REVISION HISTORY

LEGEND

WARNING

NOTE

DATEREVISION DESCRIPTION

Notes are used to highlight special operating conditions or steps of a

procedure.

Warnings are used to highlight procedures which, if not strictly

observed, may result in personal injury or loss of life.

Tips.

TIPS

1.0 Apr 20th 2018

User Manual

Revision History 2

Legend 2

GETTING STARTED 6

Introduction 7

Features 8

HDMI Support

SMA Support

Single Arm Design

More I/O

Heated & Temperature Controlled IMU

High Performance Gimbal Controller

Clean Design - Internal Wiring

Compact & Ultra Lightweight

Built For Inspection

Specications 11

Gremsy S1 Mechanical Components 12

Gremsy S1 I/O Connectors 13

Gimbal Mount: Connectors & Pinouts

Gimbal Controller: Connectors & Pinouts

Tilt Stage: Connectors & Pinouts

Gremsy S1 Electronic Diagram 19

What’s In The Box 20

Gimbal Mounting 21

Gimbal Mounting

Powering Up The Gremsy S1 22

Step 1

Step 2

Step 3

Status LED Indicator 23

Operation Modes 24

Gremsy S1 Has 2 Operation Modes

Gremsy S1 Supports

Working Operation

Swithching Between Modes

Installing Software / App 26

Using USB/BLUETOOTH Connection 27

Using USB Connection

Using BLUETOOTH Connection

CONTENTS

BALANCING 29

Mounting The Camera 30

Tilt Axis Front-Back Balance 31

Tilt Axis Vertical Balance 32

Roll Axis Balance 33

Pan Axis Balance 34

SOFTWARE - TUNING 35

Stiffness Tuning 36

General Method

Step 01 - Tilt Stiffness

Step 02 - Roll Stiffness

Step 03 - Pan Stiffness

Auto tuning 37

Filter 38

Gyro Filter

Output Filter

Default Values

Expert / advanced settings 39

Hold Strength

Gain

Default Settings

Follow Mode Settings 40

Speed

Smooth

Window

Tilt Lock

Airborne

Rotation Limit 41

Up Limit

Down Limit

Roll Offset

IMU Sensor 42

Gyro Calibration

Accelerometer Calibration

CanlinkConguration 44

Introduction

CANLINK Connection

Using CANLINK

Fine Trim The Horizon

Step 1:

Step 2:

Step 3:

REMOTE CONTROL 46

SBUS/PPM Settings 47

Receiver Connection

Channel Setting

JR/SPEKTRUM Settings 48

JR / Spektrum Satellite Receiver Connection

Channel Settings

UPGRADING FIRMWARE 49

How To Upgrade 50

TROUBLESHOOTING 51

GETTING STARTED

INTRODUCTION

S1 is the upgraded version of Gremsy T1 with many added features built

specically for inspection. Having HDMI , SMA port built in and one arm design

allows camera set up a lot easier. Moreover its compact and ultra lightweight

translate to longer ight time thus making it one highly demanded gimbal for

industrial experts.

7

GETTING STARTED

USER MANUAL

FEATURES

HDMI SUPPORT

SMA SUPPORT

SINGLE ARM DESIGN

Having HDMI ports on the gimbal allows camera setup more convenience and

clean.

Having SMA ports on the gimbal allows GPS antena of some special cameras

(Dual Pro R, for example ) could be connected easily without having the antena

cable get twisted during gimbal operation

Having single arm design enable light weight but still maintain rigidity and allow

camera set up easier.

8

GETTING STARTED

USER MANUAL

MORE I/O

HIGH PERFORMANCE

GIMBAL CONTROLLER

HEATED & TEMPERATURE

CONTROLLED IMU

Having more I/O allows user more exibilities and connections to interface with

external devices and third party products.

gMotion Controller, designed and made by Gremsy based on a 32 bit high

performance ARM microprocessor providing fast response and accurate

calculation. Sensor data and motors correction are updated as fast as 2000

times per second to enable incredibly smooth footage.

Heated and temperature controlled IMU sensor with advanced 6-point calibration

allows reliable performance even in extreme weather. Temperature is maintained

within 0.2 degrees Celsius accuracy.

9

GETTING STARTED

USER MANUAL

COMPACT & ULTRA

LIGHTWEIGHT

BUILT FOR INSPECTION

CLEAN DESIGN - INTERNAL

WIRING

Small in hand, powerful in the sky. The slimmed down S1 is small enough to t

into your backpack and take anywhere, yet strong enough to handle up to 1.5 lbs

payload.

S1 has powerful built-in functions that are completely compatible with thermal

and zoom cameras, dual camera to perfectly fulll their duties with minimal setup

and equipment.

No exterior wires, more solid. This clean design helps the S1 overcome wind

resistance with ease to bring out the best video quality while staying agile.

10

GETTING STARTED

USER MANUAL

SPECIFICATIONS

Product Name

System Type

Weight

Camera Cage (Standard) (W X L X H)

Construction

Input Voltage

Working Current

Connection

Payload

OS Platform Supported

Single Operator

Dual Operator

Pan Range

Tilt Range

Roll Range

Gremsy S1

3-Axis Digital Gyro-Stabilized

1.65 lbs / 750 g

120mm x 65mm x 72mm

All Aluminum

14 – 52V

Static Current 300mA @12V

Dynamic Current 600mA @12V

Locked Motor Current Max 3.5A @12V

USB, CAN, UART, BLUETOOTH

1.5 lbs / 700 g

Windows / Mac / iOS / Android

Follow Mode

SBUS / Spektrum / PPM / Lightbridge 2

+/- 160 degree

+/- 90 degree

+/- 45 degree

11

GETTING STARTED

USER MANUAL

GREMSY S1 MECHANICAL COMPONENTS

01. Gimbal mount

02. Pan motor

03. Pan adjustment

04. Roll motor

05. Gimbal controller

06. Roll adjustment

07. Tilt motor

08. Tilt top bar

09. Camera plate

10. Tilt front- back adjustment

11. Tilt vertical adjustment

12. Top camera screw

13. Top bar adjustment knob

01

02

03

04

05

06

09

10

11

12

13

07

08

12

GETTING STARTED

USER MANUAL

GREMSY S1 I/O CONNECTORS

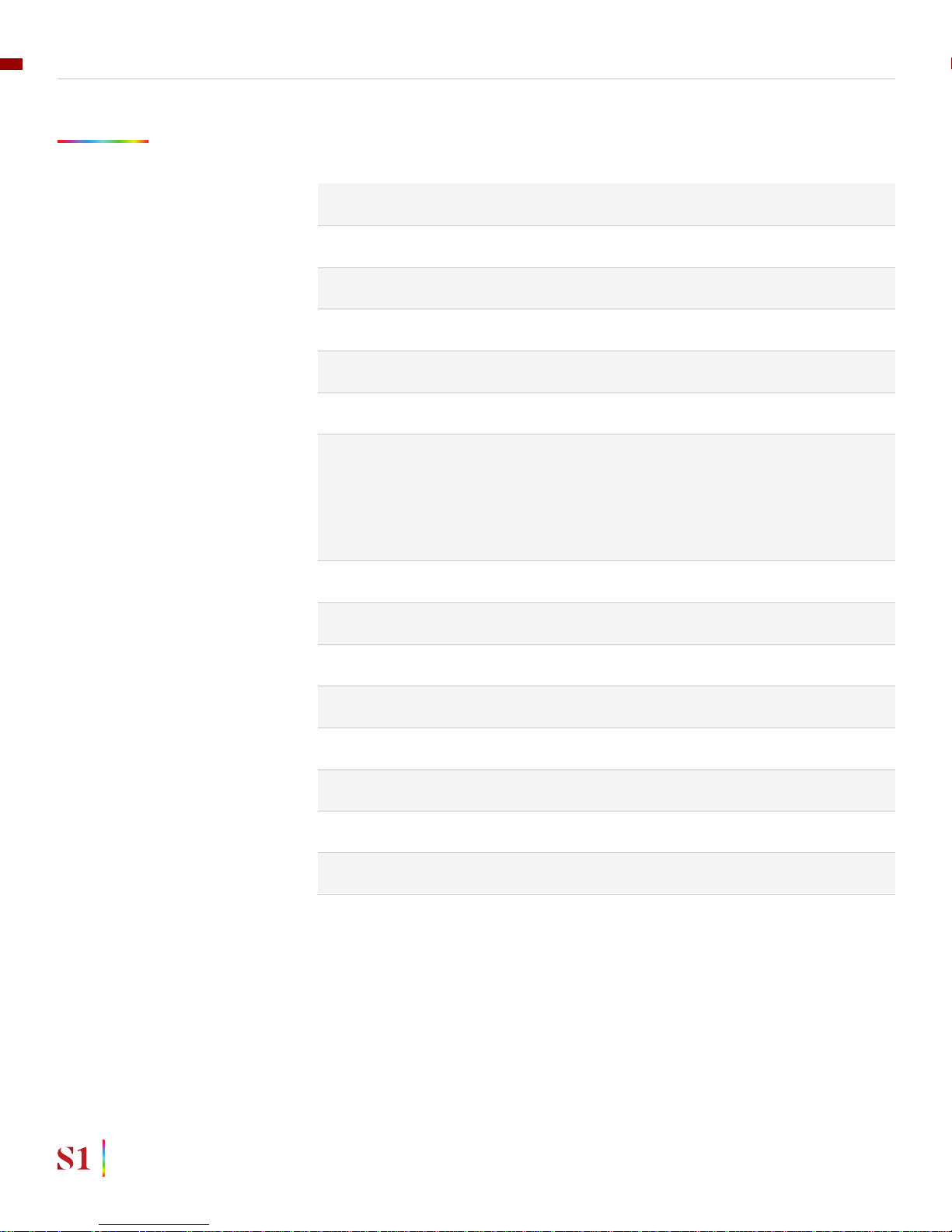

GIMBAL MOUNT:

CONNECTORS & PINOUTS

POWER: to get power directly from external batteries of the drone or other

power supply. Voltage input range from 14V to 52V and is down converted to a

stable 12V by the internal circuit to provide power to gimbal and accessories.

Connector type: MOLEX MICROFIT 3.0 2 pin

CAN: to interface with CAN bus on DJI Flight controller or another module

that uses CAN bus.

Connector type: JST SM04B-ZESS-TB

COM2: to interface with Pixhawk or Pixhawk 2 via Mavlink protocol or other

modules that use serial protocol (UART).

Connector type: JST SM04B-ZESS-TB

13

GETTING STARTED

USER MANUAL

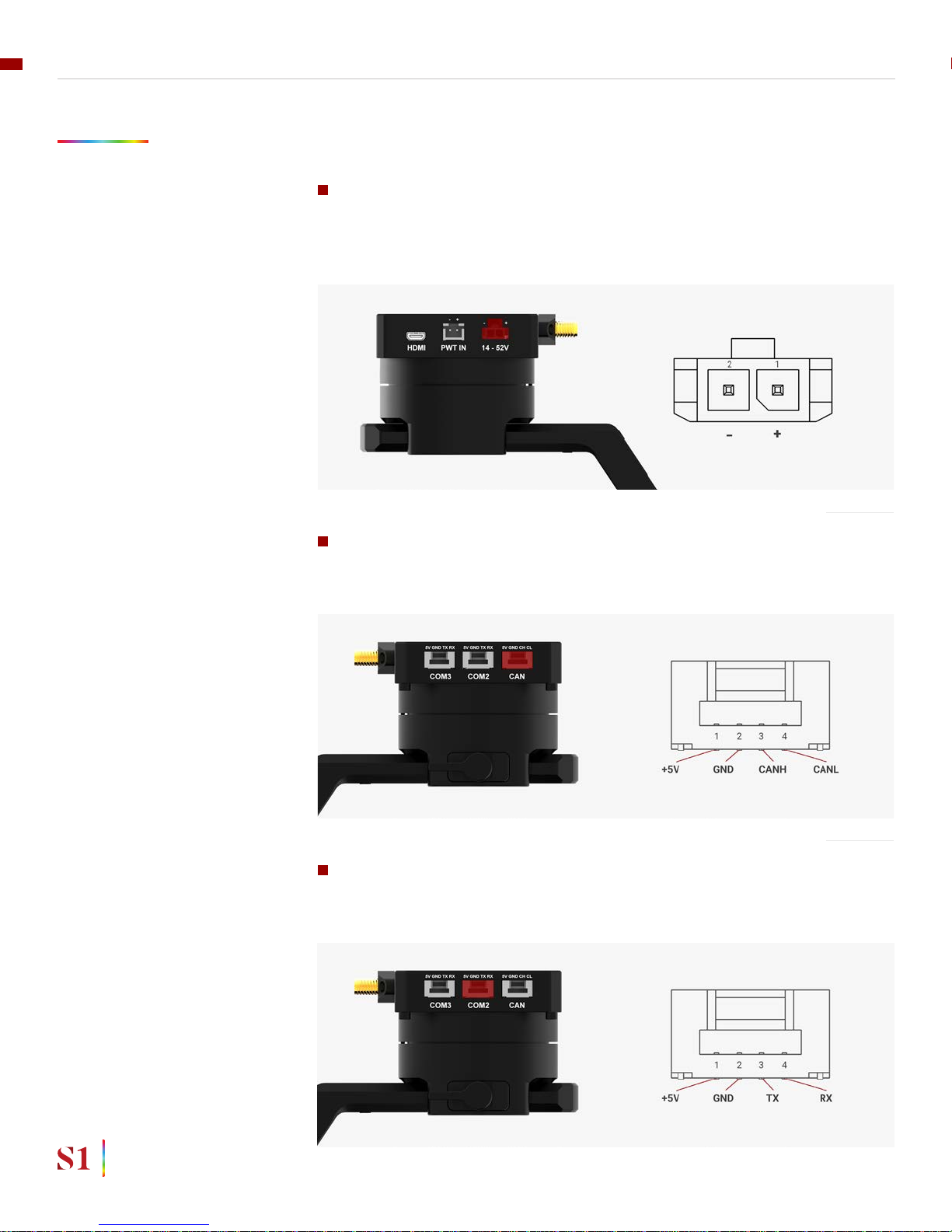

COM3: to interface with other modules that use serial protocol (UART).

Connector type: JST SM04B-ZESS-TB

SBUS: to interface with other modules that use serial protocol (UART).

Connector type: 3 pin, 2.54mm pitch

PPM: To interface with PPM receiver.

Connector type: 3 pin, 2.54mm pitch

14

GETTING STARTED

USER MANUAL

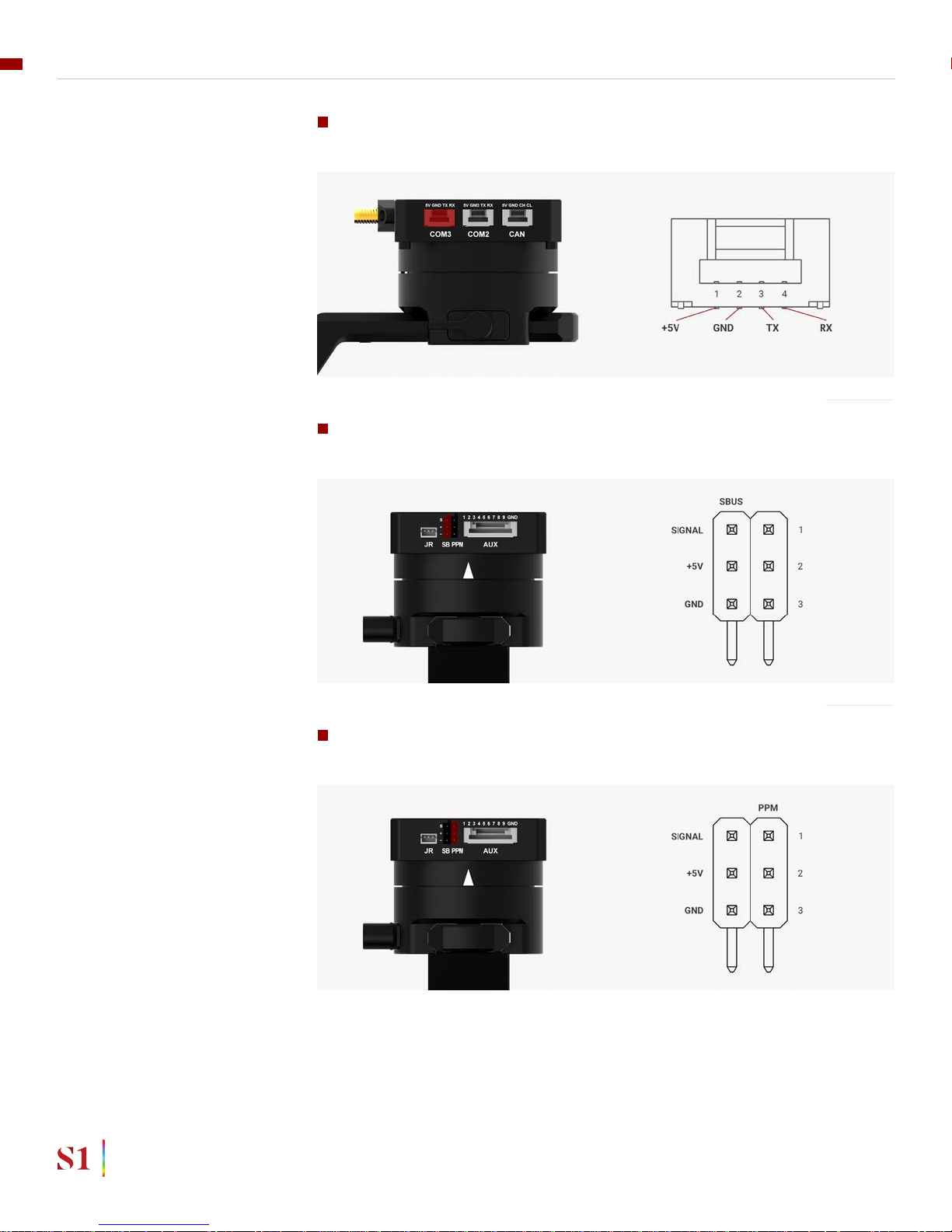

JR: to interface with JR/SPEKTRUM satellite receiver.

Connector type: JST S3B-ZR

AUX: There are S1, S2, S3, S4, S5, S6, S7,S8, S9 optional signal (0.2A max) ,

GND (1A max) for users to connect to other devices such as AV signal or camera

trigger...This port is internally connected to AUX port on the tilt stage.

Connector type: JST SM10B-ZESS-TB

PWT IN: To provide input power to PWR OUT of tilt stage .This port is internally.

Connector type: JST S2B-XH-A

15

GETTING STARTED

USER MANUAL

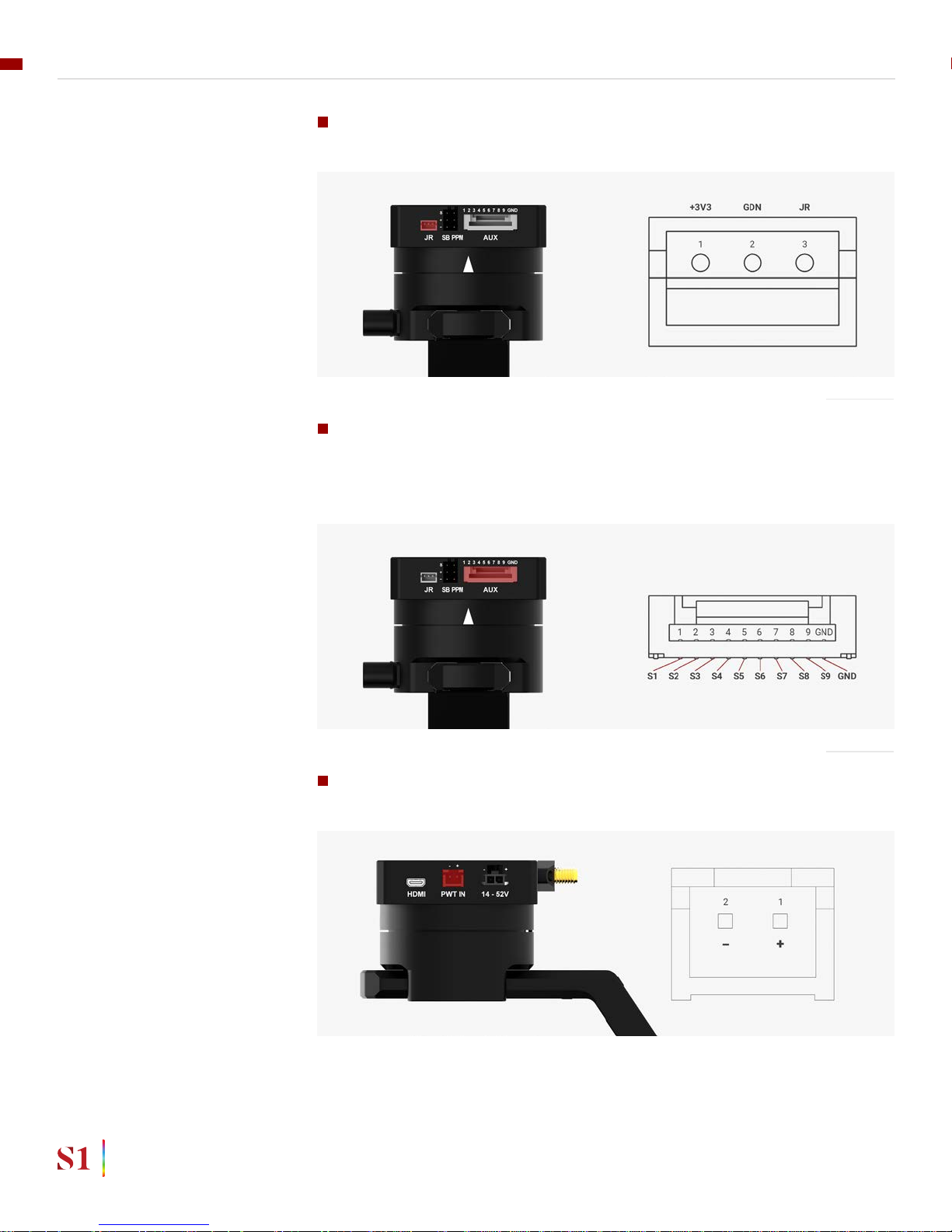

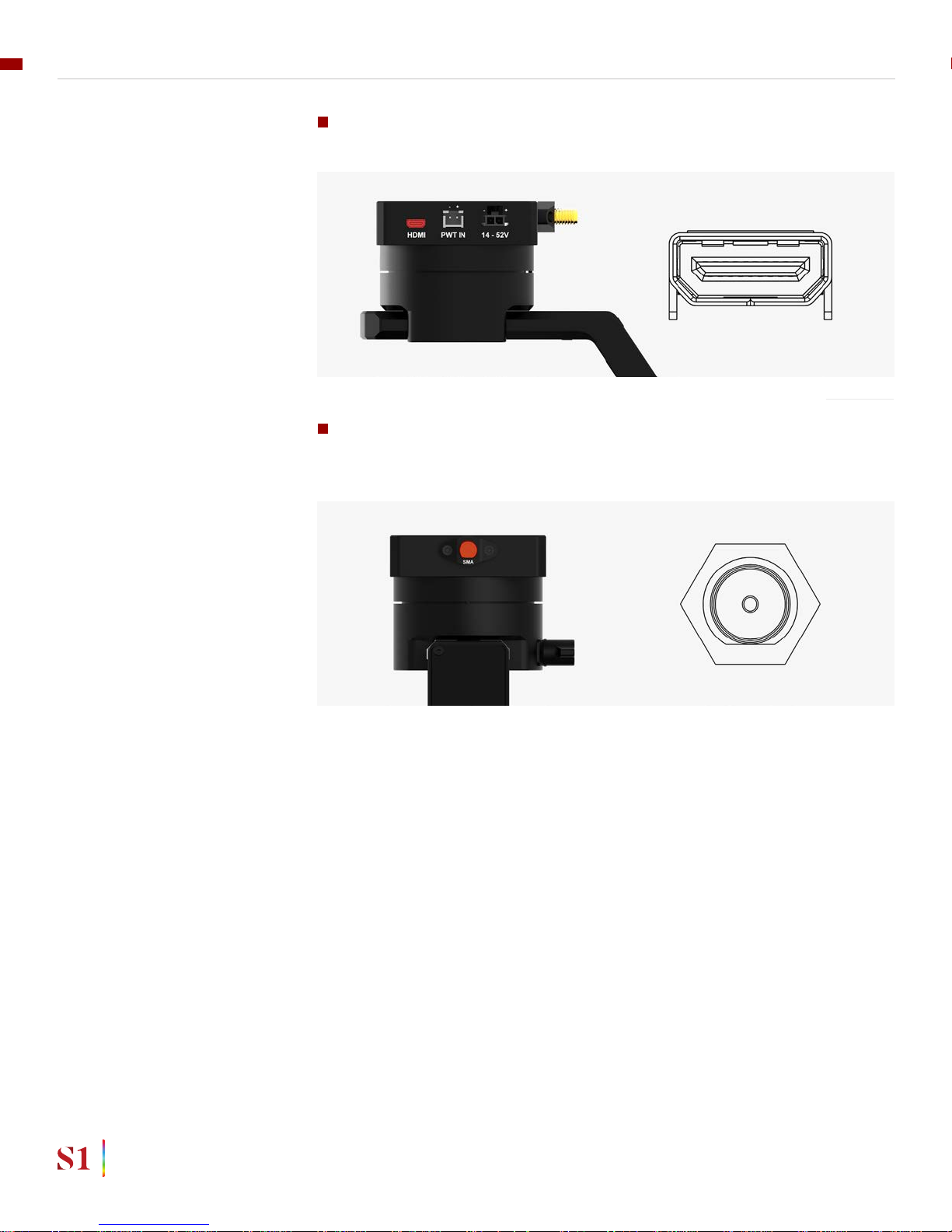

HDMI: HDMI output from tilt stage.

Connector type: Micro HDMI

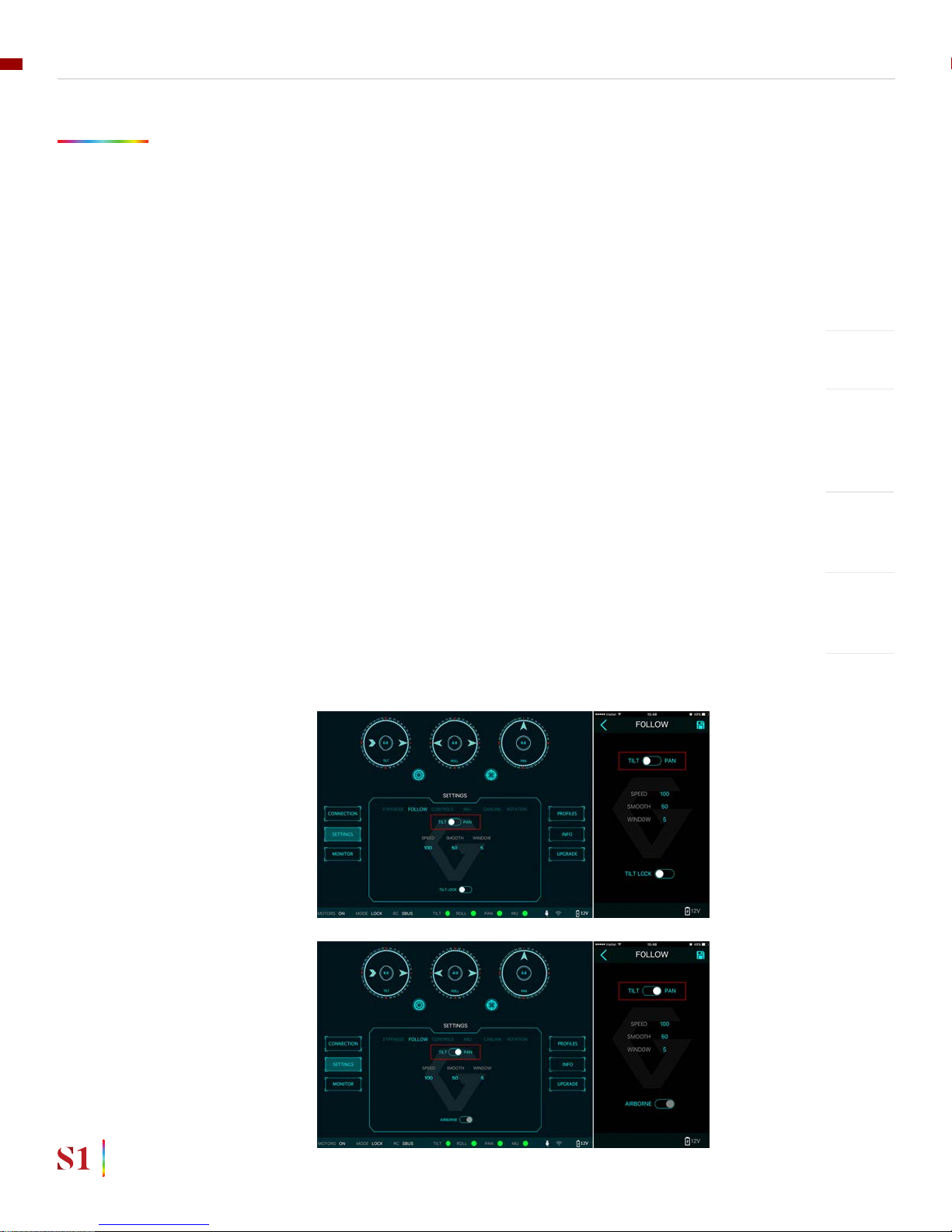

SMA: To receive SMA signal from tilt stage `..This port is internally connected

to SMA port on tilt stage.

Connector type: SMA

16

GETTING STARTED

USER MANUAL

GIMBAL CONTROLLER:

CONNECTORS & PINOUTS

TILT STAGE: CONNECTORS &

PINOUTS

USB: to interface with computer or upgrade rmware.

Connector type: Micro USB TYPE B

AUX: There are S1, S2, S3, S4, S5, S6, S7,S8, S9 optional signal (0.2A max) ,

GND (1A max) for users to connect to other devices such as AV signal or camera

trigger...This port is internally connected to AUX port on the gimbal mount.

Connector type: JST SM10B-ZESS-TB

PWT OUT: To get power input from PWT IN port on the gimbal mount .This port

is internally connected to PWT IN port on the gimbal mount.

Connector type: JST S2B-XH-A

17

GETTING STARTED

USER MANUAL

HDMI: HDMI input.

Connector type: Micro HDMI

SMA: SMA input.

Connector type: SMA

18

GETTING STARTED

USER MANUAL

GREMSY S1 ELECTRONIC DIAGRAM

19

GETTING STARTED

USER MANUAL

WHAT’S IN THE BOX

01

02

A B C D E F G

03

A. Micro USB Cable

B. Power Supply Cable

C. Canlink Cable For Pixhawk

D. Canlink Cable For DJI A3/N3

E. Sbus Cable

F. Auxiliary Cable

G. Canlink Cable For DJI A2/ Naza V2 / Wookong

x1

x1

x1

x1

x1

x2

x1

01. GREMSY S1 GIMBAL 02. SLIDE CAMERA & CAMERA SCREW

03. GREMSY S1 CABLES

20

GETTING STARTED

USER MANUAL

GIMBAL MOUNTING

GIMBAL MOUNTING

There are two ways to mount the gimbal:

Using 4x M3 to mount the top part (4 threads are arranged 32mmx32mm in

squared pattern) onto the frame or damping isolator

Using 4x M3 to mount the top part (4 threads are arranged 51mmx51mm in

squared pattern) onto the frame or damping isolator.

21

GETTING STARTED

USER MANUAL

STEP 1

STEP 2

STEP 3

POWERING UP THE GREMSY S1

Always start the gimbal with a balanced camera set up otherwise after

initialization the controller will return an error followed by a red color

indicator.

If the status LED is solid red, something is wrong with the gimbal and

motors can not start. Connect to the software/apps to check details of the

error message.

Make sure the gimbal is mounted to the drone and its power port is already

connected to the power supply correctly.

If the status LED is blinking green, the gimbal is ready for use. By default, the

gimbal is in Follow mode if the motors are turned ON by the Function Button.

Wait about 5 seconds, do not touch the gimbal or camera. The gimbal will

perform series of rotations and self tests .

Read “LED STATUS INDICATOR” in next section for more information.

NOTE

NOTE

After connecting to the power supply, the gimbal will perform series of

alignments, self tests, which last about 5 seconds and will determine the status

of the gimbal, indicated by the Status LED color. During this time, don’t touch the

gimbal or camera.

22

GETTING STARTED

USER MANUAL

STATUS LED INDICATOR

01

02

03

04

05

06

07

08

09

10

11

12

Low Battery

System Error (Motor or IMU)

Calibrating

System Boot

System Ready

Lock Mode

Follow Mode

Remote with Lock Mode

Remote with Follow Mode

Auto-tuning in process

Canlink with Lock Mode

Canlink with Follow Mode

Blink

Solid

Blink

Solid

Blink

Blink

Solid

Blink

Solid

Blink

Blink

Solid

STATE LED STATUS DESCRIPTION

23

GETTING STARTED

USER MANUAL

OPERATION MODES

GREMSY S1 HAS 2

OPERATION MODES

GREMSY S1 SUPPORTS

WORKING OPERATION

SINGLE OPERATOR: using FOLLOW mode.

DUAL OPERATOR: a second operator can use a Remote Controller (SBUS,

SPEKTRUM, PPM) to control gimbal’s movement.

LOCK MODE: is a stabilization mode where the camera maintains orientation

independently of the rest of the gimbal and the orientation can be changed by an

external control signal from remote control.

FOLLOW MODE: in this mode, the camera will mimic the operator’s movement

and allows one person to control camera tilt and pan without using an external

device like a remote control.

Gremsy S1 has 1 working operation: NORMAL

24

GETTING STARTED

USER MANUAL

SWITHCHING BETWEEN MODES

Using function button

Using mode channel on remote control

POSITIONS

High

Midle

Low

MODES

Follow mode

Motors ON

Lock mode

Motors ON

Motors OFF

PRESS TIMES

Once time

2 times

3 times

Hold 3 seconds

4 times

MODES

Turn motors ON

Lock mode

Follow mode

Turn motor OFF

Calibrate Gyros

Using software/application

If there is a remote control signal, changing modes or turning motors on/

off by other methods such as using the function button or software will not

take effect because the remote control signal has the highest priority and

override the command.

NOTE

25

GETTING STARTED

USER MANUAL

INSTALLING SOFTWARE / APP

Mobile apps are available in App Store and Google Play

App name: gTune

Searching: “gremsy gtune”

Desktop software

Download at:

www.gremsy.com -> Support -> Product Support -> Gremsy S1

26

GETTING STARTED

USER MANUAL

USING USB CONNECTION

USING USB/BLUETOOTH CONNECTION

To congure and monitor data of Gremsy software/app either USB/BLUETOOTH

connection is required.

Make sure the Silab USB driver is already installed. The driver can be

found at:

www.gremsy.com -> Support -> Product Support -> Gremsy S1

1 - Power ON the S1.

2 - Connect USB cable from gimbal controller to Mac/PC.

3 - Run the gTuneDesktop software.

4 - On Connection Tab, select the Serial option.

5 - Select the correct COM port in the list.

6 - Click on the “Connect” button.

STEPS TO CONNECT:

NOTE

27

GETTING STARTED

USER MANUAL

USING BLUETOOTH

CONNECTION

1 - Enable bluetooth adapter of mobile devices.

2 - Turn ON the gimbal and run the app

The application still supports WIFI connection like older version. In the case the

app is using WIFI as default, user can switch to bluetooth by the button on topright corner. The app will memorize the selected connection for later use.

After being accepted to use bluetooth, the app starts scanning for Gremsy

bluetooth integrated gimbals.

- If only one gimbal is found, it will be connected automatically.

- If more than one gimbal are found, a list of gimbals will be shown to let user

select the desired one

- If no gimbal found, an error will be shown.

STEPS TO CONNECT:

ON MOBILE APP

On Android: the OS also asks for Location Data permission for BLE

scanning feature (updated by Google since Android 6.0)

On iOS: the OS has issue with its bluetooth adapter itself sometimes, user

should check device’s quick settings and general settings to enable the

adapter, the bluetooth icon should appear on device’s status bar

NOTE

28

GETTING STARTED

USER MANUAL

BALANCING

To achieve the best performance from the S1, proper

balancing is necessary. Accurate balance is critical in

shots where the gimbal will be subjected to extreme

movements or accelerations. There are 3 axes that need

to be precisely balanced prior to powering up the gimbal.

MOUNTING THE CAMERA

Use a 1/4”-20 screw to secure the camera to the camera tray, then put the camera

to the gimbal and tighten the top bar screw slightly (if the camera has hot shoe

supported)

Mounting camera has large width on the second slot of the crossbar (Sony

A6000, Sony A6300)

Mounting camera has small width on the rst slot of the crossbar (Black magic

micro cinema camera, Flir Dual Pro R )

BALANCING

30

USER MANUAL

TILT AXIS FRONT-BACK BALANCE

When the proper front-back balance is achieved, the camera will stay level when

you remove your hands.

1. Loosen the thumbscrew underneath the camera tray and the top bar

adjustment knob. Then, gently slide the camera forward or backward until the tilt

axis remains level.

2. Tighten the thumbscrews to lock the camera and camera tray in position.

BALANCING

31

USER MANUAL

TILT AXIS VERTICAL BALANCE

When the proper vertical balance is achieved, you can rotate the camera in any

angle and it will stay at that position.

1. Rotate the tilt axis so that the lens is pointing upward.Then, loosen vertical

adjustment thumbscrew, gently slide the camera mount crossbar and the top bar

forward and backward until the camera remains pointing upward when released.

2. Tighten the vertical adjustment thumbscrew. Sometimes, the vertical balance

could not be achieved, the front-back balance should be re-checked in this case.

Tighten the top bar adjustment knob and camera top screw as well

BALANCING

32

USER MANUAL

ROLL AXIS BALANCE

1. Loosen the thumbscrew underneath the roll bar, then gently slide the roll bar

left or right until roll axis remains level.

2. Tighten the thumbscrew to lock the roll bar in position.

When the proper left-right roll balance is achieved, the camera will stay level when

you remove your hands.

BALANCING

33

USER MANUAL

PAN AXIS BALANCE

1. Loosen the thumbscrew, then gently slide the pan axis slider backward/forward

until it doesn’t swing and stay at any given position when released.

2. Tighten the thumbscrew to make sure pan axis slider is locked in position.

Tilt the gimbal about 20 degrees from the verticality, identify if the gimbal is front

heavy or back heavy. Slide the pan axis slider until the camera does not swing.

BALANCING

34

USER MANUAL

SOFTWARE - TUNING

After the camera is balanced on the Gremsy, it’s time to

ne tune some parameters for best performance.

STIFFNESS TUNING

GENERAL METHOD

STEP 02 - ROLL STIFFNESS

STEP 03 - PAN STIFFNESS

STEP 01 - TILT STIFFNESS

Stiffness setting has a signicant impact on the performance of the S1. This

setting adjusts the degrees to which the gimbal tries to correct for unwanted

camera movement and hold the camera stable. The higher you can run the

setting without vibration or oscillation, the better.

Start with a low value of 20 for all axes then turn motors ON. Slowly increase this

setting until you feel an oscillation in each axis, then reduce it until the oscillation

subsides. You can touch the camera to feel the oscillation during tuning. Increase

the stiffness setting 5-10 points at a time until oscillation appears then reduce 5

points until oscillation subsides.

Slowly increase this setting until you feel an oscillation in the roll axis, then

reduce the setting until the oscillation subsides. Pick the S1 up and make sure

there is no vibration when you move the gimbal around.

Slowly increase this setting until you feel an oscillation in the pan axis, then

reduce the setting until the oscillation subsides. Tilt the S1 about 20 degrees

from the verticality and make sure that no vibrations are presented.

Slowly increase this setting until you feel an oscillation in the tilt axis, then reduce

the setting until the oscillation subsides. Make sure there is no vibration when

tilting the camera up and down and when moving the gimbal in any orientation.

SOFTWARE & TUNING

36

USER MANUAL

AUTO TUNING

The Auto-Tune function provides automatic adjustment of each motor’s stiffness

value to nd a good setting, the process will take around 1-2 minutes. Please turn

motor ON prior to starting Auto-Tuning.

The settings found by Auto-Tuning are usually good to start with however,

it’s recommended to manually reduce stiffness if there is an oscillation in a

specic axis or increase stiffness in case if it is too low.

NOTE

SOFTWARE & TUNING

37

USER MANUAL

GYRO FILTER

OUTPUT FILTER

DEFAULT VALUES

FILTER

The purpose of the lters is to eliminate noise and vibration due to structural

resonances in the camera, lens, or gimbal.

Setting the lters too high or too low can cause signal disturbances that can

reduce the overall stabilization.

Denes the strength of the lter applied to Gyro sensor output. If the gimbal has

oscillations that cannot be corrected by adjusting stiffness settings, the Gyro

Filter is used to further tune the gimbal and remove the oscillation.

Denes the strength of the lter applied to motors output. If the gimbal has

oscillations that cannot be corrected by adjusting stiffness settings, the Output

Filter is used to further tune the gimbal and remove the oscillation.

1. If the gimbal is vibrating at a high frequency after tuning, increase the lter

values.

2. If the gimbal is oscillating or rocking at a low frequency after tuning, decrease

the lter values.

Gyro Filter

Output Filter

1

2

SOFTWARE & TUNING

38

USER MANUAL

HOLD STRENGTH

EXPERT / ADVANCED SETTINGS

DEFAULT SETTINGS

GAIN

There are some expert parameters that normally do not need to be adjusted.

Leave these parameters at default settings unless they are required for

troubleshooting.

If “Auto power adjustment” is enabled, “Hold strength” will be the minimum power

level required for the corresponding axis. The controller will automatically adjust

power level from minimum to maximum level depending on the displacement

between current angle and commanded angle.

If “Auto power adjustment” is not selected “Hold strength” will be constant power

level provided to the corresponding axis and should be adjusted manually. This

option is only recommended for advanced users.

For heavy cameras, it’s suggested to increase hold strength for each

axis around 10% than the default value. If “Auto power adjustment” is

not selected “Hold strength” will be xed power level provided to the

corresponding axis and should be adjusted manually. This option is only

recommended for advanced users.

NOTE

HOLD STRENGTH

GAIN

AUTO POWER ADJUSTMENT: ENABLED

120

TILT

30

ROLL

30

PAN

30

Denes how fast each axis will return to commanded position. To reload default

expert settings just press “Default” in the expert menu.

SOFTWARE & TUNING

39

USER MANUAL

SPEED

SMOOTH

WINDOW

TILT LOCK

AIRBORNE

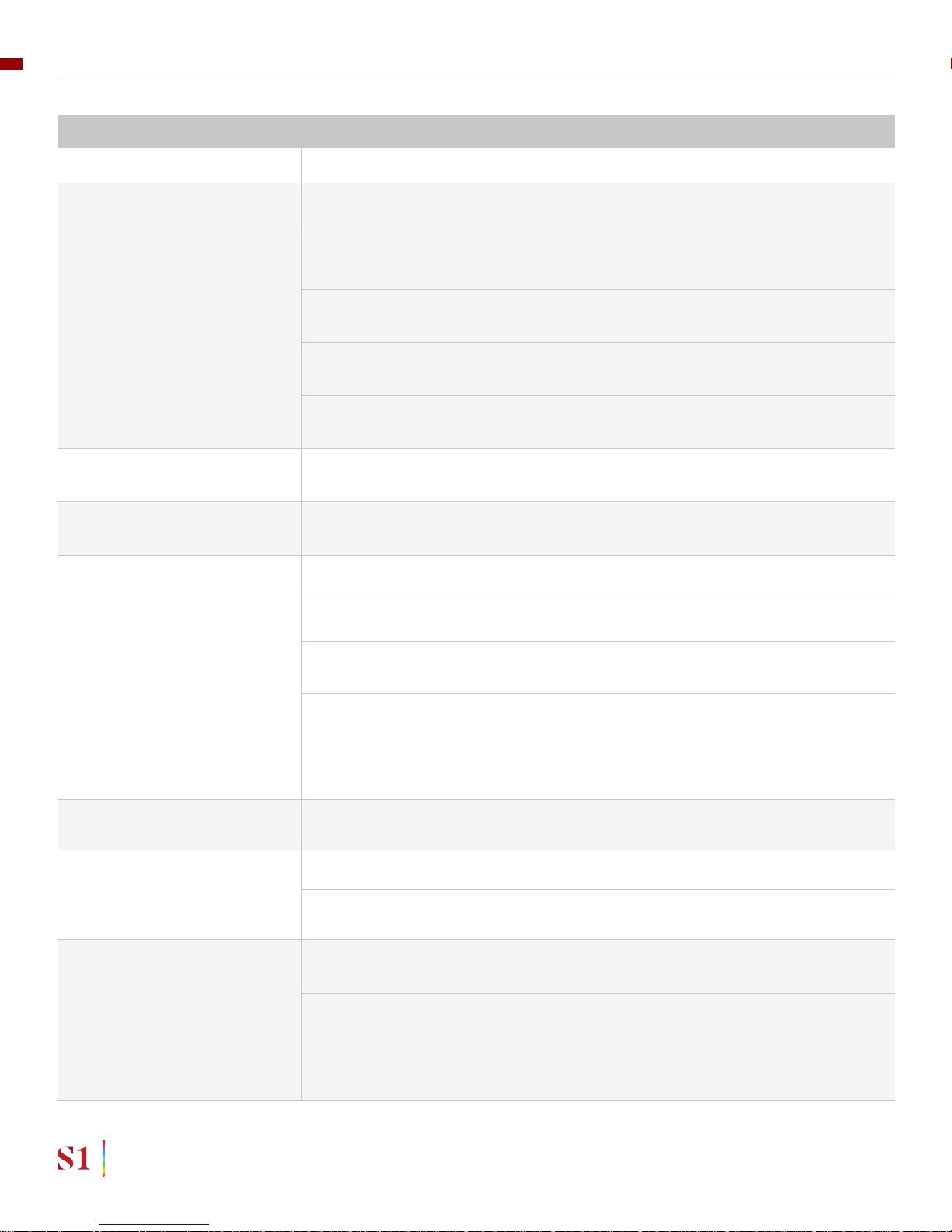

FOLLOW MODE SETTINGS

The most widely used mode of single operation is Follow mode where the gimbal

operator controls to pan and tilt of the camera. The camera movement will mimic

the user’s input from the top-mount while the footage remains stable. The follow

mode can be congured to be either very linear and robotic, or smooth and

cinematic.

Follow mode settings is available for Tilt axis and Pan axis.

Denes how fast camera will follow the movement.

Smooth out the camera movement by adjusting this parameter. The higher

the value is the smoother camera moves but at the expense of more delay in

following the movements.

When the movement is out of the window zone, the camera starts to move.

Within the window zone, the camera maintains its direction.

If this option is selected, the tilt axis will maintain its angle and only be controlled

by remote control.

This feature is not available on the S1.

SOFTWARE & TUNING

40

USER MANUAL

UP LIMIT

DOWN LIMIT

ROLL OFFSET

ROTATION LIMIT

Travel of Tilt and Roll axis can be limited using UP LIMIT and DOWN LIMIT. The

Pan axis keeps the ability to pan 360 degrees itself.

Set the up limit for Tilt or Roll axis (in 1 degree unit). The default values are -90 for

Tilt and -45 for Roll.

Set the down limit for Tilt or Roll axis (in 1 degree unit). The default values are 90

for Tilt and 45 for Roll.

Set the Roll offset (in 0.1 degree unit) is only applicable when there is no remote

control signal since remote control will override the roll angle. This is useful to

ne trim the horizon. The default value is 0.

SOFTWARE & TUNING

41

USER MANUAL

IMU SENSOR

The IMU sensor used in the S1 is a combination of a high precision 3 axis

gyroscope sensor and a 3 axis accelerometer sensor.

IMU board is enclosed in a weather proof case and being heated where the

temperature inside is controlled around 50°C with 0.2°C accuracy. Thanks to this

feature, gyro calibration is no longer required in most situations.

In order to provide extra high precision data output, the IMU is performed 6-point

calibration at Gremsy factory.

The S1 controller has a special algorithm to provide attitude estimation based on

input data from the IMU sensor. This attitude estimation helps the controller to

command motor output to compensate for camera movement.

SOFTWARE & TUNING

42

USER MANUAL

GYRO CALIBRATION

ACCELEROMETER

CALIBRATION

Thanks to temperature controlled and heated IMU, gyro calibration is not

necessary as the gyro was calibrated at the factory and the temperature inside

IMU remains constant around 50 degrees. However, if you notice drift during

operation in extreme weather (below -20C or above 50C) please re-calibrate the

gyro.

CALIB AT STARTUP: this feature is not available on the S1

After Gyro Calibration, Gyro Offset X, Y, Z will change to a new value

depending on the temperature.

NOTE

Do not use this function, please contact Gremsy Support Engineers.

Accelerometer sensor was calibrated properly at the factory to achieve

accurate horizon level with special and precise equipment. Users do not

need to do this unless it’s required for troubleshooting.

WARNING

SOFTWARE & TUNING

43

USER MANUAL

CANLINK CONNECTION

INTRODUCTION

USING CANLINK

CANLINK CONFIGURATION

FINE TRIM THE HORIZON

DJI FC

PIXHAWK

Connect the cable from CAN port on hyper quick release to CAN port on

COMPASS/GPS module on DJI FC

CANLINK is Gremsy’s proprietary solution to get information from the third party

ight controller to correct horizon drift.

Without CANLINK, our gimbal can maintain locked horizon most of the

cases where prolonged acceleration is not presented . When prolonged

acceleration is presented such as circular ight or prolonged bank turn

(where centrifugal force appears), horizon will drift after certain period of

time

In order to have Canlink worked properly, GPS module should installed

together with ight controller

Baudrate on Pixhawk should be set at 57600bps, 8 data bits, No Parity, 1

Stop bit (8N1)

Connect cable from COM2 port on hyper quick release to TELEMETRY 1/

TELEMETRY 2 on Pixhawk , Pixhawk 2. Once connected, the gimbal controller

will automatically send MAVLINK message to set attitude update rate of ight

controller at 10Hz

When the rst turn on the motor, make sure the pan axis is aligned with the

forward direction of the copter in order for the gimbal to calculate the attitude

correctly. After turning on the motor, the LED status turns to the pink color

indicating that CANLINK connection between gimbal and ight controller has

been established.

NOTE

NOTE

NOTE

There is tolerance between the gimbal’s IMU and ight controller’s IMU due to

mechanical mountings error or calibration error, for example, the gimbal’s frame

and the ight controller’ plane is not perfectly parallel with roll and pitch axis and

usually within 1-2 degree. To address this, we offer a way to ne trim the horizon

in 3 steps.

SOFTWARE & TUNING

44

USER MANUAL

STEP 1:

STEP 2:

STEP 3:

TURN MOTOR ON for the rst time, make sure the pan axis is aligned with the

forward direction of the copter during turning on the motor. LED status will

change to pink color.

Use radio control to move the pan to a position which is 180 degree away from

the forward position of the copter. Use a bubble level in order to observe the

horizon: adjust roll offset until it is level.

Use radio control to move the pan to a position which is 90 degree away from the

forward direction of the copter. Use a bubble level in order to observe the horizon:

adjust tilt offset until it is level.

If radio control is not available, switch gimbal in lock mode and rotate the

copter 180 degrees could achieve the same result.

If radio control is not available, switch gimbal in lock mode and rotate the

copter 90 degrees could achieve the same result.

TIPS

TIPS

SOFTWARE & TUNING

45

USER MANUAL

REMOTE CONTROL

S1 supports SBUS , SPEKTRUM and PPM receivers. There

are some parameters to be aware of before assigning

channels to the receiver.

SMOOTH: increasing this number will smooth out the

movement of the corresponding axis but will also cause

a delay.

SPEED MODE: when speed mode is selected, the

speed of the corresponding axis will depend on how

far the stick position is from the neutral position. It is

recommended that TILT and PAN channels should be set

to speed mode.

ANGLE MODE: when angle mode is selected, the

corresponding axis will move to the angle set by current

stick/knob position. It’s recommended ROLL channel

should be set to angle mode.

RECEIVER CONNECTION

SBUS/PPM SETTINGS

CHANNEL SETTING

Connect SBUS, PPM receiver to SBUS, PPM port which is located on the gimbal

mount.

The receiver must be connected to correct wires order. The SBUS/PPM

port has 5V output to power the receiver, please do not use external

power supply to power the receiver at the same time. Doing so may

damage the electronic inside the gimbal.

WARNING

There are 6 channels to assign: MODE, TILT, ROLL, PAN, TILT SPEED, PAN SPEED

Assign MODE channel rst then follow the order above because MODE channel

is used to change operating modes of the gimbal and should be assigned to a

3-position switch as follows:

Switch at high position: FOLLOW MODE , MOTORS ON

Switch at middle position: LOCK MODE , MOTORS ON

Switch at low position: MOTORS OFF

TILT and PAN channel should be in speed mode and ROLL channel in angle mode.

TILT SPEED or PAN SPEED could be assigned to the same channel and should be

assigned to throttle stick, dial, or other non-centering control on the transmitter.

Below is an example of channel assignment to the Futaba T8FG.

CHANNEL CONTROL NOTE

MODE

TILT

ROLL

PAN

TILT SPEED

PAN SPEED

5

2

4

1

4

6

SC

J2

T4

J1

J3

RD

3 positions switch

Speed mode

Angle mode

Speed mode

=

REMOTE CONTROL

47

USER MANUAL

JR / SPEKTRUM SATELLITE

RECEIVER CONNECTION

CHANNEL SETTINGS

JR/SPEKTRUM SETTINGS

Connect satellite receiver to the JR port on the gimbal mount as shown in the

picture. Make sure satellite receiver is already bound to the transmitter (RED led

is solid).

Choose 10 bit or 11 bit type resolution on the software and assign proper

channels as per SBUS settings.

REMOTE CONTROL

48

USER MANUAL

UPGRADING FIRMWARE

Only USB connection allows upgrading rmware. Refer to Section

“01. GETTING STARTED” for USB connection.

Make sure Silab USB driver is already installed. The driver

can be found at:

www.gremsy.com -> supports -> product support

NOTE

HOW TO UPGRADE

01 - Power on the S1.

02 - Connect USB cable from S1 controller to Mac/PC.

03 - Run the gTune Desktop software.

04 - In the software, select “Serial” option on “connection” tab.

05 - Select the port in the list.

06 - Click on the “Connect” button.

07 - Go to “Upgrade” tab.

08 - “Browse” to rmware le from your computer.

09 - Make sure the RF receiver (if available) is already removed.

10 - Click “Upgrade” button. The process will take about 2 minutes. When the

rmware is upgraded successfully, the S1 will be restarted automatically.

UPGRADING FIRMWARE

50

USER MANUAL

TROUBLESHOOTING

PROBLEM

Status LED is blinking red

Status LED is solid red during

startup

Status LED is solid red during

operation

Status LED is solid white after

start up

Gremsy T3 has oscillation in

one or more axes

Gremsy gimbal seems to be

drifting

Motors seem to be weak

Footage appears to wobble side

to side or up and down

POSSIBLE CAUSES

Low battery

Camera is not balanced well or

not installed

IMU cable is loose

Tilt motor cable or encoder

cable is loose

Roll motor cable or encoder

cable is loose

Pan motor cable or encoder

cable is loose

IMU sensor cable is loose

Excessive gyro drift

Stiffness setting is too high

Thumbscrew/top bar nut is not

tightened

Camera mounting is not stiff

enough

Filters settings are incorrect:

Gyro and output lter should

only be changed if other

methods of reducing oscillation

have failed

Gyro sensor is drifting too much

Stiffness is too low

Auto-power adjustment is not

enabled

Camera is not properly

balanced

Stiffness setting is low

SOLUTION

Recharge battery

Check camera balancing

Check in software for IMU sensor error, reseat IMU sensor connector

Check in software for Tilt error, re-seat tilt

motor connector and encoder connector

Check in software for Roll error, re-connect

roll motor connector and encoder cable

Check in software for Pan error, re-connect

pan motor connector and encoder cable

Re-seat IMU sensor connector

Re-calibrate

Reduce stiffness

Check tightening

Check camera mounting

Please read more in manual about Gyro lter

and output lter (Advanced settings)

Re-calibrate gyro

Increase stiffness

Check in Expert menu if Auto-power

adjustment is enabled or not

Check camera balance

Increase stiffness settings, start with the

axis which is poorly stabilized. Higher

Stiffness will achieve better stabilization.

The tuning process is described in the user

manual.

TROUBLESHOOTING

52

USER MANUAL

Loading...

Loading...