GREN EG-HOLZ 25, EG-HOLZ 50 Installation And User Instruction Manual

Installation and usage instruction manual

BOILERS FOR WOOD GASIFICATION

EG-HOLZ 25/50kW

Edition 2 from year 2014

1

INTRODUCTION

Dear Sir/Madam, Dear Customer,

We would like to welcome you among the happy users of boilers made by GREŃ

Company. The device is a product of long and thorough research. The use and

installation require special attention and following the requirements that follows.

This instruction manual was constructed in the most complete way and allows for

proper boiler installation, its maintenance and usage that give maximum satisfaction.

It is necessary to read and understand the following instruction manual and in case of

any doubts please contact the person who installed the boiler or directly with the

GREŃ Company.

During installation and starting of the boiler it is absolutely necessary to ensure all

safety measures are kept, double-check any steps and points that require it and

make sure that the boiler is not subjected to any damage or destruction of the boiler

or any part of the equipment as these types of damages or destruction is not covered

by the warranty.

Expecting that all future guidelines listed in this instruction will be meticulously

followed we are proud to include you as our customers.

2

5 Main rules that must be absolutely followed:

1) 1 Use only timber not longer than 50cm with big diameter and excluding any

other biomass.

2) It is forbidden to make any changes to the construction or settings of the

boiler.

3) It is necessary to follow the instruction regarding maintenance and loading of

the combustion chamber to the letter.

4) The boiler must always have the main water feed connected and be

connected with the installation that will receive the heat (Central Heating or

Hot Sanitary Water system) otherwise it might be cause of overheating which

might result in material damage or injury.

5) Before the boiler is started it is necessary to check if the boiler room is

properly ventilated and that exhaust and intake ducts are free of any

obstruction.

Users’ responsibilities:

- Usage and maintenance of the boiler are the user’s obligation and he is fully

responsible.

- Not following the instruction manual might result in interference with boiler

operation, insufficient efficiency and shortened life-span.

- The boiler use should be done only by persons physically and mentally fit.

3

Table of contents

5 Main rules that must be absolutely followed:..........................................................................3

1. BOILER INSTALLATION....................................................................................................5

1.1 CONDITIONS TO EMBED THE BOILER:...................................................................5

2. CHARACHTERISTICS OF THE BOILER...........................................................................6

2.1 PHYSICAL CHARACHTERISTICS..............................................................................6

2.2 HYDRAULIC SYSTEM CHARACHTERISTICS.........................................................7

2.3 SAFETY AND CHIMNEY..............................................................................................7

2.4 ELECTRICAL SYSTEM CHARACHTERISTICS........................................................8

2.5 MOTOR CHARACHTERISTICS.................................................................................10

2.6 WATER CIRCUIT PUMP.............................................................................................10

2.7 STB:................................................................................................................................10

3. STARTING THE BOILER...................................................................................................10

3.1 CONNECTIONS:...........................................................................................................10

3.2 HYDRAULIC CICRUIT CONNECTIONS SCHEME.................................................11

3.3 STARTING AND STOPPING THE BOILER:.............................................................13

3.4 WOOD:..........................................................................................................................14

3.5 GENERAL VERYFICATION:......................................................................................14

3.6 REMOVING OF ASH:..................................................................................................15

3.7 TURBULATORS:..........................................................................................................15

3.8 EXHAUST PIPE:...........................................................................................................15

4. UPKEEP AND MAINTENANCE OF THE BOILER:........................................................16

4.1 UPKEEP AND USE OF THE BOILER:.......................................................................16

4.2 MAINTENANCE OF THE BOILER:...........................................................................17

Example of the name plate of the EG-Holz boiler:..............................................................18

4.3 TROUBLESHOOTING:................................................................................................19

WARRANTY CARD...............................................................................................................20

NOTES......................................................................................................................................22

4

1. BOILER INSTALLATION

Responsibilities of the mounter:

The installation of the boiler must be done by a qualified mounter according to all

applicable laws.

The installers’ responsibility is to follow all instructions provided by boiler

manufacturer as well as to the instruction manual and installation guide of the boiler

and assisting equipment as well as to the hydraulic system schematics.

The mounter will be held responsible for any discrepancy in the installation.

1.1 CONDITIONS TO EMBED THE BOILER:

a) Boiler characteristics

Class: 4 according to the European Standard EN 303-5:2012;

Hydraulic requirements: test pressure 5 bar (0,5 MPa), max working pressure

of the system: 2 bar (0,2 MPa).

rotation: :

the power of the boiler must exceed or be equal to the max:

Heat acceptance (amount of heat required to heat up the rooms)

Transport loss, production of water for sanitary purposes, etc.)

b) The room in which the boiler will be placed:

The boiler must be placed in a room that is a separate space with air temperature of

no less than 15 dg. Of C.

The room must comply with all laws and regulations. Such room should be properly

prepared and equipped in sufficient ventilation. In order to facilitate easier

maintenance of the boiler and its parts it is necessary to ensure sufficient space

around and above the boiler.

WARNING: The warranty of the whole system is void in case the boiler or any part of

the equipment that can cause damage or destruction (chlorine, acid, too high

humidity).In case of any doubts please contact the producer.

5

c) Boiler placement:

It is necessary to ensure 50cm of free space on the side of the boiler, 80cm at the

back and 100cm on the front to facilitate the loading of the boiler with timber and

conduct maintenance.

2. CHARACTERISTICS OF THE BOILER

2.1 PHYSICAL CHARACTERISTICS

a) Boiler weight:

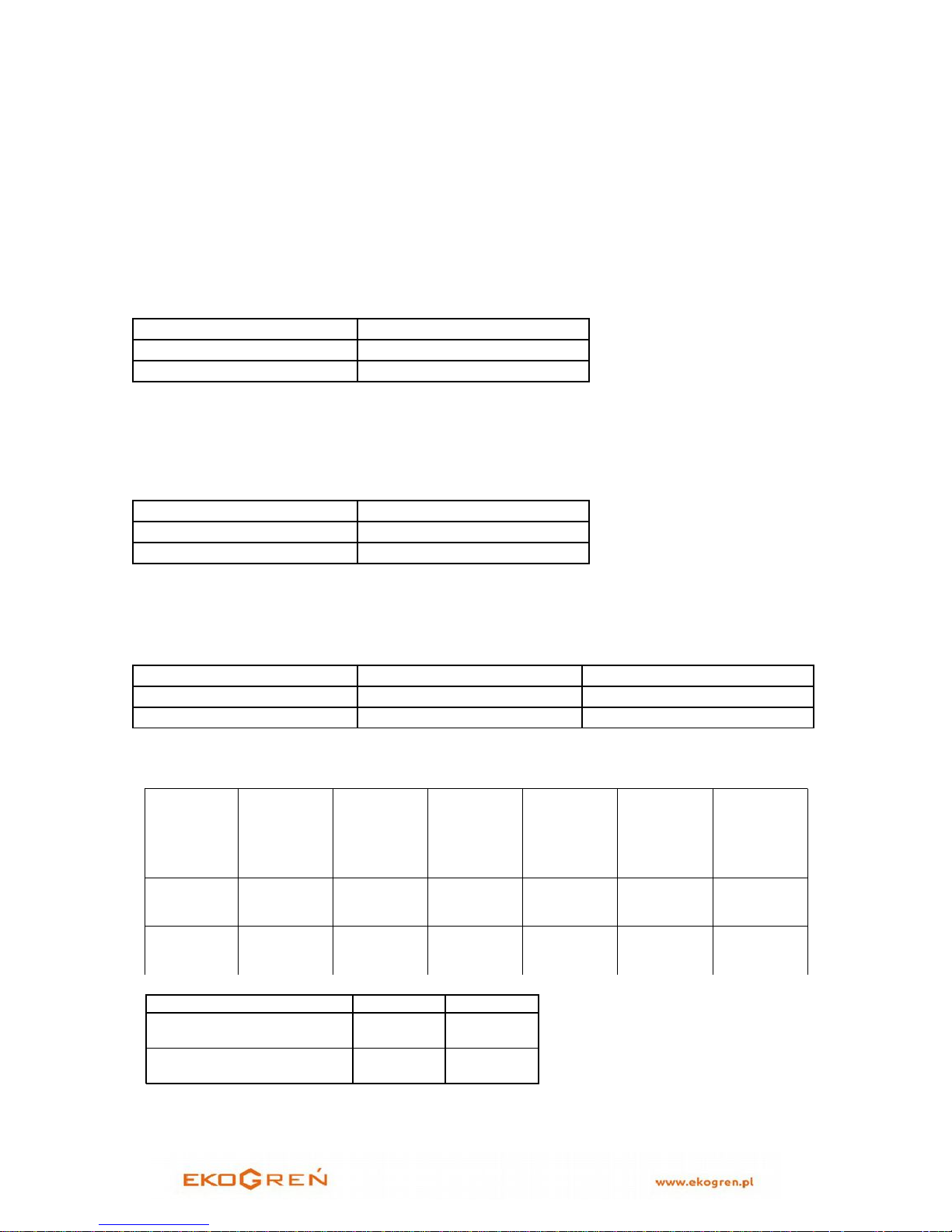

BOILER TYPE BOILER WEIGHT [kg]

EG-HOLZ 25 500

EG-HOLZ 50 690

Transporting the boiler: On the pallet using a fork lift or specially prepared loader.

BOILER ROOM CEILING HEIGHT (minimal)[mm] 2350

b) Water capacity:

BOILER TYPE WATER CAPACITY [l]

EG-HOLZ 25 120

EG-HOLZ 50 134

c) Power of the boiler

Range of boiler power for the timber with 20% humidity per gross weight and with

calorific power rating (P.C.I) which is equal or less than 3,8 kWh/kg.

BOILER TYPE POWER [kW] POWER RANGE

EG-HOLZ 25 25-30 0,25-0,30

EG-HOLZ 50 50 0,50

d) Combustion process and filling height:

BOILER

TYPE

Temperatu

re of flue

gas [°C]

Mass flow

of flue gas

[kg/s]

Min. inlet

water

temp.

[°C]

Time of

burning

[h]

Max. filling

height

[mm]

Volume of

fuel

chamber [l]

EG-Holz 25

kW

150 72 820 220

EG-Holz 50

kW

150 72 1050 280

e) Water flow:

6

Power of boiler [kW] 25 50

0,60 1,19

0,30 0,60

Water flow for temperature

difference equal 10°C [l/s]

Water flow for temperature

difference equal 20°C [l/s]

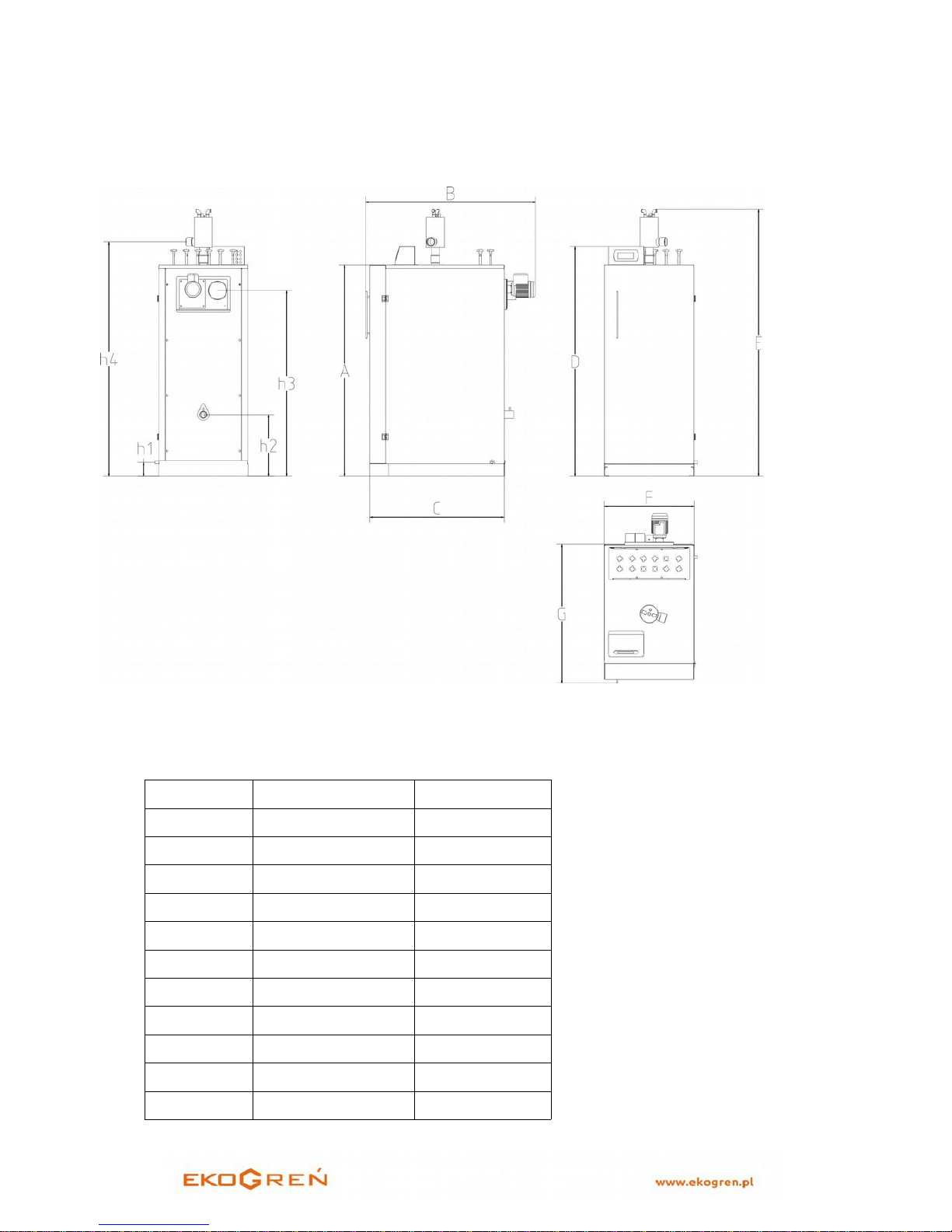

e) Basic dimensions of EG-Holz boilers:

Dimension EG-Holz 25 kW EG-Holz 50 kW

A

1388 1679

B

1133 1348

C

905 1066

D

1533 1824

E

1831 2120

F

705 713

G

926 1105

h1

65 111

h2

433 489

h3

1204 1476

h4

1574 1863

7

Figure 1: Basic dimensions of EG-Holz boilers

8

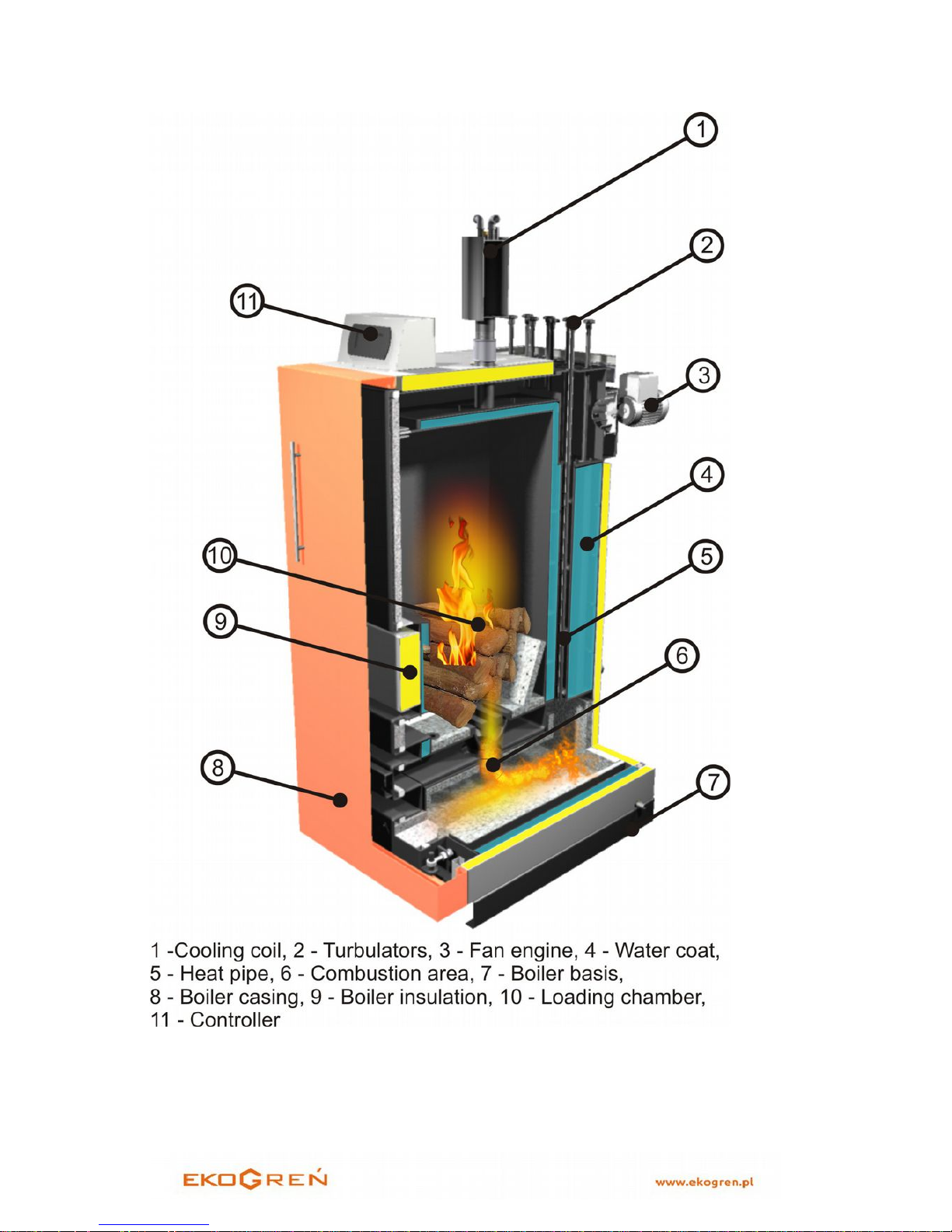

Figure 2: EG-Holz cross section

Loading...

Loading...