Greystone Energy Systems ULP1, ULP2 Installation Instructions Manual

Ultra Low Pressure Transmitter

ULP

Installation Instructions

Introduction

The Ultra Low Pressure Transmitter is used to measure dierential

pressure in the range of 0.125 to 1"wc (30 to 250 Pa). It combines

precision high sensitivity silicon sensing capabilities and the latest ASIC

technology to substantially reduce oset errors due to changes in

temperature, stability to warmup, long term instability and position

sensitivity. It is ideal for monitoring pressure for air or other clean inert

gas. It features several eld selectable uni- or bi-directional pressure

ranges and output signal types for the most exible application. The

device has an on-board auto-zero function as well as a connection for

remote zeroing. Options include an LCD to display the pressure value

and an alarm relay with a variable trip point.

Before Installation

Read these instructions carefully before installing and commissioning the Pressure Transmitter. Failure to follow these instructions

may result in product damage. Do not use in an explosive or hazard-

ous environment, with combustible or ammable gases, as a safety or

emergency stop device or in any other application where failure of the

product could result in personal injury. Take electrostatic discharge

precautions during installation and do not exceed the device ratings.

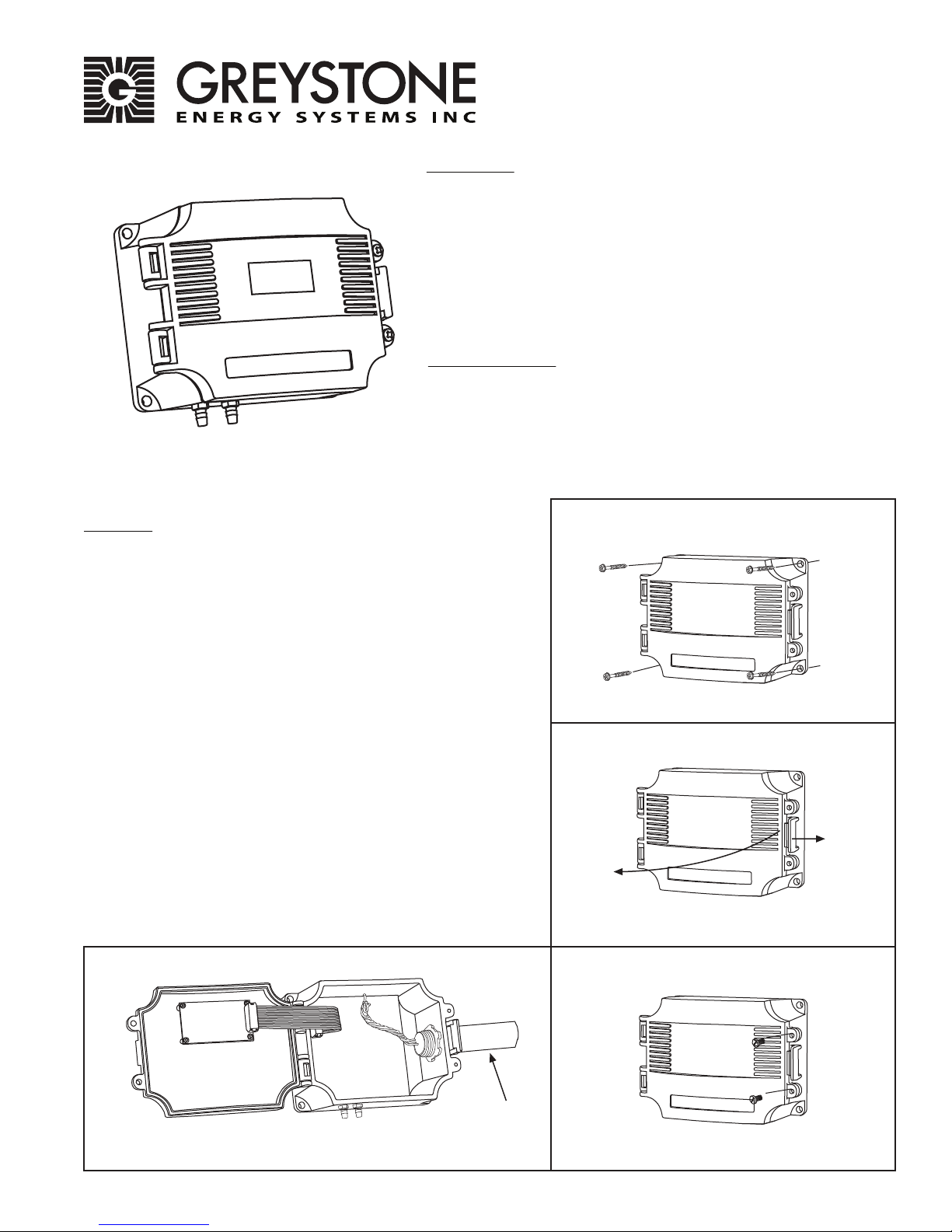

Mounting

Mount the device using the four holes on the base of the unit. Leave

enough space around the unit to connect the pressure tubing and

avoid locations with severe vibrations, excessive moisture or rapid

temperature changes. It should be mounted on a vertical surface with

the pressure ports on the bottom and the cable entrance on the right.

The enclosure has a standard ½” conduit opening and may be installed

with either conduit and a conduit coupler or a cable gland type tting.

Open the hinged cover by releasing the latch and connect the device

according to the wiring instructions. After wiring and setup are

complete, close and latch the cover. The cover may be secured with

two self-tapping screws in the holes provided. as shown in gure 1.

The enclosure has a hinged cover with latch. Open cover by pulling

slightly on the latch on the right side of the enclosure. At the same

time pulling on the cover, as illustrated in gure 2.

Feed conduit/cable gland tting through the provided hole in side of

enclosure and secure with a lock nut as show in gure 3. It is recommended that weatherproof conduit or cable gland ttings be used.

Make wiring connections as per the “Wiring” illustrations on Page 3.

Swing door closed until securely latched. For added security, 2 screws

are provided that may be installed in the integrated screw tabs. See

gure 4.

Figure 1

Figure 2

Figure 4Figure 3

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Conduit

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

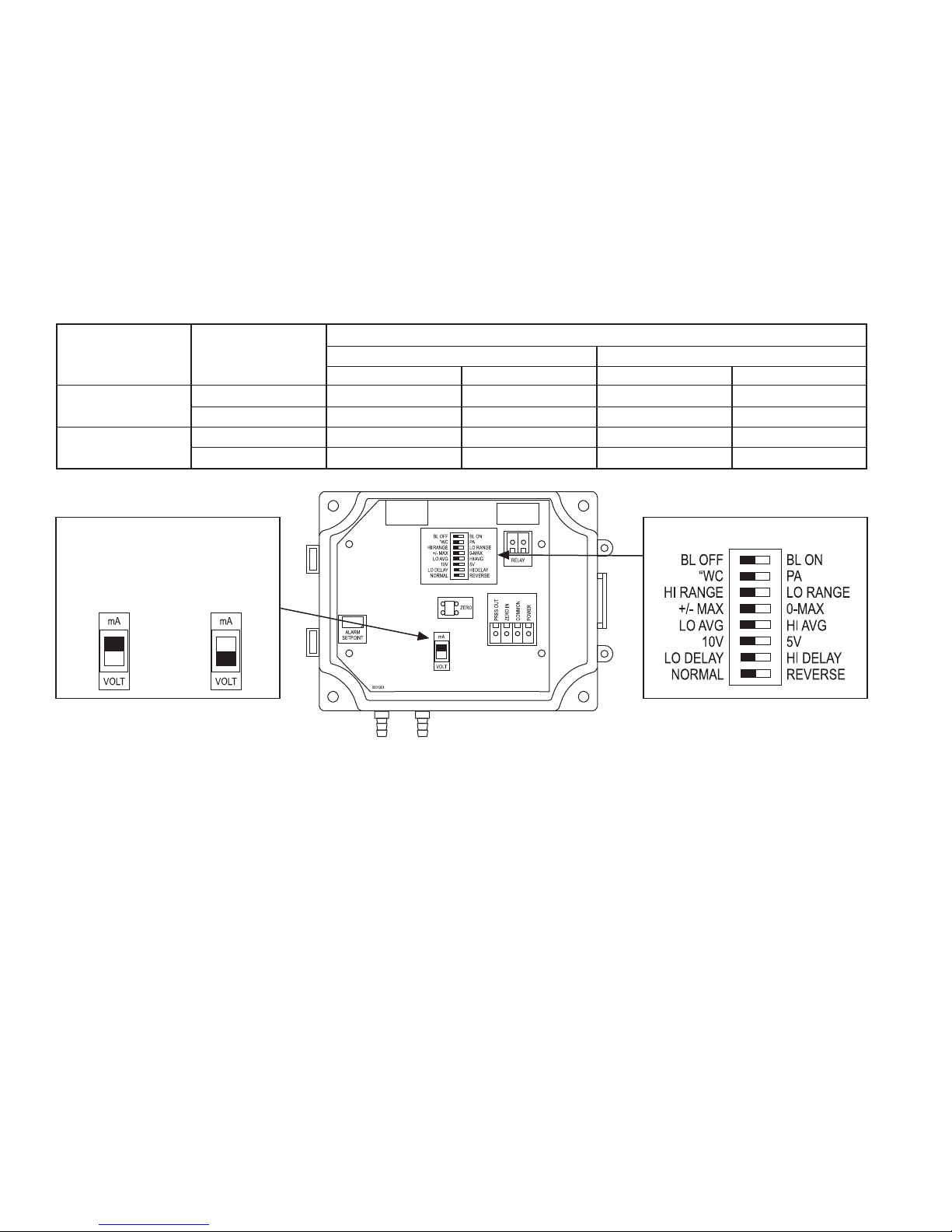

Hardware Setup

The analog output type must be set before the device is connected. Slide the switch labelled VOLT and mA to the correct

position for the required output signal type, either 4-20 mA or 0-5/10 Vdc. See gure 5. Other parameters may be set on the

DIP switches before or after the device is connected. Any DIP switch change will have an immediate eect on the operation.

DIP Switch Conguration (See gure 6)

BL OFF / BL ON Sets the LCD backlight on or o

"WC / Pa Sets the pressure units to “WC or Pascals

HI Range / LO Range* Sets the pressure range (See chart below)

+/- Max / 0 - Max Sets bi- or uni-directional pressure range

LO Avg / HI Avg Sets pressure averaging to 5 or 30 seconds

10V / 5V Sets the voltage output scale to 0-5 or 0-10 Vdc (N/A when mA output is selected)

LO Delay / HI Delay Sets the alarm delay to 10 or 60 seconds (N/A if no relay is ordered)

Normal / Reverse Sets the alarm action (N/A if no relay is ordered)

*The eect of dierent DIP switch settings on the pressure range is shown in the following table.

Model

Pressure Pressure ULP*1 ULP*2

Units Range ± Max 0 - Max ± Max 0 - Max

"WC HI Range ± 1 "wc 0-1 "wc ± 0.25 "wc 0-0.25 "wc

LO Range ± 0.5 "wc 0-0.5 "wc ± 0.125 "wc 0-0.125 "wc

Pa HI Range ± 250 Pa 0-250 Pa ± 60 Pa 0-60 Pa

LO Range ± 125 Pa 0-125 Pa ± 30 Pa 0-30 Pa

Figure 5

Output Type Selection Switch

mA = 4-20 mA

(Factory Default)

VOLT = Vdc

Figure 6

Wiring Instruction

The transmitter has standard screw block connectors. Use shielded twisted pair wiring of at least 22 AWG for all connections

and do not run device wires in the same conduit with wiring used to supply inductive loads such as motors. Disconnect the

power supply before making any connections to prevent electrical shock or equipment damage. Make all connections in

accordance with national and local electrical codes.

This is a 3-wire sourcing device. Connect the positive dc or the ac voltage hot side (24 Vac/dc ± 10%) to the POWER terminal.

The supply common is connected to the COMMON terminal. The device is reverse voltage protected and will not operate if

connected backwards. It has a half-wave rectied power supply so the supply common is the same as the signal common.

Several devices may be connected to one power supply and the output signals all share the same common. Use caution when

grounding the secondary of a transformer or when wiring multiple devices to ensure the ground point is the same on all

devices and the controller.

The analog output is available on the PRES OUT terminal. This signal is switch selectable for either voltage or 4-20 mA active

output. In voltage mode the output is 0-5 or 0-10 Vdc. These options are indicated on the circuit board. The current output

operates in the Active mode and does not require a loop power supply. This means the signal current is generated by the

transmitter and must not be connected to a powered input or device damage will result. Check the controller Analog Input to

determine the proper connection before applying power. Both current and voltage signals are referenced to the COMMON

terminal. The voltage output signal has a minimum load that it is able to drive, similarly the current signal has a maximum

load. Follow the ratings in the Specication section or inaccurate readings may result. See gure 7.

The RELAY output is a normally open dry contact. This signal can be used to directly control an alarm, ventilation fan or may

be connected to a digital input of the BAS for status monitoring. Ensure any loads connected to the relay is within the relay

rating in the Specication section. See gure 8.

The remote zero feature may be used by wiring a dry-contact (relay only) digital output between the ZERO IN and COMMON

terminals. Do not apply voltage to the ZERO IN terminal. See gure 9.

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

Loading...

Loading...