Page 1

H36.0.13.6C-07

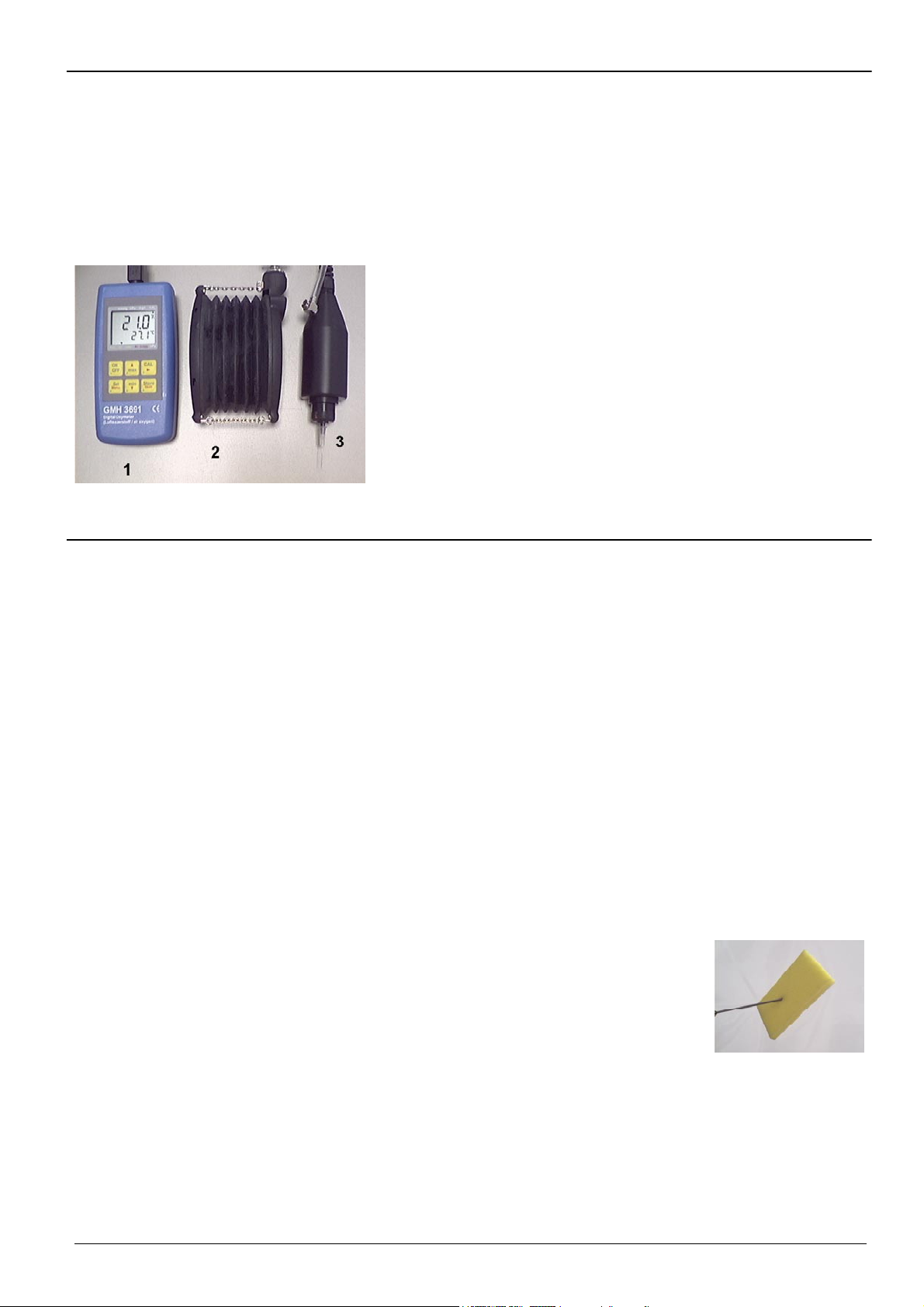

GMH 3691 GOG

For quick and cost-effective measurement of residual oxygen,

check-up of protective atmosphere in food packagings and for selective “sniffing”

Scope of supply:

1 display instrument GMH3691

2 hand pump (compress to use, the hand pump automatically

draws in the measuring gas after release, period of drawing

about 30 seconds)

3 GOG oxygen sensor with penetration needle,

optimised for quick measurement of tiniest amounts of

gases

Checking the calibration:

In order to get the optimum precision of the measurings, we suggest to check the calibration before each

measuring. This check is done at normal ambient air.

Before the check or calibration, the sensor’s temperature has to be adjusted to the ambient temperature.

In order to optimise the operational readiness of the instrument it is good practice to store it directly at the

location, were the measurings should be made.

For the check of the calibration the protection cap of the needle has to be removed. Compress the hand

pump (while the instrument is switched on) and release it afterwards. Then, already after 10 seconds the

display should show a oxygen content of 20.9 ... 21.0%. If there are greater deviations we suggest to

calibrate the instrument according to the manual GMH3691 (chapter: Calibration of the oxygen sensor).

The Measuring:

Preparation / Recommendations

Before measuring we recommend to put a rubber foam sticker onto the package.

(see illustration on the right hand side).

The sticker prevents the package from tearing up due to the penetration of the

needle. Furthermore it prevents a gap between package and needle, no ambient

air can flow in. This would corrupt the measuring.

This is especially important for the accuracy of the measurement of packages with little gas volume.

GREISINGER electronic GmbH Hans-Sachs-Straße 26 Tel.: 0049 9402 / 9383-0 http://www.greisinger.de

D-93128 Regenstauf Fax: 0049 9402 / 9383-33 Email: info@greisinger.de

Page 2

H36.0.13.6C-07

Measuring:

1. Penetrate the rubber foam sticker until the needle hits a hollow space of the package.

Attention: You must take care not to draw foodstuffs in, because otherwise the needle can

be blocked and the sensor can be contaminated.

2. Compress the hand pump completely. A valve prevents air from flowing into the package due to the

compression of the hand pump.

3. After releasing it, the pump draws the measuring gas out of the packing for ~30 seconds.

After been compressed, the

hand pump draws in for

approx. 30 seconds.

The intake / measuring can

be continued by compress the

pump again.

Compressed hand pump Uncompressed hand pump

4. The oxygen contents can read off the display already after ~10 seconds.

Note: You can only read off a valid measured value while the hand pump is drawing.

The pump can be compressed several times while connected to the same package, a reverse valve

prevents air from flowing into the package due to the compression of the hand pump, that would falsify the

measured value.

Flushing the sensor:

The measuring system must flushed with ambient air after the measuring.

Compress therefore the hand pump for 1 or 2 times.

Measuring accuracy and calibration

You could carry out a two-point-calibration of the GMH 3691 in order to get absolute precise measured

values. Therefore a second reference point - besides air- is required.

We recommend to use N2 if you want to check-up on the residual oxygen content in food packaging filled

with protective atmosphere. N2 is available in bottles and is equivalent to 0.0% oxygen.

The type of the calibration has to be selected in the device menu before calibrating.

If the whole system is carefully calibrated and the measuring will done accurately the accuracy of

measurement will be:

1 point calibration: ± 0.2% O2 ± 1digit at concentrations <10% O2

2 point calibration: ± 0.1% O2 ± 1digit at concentrations <10% O2

For information to the 2-point calibration please refer to the GMH3691 operating manual.

The measuring system is optimised for needle with ∅0.9mm. By needles with less diameter the needed

gas volume can be reduced further. But the measuring value will be lowered by the resulting under

pressure. (up to 40mbar at Ø0.45mm)

Example: 40mbar under pressure at 1000 mbar ambient pressure:

(1000-40)/1000 * 20.9% -> display 20.1%.

For measuring of protective atmosphere this error can be neglected (Example display of 1.9% instead 2.0%).

GREISINGER electronic GmbH Hans-Sachs-Straße 26 Tel.: 0049 9402 / 9383-0 http://www.greisinger.de

D-93128 Regenstauf Fax: 0049 9402 / 9383-33 Email: info@greisinger.de

Loading...

Loading...