S01.0.0X.6C-05 page 1 of 2

water flow direction

Operating Manual For

GEWAS 191 and GEWAS 191A

Scope of supply:

1 x control device GEWAS 191 or GEWAS 191A

1 x water sensor GWF-1S

1 x solenoid GMV 191 12VDC

1 x bushing

1 x sealing ring

Specification:

Voltage supply : 220/240V 50/60Hz (control device)

Power rating: approx. 3 Watt

max. switching current: 16A ohmic load (for GEWAS 191A only)

Solenoid: max. working pressure: 6bar servo controlled (pressure difference infeed/outfeed >0,5 bar)

Dimensions: control device: 126 x 79 x 54 (L x W x H)

solenoid: 82 x 52 x 41

EMC: The GEWAS 191 and GEWAS 191A correspond to the essential protection ratings established in the

Regulations of the Council for the Approximation of Legislation for the member countries regarding

electromagnetic compatibility (89/336/EWG)

Installation and commissioning:

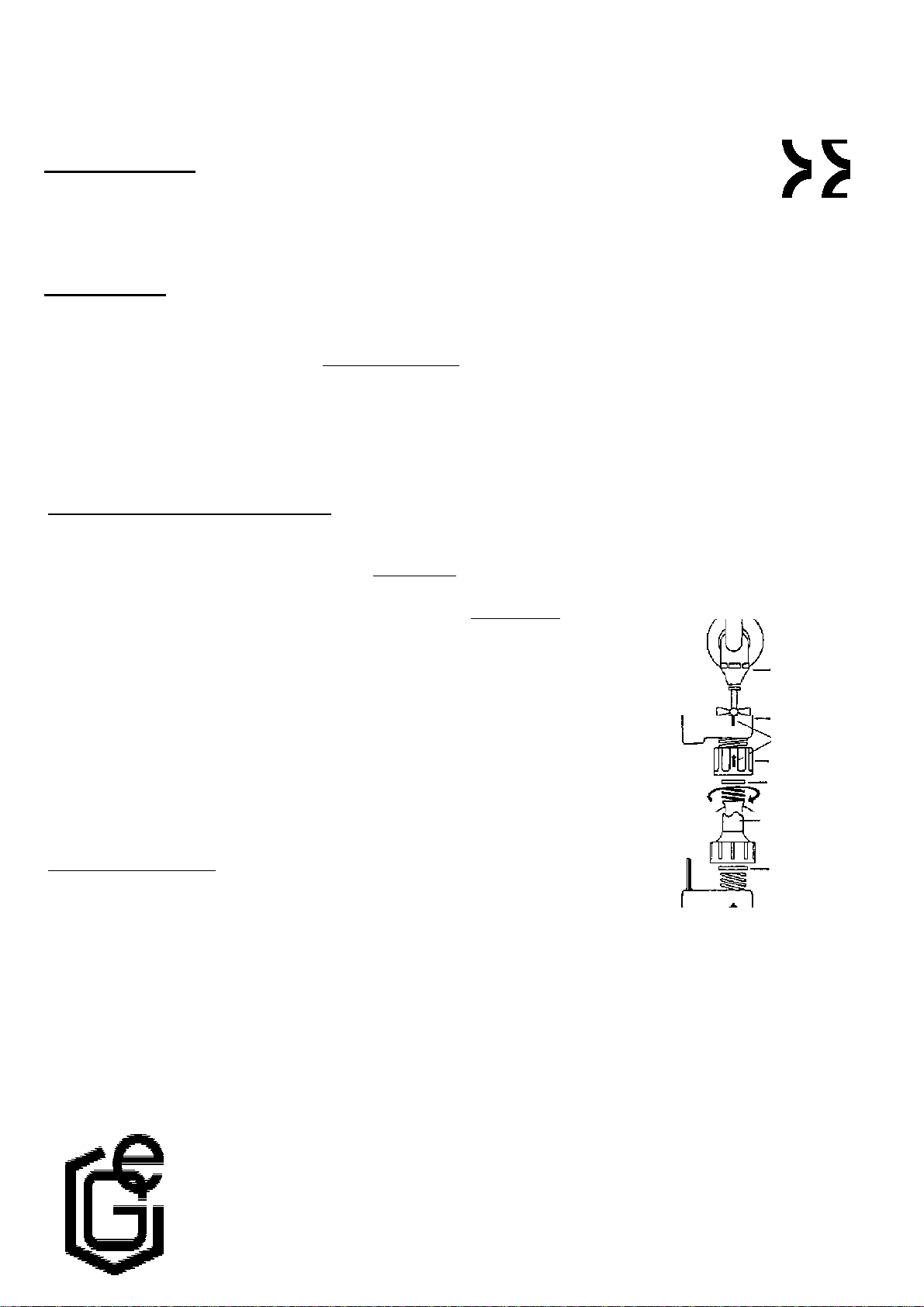

1. Installation of solenoid

- Lock water feed lines.

- Screw bushing onto the solenoid by means of a left-hand turn.

- Insert sealing ring.

- Connect solenoid and bushing to the water feed by means of a right-hand turn. The solenoid

will automatically be drawn towards the sealing.

- Check for leakage by opening the water feed.

=> in case of leakage repeat the process described above but change position of bushing on

the solenoid slightly.

- Screw water connection tube to the outlet side of the solenoid (use existing sealing ring or

make sure that tube itself is properly sealed! ).

If the installation has been carried out correcly the bushing can be tightend by hand. In case of

leakage check if sealing has been inserted and if all sealing surfaces are clean; also check if

the installation has been carried out correctly, e.g. if the bushing (both right-hand and left-hand

thread covering one half) is positioned correctly on the solenoid (p.r.t. installation of the

solenoid point 2). If necessary repeat installation process. Tightening by force (e.g. by means of

a pipe wrench) in case of a leakage at the solenoid will only damage the right- and left-hand

thread in the bushing but will do nothing to remedy the fault cause.

Advice for commissioning:

The solenoid will not be opened unless it has been connected to the activated control device.

2. Installation of control device and water sensor

- Make it a rule to read the operating and maintenance advises before starting-up the device.

- Place water sensor at desired position and fix it, if necessary.

- Connect water sensor and solenoid to the control device.

- Open water feed line unless you have already done so.

- Plug in control device into a socket outlet with earthing contact.

=> Device is now active, the solenoid is open.

- Check water connection for leakage.

- Connect device which is to be switched off in case of alarm to the socket outlet with earthing contact of the control device.

! Well done, your GEWAS device is now ready for use !

water feed

(tap)

sealing ring

bushing

solenoid

sealing ring

water feed tube

GREISINGER electronic GmbH

D - 93128 Regenstauf, Hans-Sachs-Straße 26

Fon: 09402 / 8500 od. 8748, Fax: 09402 / 1829

S01.0.0X.6C-05 page 2 of 2

Function

If the water film at the water sensor exceeds 0.5 mm the control device automatically triggers an audible alarm and switches off the

solenoid. The GEWAS 191A type also switches off the device connected to the control device.

To remove the alarm disconnect control device. Wait for approx. 5 seconds before reconnecting the device.

The alarm will also be activated if the water sensor has been disconnected.

What to do in case of an alarm

- The control device can only be switched off by disconnecting it.

- Try to find and remedy fault cause.

- Potential fault causes:

- The water sensor is defective or has been disconnected.

- The water sensor contacts are connected (e.g. by means of a piece of metal etc.)

- There is a water film at the water sensor.

- Reconnect the control device; make sure to wait at least 5 sec. after disconnection.

Operating and maintenance advise

1. The solenoid is servo-controlled; i.e. the pressure at the infeed side of the solenoid needs to exceed the outlet side pressure

by at least 0.5 bar. This condition is fullfilled if the water feed line is open and the water can flow freely at the solenoid outlet.

Unless this condition has been fullfilled the solenoid cannot open. In such a case remedy fault cause (e.g. activate water

infeed of the device connected), disconnect control device, wait for approx. 5 sec and reconnect again.

2. When dead the solenoid will always be closed. In order to guarantee the required sealing properties, you have to make sure

that there are no foreign objects (stones, sand etc.) in the solenoid line. We, therefore, recommend to clean the sieve insert of

the solenoid regularly.

3. After a short current failure the solenoid sometimes closes but does not open again. Disconnect control device and wait for

approx. 5 sec., then reconnect control device => solenoid will open.

4. In order to ensure long-time and trouble-free operation of the device, the functioning of the device has to be checked at regular

intervals (as is the case with any safety device). To do so produce an alarm at least once a month by short-circuiting both water

sensor contacts by means of a metal object (e.g. spoon, knife, etc.). Disconnect device; wait for approx. 5 sec, before

reconnecting the device. The solenoid has to react with a clearly audible "clack" sound. This is to make sure that even if the

water is calcareous and even if it is not regularly operated the solenoid is fully operational regardless of the calcareous

deposits.

6. The device has to be treated and handled carefully in accordance with the above specifications (do not throw, bump against, etc.).

7. !!! Never use GEWAS in a humid environment. !!!

Safety requirements:

This device has been designed and tested in accordance with the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special safety

advises given in this manual will be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if the device is not subjected to any other climatic

conditions than those stated under “Specification”.

2. Make sure to observe the standard regulations and safety instructions for electric, heavy and weak current plants, in particular

the national safety regulations (e.g. VDE0100).

3. If there is a risk whatsoever involved in running it, the device has to be switched off immediately and to be marked accordingly to

avoid re-starting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer time.

In case of doubt, please return device to manufacturer for repair or maintenance.

Special equipment or spare parts :

Shunt plug: GAZ-1 shunt plug in case you want to connect several water sensors

Water sensor: GWF-1S additional water sensor

Extension cable: VEKA 2 extension cable 2 m

VEKA 5 extension cable 5 m

VEKA 10 extension cable 10 m

Loading...

Loading...