Page 1

Introduction

The TTLSO single point strap-on temperature thermostat incorporates a

precision thermistor temperature sensor and provides a Form C relay output

(NO/NC) with an adjustable setpoint. The sensor is encapsulated to a 38 mm x 38

mm (1.5”x 1.5”) aluminum plate and adhered to a 38 mm x 25.4 mm (1.5 x 1“)

compressible foam. A 254 mm (10”) S/S Pipe clamp is provided to secure the

assembly to various sizes of pipe. All probes are constructed to provide excellent

heat transfer, fast response and are potted to resist moisture penetration.

Before Installation

Read these instructions carefully before installing and commissioning the

temperature thermostat. Failure to follow these instructions may result in

product damage. Do not use in an explosive or hazardous environment, with

combustible or ammable gases, as a safety or emergency stop device or in

any other application where failure of the product could result in personal

injury. Take electrostatic discharge precautions during installation and do

not exceed the device ratings.

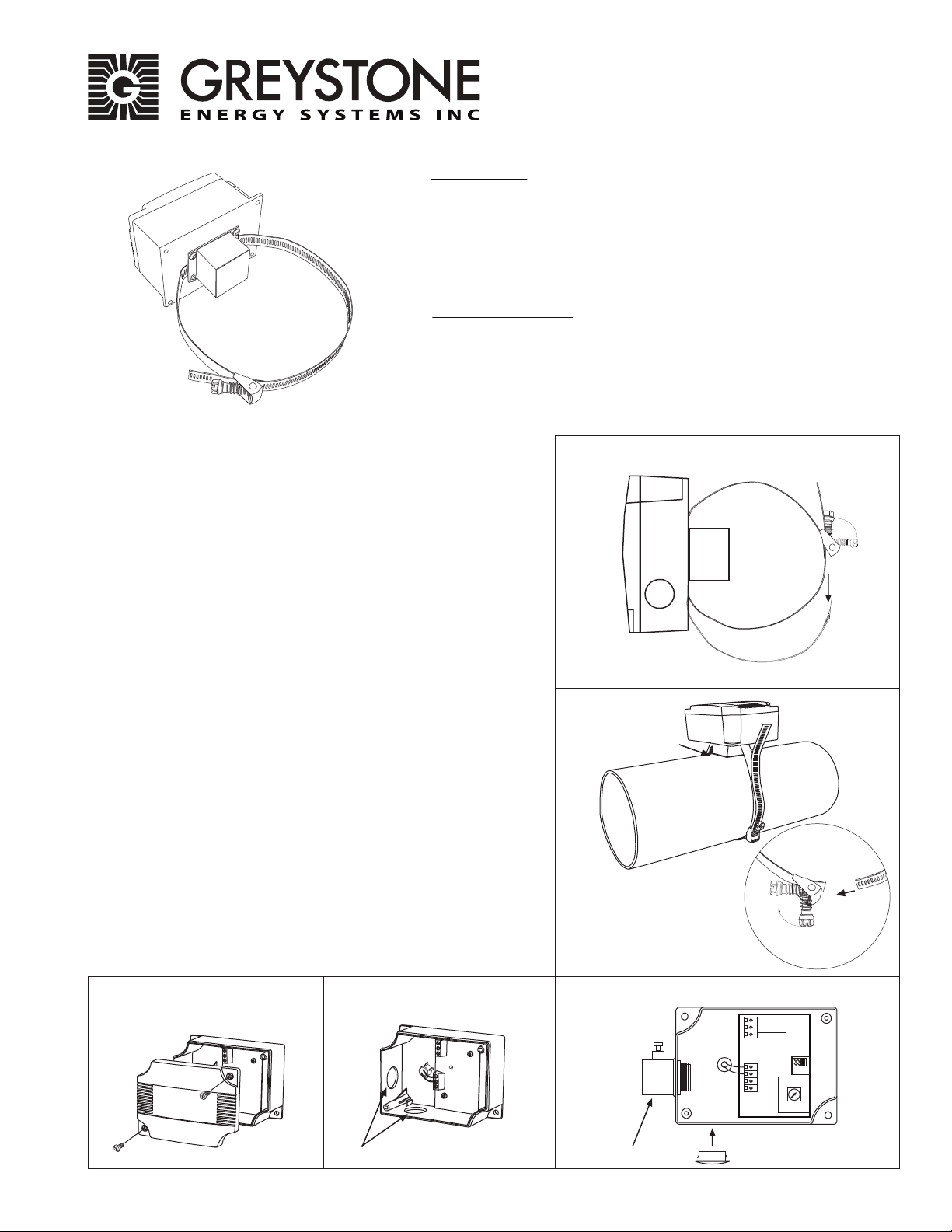

Mounting (Enclosure A)

The strap-on sensor installs directly onto any pipe where an immersion

sensor with thermowell can’t be installed.

Once a suitable spot is selected, remove a small block of insulation if

present. It is recommended that thermal compound be used to improve

heat transfer. Spread a liberal about on the pipe.

Strap-on

Temperature Thermostat

TTLSO Series

Installation Instructions

Figure 1

Open the worm gear clamp by swiveling the worm gear away from the

clamp and pull the clamp apart, as shown in Figure 1.

Place the sensor plate on the selected mounting area and wrap clamp

around the pipe. Re-insert clamp under the worm gear and pull until snug.

Lock in place by swiveling the worm gear towards the clamp. Tighten

worm gear clamp by using a standard screw driver or hex nut driver as

shown in Figure 2.

Using a Phillips screwdriver, remove the (2) screws, as shown in Figure 3.

Remove cover and set aside with screws for re-installing after wiring and

set up.

Two 21 mm (0.8125”) holes are provided for connection of either 12.77mm

(0.5” ) EMT or a cable gland style connector as shown in Figure 4. Insert the

EMT or cable gland connector through the hole and securely fasten using a

locknut. If only one connection hole is required, use the included hole cap

to cap o the unused one as shown in Figure 5. Special care must be

taken not to damage any internal components during installation.

Make wire connections as per the “Wiring” illustrations on Page 2.

Once wiring and set up are complete, re-install cover and tighten the (2)

screws using a Phillips screwdriver.

Figure 3 Figure 5Figure 4

Figure 2

Thermal Compound

DIFFERENTIAL

TEMP PWRCOM NCNO COM

EMT/Cable Gland Connection Holes

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

EMT Connector

Connection Hole Cap

HIGH

LOW

MID

Page 2

Figure 6

Figure 7

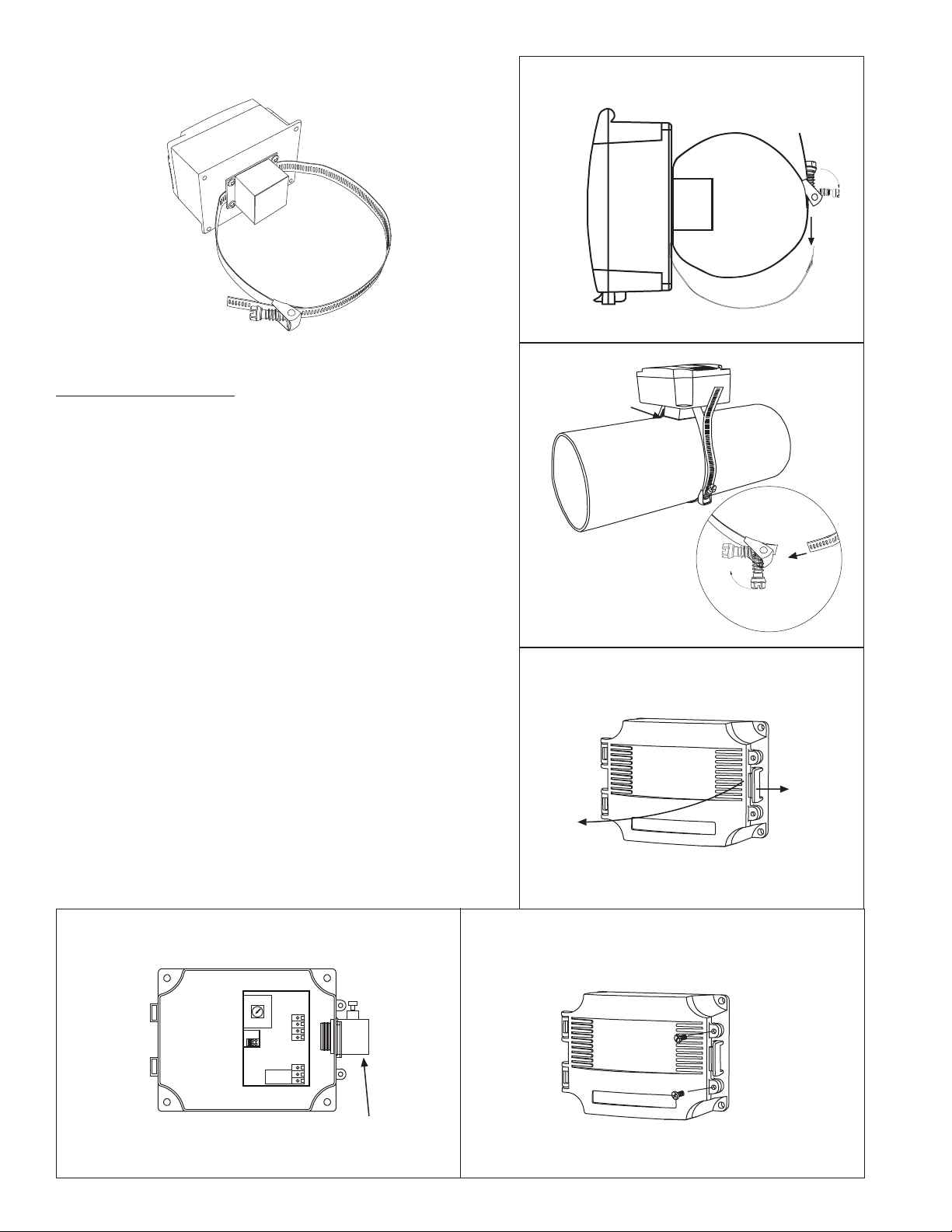

Mounting (Enclosure D)

The strap-on sensor installs directly onto any pipe where an immersion

sensor with thermowell can’t be installed.

Once a suitable spot is selected, remove a small block of insulation, if

present. It is recommended that thermal compound be used to

improve heat transfer. Spread a liberal about on the pipe.

Open the worm gear clamp by swiveling the worm gear away from the

clamp and pull the clamp apart, as shown in Figure 1.

Place the sensor plate on the selected mounting area and wrap clamp

around the pipe. Re-insert clamp under the worm gear and pull until

snug. Lock in place by swiveling the worm gear towards the clamp.

Tighten worm gear clamp by using a standard screw driver or hex nut

driver as shown in Figure 2.

The enclosure has a hinged cover with latch. Open cover by pulling

slightly on the latch on the right side of the enclosure. At the same time

pulling on the cover, as illustrated in Figure 8.

Feed conduit through the provided hole in bottom of enclosure and

secure with a lock nut as show in Figure 9. It is recommended that

weatherproof conduit or cable gland ttings be used.

Make wiring connections as per the “Wiring” illustrations on Page 2.

Swing door closed until securely latched. For added security, 2 screws

are provided that may be installed in the integrated screw tabs. See

Figure 10.

Thermal Compouind

Figure 8

Figure 9

MID

LOW

HIGH

DIFFERENTIAL

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

TEMP PWRCOM NCNO COM

EMT Connector

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

Figure 10

Page 3

Wiring

• Deactivate the 24 Vac/dc power supply until all connections are made to the device to prevent electrical shock or

equipment damage.

• Use 14-22 AWG shielded wiring for all connections and do not locate the device wires in the same conduit with

wiring used to supply inductive loads such as motors. Make all connections in accordance with national and local

codes.

• The temperature thermostat comes with the temperature sensor pre-wired to the PCB. If removal is required for

installation then it may be re-wired as shown in Figure 11.

• Pull at least six inches of control wire into the enclosure, then complete the wiring connection according to the

wire diagram for the applicable power supply as shown in Figure 12.

• Connect the DC positive or the AC voltage hot side to the PWR terminal. The supply common is connected to the

COM terminal. See Figure 12.

•The relay has both Normally Open (NO) and Normally Closed (NC) contacts available. The relay output is available

on the NO/COM/NC terminal. Make connections before applying power as shown in Figure 13.

• The setpoint dierential has 3 jumper selectable settings (Low/Mid/High) Set jumper to desired dierential as

shown in Figure 14.

• To set the switching setpoint, turn the setpoint potentiometer to the desired temperature setting as shown in

Figure 15.

• Once all connections settings are made and checked, power can be applied.

Figure 11

Temperature sensor wiring to PCB

(Factory Wired)

TEMP

Figure 12

Power Supply Wiring

No Polarity

Temperature

Sensor

DIFFERENTIAL

TEMP PWRCOM NCNO COM

HIGH

LOW

MID

Figure 13

Relay Output Wiring

NO

NC

NO

NC

24 Vdc Power Supply

Digital

Input

Figure 14 Figure 15

24 Vdc Power Supply

Setpoint Adjustment

SETPOINT

Specication:

Power Supply.......................12 to 28 Vac/dc

Consumption.......................50 mA max

Relay Contacts.....................SPDT, Form C contacts (N.O. and N.C.)

5 Amps @ 30 Vdc/250 Vac resistive

1.5 Amps @ 30 Vdc/250 Vac inductive

Relay Action..........................Activates on temperature fall

Setpoint Operation............Single-turn knob-pot on pcb

Adjustable Setpoint...........-4 to 10˚C (25 to 50˚F)

Setpoint Temperature ...... Low/Mid/High jumper selectable

Dierential 1.1/2.8/5.6 °C (2/5/10 ˚F)

Temperature Sensor..........10K ohm curve matched

precision thermistor

Sensor Accuracy..................±0.2˚C, 0 to 70˚C (±0.36˚F, 32 to 158˚F)

Probe Sensing Range ....... .-20 to 105 ˚C (-4 to 221 ˚F)

Probe Material ....................Aluminum plate

w/ compressible foam backing

Probe Diameter......... ..........38 mm (1.5”) square

Wire Material........................ PVC insulated, parallel bonded

Operating Conditions.......-10 to 50˚C (14 to 122˚F),

5 to 95% RH non-condensing

Storage Conditions............-30 to 70˚C (-22 to 158˚F),

5 to 95%RH, non-condensing

Enclosure............................... (A) ABS, UL94-5VB, IP61 (NEMA 2)

(D)-ABS, UL94-5VB, IP65 (NEMA 4X)

Wiring Connections...........Screw terminal block

(14 to 22 AWG)

Setpoint Dierential Setting

DIFFERENTIAL

HIGH

MID

LOW

HIGH - 5.6C/10F

MID = 2.8C/5F

LOW = 1.1C/2F

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

Page 4

Dimensions:

Enclosure A

53.6 mm

2.110 “

Compressible Foam

Quick release

115.8 mm

4.56 “

Enclosure D

145 mm

5.7 “

64 mm

2.5 “

1.125 “

28.58 mm

2X Ø 0.850”

28.58 mm

1.125 “

38.1 mm (1.5”)

Aluminum Plate

Compressible Foam

38.1 mm (1.5” )

Aluminum Plate

254 mm (10”)

S/S Pipe Clamp

Quick release

114.3 mm

4.5 “

84.3 mm

3.320 “

88.9 mm

3.5 “

100 mm

3.95 “

Ø 0.850”

10”S/S Pipe

Clamp

TTLSO-INS-001 06/16

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

PRINTED IN CANADA Copyright © Greystone Energy Systems Inc. All Rights Reserved

Loading...

Loading...