GREMO 1250F, 1450F Workshop Manual

Gremo

1250F/1450F

Workshop manual

Gremo AB

311 51 Ätran

Sweden

Tel. +46 346–60515

Fax. +46 346–60342

www.gremo.com

info@gremo.se

Release

Workshop manual in

original

1450F 4.1EN

©Gremo 2019

Gremo 1250F/1450F Workshop manual

Contents

1 Introduction ............................................... 1

1.1 Introduction ....................................... 1

1.2 About the documentation kit ............. 2

1.3 Presentation Gremo 1250F/

1450F............................................... 4

1.4 Intended area of use ......................... 5

1.5 Operator requirements...................... 6

1.6 Safety regulations ............................. 6

1.7 Warning symbols and

information about risks .................... 7

1.8 Construction of the machine ............. 8

1.9 Definitions ......................................... 8

1.10 Environment.................................... 8

1.11 Location of type plates and

serial numbers ................................. 9

2 Safety regulations ................................... 13

2.1 General ........................................... 13

2.2 Clothing........................................... 16

2.3 Seat belt .......................................... 16

2.4 Emergency stop.............................. 17

2.5 Emergency exit ............................... 18

2.6 Emergency alarm............................ 18

2.7 Articulated joint lock........................ 18

2.8 Boarding the machine..................... 19

2.9 Inspection of parking brake............. 20

2.10 Driving........................................... 23

2.11 Crane operation ............................ 24

2.12 Parking/storage............................. 26

2.13 Trailer transport............................. 27

2.14 Service .......................................... 28

2.15 Oil leaks ........................................ 31

2.16 Oils ................................................ 31

2.17 Batteries........................................ 32

2.18 Welding Repairs............................ 32

2.19 If by accident the machine tips

over................................................ 33

2.20 In the event of fire ......................... 35

2.21 Warning signs ............................... 36

2.22 Recovery and towing .................... 44

2.23 Winch ............................................ 47

2.24 Engine and cab heater.................. 47

2.25 Anti-skid chains............................. 47

2.26 Bogie tracks .................................. 48

2.27 Risk of strain-related injury ........... 48

2.28 Noise............................................. 48

3.7 Fuel, requirement

specification................................... 56

3.8 Cleaning of Safety Glass

Windows ........................................ 57

3.9 Welding Repairs.............................. 58

3.10 Tyres — Air pressure:

Manufacturer’s

recommendations.......................... 60

4 Engine...................................................... 65

4.1 Fuel system..................................... 65

4.2 Cooling system ............................... 67

4.3 Intercooler ....................................... 68

4.4 Exhaust system with particulate

filter ................................................ 68

4.5 Replacing drive belts....................... 70

5 Transmission 1250F/1450F .................... 73

5.1 Transmission, gearbox.................... 73

5.2 Bogie axles...................................... 74

5.3 Parking brake.................................. 76

6 Electrical system.................................... 79

7.1 Structure of wiring diagram, wire

numbering, revision state .............. 79

6.2 Component position of fuse

groups and relays .......................... 80

7.3 Relay list.......................................... 85

7.4 Connector list .................................. 86

7 Hydraulic system.................................... 91

7.1 Hydraulic system, component

position .......................................... 91

7.2 Hydraulic oil return filters ................ 91

7.3 Breather filter hydraulic oil

tank ................................................ 92

7.4 Off-line filter hydraulic oil................. 92

7.5 Pressure check working

hydraulics....................................... 93

7.6 Pressure check,

transmission .................................. 97

8 Pressurised air system.......................... 99

8.1 General ........................................... 99

8.2 Pressurised air diagram.................. 99

3 Service, maintenance and technical

information.............................................. 49

3.1 Safety rules during service ............. 49

3.2 Service and maintenance ............... 51

3.3 Volume specifications ..................... 52

3.4 Working with oils ............................. 52

3.5 Oil, requirement

specification................................... 54

3.6 Antifreeze, requirement

specification................................... 55

9 Other equipment and optional

equipment.............................................. 101

9.1 Fire extinguishing system ............. 101

10 Wiring diagram .................................... 105

10.1 Power supply .............................. 105

11 Hydraulic diagram ............................... 173

11.1 Hydraulic diagram list.................. 173

Gremo 1250F/1450F Workshop manual 1 Introduction

1.1 Introduction

1 Introduction

1.1 Introduction

For you to get the most out of your Gremo machine as an

owner or an operator, it is very important that you maintain

and handle the machine correctly.

It is also very important that you familiarise yourself with

the performance and the restrictions of the machine.

It is especially important that the owner, the operator and

those who service the machine are familiar with the

contents of this Instruction Manual and study it thoroughly

before starting and driving, or before any preventive

maintenance work is done.

The responsibility for start, driving and service belongs to

the persons performing these steps! Please make yourself

well familiar with the controls and instructions before the

machine is used. It is too late to start looking in the

Instruction Manual when an accident has already

happened.

NOTICE

In order to find out about manual updates, it is important

to inform Gremo AB of any change of address or owner.

1

1 Introduction

1.2 About the documentation kit

1.2 About the documentation kit

1.2.1 About the Instruction Manual

Gremo 1250F/1450F Workshop manual

The Instruction Manual contains important information

about your new Gremo machine, about operating the

machine, safety when working and the machine's daily

checks. In addition, it offers many valuable tips that

facilitate your daily work.

Incorrect use of the machine may result in personal injury

and product or property damage. For this reason, read the

instructions carefully before operating the machine for the

first time.

The Instruction Manual should always be accessible in the

machine. If it disappears, a new one must be ordered

immediately from the manufacturer.

CAUTION

Never operate a machine without an instruction manual.

Refer to your supervisor or the manufacturer if there is

anything in the text that you do not understand or if you

cannot find what you are looking for.

1.2.2 About the service and maintenance manual

The service and maintenance manual provided with your

machine describes service points and measures that are

important to follow and carry out in order for your new

machine to work smoothly in the future.

1.2.3 About the spare parts catalogue

The spare parts catalogue provided with your machine

helps you to easily identify the right spare part. This unique

catalogue is also available online.

1.2.4 About the workshop manual

A workshop manual describing in detail extensive repair

measures as well as containing wiring and hydraulic

diagrams for the machine is available for purchase.

The workshop manual can be ordered from your service

dealer or from Gremo AB.

2

Gremo 1250F/1450F Workshop manual 1 Introduction

1.2 About the documentation kit

1.2.5 Ordering documentation

Documentation can be ordered from your service dealer or

from Gremo AB.

Always specify the machine number and publication

number when ordering. The publication number is printed

on the lower right-hand corner of the cover.

3

1 Introduction

1.3 Presentation Gremo 1250F/1450F

1.3 Presentation Gremo 1250F/1450F

1.3.1 General description of the machine

Gremo 1250F/1450F Workshop manual

Fig. 1 Gremo 1250F/1450F

Gremo 1250F/1450F

• is a robust and versatile 12 to 14 tonne forwarder that

easily navigates all types of terrain. The forwarder is

designed and adapted for forwarding timber, the weight

of which does not exceed the machine's maximum load

capacity, from felling site in the forest to the roadside

stacking area.

• is driven by a Cummins QSB 6-cylinder, turbo-charged

6.7 litre diesel engine with intercooler and common rail

fuel system that complies with stage 3B environmental

requirements and is approved for running on

environmentally-friendly fossil-free diesel that complies

with the requirements in EN 15940, e.g. HVO diesel.

• is fitted with Gre-VT, a continual and variable

hydrostatic transmission with 2 speeds that are

controlled by GreControl. Full traction (18.4 tonnes) is

available from the start whatever program is run.

• has electric/hydraulic brakes. Four multi-disc brakes in

oil bath in the front and rear differentials.

• has a load-sensing hydraulic system with hydraulicallydriven variable fan with reversing option to blow out the

coolers controlled by GreControl; the oil is cleaned by a

return filter and a microfilter.

• has a 24 volt electrical system with dual 145 Ah

batteries.

4

Gremo 1250F/1450F Workshop manual 1 Introduction

1.4 Intended area of use

1.4 Intended area of use

The machine must only be used for what it has been

designed and adapted for, i.e. forwarding forest raw

materials, the weight of which does not exceed the

machine's maximum load capacity, from felling site in the

forest to the roadside stacking area. All other use is

prohibited.

It is not permitted to rebuild or modify the machine without

Gremo's approval.

It is not permitted to operate the machine on public roads if

it has not been adapted to comply with national road safety

rules.

1.4.1 Improper use

Do not under any circumstances use the machine for

anything it is not designed for, e.g.

The crane

• should never be used to lift loads greater than it was

designed to lift.

• should never be used to tow or push objects.

• should never be used to lift people.

The machine

• should never be used for anything other than it has

been designed for i.e. loading and unloading timber.

• should never be used if any safety feature is out of

order, e.g. if any safety sensor is disconnected.

• should never be used if a window is broken or with the

door open.

• should never be loaded with weights greater than it was

designed to handle.

• should never be parked on a slope, but must always be

parked on level ground to prevent the machine rolling

away or capsizing.

1.4.2 Prohibited operation

It is prohibited to operate the machine if:

• Protection and warning equipment is out of order or

disconnected.

• If brakes or steering system are faulty.

5

1 Introduction

1.5 Operator requirements

1.5 Operator requirements

Gremo 1250F/1450F Workshop manual

• If there are any unauthorised people or vehicles within

the machine's operating area.

• The machine can only be operated by operators with

permission from work supervisors and the necessary

knowledge.

• National laws and regulations relating to driving

licences, operator certificates, etc. must be complied

with at all times.

• Operators must be aware of and follow all local safety

rules.

• Operators must follow the manufacturer's instructions.

• Operators must read and understand the machine's

warning and information signs, as well as understand

and be able to use the machine's protection and

warning equipment.

1.6 Safety regulations

Each country has its own national and local safety

regulations, and it is the responsibility of both the owner

and the operator to know and follow these regulations. If

the recommendations in this Instruction Manual differ from

the national and local safety regulations, then the national

and local safety regulations take precedence over the

recommendations in this Instruction Manual.

During the design and testing of the machine, a great deal

of effort has been made to make the machine safe and

efficient. These efforts may be completely wasted if the

safety and maintenance regulations are not followed.

Accidents are usually caused by humans, not by the

machine. A well-maintained machine and a safety-aware

owner/operator is a profitable and safe combination.

A Gremo machine meets the requirements of the

Machinery Directive and the harmonised standards, plus

national requirements and provisions.

6

Gremo 1250F/1450F Workshop manual 1 Introduction

1.7 Warning symbols and information about risks

1.7 Warning symbols and information about

risks

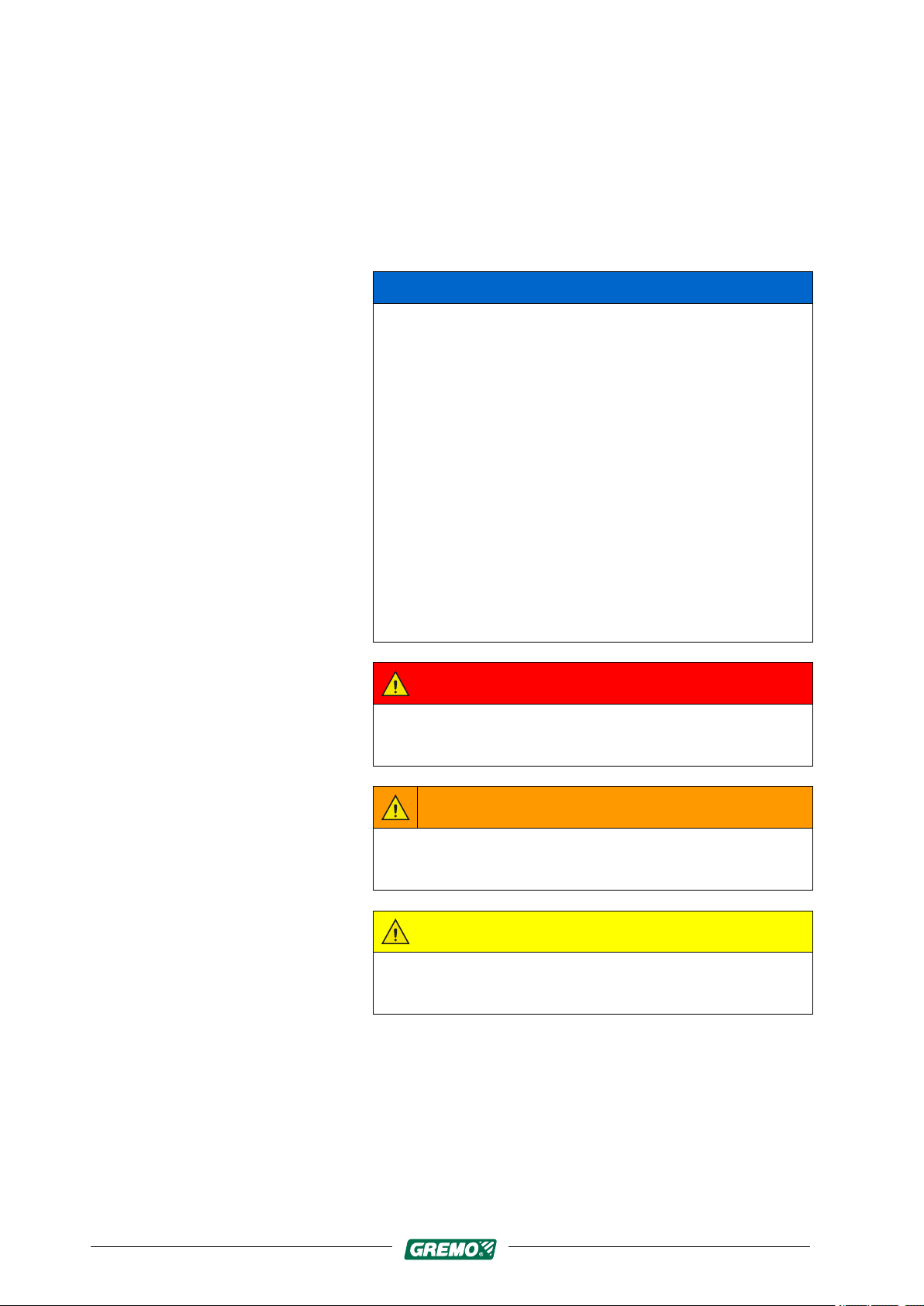

The following warning symbols and signal words are used

throughout this manual and on stickers on the machine:

NOTICE

Read this important information carefully.

If a number of risks occur simultaneously, this Instruction

Manual shows the signal word (DANGER, WARNING,

CAUTION) corresponding to the greatest risk.

NOTE! indicates that attention should be given to

anything concerning safety of the surroundings or the

machine or other important information that may

facilitate understanding or performance of a particular

task.

You can prevent accidents by reading these paragraphs

with special care and always following the instructions.

Remember that your safety and the safety of others may

be affected. It is also the responsibility of the operator to

ensure that all warning stickers are in place on the

machine and are readable.

DANGER

Informs of a very serious hazard which, if not avoided,

may be fatal or cause serious bodily harm

WARNING

Informs of a very hazard which, if not avoided, may be

fatal or cause serious bodily harm.

CAUTION

Informs of a minor hazard which, if not avoided, may

cause minor bodily harm.

7

1 Introduction

1.8 Construction of the machine

1.8 Construction of the machine

1.9 Definitions

Gremo 1250F/1450F Workshop manual

NOTICE

This Instruction Manual is designed to be valid in several

market areas and for most factory-installed equipment.

Please ignore the paragraphs which are not valid for

your machine. We reserve the right to change and

improve the design whenever we find it necessary,

without undertaking to implement these changes on

products which have already been delivered. We also

reserve the right to change data and instructions for

maintenance, service, environment and safety without

further notice.

In this Instruction Manual, the concepts of ‘front’, ‘rear’,

‘right’ and ‘left’ on the machine are defined according to

the principal direction of travel on roads, i.e. the direction

the machine travels when it is steered using the steering

wheel.

Example: the serial number of the machine is punched on

the frame in the front end of the machine, to the right of the

engine compartment.

1.10 Environment

The interplay between human beings, machines and the

environment can be influenced, and is becoming

increasingly important. We have paid attention to this

during the design of the machine and the writing of this

manual, which has a section relating to this subject. By

following these instructions when you drive and maintain

your machine, you will show consideration for humans,

animals and nature in your environment.

8

Gremo 1250F/1450F Workshop manual 1 Introduction

1.11 Location of type plates and serial numbers

1.11 Location of type plates and serial

numbers

Fig. 2 Type plates and serial numbers

1. Type plate for the grapple

2. Type plate for the crane

3. Type plate for the cab

4. Type plate for the machine

5. Type plate for the diesel engine (on the rocker cover)

6. Type plate for the climate system on the right hand side of the radiator

7. The machine's serial number is punched on the front of the right-hand branch deflector.

1.11.1 Serial number

Fig. 3 Serial number

The machine's serial number is punched on the top of the

front of the right-hand branch deflector.

9

1 Introduction

1.11 Location of type plates and serial numbers

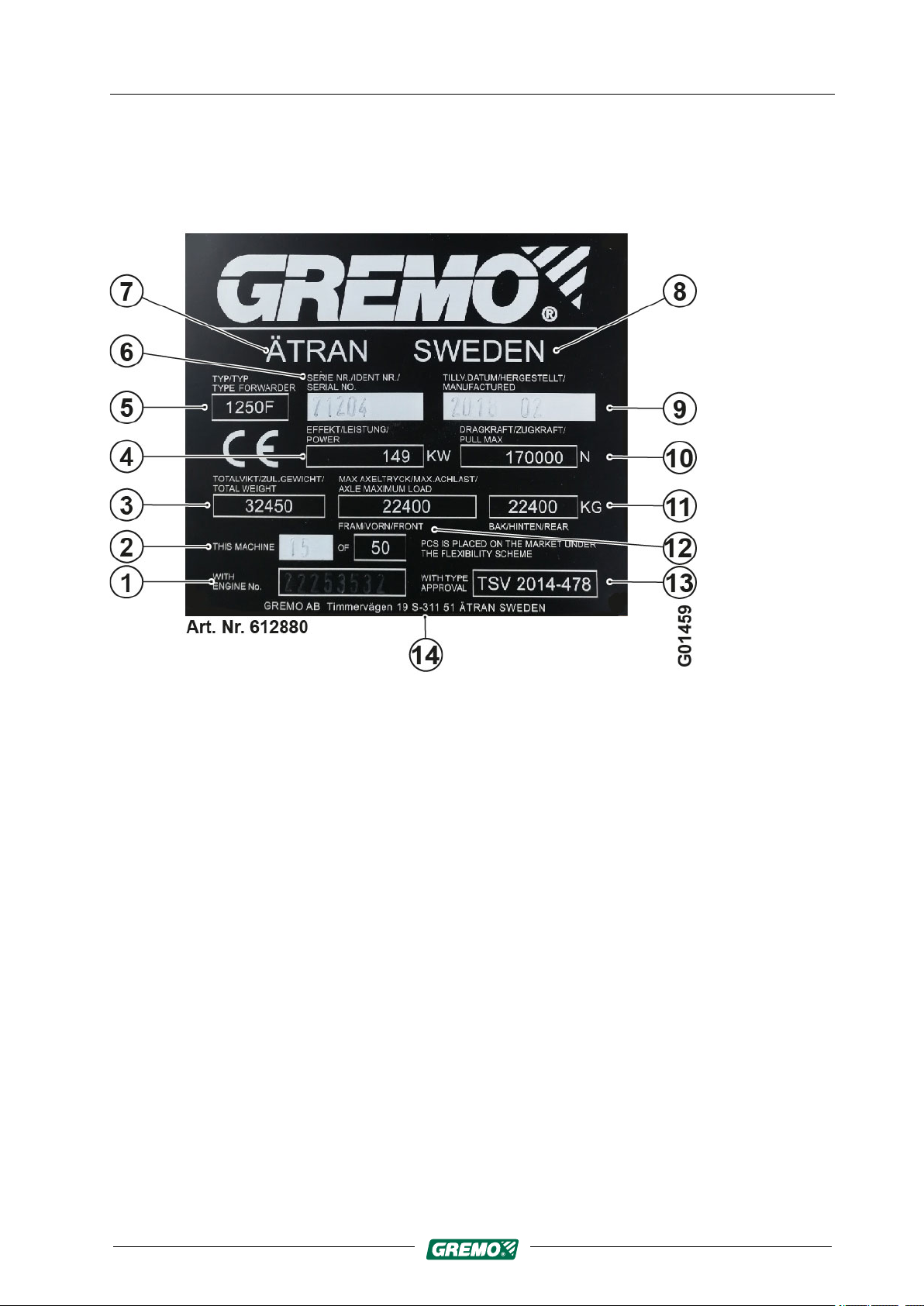

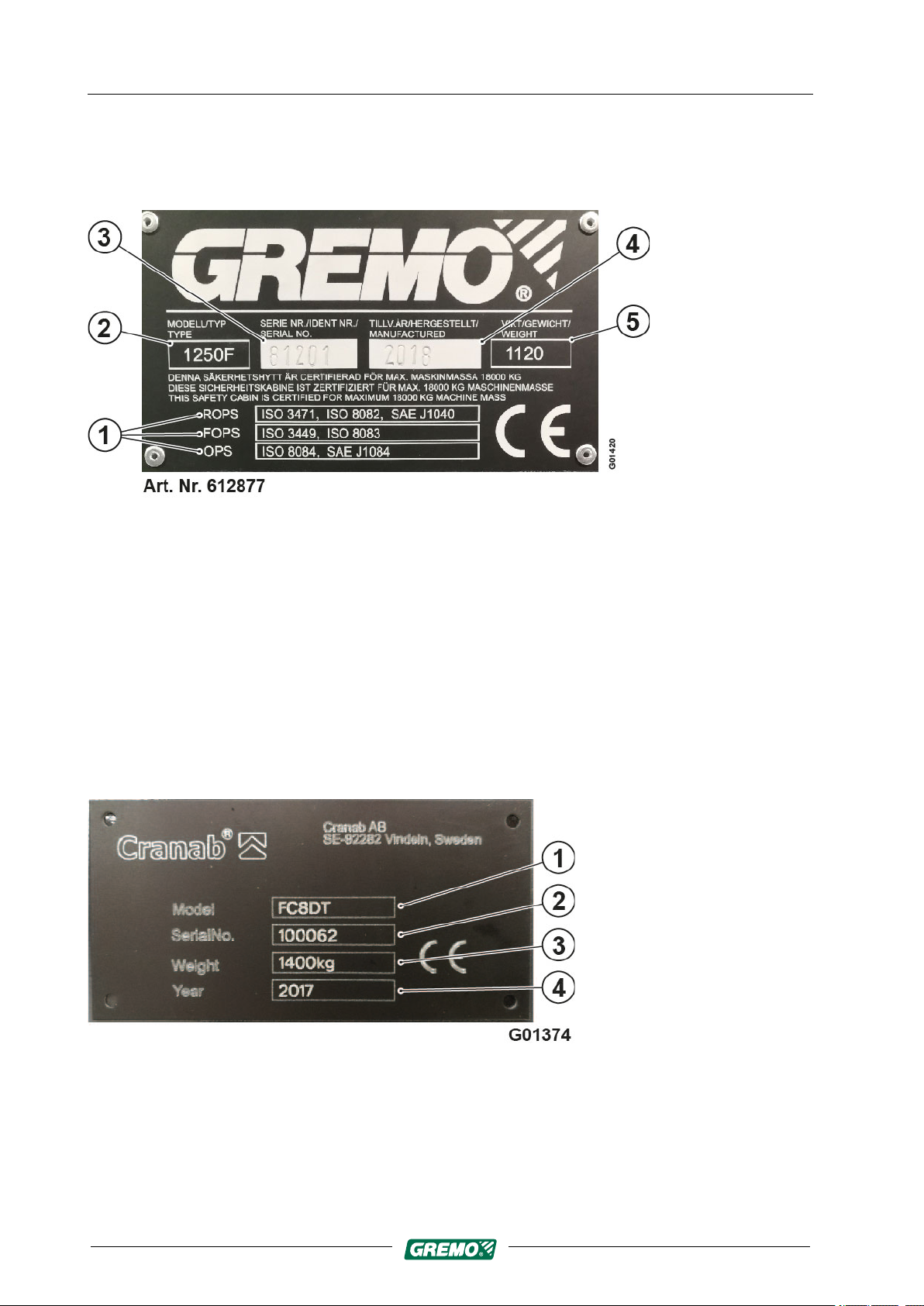

1.11.2 Type plate for the machine

The following details are shown on the machine's type

plate:

Gremo 1250F/1450F Workshop manual

1. Diesel engine’s serial number

2. Machine no. XX of XX

3. Machine's total weight

4. Diesel engine's power in KW

5. Machine model

6. Machine's serial number

7. Place of manufacture

Fig. 4 Type plate for the machine

8. Country of manufacture

9. Year and month of manufacture

10.Machine's traction in N

11. Maximum axle load, rear bogie in kg

12.Maximum axle load, front bogie in kg

13.Type approval according to:

14.Manufacturer's address

10

Gremo 1250F/1450F Workshop manual 1 Introduction

1.11 Location of type plates and serial numbers

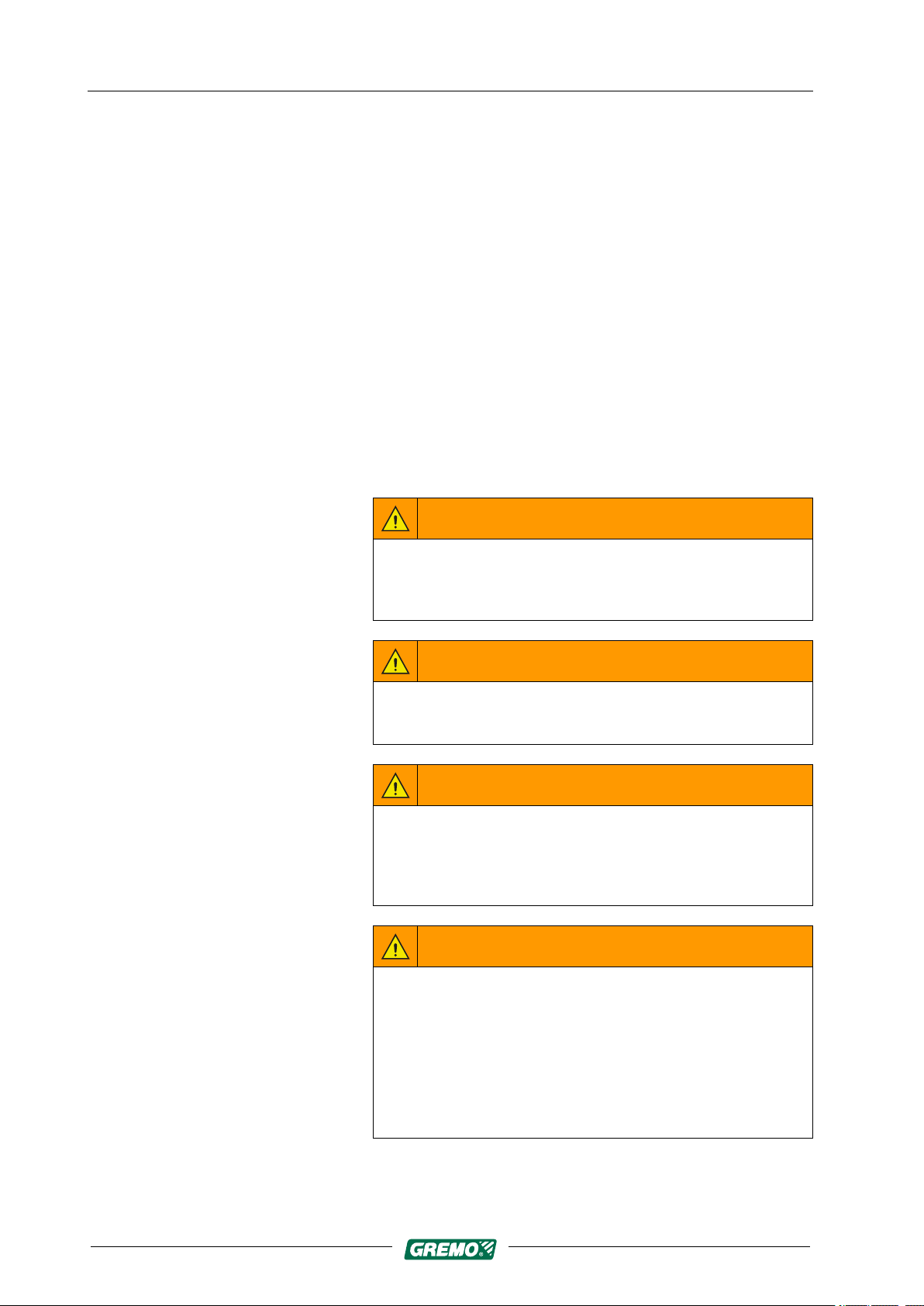

1.11.3 Type plate for the cab

The following details are shown on the cab's type plate:

1. Approved according to:

2. Model/Type

3. Serial no.

4. Year of manufacture

5. Weight

1.11.4 Example of crane type plate

Fig. 5 Type plate for the cab

The following details are shown on the crane's type plate:

1. Model/Type

2. Serial no.

3. Weight

4. Year of manufacture

Fig. 6 Type plate for the crane

11

1 Introduction

1.11 Location of type plates and serial numbers

1.11.5 Example of grapple type plate

The following details are shown on the grapple's type

plate:

Fig. 7 Type plate for the grapple

1. Model

2. Serial no.

Gremo 1250F/1450F Workshop manual

3. Weight

4. Year of manufacture

1.11.6 Type plate for the diesel engine

The machine’s chassis number (engine type and number

are normally connected to the chassis number) must be

stated when ordering spare parts.

If the engine's type plate is not legible, the engine's serial

number can also be read from the engine block on top of

the lubricating oil cooler housing.

The injection pump is itemised from Gremo AB.

The following details are shown on the engine's type plate:

1. Engine serial number

2. Engine type

3. CPL number

4. Valve clearance tolerances

12

Fig. 8 Type plate for the diesel engine

5. Power output data

6. Ignition sequence

7. Important information

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.1 General

2 Safety regulations

2.1 General

Operators, mechanics and supervisors are obliged to

study and follow the safety regulations and advice given in

this chapter.

The machine is equipped with signs, and you should make

yourself familiar with the meaning and location of these

signs. Make sure that the signs are readable and replace

any damaged signs.

Furthermore you shall always follow the laws, statutes or

other national regulations concerning traffic safety and

occupational safety. Local traffic rules and local workplace

regulations must always be followed.

WARNING

The cab is not intended for passenger transport, which is

why it lacks a seat and seat belt for passengers. There is

a risk of fatal accident for passengers!

WARNING

The bogie lift can be used as a lifting aid during service

and repairs, but always prop up the machine.

WARNING

When you lift or prop up the machine or parts of the

machine, make sure that the equipment you use is

intended for this purpose, is appropriately dimensioned,

and cannot slip or tip over!

WARNING

Risk of serious crushing injury or fatal accident!

Always switch off the engine before releasing the cab to

tip it up.

Never go under a tipped-up cab unless it is propped up.

Ensure that the cab is propped up if you need to go

under it!

13

2 Safety regulations

2.1 General

Gremo 1250F/1450F Workshop manual

WARNING

Do not leave the cab without first placing the grapple/

crane safely on the ground or in the loading platform.

WARNING

During all work on the machine, remember the risk of

slipping. You should always use a safety helmet, safety

goggles, gloves, safety boots, breathing protection and

other necessary protective equipment when required.

CAUTION

Never leave the machine unattended with the engine

running or the ignition on.

Never leave the machine unattended with the ignition

key in the ignition lock.

CAUTION

Never operate the machine with loose tools, binders, etc.

in the cab, as these items may injure you if the machine

tips over or brakes suddenly.

Secure them properly.

CAUTION

During servicing, the engine and main power switch

must always be turned off. In some cases this also

applies to fire extinguishing and other electronic

equipment.

CAUTION

14

The manufacturer is not responsible for alterations to the

electrical system of the machine, if these do not

correspond to the original state. The function of the

machine’s safety system can be affected.

CAUTION

The machine may be operated and repaired only by

personnel who have undergone training approved by the

supplier.

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.1 General

NOTICE

For your mobile phone and other portable

communication equipment you should always use

externally mounted aerials in order to prevent

interference with the computers of the machine.

NOTICE

Never use the main power switch to turn off the machine

as this can cause damage to the machine!

NOTICE

Off-road driving requires a lot of experience before you

master the machine. Because of this, you should take it

easy until you are familiar with the limitations of the

machine.

NOTICE

Always bear in mind the danger of fire, and keep the

machine clean. Check the fire extinguishing equipment

as in the instructions.

15

2 Safety regulations

2.2 Clothing

2.2 Clothing

Gremo 1250F/1450F Workshop manual

To prevent clothes getting caught or stuck, clothing should

be intact and tight fitting. Do not use loose garments such

as ties or scarves because they can get caught in levers

and rotating or protruding parts.

Do not wear jewellery as it can conduct electricity or get

stuck in moving parts.

Long hair should be tied back properly as it can easily get

caught in moving parts. Be careful when working with

welders or open flames as hair is flammable.

Always wear gloves, safety footwear, safety goggles, a

safety helmet, ear defenders and other necessary safety

equipment when required.

2.3 Seat belt

Fig. 9 Seat belt

Always use the seat belt.

Replace a damaged or worn seat belt immediately. Order

from you nearest Gremo service dealer or from Gremo AB

using spare part number 92900100.

Before you start operating the machine, check that there is

no one standing close to it. Risk distance 20 m.

Never drive with an open door. The operator’s cab is not a

safety cab if the door is open.

16

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.4 Emergency stop

2.4 Emergency stop

Check the emergency stop function daily. The emergency

stop is the red switch with the yellow plate.

The external emergency stop is located on the right-hand

ascent into the machine, and the cab emergency stop is on

the left-hand 'B' column. When you push the emergency

stop, the diesel engine stops and the brakes are applied.

Fig. 10 External emergency stop

Fig. 11 Cab emergency stop

17

2 Safety regulations

2.5 Emergency exit

2.5 Emergency exit

Fig. 12 Handle side window

Gremo 1250F/1450F Workshop manual

The left-hand side window acts as the emergency exit. To

open the window, grip the latch handle and turn it upwards

until the latch is released. The window can now be opened

outwards.

CAUTION

Note that the side window must always be unlocked

when the machine is operating, to ensure that the

operator can be rescued from outside if the machine tips

over.

Fig. 13 Opened side window

2.6 Emergency alarm

2.7 Articulated joint lock

Emergency alarm equipment, e.g. mobile phone or other

portable communication equipment, must be available.

When you work outside the machine, always take your

mobile phone or other means of communication with you.

NOTICE

The articulated joint lock and the brakes are released

when the machine starts pulling at about 1,000 rpm. If

the crane is slewed at this time, the machine may tip

unexpectedly.

18

The articulated joint lock consists of two hydraulic

cylinders which are automatically blocked and lock the

mid-section when the machine is stopped. The articulated

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.8 Boarding the machine

joint lock is released when you ”rev” with the accelerator

pedal. For settings, see GreControl in the User Manual.

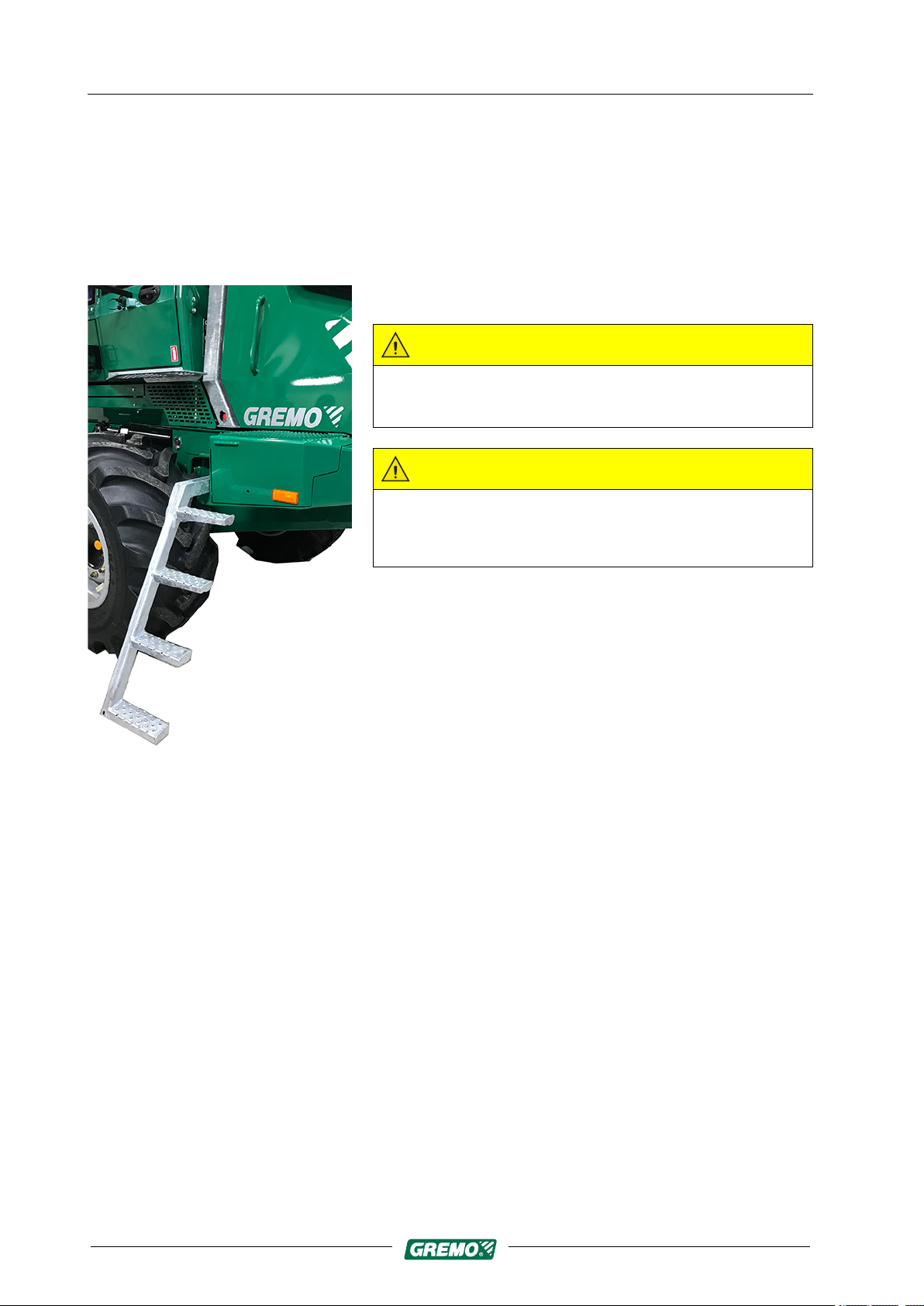

2.8 Boarding the machine

Use the ladder, and hold on to the handle on the bonnet,

the handle on the cab column and the door handle.

CAUTION

Risk of slipping – steps, platforms and chains can be

very slippery in cold weather conditions!

CAUTION

Fig. 14 Ascent

Always descend the ladder facing the machine. This way

you can see and grip the handles. Never jump from the

machine.

19

2 Safety regulations

2.9 Inspection of parking brake

2.9 Inspection of parking brake

Gremo 1250F/1450F Workshop manual

The parking brake is a safety detail and its working order

should be checked.

• Place the fully-loaded machine on a slight slope, 10-12

degrees, or a climb of 2 m per 10 m with free rolling

movement with no obstacles.

• Stop the machine.

• Engage parking brake.

• Switch off the engine.

• The machine should now be standing completely still

without rolling.

• Start the engine and turn the machine around. Repeat

the procedure with the machine facing in the other

direction.

20

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.9 Inspection of parking brake

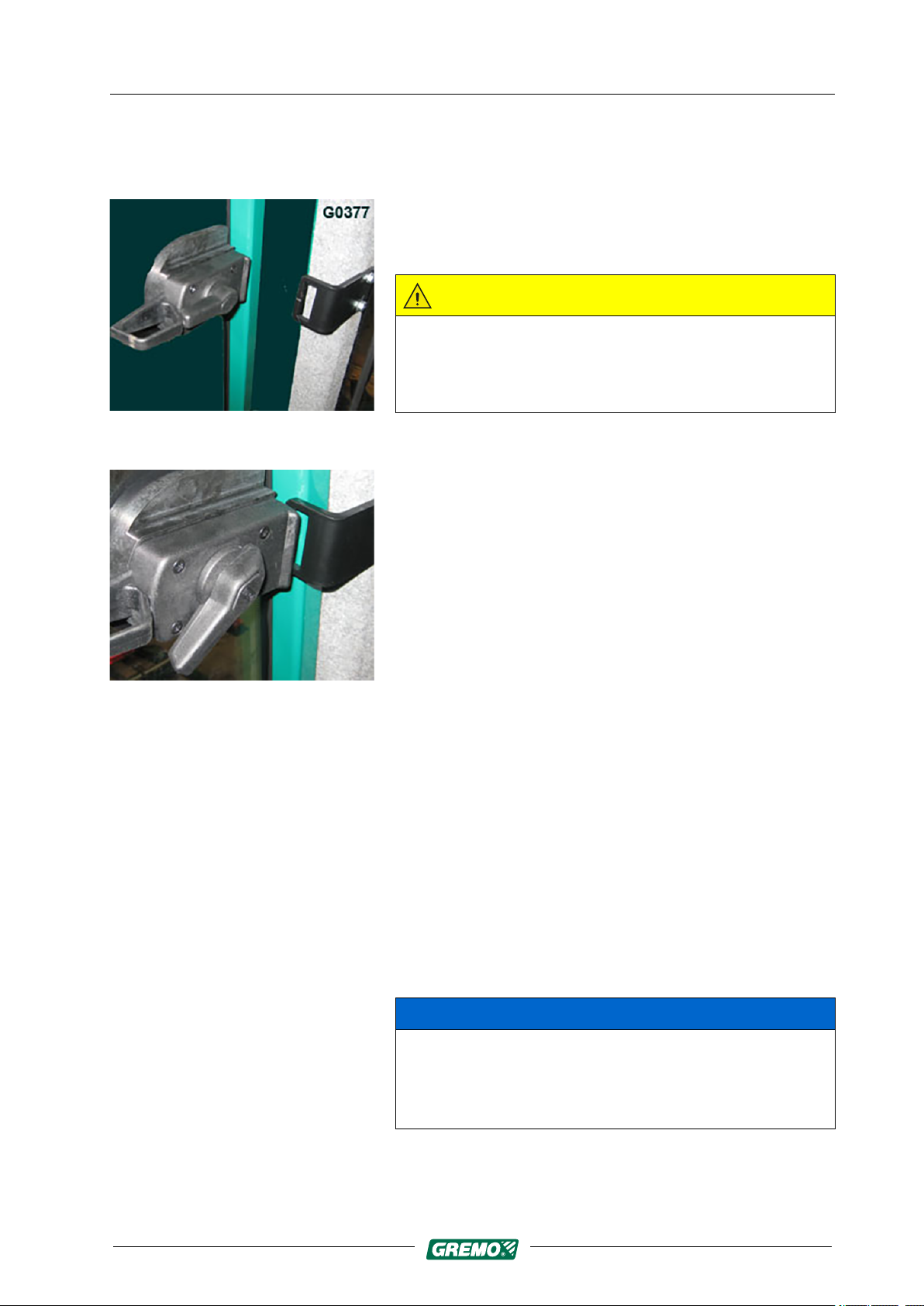

2.9.1 Manual release of parking brake

WARNING

Before starting the work of manually releasing the

parking brake, ensure that the machine's wheels are

locked to prevent it from rolling.

NOTICE

If the parking brake does not release, it may be

necessary to manually release it to move the machine.

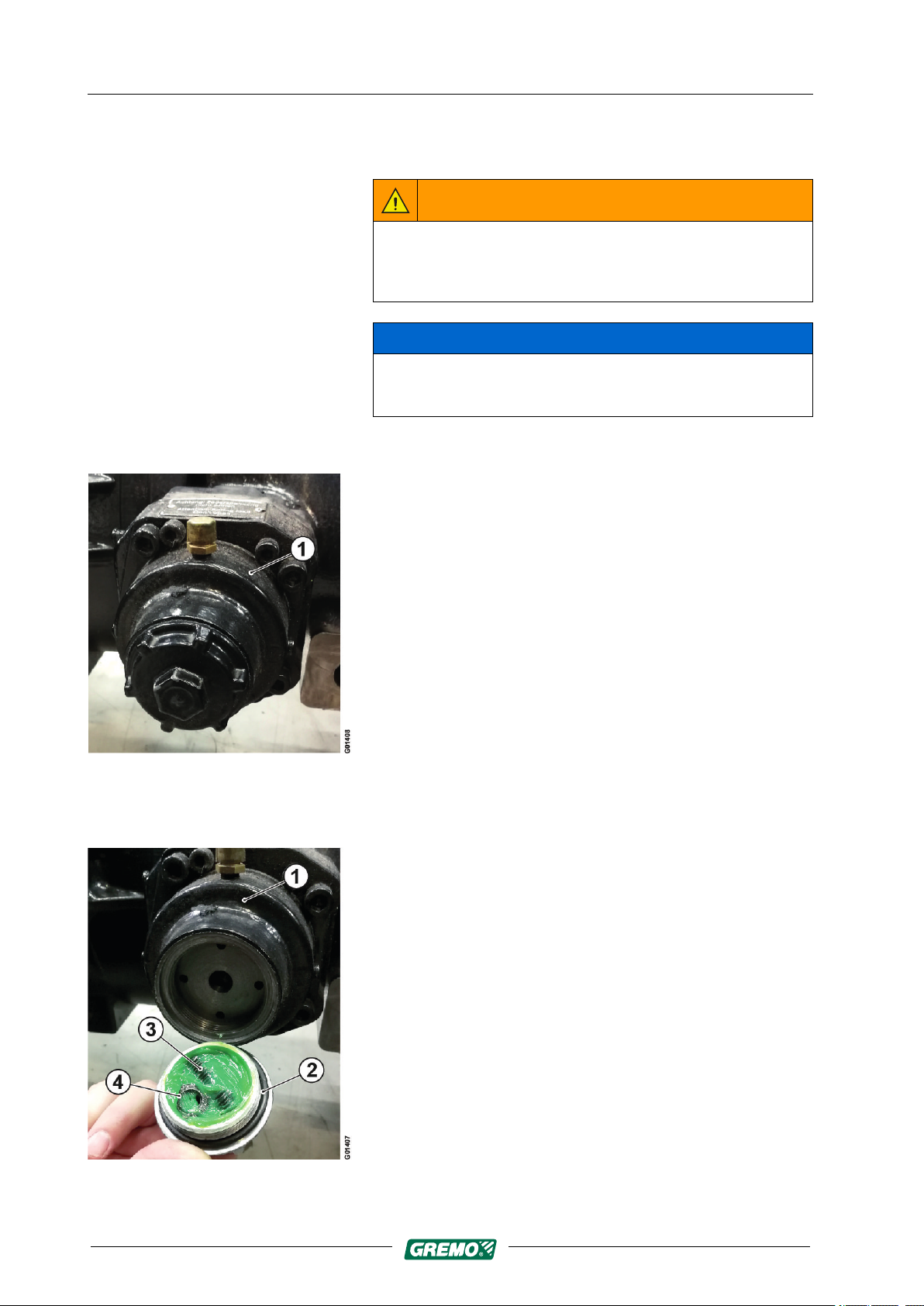

1. Parking brake cylinder

The machine's parking brake can be manually released

if a pressure drop in the hydraulic system prevents

hydraulic release.

Fig. 15

Fig. 16

2. Remove the cover plate (2).

The parking brake (1) is released using a threaded stud

(3) and washer/counter-locking nut (4) found in the

cover plate (2).

21

2 Safety regulations

2.9 Inspection of parking brake

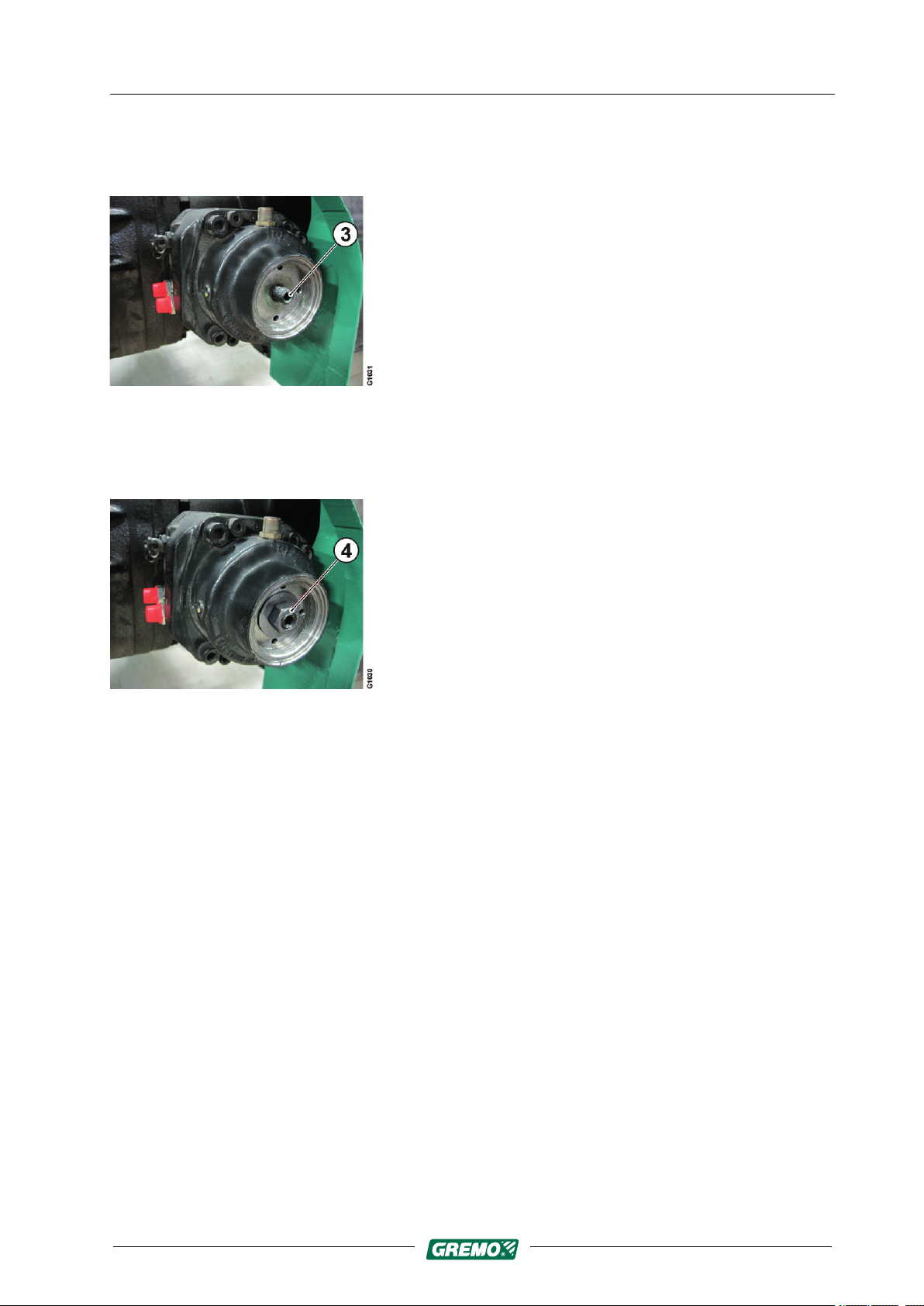

Fig. 17

Gremo 1250F/1450F Workshop manual

3. Screw the threaded stud (3) all the way in through the

hole in the brake cylinder and tighten until it stops.

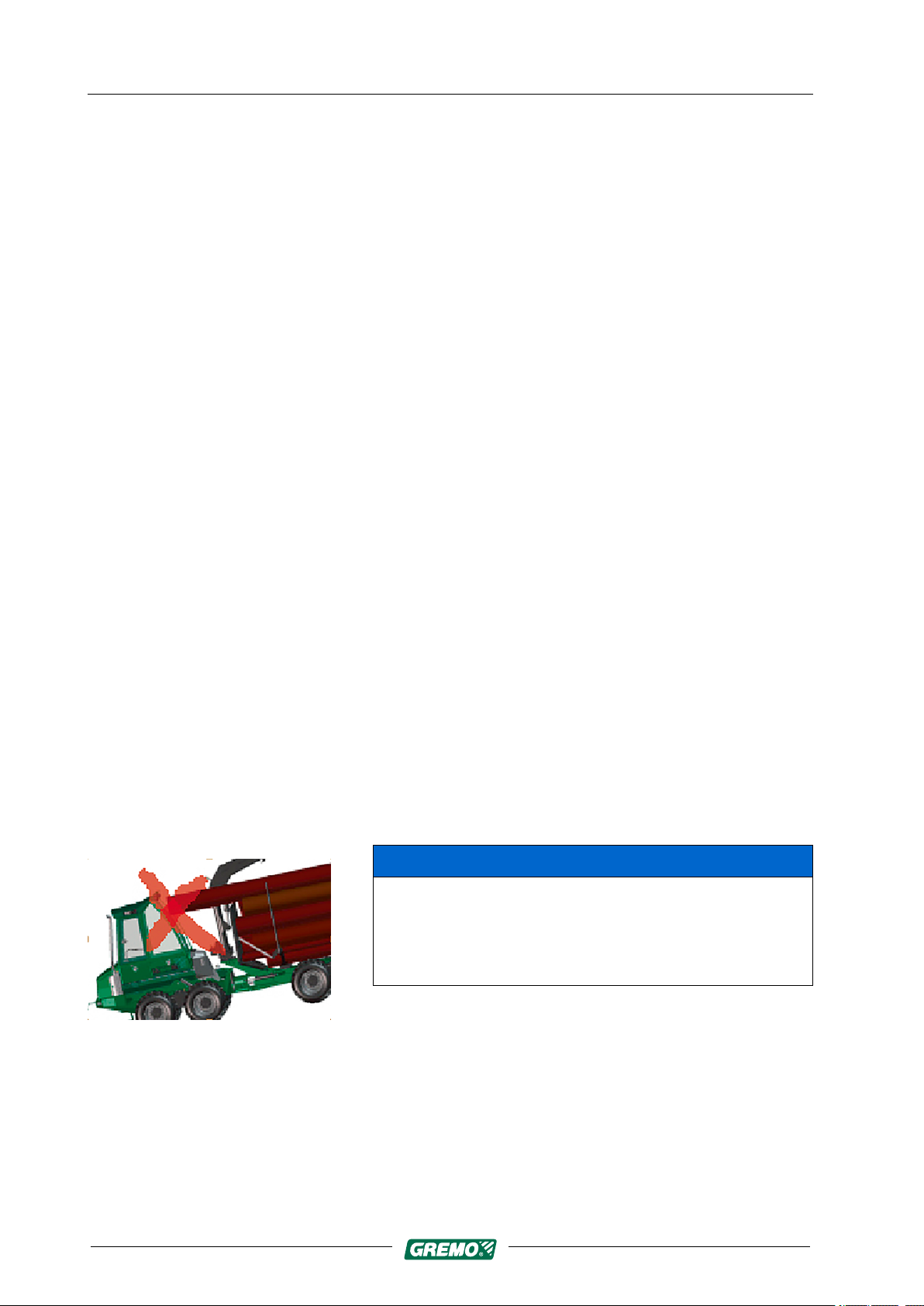

4. Fit the washer and counter-locking nut (4) and tighten

the nut to release the spring force in the brake cylinder.

Fig. 18

5. Repeat for all four brake cylinders to release the

parking brake.

Reset the parking brakes by loosening and removing the

counter-locking nuts, washers and threaded studs again,

and put them back in the cover plate.

22

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.10 Driving

2.10 Driving

The working speed is set between 1,200-1,500 rpm in the

Control System GreControl/IQAN monitor.

As soon as you start to use the crane levers the working

speed is activated, and when you release the crane levers

the revs reduce to an increased idle after the time delay

selected in GreControl. This occurs when the seat is facing

backwards towards the crane/gate.

Driving on public roads

When driving on public roads with other traffic, the steering

wheel must always be used, and the terrain driving

function must be turned off.

Driving speed

A Gremo 1050F is designed to manage a maximum load

of 10,500 kg, even on difficult terrain. Off-road driving

causes large dynamic forces on the machine. The

machine’s own weight, plus the load, increases the stress

in its construction if driven carelessly over difficult terrain.

By driving gently, with feeling and understanding, you can

avoid costly repairs and downtime.

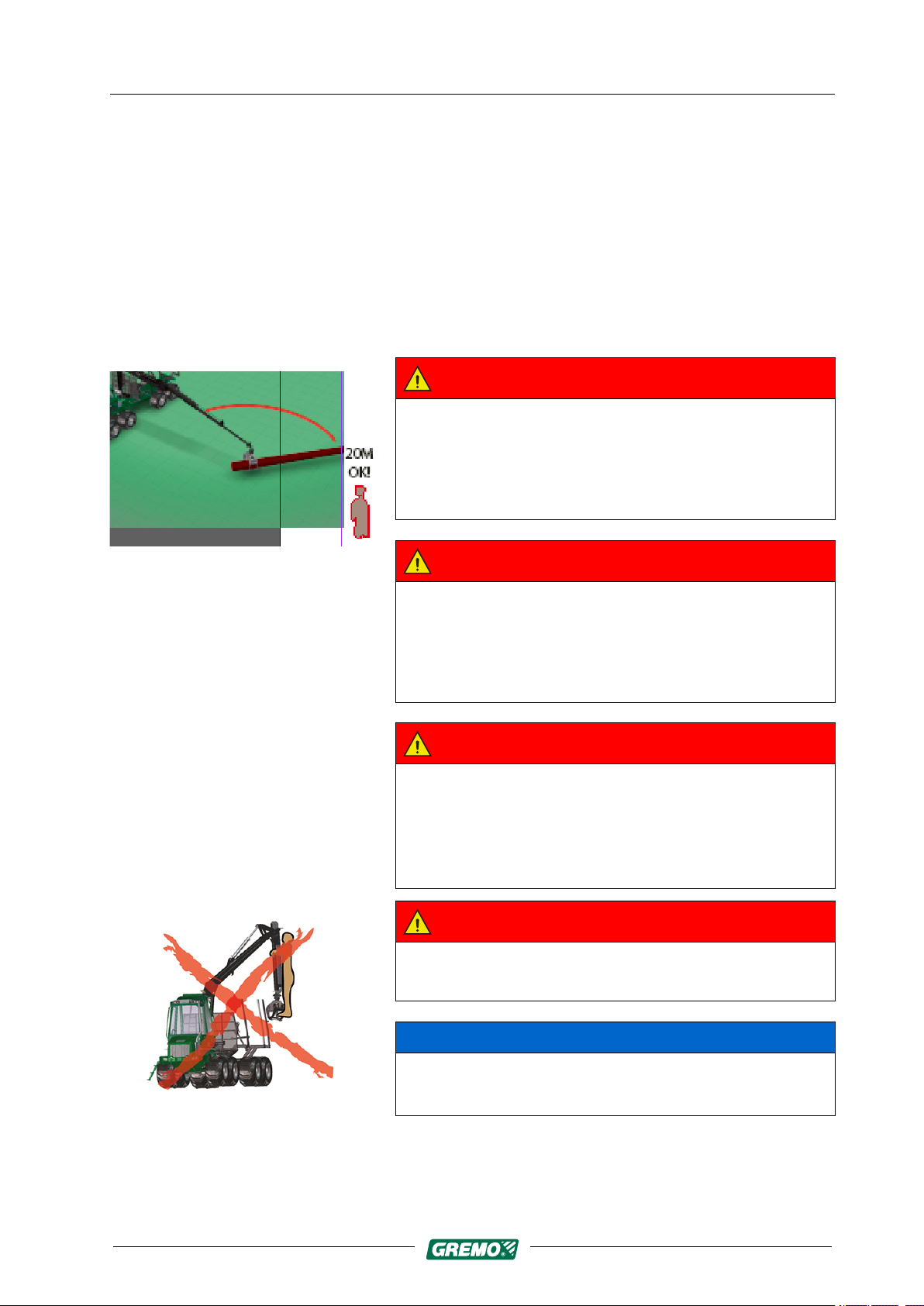

Fig. 19 Overload

Uphill

When driving uphill, the centre of gravity of the payload is

shifted backwards, exerting a lifting force on the front

carriage. If the machine is angled severely in this situation,

it can tip over..

Downhill

The load’s centre of gravity is moved forward when driving

down a slope, and exerts a pushing force on the engine. If

the machine is angled severely in this situation, it can tip

over..

NOTICE

Never load over the top of the gate!

Overloading leads to worse stability, and during downhill

driving the timber may slide over the gate and damage

the machine.

23

2 Safety regulations

2.11 Crane operation

2.11 Crane operation

Gremo 1250F/1450F Workshop manual

Read the instructions carefully before you operate the

crane for the first time. See the sub-supplier's

documentation.

There is a considerable risk of accidents if you start

without being sufficiently familiar with the design, function

and use of the crane. Ensure that you follow the applicable

laws and regulations and that you have full view of the

whole working area.

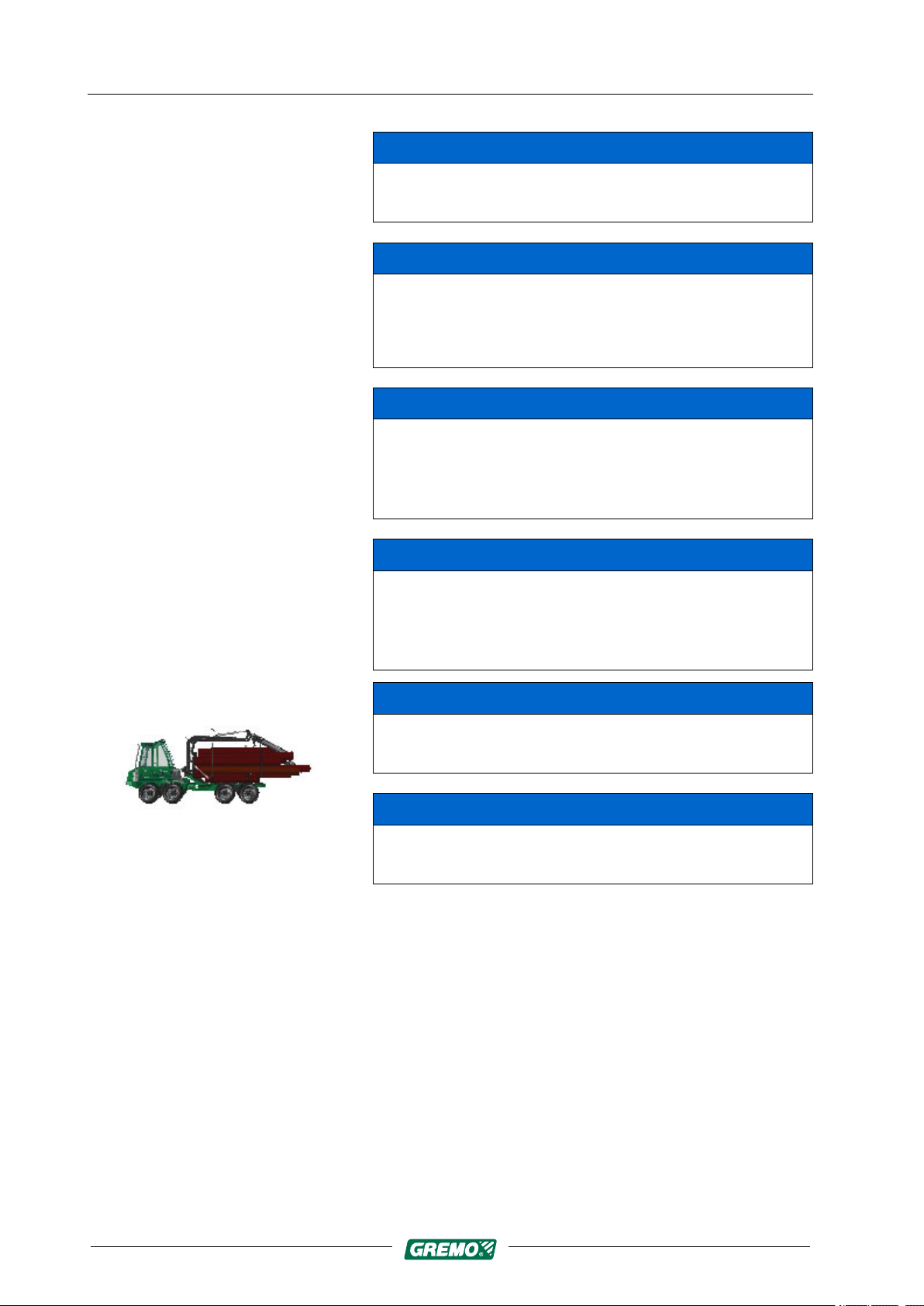

DANGER

Standing under the crane may cause danger to life!

Ensure that there are no unauthorised persons within

the working area of the crane.

Fig. 20 Crane danger area

A risk distance of at least 20 m must be observed!

DANGER

Never work underneath electric power lines.

There is a large risk that the crane touches the power

lines, and this may cause a fatal accident!

A risk distance of at least 10 m must be observed!

DANGER

If the machine comes in contact with overhead power

lines. Remain in your seat and call for assistance!

Danger!

Remain in your seat. Wait for assistance!

DANGER

Fig. 21 lifting people with crane

24

Never use the crane to lift people. Risk of injury or fatal

accident!

NOTICE

Do not move the vehicle when the crane is carrying a

load, or when the crane boom is slewed laterally.

Gremo 1250F/1450F Workshop manual 2 Safety regulations

2.11 Crane operation

NOTICE

Observe the lifting capacity limits on the load sign. Never

overload.

NOTICE

Never run the hydraulic cylinders towards the end stops

at full speed!

Risk of damage to the machine

NOTICE

The articulated joint lock and the brakes are released

when the machine starts pulling at about 1,000 rpm. If

the crane is slewed at this time, the machine may tip

unexpectedly.

Fig. 22 Parking the crane

NOTICE

During transportation the crane should be put on the

load, strapped to the timber. Observe all safety

precautions, as there may be power or telephone lines at

unexpectedly low heights.

NOTICE

Use the reach to pull the timber towards you, and then

lift.

NOTICE

It is prohibited to use the crane for towing timber or other

items.

25

2 Safety regulations

2.12 Parking/storage

2.12 Parking/storage

Gremo 1250F/1450F Workshop manual

• For safety reasons, park the machine on a level surface

when it is not to be used.

• Let the machine idle for a minute or so before turning off

the engine.

• The ladder is folded down when the switch for the

parking brake is put into parking mode.

• Stop the engine.

• Turn off the main power supply.

• Lock the machine!!

Before leaving the machine, always ensure that:

• The machine is parked on a flat surface and not on a

slope.

• The parking brake is engaged.

• The machine is completely still without using the

hydraulics to do so.

• The engine is turned off.

• The main power switch is turned off.

• The machine is locked and the keys are removed from

the machine.

WARNING

For safety reasons, do not park the machine on a slope.

There is the risk that the machine will start to move or tip

over.

26

Loading...

Loading...