Grieve Corporation 1494V-DS200 Installation Manual

Bulletin 1494V Variable Depth Disconnect Switch Installation Instructions

(Cat 1494V-DS30; -DSX30 - Series D; 1494V-DS60; -DSX60 - Series D)

(Cat 1494V-DS100; -DSX100 - Series D; 1494V-DS200; -DSX200 - Series D)

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing. Follow

NFPA 70E requirements. Install in suitable enclosure. Keep free from contaminants.

ATTENTION: The following procedures are critical to the proper operation of the disconnect handle and switch.

Failure to follow these steps can result in damage to the equipment and/or serious injury or death to the operator.

Table of Contents Page

Quick Installation Guide 2

Disconnect Switch Installation

-

- Disconnect Handle Installation

- Cutting Connecting Rod

Quick Installation Guide (continued) 3

-

Connecting Rod Installation

Connecting Rod Adjustment Procedure 4

Enclosure Without Handle Cutout 5

Locate Handle

-

- Drill Handle Holes

Door Catch Mounting Bracket Installation 6

Disconnect Switch Installation 7

Locate Disconnect Switch

-

- Install Disconnect Switch

- Assemble and Install Line Terminal Guard

Trailer Fuse Block Installation (30A, 60A, 100A) 8

Trailer Fuse Block Installation (200A) 9

Fuse Clip Installation and Phase Barrier Replacement (30A, 60A) 10

Fuse Clip Installation and Phase Barrier Replacement (100A) 11

Fuse Clip Installation (200A)

12

Phase Barrier Replacement (200A) 13

Bulletin 1494V Disconnect Switch Kit 14

Bulletin 1494V Disconnect Switch Kit Optional Accessory List 15

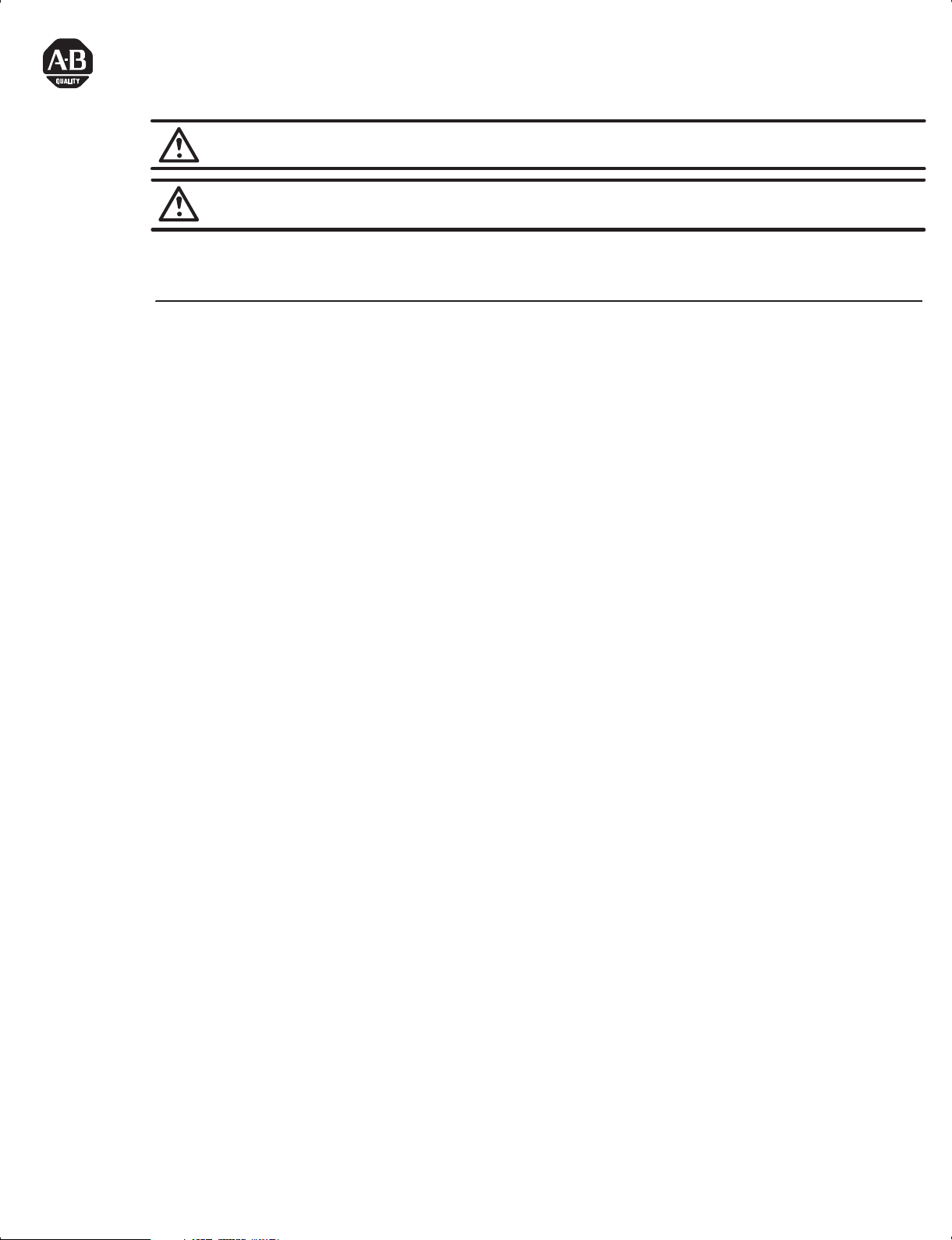

QUICK INSTALLATION GUIDE

Disconnect Switch Installation (Right hand installation shown. For left hand installation follow similar procedure.)

1

Use template A to locate handle holes on mounting plate.

4

E

L

HANDLE HO

TOP

RE TO

SURE

MEASU

INSIDE OF THE

HOLD FLUSH

TO INSIDE

OF ENCLO

TOP

OF ENCLOSURE

TAPE

BO

A

Disconnect Handle Installation

2

Install gasket.

1

2

MEASURE TO

INSIDE OF TH

OF EN

A

CLOSURE

TOP

FLUSH

E

INSIDE

HOLD

SURE

TO

F ENCLO

O

BOTT

11

ANDLE HOLE

M H

O

TT

TOP

3

Overlay template B (30 A - 100 A) over A .

5

7

Overlay template C (200 A) over A .

"

6

1

/

1

-

3

TOP

"

4

/

1

-

2

"

4

/

1

-

2

oles

es for

tch

O

"

6

swi

1

/

INSIDE

1

1

-

HOLD FLUSH

ounting H

4

TO

LOSURE

MEASURE T

CLOSURE

itch M

INSIDE OF THE

s provided with

OF ENC

Sw

OF EN

TOP

Center punch and drill (4) 11/64" hol

"

4

/

tap-tite screw

1

-

5

BOTT

C

A

or

B

1

6

Center punch and

drill (4) holes

for thread forming

(TAP-TITE) screws

provided with switch.

11/64" Dia. (30A - 100A)

7/32" Dia (200A)

Install handle and spring bracket.

2 3

Install disconnect switch.

23 - 37 lb-in

(30A - 100A)

40 - 60 lb-in

(200A)

Install defeater lever.

Cutting Connecting Rod

3

Measure working depth of enclosure.

1

Mounting

Plate

Working Depth

(Inside Flange

of Enclosure to

Mounting Plate)

Enclosure

30-40 lb-in

7-11 lb-in

Measure, mark and

2

cut connecting rod.

Remove burrs

3

N

N minus 3-1/8"

-1/4"

(30A - 100A)

N minus 3

(200A)

(2)

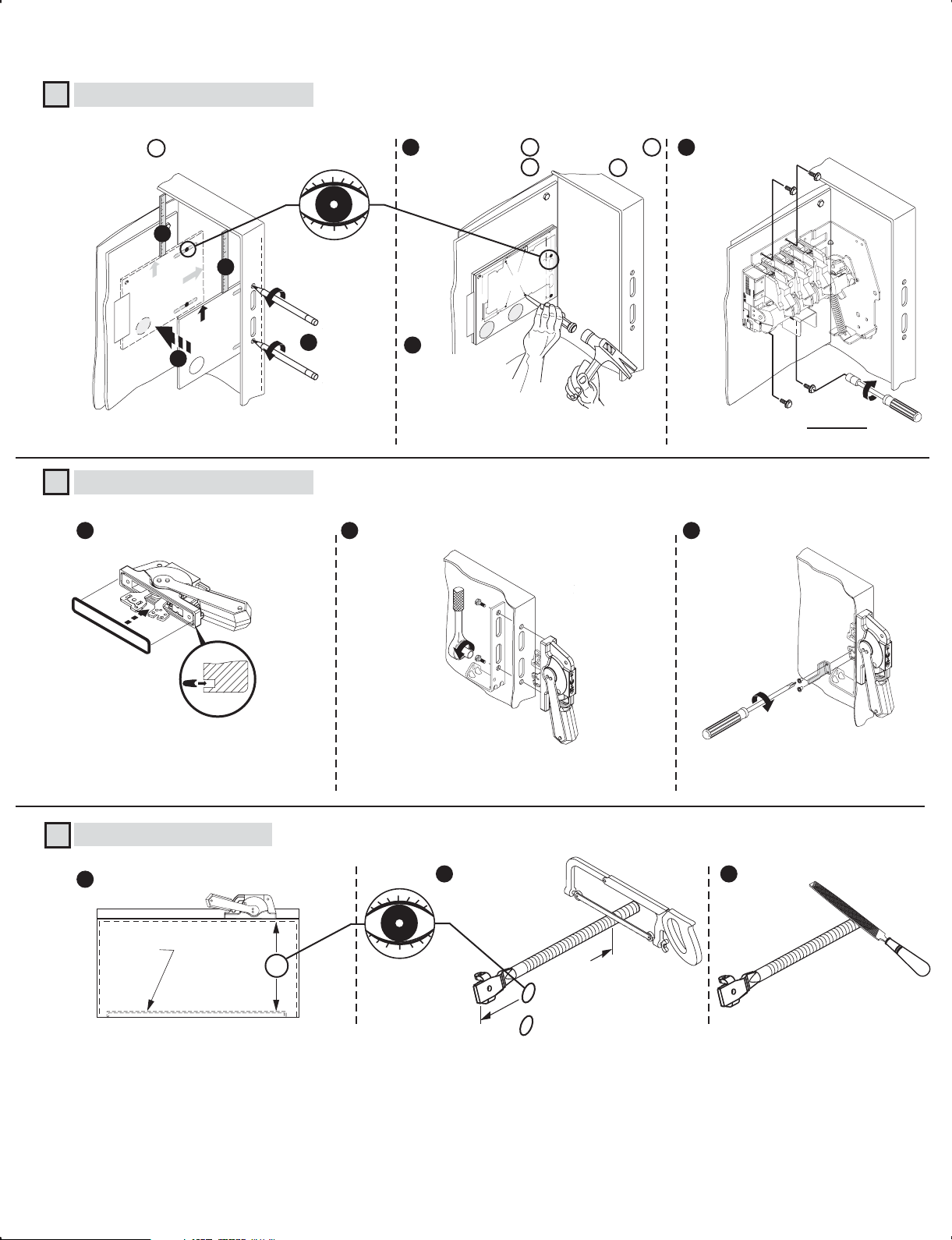

QUICK INSTALLATION GUIDE (CONTINUED)

Connecting Rod Installation

4

Verify that disconnect switch and handle are in "OFF"

1

position. (Switch blades will be visible)

Drive Bar

Rotate connecting rod into

drive bar (see table).

Switch Rating

30A - 60A - 100A

200A

Full Turns Engagement

2

10

13

Push rod down and verify if rod

is approximately 1/8" from

touching bottom of bolt head.

(If not, rotate rod up to 5 full

turns in either direction)

(200A)

Push down

4

3

(30A - 60A - 100A)

Pull up

1/8" Gap

Push rod down and

verify if rod is nearly

touching bottom of bolt

head. (If not, rotate rod

up to 5 full turns in

either direction)

Hitch Pin

Connecting

Rod

6

7

6

5

5

Primary Link

8a

Enclosure depth

8 in. or less

8b

Enclosure depth

greater than 8 in.

ATTENTION

CHECK FOR PROPER

OPERATION

(3)

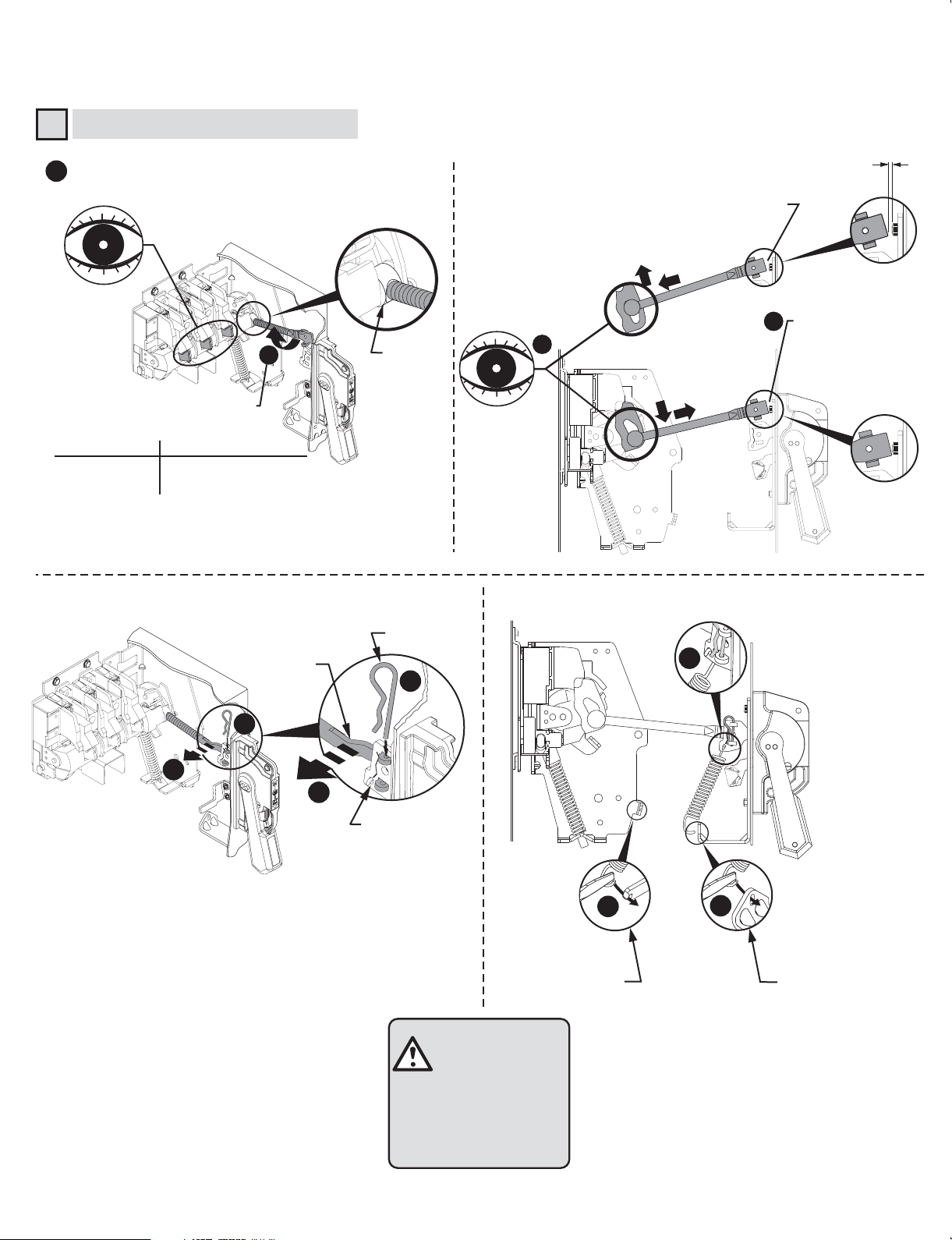

Connecting Rod Adjustment Procedure

Drive Bar

Hitch Pin

"ON" Position

1

Move disconnect handle to the "ON" position.

➊

If switch does not fully close, return handle to "OFF" position.

➋

Remove link spring hitch pin and disengage the connectiong rod from the primary link.

➌

Turn connecting rod counter-clockwise (1 or more) full turns.

➍

Re-engage connecting rod in primary link of handle, insert hitch pin and re-test

➎

Repeat ➊ - ➎ as necessary.

➏

Re-install link spring

➐

Connecting

Rod

Primary Link

"OFF" Position

2

Move disconnect handle to the "OFF" position.

➊

If switch does not fully open, return handle to "ON" position.

➋

Remove hitch pin and link spring, then disengage the connectiong rod from the primary link.

➌

Turn connecting rod clockwise (1 or more) full turns.

➍

Re-engage connecting rod in primary link of handle, insert hitch pin and re-test.

➎

Repeat ➊ - ➎ as necessary.

➏

Re-install link spring

➐

(4)

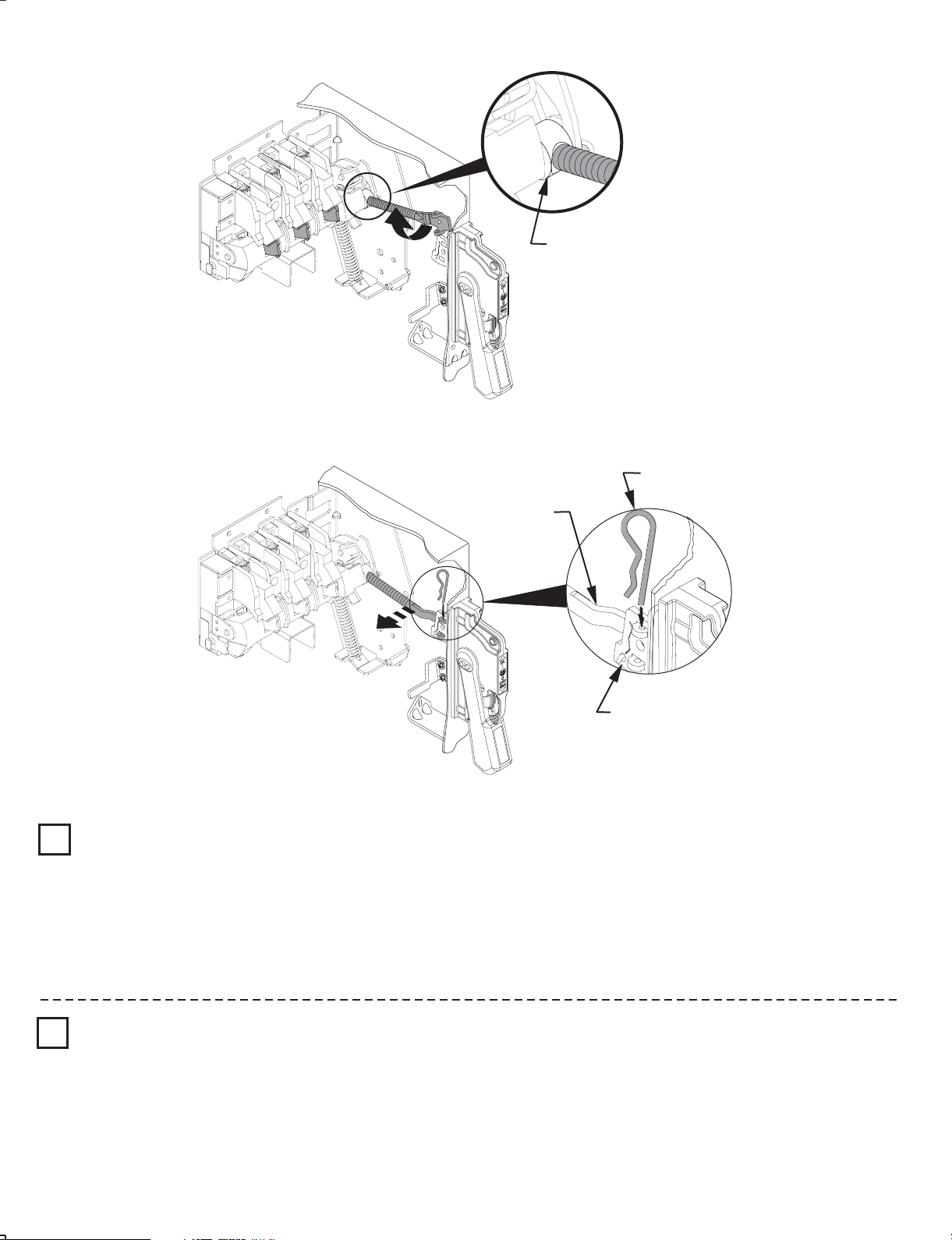

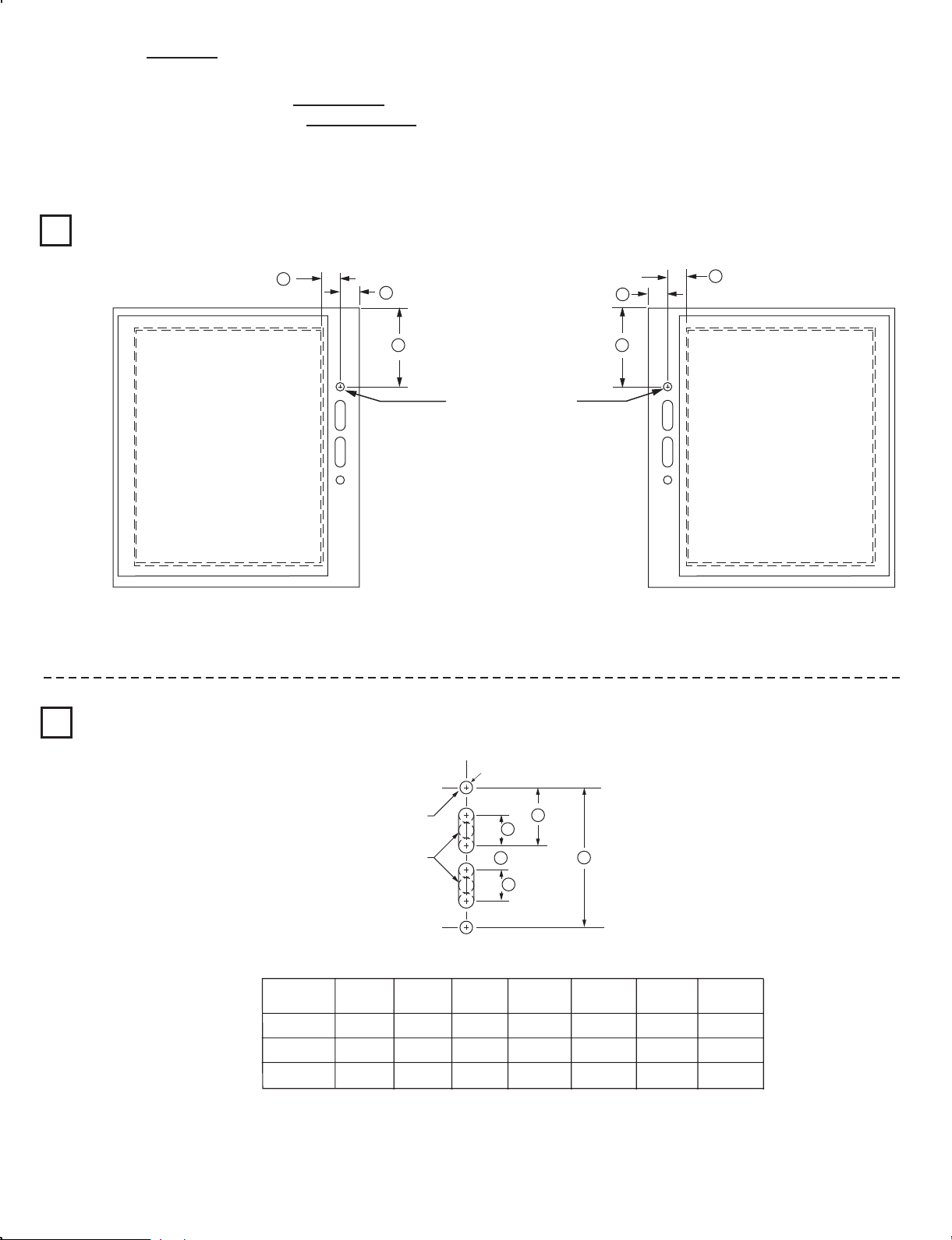

Enclosure without Handle Cutout

● Enclosures with a Flange Thickness less than 3/16" use dimensions below to install disconnect handle.

● Enclosures with a Flange Thickness 3/16" and greater use dimensions in alternate Mounting Kit 1494V-H3 to install disconnect

handle.

● Multi-Door Enclosures may require the need for a more rigid flange / mounting plate system, such as a Channel Support Kit. Use

dimensions in Channel Support Kit 1494V-H15, if handle is mounted on top of the channel.

Locate Handle

1

Drill Handle Holes

2

C

Right Hand Flange

C

B

A

B

A

Top Handle Hole

Left Hand Flange

Top Handle Hole

To make slot drill (3) 1/2" diameter holes and remove burrs

NEMA

SIZE

30A, 60A

100A

200A

A

(min)

4 - 5/8"

6 - 1/16"

10 - 1/8"

(min)

1 - 1/8"

1 - 1/8"

1 - 1/8"

(2) .265 Dia. Holes

G

H

J

H

Enclosure Dimensions

B

C

(max)

1 - 1/16"

1 - 1/16"

1 - 1/16"

F

4 - 11/16"

4 - 11/16"

4 - 11/16"

(5)

F

G

1 - 9/16"

1 - 9/16"

1 - 9/16"

H

1"

1"

1"

J

7/8"

7/8"

7/8"

Loading...

Loading...