T14.0.0Y.6C-03

Conductivity-Transmitter

with 4 pole measuring cell (graphite)

as of version 1.2 Operating Manual GLMU 200 MP

Contents

1 Intended use 2

2 General Advice 2

3 Safety Requirements 2

4 Disposal instructions 2

5 Calibration Service 2

6 Installation 3

7 Operation 4

8 Display functions 5

9 Error and system messages 5

10 Configuration 6

11 Specification 8

GREISINGER electronic GmbH

D - 93128 Regenstauf, Hans-Sachs-Straße 26

Tel.: +49 9402 9383-0, Fax: +49 9402 9383-33, eMail: info@greisinger.de

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 2 of 8

1 Intended use

The GLMU 200 MP is a transmitter for measuring conductivity or other units based on conductivity measuring in liquids.

The measurement is performed by means of alternating current flow between the poles of the measurement

cell, being in direct contact with the liquid.

The measurement is displayed via analogue standard signal output and a liquid crystal display.

The 4-20 mA model is supplied only by the current loop, the 0-.. V model required a separate power supply.

The configuration of the various parameters has to be checked prior to use.

2 General Advice

Read through this document attentively and make yourself familiar to the operation of the device before you

use it. Keep this document in a ready-to-hand way in order to be able to look up in the case of doubt.

3 Safety Requirements

This device has been designed and tested in accordance with the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures

and special safety advises given in this manual will be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if the device is not subjected to

any other climatic conditions than those stated under "Specification".

If the device is transported from a cold to a warm environment condensation may cause in a failure of the

function. In such a case make sure the device temperature has adjusted to the ambient temperature before trying a new start-up.

2. General instructions and safety regulations for electric, light and heavy current plants, including domestic

safety regulations (e.g. VDE), have to be observed.

3. If device is to be connected to other devices (e.g. via PC) the circuitry has to be designed most carefully.

Internal connection in third party devices (e.g. connection GND and earth) may result in not-permissible

voltages impairing or destroying the device or another device connected.

4. If there is a risk whatsoever involved in running it, the device has to be switched off immediately and to be

marked accordingly to avoid re-starting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer time

In case of doubt, please return device to manufacturer for repair or maintenance.

5. Warning:

Do not use these products as safety or emergency stop devices, or in any other application where failure of

the product could result in personal injury or material damage. Failure to comply with these instructions

could result in death or serious injury and material damage.

4 Disposal instructions

This device must not be disposed as ‘residual waste’.

To dispose this device, please send it directly to us (adequately stamped).

We will dispose it appropriately and environmentally friendly.

5 Calibration Services

Factory calibration certificate - DKD certificate - official certifications:

If the measuring instrument is supposed to receive a factory calibration certificate, it has to be sent to the

manufacturer.

Just the manufacturer can check the factory settings and correct them if necessary.

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 3 of 8

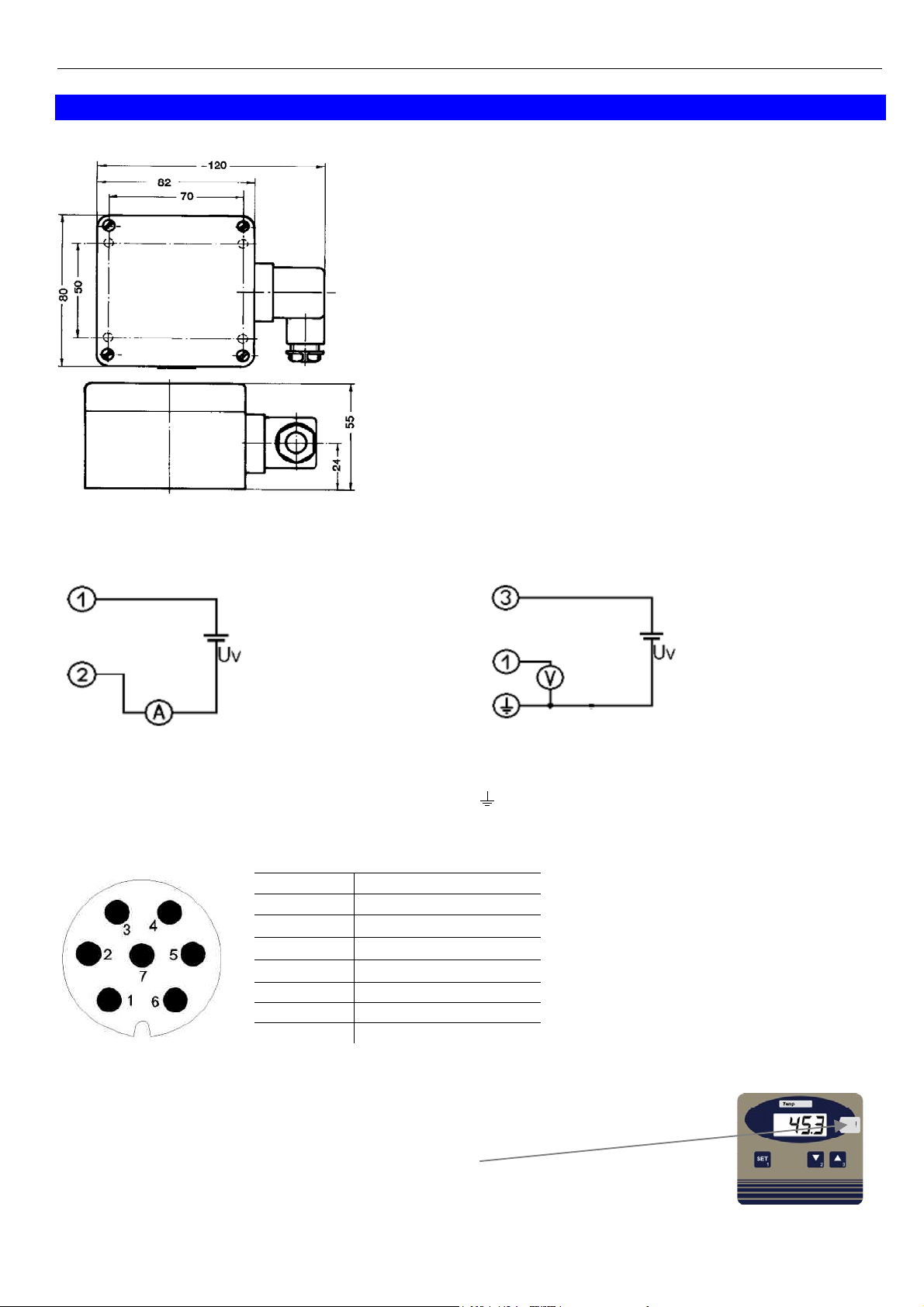

6 Installation

Dimensions

General elbow-type plug installation instructions

To mount the connection cable (2-, or 3-wire depending on type of

device) the elbow-type plug screw has to be loosened and the coupling insert has to be removed by means of a screw driver at the

position indicated (arrow).

Pull out connection cable through glanding and connect to the

loose coupling insert as described in the wiring diagram.

Replace loose coupling insert onto the pins at the transmitter housing and turn cover cap with cable outlet in the direction desired untill

it snaps on (4 different starting positions at 90° intervals).

Re-tighten the screw at the angle plug.

6.1 Assignment of elbow-type plug

4-20 mA (2-wire-connection). voltage (3-wire connection).

1 = supply +

2 = GND / signal

1 = signal +

3 = supply voltage +Uv

(4) = supply voltage -Uv

The type current or voltage output is set by works and cannot be changed

6.2 Terminal assignment of meas. cell socket

contact no.

1 temperature +

2 temperature GND

3 measuring cell 1

4 measuring cell 1

5 measuring cell 2

6 measuring cell 2

7 not used

2 pole-cell (K ~ 1)

6.3 Usage of Unit-Labels

As the transmitter is a multiple purpose device, many different display units are possible, e.g. µS/cm, kOhm·cm.

Therefore unit-labels (within scope of supply) can be shoved between the case cover

and the front foil behind the transparent unit-window.

To replace a label, unscrew the cover, pull out the old label (if present) and shove in the

new one.

The unit depends on the settings of the Cell-constant, the function and the measuring range!

Please refer to table in chapter “Configuration of the device”

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 4 of 8

7 Operation

7.1 General information about the conductivity measuring

7.1.1 The measuring cell

During the measurement, the conductivity measuring cell must be dipped at least in so far, that at least

30 mm beginning from the top of the measuring cell, is located in the medium.

The maximum immersion depth for continuous operation should not exceed 110 mm.

The measuring cell can either be stored dry or in water. After dry storage wetting time will be prolonged

slightly. If changing over from one liquid to another with conductivity varying widely make sure to properly

rinse the measuring cell with deionised water.

Attention: Measuring cell must never come into contact with water-repellent materials such as oil

or silicone.

If conductivity measured is much higher or lower than expected this may be due to the measuring being

soiled with non-conducting or conducting extraneous materials. The measuring cell has to be cleaned e.g.

with a watery soap solution.

When measuring media at low conductivity the measuring cell has to be stirred sufficiently.

7.1.2 Measuring hints

Conductivity measuring is comparably easy to perform, the precision of the instrument is very constant if it is

used as intended. Depending on the necessary accuracy the instruments can be used up to several years

without re-calibration of the cell constant.

If the accuracy should be controlled or improved, this is done by means of suitable reference solutions and

the adjusting of the cell factor.

Attention! Wrong handling of reference solution can make them useless very fast.

Measuring procedure:

Especially when measuring low conductivity: Before immersion to the measuring solution, rinse the measuring cell with deionised water.

The measuring is speeded up considerably, if the measuring cell is immersed and pulled out the solution

several times. Especially when measuring low conductivity the measuring cell needs sufficient flow during the

measuring, e.g. via stirring the solution.

Sufficient time has to be waited for, until the measuring cell has adjusted to the measuring solution temperature.

7.1.3 Temperature compensation

The conductivity of aqueous solution is temperature dependent. The dependency itself is strongly dependent

on the kind of solution. For the most applications e.g. in fish farming etc., the non linear temperature compensation of natural waters is precise (“nLF” according to EN 27888). The most common reference temperature is 25 °C.

7.1.4 .Salinity measuring

The salinity (salt content) of seawater can be determined in the measuring mode „SAL“ (basis: International

Oceanographic Tables; IOT)

The salinity of standard-seawater is 35 ‰ ( 35 g salt per 1 kg seawater).

The values are displayed in ‰ (g/kg).

7.1.5 TDS measuring

At the TDS measuring the dry residues or total d

issolved solids value is calculated by means of the conductivity and a calculation factor (C.tdS). This factor has to be evaluated for the referring type of solution.

The values are displayed in mg/l.

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 5 of 8

A

8 Display functions

8.1 Currently measured values

During normal operation the conductivity display value is displayed.

By short press of key ‘SET’ (1) the temperature in [°C] will displayed for 10 seconds.

rrow to Temp indicates

temperature display

display of conductivity value display temperature

8.1.1 Min/Max Value Memory

watch Min values (Lo): press ‘down‘(2) shortly once display changes between ‘Lo‘ and Min values

watch Max values (Hi): press ‘up‘(3) shortly once display changes between ‘Hi‘ and Max values

restore current values: press ‘down‘(2) or ’up’(3) once again current values are displayed

clear Min-values: press ‘down’(2) for 2 seconds Min values are cleared. The display shows shortly ‘CLr‘.

clear Max-values: press ‘up’(3) for 2 seconds Max values are cleared. The display shows shortly ‘CLr‘.

After 10 seconds the currently measured values will be displayed again.

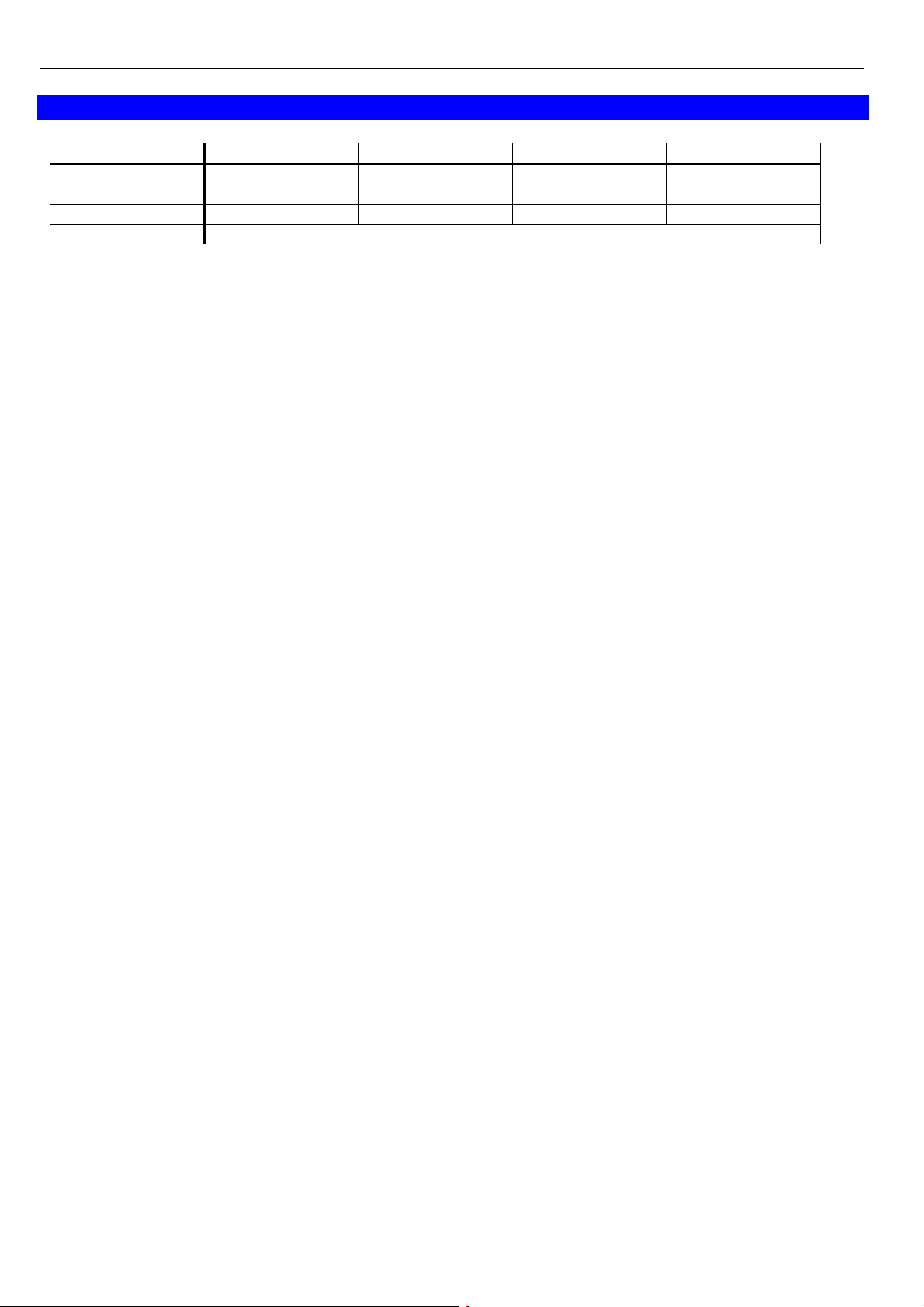

9 Error and system messages

Display Description Possible fault cause Remedy

Temperature above 140°C not allowed.

Choose right measuring range for conductivity

Temperature below -5°C not allowed.

Choose right measuring range for conductivity

Disconnect from supply and reconnect.

If error remains: return to manufacturer

Check temperature

Err.1

Err.2

Err.7

Err.9

Er.11

8.8.8.8

measuring range exceeded

Measuring value below

measuring range

System fault Error in device

Sensor error Sensor or cable defective Check sensor, cable and connections

Calculation not possible

Segment test

Wrong signal

Wrong signal

Calculation variable

missing or invalid

The transducer performs a display test for 2 seconds after power up.

After that it will change to the display of the measuring.

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 6 of 8

10 Configuration

In the configuration the devices parameters can be changed.

The jumper has to be set, p.r.t. figure right hand side. To set or

remove jumper, the housing cover has to be removed. Ex works

the jumper is set.

To change parameters press “SET” (key 1) two seconds, then the

parameter selection is started with the first parameter (display

shows “CELL”).

By pressing “SET” the desired parameter is selected, the editing of

the parameter values happens via keys 5 (key 3) or 6 (key 2).

Pressing “SET” again (after editing the parameter values) returns

to the parameter selection

Pressing “SET” again after the last parameter finishes the configuration, stores the changes and restarts the device.

10.1 'CELL': Setting of the cell-constant of the connected measuring cell

Possible inputs: 0.300...1.200. Unit is 1/cm.

The value was evaluated and stored ex works for the connected measuring cell (in between 0.80...1.20).

If the jumper is removed from

the shown contacts, the configuration is inaccessible, values are protected.

10.2 'Func': Setting of the measuring function

Possible inputs: cond conductivity

reSi: resistivity

tdS: TDS (total dissolved solids

SAL: Salinity = salt content of sea water

10.3 'rAnG': Setting of the measuring range (not at “Func SAL”)

Choice the desired measuring range (range is depending on the function set above).

Possible inputs:

Range (rAnG) = 0 Range (rAnG) = 1 Range (rAnG) = 2 Range (rAnG) = 3

Conductivity (cond) 0,0 - 200,0 mS/cm 0,00 - 20,00 mS/cm 0 - 2000 µS/cm 0,0 - 200,0 µS/cm

Resistivity (rESi) 5,0 - 100,0 Ohm·cm 50 - 1000 Ohm·cm 0,50 - 10,00 kOhm·cm 5,0 - 100,0 kOhm·cm

TDS (tdS) -- -- 0 - 2000 mg/l 0,0 - 200,0 mg/l

Salinity (SAL) 0,0 - 70,0

10.4 't.Cor': Setting of temperature compensation method (not at “Func SAL”)

Possible inputs: off: no temperature compensation

nLF:non linear compensation for natural water according to EN 27888 (DIN 38404).

For measurings of ground and surface water, drinking water or pure water.

Attention: restricted temperature range: -5..105 °C

Lin: linear temp. compensation (for other aqueous solutions, factor has to be entered)

10.5 't.Lin': Setting of temperature coefficient (only for t.Cor = Lin)

Possible input: 0.300 .. 3.000 [%]

If it is only measured in a narrow conductivity range, the temperature compensation factor of this range can

be determined.

10.6 't.rEF': Setting of reference temperature (only for t.Cor = nLF or Lin)

Possible input: 20 °C or 25 °C

10.7 'C.tdS': Setting of TDS-factor

Calculation factor for TDS (Total Dissolved Solids)-measurements, possible input: 0.40 .. 1.00.

The calculation factor depends on the composition of the medium and has to be determined

for each type of water.

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 7 of 8

10.8 'dA.Lo': Display at zero output (output scaling)

Enter the display value at which the output should have 4 mA (or 0 V).

The value range is depending on the selected measuring function (Func) and range (rAnG).

10.9 'dA.Hi': Display at maximum output (output scaling)

Enter the value at which the output should have 20 mA (or 1 / 10 V).

The value range is depending on the selected measuring function (Func) and range (rAnG).

10.10 'Unit' with Temp-arrow: Temperature unit

Temperature unit: All referring settings and displays are done in this unit.

Choice between °C and °F (ex works: °C)

10.11 'OFFS' with Temp-arrow: Offset of temperature measuring

The offset of the measuring will be shifted by this value, the input is in °C. Calculation: see below.

Max. input range: -5.0...5.0 °C or 'oFF' (= 0.0°) (factory setting = off)

10.12 'SCAL' with Temp-arrow: Scale correction of temperature measuring

The scale of the measuring is changed by this value. Calculation: see below.

Max. input range: -5.00...5.00 or 'oFF' (= 0.00) (factory setting = off)

The adjusting of the temperature by means of offset and scale is intended to be used to compensate deviations of the measuring. It is recommended to keep the scale correction deactivated (“oFF”). The display

value is given by following formula:

Temperature display = measured value - offset

With a scale correction (just for calibration laboratories, etc) the formula changes:

Temperature display = (meas. value - offset) * ( 1 + scale correction/100)

After pressing key 1 again, the instrument will restart (display 8888).

T14.0.0Y.6C-03 Operating Manual GLMU 200 MP page 8 of 8

11 Specification

Measuring range 1 (one of the following can be configured):

Range (rAnG) = 0 Range (rAnG) = 1 Range (rAnG) = 2 Range (rAnG) = 3

Conductivity (cond) 0,0 - 200,0 mS/cm 0,00 - 20,00 mS/cm 0 - 2000 µS/cm 0,0 - 200,0 µS/cm

Resistivity (rESi) 5,0 - 100,0 Ohm·cm 50 - 1000 Ohm·cm 0,50 - 10,00 kOhm·cm 5,0 - 100,0 kOhm·cm

TDS (tdS) -- -- 0 - 2000 mg/l 0,0 - 200,0 mg/l

Salinity (SAL) 0,0 - 70,0

Meas. range 2 Temperature (only display) -5.0...140.0 °C (resolution 0.1°C or 0.1°F, NTC10k)

Attention: Consider application range of measuring cell: 0..80°C

Accuracy: (at nominal temperature = 25°C)

Measuring: conductivity: ±0,5% of measured value ±0,3 FS

temperature: ±0.1°C of measured value ±1 Digit

Add. output signal: ±0.2 % FS

Measuring cell: 2 pole measuring cell with graphite electrodes, integrated NTC temperature sensor,

Cell constant K: 0.80..1.20, determined and adjusted ex works

7 pole connector

Temp. compensation: non linear function, linear function (coefficient configurable) or none

Min-/Max-Value Memory: Min and max measured values are stored

Output signal: refer to type plate, freely scaleable

Scaling: By entering display values for 4mA (or 0V) and 20mA (or 1V/10V) output

Connection: 4 - 20 mA type: 2-wire – output signal electrically isolated

options AV01 (0-1 V), AV10 (0-10 V): 3-wire – output signal electrically isolated

Auxiliary energy (supply voltage): Uv = 12 - 30 V DC (4-20 mA)

Uv = 12 - 30 V DC, max. 10mA (0-1V)

Uv = 18 - 30 V DC, max. 10 mA (0-10 V)

or refer to type plate

Rev. voltage protection: 50 V permanent

Perm. impedance (at 4-20mA): RA(Ohm) < ( (Uv – 12 V) / 0.02 A )

Example: for Uv = 18V: RA < (18 V – 12 V) / 0.02 A => RA < 300 Ohm

Permissible load (at 0-...V): RL(Ohm) > 3000 Ohm

Adjusting: via keys. Conductivity by editing cell constant K (CELL)

Temperature by offset and scale.

Display: approx. 10 mm high, 4-digit LCD-display

Ambient conditions for electronics:

Nominal temperature: 25°C

Operating condition: -25 to 50°C, 0 to 95 %RH (non-condensing)

Storage temperature: -25 to 70°C

Ambient of meas. Cell: -5 to 80°C (short time up to 100°C)

Housing: ABS (IP65)

Dimensions: 82 x 80 x 55 mm (without elbow-type plug and sensor connector)

Mounting: With holes for wall mounting (in housing - accessible after cover has been removed).

Mounting distance: 50 x 70mm, max. shaft diameter of mounting screws is 4 mm.

Electrical connection: elbow-type plug conforming to DIN 43650 (IP65),

max. wire cross section: 1.5 mm², wire/cable diameter from 4.5 to 7 mm

EMC: In accordance with EN61326 +A1 +A2 (appendix A, class B), additional errors: < 1% FS.

When connecting long leads adequate measures against voltage surges have to be taken.

The electrode connections have to be protected sufficiently against ESD pulses, if the device is used in areas with risk of ESD.

Loading...

Loading...