Greystone Energy Systems HRC Series, HRC-INS-001 Installation Instructions Manual

HRC Series RH Transmitter

Installation Instructions

Introduction

The room RH transmitter uses a highly accurate and eld-proven RH

sensor in an attractive, low prole enclosure to monitor room relative

humidity levels. Additional options include an occupancy override

button, a communication jack, a fan speed switch, a slide-pot setpoint

control, a resistive temperature sensor and a LED or LCD display. The RH

output can be selected as a linear 4-20 mA, 0-5 or 0-10 Vdc signal.

Before Installation

Read these instructions carefully before installing and commissioning

the device. Failure to follow these instructions may result in product

damage. Do not use in an explosive or hazardous environment, with

combustible or ammable gases, as a safety or emergency stop device

or in any other application where failure of the product could result in

personal injury. Take electrostatic discharge precautions during installation and do not exceed the device ratings.

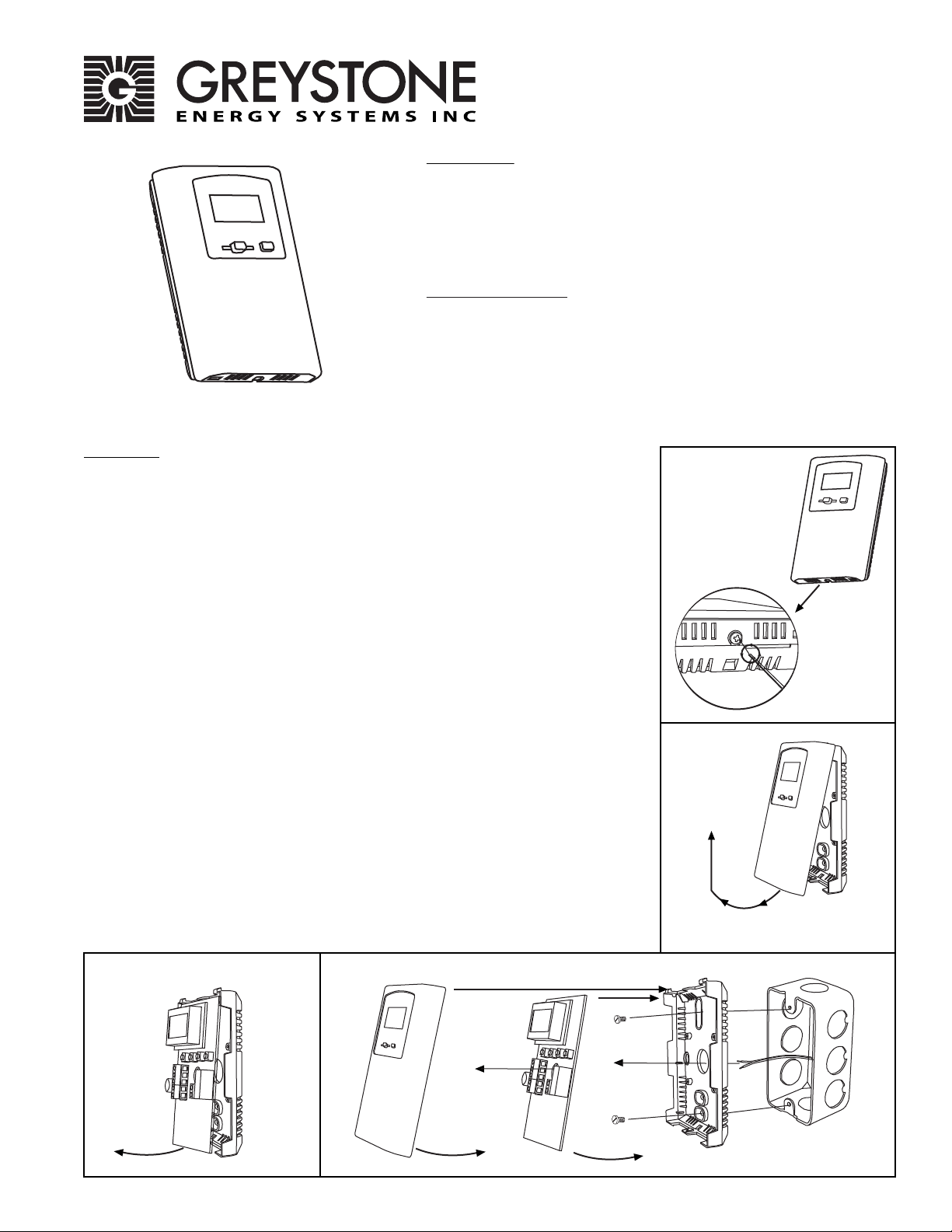

Mounting

The room RH transmitter installs directly on a standard electrical box and should be

mounted ve feet from the oor of the area to be controlled. Do not mount the sensor

near doors, opening windows, supply air diusers or other known air disturbances.

Avoid areas where the detector is exposed to vibrations or rapid temperature

changes.

The cover is hooked to the base at the top edge and must be removed from the bottom

edge rst. Use a small Phillips screwdriver to loosen the security screw as shown in

Figure 1. (Complete removal of this screw is not required). Use the screwdriver to

carefully pry each bottom corner if necessary. Tip the cover away from the base and sit it

aside as shown in Figure 2.

The PCB must be removed from the base to access the mounting holes. Follow usual

anti-static procedures when handling the PCB and be careful not to touch the sensors.

The PCB is removed by pressing the enclosure base to unsnap the latch near the bottom

edge, then the PCB can be lifted out of the base as shown in Figure 3.

Sit the PCB aside until the base is mounted on the wall. For added protection, place

the PCB in the supplied anti-static bag.

Mount the base by screwing to an electrical box or directly to the wall as shown in

Figure 4. The mounting hole locations are shown on page 3.

After the base is screwed to an electrical box or the wall using the appropriate holes,

remove the PCB from the anti-static bag, feed connection wires through center hole and

place the top of PCB into the PCB holders on backplate and snap bottom of PCB into

place as shown in Figure 4.

Make wire connections as per the Wiring Illustrations on Page 2 and install decorative

cover by placing the top of the cover into the cover holder on the top of the backplate

and snapping the bottom into place as shown in Figure 4. Tighten security screw with

a Phillips screwdriver.

Figure 1

Figure 2

Figure 3

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Figure 4

Cover PCB Backplate

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

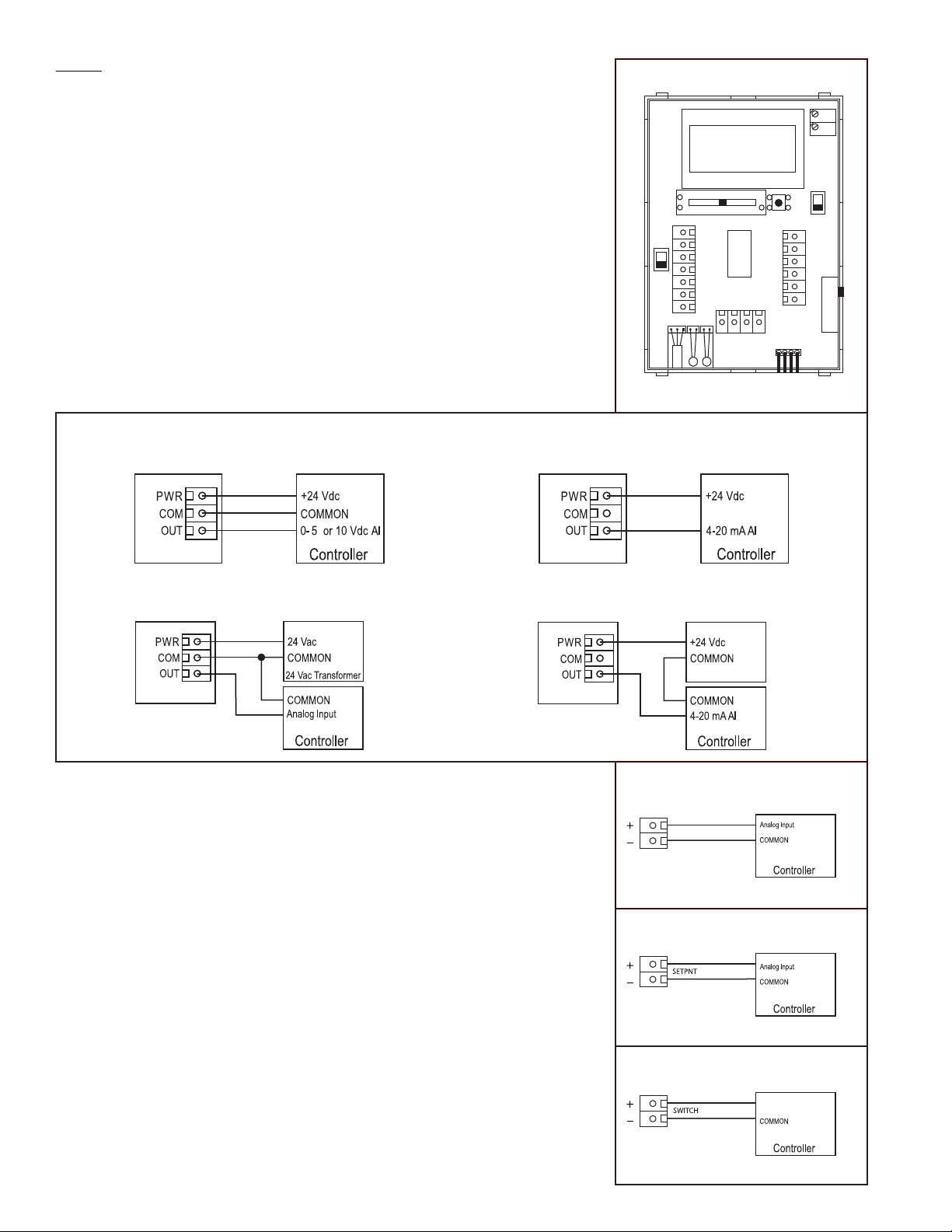

Wiring

Deactivate the 24 Vac/dc power supply until all connections are made to the device

to prevent electrical shock or equipment damage. Follow proper electrostatic

discharge (ESD) handling procedures when installing the device or equipment

damage may occur.

Use 22 AWG shielded wiring for all connections and do not locate the device wires in

the same conduit with wiring used to supply inductive loads such as motors.

Connect the cable shield to ground at the controller only. Make all connections in

accordance with national and local codes.

Connector layout is shown in Figure 5. Diagram shown includes all options. If option

is not ordered, connector will not be present.

For 4-20 mA two-wire loop-powered operation, only the POWER and OUTPUT

terminals are required if a DC power supply is used. The COMMON terminal is only

used for AC power or for a voltage output signal type. If the signal type is set to

voltage, or a 24 volt AC power supply is used, connect the positive dc voltage or the

hot side of the ac voltage to the terminal marked POWER and the power supply

common is connected to the terminal marked COMMON. The device is reverse

voltage protected and will not operate if connected backwards.

Figure 6

Wiring for voltage output signal

and 24 Vdc power from controller

Wiring for 4-20 mA loop-powered output and

external 24 Vdc power from controller

Figure 5

mA

Vdc

SETPNT +

SETPNT -

POWER

COMMON

OUTPUT

TEMP +

TEMP -

ZERO

SPAN

5v

OVERRIDE

LED +

LED -

SWITCH +

SWITCH -

FAN +

FAN -

4

123

10v

41 2 3

0001297

Wiring for all output signals and

external 24 Vac power transformer

Wiring for 4-20 mA loop-powered output and

external 24 Vdc external power supply

For three-wire voltage output operation, connect either an AC or DC power supply to

POWER and COMMON and the voltage output signal is available on the OUTPUT

terminal with respect to COMMON as shown in Figure 6.

Ensure the controller Analog Input (AI) matches the transmitter output signal type

before power is applied and that the pcb switches are set correctly for the required

signal type. The current signal has a maximum load that it will drive and the voltage

signal has a minimum load rating. Follow the ratings in the Specication section or

inaccurate readings may result.

This device has a half-wave power supply so the power supply common is the same

as the signal common. Several devices may be connected to one power supply and

the output signals all share the same common. Use caution when grounding the

secondary of a transformer or when wiring multiple devices to ensure the ground

point is the same on all devices and the controller.

The following optional features are only included if ordered. Wiring terminals are

only present for features ordered.

An optional resistive temperature sensor may also be included in the device and is

connected to the TEMP terminals as shown in Figure 7.

24 Vdc Power Supply

Figure 7

TEMP

Figure 8

Figure 9

Digital Input

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

Loading...

Loading...