H60.0.01.6C-11

Operating Manual

Resistive material moisture measuring

GMH 3810 as of version 1.5

with integrated measuring needles

GREISINGER electronic GmbH Hans-Sachs-Str. 26 Tel.: +49 9402 / 9383-0 http://www.greisinger.de

D-93128 Regenstauf Fax: +49 9402 / 9383-33 eMail: info@greisinger.de

H60.0.01.6C-11 Operating Manual GMH3810 page 2 of 14

CONTENTS

1 IN GENERAL.............................................................................................................................................................................2

1.1 S

1.2 O

1.3 D

1.4 D

1.5 P

AFETY INSTRUCTIONS .........................................................................................................................................................2

PERATING AND MAINTENANCE ..........................................................................................................................................3

ISPOSAL NOTICE .................................................................................................................................................................3

ISPLAY ELEMENTS ..............................................................................................................................................................3

USHBUTTONS ......................................................................................................................................................................3

2 DEVICE CONFIGURATION...................................................................................................................................................4

2.1 'S

2.2 'S

2.3 'U

2.4 'U

2.5 'ATC': A

2.6 'A

2.7 'P

ORT': LIMITATION OF THE MATERIAL SELECTION .................................................................................................................4

OR.X': SELECTABLE MATERIALS (NOT AVAILABLE IF SORT = OFF) ......................................................................................4

NIT %': SELECTION OF MOISTURE UNIT %U / %W...............................................................................................................4

NIT T': SELECTION OF TEMPERATURE UNIT °C /°F ..............................................................................................................4

UTOMATIC TEMPERATURE-COMPENSATION.............................................................................................................4

UTO-HOLD': AUTOMATICALLY FREEZING THE STEADY MEASURE VALUE ...........................................................................4

OWER.OFF': SELECTION OF POWER-OFF DELAY..................................................................................................................4

3 SOME BASICS OF PRECISION MATERIAL MOISTURE MEASURING ......................................................................4

3.1 M

3.2 S

3.3 A

3.4 A

3.5 M

3.6 M

OISTURE CONTENT U AND WET-BASIS MOISTURE CONTENT W ..........................................................................................4

PECIAL FEATURES OF THE DEVICE........................................................................................................................................5

UTO-HOLD FUNCTION.........................................................................................................................................................5

UTOMATIC TEMPERATURE-COMPENSATION ('ATC').............................................................................................................5

EASURING IN WOOD: MEASURING WITH TWO MEASURING-PIKES ....................................................................................5

EASURING OTHER MATERIALS ...........................................................................................................................................6

3.6.1 ‘Hard‘ Materials (concrete or similar):.......................................................................................................................6

3.6.2 ‘Soft‘ Materials:...........................................................................................................................................................6

3.6.3 Measuring bulk cargo, bales and other special measures ...........................................................................................6

3.7 M

EASURING OF MATERIALS, HAVING NO CHARACTERISTIC CURVES STORED.........................................................................6

4 HINTS FOR THE SPECIAL FUNCTIONS ............................................................................................................................7

4.1 M

4.2 P

OISTURE ESTIMATION ('WET' - 'MEDIUM' - 'DRY') .....................................................................................................7

RE-SELECTION OF FAVOURITE MATERIALS ('SORT') .............................................................................................................7

5 FAULT AND SYSTEM MESSAGES.......................................................................................................................................7

6 INSPECTION OF THE ACCURACY / ADJUSTMENT SERVICES ..................................................................................7

7 SPECIFICATION ......................................................................................................................................................................8

APPENDIX A: SORTS OF WOOD .................................................................................................................................................9

APPENDIX B: ADDITIONAL MATERIALS ..............................................................................................................................14

1 In General

1.1 Safety Instructions

This device has been designed and tested in accordance to the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special safety advises given in

this manual will be adhered to when using it.

1. Trouble-free operation and reliability of the device can only be guaranteed if it is not subjected to any other climatic conditions than those

stated under “Specification”.

2. Transporting the device from a cold to a warm environment condensation may result in a failure of the function. In such a case make sure the

device temperature has adjusted to the ambient temperature before trying a new start-up.

3. The circuitry has to be designed most carefully if the device should be connected to other devices. Internal connection in third party devices

(e.g. connection GND and earth) may result in not-permissible voltages impairing or destroying the device or another device connected.

4. Warning: Operating the device with a defective mains power supply (e.g. short circuit from mains voltage to output voltage) may result in

hazardous voltages at the device (e.g. at sensor socket)

5. Whenever there may be a risk whatsoever involved in running it, the device has to be switched off immediately and to be marked accordingly

to avoid re-starting. Operator safety may be a risk if:

- there is visible damage to the device or the device is not working as specified

- the device has been stored under unsuitable conditions for a longer time

In case of doubt, please return device to manufacturer for repair or maintenance.

6. Warning: Do not use these product as safety or emergency stop device, or in any other application where failure of the product could result in

personal injury or material damage.

Failure to comply with these instructions could result in death or serious injury and material damage.

7. Risk of injury! The used measuring heads are very sharp, use thoroughly during your measuring to eliminate a possible risk of injury.

H60.0.01.6C-11 Operating Manual GMH3810 page 3 of 14

1.2 Operating And Maintenance

• Battery

The battery has been used up and needs to be replaced, if and „bAt“ are shown in lower display. The device

!

will, however, continue operating correctly for a certain time.

the battery has been completely used up, if ´bAt´ is shown in the upper display.

The battery has to be removed, when storing device above 50°C.

Hint: We recommend removing the battery if device is not used for a longer period of time! Risk of Leakage

• Treat device and probes carefully. Use only in accordance with above specification. (do not throw, hit against etc.).

Protect plugs and sockets from soiling.

• To disconnect sensor plug do not pull at the cable but at the plug.

• When connecting the probe the plug will slide in smoothly if plug is entered correctly.

• Selection of Output-Mode: The output can be used as serial interface or as analogue output. This choice has to

be done in the configuration menu.

1.3 Disposal Notice

• Dispense exhausted batteries at destined gathering places.

• Send the device directly to us, if it should be disposed. We will dispose the device appropriate and non-polluting.

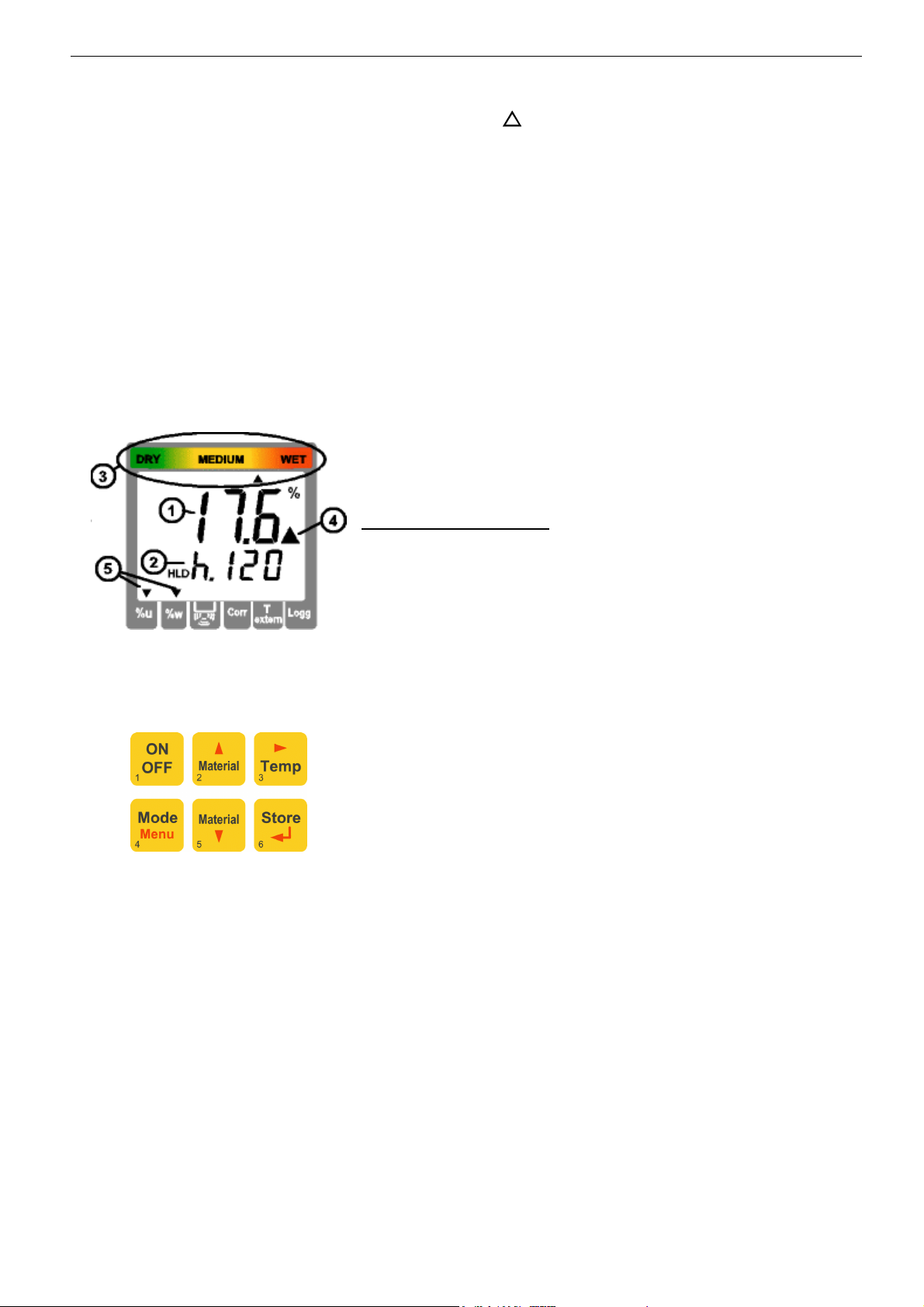

1.4 Display Elements

1 = Main Display:

2 = Auxiliary Display:

Special display elements:

3 = Moisture estimation:

4 = Warning triangle:

5 = “%u” or “%w”

Currently measured material moisture

[percent moisture content]

HLD: Measure value is ‘frozen‘ (Button 6)

Currently selected material

(or temperature when pressing Button 3)

Estimation of the material condition: via top

arrows: DRY - MEDIUM - WET

Indicates low battery

Displays unit: moisture content u or wet basis

moisture content w

All remaining arrows have no function in this version.

1.5 Pushbuttons

key 1: On/Off key

key 4: Set/Menu

press (Menu) for 2 sec.: configuration will activated

key 2, 5: During measure: select a material

p.r.t: 4.2 Pre-selection of favourite materials ('Sort')

List of selectable materials: Appendix A, Appendix B

With manual temperature compensation:

When displaying temperature (call via button 3 ‚Temp‘):

Input of temperature

up/down for configuration:

to enter values or change settings

Key 6:

Key 3: During the measure: shortly displaying temperature or changing to temperature input.

Store/↵↵↵↵:

- Measurement:

with Auto-Hold off: Hold current measuring value ('HLD' in display)

with Auto-Hold on: Start a new measure, which is ready when 'HLD' appears in the display

p.r.t. chapter 3.3 Auto-Hold Function

- Set/Menu or temperature input:

confirming of selected input, return to measure

H60.0.01.6C-11 Operating Manual GMH3810 page 4 of 14

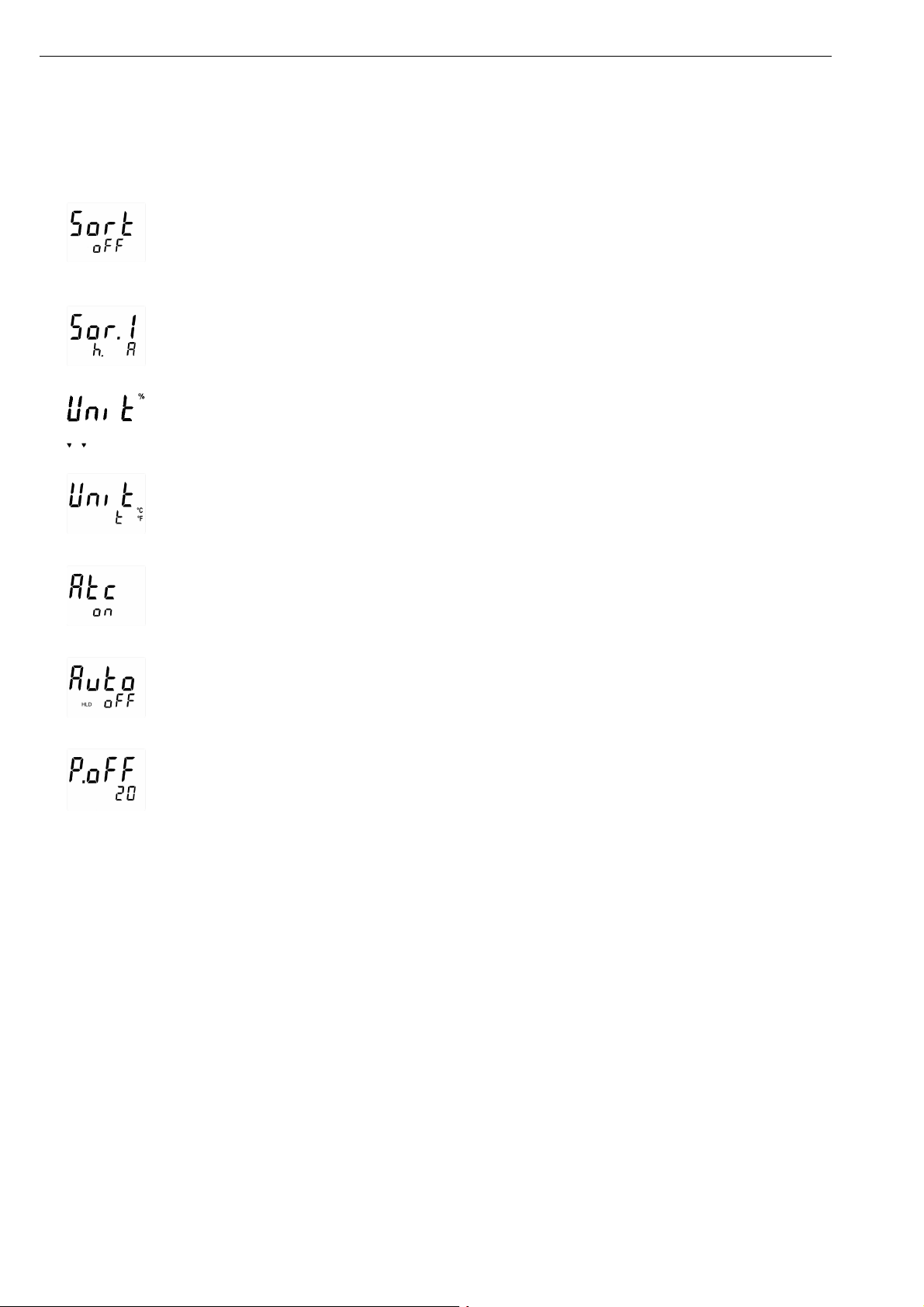

2 Device Configuration

For configuration of the device press "Menu"-key (key 4) for 2 seconds, the first menu will be shown.

Choose between the individual values that can be set by pressing the "Menu"-key (key 4) again.

The individual values are changed by pressing the keys "5" (key 2) or "6" (key 5).

Use key "Store/↵↵↵↵" (key 6) to leave configuration and to store settings.

2.1 'Sort': limitation of the material selection

off:

Unrestricted material selection via key 2 and 5

1...8:

Material selection in-between 1 up to 8 selectable materials.

2.2 'Sor.X': selectable materials (not available if Sort = off)

Depending on the number that had been entered at ‚Sort‘ menu settings from Sor.1 up to Sor.X will be available.

Select the desired material that should be available during the measure via key 2 and 5, p.r.t: 4.2

Pre-selection of favourite materials ('Sort').

2.3 'Unit %': Selection of moisture unit %u / %w

Arrow points to “%u”

Arrow points to “%w”:

Moisture display = moisture content [%u]

Moisture display = wet-basis moisture content [%u]

2.4 'Unit t': Selection of temperature unit °C /°F

°C:

°F:

All temperature values are in degrees Celsius

All temperature values are in degrees Fahrenheit

2.5 'ATC': Automatic temperature-compensation

oFF:

on:

Atc off: Manual input of the temperature for temperature-compensation

via keys.

Atc on: temperature-compensation via temperature of the internal

temperature measuring or with an external temperature probe.

2.6 'Auto-Hold': Automatically freezing the steady measure value

oFF:

on:

Auto-HLD off: continuous measuring.

Auto-HLD on: when reaching a stable measuring result, this will be frozen

with HLD. When pressing the Store-key a new measure will be initiated.

2.7 'Power.off': Selection of Power-Off Delay

1...120:

oFF:

Hint: The settings will be set to the settings ex works, if keys ‘Set‘ and ‘Store‘ are pressed

simultaneously for more than 2 seconds.

Power-off delay in minutes.

Device will be automatically switched off as soon as this time has elapsed

if no key is pressed/no interface communication takes place

Power-off function inactive (necessary for continuous operation)

3 Some Basics Of Precision Material Moisture Measuring

3.1 Moisture Content u and Wet-Basis Moisture content w

Depending on the Application one of the two units is necessary.

Carpenters, joiners and the like commonly use the moisture content u (sometimes referred to as MC).

When evaluating firewood, wood chips etc., the wet basis moisture content w is needed.

The instrument can be configured to both of the values. Please refer to chapter “configuration“.

Moisture content u or MC (relative to dry weight) = dry basis moisture content (mind the arrow at left bottom!)

The unit is %, sometimes used: % MC.

The unit expresses the moisture content like calculated below:

Moisture content u [%] = (weight

- weight

wet

Or:

) / (weight

water

weight

weight

weight

Moisture content u [%] = (weight

: weight of the wet material

wet

: weight of water in the wet material

water

: oven-dry weight of material

dry

Example: 1kg of wet wood, which contains 500g of water has a moisture content u of 100%

) / weight

dry

) *100

dry

dry

*100

H60.0.01.6C-11 Operating Manual GMH3810 page 5 of 14

Wet-Basis Moisture Content w (relative to total weight, mind the arrow at left bottom!)

The wet-basis moisture content expresses the ratio of the mass of water to the total mass of the substance. The ratio

is represented by the following equation (the unit is % as well):

wet-basis moisture w[%] = (weight

- weight

wet

) / weight

dry

wet

*100

Or:

wet-basis moisture w[%] = (weight

) / weight

water

wet

*100

Example: 1kg of wet wood, which contains 500g of water has a moisture content u of 50%

3.2 Special features of the device

466 wood specimens and 28 building materials are stored directly in the memory of the device:

Thus more exact measurements could be reached than common devices with group selections would ever reach.

Even the use of involved conversion tables for building materials will cease to exist!

Example: Common wood-moisture-measuring-devices use one single group for spruce and oak, in reality the deviation

of these characteristic curves is more than 3%! Base for this statement are complex statistical surveys, considered

measuring range 7-25%). This random error will not occur for the whole GMH38xx series, with the help of individual

characteristic curves highest resolution is achieved.

Extreme wide measuring range: 0-100% (depending on characteristic curve) percent moisture content in wood.

Moisture estimation: Additionally to the measuring value, an individual moisture estimation will be displayed

simultaneously.

3.3 Auto-Hold Function

Particularly when measuring dry wood, electrostatic charges and other similar noise could dither the measuring value.

With activated auto-hold function the device will acquire an exact measuring value automatically. During that, the

device could be put down to avoid noise through discharge of the clothing etc. After having acquired the measuring

value, the display will change to ‘HLD’: The value will be frozen as long as a new measuring is initiated by pressing

button 6 (store).

3.4 Automatic temperature-compensation ('Atc')

An exact temperature compensation is important for a reliable wood-moisture-measuring. These devices feature a

integrated temperature measuring and a manual input of the temperature.

The used temperature value therefore is:

Menu Used temperature-value

Atc on Device-internal temperature-measuring

Atc off

Manual input of temperature: shortly press Temp-Button then use 5 (button 2) or 6 (button 5) to input the

temperature confirm selection with ‘Store‘(button 6)

Table 4.2: Using of the temperature-compensation

3.5 Measuring In Wood: Measuring With Two Measuring-Pikes

For measuring wood, punch in the measuring-pikes across to the wood-grain, having a good contact between the pikes

and the wood (measuring along wood-grain deviates minimal).

DO NOT HIT ONTO THE DEVICE OR PUNCH THE NEEDLES IN WITH FORCE!

The device may be damaged.

Select correct wood-sort (see Appendix A).

Ensure measuring the correct temperature (see chapter 3.4).

Now read the measuring-value or when having activated the auto-hold-function initiate a new measuring by pressing

Store/↵↵↵↵ (button 6) .

The measured resistance will be extremely high when measuring dry wood (<15%) thus the measuring will need more

time to achieve its terminal value among other things static discharge could momentarily falsify the measuring.

Therefore beware of static discharge and wait long enough until a stable measuring value is displayed (unstable: „%“

blinking) or use the auto-hold-function (see chapter 3.3 Auto-Hold Function).

Extreme accurate measures can be carried out within the range of 6 to 30%.

Beyond this range the acquirable accuracy will lessen, but the device will deliver reference values still sufficient for the

practitioner.

It is measured between the measuring-pikes insulated among each other. Requirements for an exact measurement:

- choose correct place to measure: place should be free of irregularities like resin–clusters, knurls, rifts, etc.

- choose correct measure depth: Recommendation: for trimmed timber: press in the pikes up to 1/3 of the material

thickness.

- Perform multiple measurements: the more measurements will be averaged, the more exact the result will be.

- Pay attention to temperature-compensation: let the device adapt to the temperature of the wood (Atc on) or enter

the exact temperature manually (Atc off).

H60.0.01.6C-11 Operating Manual GMH3810 page 6 of 14

Frequent sources of errors:

- Attention with oven-dried wood: the moisture dispersion may be irregular, often in the core is more moisture than

on the edge.

- Surface-moisture: The wood-edge could be more humid than the core if the wood had been stored outside and

e.g. was in rain.

- Wood preservative and other treatment could falsify the measuring.

- Fouling at the connections and round the pikes could result in erroneous measurement, especially with dry wood.

3.6 Measuring Other Materials

3.6.1 ‘Hard‘ Materials (concrete or similar):

The needles are not intended for measuring hard building materials. For measuring those materials we suggest you

the adapter cable GMK3810 and the brush probes GBSL91 or GBSK91.

Unscrew the needle holder and mount the adapters for the banana jacks. The red jack has to be connected to the

right-hand socket, this decreases susceptibility of electromagnetic interference.

Drill two holes with Ø6mm (GBSK91) or Ø 8mm (GBSL91) at

intervals of 8 to 10cm into the material to be measured. Do not

use edgeless drills: the resulting heat will evaporate the

moisture which will result in faulty measures. Wait for at least

10min, blow out the holes to clean them from dust. Apply

conductivity compound on the brush-type probes and stick them

into the holes. Choose correct material (see Appendix B:

Additional materials), read the measuring value. Observe that

the holes dry out by-and-by, and the device will measure a value

too low, if you want to use them several times.

This effect can be compensated by using conductivity

compound: insert profuse conductivity compound between the

holes and the brush-type probe, and let the electrode stick in the

hole for about 30min before measuring (with the device

switched off ). Temperature-compensation plays no role when

using the building material measuring.

Measuring concrete with brush probe GBSL91

3.6.2 ‘Soft‘ Materials:

The most important thing is a good contact between the materials and the measuring needles. Whenever this is not

possible because of the material texture, we suggest you to use the adapter cable GMK3810 with appropriate

electrodes, such as impact electrode GSE91 or GSG91, reciprocating piston electrode GHE91.

Unscrew the needle holder and mount the adapters for the banana jacks. The red jack has to be connected to the

right-hand socket, this decreases susceptibility of electromagnetic interference.

Procedure as described in chapter measuring in wood.

3.6.3 Measuring bulk cargo, bales and other special measures

Usable probes: measuring pins GMS 300/91 mounted on GSE91 or GSG91 with adapter cable GMK3810 (red

connector to the right-hand socket).

Measuring of splints, wood chips, insulating material and similar:

When using measuring pins oscillating movements have to be avoided when pushing in the probes. Otherwise hollows

between the probes and the material may falsify the measuring. The material should be sufficiently compressed. When

in doubt repeat the measuring a few times: the highest measuring value is the most exact one.

3.7 Measuring of materials, having no characteristic curves stored

Choose the representative universal material group „h.A“, „h.b“, „h.c“ and „h.d“(for example corresponding to A,B,C

and D of the GHH91) if a conversion table exists.

Attention: The moisture evaluation wet/dry of these material groups is only valid for wood!

Please keep in mind the following when using the temperature-compensation:

Automatic temperature-compensation should always be activated when measuring wood (Act on), with all other

materials the automatic temperature-compensation should be switched off (Act off) and a manual temperature of 20°C

should be entered.

Additionally at GMH3850: The GMH3850 can store up to 4 additional user characteristic curves. For this the

corresponding reference point measurements for the respective material has to be carried out, from which the exact

moisture content has to be dedicated with the Darr-Probe or the CM-Method. The Results can be stored in the device

with the help of the GMHKonfig-Software, and can be accessed by the device directly .

H60.0.01.6C-11 Operating Manual GMH3810 page 7 of 14

4 Hints For The Special Functions

4.1 Moisture estimation ('WET' - 'MEDIUM' - 'DRY')

Additionally to the measuring value, an individual moisture estimation will be displayed simultaneously. This moisture

estimation is only a guidance value, the final evaluation is depending on the application of the material.

E.g. firewood may be already usable while instrument still displays ‘wet’!

Corresponding Standards and Instructions must be observed!

The Device can only complement the skill of a tradesman or investigator but cannot replace it!

4.2 Pre-selection of favourite materials ('Sort')

A pre-selection of different materials (up to 8) can be selected from the menu for an effective working with the device.

For example you can set the Menu Sort to 4 and save the desired materials in Sor.1, Sor.2, Sor.3 and Sor.4 if you only

measure 4 different materials. (see 2.2 'Sor.X': selectable materials (not available if Sort = off))

Only the 4 desired materials can be selected via the buttons up and down, when exiting the menu, a changing during

the measurement can be done comfortably. All materials will be available when setting Sort to off. Sor.1 to Sor.4 will

still be available in the ‘background’, when setting the menu Sort to 4 the limited selection of the 4 entered materials will

be active again. You only want to measure one material: set the menu Sort to 1 you cannot change to another

material, thus a faulty operation is impossible.

5 Fault and System Messages

Display Meaning Remedy

low battery voltage, device will continue to work for a short

time

If mains operation: wrong voltage replace power supply, if fault continues to

low battery voltage replace battery

If mains operation: wrong voltage Check/replace power supply, if fault continues

replace battery

exist: device damaged

to exist: device damaged

No display

or

weird display

Device does not

react on keypress

----

Err.1

Err.2

Err.7 system error return to manufacturer for repair

low battery voltage replace battery

If mains operation: wrong voltage Check/replace power supply, if fault continues

to exist: device damaged

system error Disconnect battery or power supply, wait

some time, re-connect

device defective return to manufacturer for repair

Sensor error: no material connected (meas. Value below

permissible range), no valid signal

charge at the probe, device will discharge (resp. at dry wood) Wait until probe has discharged

Sensor broken or device defective return to manufacturer for repair

Value exceeding measuring range Check: Is the value exceeding the measuring

Probe or device defective return to manufacturer for repair

Value below display range

Probe, cable or device defective return to manufacturer for repair

Connect meas. material

range specified? ->temperature too high!

Check: Is the

range specified? -> temperature too low

value below the measuring

!

6 Inspection of the accuracy / Adjustment Services

Accuracy can be inspected with the testing adapter GPAD 38 (extra equipment).

To check precision select material characteristic curve “.rEF”, choose as moisture display „%u“ and connect the testing

adapter to the needles. The device must display the printed value for the GMH38xx

If the precision is no more corresponding to the imprint of the GPAD 38, we suggest to send the device to the

manufacturer for a new adjustment.

H60.0.01.6C-11 Operating Manual GMH3810 page 8 of 14

7 Specification

Measuring Channel1 Channel2

Principle Resistive material-moisture-measuring Temperature-measuring via NTC

via integrated needles

matching DIN EN 13183-2: 2002

Char. curve 466 different kinds of wood

28 different building materials

Meas. range 0.0...100.0%

(depending on characteristic curve)

equal to ca. 3kOhm ... 2TerraOhm

Resolution 0.1%

Estimation Estimation of the material condition in 9 steps from DRY to WET

Accuracy (Device) ±1Digit (at nominal-temperature)

Temperature drift < 0.005

Nominal temperature 25°C

Ambient Temperature -25 ... +50°C (-13 .. 122°F)

Storage temperature -25 ... +70°C (-13 ... 158°F)

Housing Dimension: 142 x 71 x 26 mm (L x B x D)(L = 175 with measuring needles)

Weight approx. 175 g

Power Supply 9V-Battery, type IEC 6F22 (included)

Power Consumption approx. 2.3mA

Display Two 4 digits LCD’s (12.4mm high and 7 mm high) for material moisture temperature or characteristic curve,

Pushbuttons 6 membrane keys for on/off switch, menu operation, characteristic curve, hold-function etc.

Hold Function Press button to store current value.

Automatic-Off-Function Device will be automatically switched off if no key is pressed/no interface communication takes place for

moisture content 0.1°C / 0.1°F

Wood: ±0.2% moisture content (deviation from ± 0.3°C

characteristic curve, range 6..30%)

building mat.: : ±0.2% moisture content (dev. from

char. curve, range depending on char. curve)

Relative humidity 0 ... 95 %RH (non condensing)

impact resistant ABS, membrane keyboard, transparent panel.

Front side IP65, integrated pop-up-clip for table top or suspended use

hold function, etc. as well as additional pointing arrows.

the time of the power-off delay. The power-off delay can be set to values between 1 and 120 min.; it can be

completely deactivated.

moisture content -30.0... +75.0°C / -22.0... + 167.0°F

moisture content per 1K 0.005% per 1K

EMC: The device corresponds to the essential protection ratings established in the Directives of the European

Parliament and of the council on the approximation of the laws of the memberstates relating to the

electromagnetic compatibility (2004/108/EC).

EN61326 +A1 +A2 (Appendix B, class B), additional error: < 1% FS

H60.0.01.6C-11 Operating Manual GMH3810 page 9 of 14

Appendix A: Sorts of wood

Select kind of wood you want to measure, enter number on the device, e.g. birch = h. 60

Identification Number Comment Range

Group A h. A Wood-group A (equal to GHH91 selector “A”) 0..82%

Group B h. B Wood-group B (equal to GHH91 selector “B”) 1..95%

Group C h. C Wood-group C (equal to GHH91 selector “C”) 2..107%

Group D h. D Wood-group D (equal to GHH91 selector “D”) 3..121%

AS/NZS 1080.1 h. AS Australian reference characteristic curve 4..91%

Group Spruce-Pine-Fir h.402 Softwood-Group 6..99%

GMH38 reference .rEF Internal reference for determining additional characteristic curves /

calculation tables (without temperature-compensation)

Abura

Afrormosia

Afzelia

Agba

Albizia / Iatandza, New

Guinea

Albizia / Iatandza,

Solomon Island

Alder, Blush

Alder, Brown

Alder, Common

Alder, Rose

Alerce

Amberoi

Amoora, New Guinea

Andiroba

Antiaris, New Guinea

Apple, Black

Ash Silvertop

Ash, American

Ash, Bennet's

Ash, Crow's

Ash, European

Ash, Hickory

Ash, Japanese

Ash, Red

Ash, Scaly

Ash, Silver (Northern)

Ash, Silver (Queensland)

Ash, Silver (Southern)

Ash, Silver, New Guinea

Aspen, Hard

Ayan

Balau

Balau, red

Balsa

Basralocus / Angelique

Basswood

Basswood, Fijian

Basswood, Malaysian

Basswood, New Guinea

Basswood, Silver

Basswood, Solomon

Hallea ciliata

Pericopsis elata

Afzelia spp.

Gossweilerodendron

balsamiferum

Albizia falcatara

Albizia falcatara

Solanea australis

Caldcluvia paniculosa

Alnus glutinosa

Caldcluvia

australiensis

Fitzroya cupressoides

Pterocymbium beccarii

Amoora cucullata

Carapa guianensis

Antiaris toxicaria

Planachonella australis

Eucalyptus sieberi

Fraxinus americana

Flindersia bennettiana

Flindersia australis

Fraxinus excelsior

Flindersia ifflaiana

Fraxinus mandshurica

Flindersia excelsa

Ganophyllum falcatum

Flindersia schottina

Flindersia bourjotiana

Flindersia schottina

Flindersia amboinensis

Acronychia laevis

Distemonanthus

benthamianus

Shorea laevis

Shorea guiso

Ochroma pyramidale

Dicorynia guianensis

Tilia americana

Endospermum

macrophyllum

Endospermum

malacense

Endospermum

medullosum

Polyscias elegans

Polyscias elegans

h.2

h.3

h.4

h.426

h.8

h.9

h.10

h.11

h.131

h.12

h.13

h.14

h.15

h.16

h.7

h.17

h.27

h.132

h.18

h.19

h.133

h.20

h.134

h.21

h.22

h.23

h.24

h.25

h.26

h.28

h.285

h.31

h.32

h.33

h.34

h.228

h.35

h.36

h.37

h.38

h.39

7..50%

6..47%

8..42%

6..64%

5..88%

4..72%

5..65%

7..69%

2..107%

6..71%

7..61%

5..67%

3..94%

5..59%

6..83%

7..62%

2..90%

5..79%

6..76%

7..69%

7..56%

6..71%

4..79%

5..67%

5..90%

7..70%

6..88%

7..82%

5..82%

5..66%

7..54%

4..54%

4..68%

4..91%

6..55%

4..85%

4..63%

5..116%

5..76%

7..72%

4..65%

Island

Bean, Black

beech, damped

beech, european -

Beech, Myrtle

Beech, New Zeeland Red

(hearted untreated)

Beech, New Zeeland Red

(sapwood boron)

Beech, New Zeeland Red

(sapwood untreated)

Beech, Silky

Beech, Silver

Beech, Silver (sapwood

tanalith)

Beech, Silver (sapwood

untreated)

Beech, Wau

Beech, White (Fiji)

Beech, White

(Queensland)

Bintangor / Calophyllum,

Fijian

Bintangor / Calophyllum,

Malaysian

Bintangor / Calophyllum,

New Guinea

Bintangor / Calophyllum,

Phillipines

Bintangor / Calophyllum,

Solomon Islands

Binuang

Birch, American

Birch, European

Birch, White

Bishop Wood (Fiji)

Blackbutt

Blackbutt, Western

Australia

Blackwood

Bloodwood, Red

Bollywood

Bossime

Box Grey

Box Grey Coast

Box, Black

Box, Brush (Location

Castanosperum

australe

Fagus sylvatica

Fagus sylvatica

Nothofagus

cunninghamii

Nothofagus fusca

Nothofagus fusca

Nothofagus fusca

Citronella moorei

Nothofagus menziesii

Nothofagus menziesii

Nothofagus menziesii

Elmerrilla papuana

Gmelina vitiensis

Gmelina leichardtii

Calophyllum

leucocarpum

Calophyllum curtisii

Calophyllum

papuanum

Calophyllum

inophyllum

Calophyllum kajewskii

Octomeles sumatrana

Betula lutea

Betula pubescens

Schizomeria ovata

Bischofia javanica

Eucalyptus pilularis

Eucalyptus patens

Acacia melanoxylon

Corymbia gunmifera

Litsea reticulata

Drypetes spp,

Eucalyptus moluccana

Eucalyptus bosistoana

Eucalyptus lafgiflorens

Lophostemon

h.40

h.87

h.86

h.41

h.42

h.43

h.44

h.45

h.46

h.47

h.48

h.49

h.50

h.51

h.53

h.54

h.55

h.56

h.57

h.130

h.59

h.60

h.58

h.61

h.62

h.63

h.64

h.66

h.67

h.70

h.75

h.76

h.71

h.74

6..87%

6..55%

5..85%

6..76%

7..87%

2..97%

5..84%

8..66%

8..58%

6..76%

4..92%

7..96%

5..77%

6..81%

5..81%

6..76%

4..98%

6..78%

6..85%

5..73%

7..72%

5..96%

7..75%

5..73%

4..92%

6..88%

6..75%

7..78%

5..78%

7..62%

8..73%

7..76%

5..92%

5..53%

H60.0.01.6C-11 Operating Manual GMH3810 page 10 of 14

Unknown)

Box, Brush (N.S.W.)

Box, Brush (Queensland

Box, Kanuka

Boxwood, New Guinea

Boxwood, Yellow

Brachychiton

Bridelia

Brigalow

Brownbarrel

Bubinga

Buchanania

Burckella, Solomon

Island

Butternut, Rose

Camphorwood, New

Guinea

Campnosperma

(Malaysia)

Campnosperma

(Solomon Island)

Cananga (Phillipines)

Canarium Solomon

Island

Canarium, African

Canarium, Fijian

Canarium, New Guinea

Candlenut

Carabeen, Yellow

Cathormion, New Guinea

Cedar , Amercan

Cedar, incense

Cedar, White

Cedar, Yellow

Celtis, New Guinea

Celtis, Solomon Island

Cheesewood, White

(Queensland) /Asian

Alstonia

Chengal (Malaysia)

Cherry, American

Cherry, European

Cleistocalyx

Coachwood

Coondoo, Blush

Cordia, New Guinea

Corkwood, Grey

Courbaril

Cudgerie, Brown

Cupiuba

Curupixá

Cypress

Cypress, Northern

Cypress, Rottnest Island

Cypress, White

confertus

Lophostemon

confertus

Lophostemon

confertus

Tristania laurina

Xanthophyllum

papuanum

Planchonella

pholmaniana

Brachychiton

carrthersii

Bridelia minutiflora

Acacia harpohylla

Eucalyptus fastigata

Guibourtia demeusii

Buchanania

arborescens

Burckella obovata

Blepharocarya

involucrigera

Cinnamomum spp,

Campnosperma curtisii

Campnosperma

kajewskii

Canagium odoratum

Canarium salomonese

Canarium Scheinfurthii

Canarium oleosum

Canarium vitiense

Aleurites moluccana

Sloanea woollsii

Cathormion

umbellatum

Cedrela odorata

Calocedrus decurrens

Melia azedarach

Chamaecyparsis

nootkatensis

Celtis spp,

Celtis philippinesis

Alstonia scholaris

Neobalanocarpus

heimii

Prunus serotina

Prunus avium

Cleistocalyx mirtoides

Ceratopetalum

apetalum

Planchonella laurifolia

Cordia dichotoma

Erythrina vespertillio

Hymenaea coubaril

Canarium

australasicum

Goupia glabra

Micropholis

Cupressus spp,

Callitris intratropica

Callitris preisii

Callitris glaucophylla

h.72

h.73

h.77

h.78

h.79

h.80

h.81

h.82

h.83

h.84

h.85

h.88

h.89

h.90

h.91

h.92

h.93

h.97

h.94

h.95

h.96

h.98

h.99

h.100

h.102

h.65

h.101

h.457

h.103

h.104

h.105

h.106

h.216

h.217

h.107

h.108

h.109

h.110

h.111

h.112

h.113

h.147

h.114

h.456

h.115

h.116

h.117

4..55%

7..46%

6..78%

5..69%

7..62%

5..55%

5..103%

5..83%

5..80%

7..70%

4..76%

4..59%

5..69%

6..74%

8..95%

3..78%

7..62%

4..65%

7..80%

5..77%

5..75%

0..168%

6..67%

4..56%

8..67%

5..96%

7..86%

4..91%

5..67%

4..56%

5..77%

4..76%

5..97%

7..68%

5..85%

4..84%

6..60%

5..51%

6..57%

7..53%

7..67%

6..56%

6..52%

5..89%

6..78%

7..80%

6..86%

Dakua, Salusalu (Fiji)

Dibetou/African walnut

Dillenia (Solomon Island)

Doi (Fiji)

Duabanga, New Guinea

Ebony, african

Ekki

Elm, European

Elm, White

Evodia, White

Figwood (Moreton Bay)

fir, alpine

fir, amabilis

Fir, Douglas

Fir, Douglas (New

Zealand) (sapwood

treated)

Fir, Douglas (New

Zealand) (sapwood

untreated)

Fir, Douglas (New

Zealand) (truewood

untreated)

fir, grand

Fir, Spruce

fir, white / fir, silver

Galip

Garo-Garo

Garuga

Goncalo Alvez

Greenheart

Greenheart, Queensland

Guarea, black

Guarea, white

Guariuba

Gum, Black

Gum, Blue, Sidney

Gum, Blue, Southern

Gum, Grey

Gum, Grey, Mountain

Gum, Maiden's

Gum, Manna

Gum, Mountain

Gum, Pink

Gum, Red, American

Gum, Red, Forest

Gum, Red, River

Gum, Rose / Gum,

Saligna

Gum, Shining

Gum, Spotted (Victoria)

(Lemon-Scented)

Gum, Sugar

Gum, White Dunn's

Gum, Yellow

Handlewood, Grey

Handlewood, White

Hardwood, Johnstone

Decussocarpus

vitiensis

Lovoa trichilioides

Dillenia salomonese

Alphitonia zizphoides

Duabanga moluccana

Diospyros spp,

Lophira alata

Ulmus spp,

Ulmus americana

Melicope micrococca

Ficus macrophylla

Abies lasiocarpa

Abies amabilis

Pseudotsuga menziesii

Pseudotsuga menziesii

Pseudotsuga menziesii

Pseudotsuga menziesii

Abies grandis

Abies magnifica

Abies alba

Canarium indicum

Matrixiodendron

pschyclados

Garuga floribunda

Astronium spp,

Ocotea rodiaei

Endiandra compressa

Guarea cedrata

Guarea cedrata

Clarisia racemosa

Nyssa sylvatica

Eucalyptus saligna

Eucalyptus globulus

Eucalyptus punctata

Eucalyptus

cypellocarpa

Eucalyptus maidenii

Eucalyptus viminalis

Eucalyptus

dalrympleana

Eucalyptus fasciculosa

Liquidambar styraciflua

Eucalyptus tereticomis

Eucalyptus

camaldulensis

Eucalyptus grandis

Eucalyptus nitens

Corymbia spp,

Eucalyptus cladocalyx

Eucalyptus dunnii

Eucalyptus leucoxylon

Aphanante

phillipinensis

Strebulus pendulinus

Bakhousia bancroftii

h.118

h.119

h.120

h.121

h.124

h.125

h.29

h.374

h.373

h.135

h.139

h.410

h.411

h.122

h.140

h.141

h.142

h.412

h.413

h.414

h.143

h.144

h.145

h.146

h.148

h.149

h.68

h.69

h.150

h.162

h.152

h.151

h.153

h.154

h.155

h.156

h.157

h.158

h.166

h.159

h.160

h.161

h.163

h.164

h.165

h.167

h.168

h.169

h.170

h.171

6..83%

7..68%

4..65%

5..72%

4..72%

6..55%

4..73%

7..51%

5..69%

5..60%

7..56%

6..80%

4..91%

5..91%

6..73%

5..108%

3..99%

4..91%

5..97%

5..93%

5..64%

5..67%

6..53%

6..45%

6..100%

7..82%

7..94%

9..67%

8..57%

7..76%

7..76%

6..79%

5..89%

6..79%

7..79%

4..80%

3..89%

6..85%

5..92%

7..82%

7..94%

7..81%

5..83%

4..72%

6..79%

4..72%

7..73%

5..66%

7..58%

5..62%

H60.0.01.6C-11 Operating Manual GMH3810 page 11 of 14

River

Hemlock / Hemlock,

Western

Hemlock, Chinesische

Hevea

Hickory

Hollywood, Yellow

Horizontal

Incensewood

Iroko

Ironbark, Grey

Ironbark, Grey

Ironbark, Red

Ironbark, Red, Broad

Leaved

Ironbark, Red, Narrow

Leaved

Jarrah

Jelutong

Jequitibá

Kahikatea (New Zealand)

(Boron)

Kahikatea (New Zealand)

(Thanalith)

Kahikatea (New Zealand)

(untreated)

Kamarere (Fiji)

Kamarere (New Guinea)

Kapur

Karri

Kauceti

Kauri

Keledang

Kempas

Keranji (Malaysia)

Keruing

Kiso

Lacewood, Yellow

Laran

Larch

Larch, American / Larch,

Western

Larch, Japanese

Lauan, Red

Leatherwood

Lightwood

Limba

Lime, European

Louro, Red

Macadamia

Magnolia

Mahogany, Brush

Mahogany, Miva

Mahogany, New Guinea

Mahogany, Red

Mahogany, Rose

Mahogany, Southern

Mahogany, White

Tsuga heterophylla

Tsuga chinensis

Hevea Brasiliensis

Carya spp.

Premna lignum-vitae

Anodopetalum

biglandulosum

Pseudocarapa nitidula

Chlorophora excesla

Eucalyptus

drephanophylla

Eucalyptus paniculata

Eucalyptus sideroxylon

Eucalyptus fibrosa

Eucalyptus cerbra

Eucalyptus marginata

Dyera costulata

Cariniana spp,

Dacrycarpus

docrydiodies

Dacrycarpus

docrydiodies

Dacrycarpus

docrydiodies

Eucalyptus deglupta

Eucalyptus deglupta

Dryobalanops spp,

Eucalyptus diversicolor

Kermadecia vitiensis

Agathis australis,

boroneensis

Artocarpus lanceifolius

Koomapassia excelsa

Dialium platysepalum

Dipterocarpus spp,

Chisocheton

schumannii

Polyalthia oblongifolia

Anthocephalus

chinensis

Larix decidua

Larix occidentalis

Larix kaempferi

Shorea negrosensis

Eucryphia lucida

Acacia implexa

Terminalia superba

Tilia vulgaris

Ocotea rubra

Floyda praealta

Magnolia

acuminata/grandiflora

Geissos benthamii

Dysoxylum muelleri

Dysoxylum spp,

Eucalyptus botryoides

Dysoxylum fraseranum

Eucalyptus botryoides

Eucalyptus

acmenoides

h.172

h.173

h.174

h.175

h.176

h.177

h.178

h.179

h.180

h.181

h.182

h.183

h.184

h.185

h.186

h.187

h.188

h.189

h.190

h.191

h.192

h.193

h.194

h.200

h.201

h.202

h.203

h.204

h.205

h.218

h.219

h.223

h.221

h.220

h.222

h.224

h.225

h.226

h.227

h.229

h.231

h.232

h.233

h.242

h.243

h.241

h.244

h.245

h.246

h.247

8..54%

5..75%

7..71%

6..69%

7..67%

7..84%

8..58%

7..46%

7..88%

5..86%

8..79%

8..81%

5..86%

5..92%

0..104%

5..64%

7..63%

6..73%

6..74%

5..66%

5..83%

7..73%

5..79%

4..57%

5..78%

0..132%

4..89%

5..51%

6..64%

6..54%

5..68%

7..67%

5..69%

5..98%

5..99%

5..62%

6..79%

7..62%

6..56%

4..78%

5..76%

7..59%

6..88%

7..57%

8..73%

6..74%

7..91%

7..65%

5..82%

6..93%

Mahogony Khaya

Mahogony, American

Mahogony, Phillipines

Mahogony, Phillipines

Mahogony, Sapelli /

Sapele

Mahogony, Sipo / Utile

Mahogony, Tiama / gedu

nohor

Mako

Makoré

Makorè

Malas

Malletwood

Malletwood, Brown

Manggachapui

Mango

Mango, Phillipines

Mangosteen (Fiji)

Mangrove, Cedar

Maniltoa (Fiji)

Maniltoa (New Guinea)

Mansonia

Maple, New Guinea

Maple, Queensland

Maple, Rose

Maple, Scented

Mararie

Marri

Masiratu

Massandaruba

Matai

Mengkulang

Meranti, Buik from 1999

Meranti, Dark Red

Meranti, Nemesu from

1999

Meranti, Seraya from

1999

Meranti, Tembaga from

1999

Meranti, White

Meranti, Yellow

Merawan

Merbau

Mersawa

Messmate

Moabi

Mora

Moustiqaire

Musizi

Neuburgia

Nutmeg (Fiji)

Nutmeg (New Guinea)

Nyatoh

Oak, European

Oak, Japanese

Oak, New Guinea

Khaya spp,

Swietenia spp,

Parashorea plicata

Shorea almon

Entandrophragma

cylindricum

Entradrophragma utilie

Entadrophragma

angolense

Trischospermum richii

Thieghemmella

africana

Thieghemella heckelii

Homalium foetidum

Rhodamnia argentea

Rhodamnia rubescens

Hopea acuminata

Mangifera minor

Mangifera altissima

Garcinia myrtifolia

Xylocarpus

australasicus

Maniltoa grandiflora

Maniltoa pimenteliana

Mansonia altissima

Flindersia

pimentelianan

Flindersia brayleyana

Cryptocarya

erythroxylon

Flindersia laevicarpa

Pseudoweinwannia

lanchanocarpa

Eucalyptus calophylla

Degeneria vitiensis

Manilkara kanosiensis

Podocarpus spicatus

Heritiera spp,

Shorea platiclados

Shorea spp,

Shorea pauciflora

Shura curtisii

Shorea leprosula

Shorea hypochra

Shorea multiflora

Hopea sulcala

Intsia spp,

Anisoptera laevis

Eucalyptus obliqua

Baillonella toxisperma

Mora excelsa

Cryptocarya spp,

Maesopsis eminii

Neuburgia collina

Myrstica spp,

Myrstica buchneriana

Palaquium spp,

Quercus robur L.,

Quercus spp,

Castanopsis

acuminatissima

h.235

h.234

h.236

h.237

h.238

h.239

h.240

h.248

h.123

h.249

h.250

h.251

h.252

h.253

h.254

h.255

h.256

h.257

h.258

h.259

h.260

h.261

h.262

h.263

h.264

h.265

h.266

h.267

h.268

h.269

h.270

h.271

h.272

h.274

h.275

h.276

h.277

h.273

h.278

h.279

h.280

h.281

h.282

h.283

h.284

h.286

h.287

h.290

h.291

h.292

h.126

h.127

h.293

7..82%

6..84%

5..93%

4..67%

5..99%

6..110%

10..54%

3..68%

6..86%

7..80%

5..72%

5..68%

5..70%

6..87%

4..68%

7..93%

5..68%

6..82%

6..58%

6..58%

7..80%

6..87%

5..136%

6..64%

7..57%

8..75%

5..64%

5..67%

4..65%

6..73%

5..67%

4..61%

5..94%

4..91%

5..62%

3..72%

4..94%

0..111%

4..90%

6..84%

4..96%

8..75%

6..83%

5..59%

4..77%

7..94%

7..75%

5..74%

5..78%

4..71%

4..87%

4..91%

4..90%

H60.0.01.6C-11 Operating Manual GMH3810 page 12 of 14

Oak, Red

Oak, Silky, Fishtail

Oak, Silky, Northern

Oak, Silky, Red

Oak, Silky, Southern

Oak, Silky, White

Oak, Tasmanian

Oak, Tulip, Blush

Oak, Tulip, Brown

Oak, Tulip, Red

Oak, Tulip, White

Oak, WhiteObah

Obeche

Odoko

Olive

Olivillo

Opepe

Padauk, African

Palachonella, Fijian

Palachonella, New

Guinea

Palachonella, New

Guinea

Palachonella, Solomon

Island

Paldao

Panga Panga

Papuacedrus

Parinari, Fijian

Penarahan

Peppermint, BroadLeaved

Peppermint, NarrowLeaved

Peroba, White

Persimmon

Perupok (Malaysia)

Perupok (Malaysia)

Pillarwood

Pine / Pine, Stone

Pine, Aleppo

Pine, Austrian

Pine, Beneguet

Pine, Black

Pine, Bunya

Pine, Canary Island

Pine, Celery-Top

Pine, Hoop

Pine, Huon

Pine, King William

Pine, Klinki

Pine, LoblollyPine, LongpolePine, Maritime

Pine, Parana Red

Pine, Parana White

Quercus spp,

Neorites kevediana

Cardwellia sublimia

Stenocarpus salignus

Grevillea robusta

Stenocarpus sinuatus

Eucalyptus regnans

Argyrodendron

actinophyllum

Argyrodendron

trifoliolatum

Argyrodendron

peralatum

Petrygota horsfieldii

Quercus spp,

Eugenia spp,

Triplochiton

scleroxylon

Scottellila coriancea

Olea hochstetteri

Atextoxicon

puncttatum

Nauclea diderrichii

Pterocarpus soyauxii

Planchonella vitiensis

Planchonella

kaernbachiana

Planchonella

thyrsoidea

Planchonia papuana

Dracontomelum dao

Millettia stuhlmannii

Papuacedrus papuana

Oarinari insularum

Myristica iners

Eucalyptus dives

Eucalyptus australiana

Paratecoma peroba

Diospyros pentamera

Kokoona spp,

Lophopetalum

subovatum

Cassipourea malosano

Pinus pinea

Pinus halepensis

Pinus nigra

Pinus kesya

Prumnoptys amarus

Pinus bidwillii

Pinus canariensis

Phyllocladus

aspenifolius

Araucaria

cunninghamii

Dacrydium franklinii

Athrotaxis selaginoides

Araucaria hunsteinii

Pinus taeda

Pinus contorta

Pinus pinaster

Araucaria angustifolia

Araucaria angustifolia

h.128

h.294

h.295

h.296

h.297

h.298

h.299

h.300

h.301

h.302

h.303

h.129

h.304

h.1

h.305

h.306

h.307

h.52

h.308

h.347

h.348

h.349

h.350

h.309

h.312

h.314

h.315

h.316

h.317

h.318

h.319

h.320

h.321

h.322

h.323

h.345

h.324

h.212

h.325

h.326

h.327

h.328

h.329

h.330

h.331

h.332

h.333

h.209

h.207

h.334

h.335

h.336

5..91%

3..59%

5..83%

6..67%

5..64%

6..64%

7..87%

6..60%

9..60%

9..87%

5..69%

5..81%

5..66%

5..50%

6..72%

7..80%

5..70%

7..73%

4..79%

6..61%

4..71%

2..67%

4..57%

4..86%

6..45%

6..88%

4..78%

6..94%

6..94%

8..76%

7..60%

5..70%

1..135%

8..98%

4..79%

6..87%

8..76%

5..106%

8..104%

5..76%

8..69%

6..80%

7..71%

7..79%

8..70%

7..67%

4..91%

5..91%

5..96%

8..74%

6..39%

7..58%

Pine, Pitch-, american

Pine, Pitch-, caribbean

Pine, Radiata

Pine, Radiata (New

Zealand) (sapwood aac)

Pine, Radiata (New

Zealand) (sapwood

boliden)

Pine, Radiata (New

Zealand) (sapwood

boron)

Pine, Radiata (New

Zealand) (sapwood

tanalith)

Pine, Radiata (New

Zealand) (sapwoodt

untreated)

Pine, Red

Pine, Scotts

Pine, Shortleaf

Pine, Slash

(Queensland)

Pine, Southern

Pine, Southern, yellow /

Pine, Ponderosa

Pine, Sugar

Pine, western white

Pittosporum (Tasmania)

Planchonia

Pleiogynium / Podo

Podocarp, Fijian

Podocarp, Red

Poplar, Black

Poplar, Pink

Quandong, Brown

Quandong, Silver

Quandong, Solomon

Island

Qumu

Raintree (Fiji)

Ramin

Redwood / Sequoia

Rengas

Resak (Malaysia)

Rimu (non-truewood

boron)

Rimu (non-truewood

tanalith)

Rimu (non-truewood

untreated)

Rimu (truewood

untreated)

Robinia

Roble Pellin

Rock maple

Rosewood, Brasilian

Rosewood, Indian

Rosewood, New Guinea

Rosewood, Phillippines

Sapupira

Pinus palustris

Pinus caribaea

Pinus radiata

Pinus radiata

Pinus radiata

Pinus radiata

Pinus radiata

Pinus radiata

Pinus resinosa

Pinus sylvestris L.

Pinus echinata

Pinus elliottii

Pinus echinata

Pinus ponderosa

Pinus lambertiana

Pinus monticola

Pittosporum bicolor

Pleiogynium timorense

Podocarpus neriifolia

Decussocarpus

vitiensis

Euroschinus falcata

Populus nigra

Euroschinus falcata

Eurocarpus

coorangooloo

Elaecarpus

angustifolius

Elaecarpus spaericus

Acacia Richii

Samanea saman

Gonystylus spp,

Sequoia sempervirens

Gluta spp,

Cotylelobium

melanoxylon

Dacrydium cupresinum

Dacrydium cupresinum

Dacrydium cupresinum

Dacrydium cupresinum

Robinia pseudoacacia

Nothofagus obliqua

Acer saccharum

Dalbergia nigra

Dalbergia latifolia

Pterocarpus indicus

Pterocarpus indicus

Hymenolobium

excelsum

h.211

h.210

h.337

h.338

h.339

h.340

h.341

h.342

h.343

h.206

h.213

h.344

h.214

h.208

h.215

h.406

h.346

h.351

h.352

h.353

h.354

h.313

h.355

h.356

h.357

h.358

h.359

h.360

h.361

h.362

h.363

h.364

h.365

h.366

h.367

h.368

h.369

h.370

h.6

h.311

h.310

h.371

h.372

h.375

6..65%

6..93%

5..100%

7..78%

6..85%

6..69%

5..73%

5..91%

2..99%

6..94%

5..96%

6..86%

5..97%

5..96%

4..97%

5..98%

4..82%

5..73%

7..57%

6..79%

6..83%

4..91%

6..67%

5..75%

5..65%

3..67%

5..67%

5..49%

6..54%

5..88%

4..85%

3..94%

7..65%

7..65%

8..69%

8..44%

2..72%

6..72%

5..92%

5..58%

4..91%

5..66%

10..54%

5..68%

H60.0.01.6C-11 Operating Manual GMH3810 page 13 of 14

Sasauria (Fiji)

Sassafras

Sassafras, Southern

Satinash, Blush

Satinash, Grey

Satinash, New Guinea

Satinash, Rose

Satinay

Satinbox

Satinheart, Green

Satinwood, Tulip

Scentbark

Schizomeria, New

Guinea

Schizomeria, Solomon

Island

Sepetir

Sheoak, Fijian Beach

Sheoak, River

Sheoak, Rose

Sheoak, Western

Australia

Silkwood, Bolly

Silkwood, Silver

Simpoh (Phillippines)

Sirus, White

Sirus, White

Sloanea

Spondias

Spruce, European

Spruce, Norway /Norway

Spruce

Spruce, Sitka

Sterculia, Brown

Stringybark, Brown

Stringybark, Darwin

Stringybark, Yellow

Suren

Sweet chestnut

Sycamore

Sycamore, Satin

Tallowwood

Tatajuba

Taun Maleisien

Taun New Guinea

Taun Phillipines

Dysoxylum

quercifolium

Doryphora sassafras

Atherospherma

moschatum

Acmena Hemilampra

Syzygium gustavioides

Syzygium

butterneranum

Syzygium francisii

Syncarpia hilii

Phenbalium

saquameum

Geijera salicifolia

Rhodosphaera

rhodanthema

Eucalyptus

aromapholia

Schizomeria serrata

Schizomeria serrata

Sindora coriaceae

Casuarina nodiflora

Casuarina

cunninghamiana

Casuarina torulosa

Allocasuarina

fraserana

Cryptocarya ablata

Flindersia acuminata

Dillenia philippinensis

Ailainthus peekelii

Ailainthus triphysa

Sloanea spp,

Spondias mariana

Picea abies Karst.

Picea abies

Picea sitchensis

Sterculia spp,

Eucalyptus capitellata

Eucalyptus tetrodonta

Eucalyptus muelleriana

Toona cilata

Castanea sativa

Acer pseudoplatanus

Ceratopetalum

succirubrum

Eucalyptus microcorsis

Bagassa guianesis

Pometia pinnata

Pometia pinnata

Pometia pinnata

h.376

h.377

h.378

h.379

h.380

h.381

h.382

h.383

h.384

h.385

h.386

h.387

h.388

h.389

h.390

h.391

h.392

h.393

h.394

h.395

h.396

h.397

h.398

h.399

h.400

h.401

h.136

h.137

h.138

h.230

h.403

h.404

h.405

h.407

h.199

h.5

h.408

h.409

h.30

h.195

h.196

h.197

4..69%

6..70%

7..66%

3..84%

5..82%

5..68%

5..59%

4..92%

5..92%

8..51%

6..94%

5..70%

5..81%

4..60%

1..88%

6..71%

7..59%

8..58%

7..64%

8..53%

7..71%

5..86%

5..74%

7..70%

5..77%

4..72%

6..101%

6..105%

5..98%

4..91%

6..83%

5..81%

9..77%

6..103%

2..107%

7..57%

7..63%

4..92%

7..44%

0..105%

6..103%

7..99%

Taun Solomon Island

Tawa

Tawa (sap & heart boron)

Tawa (sap & heart

untreated)

Teak

Terap

Terentang

Terminalia Braun

Terminalia Gelb

Tetrameles

Tingle, Red

Tingle, Yellow

Tornillo

Totara

Touriga, Red

Tristiropsis, New Guinea

Tulipwood

Turat

Turpentine

Vaivai-Ni-Veikau

Vatica, Phillippines

Vitex, New Guinea

Vuga

Vutu

Walnut, American

Walnut, Blush

Walnut, European

Walnut, Queensland

Walnut, Rose

Walnut, White

Walnut, Yellow

Wandoo

Wattle, Hickory

Wattle, Silver

Wengé

Western Red Cedar

Whitewood, American

Woodchips GSF38 probe h.461

Woolybutt

Yaka

Yasi-Yasi I (Fiji)

Yasi-Yasi II (Fiji)

Yate

Yertschuk

Pometia pinnata

Beilschmiedia tawa

Beilschmiedia tawa

Beilschmiedia tawa

Tectona grandis

Artocarpus elasticus

Campnosperma

brevipetiolata

Terminalia microcarpa

Terminalia complanata

Tetrameles nudiflora

Eucalyptus jacksonii

Eucalyptus guilfolei

Cedrelinga

catenaeformis

Podocarpus totara

Calophyllum

constatum

Tristiropsis canarioides

Harpullia pendula

Eucalyptus

gomophocephala

Syncarpia glomulifera

Serianthes myriadenia

Vatica, manggachopi

Vitex cofassus

Metrosideros collina

Barringtonia edulis

Juglans nigra

Beilschmiedia

obtusifolia

Junglans regia

Endiandra palmerstonii

Endiandra muelleri

Cryptocarya obovota

Beilschmiedia

bancroftii

Eucalyptus wandoo

Acacia penninervis

Acacia dealbata

Millettia laurentii

Thuja plicata

Liriodendron tulipifera

Eucalyptus longifolia

Dacrydium

nausoriensis/nidilum

Syzygium effusum

Syzygium spp,

Eucalyptus cornuta

Eucalyptus considenia

h.198

h.415

h.416

h.417

h.418

h.419

h.420

h.421

h.422

h.423

h.424

h.425

h.427

h.428

h.429

h.430

h.432

h.431

h.433

h.434

h.435

h.436

h.437

h.438

h.288

h.439

h.289

h.440

h.441

h.442

h.443

h.444

h.445

h.446

h.448

h.449

h.447

h.450

h.451

h.452

h.453

h.454

h.455

4..70%

8..51%

6..61%

7..64%

6..80%

2..169%

5..77%

3..71%

3..87%

5..70%

5..110%

5..105%

5..71%

7..63%

8..73%

6..70%

7..76%

7..71%

5..91%

5..61%

7..63%

5..78%

6..56%

4..55%

5..87%

8..64%

7..59%

6..101%

3..78%

7..63%

5..66%

7..87%

7..64%

7..73%

7..55%

6..56%

5..99%

5..145%

7..80%

6..69%

4..71%

5..82%

6..73%

7..88%

H60.0.01.6C-11 Operating Manual GMH3810 page 14 of 14

Appendix B: Additional materials

Select material you want to measure, enter number on the device, e.g. concrete b25 = b. 6

Measuring of building materials

Material Number Range

Concrete

Concrete 200kg/m³ B15 (200 kg Concrete per 1m³ sand) b. 5 0,7..3,3%

Concrete 350kg/m³ B25 (350 kg Concrete per 1m³ sand) b. 6 1,1..3,9%

Concrete 500kg/m³ B35 (500 kg Concrete per 1m³ sand) b. 7 1,4..3,7%

gas-aerated concrete (Hebel) b. 9 1,6..173,3%

gas-aerated concrete (Ytong PPW4, gross density 0,55) b. 27 1,6..53,6%

Screed

Anhydrit screed AE, AFE b. 1 0,0..30,3%

Ardurapid screed-concrete b. 2 0,6..3,4%

Elastizell screed b. 8 1,0..24,5%

Screed-plaster b. 11 0,4..9,4%

Wood-concrete screed b. 13 5,3..20,0%

Screed-concrete ZE, ZFE without additives b. 21 0,8..4,6%

Screed-concrete ZE, ZFE with bitumen additives b. 22 2,8..5,5%

Screed-concrete ZE, ZFE with synthetic additives b. 23 2,4..11,8%

Miscellaneous

Asbestos cement panels b. 3 4,7..34,9%

Bricks clay bricks b. 4 0,0..40,4%

Plaster b. 10 0,3..77,7%

Plaster synthetic b. 12 18,2..60,8%

On-wall plaster b. 20 0,0..38,8%

Lime mortar KM 1:3 b. 14 0,4..40,4%

Lime sand bricks (14 DF (200), gross density 1,9) b. 28 0,1..12,5%

Limestone b. 15 0,4..29,5%

MDF b. 16 3,3..52,1%

Cardboard b. 17 9,8..136,7%

Stone-timber b. 18 10,5..18,3%

Polystyrene b. 25 3,9..50,3%

soft-fibre-panel-wood, bitumen b. 26 0,0..71,1%

Concrete mortar ZM 1:3 b. 19 1,0..10,6%

Concrete bounded fake boards b. 24 3,3..33,2%

The accuracy of measuring building materials depends on manufacturing and using. The used additives may vary from

manufacturer to manufacturer, therefore deviating measure results may occur. The given measuring-range is the

theoretically measurable range.

Estimation of additional materials

Following materials may be well estimated with the help of the device, but you won’t reach such high accuracy than

with materials listed in appendix A and B.

Material Number

Hay, flax h. 458

Straw, grain h. 459

Cork h. A

Fibre board h. C

Wood fibre insulating wall panel h. C

Wood fibre hard disks h. C

Kauramin-fake boards h. C

Melamine-fake boards h. A

Paper h. C

Phenolic resin-fake boards h. A

Textiles h. C (D)

Loading...

Loading...