Gresham GD10 Maintenance Instructions Manual

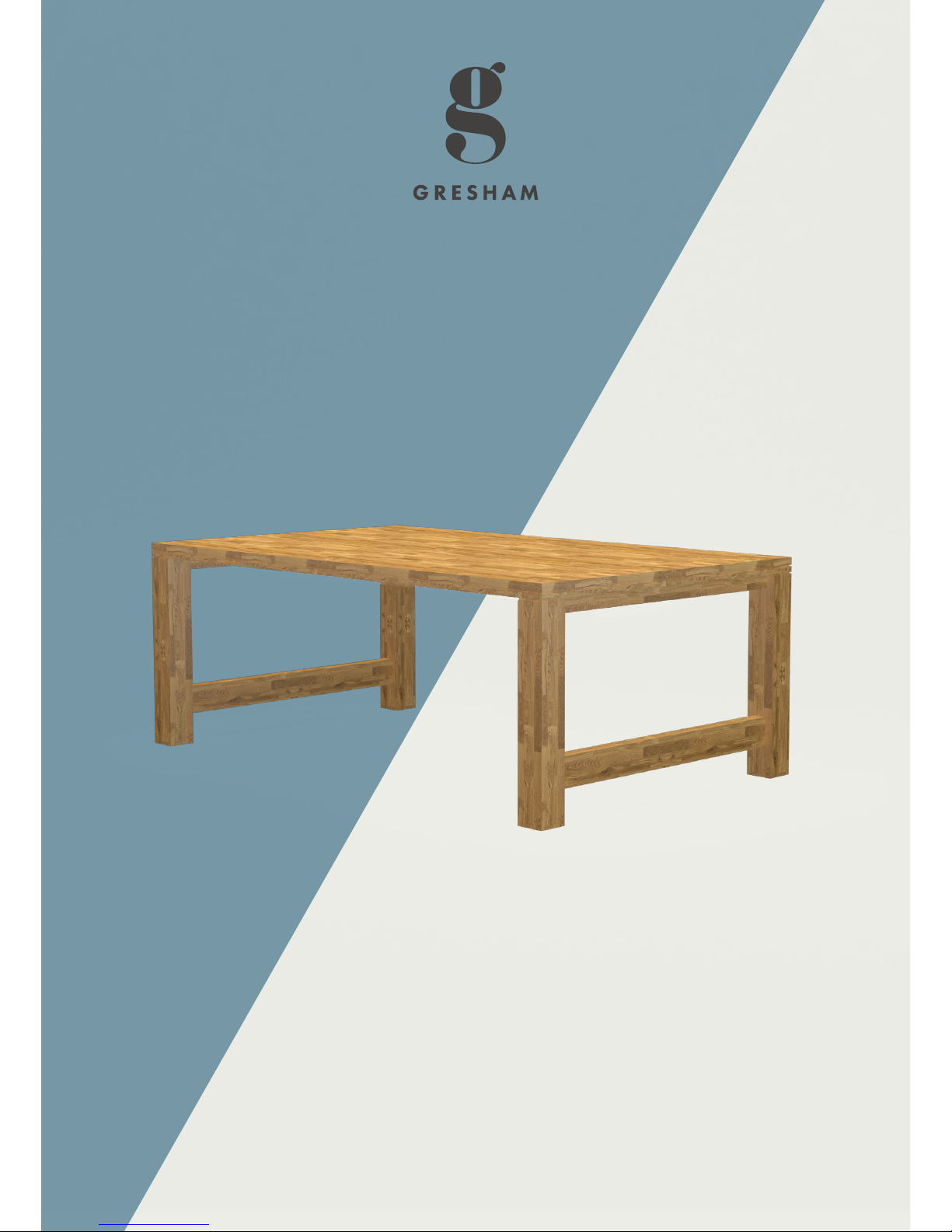

GD10 TABLE

CARE AND MAINTENANCE INSTRUCTIONS

• Regular gentle dusting will help maintain the surface of the

furniture. Always use a nonabrasive, lint free cloth.

• When cleaning or lightly buffing, move the cloth in the direction

of the wood grain.

• When necessary, a non-abrasive, lint-free cloth slightly

dampened in warm, clean water can be used to carefully remove

dirt. In extreme cases, warm soapy water or a mild washingup liquid / water solution can be used. However, avoid pooling

water. The furniture must be immediately dried with a clean, dry,

non-abrasive, lint free cloth. Either dab the moist areas with a

cloth or move it in the direction of the grain.

• All spillages must be removed immediately. Water or any

moisture must not be allowed to settle on the surface as this

may penetrate the oil finish and result in a ‘watermark’ within the

wood.

• Do not use neat, strong cleaning fluids or abrasive materials as

these may affect the surface coating or wood beneath and result

in an uneven, patchy finish.

• Do not use silicon, oil based or wax polishes as these may leave

an uneven surface residue which will discolour the wood finish

and may result in further damage.

• If attempting to clean a product using anything other than a

dusting cloth or with cleaning products, it is recommended that

the process is first trialled in a small, discreet area to ensure no

damage or discolouration occurs.

• Though more durable than veneered products, solid wood

furniture should be positioned to avoid direct sunlight as this

may bleach the wood and change its colouring / shading

unevenly.

• Avoid direct sunlight, radiators, humidifiers, fireplaces or

positions where there are successive changes in temperature

that may affect the wood’s moisture content and result in uneven

warping of the wood components.

• It is recommended that coasters are used with extremely hot,

cold or damp objects rather than placing them directly on to

the GD10 surfaces. However, anything left on the surface for a

considerable amount of time may result in permanent shadowing

beneath due to the affect of both natural and artificial light

bleaching the wood.

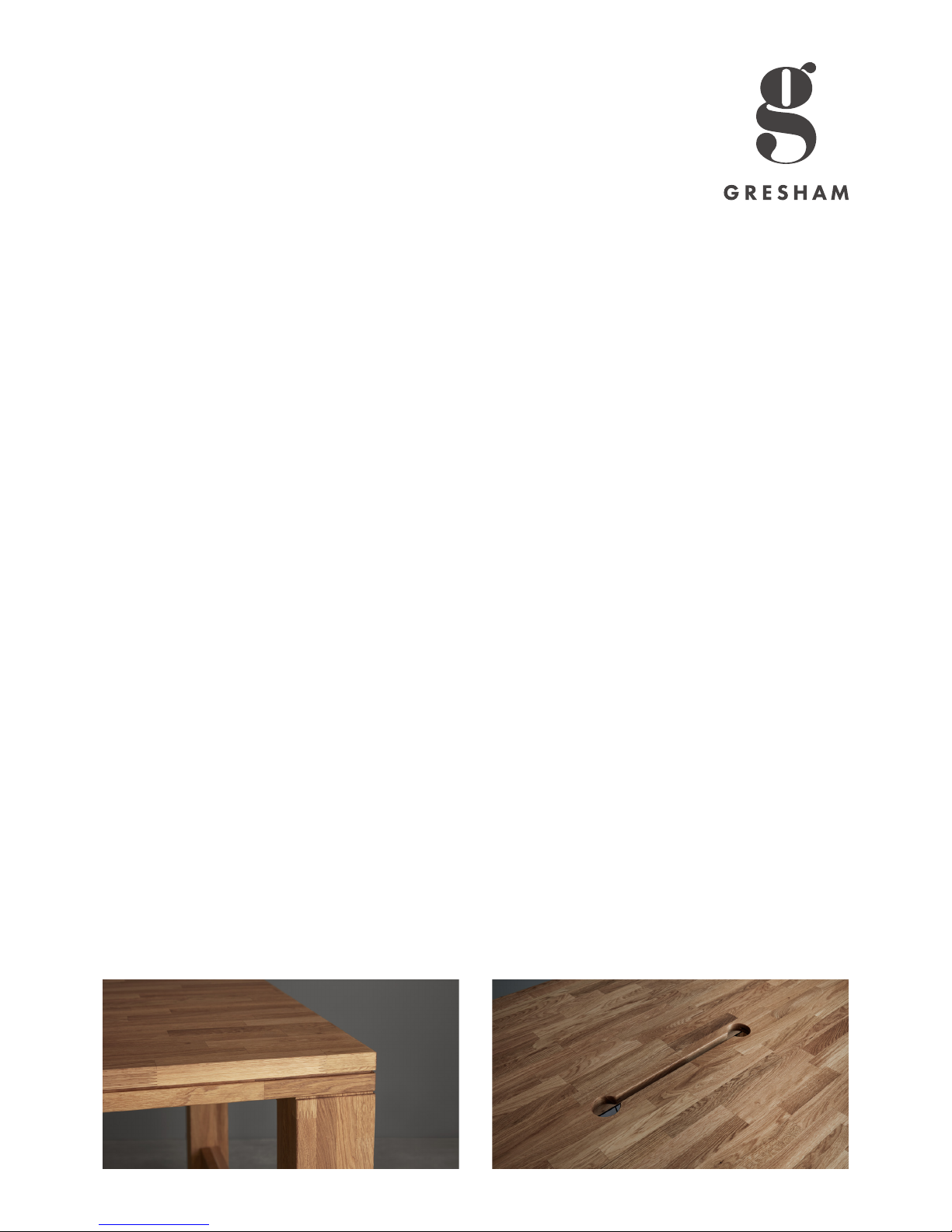

• A periodic re-application of the Tung oil is recommended to

refresh the look of your GD10 product and maintain its durability.

Alternative oils, such as ‘Linseed’ could be used, however, Tung

oil resists liquids and is less susceptible to mould than other oils.

Also, Tung oil completely dries, leaving clean surfaces whilst

other oils never fully harden and transfer a residue on to clothing.

• GD10 products have been designed for assembly on site.

As such, it is recommended that the assembly fittings are

periodically checked and re-tightened, as necessary.

GD10 CARE & MAINTENANCE

GD10 products are manufactured using engineered solid wood oak for consistency of strength

and dimensions. Pre-machined staves are finger-jointed and laminated together using waterbased adhesives and resulting in the distinct ‘block board’ appearance. Being manufactured

from a naturally occurring material means that each piece is unique, and no two pieces will be

the same in depth and shade of colour or grain detail. As part of the manufacturing process,

GD10 products are finished by successive coats of Tung oil. This is a naturally occurring

oil which is produced from the seeds of the Tung tree, which when applied results in a near

transparent coat which hardens upon exposure to air and deepens; enhancing the shades

within the wood grain. This coating helps to resist liquid ingress and staining, as well as

abrasion caused by dirt in the normal office environment, however, it is not impervious, like a

lacquered finish. To ensure your products are maintained to the standard in which they were

installed, it will be necessary to follow a few simple steps:

Loading...

Loading...