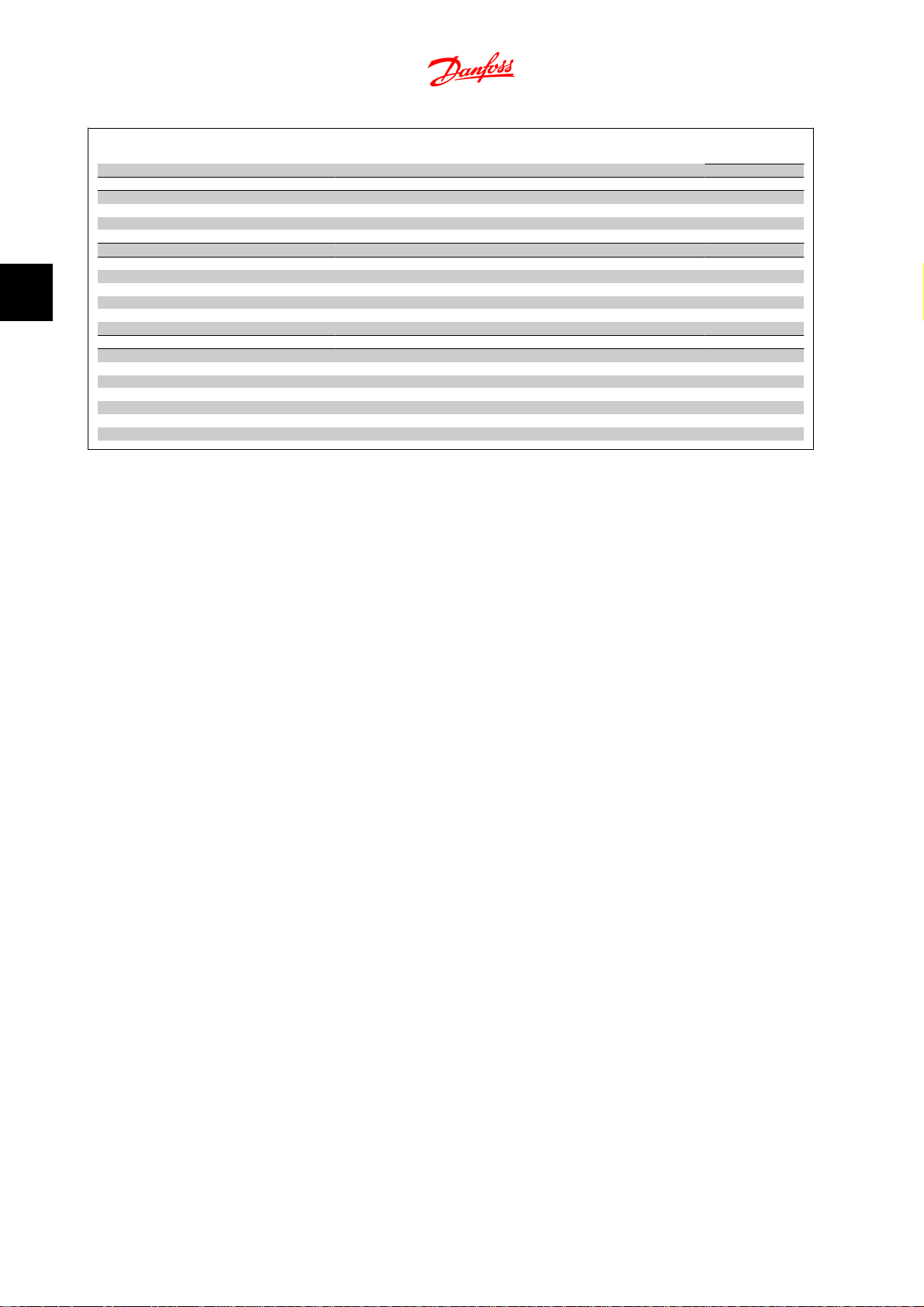

Details of terminal tightening torques.

Frame

M1 0.18 - 0.75 0.25 - 0.75 0.37 - 0.75 1.4 0.7 - 0.15 3 0.5

M2 1.5 1.5 1.5 - 2.2 1.4 0.7 - 0.15 3 0.5

M3 2.2 2.2 - 3.7 3.0 - 7.5 1.4 0.7 - 0.15 3 0.5

1)

Spade connectors

1 x 200-240V3 x 200-240V3 x 380-480

Power (kW) Torque (Nm)

V

Line Motor

DC connection/Brake

Control Ter-

1)

minals

Ground Relay

3.1: Tightening of terminals.

3.1.2. Fuses

Branch circuit protection:

In order to protect the installation against electrical and fire hazards, all branch circuits in an installation, switch gear, machines, etc. must be short-

circuited and overcurrent protected according to national/international regulations.

Short circuit protection:

Danfoss recommends using the fuses mentioned in the following tables to protect service personnel or other equipment in case of an internal failure in

the unit or short-circuit on the DC link. The adjustable frequency drive provides full short-circuit protection in case of a short-circuit on the motor or brake

output.

3

Overcurrent protection:

Provide overload protection to avoid overheating of the cables in the installation. Overcurrent protection must always be carried out according to national

regulations. Fuses must be designed for protection in a circuit capable of supplying a maximum of 100,000 A

NonUL compliance:

If UL/cUL is not to be complied with, Danfoss recommends using the fuses mentioned in table 1.3, which will ensure compliance with EN50178:

In case of malfunction, not following the fuse recommendation may result in damage to the adjustable frequency drive.

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

(symmetrical), 480 V maximum.

rms

7

3. Electrical Installation VLT Micro Drive FC 51 Instruction Manual

3

FC 51 Bussmann Bussmann Bussmann Littel fuse

1 X 200-240 V

kW Type RK1 Type J Type T Type RK1 Type CC Type RK1 Type gG

0K18 - 0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 15A

0K75 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

1K5 KTN-R35 JKS-35 JJN-35 KLN-R35 - A2K-35R 35A

2K2

3 x 200-240 V

0K25 KTN-R10 JKS-10 JJN-10 KLN-R10 ATM-R10 A2K-10R 10A

0K37 KTN-R15 JKS-15 JJN-15 KLN-R15 ATM-R15 A2K-15R 15A

0K75 KTN-R20 JKS-20 JJN-20 KLN-R20 ATM-R20 A2K-20R 20A

1K5 KTN-R25 JKS-25 JJN-25 KLN-R25 ATM-R25 A2K-25R 25A

2K2 KTN-R30 JKS-30 JJN-30 KLN-R30 ATM-R30 A2K-30R 30A

3K7 KTN-R45 JKS-45 JJN-45 KLN-R45 - A2K-45R 45A

3 x 380-480 V

0K37 - 0K75 KTS-R10 JKS-10 JJS-10 KLS-R10 ATM-R10 A6K-10R 10A

1K5 KTS-R15 JKS-15 JJS-15 KLS-R15 ATM-R15 A2K-15R 15A

2K2 KTS-R20 JKS-20 JJS-20 KLS-R20 ATM-R20 A6K-20R 20A

3K0 KTS-R25 JKS-25 JJS-25 KLS-R25 ATM-R25 A6K-25R 25A

4K0 KTS-R30 JKS-30 JJS-30 KLS-R30 ATM-R30 A6K-30R 30A

5K5 KTS-R35 JKS-35 JJS-35 KLS-R35 - A6K-35R 35A

7K5 KTS-R45 JKS-45 JJS-45 KLS-R45 - A6K-45R 45A

KTN-R45 JKS-45 JJN-45 KLN-R45 - A2K-45R 45A

Ferraz-

Shawmut

Ferraz-

Shawmut

Max. fuses non-UL

3.2: Fuses

3.1.3. EMC-correct Installation

Following these guidelines is advised where compliance with EN 61000-6-3/4, EN 55011 or EN 61800-3

is in EN 61800-3

Second environment

, then it is acceptable to deviate from these guidelines. However, it is not recommended.

First environment

is required. If the installation

Good engineering pract ice to ensure EMC-correct electrical installation:

• Use only braided shielded/armored motor cables and control cables.

The shield should provide a minimum coverage of 80%. The shield material must be metal, not limited to but typically copper, aluminum, steel

or lead. There are no special requirements for the line cable.

• Installations using rigid metal conduits are not required to contain shielded cable, but the motor cable must be installed in a conduit separate

from the control and line cables. Full connection of the conduit from the drive to the motor is required. The EMC performance of flexible conduits

varies greatly, and information from the manufacturer must therefore be obtained.

• Connect the shield/armor/conduit to ground at both ends for motor cables and control cables.

• Avoid terminating the shield/armor with twisted ends (pigtails). This type of termination increases the high frequency impedance of the shield,

which reduces its effectiveness at high frequencies. Use low impedance cable clamps or glands instead.

• Ensure good electrical contact between the de-coupling plate and the metal chassis of the adjustable frequency drive; see Instruction MI.

02.BX.YY

• Avoid using unshielded/unarmored motor or control cables inside cabinets housing the drive(s), whenever possible.

8

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

VLT Micro Drive FC 51 Instruction Manual 3. Electrical Installation

3.2. Line Connection

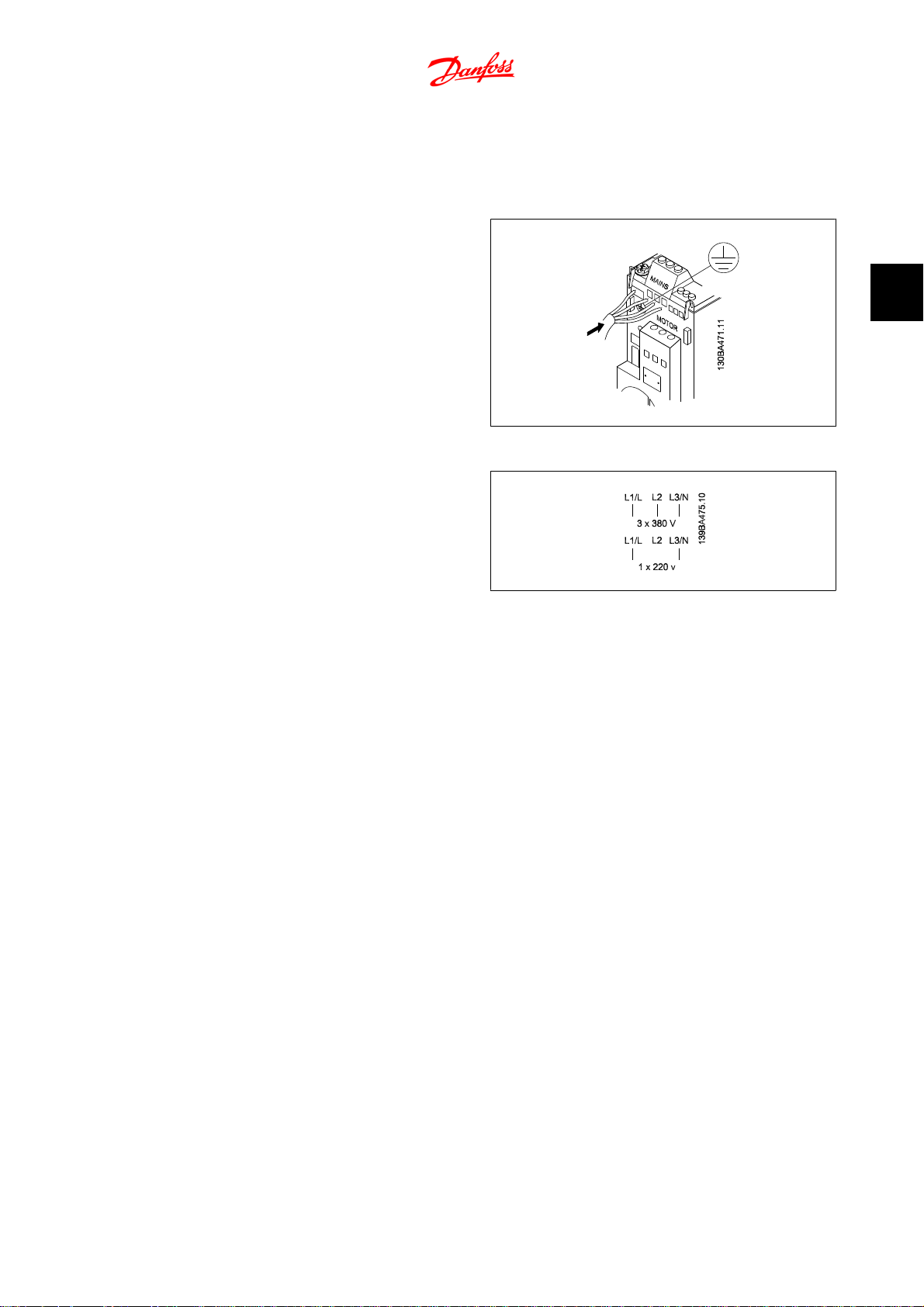

3.2.1. Connecting to Line Power

Step 1: First mount the ground cable.

Step 2: Mount wires in terminals L1/L, L2 and L3/N and tighten them.

3.1: Mounting of ground cable and line power wires.

For a 3-phase connection, connect the wires to all three terminals.

For a single-phase connection, connect the wires to terminals L1/L and

L3/N.

3

3.2: Three-phase and single-phase wire connections.

3.3. Motor Connection

3.3.1. How to Connect the Motor

See the chapter

• Use a shielded/armored motor cable to comply with EMC emission specifications, and connect this cable to both the decoupling plate and the

• Keep motor cable as short as possible to reduce the noise level and leakage currents.

For further details on mounting of the decoupling plate, please see instruction MI.02.BX.YY.

Specifications

motor metal.

for correct dimensioning of motor cable cross-section and length.

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

9

3

3. Electrical Installation VLT Micro Drive FC 51 Instruction Manual

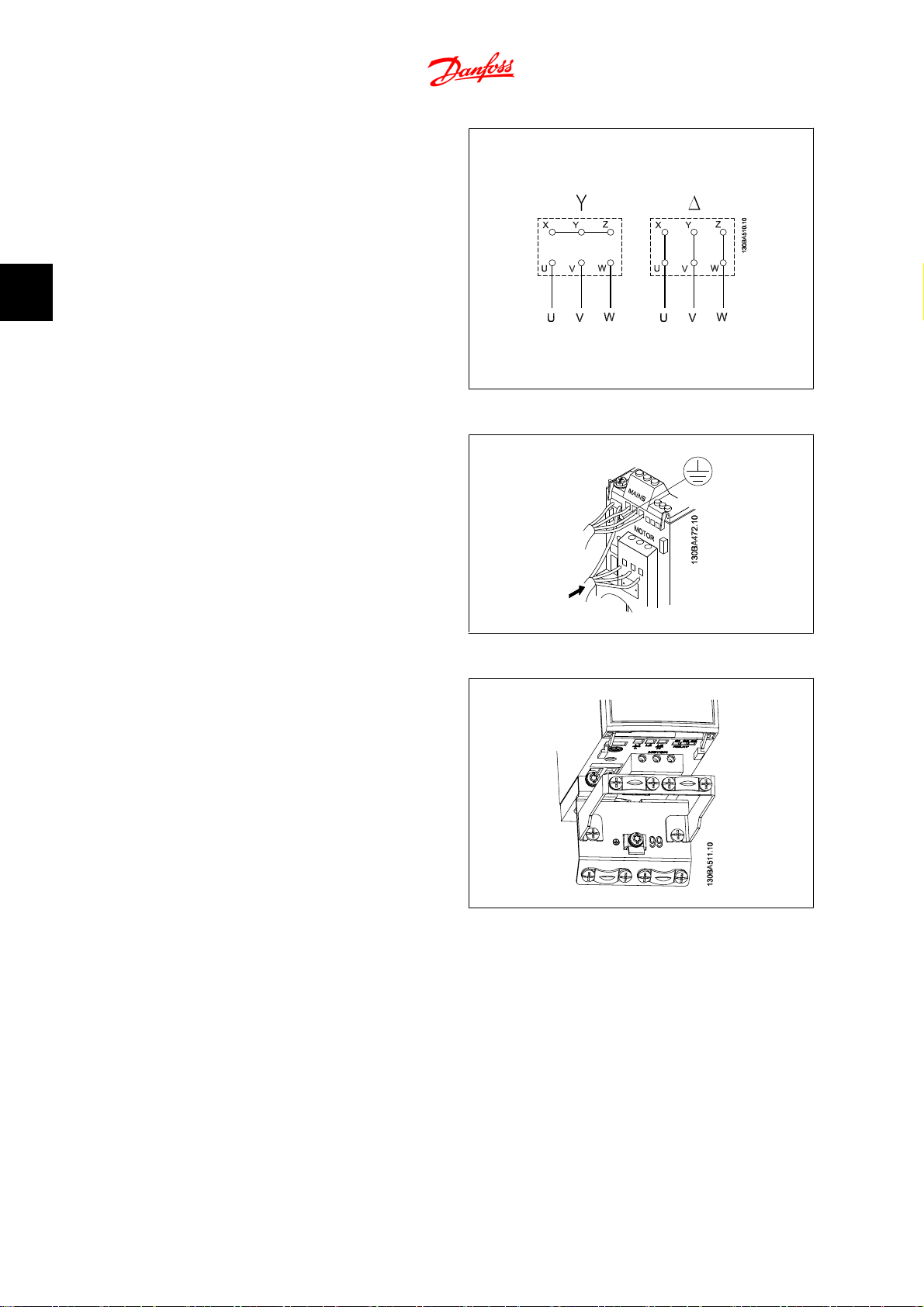

All types of three-phased asynchronous standard motors can be connec-

ted to the adjustable frequency drive. Normally, small motors are star-

connected (230/400 V, Δ/Y). Large motors are delta-connected (400/690

V, Δ/Y). Refer to the motor nameplate for correct connection and voltage.

3.3: Star and delta connections.

Step 1: First, mount the ground cable.

Step 2: Connect wires to terminals either in star or delta-connection. See

the motor nameplate for further information.

For EMC-correct installation, use optional de-coupling plate; see chapter

Options for VLT Micro Drive FC 51

.

3.4: Mounting of ground cable and motor wires.

3.5: VLT Micro Drive with de-coupling plate

10

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

VLT Micro Drive FC 51 Instruction Manual 3. Electrical Installation

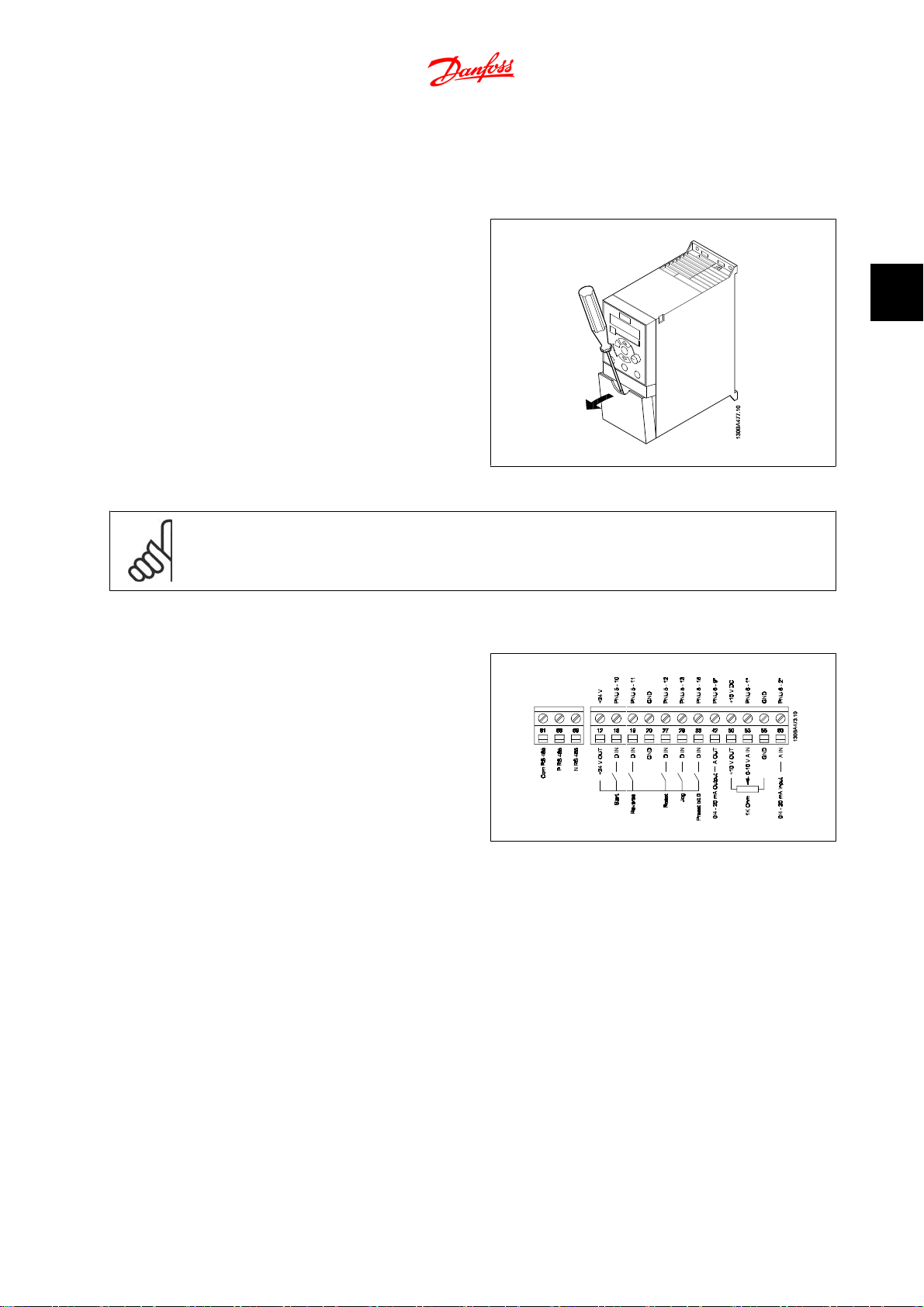

3.4. Control Terminals

3.4.1. Access to Control Terminals

All control cable terminals are located underneath the terminal cover in

front of the adjustable frequency drive. Remove the terminal cover using

a screwdriver.

3.6: Removing the terminal cover.

3

NOTE

See back of terminal cover for outlines of control terminals and switches.

3.4.2. Connecting to Control Terminals

This illustration shows all the control terminals on the VLT Micro Drive.

Applying Start (term. 18) and an analog reference (term. 53 or 60) makes

the adjustable frequency drive run.

3.7: Overview of control terminals in the PNP configuration

and factory settings.

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

11

3. Electrical Installation VLT Micro Drive FC 51 Instruction Manual

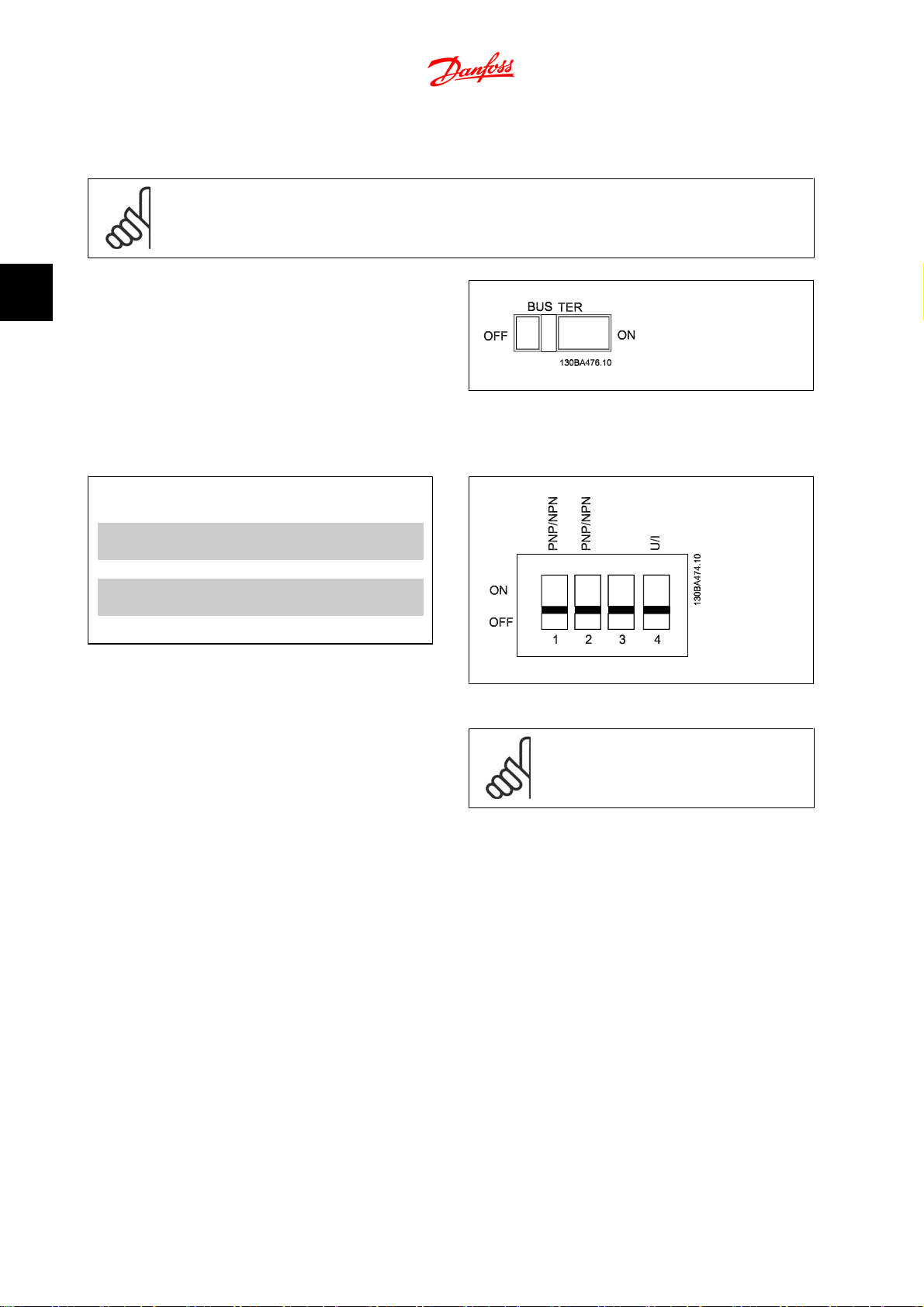

3.5. Switches

NOTE

Do not operate switches with power on the adjustable frequency drive.

3

Bus termination:

Switch

BUS TER

pos. ON terminates the RS-485 port, terminals 68, 69.

See the power circuit drawing.

Default setting = Off.

S200 Switches 1-4:

Switch 1: *OFF = PNP terminal 29

ON = NPN terminal 29

Switch 2: *OFF = PNP terminals 18, 19, 27 and 33

ON = NPN terminals 18, 19, 27 and 33

Switch 3: No function

Switch 4: *OFF = Terminal 53 0-10 V

ON = Terminal 53 0/4-20 mA

* = default setting

3.3: Settings for S200 Switches 1-4

3.8: S640 Bus termination.

3.9: S200 Switches 1-4.

NOTE

Parameter 6-19 must be set according to Switch 4 po-

sition.

12

MG.02.A2.22 - VLT® is a registered Danfoss trademark.

Loading...

Loading...