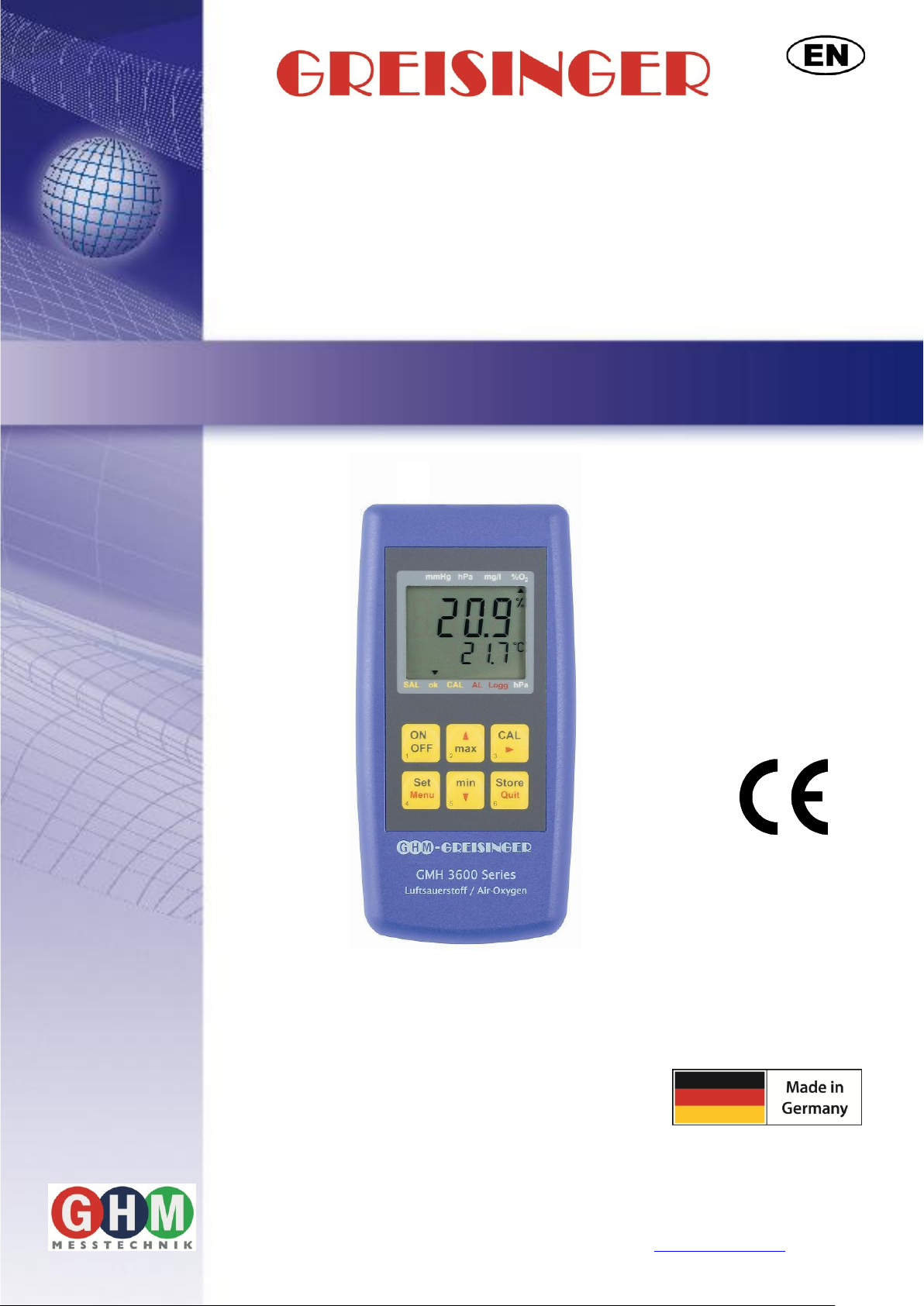

As of Version 1.2 Operating Manual GMH 3692

Oxygen meter for oxygen in gases

with integrated temperature and pressure measuring

Please keep for future reference!

WEEE-Reg.-Nr. DE 93889386

H74.0.14.6C-05

GHM Messtechnik GmbH • Standort Greisinger

+49 (0) 9402 / 9383-0 +49 (0) 9402 / 9383-33 info@greisinger.de

Hans-Sachs-Str. 26 • D-93128 Regenstauf

H74.0.14.6C-05 Operating Manual GMH 3692 page 2 of 12

Contents

1 GENERAL NOTE ...................................................................................................................................................... 2

2 DESIGNATED USE ................................................................................................................................................... 3

3 SAFETY ...................................................................................................................................................................... 3

3.1 SAFETY SIGNS AND SYMBOLS ................................................................................................................................ 3

3.2 SAFETY GUIDELINES .............................................................................................................................................. 3

4 PRODUCT DESCRIPTION ...................................................................................................................................... 4

4.1 SCOPE OF SUPPLY .................................................................................................................................................. 4

4.2 OPERATION AND MAINTENANCE ADVICE .............................................................................................................. 4

4.3 START OF OPERATION ........................................................................................................................................... 4

4.4 ANSCHLÜSSE ......................................................................................................................................................... 5

4.5 DISPLAY ELEMENTS ............................................................................................................................................... 5

4.6 PUSHBUTTONS ....................................................................................................................................................... 5

4.7 POP-UP CLIP ........................................................................................................................................................... 6

5 CONFIGURATION ................................................................................................................................................... 6

6 OXYGEN MEASURING IN GASES- PLEASE NOTE ......................................................................................... 8

6.1 CHOICE OF SENSING ELEMENTS# .......................................................................................................................... 8

6.2 APPLICATION OF THE DIFFERENT SENSOR TYPES GGO ..., GOO ... AND GGA ..................................................... 8

7 CALIBRATION OF THE SENSOR......................................................................................................................... 9

7.1 ONE POINT CALIBRATION ('(AL 1-PT') ................................................................................................................... 9

7.2 2 / 3-POINT CALIBRATION ('(AL 2-PT, (AL 3-PT') .................................................................................................. 9

7.3 EVALUATION OF SENSOR STATE (ELE[) ................................................................................................................ 9

7.4 CALIBRATION INTERVAL ([.INT) .......................................................................................................................... 10

8 INSPECTION OF THE ACCURACY / ADJUSTMENT SERVICES ................................................................ 10

9 SERIAL INTERFACE ............................................................................................................................................. 10

10 ALARM („AL.“) ................................................................................................................................................... 10

11 ERROR AND SYSTEM MESSAGES ................................................................................................................ 11

12 SPECIFICATION ................................................................................................................................................. 12

13 RESHIPMENT AND DISPOSAL ....................................................................................................................... 12

1 General Note

Read this document carefully and get used to the operation of the device before you use it. Keep this

document within reach for consulting in case of doubt.

If the device is stored at temperatures above 50°C the battery has to be removed from the device.

NOTE: We recommend taking out battery if device is not used for a longer period of time.

Risk of leakage!

H74.0.14.6C-05 Operating Manual GMH 3692 page 3 of 12

DANGER

Caution! This symbol warns of imminent danger, death, serious injuries

and significant damage to property at non-observance.

Attention! This symbol warns of possible dangers or dangerous

situations which can provoke damage to the device or environment at

non-observance.

Note! This symbol point out processes which can indirectly influence

operation or provoke unforeseen reactions at non-observance.

DANGER

DANGER

DANGER

2 Designated Use

The GMH 3692 is measuring oxygen in air and gas mixtures either as partial pressure or as concentration in

%vol.

For the measuring an external sensor of the type GOO-... or GGO... has to be connected to the MINI-DINsocket.

Due to the properties of the sensor, it has to be calibrated regularly (e.g. at fresh air = 20.95%) to get precise

values. If the sensor is used up, this will be detected during the calibration, the sensor has to be regenerated

or replaced before continuing with measuring.

The safety requirements (see below) have to be observed.

The device must be used only according to its intended purpose and under suitable conditions.

Use the device carefully and according to its technical data (do not throw it, strike it, …)

Protect the device from dirt.

3 Safety

3.1 Safety signs and symbols

Warnings are labeled in this document with the followings signs:

3.2 Safety guidelines

This device has been designed and tested in accordance with the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures

and special safety advises given in this manual will be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if the device is not subjected

to any other climatic conditions than those stated under "Specification".

If the device is transported from a cold to a warm environment condensation may cause in a failure. In

such case make sure the device temperature has adjusted to the ambient before trying a new start-up.

2. If there is a risk whatsoever involved in running it, the device has to be switched off

immediately and to be marked accordingly to avoid re-starting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer time.

In case of doubt, please return device to manufacturer for repair or maintenance.

3. Do not use these products as safety or emergency stop devices or in any other application

where failure of the product could result in personal injury or material damage.

Failure to comply with these instructions could result in death or serious injury and material

damage.

4. This device must not be used at potentially explosive areas! The usage of this device at

potentially explosive areas increases danger of deflagration, explosion or fire due to

sparking.

H74.0.14.6C-05 Operating Manual GMH 3692 page 4 of 12

4 Product Description

4.1 Scope of supply

The scope of supply includes:

GMH 3692 with 9V-battery

Operating manual

The necessary oxygen sensor is chosen separately due to application.

4.2 Operation and maintenance advice

1. Battery operation

If and ‘bAt’ are shown in the lower display the battery has been used up and needs to be replaced.

However, the device will operate correctly for a certain time. If ‘bAt’ is shown in the upper display the

voltage is too low to operate the device; the battery has been completely used up.

The battery has to be taken out, when storing device above 50 °C.

We recommend taking out battery if device is not used for a longer period of time.

After recommissioning the real-time clock has to be set again.

2. Mains operation with power supply

When using a power supply please note that operating voltage has to be 10.5 to 12 V DC.

Do not apply overvoltage!! Cheap 12V-power supplies often have excessive no-load voltage.

We, therefore, recommend using regulated voltage power supplies.

Trouble-free operation is guaranteed by our power supply GNG10/3000.

Prior to connecting the power supply to the mains make sure that the operating voltage stated at the

power supply is identical to the mains voltage.

3. Treat device and sensor carefully. Use only in accordance with above specification. (do not throw, hit

against etc.). Protect plug and socket from soiling.

4.3 Start of Operation

Switch the device on with the key “ON OFF”. The Instrument is performing a self diagnosis, during this time

all display segment are shown.

Afterwards the instrument signals, if it was user adjusted („[ORR“)

The device starts measurement afterwards.

H74.0.14.6C-05 Operating Manual GMH 3692 page 5 of 12

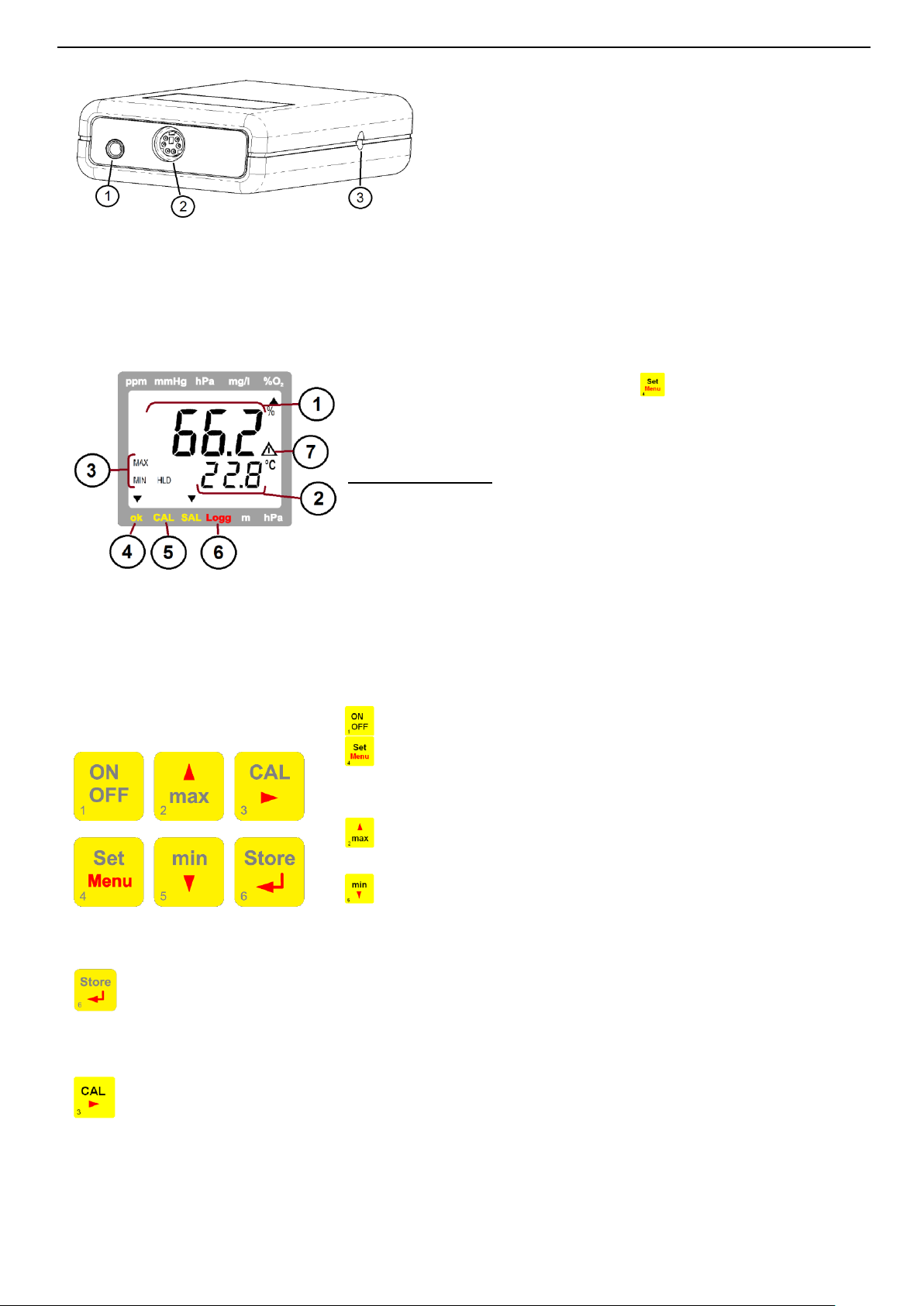

1.

Output: Operation as interface for t he connection of

galvanically isolated adapters (accessories: GRS

3100, USB 3100)

Attention: The mode of operation has to be

configured (p.r.t Chapter 5) and influences the power

consumption.

2.

Sensor connection MiniDIN

3.

Power supply: d.c.connector (internal pin Ø 1.9 mm) for external 10.5-12V direct voltage supply

1 = Main Display:

Possible displays:

Oxygen concentration in % (% O2 Vol)

Oxygen partialpressure (hPa or mmHg)

(change with -key)

2 = secondary

display:

Display of sensor temperature or absoute

pressure (alternating, please refer to Chapter

5. LcD.2)

Special elements:

3 = MIN/MAX/HLD:

Shows, if minimum/maximum/

memorized measuring value is in display

4 = ok-arrow:

Signals, if oxygen and temperature values

are stable

5 = CAL- arrow:

Signals, if automatic calibration is in

progress

6 = Logg - arrow

No function

7 = Warning sign:

Signals weak battery or other warning

message

Die restlichen Pfeile haben in dieser Gerätevariante keine Funktion

On / off key

Set/Menü

Press 2 sec.: (Menu): call configuration menu

Press shortly: Change the oxygen display unit

(please refer to chapter 5)

+

min/max when taking measurements:

press shortly: min. or max. measured oxygen value and

referring temperature and pressure values

will be displayed

press for 2 sec.: the min. or max. value will be deleted

Configuration: to enter values, or change settings

Store/Enter

- Measuring:

with Auto-Hold off: hold and save current measuring value (‘HLD’ is displayed)

with Auto-Hold on: start new measuring, It is finished , when “HLD’ shows in display

- Set/Menu: confirm settings, return to measuring

CAL:

press shortly: display of sensor state rating

press for 2 sec: start sensor calibration

4.4 Anschlüsse

4.5 Display elements

4.6 Pushbuttons

H74.0.14.6C-05 Operating Manual GMH 3692 page 6 of 12

Pop-up clip closed

Pop-up clip at position 90°

Pop-up clip at position 180°

Device attached to a belt

Device set up on a table

Device suspended from

magnetic holder

GMH 1300

1 2 3

4 5 6

ON

OFF

max

Store

CAL

min

Set

Menu Quit

1 2 3

4 5 6

ON

OFF

max

Store

CAL

min

Set

Menu Quit

CAL

CAL

max

CAL

max

Store

CAL

min

1 2 3

4 5 6

ON

OFF

max

Store

CAL

min

Set

Menu Quit

Store

CAL

4.7 Pop-up clip

Handling:

• Pull at label “open” in order to swing open the pop-up clip.

• Pull at label “open” again to swing open the pop-up clip further.

Function:

• The device with a closed pop-up clip can be plainly laid onto a table or attached to a belt, etc.

• The device with pop-up clip at position 90° can be set up on a table, etc.

• The device with pop-up clip at position 180° can be suspended from a screw or the magnetic holder

GMH 1300.

5 Configuration

Some menu points depend on current device settings.

To change device settings, press „Menu“ for 2 seconds. This will activate the configuration menu (main

display: “Set”). Pressing „Menu“ changes between the menus points, pressing jumps to the

referring parameters, which can be selected with key .

The parameters can be changed with or . Pressing „Menu“ again jumps back to the main

configuration menu and saves the settings. "Quit" finishes the configuration and returns to standard

measuring operation.

H74.0.14.6C-05 Operating Manual GMH 3692 page 7 of 12

Menu

Parameter

Value

Description

key Menu

key

key or

p.r.t

SET

(ONF

Set Configuration: General configurations

[H 2

P 02

hPa

Oxygen partial pressure display in hPa

*

P 02

mmHg

Oxygen partial pressure display in mmHg

LCD.2

T

Second. display always temperature

P

Second. display always absolute pressure

P T

Second. display alternates between temperature and abs. pressure

U N,T

T

°C

All temperatures in degree Celsius (ex works setting)

°F

All temperatures in degree Fahrenheit

[AL.P

1-PT

Simple one point calibration at air

2-PT

2 point calibration at air and 0% (e.g. N2 ) or 100 %

3-PT

2 point calibration at air and 0% (e.g. N2 ) and 100 %

[. INT

1 … 365

Calibration reminder period (in days)

OFF

No calibration reminder

A VTO

HLD

ON

Auto measuring value identification Auto Hold (when logger = off)

OFF

Standard hold function on key press (when logger = off)

P.OFF

1 … 120

Power-off delay in minutes. Device will be automatically switched off as

soon as this time has elapsed if no key is pressed/no interface

communication takes place. (ex works setting 20min)

OFF

Automatic power-off function deactivated (continuous operation)

ADR

0 1, 1 1,2 1, … 9 1

Base address for serial interface communication (ex works setting 01)

SET

(ORR

Set Corr: Input adjustment

0FFS

°C or °F

-5.0 °C .. 5.0 °C

or.

-9.0 °F .. 9.0 °F

The zero point of the temperature measuring is shifted for the entered

value.

This can be used to compensate sensor and instrument deviations

OFF

No zero adjustment for temperature measurement (=0.0°)

S[AL

°C or °F

-5.00 ... 5.00 %

The slope of the temperature measurement is corrected by this value.

This can be used to compensate sensor and instrument deviations

OFF

No slope adjustment for temperature measurement (=0.00)

0FFS

hPa

-20 .. 20 hPa

The zero point of the pressure measuring is shifted for the entered value.

This can be used to compensate sensor deviations

OFF

No zero adjustment for pressure measurement (=0.0°)

SET

AL

Set Alarm: Einstellung der Alarmfunktion

AL. 1

ON / NO.SO

Messkanal Sauerstoff: Alarm an mit Hupe / Alarm an ohne Hupe

OFF

keine Alarmfunktion für Messkanal Sauerstoff

AL.,N

[ONC

Alarmkanal Sauerstoff: Konzentration in %

P. 02

Alarmkanal Sauerstoff: Partialdruck in hPa oder mmHg

A 1.LO

z.B. 0.0..100.0 %

Min-Alarm-Grenze Sauerstoff (nicht bei AL. 1. oFF)

A 1.H,

z.B. 0.0..100.0 %

Max-Alarm-Grenze Sauerstoff (nicht bei AL. 1. oFF)

AL. 2

ON / NO.SO

Alarm Temperaturmessung an mit Hupe / Alarm an ohne Hupe

OFF

keine Alarmfunktion für Temperaturmessung

A2.LO

-5.0 ..+ 50.0 °C

Min-Alarm-Grenze Temperatur (nicht bei AL. 2. oFF)

A2.H,

-5.0 ..+ 50.0 °C

Max-Alarm-Grenze Temperatur (nicht bei AL. 2. oFF)

Pressing “menu” and “store” at the same time for more than 2 seconds will reset the device to

factory defaults

If no key is pressed within 2 minutes the configuration will be aborted. All changes will not be saved!

H74.0.14.6C-05 Operating Manual GMH 3692 page 8 of 12

6 Oxygen Measuring in Gases- Please Note

The GMH 369x is designed for measuring the oxygen partial pressure or the oxygen concentration (%vol,

calculated from partial pressure and ambient pressure) in gases. Please keep in mind:

The sensor hast o calibrated regularily, e.g. at fresh ambient air

The calibration and the measuring are pressure depending!

The instrument automatically measures the ambient pressure, be sure, that instruments pressure is

the same like the pressure at the sensors membrane. For the full automatic compensation a precision

pressure sensor is integrated in the instrument.

The sensor temperature has to be the same like the gas temperture!

Temperature differences may falsify the results!

Please have in mind that temperature adoption of the sensor and the air may take several hours.

A suitable ventilation or gasflow around the sensor would speed up this process significantly.

The sensor consists of a sensing element (GOEL xxx) enclose in a sensor housing (GGO/ GGA/GOO).

When purchasing a Sensor GGO/GGA/GOO xxx, a sensor element is already integrated, e.g. a GGO 370:

contains housing GGO and a sensor element GOEL 370.

6.1 Choice of Sensing Elements#

GOEL 370:

Universal sensor element with special protection measures especially for diving application (“Nitrox”).

Very long life time, also suitable for application with larger CO2 concentrations.

GOEL 380:

Fast responding for low oxygen concentration e.g. protection atmosphere below 1%, max 25%.

For application without larger CO2 concentration.

Sensors are not allowed to used in „under-Water-Diving-Application (e.g. Rebreather)

DANGER

6.2 Application of the different sensor types GGO ..., GOO ... and GGA

GGO (closed sensor)

For measurements at atmosphere and in systems without over or under pressure the GGO... is sufficient.

Additionally the GGO can be screwed tightly into systems with small over or under pressure.

Attention! Mind the maximum pressure and the maximum pressure difference at the membrane.

If instrument and sensor pressure are different, it will be compensated wrong!

GOO 370 / 380 (open sensor)

The sensor is equipped with drillings at the end and because of its special construction the measuring gas

streams optimally around the sensor. No pressure can appear while gas blows to the sensor, which

otherwise would result in erroneous measures. The temperature compensation speed of the sensor also is

optimised by this design.

Especially the measuring of gases from compressed gas bottles, where the expansion of the gas

leaving the bottle lowers the temperature, is optimised with regard to the temperature compensation and

pressure errors. The gas flow should be chosen in a suitable range, where no overpressure can happen,

esp. if the sensor is connected directly to the source e.g. by means of a tube.

GGA (closed sensor with pressure port)

Not suitable for GMH 3692

H74.0.14.6C-05 Operating Manual GMH 3692 page 9 of 12

7 Calibration of the Sensor

In order to compensate for ageing of the sensor, the sensor has to be calibrated at regular intervals.

The device is equipped with an easy-to-use calibration functions.

We recommend to calibrate the sensor at least all 7 days, or to get maximum precision, before each

measuring series.

7.1 One Point Calibration ('(AL 1-PT')

The calibration adjusts the sensor to the oxygen content of the atmosphere (20.95%). Therefore simply

expose the sensor to the ambient air (sufficient ventilation in closed rooms has to be ensured)

Start calibration: press -key for 2 seconds

The display will show 'A,R , and as soon the values for oxygen and temperature are stable, the

calibration will be finished

Then the electrode state resulting of the successful calibration will be shown for a short time (evaluation in

10% steps: xx% ELE[).

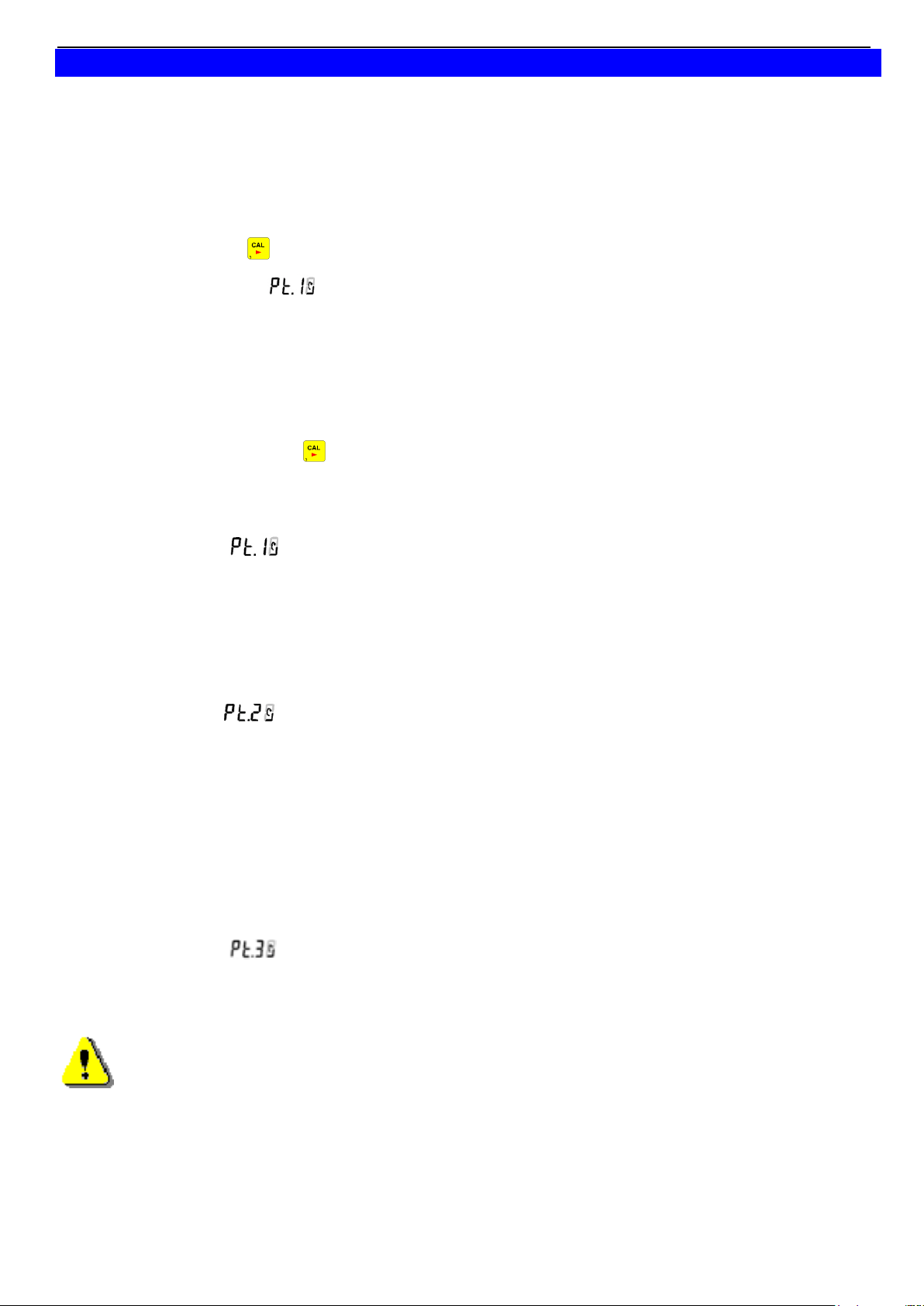

7.2 2 / 3-Point Calibration ('(AL 2-PT, (AL 3-PT')

The sensor will be automatically calibrated to the oxygen content of the atmosphere (20.95%) and one or two

additional concentrations. As reference gases usually Nitrogen (0% vol O2) or pure oxygen are used

1. Start calibration: press -key for 2 seconds

2. First calibration reference: (Pt.1)

As first reference at a 3-point calibration, the zero reference has to be applied (NULL),

at a 2-point calibration either 100% or 0%(NULL).

The display will show , and the referring reference which should be applied:

- NULL for 0% oxygen

- 0.2 for pure oxygen

As long as the display blinks, no valid reference is recognised by the instrument.

As soon the values for oxygen and temperature are stable, the calibration of the first point will be finished.

The instrument tells you to apply the next reference (possible references are blinking in the display).

3. Second calibration reference: (Pt.2)

The display will show , and the referring reference which should be applied:

- A,R for ambient air

- 0.2 for pure oxygen

- NULL for 0% oxygen

As long as the display blinks, no valid reference is recognised by the instrument.

As soon the values for oxygen and temperature are stable, the calibration of the second point will be

finished. At 2-point calibration the calibration will be finished and the electrode state resulting of the

successful calibration will be shown for a short time (evaluation in 10% steps: xx% ELE[).

At 3-point calibration the instrument tells you to apply the next reference (possible reference is blinking)

4. Third calibration reference: (Pt.3)

The display will show , and the referring reference which should be applied:

As soon the values for oxygen and temperature are stable, the calibration of the second point will be

finished. At 2-point calibration the calibration will be finished and the sensor state resulting of the successful

calibration will be shown for a short time (evaluation in 10% steps: xx% ELE[).

In case of error messages being displayed during the calibration process, please refer to our notes

at the end of this manual! If a calibration cannot be carried out after an extended period of time, at

least one of the measuring values is unstable (oxygen partial pressure, temperature).

Please check your measuring arrangements!

7.3 Evaluation of Sensor State (ELE[)

Watch sensor state: press key "CAL" shortly once display show for a short time xx% ELE[.

It will show the electrode state resulting of the last successful calibration carried out.

The valuation is displayed in 10 percent steps: 100% means optimal sensor condition. Lower values are

indicating that the sensor life time will be reached soon.

Remark: But also an erroneous pressure may be the cause of low valuation values.

H74.0.14.6C-05 Operating Manual GMH 3692 page 10 of 12

1 2 3 4 Code

Name/Function

1 2 3 4 Code

Name/Function

x x x x 0

read nominal value

x x x x 199

read measuring type in display

x x x x 3

read system status

x x x x 200

read min. display range

x 12

read ID-no.

x x x x 201

read max. display range

x x x 22

read min alarm limit

x x x x 202

read unit of display

x x x 23

read max alarm limit

x x x x 204

read decimal point of display

x x x x 176

read min measuring range

x 208

read channel count

x x x x 177

read max measuring range

x 222

read turn-off-delay

x x x x 178

read measuring range unit

x 223

Set turn-off-delay

x x x x 179

read measuring range decimal point

x 240

Reset

x x x x 180

read measuring type

x 254

read program identification

7.4 Calibration Interval ([.INT)

You can enter the interval after which the device reminds you to recalibrate in the configuration.

The interval times should be chosen according to the application and the stability of the sensor.

“CAL” flashes on the display as soon as the interval has expired.

8 Inspection of the accuracy / Adjustment Services

The instrument can be sent to the manufacturer for adjustment and function test.

Only the manufacturer can check all systems on correct them if necessary.

Calibration certificates – DKD-certificates – other certificates:

If device should be certificated for its accuracy, it is the best solution to return it to the manufacturer.

(please specify references, e.g. 20.9 and 100%).

If the instrument is certified with its sensor, this proves for example the linearity of the measuring chain,

regular recalibration by the user is still necessary!

9 Serial Interface

With an electrically isolated interface converter USB3100, GRS3100 or GRS3105 (accessory) the device can

be connected to a PC.

With the GRS3105 it is possible to connect up to 5 instruments of the GMH3000 family to a single interface

(please also refer to GRS3105-manual). As a precondition the base addresses of all devices must not be

identical, make sure to configure the base addresses accordingly (refer menu point “Adr.” in chapter 5).

In order to avoid transmission errors, there are several security checks implemented (e.g. CRC).

The following standard software packages are available for data transfer:

GSOFT3050: Operating and evaluation software for instruments with integrated logger function

EBS20M/ -60M: 20- / 60-channel software to record and display the measuring values

GMHKonfig: Software for a comfortable configuration of the device (e.g. freeware)

In case you want to develop your own software we offer a GMH3000-development package including

- an universally applicable 32bit Windows functions library ('GMH3000.DLL') with documentation that can

be used by all 'serious' programming languages.

- Programming examples for Visual Studio 2010 (C#, C++), Visual Basic 6.0™, Delphi 1.0™, Testpoint™,

Labview™

The Device has 4 Channels:

- oxygen concentration % Vol

- oxygen partial pressure in hPa or mmHg

- temperature value at the time of recording in °C or °F

- absolute pressure in hPa abs or mmHg abs

Supported Interface-functions:

The measuring and range values read via interface are always in the selected display unit!

10 Alarm („AL.“)

There are three possible settings:

Alarm off (AL. oFF), on with buzzer (AL. on), on without buzzer (AL. no.So).

Following conditions will display an alarm, when the function is activated (on or no.So):

- Value is below lower (AL. Lo) or above upper alarm rail (AL.Hi).

- Sensor error

- Low battery (bAt)

- Err.7: System error (always with buzzer)

In case of an alarm and when polling the interface the “prio”-flag is set in the returned message.

H74.0.14.6C-05 Operating Manual GMH 3692 page 11 of 12

Display

Meaning

Remedy

low battery voltage, device will continue to work

for a short time

replace battery

If mains operation: wrong voltage

replace power supply, if fault continues to

exist: device damaged

low battery voltage

replace battery

If mains operation: wrong voltage

Check/replace power supply, if fault

continues to exist: device damaged

No display

or

weird display

Device does not

react on keys

low battery voltage

replace battery

If mains operation: wrong voltage

check/replace power supply, if fault

continues to exist: device damaged

system error

disconnect battery or power supply, wait

some time, re-connect

device defective

return to manufacturer for repair

SENS

ERRO

sensor error: no sensor cable connected

connect suitable sensor

Sensor, cable or instrument defect

return to manufacturer for repair

ERR.1

Value exceeding measuring range

Check: Is the value exceeding the

measuring range specified? ->value too

high!

Wrong sensor connected

Check sensor

Sensor, cable or instrument defect

return to manufacturer for repair

ERR.2

Value below display range

Check: Is the value below the measuring

range specified? ->value too low!

Wrong sensor connected

Check sensor

Sensor, cable or instrument defect

return to manufacturer for repair

ERR.7

system error

return to manufacturer for repair

>CAL<

CAL flashing in

display

either preset calibration interval has expired or

last calibration is not valid

device has to be calibrated!

[AL ERR.1

wrong reference point at air

check sensor and reference gas

[AL ERR.2

slope too low

reference gas wrong

check sensor and reference gas

sensor element is defect

replace sensor element

[AL ERR.3

slope too high

reference gas wrong

check sensor and reference gas

sensor element is defect

replace sensor element

[AL ERR.4

incorrect calibration temperature

calibration can only be done at 0…50 °C

[AL ERR.5

Zero value to low/negative

sensor element is defect

replace sensor element

[AL ERR.6

zero value to high

reference gas wrong

check sensor and reference gas

sensor element is defect

replace sensor element

[AL ERR.7

incorrect calibration pressure

check calibration pressure

[AL ERR.8

signal not stable / timeout

check sensor and reference gas

[AL ERR.9

sensor not known: cannot be calibrated

check sensor and wiring

11 Error and System Messages

If “BAT“ is flashing, the battery will be exhausted soon. Further measurements are possible for short time.

If “BAT“ is displayed continuously the battery is ultimately exhausted and has to be replaced. Further

measurements aren’t possible any more.

Messages During Calibration/Adjustment

H74.0.14.6C-05 Operating Manual GMH 3692 page 12 of 12

Measuring ranges

Oxygen concentration

0.0 ... 100.0 % O2 (Vol)

electrochemical sensors GGO / GOO

Oxygen partial pressure

0 ... 1100 hPa O2

“ “ “

Sensor temperature

-5.0 ... + 50.0 °C

NTC 10k (integr. in GGO / GOO cable)

Absolute pressure

10 ... 1200 hPa abs.

integrated pressure sensor

Accuracy

(instrument without

sensor, at 25°C, 1000

hPa abs)

Oxygen concentration

±0.1 % O2 (Vol)

Oxygen partial pressure

± 1 hPa

Sensor temperature

± 0.1 °C

Accuracy

Absolute pressure

3 hPa or 0.1% of measured value (the higher one to be applied)

Working conditions

-20 ... 50 °C; 0 ... 95 % r.H. (not condensing)

Nom. temperature

25°C

Storage temp.

-20 ... 70 °C

Connections

O2 & temperature

6 pole Mini-DIN Socket

Interface /

serial, (3.5mm audio plug),via isolated adapter GRS3100, GRS3105 or

USB3100 (accessories) for PC-USB or RS232- connection

external supply

d.c. connector (diameter of internal pin 1.9 mm) for external 10.5-12V

direct voltage supply. (suitable power supply: GNG10/3000)

Display

4 digit 7-segment 2 lines, additional segments

Calibration

automatic

1 -, 2- or 3-point calibration,

0%, 100% or ambient air (20.95%)

GLP

adjustable calibration intervals (1 to 365 days, CAL warning after

expiration)

Alarm

Buzzer / visual / interface

2 channels: selectable oxygen unit and temperature

Additional functions

Min / max / hold / auto hold

Housing

Break-proof ABS housing

Protection class

Front side IP65

Dimensions L*B*H [mm]

Weight

Without pressure port: 142 x 71 x 26 mm (L x B x H)

approx. 160 g (incl. battery)

Power supply

Current consumption

9V-Battery, Type IEC 6F22 (in scope of supply) or external supply

Ca. 0.6 mA (if Out = Off ca. 0.4mA)

Change battery indicator

Automatic at weak battery and ’ bAt ’

Auto-Off-Function

Device will be automatically switched off if no key is pressed/no

interface communication takes place for the time of the power-off delay.

The power-off delay can be set to values between 1and 120 min.; it can

be completely deactivated.

EMI

The device corresponds to the essential protection ratings established in

the Regulations of the Council for the Approximation of Legislation for

the member countries regarding electromagnetic compatibility

(2004/108/EG). Additional fault: <1%

Dispense exhausted batteries at destined gathering places.

This device must not be disposed as “residual waste”. To dispose this device, please send it

directly to us (adequately stamped). We will dispose it appropriately and environmentally friendly.

DANGER

All devices returned to the manufacturer have to be free of any residual of measuring media and

other hazardous substances. Measuring residuals at housing or sensor may be a risk for persons

or environment

Use an adequate transport package for reshipment, especially for fully functional devices. Please

make sure that the device is protected in the package by enough packing materials.

12 Specification

13 Reshipment and Disposall

H36.0.13.6C-07

GMH 3691 GOG

For quick and cost-effective measurement of residual oxygen,

check-up of protective atmosphere in food packagings and for selective “sniffing”

Scope of supply:

1 display instrument GMH3691

2 hand pump (compress to use, the hand pump automatically

draws in the measuring gas after release, period of drawing

about 30 seconds)

3 GOG oxygen sensor with penetration needle,

optimised for quick measurement of tiniest amounts of

gases

Checking the calibration:

In order to get the optimum precision of the measurings, we suggest to check the calibration before each

measuring. This check is done at normal ambient air.

Before the check or calibration, the sensor’s temperature has to be adjusted to the ambient temperature.

In order to optimise the operational readiness of the instrument it is good practice to store it directly at the

location, were the measurings should be made.

For the check of the calibration the protection cap of the needle has to be removed. Compress the hand

pump (while the instrument is switched on) and release it afterwards. Then, already after 10 seconds the

display should show a oxygen content of 20.9 ... 21.0%. If there are greater deviations we suggest to

calibrate the instrument according to the manual GMH3691 (chapter: Calibration of the oxygen sensor).

The Measuring:

Preparation / Recommendations

Before measuring we recommend to put a rubber foam sticker onto the package.

(see illustration on the right hand side).

The sticker prevents the package from tearing up due to the penetration of the

needle. Furthermore it prevents a gap between package and needle, no ambient

air can flow in. This would corrupt the measuring.

This is especially important for the accuracy of the measurement of packages with little gas volume.

GREISINGER electronic GmbH Hans-Sachs-Straße 26 Tel.: 0049 9402 / 9383-0 http://www.greisinger.de

D-93128 Regenstauf Fax: 0049 9402 / 9383-33 Email: info@greisinger.de

H36.0.13.6C-07

Measuring:

1. Penetrate the rubber foam sticker until the needle hits a hollow space of the package.

Attention: You must take care not to draw foodstuffs in, because otherwise the needle can

be blocked and the sensor can be contaminated.

2. Compress the hand pump completely. A valve prevents air from flowing into the package due to the

compression of the hand pump.

3. After releasing it, the pump draws the measuring gas out of the packing for ~30 seconds.

After been compressed, the

hand pump draws in for

approx. 30 seconds.

The intake / measuring can

be continued by compress the

pump again.

Compressed hand pump Uncompressed hand pump

4. The oxygen contents can read off the display already after ~10 seconds.

Note: You can only read off a valid measured value while the hand pump is drawing.

The pump can be compressed several times while connected to the same package, a reverse valve

prevents air from flowing into the package due to the compression of the hand pump, that would falsify the

measured value.

Flushing the sensor:

The measuring system must flushed with ambient air after the measuring.

Compress therefore the hand pump for 1 or 2 times.

Measuring accuracy and calibration

You could carry out a two-point-calibration of the GMH 3691 in order to get absolute precise measured

values. Therefore a second reference point - besides air- is required.

We recommend to use N2 if you want to check-up on the residual oxygen content in food packaging filled

with protective atmosphere. N2 is available in bottles and is equivalent to 0.0% oxygen.

The type of the calibration has to be selected in the device menu before calibrating.

If the whole system is carefully calibrated and the measuring will done accurately the accuracy of

measurement will be:

1 point calibration: ± 0.2% O2 ± 1digit at concentrations <10% O2

2 point calibration: ± 0.1% O2 ± 1digit at concentrations <10% O2

For information to the 2-point calibration please refer to the GMH3691 operating manual.

The measuring system is optimised for needle with ∅0.9mm. By needles with less diameter the needed

gas volume can be reduced further. But the measuring value will be lowered by the resulting under

pressure. (up to 40mbar at Ø0.45mm)

Example: 40mbar under pressure at 1000 mbar ambient pressure:

(1000-40)/1000 * 20.9% -> display 20.1%.

For measuring of protective atmosphere this error can be neglected (Example display of 1.9% instead 2.0%).

GREISINGER electronic GmbH Hans-Sachs-Straße 26 Tel.: 0049 9402 / 9383-0 http://www.greisinger.de

D-93128 Regenstauf Fax: 0049 9402 / 9383-33 Email: info@greisinger.de

Loading...

Loading...