Greyline ISM 5.0 User Manual

www.greyline.com

USER'S GUIDE

Installation & Operation

Instructions

Insertion Magmeter

Model ISM 5.0

Manual Series 1.2

Note: This page has been left blank intentionally.

ISM 5.0 INSERTION MAGMETER

Installation and Operation Guide

www.greyline.com

Page 2

SAFETY INFORMATION

Messages identified as “Caution” contain information regarding potential damage to the

product or other ancillary products.

Messages identified as “Important Note” contain information critical to the proper operation of

the product.

Messages identified as “Warning” contain information regarding the personal safety of

individuals involved in the installation, operation or service of this product.

! i !

This meter was calibrated at the factory before shipment. To ensure correct use of the meter, please read

this manual thoroughly.

Regarding this Manual:

•

This manual should be passed on to the end user.

•

Before use, read this manual thoroughly to comprehend its contents.

•

The contents of this manual may be changed without prior notice.

•

All rights reserved. No part of this manual may be reproduced in any form without

GREYLINE’s written permission.

•

GREYLINE makes no warranty of any kind with regard to this material, including, but

not limited to, implied warranties of merchantability and suitability for a particular

purpose.

•

All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors are found, please inform GREYLINE.

•

GREYLINE assumes no responsibilities for this product except as stated in the warranty.

•

If the customer or any third party is harmed by the use of this product, GREYLINE

assumes no responsibility for any such harm owing to any defects in the product which

were not predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of installation,

operation, service, and repair of this product. Failure to comply with these precautions or with

specific WARNINGS given elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the product. GREYLINE Instruments assumes no liability for the

customer’s failure to comply with these requirements. If this product is used in a manner not

specified in this manual, the protection provided by this product may be impaired.

The following symbols are used in this manual:

WARNING

CAUTION

IMPORTANT NOTE

Page 3

1.1

2.1

3.1

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................................ 4

1.2

PURPOSE OF THIS GUIDE ..................................................................................................................... 4

1.3

TYPICAL INSERTION ELECTROMAGNETIC FLOW METER .................................................... 4

1.4

STANDARD FEATURES AND SPECIFICATIONS ......................................................................... 5

1.5

ADDITIONAL REQUIRED HARDWARE ................................................................................................. 5

1.6

ADDITIONAL HARDWARE THAT MAY BE REQUIRED .......................................................... 6

1.5.1 Grounding Rings ................................................................................................................................... 6

UNPACKING ......................................................................................................................................................................... 7

2.2

CHECKING THAT YOU HAVE RECEIVED EVERYTHING .............................................................. 7

INSTALLATION, REMOVAL & ADJUSTMENT ................................................................................................. 8

3.2

INSTALLATION SITE SELECTION .................................................................................................... 8

3.3

MECHANICAL INSTALLATION ................................................................................................................... 10

3.3.1

Installation Kit ................................................................................................................................... 11

3.3.2

GREYLINE Standard Installation Hardware Kit ................................................................. 11

4.1

3.3.3

GREYLINE Hot Tap Installation Hardware Kit ................................................................... 11

3.3.4

Customer Supplied Installation Hardware ........................................................................... 12

3.3.5

Confirming the Stack Height ....................................................................................................... 13

3.3.6

Installing Grounding Rings .......................................................................................................... 14

3.3.7

Installing the Flow Meter ............................................................................................................. 15

3.4

INSERTION OF THE METER .............................................................................................................. 16

3.4.1

Inserting the Flow Meter ............................................................................................................... 16

REMOVAL OF THE

3.5

WIRING CONNECTIONS ...................................................................................................................... 18

3.5.1

3.5.2

START-UP & COMMISSIONIING FOR GREYLINE INSERTION ELECTROMAGNETIC FLOW

METERS..................................................................................................................................................................... 21

4.2

HELPFUL HINTS FOR START-UP AND COMMISSIONING ................................................. 21

4.3

START-UP AND COMMISSIONING ................................................................................................ 22

4.4

START-UP AND COMMISSIONING WORKSHEET .................................................................. 23

METER……………………………………………………………………………………………………… 17

Signal and Power Wiring Connections ................................................................................... 18

Earth Connection ............................................................................................................................. 20

4.5

TROUBLESHOOTING GUIDE ............................................................................................................. 24

4.4.1 Earth Connections & Electrical Noise Reduction ................................................................. 24

APPENDIX

Conditions of Sale …………………………………………………………………………………………………………………26

Applications Hotline ……………………………………………………………………………………………………………..27

Product Return Procedure …………………………………………………………………………………………………….27

Page 4

water and steam systems, according to their individual trades. Death or permanent injury may

result from accidents with these systems.

!

SECTION 1.0: INTRODUCTION

We, at GREYLINE Instruments, would like to thank you for purchasing our quality American made

ISM 5.0 Insertion Magmeter. As our valued customer, our commitment to you is to provide

reliable service, while continuing to offer you quality products to meet your growing flow

measurement needs.

1.1 PURPOSE OF THIS GUIDE

fast

We have written this guide to provide the persons responsible for the installation, operation and

maintenance of your flow meter with the most specific equipment information they will need.

This is NOT an electrical or plumbing trade manual.

WARNING

Please do not permit persons to install, operate or maintain this equipment unless they have a

This guide is the basic reference tool for all GREYLINE ISM 5.0 Insertion Magmeters. If you have

not purchased all of the options, there will be references in this manual which are not applicable

to your meter(s).

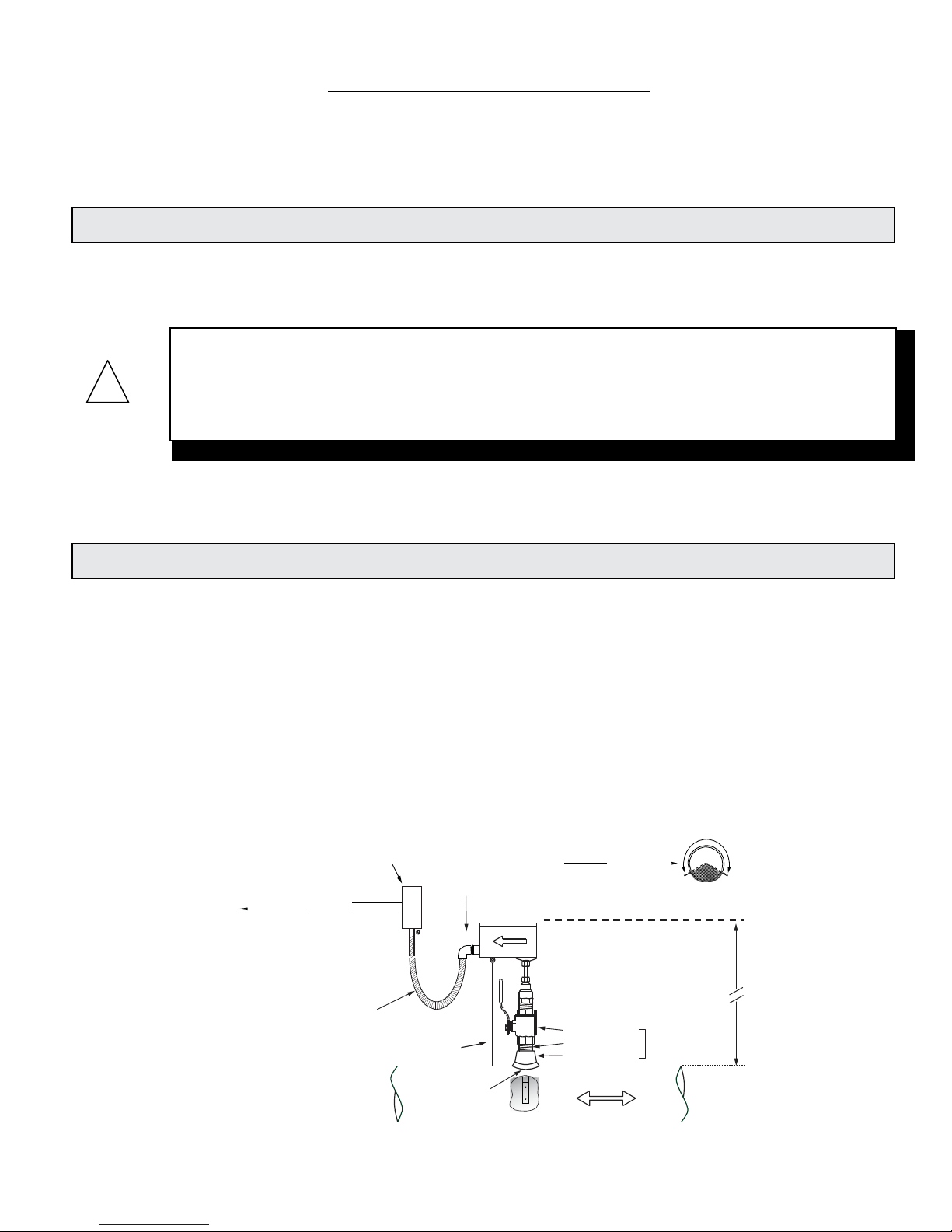

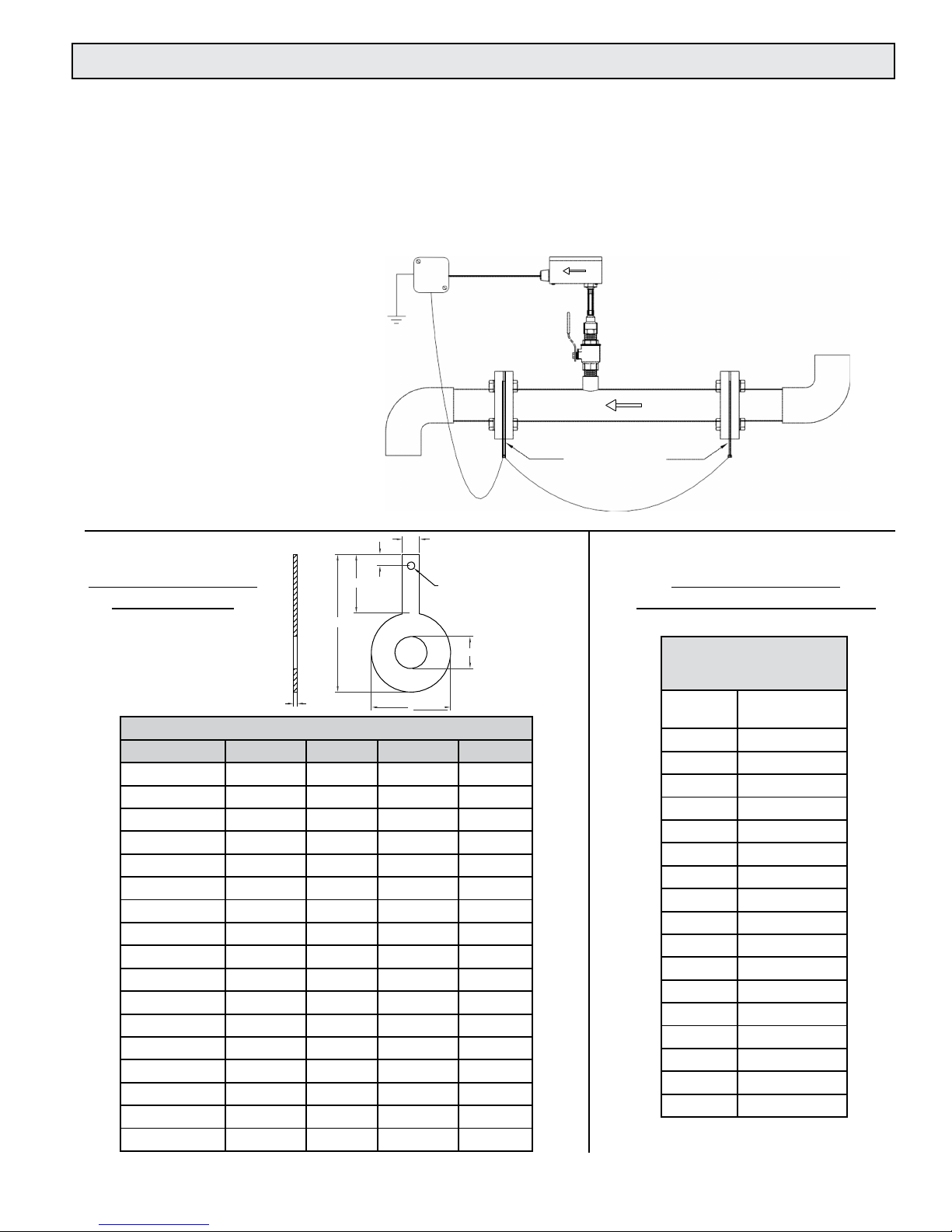

1.2 TYPICAL INSERTION ELECTROMAGNETIC FLOW METER

Faraday’s Law of electromagnetic induction states that a voltage will be induced in a conductor

when it passes through a magnetic field, and the induced voltage will be directly proportional to

the velocity of the conductor.

GREYLINE ISM 5.0 Insertion Magmeters generate pulsating magnetic fields that are used to induce

a voltage into the conductive fluid flowing through the pipe. Electrodes located on the flow meter

sensor head measure the induced voltage. Circuitry within the flow meter electronics

then converts the voltage to digital and analog signals that convey flow rate and total data via

connecting the cable to any of GREYLINE’s display devices, Btu meters and/or to a data

acquisition system.

complete knowledge of their trade skills and are competent to work on high pressure hot and cold

Typical Meter Installation

(New construction or scheduled shutdown)

Output sign al(s)

to control

system

Greyline

Displa y or

BTU Meter

(Optional )

Allow enough slack

in the flexibl e liquidtight conduit to

permit th e meter to

be remov ed

from the val ve.

Custom er provided

conduit and adapters

Note: Installati on kits vary based on pipe material and application. For install ations in pressurized (live)

systems, use "Hot tap" 1¼ inch installation kit and drill hole using a 1 inch wet tap drill.

½" FNPT

conduit connection

Insertion depth

gage provided

with ea ch meter

Minim um Hole Size = 1"

Must be centered

•

Install in vertical or horizontal pipe

•

For horizontal pipe position meter

anywhere in upper 240˚

Standard Installatio n

Kit for Steel Pipe

1" Full port bal l valve

1" Close nippl e

1" Branch outl et

FLOW

FOR INSTALLATION

1¼" for

hot tap

CLEARANCE

REQUIRED

Typically

30" - 40"

dependi ng on

pipe size and

height of v alve

assembly.

enclosure

Page 5

1.3 STANDARD FEATURES AND SPECIFICATIONS

Accuracy

Sensing Method

Pipe Size Range

± 1.0% of reading from 2 to 20 ft/sec

± 0.02 ft/sec below 2 ft/sec

Electromagnetic, no moving parts

3” through 72” nominal

Input Power

20 - 28 VAC 50/60Hz, 250 mA maximum

20 - 28 VDC, 250 mA maximum

Liquid Temperature Range

15° to 250° F

Ambient Temperature Range

-5° to 150° F

Operating Pressure

400 PSI maximum

Pressure Drop

Less than 0.1 psi at 12 ft/s velocity in 3” and larger pipes

Materials of Construction

Wetted metal components - 316L stainless steel

Sensor head - Polystyrene

Electronics enclosure - Powder coat painted cast aluminum

Enclosure Rating

Watertight, airtight, dust proof powder coated cast aluminum.

Electrical Connections

25’ of PVC jacketed cable with ½” NPT conduit connection

Output Signal(s)

Analog output (Isolated), selectable 4-20 mA, 0-10 V or 0-5 V

Frequency output, 0-15 V peak pulse, 0-500 Hz maximum

Scalable pulse output, isolated dry contact, contact rating 50 VDC @ 100 mA

maximum, pulse duration: 0.5, 1, 2 or 6 seconds

This product is covered by one or more of the following patents: 6,431,011 and 6,463,807.

1.4

ADDITIONAL REQUIRED HARDWARE

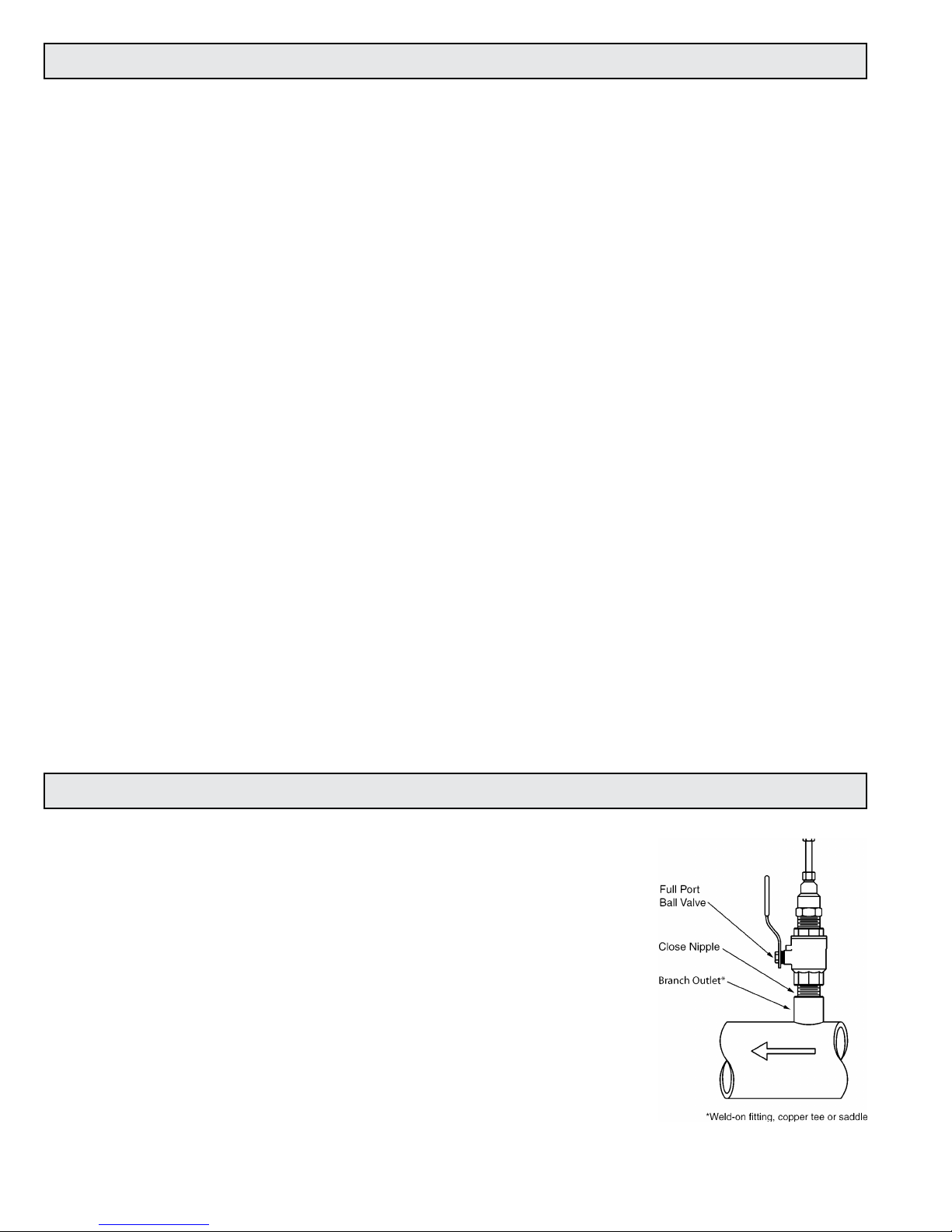

All GREYLINE insertion type meters can be installed and removed via

a 1” or larger full port ball valve without system shutdown. The terms

“Standard” and “Hot Tap” refer to the installation method of the

isolation valve kit only.

Standard Installation Hardware: For new construction or scheduled

shutdown; once kit is installed, the flow meter can be installed

or removed without system shutdown.

Hot Tap Installation Hardware: For applications which require the

access hole in the pipe to be drilled through the valve using a

wet tap drilling machine while the hydronic system is

pressurized and operating.

NOTE: Installation hardware materials vary greatly based on pipe

material, pipe size and standard vs. hot tap versions.

Page 6

5/8

3/8

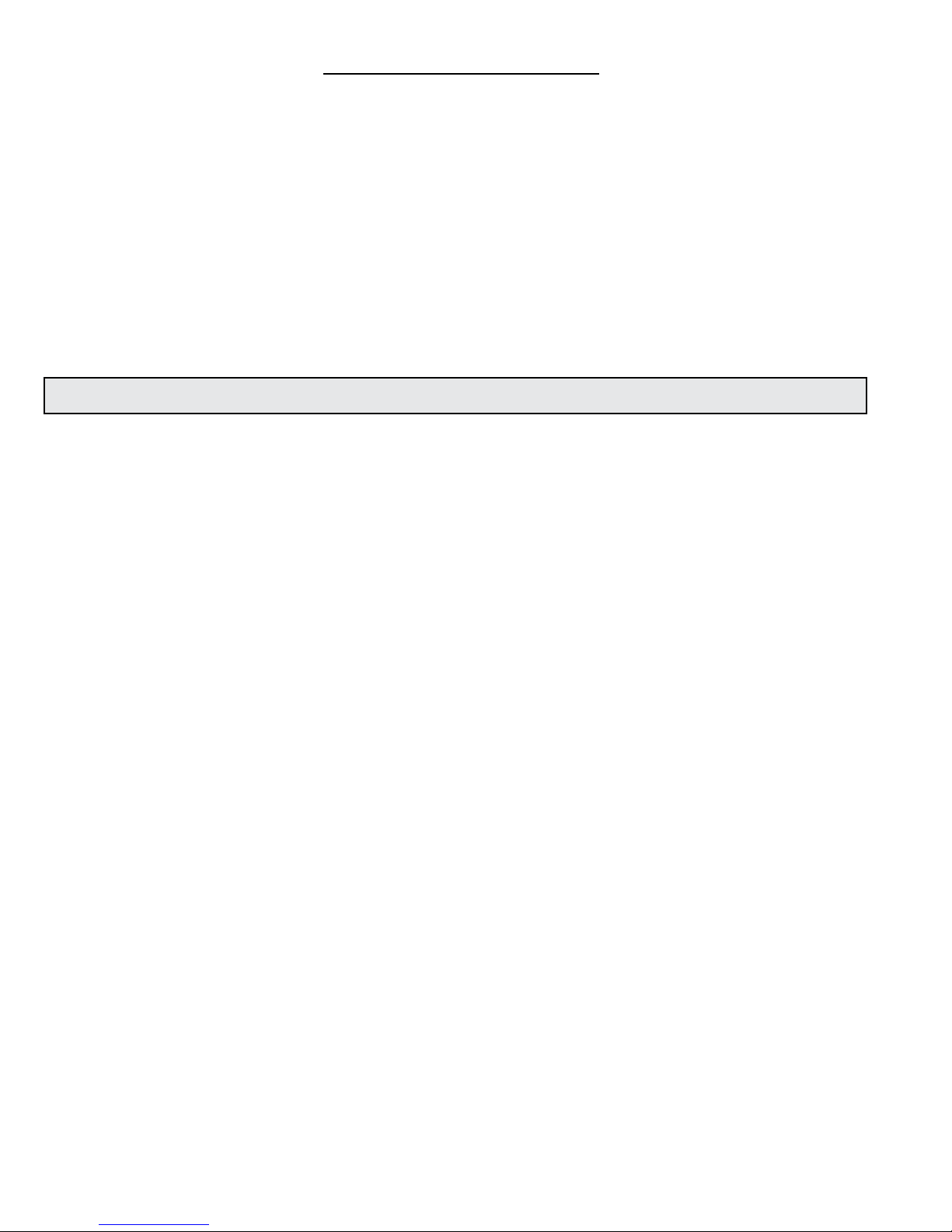

GROUNDING RING

DIMENSIONS

D

1/4

GROUNDING RING

ORDERING INFORMATION

C

Bore

1/8”

A

ANSI Class 150

316 Stainless Steel

Grounding Rings (pair)

Nominal

Size

GREYLINE

Part 1” 19265

1½” 19266

2” 19267

3” 19268

4” 19269

6” 19270

8” 19271

10” 19272

12” 19273

14” 19274

16” 19275

18” 19276

20” 19277

24” 19278

30” 19279

36” 19280

42” 19281

Grounding Rings

Grounding Ring Dimensions

Nominal Size

Bore A C D

1”

1 - 1/16

2 - 5/8

4 - 9/16

1 - 15/16

1.5”

1 – 9/16

3 – 3/8

5 - 5/16

1 - 15/16

2”

2 – 1/16

4 – 1/8

6 - 1/16

1 - 15/16

3”

3 – 1/16

5 – 3/8

7 - 5/16

1 - 15/16

4”

4 – 1/16

6 – 7/8

8 - 13/16

1 - 15/16

6” 6

8 – 3/4

10 - 11/16

1 - 15/16

8” 8

11

12 - 15/16

1 - 15/16

10”

9 – 1/2

13 – 3/8

15 - 5/8

2 - 1/4

12”

11 – 9/16

16 – 1/8

18 - 9/16

2 - 7/16

14”

13 – 1/2

17 – 3/4

20 - 3/8

2 - 5/8

16”

15 – 1/4

20 – 1/4

22 - 7/8

2 - 5/8

18”

17 – 3/8

21 – 5/8

24 - 1/4

2 - 5/8

20” 19

23 - 7/8

26 - 11/16

2 - 13/16

24” 23

28 – 1/4

31 - 1/8

2 - 7/8

30” 29

34 – 3/4

38

3 - 1/2

36” 35

41 – 1/4

45 - 1/4

4

42” 41

48

52 - 1/2

4 - 1/2

1.5 ADDITIONAL HARDWARE THAT MAY BE REQUIRED

1.5.1 Grounding Rings

Grounding rings may be required whenever meters are installed in non-metallic or lined pipes.

Grounding rings placed before and after the meter eliminate electrical noise that will interfere

with the proper operation of the meter. GREYLINE provides grounding rings as an optional

accessory. Grounding ring dimensional information and part numbers are listed below. For proper

operation, grounding rings are required before and after the meter.

Typical Installation

Non-conductive Pipe

Page 7

SECTION 2.0: UNPACKING

GREYLINE insertion magnetic flow meters are packed and shipped in individual cartons. An optional

installation hardware kit INSTL 1 or INSTL 2, if ordered, will be packaged with each meter. All other

installation hardware and peripheral devices, including Btu meters and display modules, will be

packaged and shipped separately.

Please open all packages with care to prevent damage to their contents. Carefully inspect each item for

signs of damage in transit. The flow meter stem should be straight and free of blemishes or abrasions.

The sensor head should have a smooth continuous surface that is free of abrasions.

All GREYLINE products are shipped insured unless the customer specifically requests otherwise.

Please notify the shipping company and GREYLINE immediately if any items are damaged in transit.

Save all

2.1

packing material for inspection by the shipper.

CHECKING THAT YOU HAVE RECEIVED EVERYTHING

Standard Documentation

Enclosed with each meter is a comprehensive documentation package that includes the

following items:

Installation and Operation Guide

Flow Meter Certificate of Calibration

Please notify GREYLINE if any of these documents are missing.

ISM 5.0 Insertion Magmeter Flow Meters

Optional INSTL1 or INSTL2 Installation Hardware Kit, if ordered

Loading...

Loading...