H49.0.02.6B-06

as of Version 1.8

Operating Manual Precision Thermometer

Pt100 4-Wire

GMH 3750

GREISINGER electronic GmbH

D - 93128 Regenstauf, Hans-Sachs-Straße 26

Phone: +49 9402 / 9383-0, Fax: +49 9402 / 9383-33, eMail: info@greisinger.de

H49.0.02.6C-06 Operating Manual GMH 3750 Page 2 of 16

_____________________________________________________ _______________________________________________________________________________

Contents

1 INTENDED USE .........................................................................................................................................3

2 GENERAL ADVICE...................................................................................................................................3

3 SAFETY INSTRUCTIONS ........................................................................................................................3

4 OPERATING AND MAINTENANCE ......................................................................................................4

5 CONNECTIONS..........................................................................................................................................4

6 DISPLAY- AND BUTTON ELEMENTS..................................................................................................5

7 START OF OPERATION ..........................................................................................................................5

8 DEVICE CONFIGURATION ....................................................................................................................6

9 SPECIAL FUNCTIONS..............................................................................................................................8

9.1 DISPLAY RESOLUTION ..............................................................................................................................8

9.2 USER SENSOR CURVE ('LIN USER')..........................................................................................................8

9.3 ZERO DISPLACEMENT ('OFFSET') ..............................................................................................................8

9.4 SCALE CORRECTION ('SCALE')..................................................................................................................8

9.5 AVERAGE FILTER („T.AUG“) ...................................................................................................................9

9.6 OUTPUT („OUT“).....................................................................................................................................9

9.7 ALARM („AL.“)......................................................................................................................................10

9.8 REAL TIME CLOCK („CLOC“) ...............................................................................................................10

10 PROBE CONNECTION........................................................................................................................11

11 CALIBRATION SERVICES ................................................................................................................11

12 OPERATION OF LOGGER.................................................................................................................12

12.1 STORING SINGLE MEASUREMENTS („FUNC-STOR“) ...............................................................................12

12.2 AUTOMATIC RECORDING WITH SELECTABLE LOGGER CYCLE TIME „FUNC CYCL“..............................13

13 SOME BASICS OF PRECISION TEMPERATURE MEASURING ...............................................14

14 FAULT AND SYSTEM MESSAGES...................................................................................................15

15 DISPOSAL NOTES ...............................................................................................................................15

16 SPECIFICATION ..................................................................................................................................16

© Copyright 2008 GREISINGER electronic GmbH. All Rights Reserved.

No part of this documentation may without previous written permission of the company

GREISINGER electronic GmbH stored in some form, reproduced, processed,

duplicated or spread become.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 3 of 16

_____________________________________________________ _______________________________________________________________________________

1 Intended Use

The GMH 3750 is a precision thermometer for the measurement of the temperature with

exchangeable 4-wire Pt100 temperature sensors. With high resolution and precision temperature

values can be measured from -200 to 850 °C.

The device is to be protected against wetness and soiling and has to be stored and operated only

within the permissible environmental conditions and connection data (see “Specification”).

2 General Advice

Read through this document attentively and make yourself familiar to the operation of the device

before you use it. Keep this document in a ready-to-hand way in order to be able to look up in the

case of doubt.

3 Safety Instructions

This device has been designed and tested in accordance to the safety regulations for electronic

devices. However, its trouble-free operation and reliability cannot be guaranteed unless the

standard safety measures and special safety advises given in this manual will be adhered to when

using it.

1. Trouble-free operation and reliability of the device can only be guaranteed if it is not subjected

to any other climatic conditions than those stated under “Specification”.

Transporting the device from a cold to a warm environment condensation may result in a failure

of the function. In such a case make sure the device temperature has adjusted to the ambient

temperature before trying a new start-up.

2. The circuitry has to be designed most carefully, especially if the device should be connected to

other devices. Internal connection in third party devices (e.g. connection GND and earth) may

result in not-permissible voltages impairing or destroying the device or another device

connected.

3. Warning: Operating the device with a defective mains power supply (e.g. short circuit from

mains voltage to output voltage) may result in hazardous voltages at the device (e.g. at sensor

socket)

4. Whenever there may be a risk whatsoever involved in running it, the device has to be

switched off immediately and to be marked accordingly to avoid re-starting. Operator safety may

be a risk if:

• there is visible damage to the device

• the device is not working as specified

• the device has been stored under unsuitable conditions for a longer time

In case of doubt, please return device to manufacturer for repair or maintenance.

5.

Warning: Do not use these product as safety or emergency stop device, or in any other

application where failure of the product could result in personal injury or material damage.

Failure to comply with these instructions could result in death or serious injury and material

damage.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 4 of 16

_____________________________________________________ _______________________________________________________________________________

4 Operating and Maintenance

• Battery Operation

The battery has been used up and needs to be replaced, if „bAt“ are shown in lower display.

The device will, however, continue operating correctly for a certain time.

The battery has been completely used up, if ´bAt´ is shown in the upper display.

The battery has to be taken out, when storing device above 50°C.

Hint: We recommend to remove the battery if device is not used for a longer period of time!

• Mains Operation

Attention: When using a power supply unit please note that operating voltage has to be 10.5 to

12 V DC. Do not apply overvoltage!! Simple 12V-power supplies often have excessive no-load

voltage. We, therefore, recommend using regulated voltage power supplies. Trouble-free

operation is guaranteed by our power supply GNG10/3000.

Prior to connecting the plug power supply with the mains supply make sure that the operating

voltage stated at the power supply is identical to the mains voltage.

• Treat device and probes carefully. Use only in accordance with above specification. (do not

throw, hit against etc.). Protect plugs and sockets from soiling.

• To disconnect sensor plug do not pull at the cable but at the plug.

• When connecting the probe the plug will slide in smoothly if plug is entered correctly.

Selection of Output-Mode: The output can be used as serial interface or as analogue output. This

choice has to be done in the configuration menu.

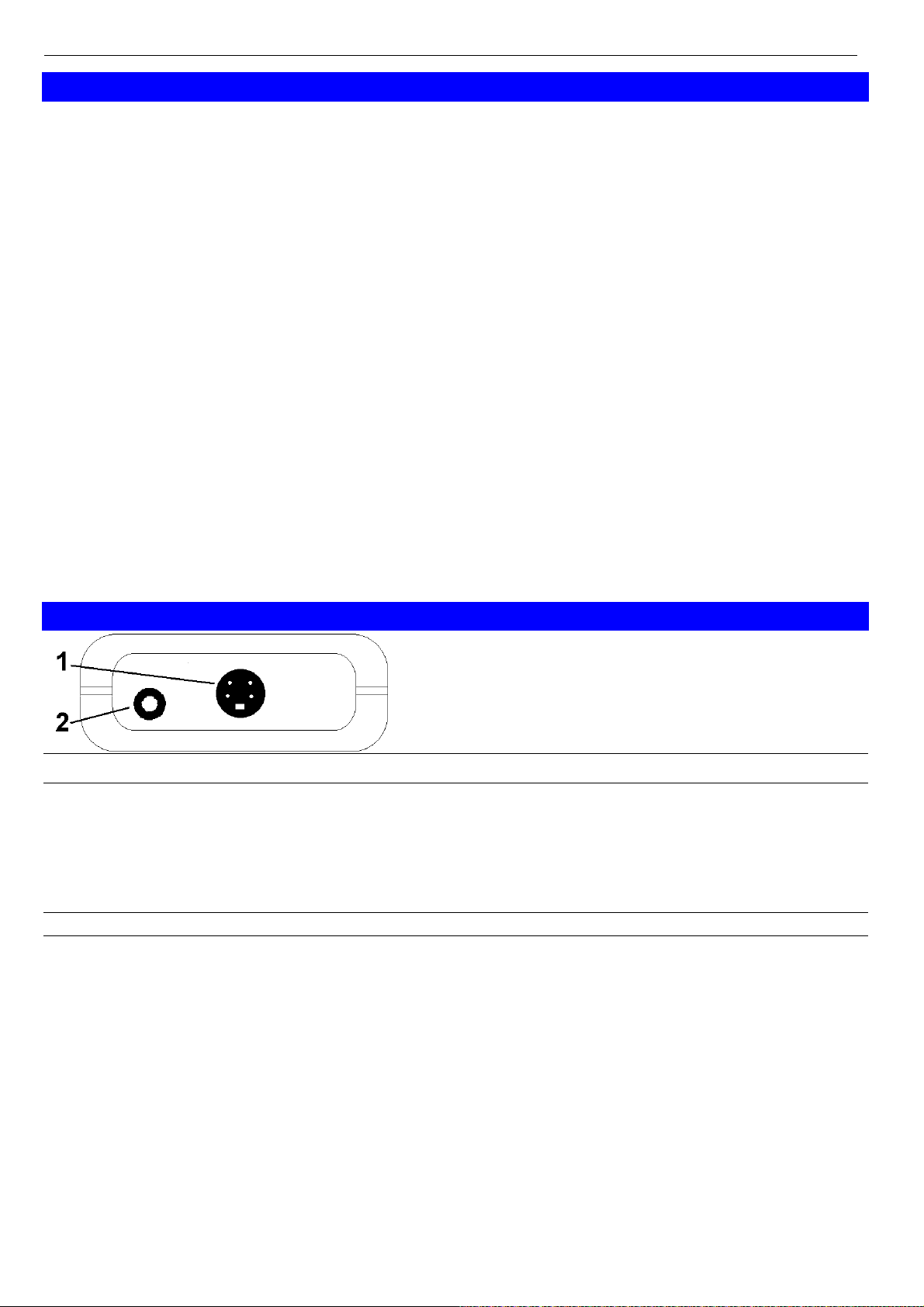

5 Connections

1 Probe connection: 4 pole Mini-DIN-Socket, for Pt100 4-wire probes (see also chapter 10)

2 Output: 3-pole stereo phone socket Ø3mm

Operation as interface: Connection to optically isolated interface adapter (accessory: USB 3100,

GRS 3100, ..)

Operation as analogue output: Connection via suitable 2pole cable.

Attention: The output mode has to be configured (see chapters 8, 9.6) and influences battery life!

The mains socket is located at the left side of the instrument

H49.0.02.6C-06 Operating Manual GMH 3750 Page 5 of 16

_____________________________________________________ _______________________________________________________________________________

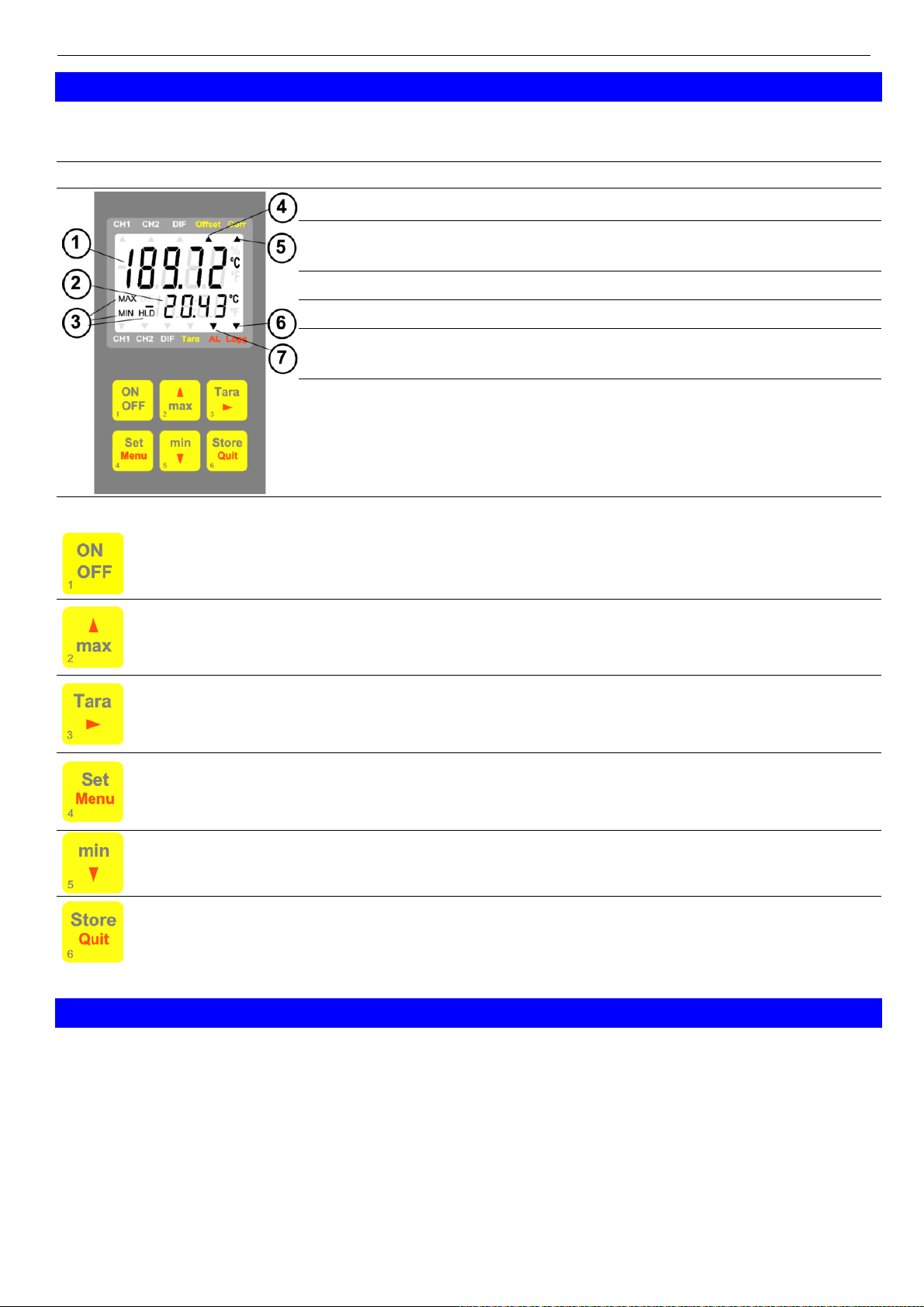

6 Display- and Button Elements

a

) Display Elements

1 Main Display: Currently measured temperature

2 Auxiliary Display: Display of min, max or hold values

Special display elements:

3 Min/Max/Hold: shows if a min., max. or hold value is displayed in

the auxiliary display

4 „Offset“ arrow: indicates that zero point offset is activated

5 „Corr“ arrow: indicates that a scale correction is activated

6 „Logg“ arrow: Shown if logger function is selected,

flashes if cyclic logger is running

7 „Alarm“ arrow: Flashes if alarm is present

b) Pushbuttons and Operation

Key 1:

On/Off

Key 2:

press shortly: maximum measured value will be displayed

press for 2 sec.: the max. value will be deleted

Key 3:

Function only during configuration: Selection of menu-parameter

Key 4:

press (Menu) for 2 sec.: configuration will be activated

Key 5:

press shortly: minimum measured value will be displayed

press for 2 sec.: the min. value will be deleted

Key 6:

Measurement: Hold current measuring value ('HLD' in display) or operation of logger

functions (p.r.t. Chapter 12)

7 Start of Operation

Connecting Temperature probe to the instrument.

Switch instrument on with key 1 „ON OFF”

The device is ready to measure.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 6 of 16

_____________________________________________________ _______________________________________________________________________________

8 Device Configuration

Note: Some menu items will be shown depending on the actual device configuration

(e.g. some items are disabled when the logger contains data).

Please note the hints by the menu items.

Press for 2 seconds.

Enter Configuration:

The main menu will be

shown

or

Navigation:

choose menu branch (*1)

choose the parameter (*2)

/

edit the parameter values (*2)

Stores the settings, jumps back to the main menu

Stores the settings, leaves configuration

Menu(*1) Parameters/Values (*2) Meaning p.r.t.

/

Read Logg: single value-logger read out

12

(only when data existing! Please refer to chapter 12)

Set Configuration: Generic Settings

°C:

°F:

All temperature values are in degrees Celsius

All temperature values are in degrees

*

Fahrenheit

0.1° / 0.01°:

Auto:

E.751

USEr

Resolution 0.1° / 0.01°

Resolution is selected automatically

characteristic curve according to EN60751

User sensor curve (Predefined to EN60751

*9.1

*

values, changeable by software GMHKonfig)

-2.50...2.50°C /

Zero correction

*9.3

-4.50...4.50°F

oFF:

-2.000...2.000:

oFF:

1...30:

oFF:

1...120

Zero displacement inactive (=0.0°)

Scale correction [in %]

Scale correction factor inactive (=0.000)

Average filter (period in seconds)

Average filter inactive

Power-off delay in minutes. Device will be

*9.4

*9.5

automatically switched off as soon as this time

has elapsed if no key is pressed or no

interface communication takes place

oFF

Power-off function inactive (continuous

operation)

oFF:

SEr:

dAC:

No output function

Output is serial interface

Output is analogue output

9.2

9.6

H49.0.02.6C-06 Operating Manual GMH 3750 Page 7 of 16

_____________________________________________________ _______________________________________________________________________________

01,11..91

Base address of device for interface

communication

-200..850°C /

-328...1562°F

Zero point of analogue output: Temperature at

which the analogue output potential should be

0V

-200..850°C /

-328...1562°F

Scale of analogue output : Temperature value

at which the analogue output potential should

be 1V

On / No.So

Alarm on with horn-sound / Alarm on without

horn-sound

OFF

-200°C ...

no alarm function

Min alarm rail (not when AL. oFF)

AL.Hi

AL.Lo ...

Max alarm rail (not when AL. oFF)

850°C

Set Logger: Setting of Logger Function

CYCL Cyclic: logger function cyclic logger

Stor Store: logger function individual value logger

OFF

0:01... 60:00

No logger function

Cycle time of cyclic logger [minutes:seconds]

9.6

9.6

9.6

9.7

*12

*12

Set Clock: Setting of Real Time Clock

HH:MM Clock: Setting of time hours:minutes

9.8

YYYY Year

TT.MM Date: day.month

(*) If the logger memory contains data already, the menus/parameters marked with (*)

can not be invoked! If these should be altered the logger has to be stopped and the

memory has to be cleared before!

Hint: Restoring of ex-works settings

The settings will be set to the settings ex works, if keys ‘Set‘ and ‘Store‘ are pressed

simultaneously for more than 2 seconds.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 8 of 16

_____________________________________________________ _______________________________________________________________________________

9 Special Functions

9.1 Display Resolution

Standard setting: 'Auto', i.e. the device automatically switches over to the optimum resolution

between .01° and 0.01°.

If temperatures to be measured are near the switching threshold, a fixed resolution may be better,

e.g. for easy manual recording. In such a case please set the optimum resolution to the desired

value.

9.2 User Sensor Curve ('Lin USEr')

By means of this function besides the standard conversion of resistance to temperature following

EN60751(Lin E.751) also other curves can be used. The user sensor curve can be read and edited

by the configuration software GMHKonfig. The standard setting ex works is also set to the

EN60751 data. The curve is defined by a table with two columns (input resistance[Ohm]/output

temperature [°C]) with 50 rows.

Info: the sensor curve following EN60751 uses the international temperature scale ITS90 and

following formulas:.

Temperatures < 0°C:

R

(T) := 100 · [1 + 3.9083·10-3·T – 5.775·10-7·T2 – 4.183·10

neg

Temperatures >= 0°C:

-12

·(T – 100)·T3]

R

(T) := 100 · (1 + 3.9083·10-3·T – 5.775·10-7·T2)

pos

Please notice: Temperature measurements with the user sensor curve are allowed only within

the temperature range which has been used to generate the user sensor curve.

Measuring with activated user sensor curve beyond the checked temperature range may

lead to larger errors. Therefore the sensor curve acc. to EN 60751 (Lin E.751) has to be

used for temperature measurements beyond the checked temperature range.

9.3 Zero Displacement ('Offset')

The zero displacement is used to adjust the measuring display for probe deviations.

temperature displayed = temperature measured - offset

Standard setting: 'off' = 0.0°, i.e. no zero displacement will be carried out. Together with the scale

correction (see below) this factor is mainly used to compensate for sensor deviations.

Unless the factor is set to 'off', the offset arrow in the display shows an active zero displacement.*)

9.4 Scale Correction ('Scale')

The scale correction is used to adjust the measuring display for probe deviations. (factor is in %):

displayed temperature[°C] = measured temperature[°C] * (1+Scal/100)

or: displayed temperature[°F] = (measured temperature [°F]-32°F) * (1+Scal/100) + 32°F

Standard setting: 'off' =0.000, i.e. temperature is not corrected.

Unless the factor is set to 'off', the Corr arrow in the display shows an active scale correction.*)

*) The standard curve (Lin E.751) and the user sensor curve (Lin USEr) posses separate

correction settings.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 9 of 16

_____________________________________________________ _______________________________________________________________________________

9.5 Average filter („t.AuG“)

The filter forms the arithmetic floating average over the entered time. The displayed value will be

correspondingly slower in this case.

9.6 Output („Out“)

The output can be either used as serial interface (for USB 3100, GRS 3100 or GR S3105 interface

converters) or as analogue output (0-1V). If none of both is needed, we suggest to switch the

output off, because battery life then is extended

a) Operation as analogue Output („Out dAC“)

With the DAC.0 and DAC.1 values the output can be rapidly scaled to Your efforts.

Example: -50°C ... 250°C should correspond to 0 ... 1V at the output

Set “DAC.0” to –50.00°C and “DAC.1” to 250.0°C -> finished.

Keep in mind not to connect low-resistive loads to the output, otherwise the output value will be

wrong and battery life is decreased. Loads above ca 10kOhm are uncritical.

If the display exceeds the value set by DAC.1, then the device will apply 1V to the output

If the display falls below the value set by DAC.0, then the device will apply 0V to the output

In case of an error (Err.1, Err.2, no sensor, etc.) the device will apply slightly above 1V to the

output.

Plug wiring:

GND

+Uout

Attention!

The 3rd contact has be left floating

Only stereo plugs are allowed!

b) Operation as interface („Out SEr“)

By using an electrically isolated interface converter USB 3100, GRS 3100 or GRS 3105

(accessory) the device can be connected to a PC.

Configure Base address ('Adr.'): With the GRS 3105 it is possible to connect up to 5 instruments

to a single interface. In this case the devices have to have different addresses, eg. Device 1:

address 01, device 2: address 11, device 3: address 21 ...

In order to avoid transmission errors, there are several security checks implemented (e.g. CRC).

The following standard software packages are available for data transfer:

! EBS9M: 9-channel software to record and display the measuring values

! GSOFT3050: operation and read out software for devices of GMH3000 series with logger

! GMHKonfig: free set-up software

In case you want to develop own software we offer a GMH3000-development package including

! An universally applicable Windows function library ('GMH3000.DLL') with documentation that

can be used by all serious programming languages. Applicable for Windows 95 / 98™,

Windows NT™, Windows2000™, Windows XP™ and VISTA

!

Programming examples for Visual Basic 6.0™, Delphi 1.0™, Testpoint™, Labview™ and others

H49.0.02.6C-06 Operating Manual GMH 3750 Page 10 of 16

_____________________________________________________ _______________________________________________________________________________

Supported interface functions with 'GMH3000.DLL' :

code name / function code name / function

0 Read nominal values 201 Read max. display range

3 Read system status 202 Read unit of display

6 Read min. values 204 Read decimal point of display

7 Read max values 208 Read channel count

12 Read ID-no 214 Read scale correction

22 Read min. alarm rail 215 Set scale correction

23 Read max. alarm rail 216 Read zero displacement

32 Read configuration flag

Alarm function: 1, Alarm horn: 3

BitLoggerOn: 50, BitCyclicLogger: 51

217 Set zero displacement

222 Read power – off time

223 Set power – off time

102 Set min. alarm rail 224 Logger: read data cyclic logger

103 Set max. alarm rail 225 Logger: read cycle time (LoGG - CYCL)

160 Set configuration flag (see 32) 226 Logger: set cycle time (LoGG - CYCL)

174 Delete min. value 227 Logger: start recording

175 Delete max. value 228 Logger: read # of data

176 Read min. measuring range 229 Logger: read status

177 Read max. measuring range 231 Logger: read stop time

178 Read measuring range unit 233 Read real time clock (CLOC)

179 Read measuring range decimal point 234 Set real time clock (CLOC)

180 Read measuring type 236 Read logger memory size

194 Set display unit 240 Reset

199 Read measuring type in display 254 Read program identification

200 Read min. display range 260 Logger: read data manual logger

Note: The measuring and display range values read via interface are always in the selected

display unit (°C/°F)!

9.7 Alarm („AL.“)

There are three possible settings:

Alarm off (AL. oFF), on with horn sound (AL. on), on without horn sound (AL. no.So).

Following conditions will display an alarm, when the function is activated (on or no.So):

- Value is below lower (AL. Lo) or above upper alarm rail (AL.Hi).

- Sensor error

- Low battery (bAt)

- Err.7: System error (always with sound)

In case of an alarm and when polling the interface the “prio”-flag is set in the returned message.

9.8 Real Time Clock („CLOC“)

The real time clock is used for the logger function: Recorded values are also containing the point of

time, when they were measured. Please check the settings when necessary.

If the battery was replaced the referring menu ‚CLOC‘ will automatically be started

H49.0.02.6C-06 Operating Manual GMH 3750 Page 11 of 16

_____________________________________________________ _______________________________________________________________________________

10 Probe Connection

The device is constructed and optimised for the connection of a Pt100 4-wire probe via 4 pole

Mini-Din connectors.

4-wire connection

Pt100

Figure shows upon probe jack pins

It is also possible to connect an 3- or 2-wire probe to the device. Please observe that in

consequence of the cable and contact resistance an increased measuring fault will occur.

The connection of this probes should be carried out as follows:

3-wire connection 2-wire connection

Pt100

Pt100

11 Calibration Services

Factory calibration certificate - DKD certificate - official certifications

If the measuring instrument is supposed to receive a factory calibration certificate, it has to be sent

to the manufacturer. (declare test levels, e.g. –20°C, 0°C; 70°C).

If the factory calibration certificate is issued for the instrument including a probe, extremely high

precision can be achieved.

Just the manufacturer can check the factory settings and correct them if necessary.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 12 of 16

_____________________________________________________ _______________________________________________________________________________

12 Operation Of Logger

The device supports two different logger functions:

„Func-Stor“: manual recording via keypress “Store” (key 6).

„Func-CYCL“: automatic recording with the selected recording interval/cycle

The logger records 1 measurement result each time

The data set consists of: - measuring value at time of recording

- time and date of recording

For the read out and evaluation of the data the software GSOFT3050 (V1.7 or higher) has to be

used. The software also allows easy configuration and starting of the logger.

When the logger is activated (Func Stor or Func CYCL) the hold function is no longer available, key

6 is solely used for the operation of the logger functions.

12.1 Storing Single Measurements („Func-Stor“)

a) Record Measuring:

If the logger function “Func Stor” was activated (see chapter 8 “Device Configuration”), up to 99

measuring data sets can be recorded manually.

Press shortly: Data set will be recorded (“St. XX” will be shown shortly. XX is the

number of the data set)

If the logger memory is full, the display will show:

b) Viewing Recorded Measurings:

Stored data sets can be either read out via PC Software GSOFT3050, or be viewed in the

display directly.

Press for 2 seconds: The display will show:

Please note: ”rEAd Logg” only appears, if there are already data stored! If memory is

empty, the configuration menu will show.

Press shortly: Changing between measuring value and date+time of data set

or

Changing between the data sets

Exit logger data display

c) Clear recorded measurings:

If there are already data sets stored, these can be deleted via the store key:

Press for 2 seconds: Calling of clear-Menu

Change selection by: or :

Clear nothing (cancel menu)

Clear all recordings

Clear the last recording

Stores the settings

H49.0.02.6C-06 Operating Manual GMH 3750 Page 13 of 16

_____________________________________________________ _______________________________________________________________________________

12.2 Automatic Recording With Selectable Cycle Time „Func CYCL“

If the logger function “Func CYCL” was activated (see chapter 8 “Device Configuration”), and the

logger was started, it automatically records data sets at intervals of the selected logger cycle time

The logger cycle time is selectable from 1s to 60min (see chapter 8 “Device Configuration”).

Max. number of measurings:16384

a) Starting a recording:

press for 2 seconds: the recording will be started.

Each recodring is signales with a short diplay of ‘St.XXXXX’. XX is the number of the data set.

If the logger memory is full, the display will show

b) Stop the recording:

Press for 2 seconds: If a recording is running, the Stop menu will be shown

Change selection by: or :

Do not stop the recording

Stop the recording

Stores the settings

Note: If you try to switch off the instrument in the cyclic recording operation, You will be

asked automatically if the recording should be stopped.

The device can only be switched off after the recording has been stopped!

The Auto-Power-Off-function is deactivated during recording!

c) Clear recorded measurings:

Press for 2 seconds: If logger data are present and the recording was stopped, the

clear menu will be shown

Change selection by:

Clear nothing

(cancel menu)

Clear all recordings

Stores the settings

or :

H49.0.02.6C-06 Operating Manual GMH 3750 Page 14 of 16

_____________________________________________________ _______________________________________________________________________________

13 Some Basics Of Precision Temperature Measuring

Probe Precision/Device Precision

The device is very precise (please refer to technical data). To be able to use this high precision, the connected

temperature probe has to be as precise as possible, too. The following precision classes are available as a standard at

reasonable prices (Platinum resistor thermometers according to EN60751):

Class Error ranges

B ± (0,3 + 0,005 • | Temperature |)

1/3 B (=1/3 DIN) ± (0,1 + 0,0017 • | Temperature |)

1/10 B (=1/10 DIN) ± (0,03 + 0,0005 • | Temperature |)

A ± (0,15 + 0,002 • | Temperature |)

Fehler Gerät und Temperaturfühler

B

1/3B

4

1/10B

3

A

GMH37xx

2

Fehler [°C]

1

0

-200 -100 0 100 200 300 400 500 600 700 800

T [°C]

1,2

1

0,8

0,6

Fehler [°C]

0,4

0,2

0

-50 0 50 100 150

Error over measuring range

For applications demanding higher precision than given by this classes we suggest to adjust the device to the used

probe or to get a calibration certificate for the device combined with the probe.

Attention: if an adjusted or calibrated probe is replaced, also the adjustment or calibration certificate has to be renewed

to maintain the referring overall precision! Be careful when buying third party temperature probes: Besides the standard

EN60751 there are some other obsolete or unusual standards on the market. If such a probe has to be connected, the

user sensor curve (have a look to the referring chapter) can be used to adjust the instrument!

4-Wire-Measuring

When using resistance thermometers as the Pt100 a quite large measuring error can be caused by inadequate cables

and connections. Using 4wire measuring avoids this kinds of errors mainly caused by unwanted resistances. It is

suggested to use suitable probes and extensions only. (For pin assignment please refer to chapter 7)

Heat loss caused by probe construction:

Especially when measuring temperatures which deviate very much from the ambient temperature, measuring errors

often occur if the heat loss caused by the probe is not considered. When measuring fluids therefore the probe should be

emerged sufficiently deep and be stirred continuously. When measuring gases the probe should also emerge as deep

as possible in the gas to be measured (e.g. when measuring in channel/pipes) and the gas should flow around the probe

at sufficient flow.

Measuring Surface Temperature

If temperature of the surface of an object has to be measured, one should pay attention especially when measuring hot

(or very cold) surfaces, that the ambient air cools (or heats) the surface. Additionally the object will be cooled (or heated)

by the probe or the probe can have a better heat flow to the ambient temperature as to the objects surface.

Therefore specially designed surface probes should be used. The measuring precision depends mainly on he

construction of the probe and of the physics of the surface itself. If selecting a probe try to choose one with low mass

and heat flow from sensor to handle. Thermally conductive paste can increase the precision in some cases.

Allowable temperature Range Of Probes

Pt100 Sensors are defined over a wide temperature range. Depending on probe materials and sort of sensor (e.g. hybrid

sensors, wire wound resistors...) the allowable temperature ranges have to be considered. Exceeding the ranges at

least causes a wrong measuring, it may even damage the probe permanently!

Often it also has to be considered, that the temperature range is just valid for the probe tube, (plastic-) handles can’t

stand the same high temperatures. Therefore the tube length should be selected long enough, that temperature keeps

low at the handle.

Self Heating

The measuring current of the instrument is just 0.3mA. Because of this comparably low current practically now self

heating effect has to be considered, even at air with low movement the self heating is <= 0.01°C.

Cooling by Evaporation

When measuring air temperature the probe has to be dry. Otherwise the cooling due to the evaporation causes too low

measuring.

Fehler Gerät und Temperaturfühler

B

1/3B

1/10B

A

GMH37xx

T [°C]

Error over range –50...150°C

H49.0.02.6C-06 Operating Manual GMH 3750 Page 15 of 16

_____________________________________________________ _______________________________________________________________________________

14 Fault and System Messages

Display Meaning Remedy

Low battery voltage, device will

continue to work for a short time

If mains operation: wrong voltage Check/replace power supply, if fault

Low battery voltage Replace battery

If mains operation: wrong voltage Check/replace power supply, if fault

Replace battery

continues to exist: device damaged

continues to exist device damaged

No display

Or

Weird display

Low battery voltage Replace battery

If mains operation: wrong voltage Check/replace power supply, if fault

continues to exist device damaged

System error Disconnect battery or power supply, wait

Device does not

react on

Device defective Return to manufacturer for repair

some time, re-connect

keypress

Sensor error, no sensor connected Connect sensor to socket---Sensor/cable or device defective Return to manufacturer for repair

Err.1

Value exceeding measuring range Check: Is the value exceeding the

measuring range? Temperature too high!

Wrong probe connected Check probe

Sensor/cable defective Replace

Err.2

Value below display range Check: Is the value below the measuring

range? Temperature too low!

Wrong probe connected Check probe

Sensor/cable defective Replace

Err.3 Value exceeding display range Set resolution to 0.1° or Auto

Err.4 Value below display range Set resolution to 0.1° or Auto

Err.7 System error Return to manufacturer for repair

15 Disposal notes

Dispense exhausted batteries at destined gathering places.

This device must not be disposed as ‘residual waste’.

To dispose this device, please send it directly to us (adequately stamped).

We will dispose it appropriately and environmentally friendly.

H49.0.02.6C-06 Operating Manual GMH 3750 Page 16 of 16

_____________________________________________________ _______________________________________________________________________________

16 Specification

Supported probes

Sensor Curve

Pt100 4-wire (2 or 3-wire possible)

According to EN60751

or with user-sensor curve (table of 50 rows)

Probe connection

Measuring Ranges 0,01°C:

4pole Mini-DIN socket

0,1°C:

-199,99...199,99

-200,0...850,0

0,01°F:

-199,99...199,99

0,1°F:

-328,0...1562,0

Precision without probe ±1Digit (at nominal temperature)

Range 0,01°C/F: ±0,03°C / 0,06°F Range 0,1°C/F: ±0,1°C / ±0,2°F

Measuring

4-wire measuring with thermovoltage compensation,

measuring current 0.3mA

Temperature drift

Nominal temperature

<=0.002K pro 1K

25°C

Ambient Temperature -25 ... +50°C (-13 .. 122°F)

Relative humidity 0 bis 95%r.F. (not condensing)

Storage temperature -25 ... +70°C (-13 .. 158°F)

Housing

impact-resistant ABS plastic housing, membrane keyboard, transparent

panel. Front side IP65,integrated pop-up clip for table top or suspended

use.

Dimensions 142 x 71 x 26 mm (L x B x D)

Weight Approx. 155 g

Output

3.5mm audio plug, stereo

either serial interface: via optically isolated interface adapter USB 3100, GRS 3100 or

GRS 3105 (accessory) connectable to PCs with USB- or RS232-interfaces.

or analogue output: 0..1V, freely scaleable (resolution 13bit,

accuracy 0.05% at nominal temperature, cap. load <1nF)

Min/Max-Alarm

The measuring value is constantly monitored for the min and max rails.

Alarming is done by integrated horn, display and interface

Real time clock

Logger:

Integrated clock with date and year

2 Functions: individual value logger („Stor“) and cyclic logger („CYCL“)

Memory Stor: 99; CYCL: 16384

Cycle time CYCL 0:01...60:00 (minutes:seconds, min 1s, max 1h)

Power Supply

9V-Battery, type 6F22 (included) as well as additional d.c. connector

(diameter of internal pin 1.9 mm) for external 10.5-12V direct voltage

supply. (suitable power supply: GNG10/3000)

Power

Consumption

Output off ca. 0,90mA

Output serial interface ca. 1,15mA

Analogue output ca. 1,25mA

Display

Pushbuttons

Two 4 ½ digits LCD’s (12.4mm and 7 mm high), additional segments

6 membrane keys

Min-/Max Value Memory Both the max. and the min. value will be memorised

Hold function

Automatic-OffFunction

Press button to store current value.

Device will be automatically switched off if not operated for longer time

(adjustable from1..120min)

EMC: The device corresponds to the essential protection ratings established in the Regulations

of the Council for the Approximation of Legislation for the member countries regarding

electromagnetic compatibility (2004/108/EG) EN61326 +A1 +A2 (Appendix B, class B), additional

error: < 1% FS

Loading...

Loading...