Grieve Corporation S7999 Installation Manual

S7999 ControLinks™

Display Module

PRODUCT DATA

•

Operating Status:

— Source of demand/control.

— Actuator positions.

— Hold status.

— Total cycles.

— Total hours of operation.

— Run time.

• Fault history of six most recent faults.

— Fault code.

— Fault message.

— Cycles at time of fault.

APPLICATION

The S7999 ControLinks ™ Display Mo dule (DM) pr ovides loca l

or remote annunciat ion of s ystem op eration, fault informatio n,

diagnostic information, actuator settings and configuration

settings of the ControLinks™ System.

FEATURES

•

Communication interface capability to the

ControLinks™ System.

•

Dependable, long-term operation provided by

microcomputer technology.

•

Local or remote system annunciation provided

by a 2-row by 20-column display.

• Diagnostic information:

— Input/Output status.

— Demand/control input and position.

— Fuel selection.

— Fuel position.

• Motor settings:

— Light-off position of fuel, air and FGR.

— purge position of fuel, air and FGR.

— Programmed stop position of fuel, air and FGR.

• Configuration settings:

— Low Fire Hold input (XmA).

— FGR Purge position.

— Manual potentiometer limit enabled/disabled.

— R7999 hardware/software revision.

— Display Module (DM) software revision.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Wiring ............................................................................... 4

Display Module Operation ................................................ 5

Troubleshooting ................................................................ 10

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

65- 0262

S7999 CONTROLINKS™ DISPLAY MODULE

SPECIFICATIONS

Electrical Ratings:

Voltage and Frequency: 13 Vdc peak full wave rectified

(+20/-15%).

Power Dissipation: 7W maximum.

VA Consumption: 2 VA maximum.

Terminal Ratings:

Power: 13 Vdc peak full wave rectified.

Earth Ground.

Environmental Ratings:

Ambient Temperature Ranges:

Operating: -40°F (-40°C) to +140°F (+60°C).

Storage: -60°F (-51°C) to +150°F (+66°C).

Humidity: 85 percent relative humidity continuous,

noncondensing.

Vibration: 0.5G enviro nment.

Mechanical:

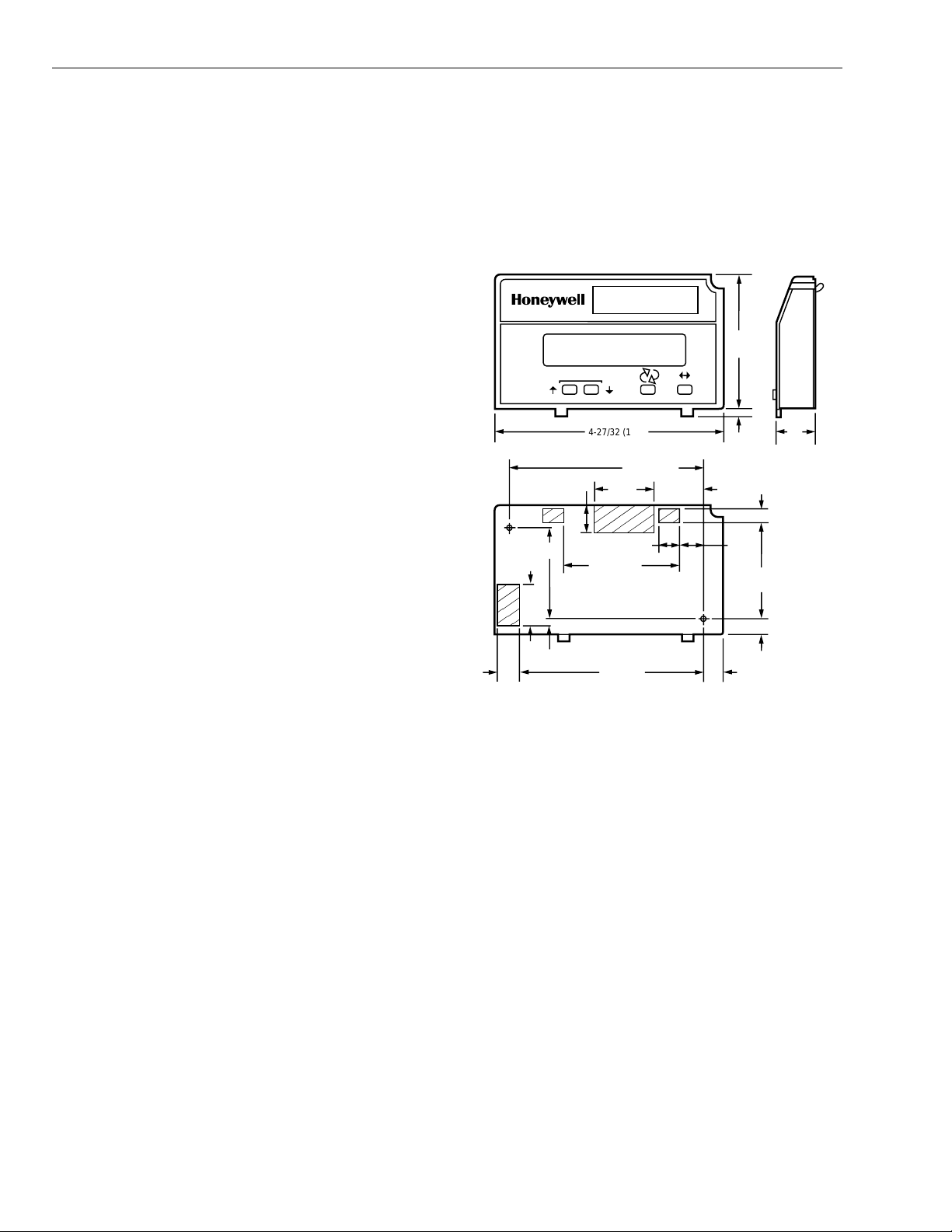

Dimensions: See Fig. 1.

Weight: 4 ounces (124 grams), unpacked.

Display:

40 character (2 rows by 20 columns).

Approvals:

Underwriters Laboratories Inc.: Component Recognized.

IRI: Acceptable.

Federal Communicati ons Commi ssio n:

Part 15, Class B emissions.

EN60730: For compliance with remote DM mounting

requirements, provide electrical insulation separation by

insulation using d oub le or re info rce d i ns ula tio n. Do thi s b y:

Optically isolat ing the communication or re mote reset lines

from the control cabinet, or provide physical separation

from the communicati on or remote dis play cov er asse mbly

(part number 204718A) or other suitable enclosure that

meets the IP40 class of protection.

Accessories:

203541 ControlBus 5-wire Electrical Connector.

203765 Remote Display Mounting Bracket.

204718A NEMA 4 Cover Assembly for S7999 DM.

204718B NEMA 1 Cover Assembly for S7999 DM.

205321B Remote Display Flush Mount Kit.

203968A DM Remote Power Supply.

ControLinks™

2-3/4

(69)

SCROLL

15/

32

(12)

1-15/16

(49)

29/32

(23)

5/32 (4)

19/32

(15)

4-27/32 (123)

4-3/32 (104)

1-1/4

(32)

7/16 (11)

2-7/16 (62)

3-7/8 (99)

1-1/32

(26)

13/

32

(11)

5/32

(4)

1/2

(13)

5/16

(8)

2-1/32

(52)

5/15

(8)

Fig. 1. Approximate dimensions of

S7999 ControLinks™ DM in in. (mm).

29/32

(23)

M20041

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.

Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0262 2

S7999 CONTROLINKS™ DISPLAY MODULE

INSTALLATION

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect the power supply before beginning

installation to prevent electrical shock and equipment

damage. More than one power supply disconnect can

be involved.

When Installing This Product…

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and marked

on the product to make sure the product is suitable for

your application.

3.

Installer must be a trained, experienced, flame

safeguard service technician.

4.

After installation is complete, check out the product

operation as provided in these instructions.

5.

Be sure wiring complies with all applicable codes,

ordinances and regulations.

6.

See Fig. 5, 6 and 7 for S7999 unique wiring

connections.

Weather

The S7999 is not designed to be weather tight. If installed

outdoors, the S7999 must be protected by an approved

weather-tight enclosure such as the 204718A or 204718C

NEMA 4 Enclosure listed in Accessories.

Remote Mounting DM

The DM can be mounted either on the face of a panel door or

on other remote locatio ns. See Fig. 2. When moun ting the D M

on the face of a door panel, closely follow these instructions:

IMPORTANT

1. This equipment generates, uses and can radiate

radio frequency energ y and, if not ins talle d and use d

in accordance with the instructions, can cause

interference to radio communications. It has been

tested and found to comp ly with the limi ts for a Class

B computing device of Part 15 of FCC rul es which

are designed to provided reasonable protection

against such interference when operated in a

commercial environment. Operation of this

equipment in a residential area can cause

interference, in which case, users, at their own

expense, can be required to take whatever

measures are required to correct this interference.

2. This digital apparatus does not exceed t he Class B

limits for radio noise for digital apparatus set out in

the Radio Interference Regulations of the Canadian

Department of Communications.

Humidity

Install the S7999 where the relative humidity never reaches

the saturation point. The S7999 ControLinks™ is designed to

operate in a maximum 85% RH continuous, noncondensing,

moisture environment.

Vibration

Do not install the S7999 whe re it c an be subje cted to vib ration

in excess of 0.5G continuous maximum vibration.

Fig. 2. Panel mounting of a display module.

1.

Select the location on th e doo r pan el fo r flus h m oun tin g.

2.

Pay attention to the insertion di me ns ion s of th e tw o DM

screws, two interlocking ears, and the two plug-in

connections to allow for sufficient clearance.

3.

Use the DM or Data Control Bus Modul e™ as a templa te

(Fig. 16) and mark the two screw locations, interlocking

ear locations and the two plug-in connector locations.

4.

Drill the pilot holes for the mounting screws.

5.

Cut holes in the d oor pa nel for the interlocking ea rs and

the two plug-in conn ectors.

6.

Mount the DM, securing it with the tw o s cre ws prov id ed

in the DM bag assembly.

Use the 203765 Remote Display Mounting Bracket when

mounting the DM on a wall or remote location:

1.

Use the 203765 Remote Displa y Mou nting Bra cket as a

template to mark the four screw locations.

2.

Drill the pilot holes for the four mounting screws.

3.

Mount the 203765 Remo te Display M ounting Bracket b y

securing the four no. 6 screws (M3.5 x 0.6).

See Fig. 3.

4.

Mount the DM by aligning the tw o int erlo ck in g ears with

the two mating slots on the remote mounting bracket.

5.

Insert the two interlocking ears into the two m ating sl ots.

6.

Push on the lower corners of the DM to secure it to the

remote mounting bracket.

7.

Make sure the DM is firmly in place.

3 65-0262

S7999 CONTROLINKS™ DISPLAY MODULE

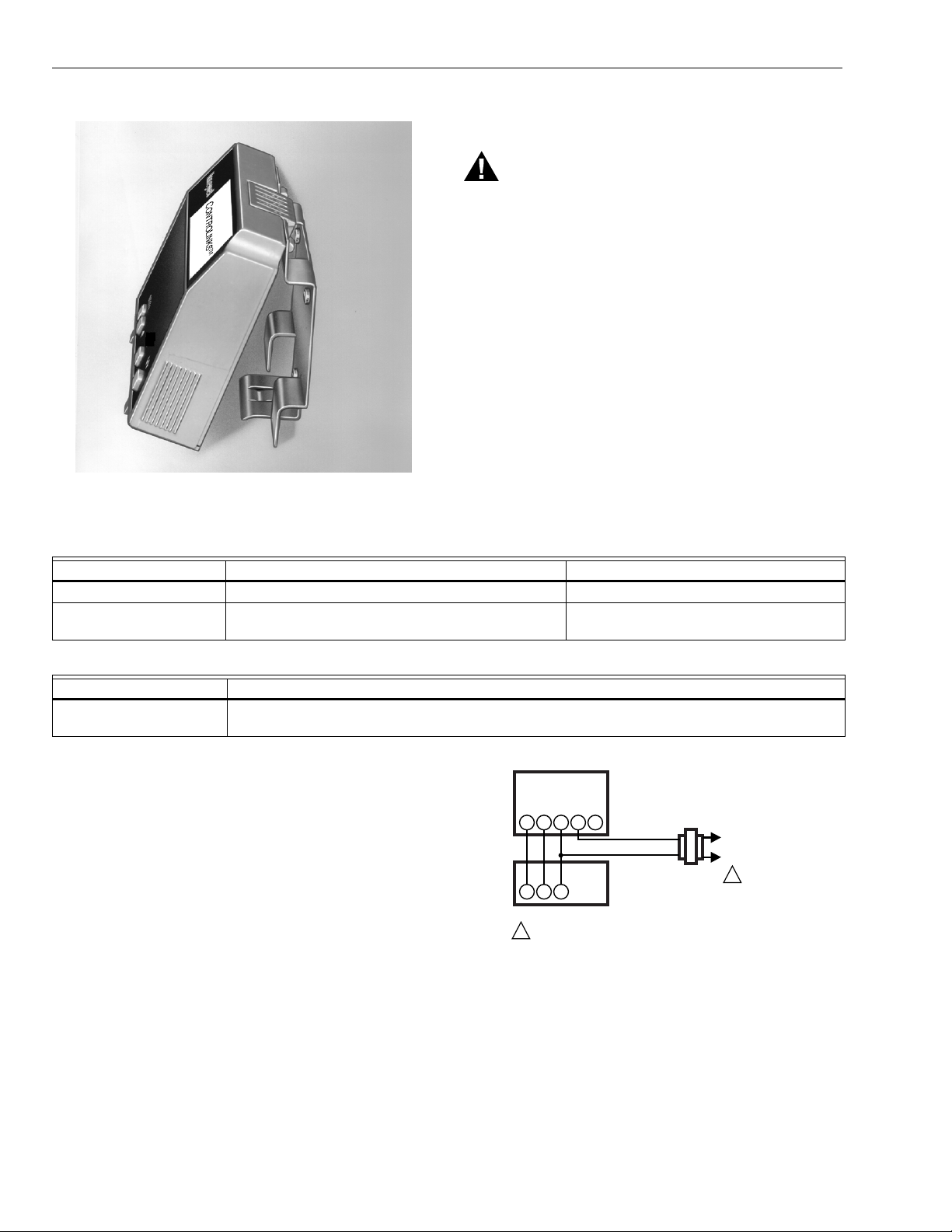

Fig. 3. Remote mounting of a Display Module using

a 203765 Remote Display Mounting Bracket.

WIRING

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

To prevent electrical shock and equipment damage,

disconnect the power suppl y from the main disc onnect

before beginning installation. More than one

disconnect can be involved.

1.

Refer to Fig.4, 5 and 6 for proper wiring.

2.

Make sure all wiring complies with all applicable

electrical codes, ordinances and regulations.

3.

For recommended wire size and type, see Table 1.

4.

For Recommended grounding practices, see Table 2.

5.

For DM: The DM is powered from a low voltage,

energy-limited source. It can be mounted outside of a

control panel if it is protected from mechanical damage.

NOTE: A 13 Vdc power supply must be used any time the

DM is used.

Table 1. Recommended Wire Size and Part Number.

Application Recommended Wire Size Recommended Part Number

Display Module 22 AWG two -w ire t wisted pair with ground or fi ve -wire. Belden 8723 shielded cable or equivalent.

13 Vdc full wave rectified

transformer power input.

18 AWG wi re in su lated for voltages and tem pe ratu r es

for given application.

TTW60C, THW75C, THHN90C.

Table 2. Recommended Grounding Practices.

Ground Type Recommended Practice

Signal ground (DM) Use the shield of the signal wire to ground the device to the signal ground terminal of each device.

Connect the shield at both ends of the daisy chain to ground.

6.

Recommended wire routing :

a. Display Module:

S7999

(1) Do not route the Display Module wiring in

conduits that carry line voltage circuits.

(2) Avoid routing the Display Module wiring close to

ignition transformer leadwires.

(3) Route the Display Module wiring outs id e of

conduit if properl y supported and protecte d fro m

damage.

7.

Maximum wire lengths:

a. DM: The maximum length interconnecting wire is

4000 ft (1219m).

8.

Install all electrical connectors.

9.

Restore power to the panel.

ABC (std)

1

ABC

123

R7999

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED. M17923

+ 13 vdc

2

3

54

L1

(HOT)

L2

1

Fig. 4. Wiring the display module.

65-0262 4

Loading...

Loading...