Page 1

Operating Manual

Water analysis – hand-held

meter

G 7500 series

Keep for later use.

www.ghm-group.de

Companies / Brands of the GHM

Englisch

Page 2

H87.0.0X.6C-01 Operating manual G 7500 Series page 2 of 34

Index

1 GENERAL NOTE ............................................................................................................... 3

2 SAFETY ................................................................................................................................ 3

2.1 INTENDED USE .................................................................................................................. 3

2.2 SAFETY GUIDELINES .......................................................................................................... 3

2.3 QUALIFIED PERSONNEL ...................................................................................................... 3

2.4 SAFETY SIGNS AND SYMBOLS ............................................................................................ 4

2.5 FORESEEABLE MISUSE ....................................................................................................... 5

2.6 SAFETY INSTRUCTIONS ...................................................................................................... 5

3 PRODUCT SPECIFICATION ........................................................................................... 7

3.1 SCOPE OF DELIVERY .......................................................................................................... 7

3.2 OPERATING AND MAINTENANCE ....................................................................................... 7

3.3 CONNECTIONS ................................................................................................................... 7

3.4 SUPPORT AND RETAINING CLIP ........................................................................................... 8

4 OPERATION ....................................................................................................................... 9

4.1 KEYPAD ............................................................................................................................ 9

4.2 STATUS LINE ................................................................................................................... 10

4.3 DISPLAY ELEMENTS ......................................................................................................... 10

5 START OPERATION ....................................................................................................... 11

6 BASICS OF THE MEASUREMENT .............................................................................. 11

6.1 PH MEASUREMENT .......................................................................................................... 11

6.2 BASICS ABOUT CONDUCTIVITY ........................................................................................ 15

6.3 CONDUCTIVITY MEASUREMENT ....................................................................................... 15

6.4 ELECTRODES / MEASURING CELLS ................................................................................... 15

6.5 TEMPERATURE COMPENSATION ....................................................................................... 16

6.6 DESIGN OF THE SENSOR GWO 5610 ................................................................................ 17

6.7 COMMISSIONING / FILLING OF THE SENSOR GWO 5610 ................................................... 19

6.8 SENSOR GWO 5610 MAINTENANCE ................................................................................ 20

6.9 BASICS ABOUT OXYGEN MEASURING ............................................................................... 21

6.10 AMBIENT PRESSURE AND MEASURING DEPTH OF THE ELECTRODE ................................ 21

6.11 CORRECTION OF SALINITY ............................................................................................ 21

7 CONFIGURATION........................................................................................................... 22

7.1 DEVICE MENU .................................................................................................................. 22

7.2 PH CHANNEL MENU ......................................................................................................... 25

7.3 TEMPERATURE CHANNEL MENU ....................................................................................... 27

7.4 OXYGEN CHANNEL MENU ................................................................................................. 27

7.5 CONDUCTIVITY CHANNEL MENU ...................................................................................... 28

8 ERROR CODES (IN DATASET) .................................................................................... 29

9 CALIBRATION ................................................................................................................. 30

9.1 GENERAL INFORMATION .................................................................................................. 30

9.2 PH CALIBRATION ............................................................................................................. 30

9.3 O

2

CALIBRATION ............................................................................................................. 30

10 CALIBRATION AND ADJUSTMENT SERVICE ..................................................... 31

11 REPLACING RECHARGEABLE BATTERIES ....................................................... 31

12 RESHIPMENT AND DISPOSAL ................................................................................. 32

Page 3

H87.0.0X.6C-01 Operating manual G 7500 Series page 3 of 34

12.1 RESHIPMENT ................................................................................................................ 32

12.2 DISPOSAL ..................................................................................................................... 32

13 SPECIFICATION .......................................................................................................... 33

13.1 MEASUREMENTS AND ACCURACY ................................................................................. 33

13.2 GENERAL SPECIFICATION .............................................................................................. 34

14 TERMS OF LICENSE ................................................................................................... 34

14.1 FREERTOS .................................................................................................................. 34

14.2 FATFS .......................................................................................................................... 34

1 General Note

Read this document carefully and get used to the operation of the device before you

use it. Keep this document within easy reach near the device for consulting in case

of doubt.

2 Safety

2.1 Intended Use

The device is exclusively designed for measuring of pH and conductivity or pH and

dissolved oxygen in water (saltwater and freshwater).

Personnel which starts up, operates and maintains the device has to have sufficient

knowledge of the measuring procedure and the meaning of the resulting measured

values, this manual delivers a valuable help for this. The instructions of the manual

have to be understood, regarded and followed.

To be sure that there´s no risk arising due to misinterpretation of measured values,

the operator must have further knowledge in case of doubt - the user is liable for any

harm/damage resulting from misinterpretation due to insufficient knowledge.

The manufacturer will assume no liability or warranty in case of usage for other

purpose than the intended one, ignoring this manual, operating by unqualified staff

as well as unauthorized modifications to the device.

2.2 Safety guidelines

This device has been designed and tested in accordance with the safety regulations

for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the

standard safety measures and special safety advises given in this manual will be

adhered to when using the device.

2.3 qualified personnel

The device may only be installed by qualified personnel who have read and

understood this manual and who are able to use the devices professionally. Qualified

personnel are persons who are familiar with the installation, assembly,

commissioning and operation of these devices and who have the necessary

qualifications to carry out their duties.

Page 4

H87.0.0X.6C-01 Operating manual G 7500 Series page 4 of 34

2.4 Safety signs and symbols

The following signs in this document highlight warnings:

Caution! This symbol warns of imminent danger, death, serious

injuries and significant damage to property at non-observance.

This symbol indicates danger for living tissue as well as a variety of

materials, which can be damaged or destroyed when coming into

contact with this chemical. Caustic effect, protective equipment

required!

This Symbol indicates dangers to all living beings that may result in

death or acute or chronic health hazards when inhaled, swallowed, or

absorbed through the skin of this chemical.

This Symbol indicates irritant substances that can cause inflammation

on short-term, prolonged or repeated contact with the skin or mucous

membranes.

Attention! This symbol warns of possible dangers or dangerous

situations that can provoke damage to the device or environment at

non-observance.

Note! This Symbol indicates operations which, if ignored, may have an

indirect effect on operation, possibly leading to incorrect measurement

results or triggering an unforeseen reaction.

This symbol instructs the use of eye protection which protects the eyes

from harmful influences when working with powerful light, UV radiation,

laser, chemicals, dust, splinters or weather influences.

This symbol instructs the use of protective gloves which offer

protection from mechanical, thermal, chemical, biological or electrical

hazards.

Page 5

H87.0.0X.6C-01 Operating manual G 7500 Series page 5 of 34

2.5 Foreseeable misuse

The fault-free function and operational safety of the product can only be guaranteed if

generally applicable safety precautions and the device-specific safety instructions for

this document are observed.

If these notices are disregarded, personal injury or death, as well as property damage

can occur.

This device must not at all be used in potentially explosive

environment! The usage of this device at potentially explosive areas

increases danger of deflagration, explosion or fire due to sparking.

This device is not suitable for medical applications.

The device is not suitable for direct contact with food products.

Take samples and dispose them correctly after the measurement.

2.6 Safety instructions

This device has been designed and tested in accordance with the safety regulations

for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the

standard safety measures and special safety advises given in this manual will be

adhered to when using the device.

The O2 sensor contains potassium hydroxide. This causes burns. All

contact with the skin, clothing and eyes should be avoided.

Nevertheless, should contact occur, take

the following measures.

– Eyes: Flush with flowing water for at least 15 minutes, seek medical

attention!

– Skin: Wash with large amounts of water for several minutes!

– Clothing: Remove immediately!

– If swallowed: Drink large amounts of water, do not induce vomiting

and seek medical

Attention!

If there is a risk whatsoever involved in running it, the device has to be

switched off immediately and to be marked accordingly to avoid restarting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer

time.

In case of doubt, please return device to manufacturer for repair or

maintenance.

Page 6

H87.0.0X.6C-01 Operating manual G 7500 Series page 6 of 34

Do not use this product as safety or emergency stop devices or in any

other application where failure of the product could result in personal

injury or material damage.

Failure to comply with these instructions could result in death or

serious injury and material damage

When interacting with chemicals at least the following points must be

ensured:

1. Obey all notes on the container of chemicals.

2. Obey all notes in the safety specification sheet of chemicals.

3. Consider any statutory provisions guidelines and guidelines of

chemicals when disposing!

This is also for accidentally spilled chemicals, dried residues,

soiled rags or similar.

4. Always wear suitable protective clothing (e.g. protection goggles,

safety gloves, face mask, etc.)!

5. Never eat, drink or smoke in the operational area of chemicals!

6. In case of problems instantly consult skilled personnel.

Suitable clean-up possibilities (eye wash, etc.) must exist

within spitting distance!

Trouble-free operation and reliability of the device can only be

guaranteed if the device is not subjected to any other climatic

conditions than those stated under specification

Page 7

H87.0.0X.6C-01 Operating manual G 7500 Series page 7 of 34

3 Product Specification

3.1 Scope of delivery

The scope of supply includes:

Device with 3 rechargeable batteries type AAA

Short manual

Operating manual and calibration protocol as pdf file in mass storage memory.

3.2 Operating and Maintenance

1. Battery operation:

If the battery has been used up and needs to be recharged, the device will display

BAT. in the upper status line. The device will, however, continue operating correctly

for a certain time.

The battery has been completely discharged, if batteries empty is shown in the

main display and the red backlight will blink. The device will than turn off

automatically.

The device has a deep discharge protection, when the batteries

reach a limit value, the device can no longer be turned on!

2. Treat device and electrodes carefully. Use only in accordance with above

specification (do not throw, hit against etc.).

The measuring values can be influenced by contamination.

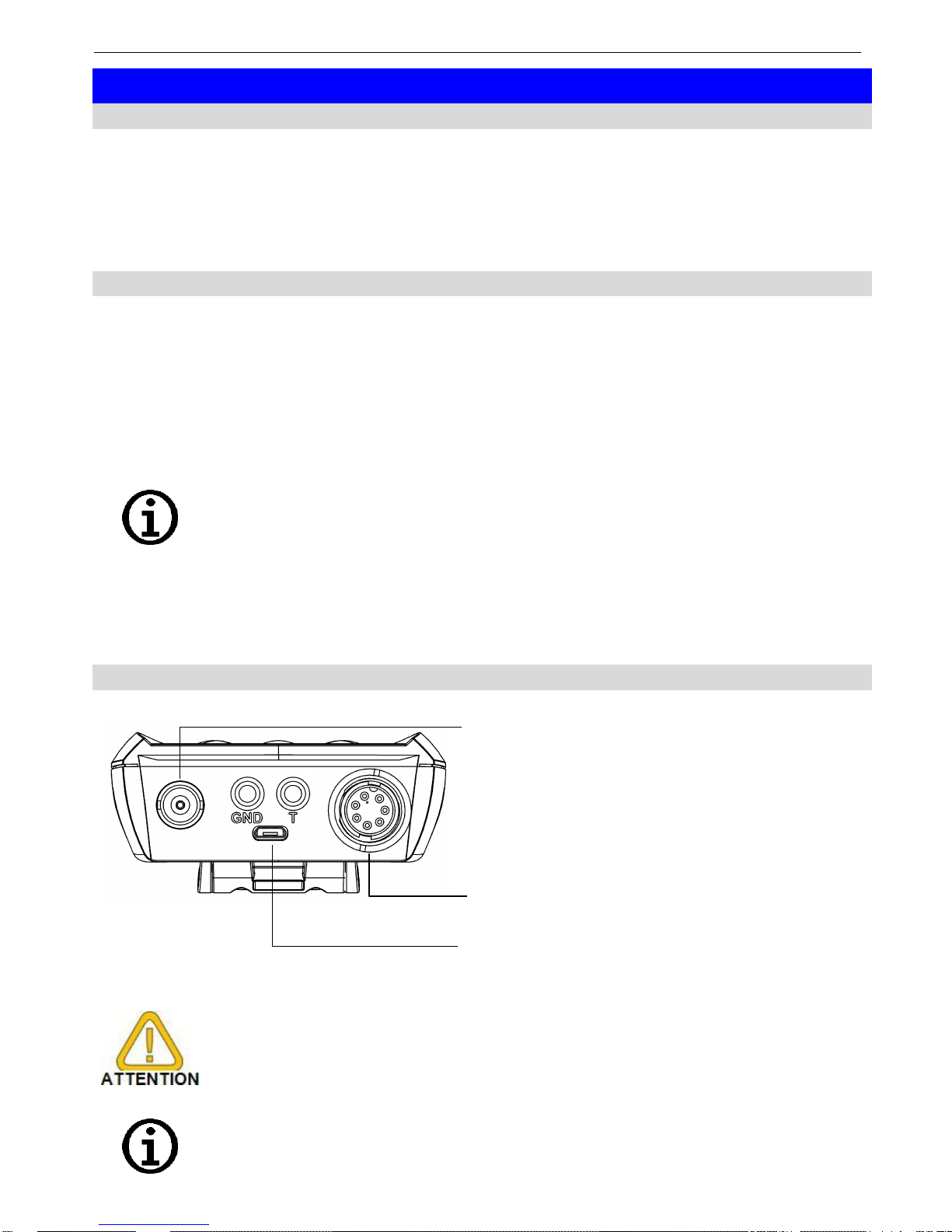

3.3 Connections

Front view

Connector

Probetype (standard)

BNC

pH (GE 125)

Banana

6 mm

(GND)

Resistive temperature probe

(PT 1000 or NTC 10 k)

common, needed only for

separate temperature probe

Banana

6 mm (T)

Resistive temperature probe

(GE 125 banana plug)

7-pol. LTW

Oxygen (GWO 5610) or

conductivity (LF 425)

Micro USB

For power supply or device

communication

Waterproofness is only guaranteed for plug connections in the

plugged-in state in combination with waterproof cable plugs.

The temperature measurement can be influenced by conductive

liquids on the banana sockets. We recommend always keeping the

connections dry.

Page 8

H87.0.0X.6C-01 Operating manual G 7500 Series page 8 of 34

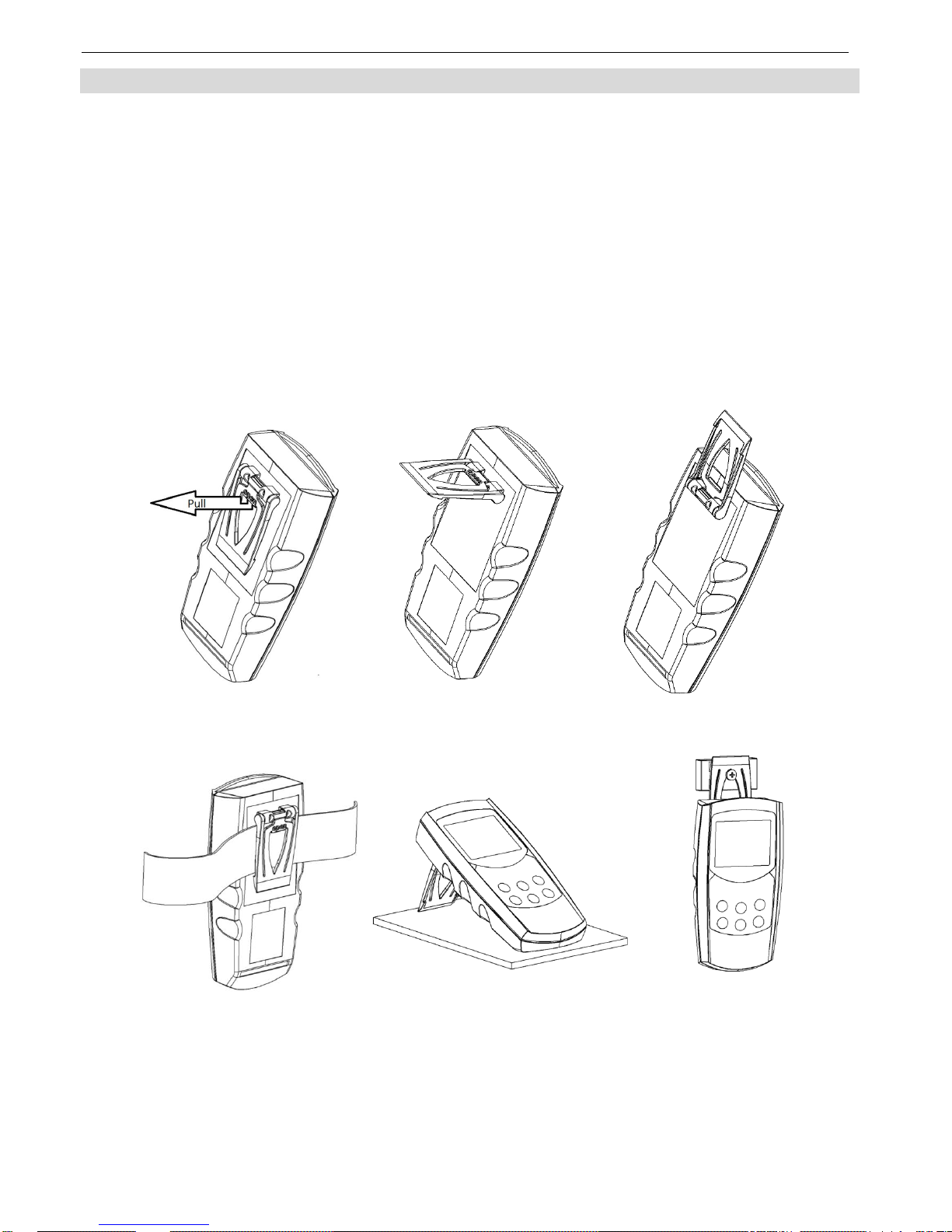

3.4 support and retaining clip

The stand is provided as a means to prop up or support the device in a stable

surface, for hanging on the wall or for attachment to a belt.

Instruction:

- Leave the stand collapsed in order to lay the product flat on a stable surface or

to hang it on a belt.

- Pull the grip labelled open in order to fold it out to a 90° angle. Now, the

product can be positioned on a stable surface.

- Pull the grip labelled open again in order to fold it out to a 180° angle. Now the

product can be hung.

- The product can be positioned ideally so that the display can always be read

clearly and easily depending on its use.

Pop-up clip closed

Pop-up clip at position 90°

Pop-up clip at position 180°

Device attached to a belt

Device set up on a table

Device suspended from

magnetic holder

GMH 1300

Page 9

H87.0.0X.6C-01 Operating manual G 7500 Series page 9 of 34

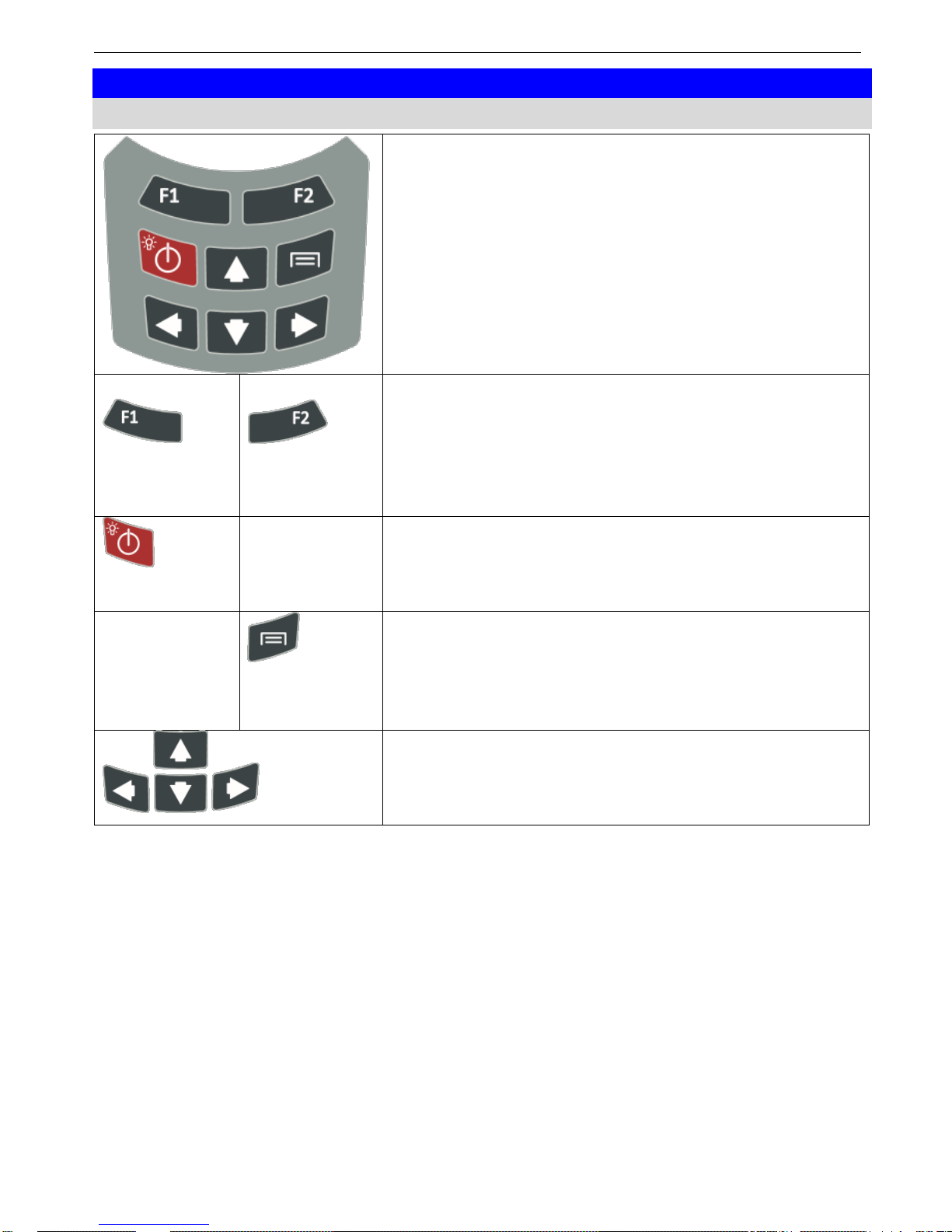

4 Operation

4.1 Keypad

With the keypad the device functions, display

mode, etc. can be set by user interaction.

The display will contain specific information for the

F1 and F2 soft-keys.

F1 and F2 soft-key

Depending to the device state (view, menu,

channel, …) the dark accentuated texts in the

display directly above the soft-keys are describing

the soft-keys function (e.g. ‘back’ for F1 and

‘change’ for F2).

power button

Will turn the device on (only when rechargeable

batteries are not empty) or off (only when the logger

is not running).

device settings

Will open the device-settings-menu.

Here anything that’s not related to a physical

measuring e.g. the date, time USB-mode and

language can be changed.

directional pad (up, down, right, left)

For navigation within a menu, for changing the

selected channel (up and down) or changing the

view (right and left).

Page 10

H87.0.0X.6C-01 Operating manual G 7500 Series page 10 of 34

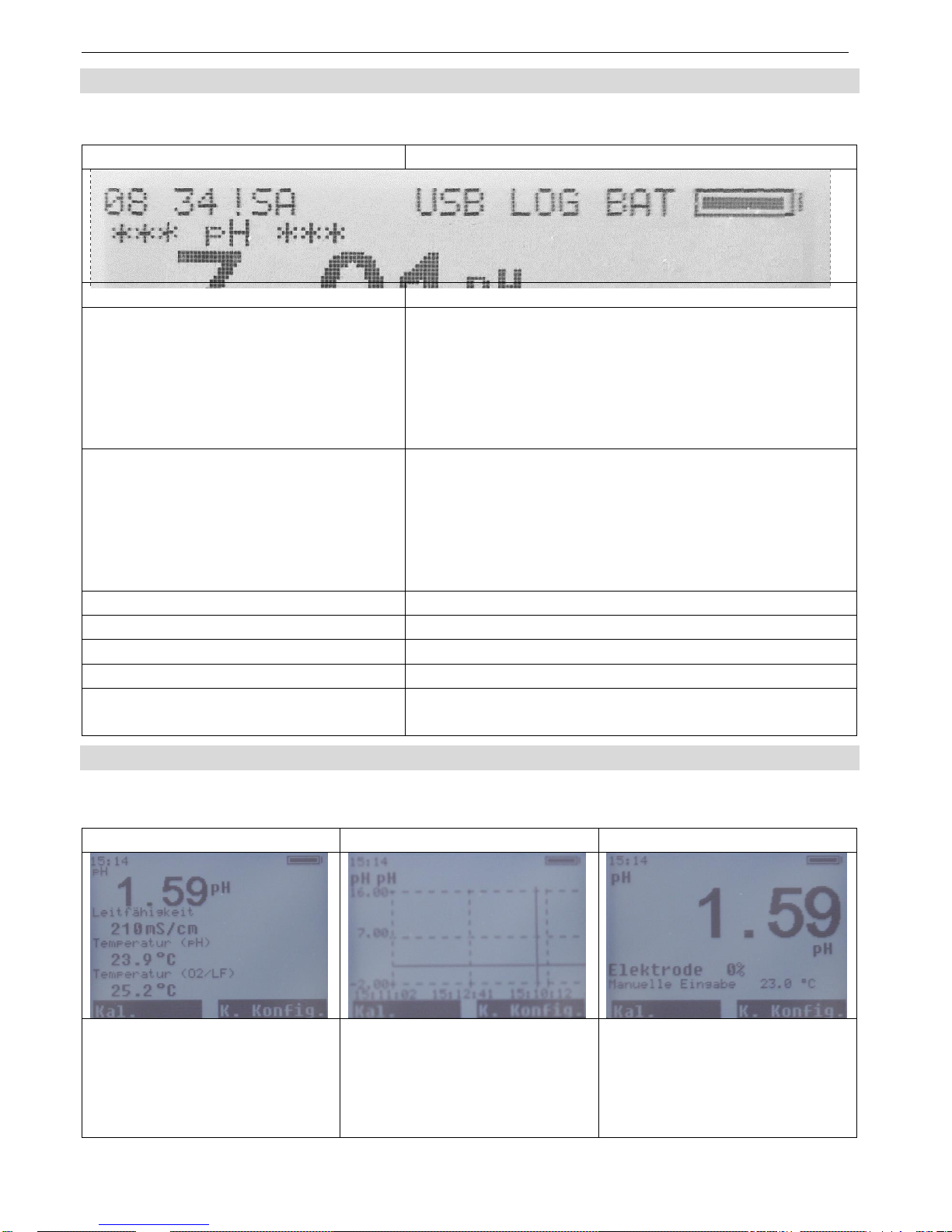

4.2 Status line

The status line is the first line in the display.

Display

Meaning

Current time

If time is flashing, time must be reseted

!

Internal memory error. When this error won’t

disappear after restarting the device, it should

be returned for repairing. The device will go to a

safe fallback mode were device settings are

stored and recalled from the mass storage

memory if this is available.

S

Saving to the internal mass storage memory

takes longer than intended. When the S will be

shown permanently in the display, please let

Windows check the mass storage device for

errors. When the S still shows up, the device

needs to be send back for repairing.

A

Alarm of a channel is active

USB

USB connection has been established.

LOG

Logger is active

BAT

Rechargeable battery capacity critically low

Battery indicator

If the battery capacity flashes, the battery is

being charged

4.3 Display elements

Views can be changed by the right and left keys of the directional pad. With the keys

up and down the channel can be changed.

Table view

Chart view

Large view

All channels in one row

Chart of one channel

Display of one channel

with specific parameters

(here: electrode quality

and temperature

compensation)

Page 11

H87.0.0X.6C-01 Operating manual G 7500 Series page 11 of 34

4.3.1 Menu

Depending on the selected channel, you can switch to the channel configuration

menu by pressing the function key F2. Here, channel-specific settings can be made.

5 Start operation

Charge the rechargeable batteries by connecting a power supply or the computer to

the micro USB connector.

Connect all desired probes or electrodes.

Turn on the device by pressing the power button.

Change date, time and language by pressing the device settings key and save the

changes made.

6 Basics of the measurement

At first the basics of all measurements will be depicted. Some channel specific

settings depend on these basics.

6.1 pH measurement

The pH value describes the acidic or alkaline behavior of an aqueous solution.

pH values below 7 are acidic (smaller values indicate higher acidity), and values

above 7 are alkaline; pH 7 = neutral.

The pH measurement is very precise, but also sensitive. The measured signals are

very weak (high-impedance), especially when measured in weak or low-ion media.

Therefore, always take measures to

To determine the pH value of a solution, its temperature needs to be

known. The reason is that most liquids change their pH value with the

temperature.

- avoid interference (electrostatic charges, etc.)

- keep plug contacts clean and dry

- prevent electrodes (except special waterproof versions) from extended

immersion above the shaft

- calibrate the electrode at sufficient intervals (see below). The frequency of

calibration can range from every hour to several weeks, depending on the

electrode and the application.

- use a suitable electrode. See chapter Fehler! Verweisquelle konnte nicht

gefunden werden.

Page 12

H87.0.0X.6C-01 Operating manual G 7500 Series page 12 of 34

6.1.1 Design

1. Coaxial cable

2. Reference electrode

3. Measuring electrode

4. Refill opening

5. Electrolyte

6. Internal buffer

7. Diaphragm

8. Glass membrane / source layer

The diaphragm, which establishes a connection between the electrolyte and the liquid

to be measured, can be designed in different ways. Clogging or soiling of the

diaphragm is a frequent cause of a malfunctioning or sluggish electrode. Always

handle the glass membrane with extreme care. The so-called source layer forms

there. This is crucial for the measurement and must always be kept moist.

There are also electrodes with integrated temperature sensors.

6.1.2 pH electrode

Normally, so-called pH single-rod measuring chains are used. They

include all necessary components that are integrated in an electrode.

Page 13

H87.0.0X.6C-01 Operating manual G 7500 Series page 13 of 34

6.1.3 Further information

pH electrode is a wear part. If the signal is very slow or the required values are no

longer observed after careful cleaning and possible regeneration, the electrode must

be replaced. When using the electrodes, be aware that various substances in

aqueous solutions can corrode glass and that chemicals can produce a chemical

reaction with the KCl solution in the electrode, which can result in blockage of the

diaphragm.

Examples:

In solutions that contain proteins, such as for measurements in medical and

biological applications, KCl can cause denaturation of the protein.

Coagulated paints

Solutions that contain high concentrations of silver ions

Substances that accumulate on the glass membrane or the diaphragm affect the

measurement and must be removed regularly. This can be achieved for example

with automatic cleaning systems.

6.1.4 Choosing a pH electrode

GE 100 BNC is a universal electrode with two ceramic diaphragms and liquid

GE 101 BNC is preferably used for small sample amounts. It comprises a glass

electrode with two ceramic diaphragms and liquid electrolyte.

GE 104 BNC is preferably used for measurements in low-ionic media, such as

rainwater, aquarium water and deionised water.

GE 114 WD is a universally applicable, durable and low-maintenance gel

electrode with Pellon diaphragm. It can be used for measurements in drinking

water, swimming pools, aquaria and slightly contaminated waste water.

GE 117 BNC is a temperature-compensated gel electrode with two ceramic

diaphragms and PH 13.5 cable screw coupling.

GE 120 BNC is an insertion electrode and is preferably used for measurements

in cheese, fruit and meat. For measurements in products containing proteins,

the electrode must be cleaned with a special cleaner. For this purpose, we

recommend the GRL 100 pepsin cleaning solution.

GE 125 BNC is a waterproof, universally applicable, durable and low-

maintenance gel electrode with ceramic diaphragm. It can be immersed above

the shaft for an extended time.

GE 151 BNC is a glass electrode and is preferably used in galvanic

applications for paints and lacquers.

GE 173 BNC is an alkaline-resistant glass electrode with ground diaphragm

and gel electrolyte for chemical and waste water applications.

Page 14

H87.0.0X.6C-01 Operating manual G 7500 Series page 14 of 34

6.1.5 Service life

The service life of electrodes is normally at least 8 to 10 months. When

cared for properly, this can usually increase to more than 2 years. The

actual life will vary depending on the particular application.

6.1.6 Care and maintenance

The GAK 1400 working and calibration set includes all necessary

products for calibration, care and maintenance of the electrode.

Normal cleaning takes place with the GRL 100 pepsin cleaning

solution into which the electrode is immersed for 5 minutes before

being rinsed off with clean water.

Crystallization of the 3 mol/l KCL solution is unavoidable. Crystallized

potassium chloride on the protective cap and shaft can easily be

removed with a fingernail or cloth and is therefore does not constitute

a defect or cause for complaint.

Dirty electrodes must be cleaned. The suitable cleaning agents for the pH glass

membrane are listed in the table below.

Impurities

Cleaners

General residue

Mild detergent

Inorganic coatings

1 mol/l HCl solution or GRL 100 pepsin

cleaning solution

Metal compounds

1 mol/l HCl solution or GRL 100 pepsin

cleaning solution

Oil and grease

Special cleaner or solvent

Biological coatings with protein

1% pepsin enzyme in 0.1 molar GRL 100

HCl solution

Biological coatings with protein

Acetone

Extremely resistant residues

Hydrogen peroxide or sodium hypochloride

The material of the pH probe must always be protected. Plastic shafts must not be

cleaned in solvents, etc. If in doubt, contact the manufacturer to inquire about suitable

cleaners for the existing electrode. This is also important in the case of aggressive

substances or other substances that are not primarily water-based!

Page 15

H87.0.0X.6C-01 Operating manual G 7500 Series page 15 of 34

6.2 Basics about conductivity

Definition of conductivity :

The ability of a material to conduct electric current:

l: length of the material

A: diameter

R: measured resistance

Unit

, common for liquids:

and

The conductivity is the reciprocal value of the resistivity.

(The conductance is the reciprocal value of the measured resistance R)

6.3 Conductivity measurement

The conductivity measurement is a rather uncomplicated measurement. The

standard measuring cells are stable for a long time if used correctly and can be

adjusted by slope correction.

Range

1 2 3

4

45..500 mS/cm

5.0..50.0

mS/cm

500..5000

µS/cm

0.0..500.0

µS/cm

Within the integrated automatic range selection, the range with the best resolution is

automatically selected.

6.4 Electrodes / measuring cells

6.4.1 Design and selection

Basically there are two types of measuring cells: 2-pole and 4-pole cells. The

operation is done similarly; the 4-pole measuring cells can compensate polarization

effects and – up to some degree – soiling due to its complex measuring method.

2-pole measuring cell

4-pole measuring cell

6.4.2 Calibration / Adjustment of measuring cells

Especially in harsh environments and over long time the cell constants of measuring

cells are drifting. Depending on the application and usage we recommend a regular

checking of the precision of the measuring chain: instrument + cell. For this there are

control solutions available (GKL 100, 101, 102). At normal usage a checking each

half year is recommended.

Page 16

H87.0.0X.6C-01 Operating manual G 7500 Series page 16 of 34

6.5 Temperature compensation

The conductivity of aqueous solutions depends on its temperature. The temperature

dependency is strongly dependent on the type of solution. The temperature

compensation recalculates solutions’ conductivity to a consistent reference

temperature. The most common reference temperature is 25 °C, but 20 °C can also

be selected.

6.5.1 Temperature compensation “NLF” according to EN 27888

For most applications (e.g. in the area of fish farming, surface or drinking water

measurements, etc.) the non-linear temperature compensation for natural water

(“nLF”, according to EN 27888) is sufficiently accurate.

Recommended application range of nLF-compensation: between 60 µS/cm and 1000

µS/cm.

6.5.2 Linear temperature compensation

If the actual function needed for exact temperature compensation is not known,

“linear temperature compensation” is normally selected (Menu, t.Cor = Lin, t.Lin

corresponds

), i.e. one assumes that the actual temperature dependency at the

considered concentration range is approximately equal:

Temperature coefficient of about 2.0 %/K are most common.

A temperature coefficient can be determined for example by measuring a solution

with deactivated temperature compensation at two different temperatures (T1 and

T2).

TK

lin

is the value input at the menu

LF

T1

conductivity at temperature T1

LFT2 conductivity at temperature T2

Page 17

H87.0.0X.6C-01 Operating manual G 7500 Series page 17 of 34

6.6 Design of the sensor GWO 5610

6.6.1 General

The oxygen sensor is an active sensor. It consists of a platinum cathode, a lead

anode and potassium hydroxide (KOH) as an electrolyte. If oxygen is present, it is

reduced on the platinum cathode and the sensor delivers a signal. If no oxygen is

present, no signal is delivered. The anode is consumed by the oxygen measurement.

The sensor ages. Furthermore, the sensor loses water through the permeable

membrane, in particular, when it is stored in dry air. Therefore, it should be checked

and maintained regularly and replaced as necessary.

The electrode contains potassium hydroxide. This causes burns. All

contact with the skin, clothing and eyes should be avoided.

Nevertheless, should contact occur, take the following measures.

Eyes: Flush with flowing water for at least 15 minutes, seek medical

attention!

Consult a doctor.

Always store oxygen sensor GWO 5610 wet!

- In a storage bottle filled with water or

- place in a container with water.

After prolonged storage before the measurement, clean the membrane

with a soft paper towel of possible coverings (algae, bacteria, ...).

6.6.2 Design

Shaft

Membrane

Refill opening

Storage bottle

Platinum electrode

Page 18

H87.0.0X.6C-01 Operating manual G 7500 Series page 18 of 34

Platinum electrode

If oxygen is present, it is reduced on the platinum electrode and the sensor delivers a

signal. Soiling on the platinum electrode or between the membrane and electrode can

influence the measurement.

Storage bottle

The storage bottle is provided to keep the membrane moist. The service life of the

sensor is extended as a result. Distilled or deionized water is in the storage bottle; do

not add any other liquids!

Membrane head

The membrane head is covered with a thin plastic membrane. Faulty measurements

will occur if the membrane is damaged or there are large air bubbles or even an air

bubble ring on the membrane. This can also be the cause if a sensor can no longer

be calibrated. The GWOK 02 membrane head is a spare part and can be re-ordered

separately.

Refill opening

Electrolyte must be filled or added for the initial commissioning of a sensor which is

delivered dry, when performing maintenance or after use at high temperatures.

6.6.3 Service life

The sensor signal deteriorates relatively quickly at the end of the service life of the

sensors. The electrode evaluation in %, therefore, can only be used as a guide value.

A value of 70% does not mean that exactly 70% of the service life is still available,

rather that the electrode signal has 70% of a comparison signal.

The sensor evaluation is updated by the measuring device after a

successfully performed calibration of the oxygen sensor.

The nominal service life can be reduced significantly due to use. Influential factors

include:

▪ Storage / operating temperature

▪ Contamination of the measured water

▪ Mechanical stress of the sensor membrane

▪ Storage in dry air

▪ Continuous use in elevated carbon dioxide concentrations

6.6.4 Operating position

The oxygen sensor should be arranged vertically upwards with the connecting cable.

A slight angle of inclination does not impair the measurement.

Page 19

H87.0.0X.6C-01 Operating manual G 7500 Series page 19 of 34

6.6.5 Measurement accuracy

The measurement accuracy can be impaired by:

▪ An inadequate flow below the necessary value of approx. 30cm/sec.

▪ The water temperature and sensor temperature must be the same. The most

accurate measurements are provided when the measuring temperature is

calibrated.

6.6.6 Visible residues inside the membrane cap

As a reaction product, lead oxides (brown or red, from reaction with oxygen) and lead

carbonate (white, from reaction with carbon dioxide) are created during operation on

the lead anode. These substances can collect on the membrane, but they do not

usually affect the measurement function. Most of these substances can be removed

during the maintenance of the sensor.

Prior to screwing on the membrane cap, they should be removed as far as possible in

order to prevent particles from being trapped between the membrane and the

platinum cup. A rapid or excessive formation of lead carbonate after commissioning is

an indication of air in the sensor. This is usually due to incomplete filling or a leak due

to improper fitting of the cap / fill screw or membrane leak.

6.7 Commissioning / filling of the sensor GWO 5610

The electrode contains potassium hydroxide. This causes burns. All

contact with the skin, clothing and eyes should be avoided.

Nevertheless, should contact occur, take the following measures.

a) Eyes: Flush with flowing water for at least 15 minutes, seek medical

attention!

b) Skin: Wash with large amounts of water for several minutes!

c) Clothing: Remove immediately!

d) If swallowed: Drink large amounts of water, do not induce vomiting

and seek medical attention!

Protective goggles must be worn for all of the following activities!

Protective gloves must be worn for all of the following activities!

The sensor is delivered dry. Therefore, the sensor is well-suited for storage. The

sensor must be filled in good time before the measurement. A wait time of approx. 2

hours after filling should be planned in order to allow the sensor to stabilize.

Page 20

H87.0.0X.6C-01 Operating manual G 7500 Series page 20 of 34

6.8 Sensor GWO 5610 maintenance

After every calibration the sensor quality in % will be shown in the large digit display.

When the quality is below 25 % the sensor should be maintained.

Attention! The electrolyte is corrosive.

To maintain electrode please proceed as follows:

1. Unscrew diaphragm head and wipe clean of electrolyte solution using a paper

cloth. Do not touch electrolyte. If your skin had contact with electrolyte,

immediately rinse thoroughly with clear water.

2. Clean silver cathode with sand paper (grain size 240). Do not polish silver

cathode, surface should stay rough. Remove all dust.

3. Remove filling screw and top up lost electrolyte (e.g. using disposable syringe))

4. Put back and tighten filling screw.

5. Top up diaphragm head with electrolyte avoiding air bubbles and place on table

(cover table with absorbent paper first).

6. Keep electrode in a vertical position and screw diaphragm head to the electrode

from the bottom. Electrolyte will be forced out of the diaphragm head and spill

over (put on disposable gloves or use paper towel to touch diaphragm head).

7. Wipe up excess electrolyte with paper cloth.

8. Check cathode for air bubbles.

If there are large air bubbles, remove diaphragm head again and repeat process

as of point 5. If O-ring has been damaged, it has to be replaced.

When maintenance has been completed plug on protective flask. Re-connect

electrode to measuring device and wait for at least 3 hours till electrode can be

calibrated.

Page 21

H87.0.0X.6C-01 Operating manual G 7500 Series page 21 of 34

6.9 Basics about oxygen measuring

Please observe the following points when measuring dissolved oxygen:

- For measuring remove the protective flask.

- Do not disconnect electrode from device.

If electrode has been disconnected, wait 2..3 hours till the final electrode

signal has settled

before carrying out measurements or a calibration.

- Electrode needs to be calibrated (p.r.t. 'How to calibrate oxygen electrode')

- The temperatures of the electrode and of the liquid to be measured have

to be identical

(if necessary, wait till temperatures match)

- The Electrode has to be submerged at least 3 cm into the liquid to being

measured

- The measured liquid has to stream along the electrode membrane with

at least 30 cm/sec

for measurements to be sufficiently accurate: either stir continuously or

use agitator.

- The electrode measurement is sensitive against shocks!

By stirring of the electrode in the measured liquid be careful that the

electrode does not hit the

container. A vibration of the electrode has a effect to the measured value.

-The optimum operation position is: with the sensor inlet pointing downwards

The instrument calculates the oxygen concentration [mg/l], the oxygen saturation [%]

from the electrode signal and the temperature. According to DIN38408-C22 all

measurements refer to steam saturated air.

6.10 Ambient pressure and measuring depth of the electrode

The pressure at the sensor membrane is important for:

The calculation of the oxygen saturation (%sat).

At air water can get 100% saturation. Assumed that there are no oxygen

consuming processes (biological degradation, chemical effects) and that there

are no oxygen enriching processes (e.g. excessive ventilation or

photosynthesis)

The calculation of oxygen concentration (mg/l or ppm)

The electrode evaluation at calibration

Therefore it is necessary to compensate the pressure influence via integrated sensor

or, like practiced with more primitive instruments via tables and manual input of

pressure or Elevation above sea level values.

6.11 Correction of salinity

The higher the salinity (salt content) the lower the solubility of oxygen in water, i.e.

although the partial oxygen pressure is the same, the quantity of oxygen dissolved in

water (mg/l) is lower. Therefore, determination of the oxygen concentration requires

entering the salinity of the medium (p.r.t. 'Configuration'). The correction of salinity is

based on media on a water basis, whose chemical content is similar to sea water.

The corrections are based on the 'International Oceanographic Tables' (IOT).

Page 22

H87.0.0X.6C-01 Operating manual G 7500 Series page 22 of 34

7 Configuration

There are various configuration parameters available depending on the

product version and configuration. They can differ depending on the

product version and configuration.

In order to configure the product, you must first open the device settings menu. The

menu is opened as shown in the illustration. Prerequisite, The product is switched on.

1. Press the menu key for 1 second, to open the device settings menu.

2. The device settings menu appears in the display. The first parameter is shown.

3. By briefly pressing the Up button and the Down button, you can scroll through

the parameters. Select the parameter you would like to configure.

4. When you have selected the desired parameter, select them with the function

button F2. You can change the parameter to the desired value.

5. With the function button F1 you leave the device settings menu. The main

display is shown.

Representation:

Call up menu

Next

parameter

Change

parameter

Change value

Save changes

1 s

7.1 Device menu

<-- -->

<--

time and date

USB-mode

mass storage

COM port

logging time

logging

not activated

cyclic

on keypress

logging time

location

list 20 location names with up to 21

ASCII characters

language

German

English

backlight

auto-off

off

on

brightness

alarm activity

off

sound

blink

sound and blink

pH channels

inactive

Page 23

H87.0.0X.6C-01 Operating manual G 7500 Series page 23 of 34

active

O2/cond. channels

inactive

active

7.1.1 time and date

Here time and date can be set. The time is shown on the left in the upper status line.

When the time blinks, the time is invalid.

Depending on the language different time-zones are used. In German

MESZ/MEZ (automatic setting of daylight saving time) is used, in all

other languages UTC is used.

All time bases in terminal or data logging files are in UTC to ensure

trouble-free data exchange.

7.1.2 USB-mode

7.1.2.1 mass storage

In USB mass storage the device can no longer access the internal memory. The

logger can no longer be started. Accessing the internal mass storage memory can be

done without driver installation. Logger data can be copied or deleted.

The logger data are stored into a CSV file.

The location depends on the starting time of the logger.

Example: Logger was started 31st December 2020 at 19:11. The CSV files are then

located in the folder \DATA\20201231\1911\ .

Single shot logger data is always stored inside the \HISTORY\ directory.

Calibration data are stored like logger data, but inside the \CAL_DATA directory.

7.1.2.2 COM port

In this mode the computer can directly communicate with the device after driver

(windows only) installation. (115200 8N1 \r\n as end marking)

The following commands are supported:

GetChannelMenu: #

menu output with all settings

GetLastValue: #

output of the last measured value

GetCalibrationReport: #

displays the last calibration values

DeviceInformation: 0

device and license information

AddLocationDescription: ##

changes the location description of location ##

# is the channel number starting from 0.

Nr.

channel

Data name (Prefix)

0

oxygen

O2

1

pH

PH

2

conductivity

COND

3

temperature (pH)

T_PH

4

temperature (O2/LF)

T_COND

5

air pressure

PRES

6

device menu (value = battery capacity in %)

DEV

7.1.3 alarm activity

The alarm activity means what action should be done when an alarm (of any channel)

is active. The alarm activity will happen only when a channel’s alarm condition is true,

Page 24

H87.0.0X.6C-01 Operating manual G 7500 Series page 24 of 34

the channel is active and the alarm function is activated. The device will show ‘A’ in

the status line, even if the alarm activity is off.

7.1.4 logger

Three different functionalities can be set

not activated

cyclic

on keypress

7.1.4.1 not activated

The logger is not active, USB settings an channel calibration can be used.

7.1.4.2 cyclic

When the logger started, each channel will be recorded. The logging interval is in

seconds. On record start, a new folder will be created in the mass storage memory

(e.g. the logger was started 31st December 2020 at 19:11, a folder

\DATA\20201231\1911\ will be created). In this folder the channel settings (JSN file)

and the measured values (CSV file) are stored.

When the logger is set to on, channel settings can no longer be changed or

calibration can no longer be performed. The device can no longer be turned off by the

on/off button, instead the device menu will be shown.

To start the logger in the normal display the F1-key will be entitled with “start”.

When the logger is running, the F1-key will be entitled with “stop” and can be stopped

by pressing the F1-key.

7.1.4.3 on keypress

With “on keypress” one measuring will be added to the files inside the HISTORY

directory. A location is also stored to this dataset, this can be selected from a list.

The location description can be set via COM port interface command (see above).

The location description must only contain ASCII-letters and numbers, no special

characters. Up to 22 letters can be used for the location description. The maximum

length of the location list is 20 entries.

The description text can also be changed directly in mass storage device. The folder

LOCATION contains 20 *.LOC files that can be changed with every text editor. After

changing the device must be restarted to read in the files.

In display mode the F1-key will be entitled with “logger”, on each keypress of the F1key one dataset is stored. During the saving progress the F1-key will be entitled with

“wait…”

7.1.5 pH channels and O2/cond. channels

When set to ‘inactive’ all depending channels are turned off.

All these channels will no longer be shown in the display.

In any logger recording an error message will be stored for inactive channels. Only

one of these options can be set to ‘inactive’.

Page 25

H87.0.0X.6C-01 Operating manual G 7500 Series page 25 of 34

7.2 pH channel menu

<-- -->

<--

measurement

pH

voltage

Voltage (H)

alarm

function

off

on

min.-limit

max.-limit

temp.

compensation

ATC

off

on

reference channel

banana sockets

O2/cond. electrode

pH probe

buffer

GMH standard

DIN standard

no detection

calibration mode

standard

strict

fast

7.2.1 temperature compensation

7.2.1.1 ATC

The automatic temperature compensation (ATC) can be switched on or off.

When deactivated, the temperature has to be set manually.

When activated the temperature is measured from the reference channel.

7.2.2 reference channel

Here the cannel for the ATC can be selected.

7.2.2.1 banana sockets

Reference temperature measured from RTD on banana sockets.

With a pH electrode with internal RTD only socket T is connected (common GND with

BNC connector).

With an external RTD probe both sockets are used (as it’s an RTD sensor, T or GND

have no polarity).

7.2.2.2 O2/cond. electrode

Reference temperature measured from oxygen or conductivity electrode. Inside the

electrode is an integrated RTD sensor. The electrode needs to be inside the same

fluid as the pH electrode. According to the size of the oxygen or conductivity

electrode, the integrated RTD sensor is very slow.

Page 26

H87.0.0X.6C-01 Operating manual G 7500 Series page 26 of 34

7.2.3 buffer

The buffers are auto detected. When the buffer is not recognized (no PHL or DIN

buffer, very bad electrode, extreme temperature or contaminated buffer solution) the

device will ask for manual input of pH value and temperature.

On manual input and using oft he listed standard buffers, please check the electrode

quality after calibration. If in doubt prepare new buffer solutions and clean or replace

the electrode. At extreme temperatures, try to bring them to room temperature (20..25

°C).

7.2.3.1 PHL standard

For calibration the standard buffers for the GMH handheld instruments are used.

These are pH 4 (red), pH 7 (green) und pH 10 (blue).

7.2.3.2 DIN standard

For calibration DIN standard buffers are used.

pH 1,680

pH 3,557

pH 3,776

pH 4,001

pH 6,881

pH 7,429

pH 9,225

pH 10,062

7.2.3.3 No detection

Device will ask for manual buffer input after detecting a stable value within the valid

temperature range.

7.2.4 calibration mode

This setting has strong influence about the accuracy and duration of the calibration

process.

7.2.4.1 standard

allowed deviance 0,075 mV between last 45 measurements

7.2.4.2 strict

allowed deviance 0,075 mV between 45 measurements and allowed deviance 0,01

mV between last 10 measurements

7.2.4.3 fast

allowed deviance 0,23 mV between last 10 measurements

Page 27

H87.0.0X.6C-01 Operating manual G 7500 Series page 27 of 34

7.3 temperature channel menu

Independent available for both, temperature (O2/LF) and temperature (pH)

sensortype

NTC 10 k

NTC 10 k only

available for O2/LF

Pt1000

unit

°C

°F

K

alarm

function

off on

min.-limit

max.-limit

7.3.1 sensortype

The channel temperature (O2/LF) will change the sensortype automatically when an

electrode is changed.

Conductivity electrode (LF 425) sensortype: Pt1000

Oxygen electrode (GWO 5610) sensortype: NTC 10 k

When other electrodes are used, the setting has to be changed manually.

Pt1000 is normally the correct setting for temperature (pH) as it’s standard electrode is

the GE 125.

When using different electrodes, check the manual of the electrode for the correct

setting.

7.4 oxygen channel menu

measurement

O2 concentration

[mg/l]

O2 saturation

[%]

O2 partial pressure

[hPa]

alarm

function

off on

min.-limit

max.-limit

salinity

auto pressure

comp.

off

on

absolute pressure

7.4.1 salinity

Input of salinity. The oxygen value will be re-calculated on values not equal to 0.

7.4.2 auto pressure comp.

Automatic pressure compensation or manual input.

7.4.3 absolute pressure

Manual input of the air pressure.

Page 28

H87.0.0X.6C-01 Operating manual G 7500 Series page 28 of 34

7.5 conductivity channel menu

measurement

conductivity

salinity

alarm

function

off

on

min.-limit

max.-limit

cell factor

auto-range

off

on

range

temp compensation

off

NLF

linear

lin. coefficient

reference

temperature

T=25 °C

T=20 °C

7.5.1 cell factor

Manual input of the cell factor. G 7500 sets with conductivity electrode are

preconfigured with the electrode’s cell factor.

7.5.2 auto-range

Automatic range selection of the conductivity measurement is active.

auto-range: 0 µS/cm..500 mS/cm

7.5.3 range

Manual range selection when auto-range is not active.

45..500 mS (range: 1)

5,0..50,0 mS (range: 2)

5..5 000 µS/cm (range: 3)

0,0..500,0 µS/cm (range: 4)

7.5.4 linearization

Linearization of the measured value according to nlF or manual input.

7.5.5 lin. coefficient

Manual linearization coefficient (only with linearization is linear input).

7.5.6 reference temperature

Reference temperature of the measured conductivity.

Page 29

H87.0.0X.6C-01 Operating manual G 7500 Series page 29 of 34

8 Error codes (in dataset)

While logging data or querying values via interface, the error codes will not be shown

as human readable text. This is because the relation between error and error

message would get lost between different languages.

Error code

Text

Hint

0

OK

no error

100000000

measuring range overrun

check calibration and sensor

100000001

measuring range underrun

check calibration and sensor

100000010

calculation failed

check settings

100000011

system error

restart device*

100000012

battery empty

recharge device

100000013

no sensor

connect sensor

100000014

recording error

restart device*

100000015

EEPROM checksum wrong

restart device*

100000016

system restarted

device is restarting, wait shortly

100000017

data pointer error

restart device*

100000018

data invalid

restart device*

100000020

recording stopped

logger has been stopped

100000021

recording started

logger has been started

100000022

channel deactivated

channel is deactivated via device

settings

100000023

temp. channel deactivated

check temperature compensation

settings,

activate O2/cond. channel

100000024

no temp. sensor

plug in temperature sensor check

temperature compensation

settings,

activate O2/cond. channel

100000025

no data available

device has not measured anything

-23

sensor module not responding

restart device*

-10

not existing

restart device*

-255

unexpected error

restart device*

-100

calibration error

try to calibrate again

-75

not found

restart device*

-101

not calibrated

perform a calibration

-253

Value not stable

Ensure a stable environment

-251

Not in the temperature range

Check temperature

*Resend device for service, when the error does not disappear

Page 30

H87.0.0X.6C-01 Operating manual G 7500 Series page 30 of 34

9 Calibration

9.1 General information

Each channel that supports a calibration will show cal. Above the F1-key.

The Calibration will only be available when the logger is set to “not active”.

When you press the F1-key the calibration wizard will guide you through the

calibration steps. Depending on the channel you will need to have buffer solutions

prepared.

More point calibration can be done (if supported from the measuring channel) after

the 1st calibration point is finished. You don’t need to select how many points should

be calibrated and you don’t need to follow a predefined order of buffer values, you

can just use them in random order.

9.2 pH calibration

Required Accessories:

Buffer solutions (e.g. the PHL buffer solutions with ph 4, ph 7 and ph 10)

deionized water for cleaning between changing buffer solutions

If necessary, liquid thermometers to determine the temperature of the buffer solutions

(if no GE 125 or similar is used)

Start the calibration process, see above.

Follow the instructions of the device:

Clean the electrode and immerse it in the first buffer solution.

After the buffer solution has been determined, continue with the next buffer solution

or complete the calibration.

A certain sequence of buffer solutions is not specified.

If no temperature reference is present, the temperature of the buffer solution must

also be determined with another measuring instrument and entered.

The electrode evaluation after completion of the calibration process informs about the

state of the electrode.

9.3 O2 calibration

Required Accessories:

GCAL 3610 calibration vessel for oxygen sensor, alternatively use a moist cloth.

deionized water for cleaning the sensor.

Start the calibration process, see above.

Follow the instructions of the device:

Clean the sensor and plug it into GCAL 3610.

Alternatively, wrap the sensor loosely into a moist cloth.

The sensor evaluation after completion of the calibration process informs about the

state of the sensor.

Page 31

H87.0.0X.6C-01 Operating manual G 7500 Series page 31 of 34

10 Calibration and adjustment service

The certificates are categorised as ISO calibration certificates and DAkkS calibration

certificates. The purpose of the calibration is to verify the precision of the measuring

device by comparing it with a traceable reference.

The ISO standard 9001 is applied for the calibration certificates. These

certificates area affordable alternative to the DAkkS calibration

certificates and provide information of the traceable reference, a list of

individual values and documentation.

The DAkkS calibration is based on DIN EN ISO/17025, the

accreditation basis recognised worldwide. These certificates offer highquality calibration and consistently high quality. DAkkS calibration

certificates can only be issued by accredited calibration laboratories

which have demonstrated their expertise in accordance with DIN EN

ISO/IEC 17025. The ISO calibration includes any necessary

adjustment with the purpose of minimising a deviation of the measuring

device.

DAkkS calibration certificates are accompanied with a list of individual

measurements before and after the adjustment, documentation and, if

applicable, graphic representation, calculation of the expanded

measuring uncertainty and traceability to the national standard.

The product is delivered with a test report. This confirms that the

measuring device has been adjusted and tested.

Only the manufacturer can check the basic settings and make

corrections if necessary.

11 Replacing rechargeable batteries

Using damaged or unsuitable batteries can generate heat, which can

cause the batteries to crack and possibly explode!

If the batteries have different charge levels, leaks and thus damage to

the product can occur.

- Use new, high-quality batteries!

- Do not use different types of batteries!

- Remove depleted batteries and dispose of them at a suitable

collection point!

Unnecessary screwing places the water-tightness of the product,

among other things, at risk and should be avoided.

Read the following handling instructions before replacing batteries and

follow them step by step. If disregarded, the product could be damaged

or the protection from moisture could be diminished.

Page 32

H87.0.0X.6C-01 Operating manual G 7500 Series page 32 of 34

Required tools: 1x Phillips screwdriver PH 1

Remove device from silicone cover.

Unscrew 3 screws on the device bottom. Carefully open the top cover and fold to

the right (see picture). The cover is attached to the PCB by a flexprint connector.

When ripping out the flexprint connector from the socket, the keypad will no

longer work and the device needs to be sent in for repairing.

Carefully change the 3

rechargeable Ni-MH batteries

(type AAA). Take care of the

polarity that is printed inside the

holder. The batteries have to slip

in without any force.

Check the sealing in top cover

must be clean and without any

damage.

Attach top cover and hand-tight

the screws. When tightened to

strong or to weak the sealing can

be affected.

Insert device into silicone cover.

12 Reshipment and disposal

12.1 Reshipment

All devices returned to the manufacturer have to be free of any residual

of measuring media and other hazardous substances.

Measuring residuals at housing or sensor may be a risk for persons or

environment

Use an adequate transport package for reshipment, especially for fully

functional devices. Please make sure that the device is protected in the

package by enough packing materials.

Add the completed reshipment form of the GHM website

https://www.ghm-group.de/infothek/#downloadcategory--8

12.2 Disposal

Dispense exhausted batteries at destined gathering places The device

must not be disposed in the unsorted municipal waste! Send the device

directly to us (sufficiently stamped), considering the above if it should be

disposed. We will dispose the device appropriate and environmentally

sound.

Private user can return the device at the municipal collection points for

small electrical appliances.

Page 33

H87.0.0X.6C-01 Operating manual G 7500 Series page 33 of 34

13 Specification

13.1 measurements and accuracy

pH

suggested probe

GE 125 (waterproof with Pt 1000 temperature probe)

connector

BNC-Buchse (waterproof)

pH

-2,00..+16,00 pH (+-0,25 % FS)

ORP

-2 000..+2 000 mV (+-0,25 % FS)

ORP (hydrogen referenced)

-1 775..+2 148 mV (+-0,25 % FS)

(for electrodes with 3 mol/l KCL electrolyte 0..100 °C)

temperature compensation

automatic or manual

Pt1000

(via banana connector or O2/conductivity probe)

accuracy requirements

Ta, Tm = 25 °C

dissolved oxygen

suggested probe

GWO 5610 (with NTC 10 k temperature probe)

connector

7-pol. LTW (waterproof)

oxygen saturation

0,0..500,0 % sat (+-1,5 % FS)

oxygen concentration

0,0..50,0 mg/l (+-1,5 % FS)

oxygen partial pressure

0..1 013 hPa (+-1,5 % FS)

temperature compensation

automatic: 0,0..+50,0 °C

salinity correction

off, 0..70 g/kg

accuracy requirements

Ta, Tm = 20 °C, 100 % sat. O2

direct flow > 20 cm/s

conductivity

suggested probe

LF 425 (with Pt 1000 temperature probe)

connector

7-pol. LTW (waterproof)

conductivity

auto-range: 0 µS/cm..500 mS/cm (+-0,5 % FS)

45..500 mS (Range: 1)

5,0..50,0 mS (Range: 2)

500..5 000 µS/cm (Range: 3)

0,0..500,0 µS/cm (Range: 4)

salinity

0,0..70,0 g/kg (+-0,5 % FS)

temperature compensation

automatic: -5,0..+100,0 °C

reference temperature

20 °C, 25 °C

linearization

off, manual linear input or non linear function for

natural water according to DIN EN27888 (ISO 7888)

accuracy requirements

Ta, Tm = 25 °C

temperature (banana plug)

sensor type

Pt 1000

Measuring range

Pt 1000: -10,0..+ 150,0 °C (+-0,25 % FS)

temperature (O2/LF electrode)

sensor type

Pt 1000 or NTC 10k

measuring range (Pt1000)

-10,0..+110,0 °C (+-1,0 % FS)

measuring range (NTC 10k)

-10,0..+110,0 °C (+-0,5 % FS)

Ta = ambient temperature, Tm = media temperature

Page 34

H87.0.0X.6C-01 Operating manual G 7500 Series page 34 of 34

GHM GROUP – Greisinger | GHM Messtechnik GmbH

Hans-Sachs-Str. 26 | 93128 Regenstauf | GERMANY

Phone +49 9402 9383-0 | Fax +49 9402 9383-33

www.greisinger.de | info@greisinger.de

13.2 general specification

data logger

internal mass storage (since 2018: 8 GB)

display

monochrome 180 x 128 px LC-Display

(white and red backlight)

primary power supply

3x AAA Ni-MH rechargeable batteries (750 mAh)

current consumption

approx. 75 mA in use, approx. 0,6 mA in standby

interface/supply

type

micro USB

USB mode

CDC (COM port, driver on mass storage)

MSC (mass storage, no driver needed)

DFU (firmware update, driver on mass storage)

USB current consumption

max. 500 mA (rechargeable batteries charging)

working condition

-25..+50 °C, 0..95 % r.F. (non condensing)

storage condition

-25..+70 °C

protection class

IP65 / IP67

housing

impact resistant ABS, with support and retaining clip

dimension

160 x 86 x 37 mm (H x B x T) incl. silicone cover

weight

approx. 300 g incl. rechargeable batteries

scope of supply

device, rechargeable batteries, micro USB cable and

short manual

14 Terms of license

14.1 FreeRTOS

Copyright (C) 2016 by Real Time Engineers Ltd.

All rights reserved

The source code is licensed under the MIT open source license.

The full text of the MIT open source license is available here:

https://www.freertos.org/a00114.html

14.2 FatFS

Copyright (C) 2017 by ChaN

All right reserved.

FatFs module is an open source software.

Redistribution and use of FatFs in source and binary forms, with or without

modification, are permitted provided that the following condition is met:

1. Redistributions of source code must retain the above copyright notice, this

condition and the following disclaimer.

This software is provided by the copyright holder and contributors “AS IS” and any

warranties related to this software are DISCLAIMED.

The copyright owner or contributors be NOT LIABLE for any damages caused by use

of this software.

Loading...

Loading...